Development of Low Silver AgCuZnSn Filler Metal for Cu/Steel Dissimilar Metal Joining

Abstract

:1. Introduction

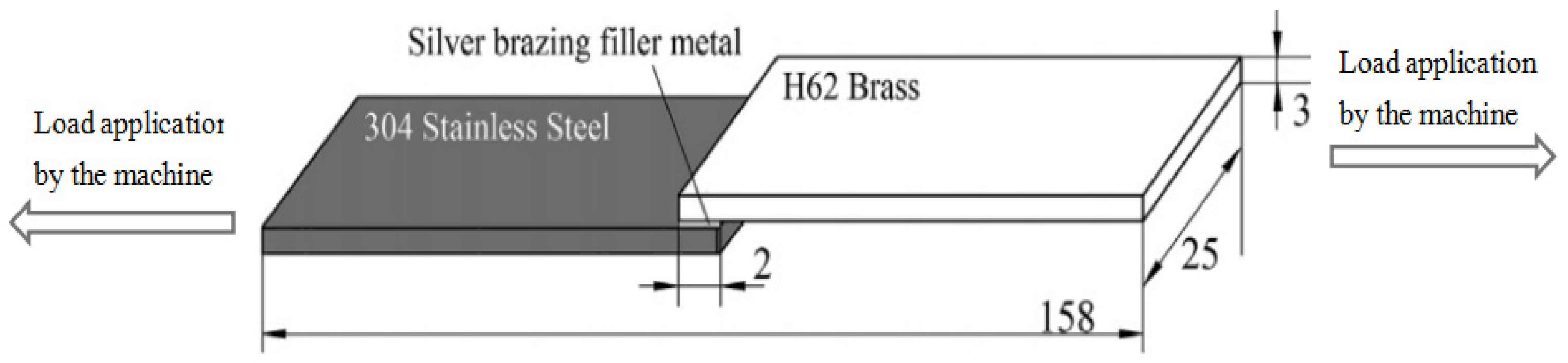

2. Experimental Procedure

3. Results and Discussion

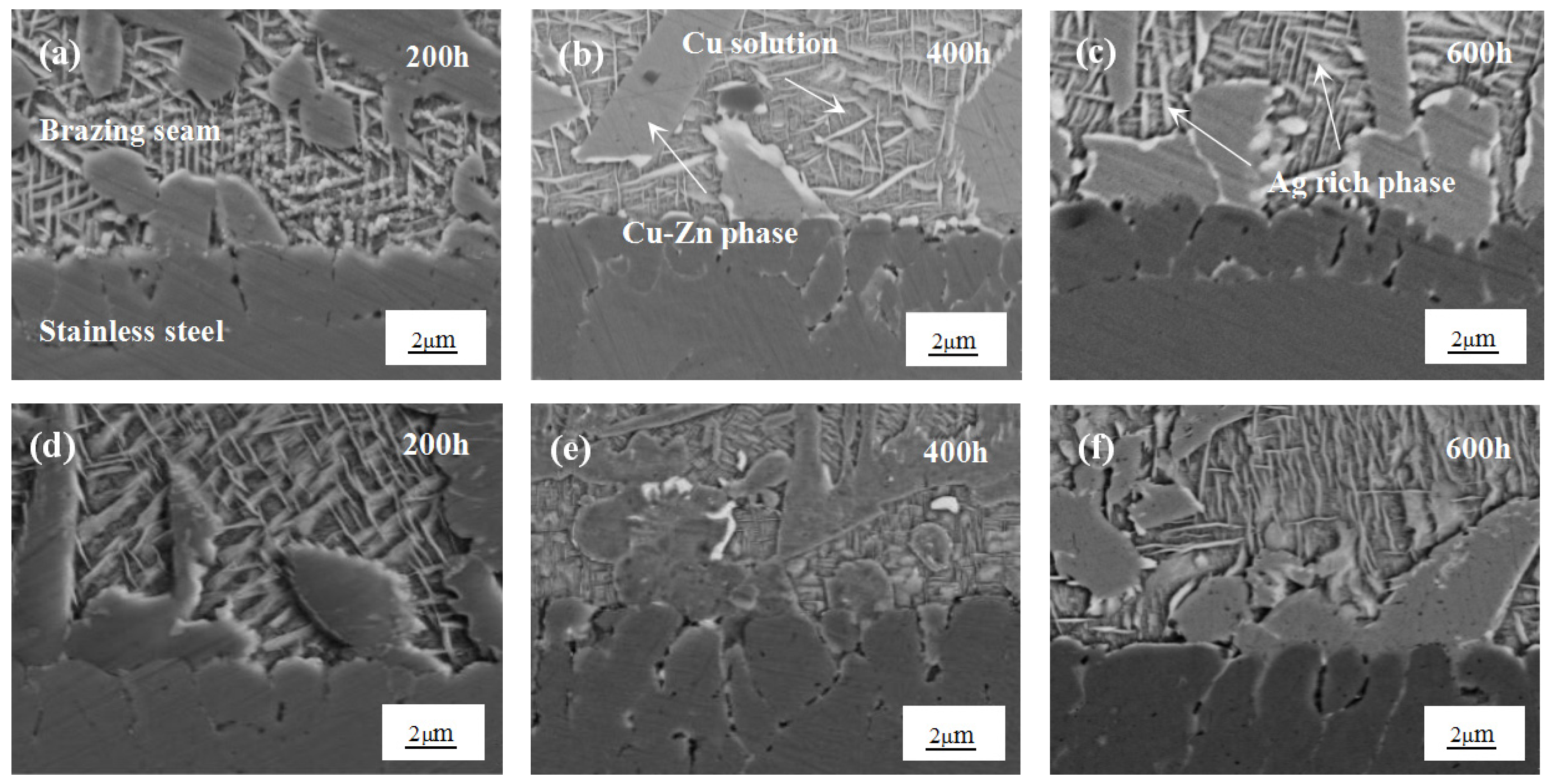

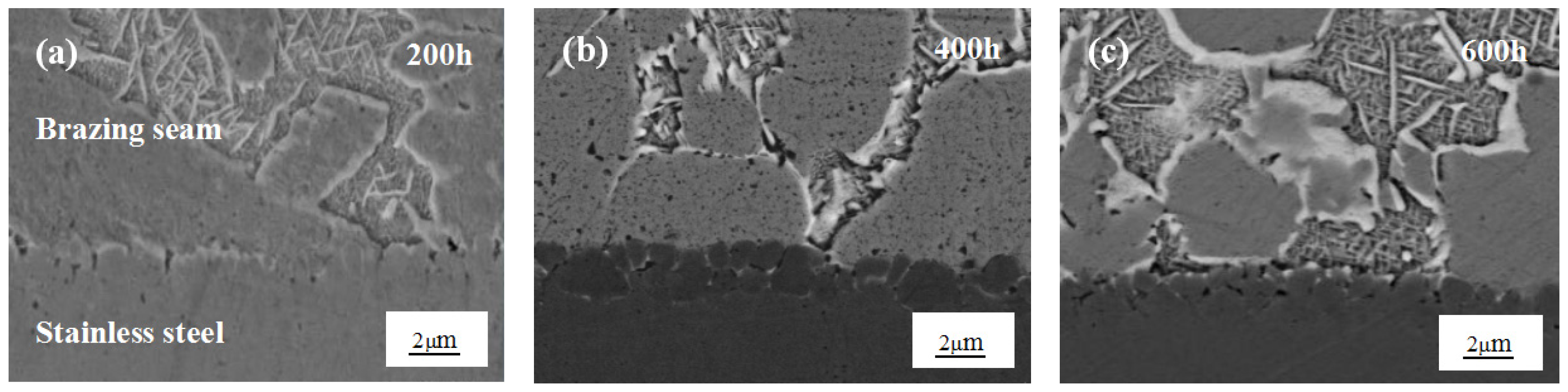

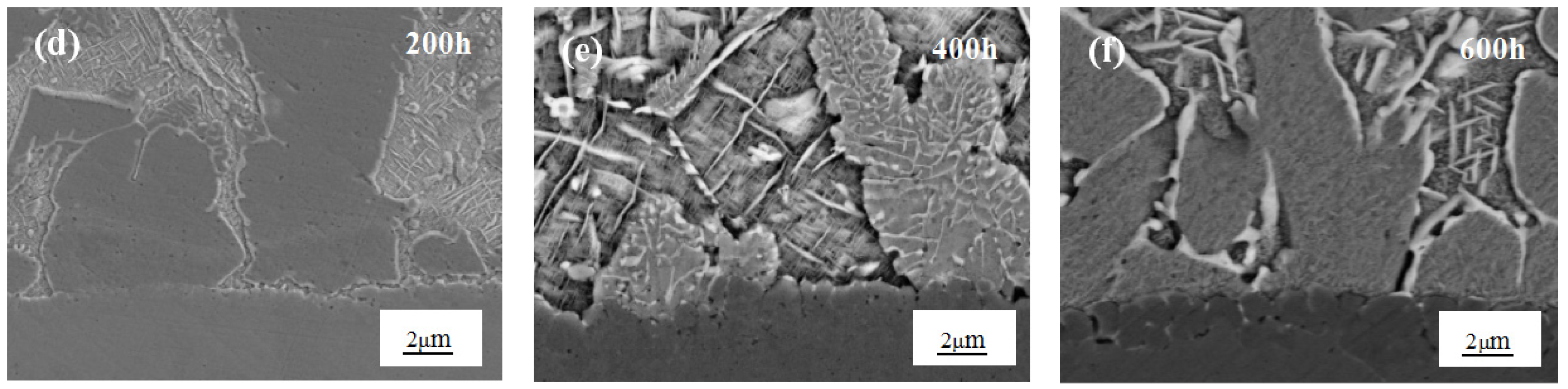

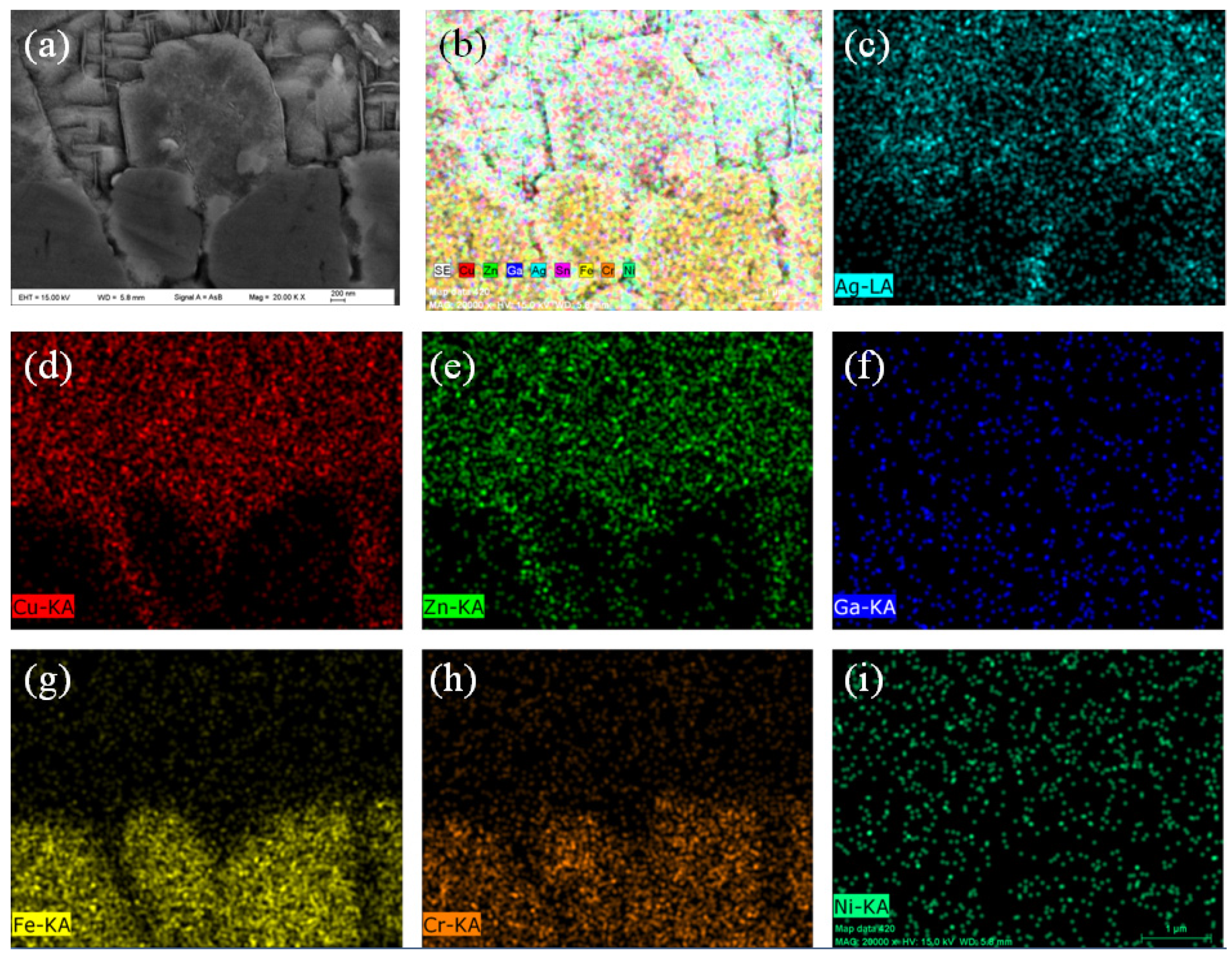

3.1. Effect of the Aging Treatments on the Interfacial Microstructure of the Brazed Joints

