Influence of Strain Rate and Waveshape on Environmentally-Assisted Cracking during Low-Cycle Fatigue of a 304L Austenitic Stainless Steel in a PWR Water Environment

Abstract

:1. Introduction

2. Experimental Conditions

2.1. Material and Specimens

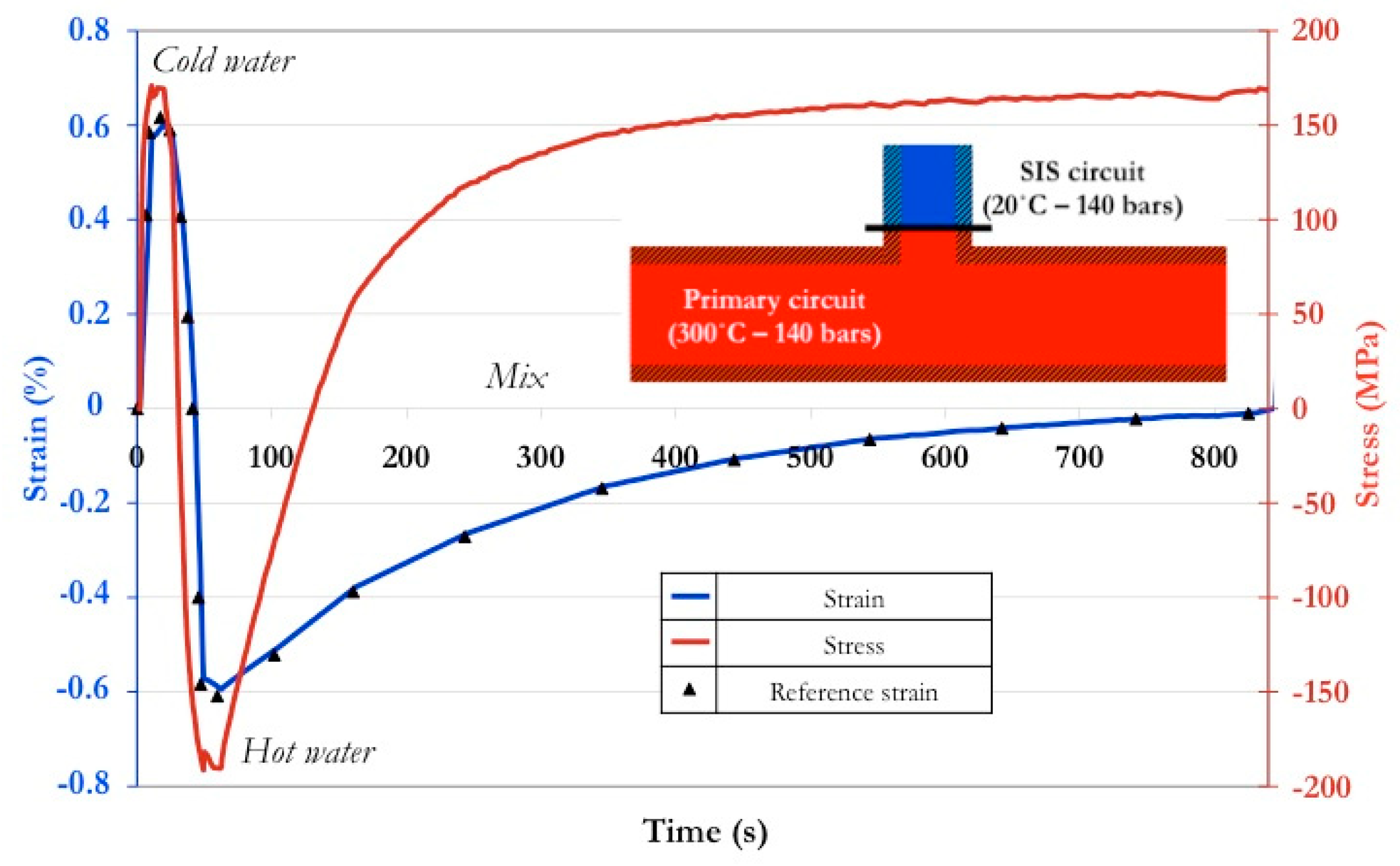

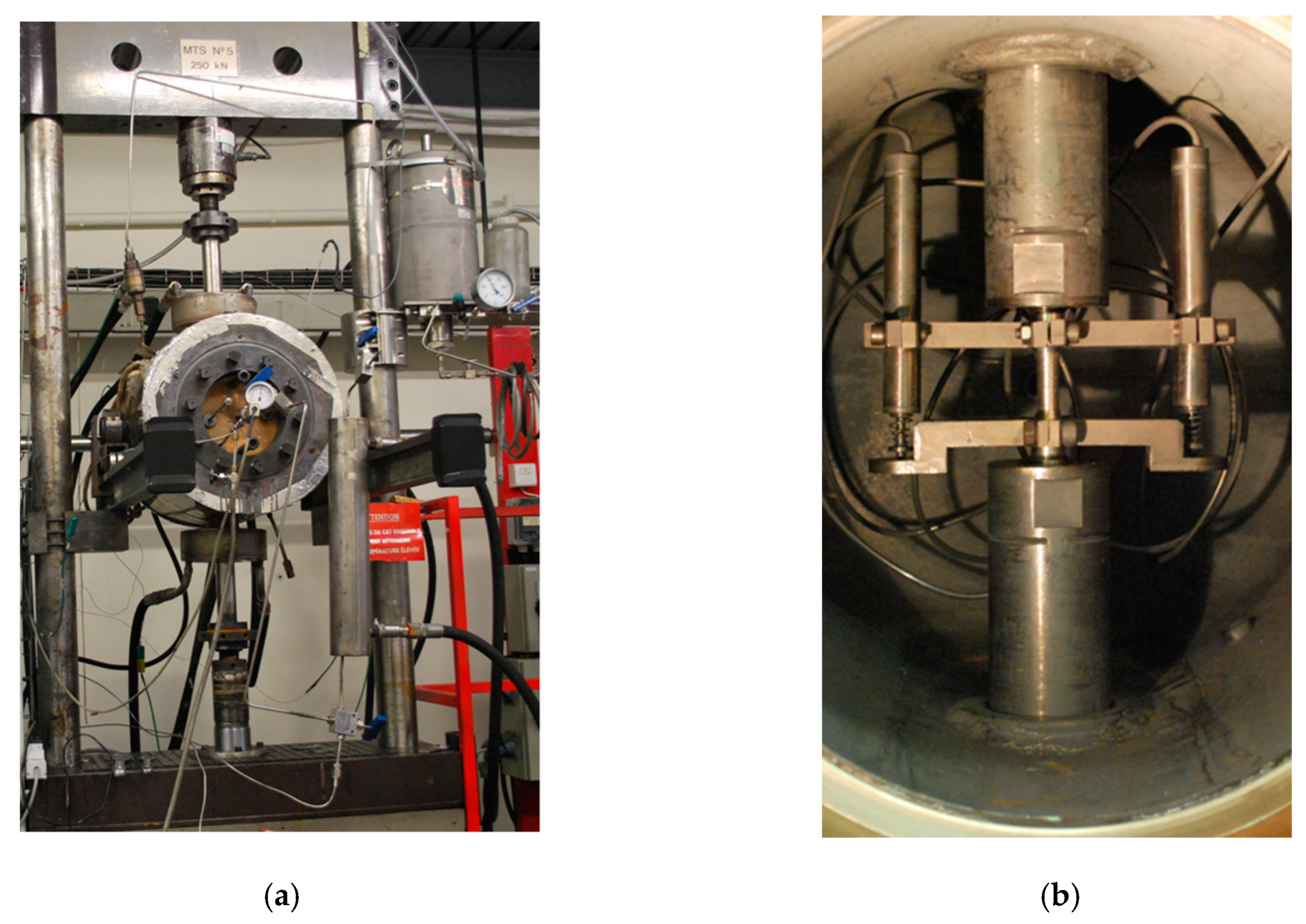

2.2. Test Procedures

- -

- Dissolved oxygen content: lower than 0.01 ppm;

- -

- Hydrogen: 25–35 cc (STP)/kg PWR water;

- -

- Cl and F: lower than 0.05 ppm;

- -

- B: ~1000 ppm (adjusted by boric acid additions);

- -

- Li: quantity needed for adjustment of pH (~2 ppm);

- -

- -

- Conductivity: 2–40 μS/cm.

3. Results

3.1. Influence of Strain Rate and/or Complex Loading on Cyclic Behavior and Fatigue Life in Air

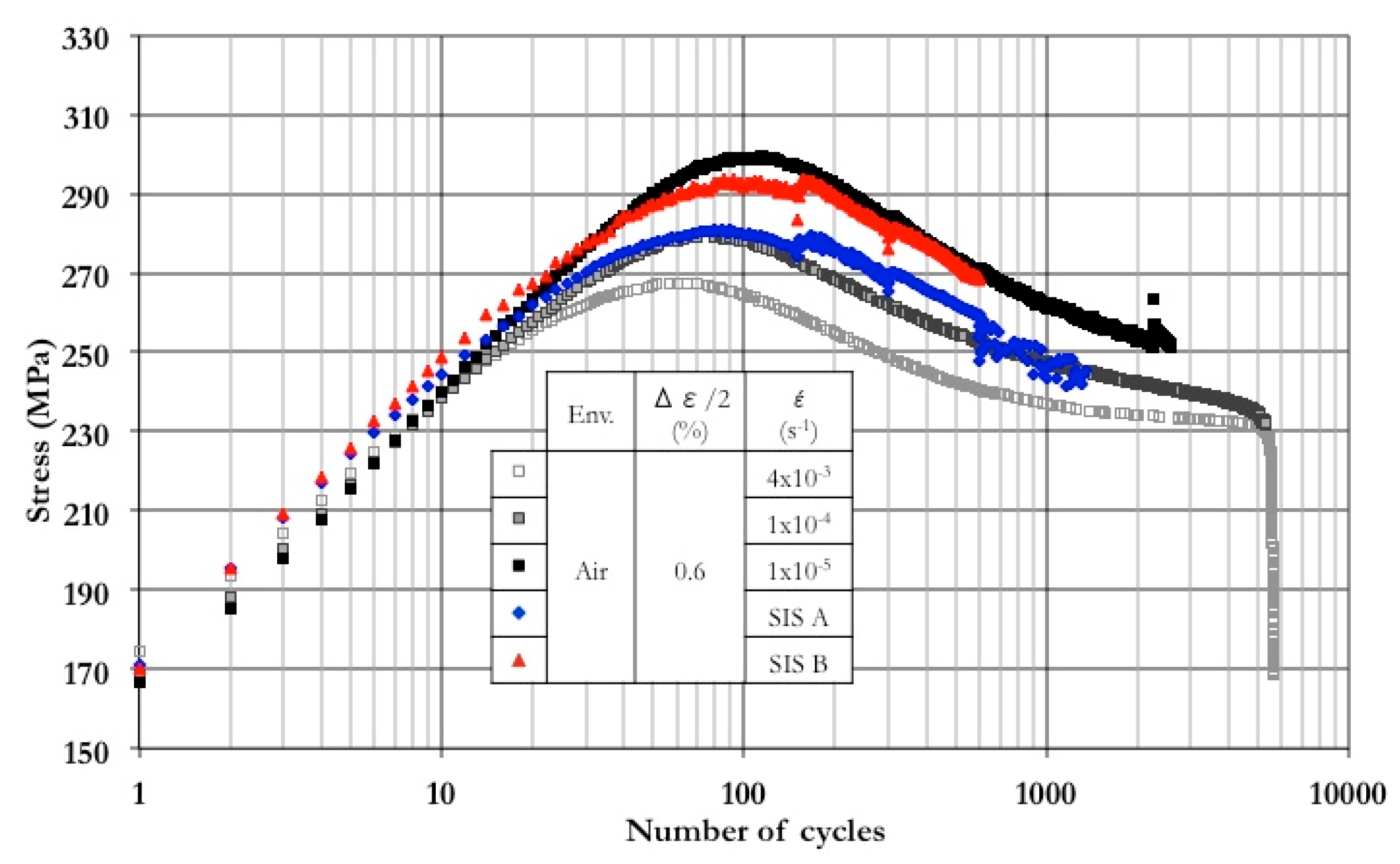

3.2. Influence of Strain Rate and/or Complex Loading on Cyclic Behavior and Fatigue Life in the PWR Environment

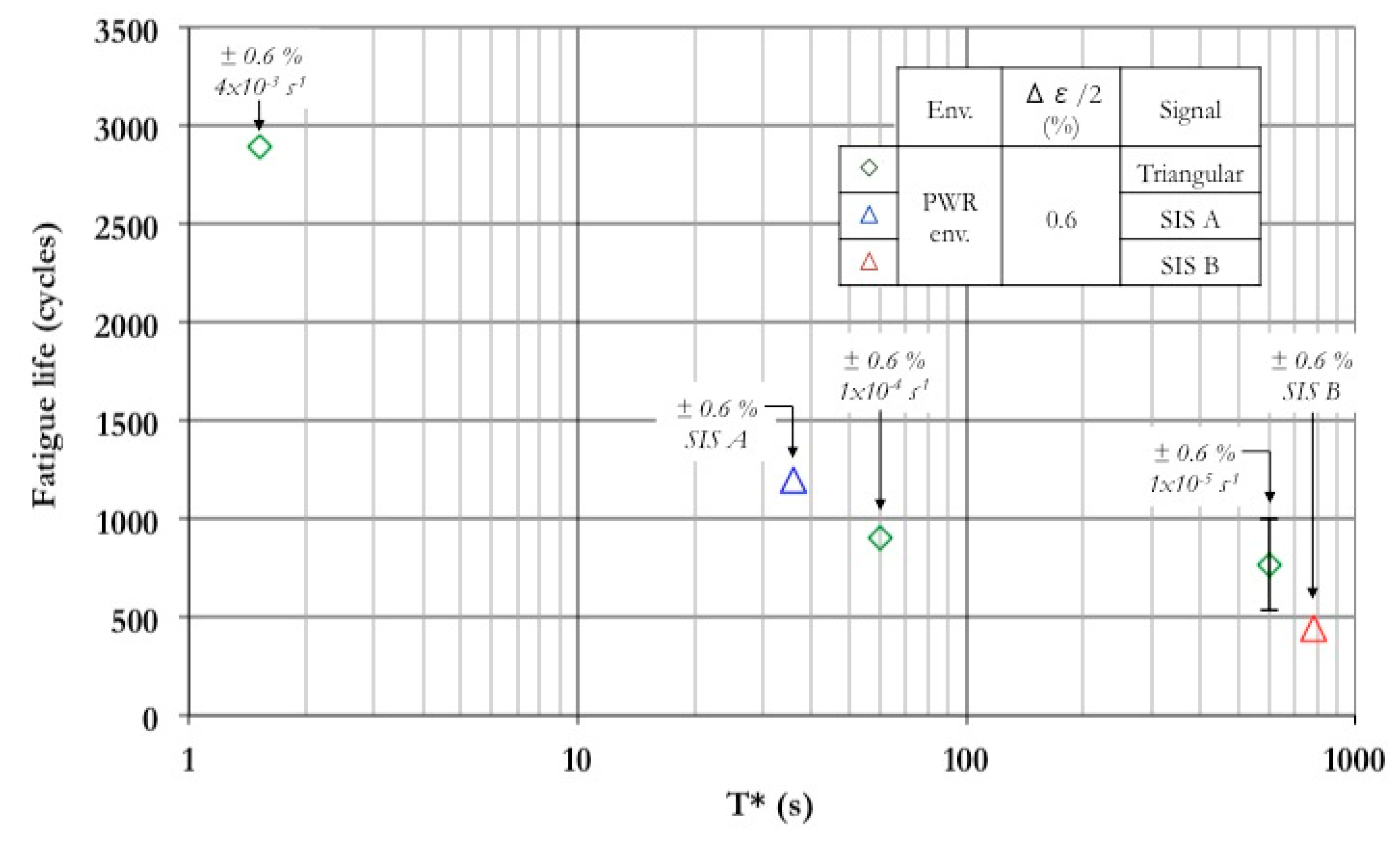

4. Discussion and Analysis

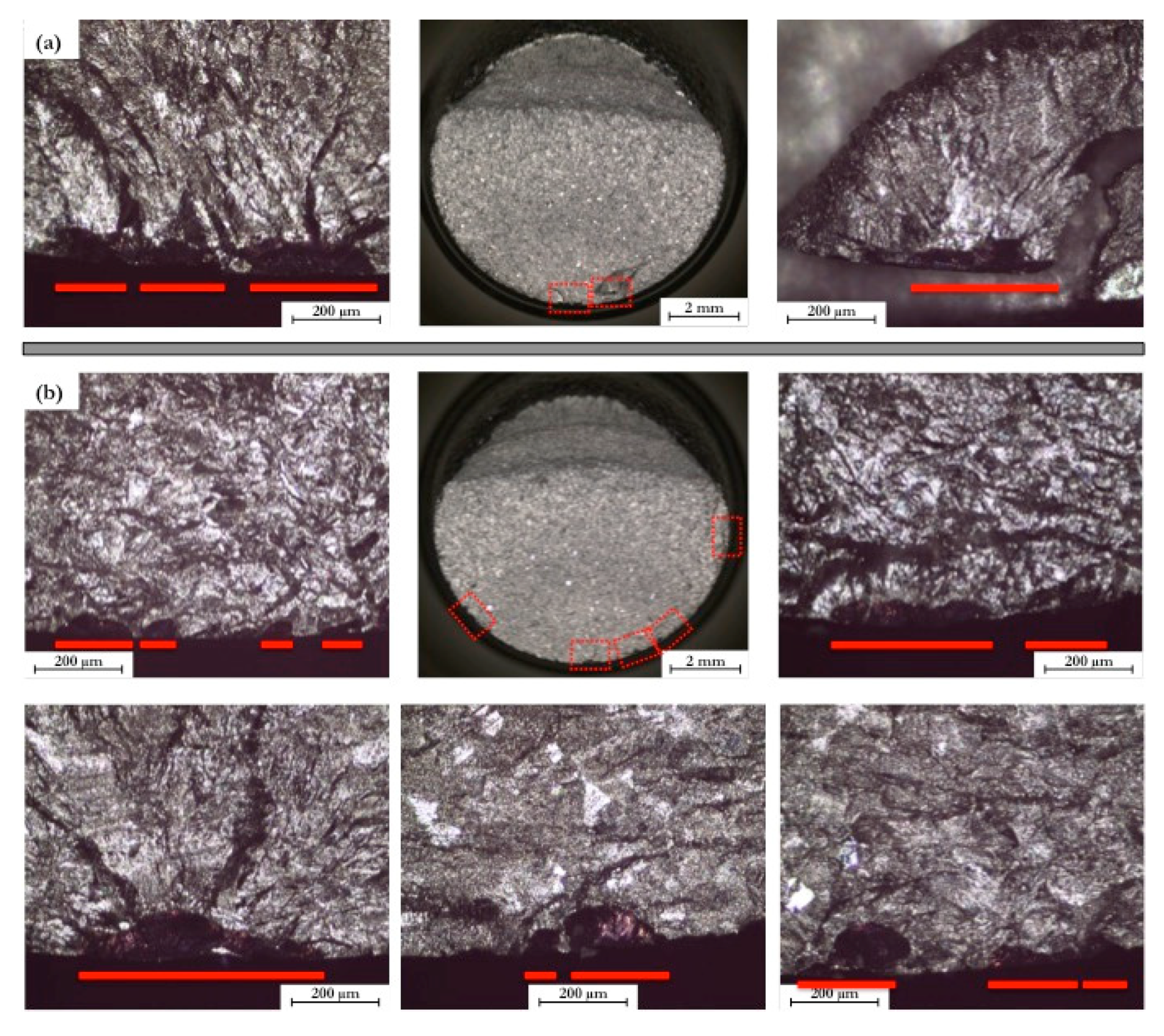

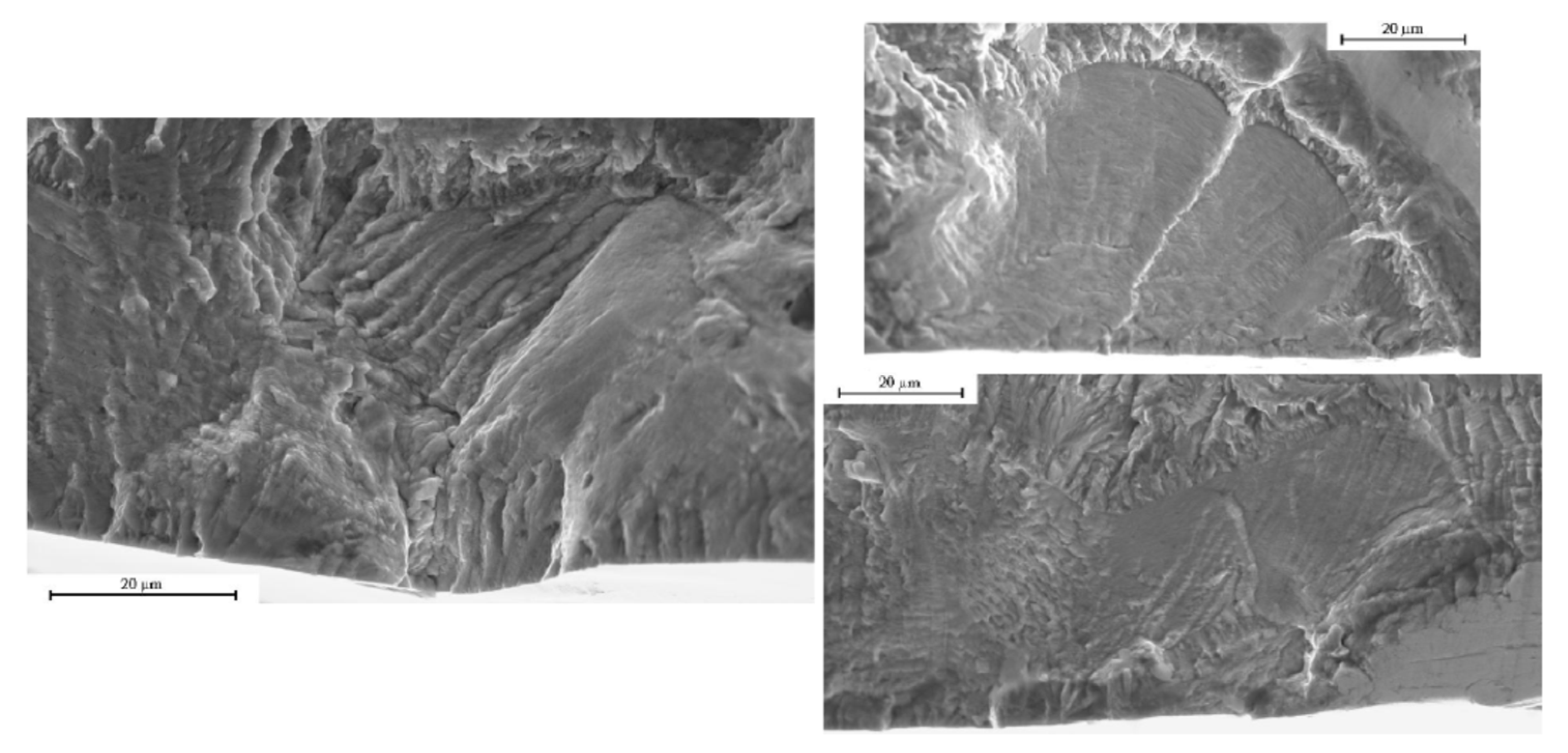

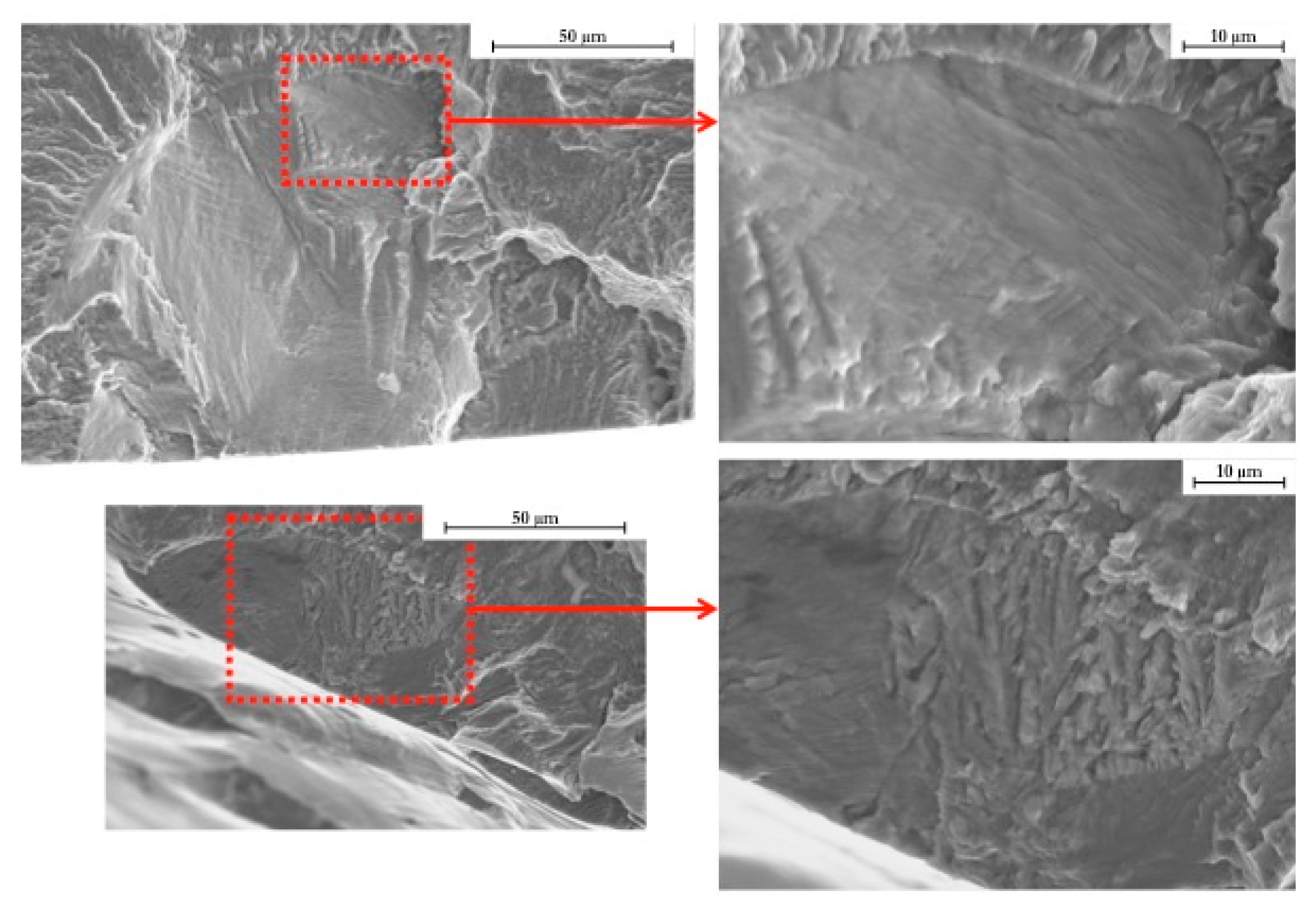

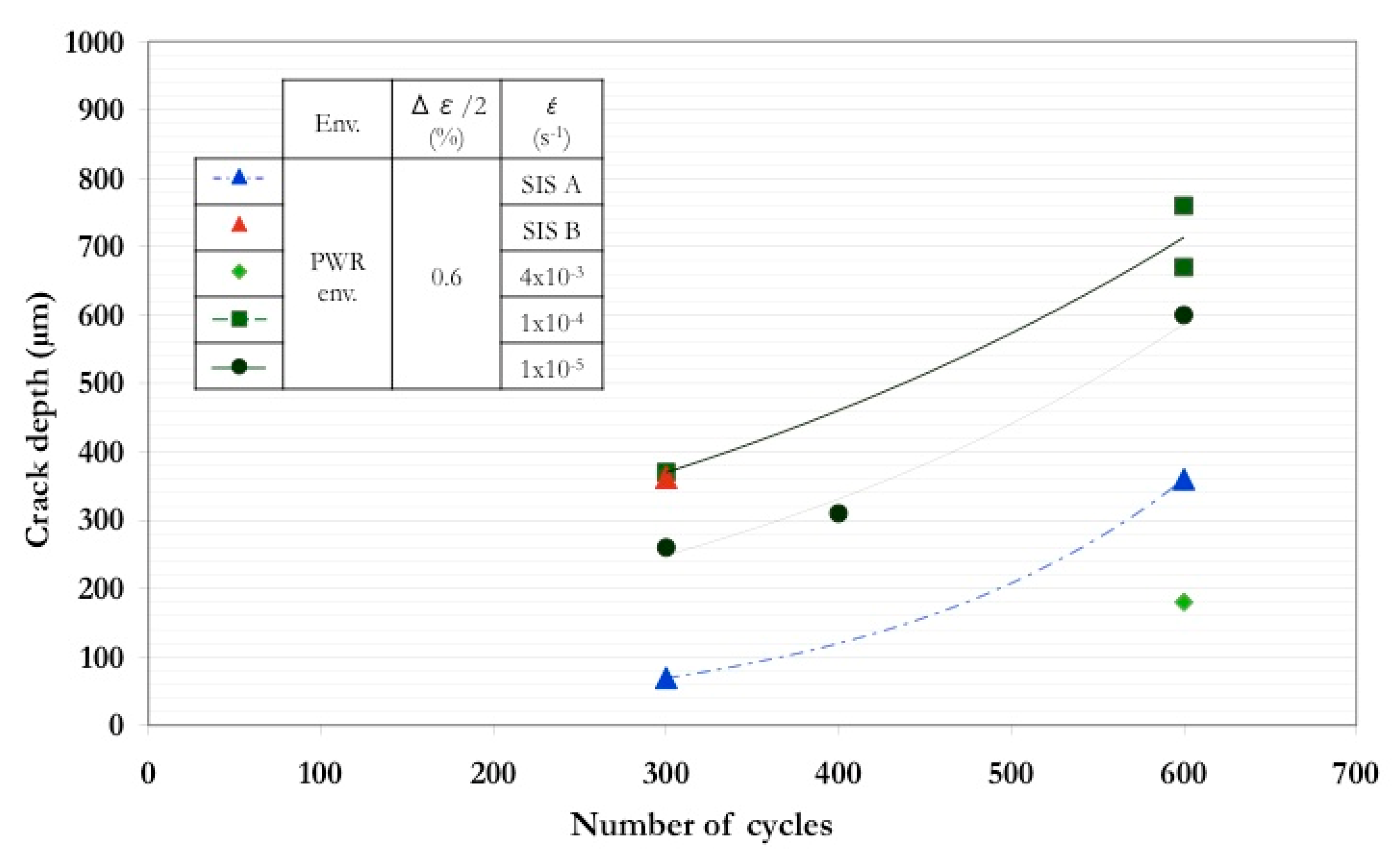