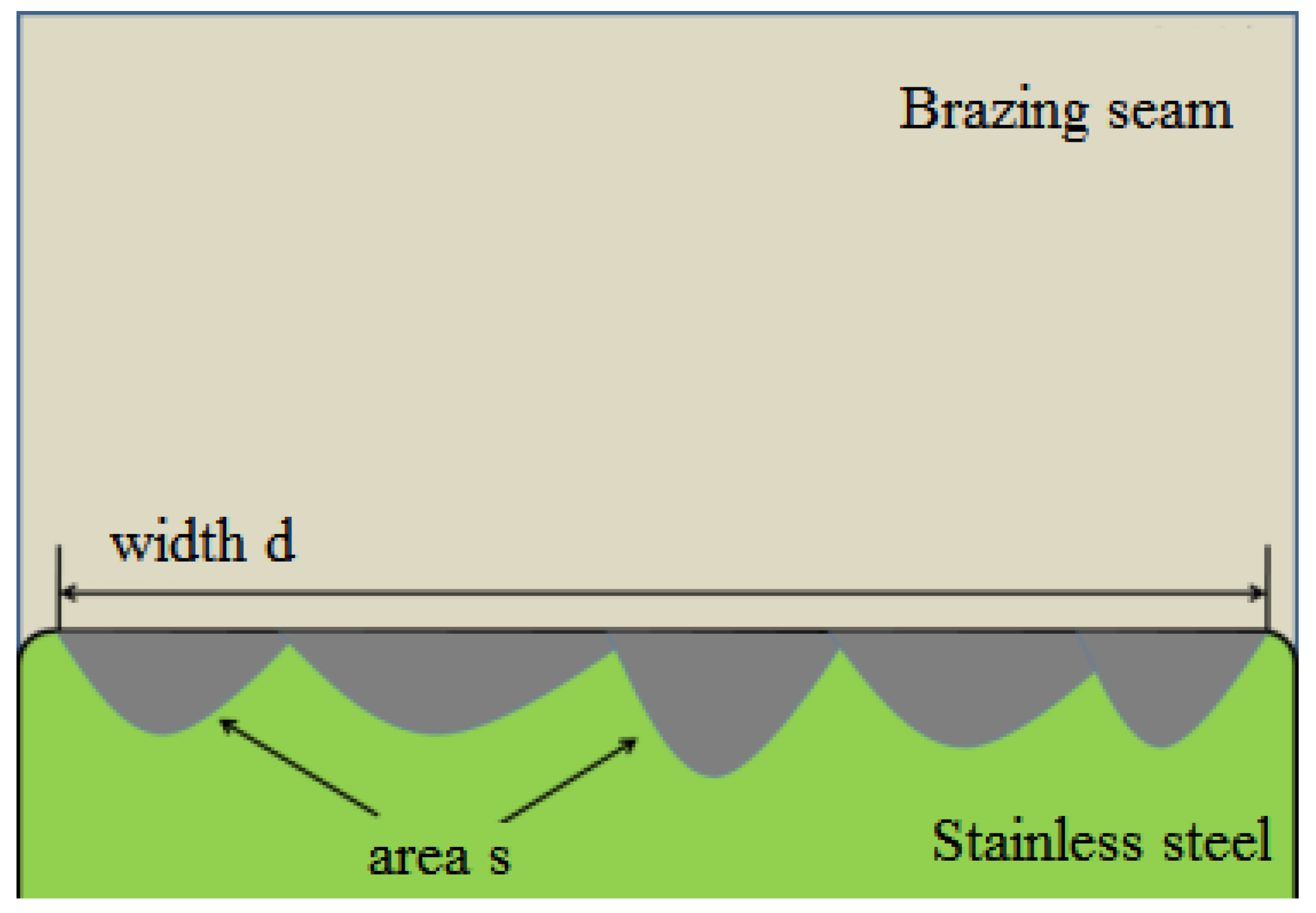

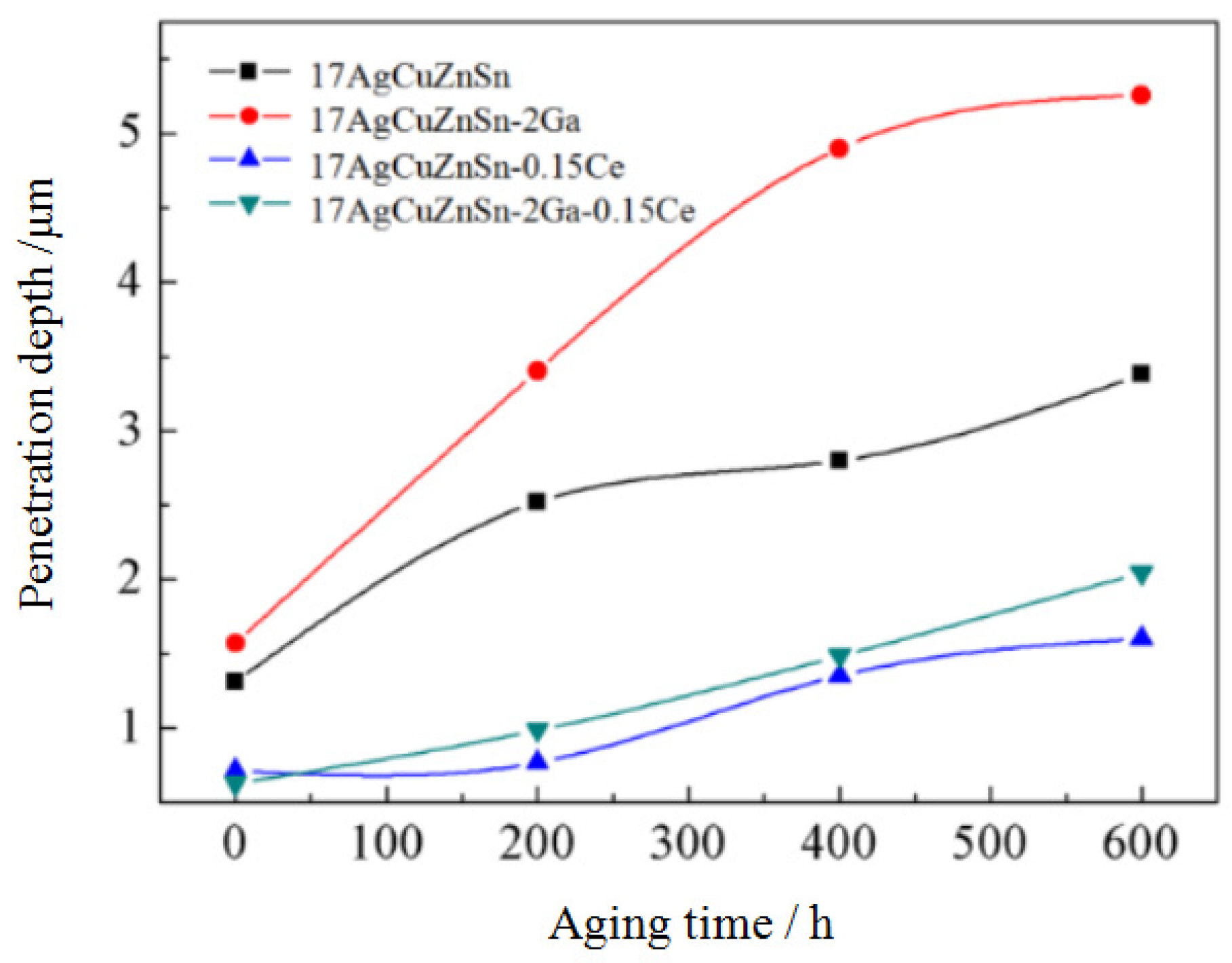

3.2. Effect of the Aging Treatment on Intergranular Penetration Depth in the Brazed Joints

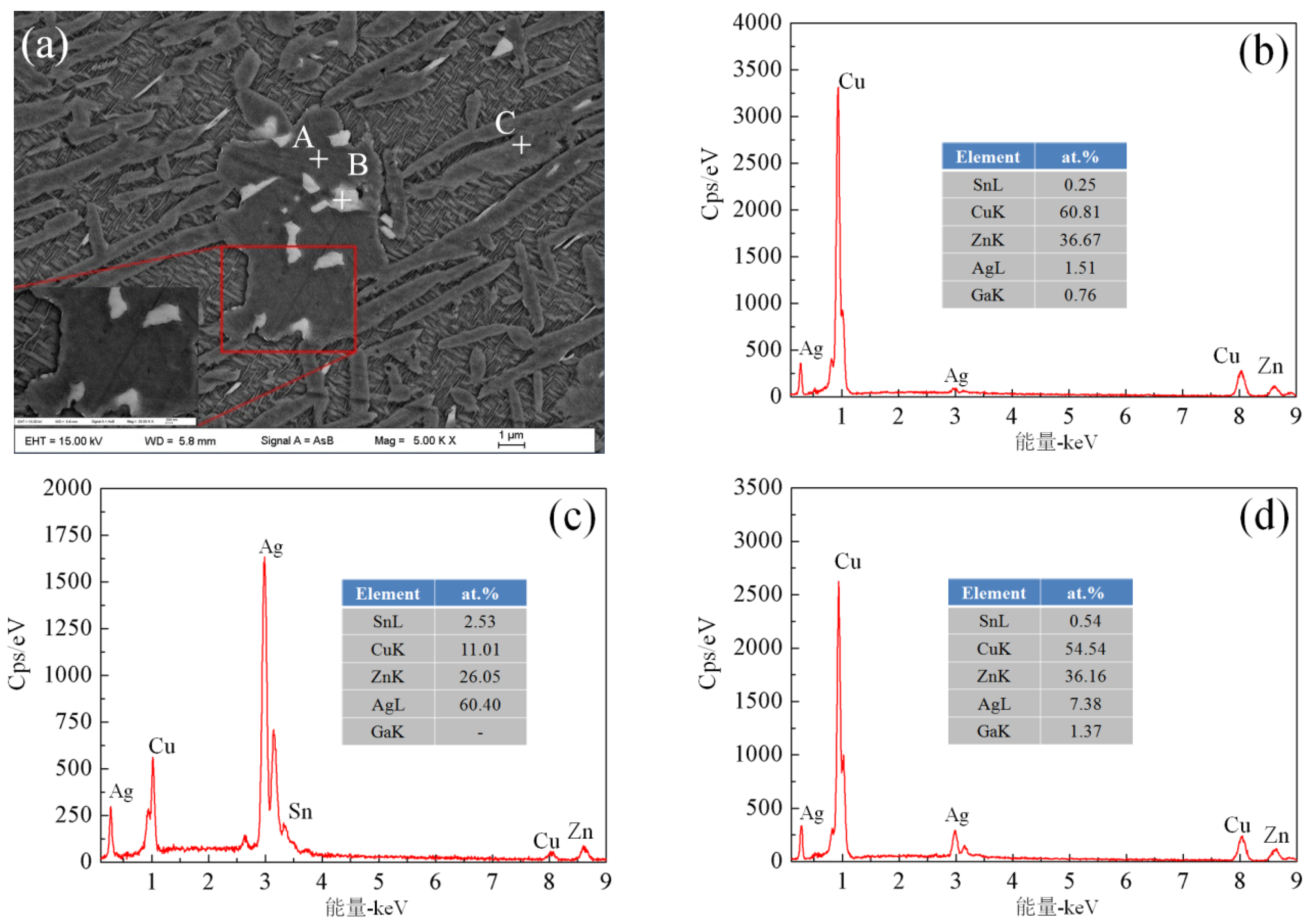

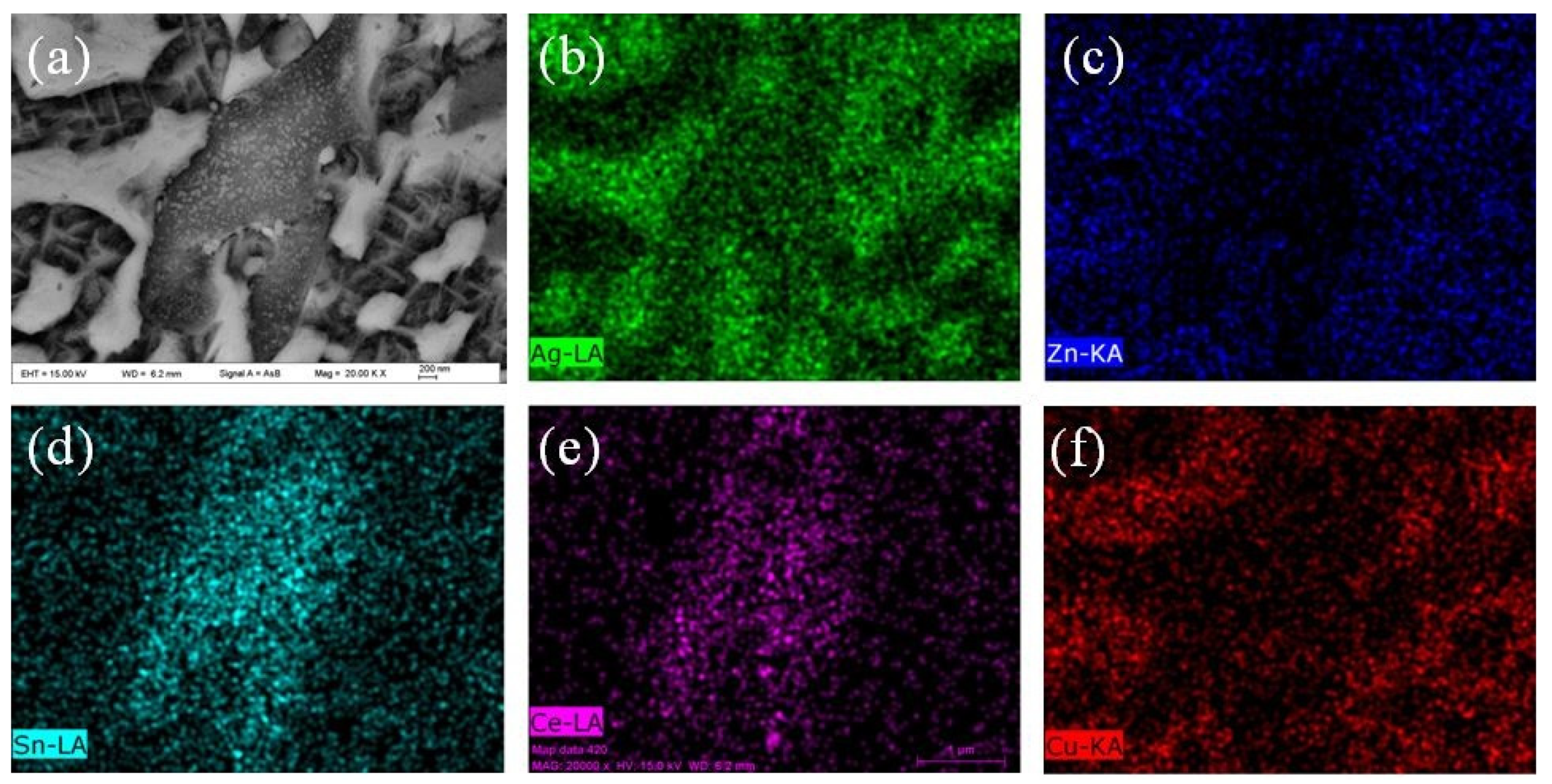

3.3. Effect of the Aging Treatment on the Microstructure of the Brazing Seam

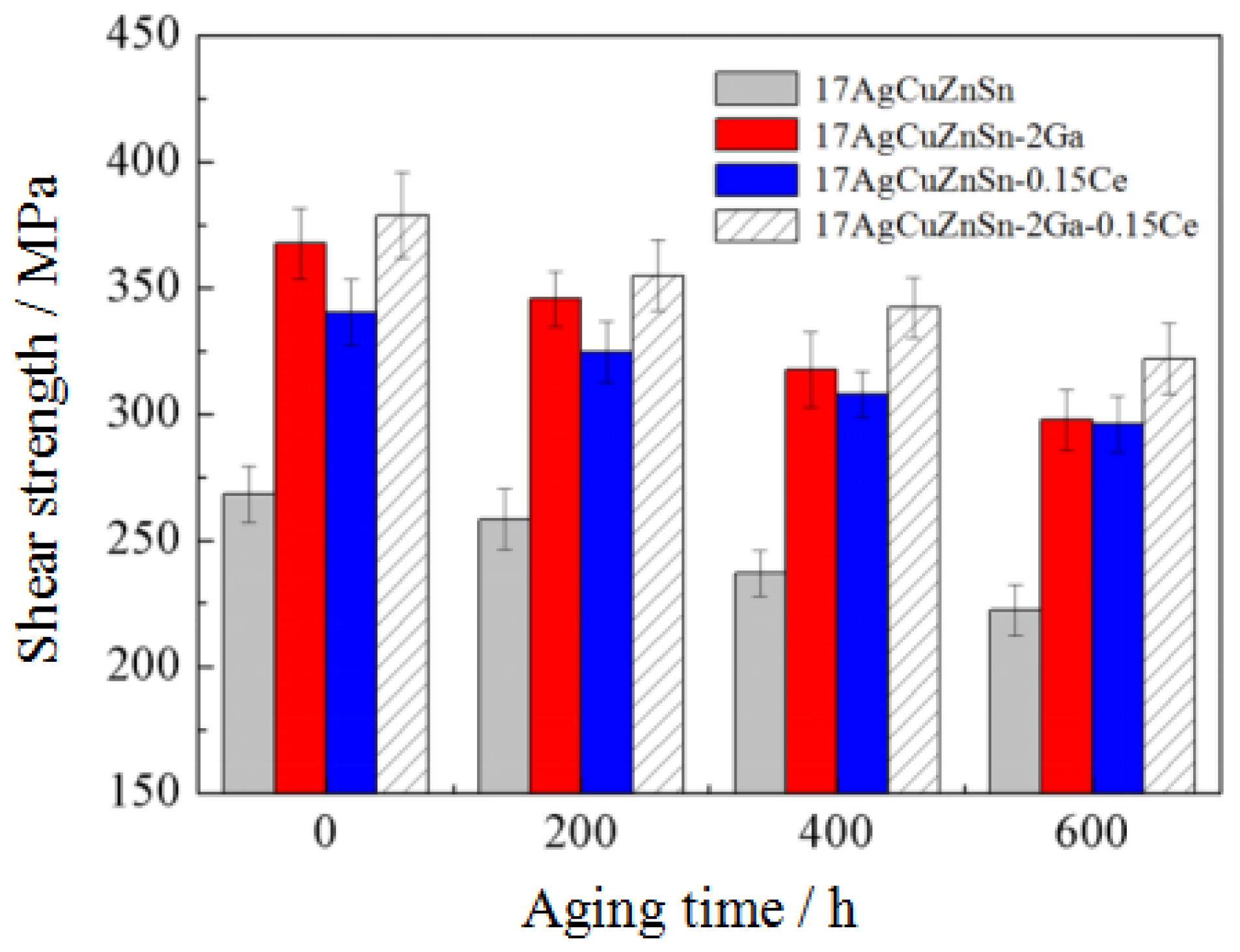

3.4. Effect of the Aging Treatment on the Mechanical Properties of Brazed Joints