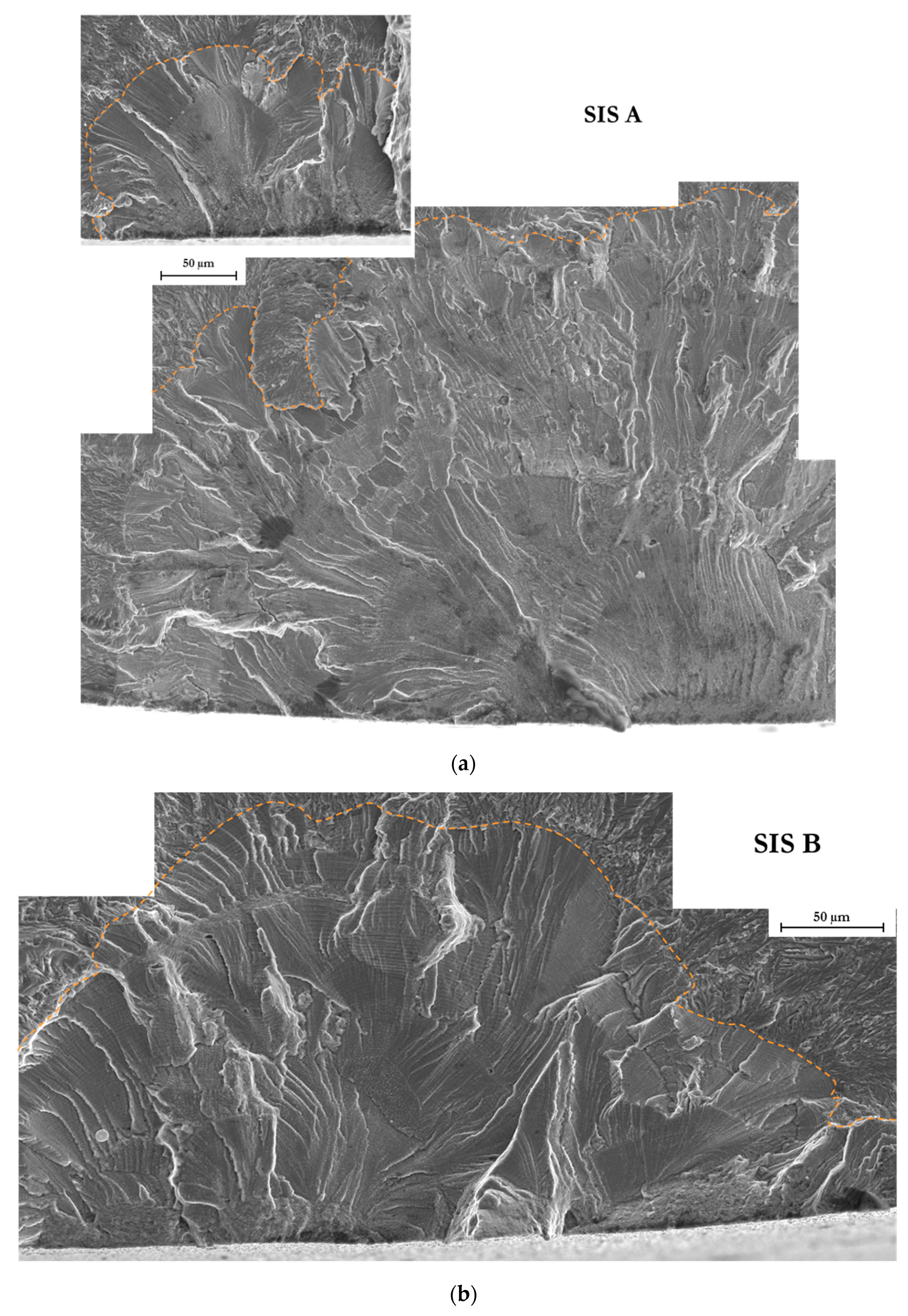

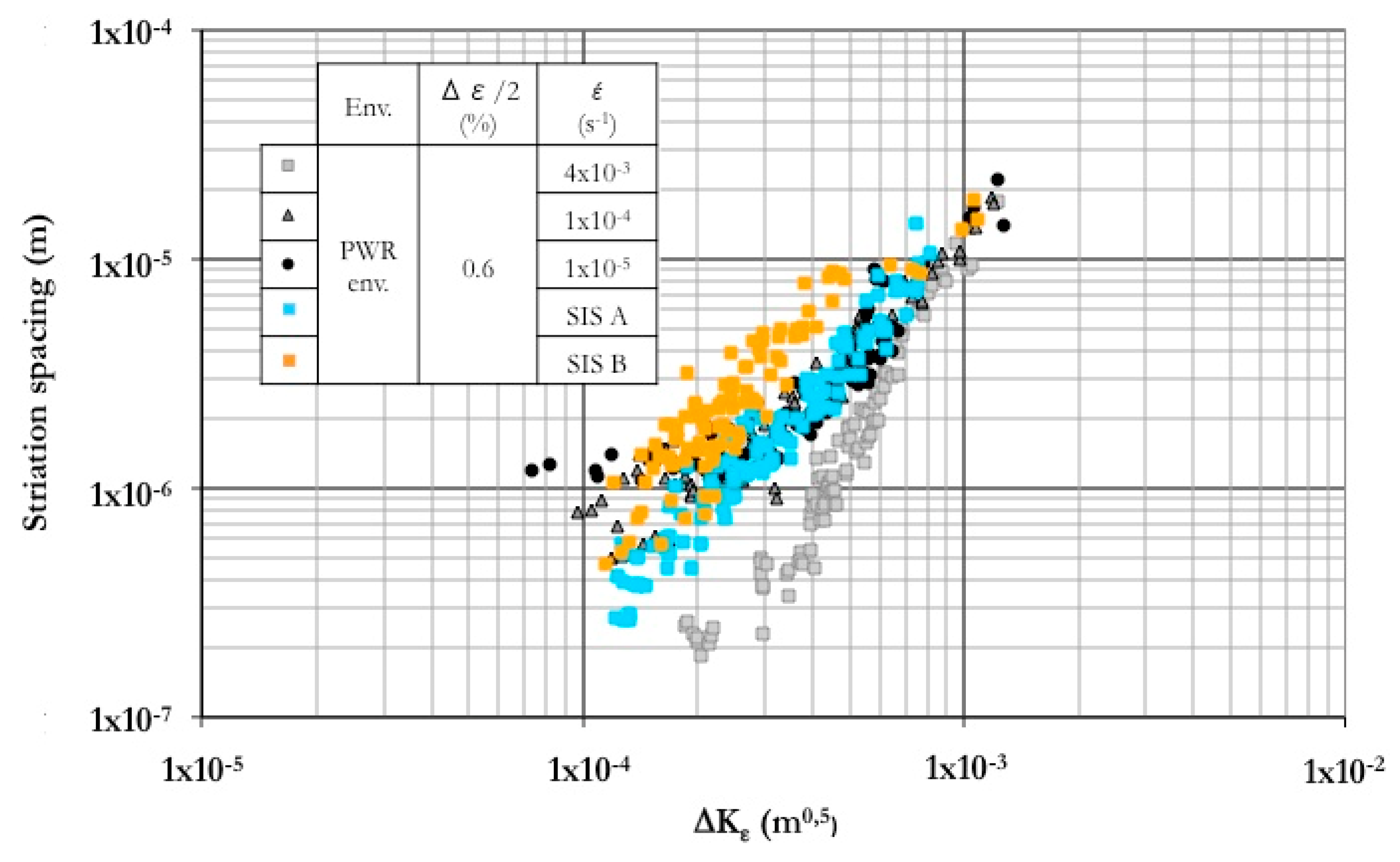

4.1. Analysis of the Propagation Stage

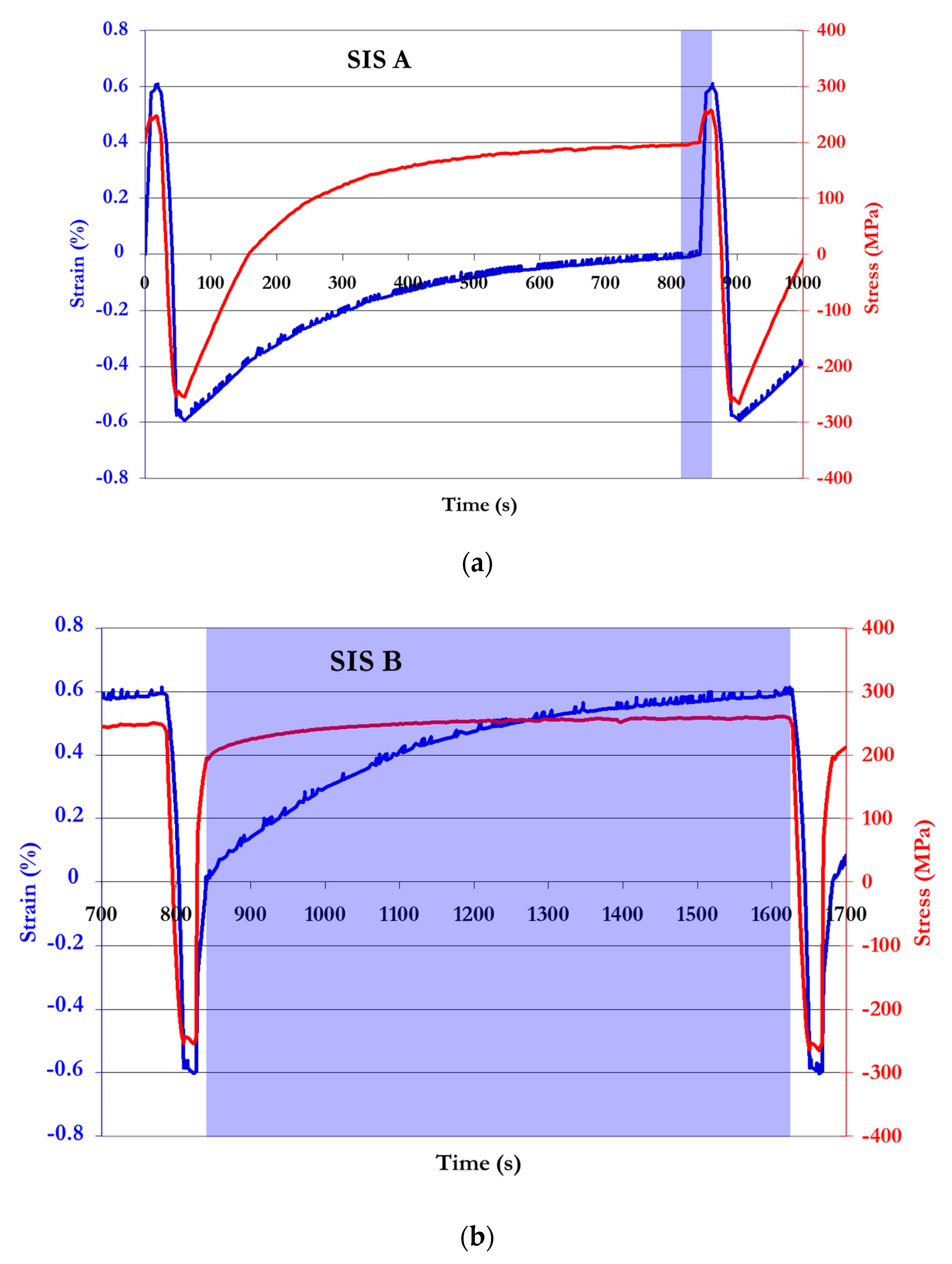

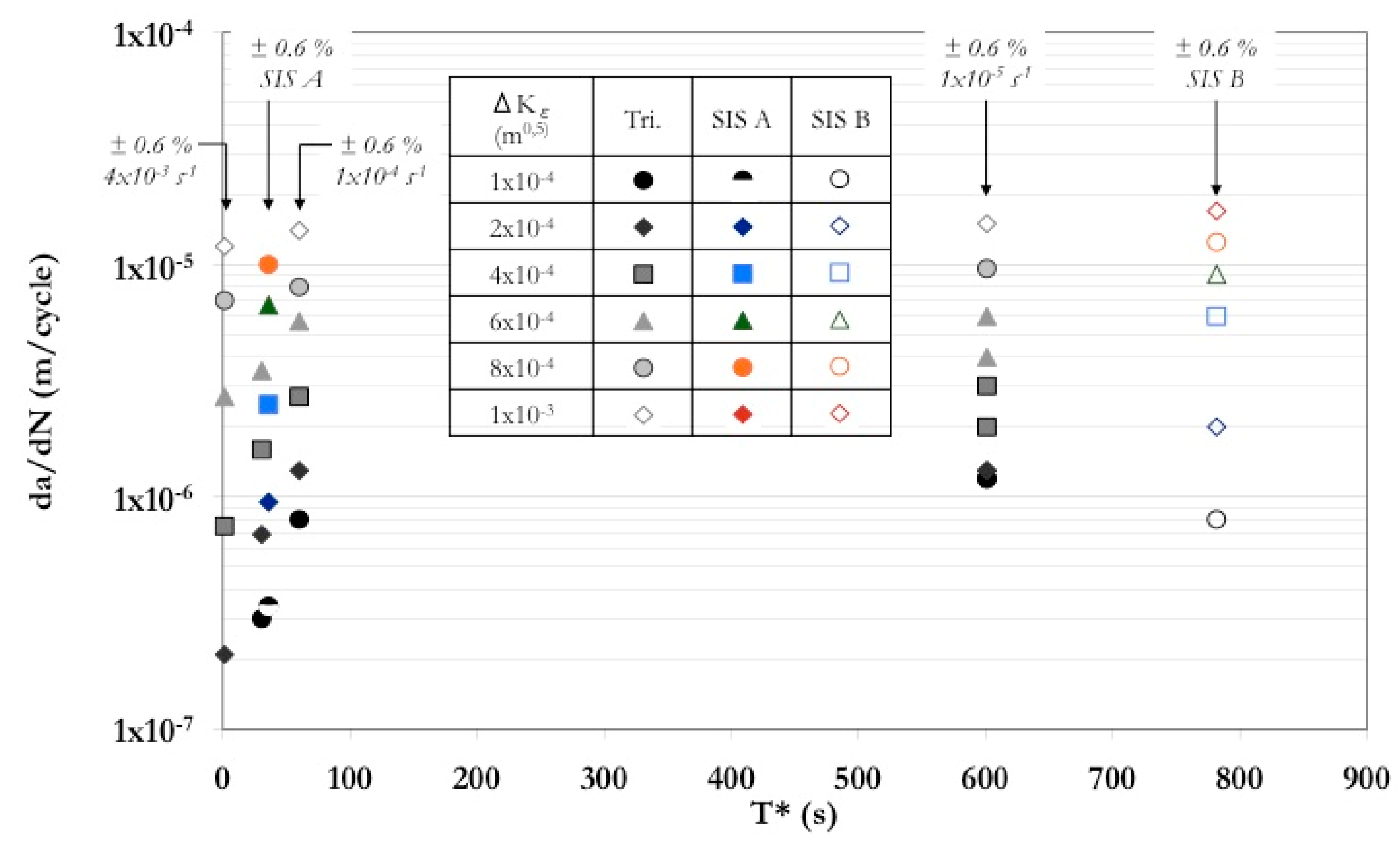

4.2. Analysis of the Influence of the Signal Shape on Fatigue Crack Growth in a PWR Environment

5. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chopra, O.K.; Shack, W.J. The effect of lwr coolant environments on the fatigue life of reactor materials. In Proceedings of the ASME 2006 Pressure Vessels and Piping/ICPVT-11 Conference, Vancouver, BC, Canada, 23–27 July 2006; American Society of Mechanical Engineers: New York, NY, USA, 2006; pp. 191–204. [Google Scholar]