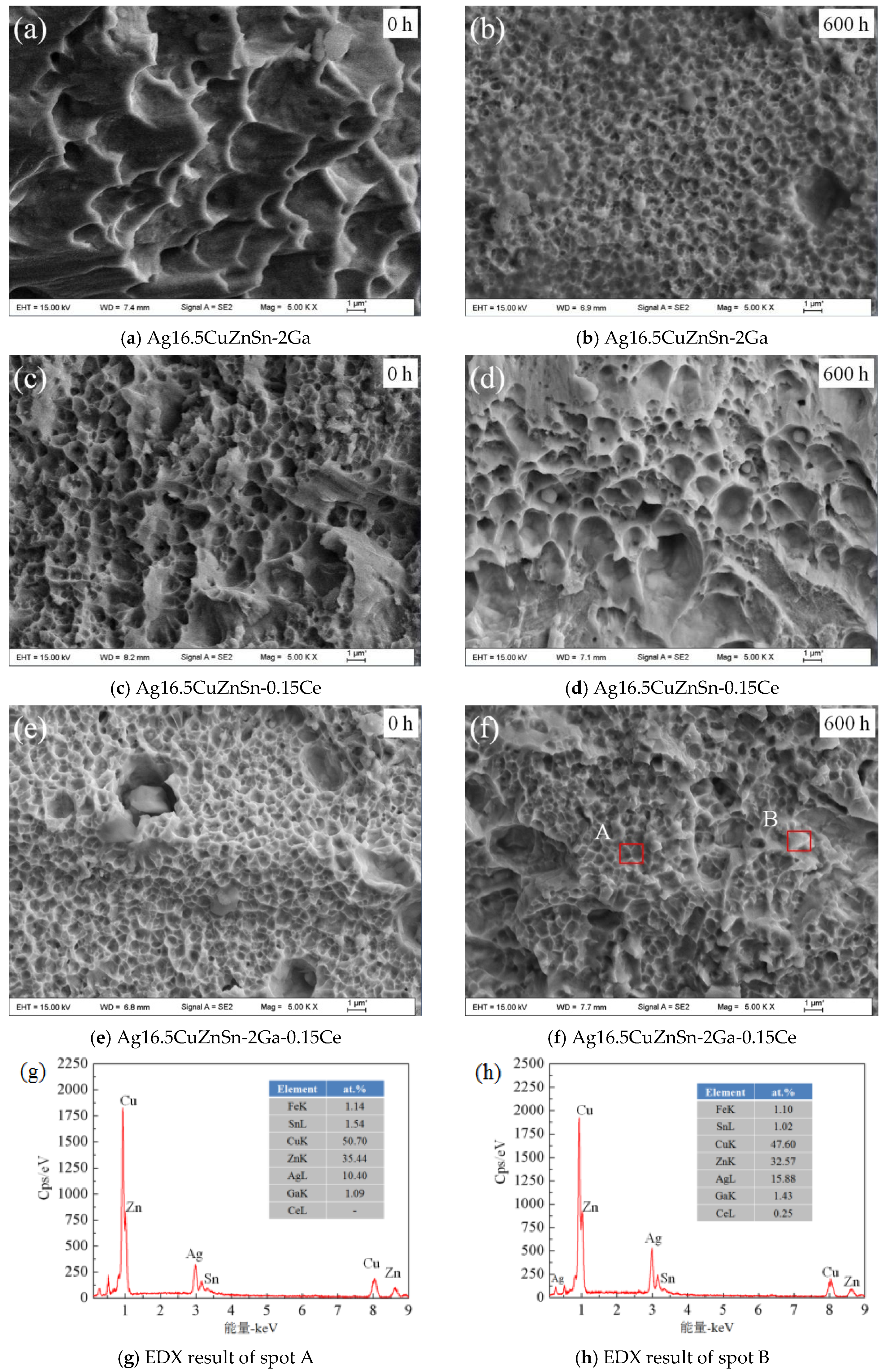

3.5. Effect of the Aging Treatment on the Fracture Morphology of Brazed Joints

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Phanikumar, G.; Manjini, S.; Dutta, P.; Chattopadhyay, K.; Mazumder, J. Characterization of a continuous CO2 laser-welded Fe-Cu dissimilar couple. Metall. Mater. Trans. A 2005, 36, 2137–2147. [Google Scholar] [CrossRef]