- Tsutsumi, K.; Dodo, T.; Kanasaki, H.; Nomoto, S.; Minami, Y.; Nakamura, T. Fatigue behavior of stainless steel under conditions of changing strain rate in PWR primary water. In Pressure Vessel and Piping Codes and Standards; ASME: New York, NY, USA, 2001; pp. 135–141. [Google Scholar]

- Higuchi, M.; Sakaguchi, K.; Nomura, Y. Effects of strain holding and continuously changing strain rate on fatigue life reduction of structural materials in simulated lwr water. In Proceedings of the ASME 2007 Pressure Vessels and Piping Conference, San Antonio, TX, USA, 22–26 July 2007; American Society of Mechanical Engineers: New York, NY, USA, 2007; pp. 123–131. [Google Scholar]

- Huin, N. Environmental Effect on Cracking of an 304L Austenitic Stainless Steels in PWR Primary Environtment under Cyclic Loading. Ph.D. Thesis, ISAE-ENSMA National School of Mechanics and Aerotechics-Poitiers, Poitiers, France, 2013. [Google Scholar]

- Atkinson, J.D.; Forrest, J.E. Factors influencing the rate of growth of fatigue cracks in rpv steels exposed to a simulated PWR primary water environment. Corros. Sci. 1985, 25, 607–631. [Google Scholar] [CrossRef]

- Alain, R.; Violan, P.; Mendez, J. Low cycle fatigue behavior in vacuum of a 316L type austenitic stainless steel between 20 and 600 °C: 1. Fatigue resistance and cyclic behavior. Mater. Sci. Eng. A 1997, 229, 87–94. [Google Scholar] [CrossRef]

- Gerland, M.; Alain, R.; Saadi, B.A.; Mendez, J. Low cycle fatigue behaviour in vacuum of a 316L-type austenitic stainless steel between 20 and 600 °C: 2. Dislocation structure evolution and correlation with cyclic behaviour. Mater. Sci. Eng. A 1997, 229, 68–86. [Google Scholar] [CrossRef]

- Mannan, S.L. Role of dynamic strain-aging in low-cycle fatigue. Bull. Mater. Sci. 1993, 16, 561–582. [Google Scholar] [CrossRef]

- Poulain, T.; Mendez, J.; Henaff, G.; de Baglion, L. Analysis of the ground surface finish effect on the lcf life of a 304L austenitic stainless steel in air and in PWR environment. Eng. Fract. Mech. 2017, 185, 258–270. [Google Scholar] [CrossRef]

- Petitjean, S. Influence de l’état de surface sur le comportement en fatigue à grand nombre de cycles de l’acier inoxydable austénitique 304L. Ph.D. Thesis, Université de Poitiers, Poitiers, France, 2003. [Google Scholar]

- De Baglion, L.; Mendez, J. Low cycle fatigue behavior of a type 304L austenitic stainless steel in air or in vacuum, at 20 °C or at 300 °C: Relative effect of strain rate and environment. Procedia Eng. 2010, 2, 2171–2179. [Google Scholar] [CrossRef]

- De Baglion, L.; Mendez, J.; Le Duff, J.-A.; Lefrancois, A. Influence of PWR primary water on lcf behavior of type 304L austenitic stainless steel at 300 °C—comparison with results obtained in vacuum or in air. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 463–472. [Google Scholar]

- Huin, N.; Tsutsumi, K.; Couvant, T.; Henaff, G.; Mendez, J. Fatigue life of the strain hardened austenitic stainless steel in simulated pressurized water reactor primary water. J. Press. Vessel Technol. 2014, 136, 031405. [Google Scholar] [CrossRef]