- Jafari, M.; Abbasi, M.; Poursina, D.; Gheysarian, A.; Bagheri, B. Microstructures and mechanical properties of friction stir welded dissimilar steel-copper joints. J. Mech. Sci. Technol. 2017, 31, 1135–1142. [Google Scholar] [CrossRef]

- Yao, C.; Xu, B.; Zhang, X.; Huang, J.; Fu, J.; Wu, Y. Interface microstructure and mechanical properties of laser welding copper-steel dissimilar joint. Opt. Lasers Eng. 2009, 47, 807–812. [Google Scholar] [CrossRef]

- Chen, S.; Zhai, Z.; Huang, J.; Zhao, X.; Xiong, J. Interface microstructure and fracture behavior of single/dual-beam laser welded steel-Al dissimilar joint produced with copper interlayer. Int. J. Adv. Manuf. Technol. 2016, 82, 631–643. [Google Scholar] [CrossRef]

- Leon-Patino, C.A.; Aguilar-Reyes, E.A.; Braulio-Sanchez, M.; Rodríguez-Ortiz, G.; Bedolla-Becerril, E. Microstructure and shear strength of sintered Cu-Al2O3 composite joined to Cu using Ag-Cu and Cu-Zn filler alloys. Mater. Des. 2014, 54, 845–853. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, J.; Zhang, B.; Jing, X. Ag-Cu-Zn Alloy for Brazing TiC Cermet/Steel. Mater. Lett. 2005, 59, 110–113. [Google Scholar] [CrossRef]

- Venkateswaran, T.; Xavier, V.; Sivakumar, D.; Pant, B.; Janaki Ram, G.D. Brazing of stainless steels using Cu-Ag-Mn-Zn braze filler: Studies on wettability, mechanical properties, and microstructural aspects. Mater. Des. 2017, 121, 213–228. [Google Scholar]

- Alexander, V.; Joerg, B.; Sigurd, J.; Dieter, K.; Georg, P.; Wolfgang, K. Use of Silver Alloys as Cadium-Free Brazing Solder. U.S. Patent 5352542, 4 October 1994. [Google Scholar]

- Sui, F.; Long, W.; Liu, S.; Zhang, G.; Bao, L.; Li, H.; Chen, Y. Effect of Calcium on the Microstructure and Mechanical Properties of Brazed Joint Using Ag-Cu-Zn Brazing Filler Metal. Mater. Des. 2013, 46, 605–608. [Google Scholar] [CrossRef]