- Tsutsumi, K.; Huin, N.; Couvant, T.; Henaff, G.; Mendez, J.; Chollet, D. Fatigue life of the strain hardened austenitic stainless steel in simulated PWR primary water. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 155–164. [Google Scholar]

- Le Duff, J.A.; Lefrancois, A.; Vernot, J.P. Effects of surface finish and loading conditions on the low cycle fatigue behavior of austenitic stainless steel in PWR environment comparison of LCF test results with NUREG/CR-6909 life estimations. In Proceedings of the ASME 2008 Pressure Vessels and Piping Conference; Chicago, IL, USA, 27–31 July 2008, American Society of Mechanical Engineers: New York, NY, USA, 2008; pp. 453–462. [Google Scholar]

- Le Duff, J.A.; Lefrancois, A.; Vernot, J.P. Effects of surface finish and loading conditions on the low cycle fatigue behavior of austenitic stainless steel in PWR environment for various strain amplitude levels. In Proceedings of the ASME 2009 Pressure Vessels and Piping Conference, Prague, Czech Republic, 26–30 July 2009; American Society of Mechanical Engineers: New York, NY, USA, 2009; pp. 603–610. [Google Scholar]

- Le Duff, J.A.; Lefrancois, A.; Vernot, J.P.; Bossu, D. Effect of loading signal shape and of surface finish on the low cycle fatigue behavior of 304L stainless steel in PWR environment. In Proceedings of the ASME 2013 Pressure Vessels and Piping Conference, Paris, France, 14–18 July 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; pp. 233–241. [Google Scholar]

- Mendez, J. On the effects of temperature and environment on fatigue damage processes in ti alloys and in stainless steel. Mater. Sci. Eng. A 1999, 263, 187–192. [Google Scholar] [CrossRef]

- Boettner, R.C.; Laird, C.; McEvily, A.J. Crack nucleation and growth in high strain-low cycle fatigue. Trans. AIME 1965, 233, 379–387. [Google Scholar]

- Kamaya, M. Low-cycle fatigue crack growth prediction by strain intensity factor. Int. J. Fatigue 2015, 72, 80–89. [Google Scholar] [CrossRef]

- Sakaguchi, K.; Nomura, Y.; Suzuki, S.; Tsutsumi, K.; Kanasaki, H.; Higuchi, M. Effect of factors on fatigue life in PWR water environment. In Proceedings of the ASME 2006 Pressure Vessels and Piping/ICPVT-11 Conference, Vancouver, BC, Canada, 23–27 July 2006; American Society of Mechanical Engineers: New York, NY, USA, 2006; pp. 103–111. [Google Scholar]

- Shoji, T.; Takahashi, H.; Suzuki, M.; Kondo, T. A new parameter for characterizing corrosion fatigue crack growth. J. Eng. Mater. Technol. 1981, 103, 298–304. [Google Scholar] [CrossRef]

- Tice, D.R. Assessment of environmentally assisted cracking in PWR pressure vessel steels. Int. J. Press. Vessels Pip. 1991, 47, 113–126. [Google Scholar] [CrossRef]

- Gilman, J.D. Further development of a model for predicting corrosion fatigue crack growth in reactor pressure vessel steels. J. Press. Vessel Technol. 1987, 109, 340–346. [Google Scholar] [CrossRef]

- Schack, W.J.; Kassner, T.F. Review of Environmental Effects on Fatigue Crack Growth of Austenitic Stainless Steel; Argonne National Laboratory: Argonne, IL, USA, 1994. [Google Scholar]

- Vormwald, M.; Seeger, T. The consequences of short crack closure on fatigue crack growth under variable amplitude loading. Fatigue Fract. Eng. Mater. Struct. 1991, 14, 205–225. [Google Scholar] [CrossRef]

- Wei, R.P.; Simmons, G.W. Recent progress in understanding environment-assisted fatigue crack growth. Int. J. Fract. 1981, 17, 235–247. [Google Scholar] [CrossRef]

| L Direction | T Direction | |||

|---|---|---|---|---|

| 20 °C | 300 °C | 20 °C | 300 °C | |

| Yield strength σy 0.2 (MPa) | 214 | 130 | 224 | 133 |

| Ultimate Tensile strength (MPa) | 592 | 414 | 593 | 409 |

| Tensile Elongation A% | 57 | 39 | 57 | 39 |

| Reduction in section area Z% | 84 | 78 | 81 | 75 |

| Segment 1 | Segment 2 | Negative Strain Rate | Segment 3 | Segment 4 | |

|---|---|---|---|---|---|

| Duration (s) | 10 | 10 | 40 | 140 | 640 |

| Mean strain rate (s−1) | 3.00 × 10−4 | 3.00 × 10−4 | 3.00 × 10−4 | 1.88 × 10−5 | 4.84 × 10−6 |

| Signal | NR (Cycles) | Maximum Crack Depth (μm) | Surface Crack Length (μm) | Cracked Area (μm2) |

|---|---|---|---|---|

| SIS A | 2,163,000 | 92 | 305 | 0.20 |

| SIS B | 654,600 | 129 | 580 | 0.26 |

| Signal | NLCF (Cycles) | NR (Cycles) | Maximum Crack Depth (μm) | Surface Crack Length (μm) | Cracked Area (μm2) |

|---|---|---|---|---|---|

| SIS A | 300 | 6,858,800 (+1,045,800 *) | 69 | 0.10 | 0.02 |

| 600 | 472,400 | 360 | 0.75 | 0.23 | |

| SIS B | 300 | 483,200 | 362 | 0.59 | 0.18 |

| Fatigue Crack Growth Law Parameters | Np (20 μm to 3 mm) (Cycles) | N5 (Cycles) | ||

|---|---|---|---|---|

| C | M | |||

| SIS A | 12 | 1.96 | 952 | 1200 |

| SIS B | 0.84 | 1.54 | 452 | 440 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poulain, T.; de Baglion, L.; Mendez, J.; Hénaff, G. Influence of Strain Rate and Waveshape on Environmentally-Assisted Cracking during Low-Cycle Fatigue of a 304L Austenitic Stainless Steel in a PWR Water Environment. Metals 2019, 9, 197. https://doi.org/10.3390/met9020197

Poulain T, de Baglion L, Mendez J, Hénaff G. Influence of Strain Rate and Waveshape on Environmentally-Assisted Cracking during Low-Cycle Fatigue of a 304L Austenitic Stainless Steel in a PWR Water Environment. Metals. 2019; 9(2):197. https://doi.org/10.3390/met9020197

Chicago/Turabian StylePoulain, Thibault, Laurent de Baglion, Jose Mendez, and Gilbert Hénaff. 2019. "Influence of Strain Rate and Waveshape on Environmentally-Assisted Cracking during Low-Cycle Fatigue of a 304L Austenitic Stainless Steel in a PWR Water Environment" Metals 9, no. 2: 197. https://doi.org/10.3390/met9020197

APA StylePoulain, T., de Baglion, L., Mendez, J., & Hénaff, G. (2019). Influence of Strain Rate and Waveshape on Environmentally-Assisted Cracking during Low-Cycle Fatigue of a 304L Austenitic Stainless Steel in a PWR Water Environment. Metals, 9(2), 197. https://doi.org/10.3390/met9020197