- Ma, X.; Li, L.-F.; Zhang, Z.-H.; Wang, H.; Wang, E.-Z.; Qiu, T. Microstructure and Melting Properties of Ag-Cu-In Intermediate Temperature Brazing Alloys. Rare Met. 2015, 34, 324–328. [Google Scholar] [CrossRef]

- Lai, Z.; Xue, S.; Han, X.; Gu, L.; Gu, W. Study on Microstructure and Property of Brazed Joint of AgCuZn-X (Ga, Sn, In, Ni) Brazing Alloy. Rare Metal. Mater. Eng. 2010, 39, 397–400. [Google Scholar]

- Li, Z.; Jiao, N.; Feng, J.; Chen, Y. Effect of P and rare-earth La on microstructure and property of AgCuZnSn brazing alloy. Trans. Chin. Weld. Inst. 2007, 28, 1–4. [Google Scholar]

- Wang, X.; Yu, D.; He, Y.; Huang, S.; Chen, R. Effect of Sn Content on Brazing Properties of Ag Based Filler Alloy. Mater. Sci. 2013, 3, 16–21. [Google Scholar]

- Ma, C.; Xue, S.; Zhang, T.; Jiang, J.; Long, W.; Zhang, G.; Zhang, Q.; He, P. Influences of In on the Microstructure and Mechanical Properties of Low Silver Ag-Cu-Zn Filler Metal. Rare Met. Mater. Eng. 2017, 46, 2565–2570. [Google Scholar]

- Cao, J.; Zhang, L.X.; Wang, H.Q.; Wu, L.Z.; Feng, J.C. Effect of Silver Content on Microstructure and Properties of Brass/steel Induction Brazing Joint Using Ag-Cu-Zn-Sn Filler Metal. J. Mater. Sci. Technol. 2011, 27, 377–381. [Google Scholar] [CrossRef]

- Ma, C.; Xue, S.; Wang, B. Study on novel Ag-Cu-Zn-Sn brazing filler metal bearing Ga. J. Alloys Compd. 2016, 688, 854–862. [Google Scholar] [CrossRef]

- Lai, Z.M. Effects of Ga/In and rare earth Ce on microstructures and properties of brazed joint of 30AgCuZn filler metal. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 1 March 2011. [Google Scholar]

- GB/T 11363-2008. Test Method of the Strength for Brazed and Soldered Joint; Standardization Administration of China: Beijing, China, 2008. [Google Scholar]

- Test Method Standard Microcircuits, MIL-STD-883G, METHOD 2019.7, Die Shear Strength; Military and Government Specs & Standards (Naval Publications and Form Center) (NPFC): Englewood, CO, USA, 2018.

- Ina, K.; Koizumi, H. Penetration of liquid metals into solid metals and liquid metal embrittlement. Mater. Sci. Eng. A 2004, 387–389, 390–394. [Google Scholar] [CrossRef]

- Lian, X.; Qu, W.; Li, H.; Wang, G. Grain boundary penetration behavior analysis of OFC brazed with AgCu28 brazing filler. J. Beijing Univ. Aeronaut. Astronaut. 2014, 40, 717–720. [Google Scholar]

- Beura, V.K.; Xavier, V.; Venkateswaran, T.; Kulkarni, K.N. Interdiffusion and microstructure evolution during brazing of austenitic artensitic stainless steel and aluminum-bronze with Ag-Cu-Zn based brazing filler material. J. Alloys Compd. 2018, 740, 852–862. [Google Scholar] [CrossRef]

- Troparevsky, M.C.; Morris, J.R.; Daene, M.; Wang, Y.; Lupini, A.R.; Stocks, G.M. Beyond Atomic Sizes and Hume-Rothery Rules: Understanding and Predicting High-Entropy Alloys. JOM 2015, 67, 2350–2363. [Google Scholar] [CrossRef]

- Chi, C.-T.; Chao, C.-G.; Liu, T.-F.; Lee, C.-H. Aluminum element effect for electron beam welding of similar and dissimilar magnesium-aluminum-zinc alloys. Scr. Mater. 2007, 56, 733–736. [Google Scholar] [CrossRef]

| No. | Ag | Cu | Zn | Sn | Ga | Ce |

|---|---|---|---|---|---|---|

| 1 | 16.5 | Bal. | 35.44 | 2 | 0 | 0 |

| 2 | 16.5 | Bal. | 34.60 | 2 | 2 | 0 |

| 3 | 16.5 | Bal. | 34.26 | 2 | 0 | 0.15 |

| 4 | 16.5 | Bal. | 32.70 | 2 | 2 | 0.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, P.; Zou, Y.; He, P.; Pei, Y.; Sun, H.; Ma, C.; Luo, J. Development of Low Silver AgCuZnSn Filler Metal for Cu/Steel Dissimilar Metal Joining. Metals 2019, 9, 198. https://doi.org/10.3390/met9020198

Xue P, Zou Y, He P, Pei Y, Sun H, Ma C, Luo J. Development of Low Silver AgCuZnSn Filler Metal for Cu/Steel Dissimilar Metal Joining. Metals. 2019; 9(2):198. https://doi.org/10.3390/met9020198

Chicago/Turabian StyleXue, Peng, Yang Zou, Peng He, Yinyin Pei, Huawei Sun, Chaoli Ma, and Jingyi Luo. 2019. "Development of Low Silver AgCuZnSn Filler Metal for Cu/Steel Dissimilar Metal Joining" Metals 9, no. 2: 198. https://doi.org/10.3390/met9020198

APA StyleXue, P., Zou, Y., He, P., Pei, Y., Sun, H., Ma, C., & Luo, J. (2019). Development of Low Silver AgCuZnSn Filler Metal for Cu/Steel Dissimilar Metal Joining. Metals, 9(2), 198. https://doi.org/10.3390/met9020198