Comparison of Linear and Nonlinear Ultrasonic Parameters in Characterizing Grain Size and Mechanical Properties of 304L Stainless Steel

Abstract

1. Introduction

2. Experimental Procedures

2.1. Specimen Preparation

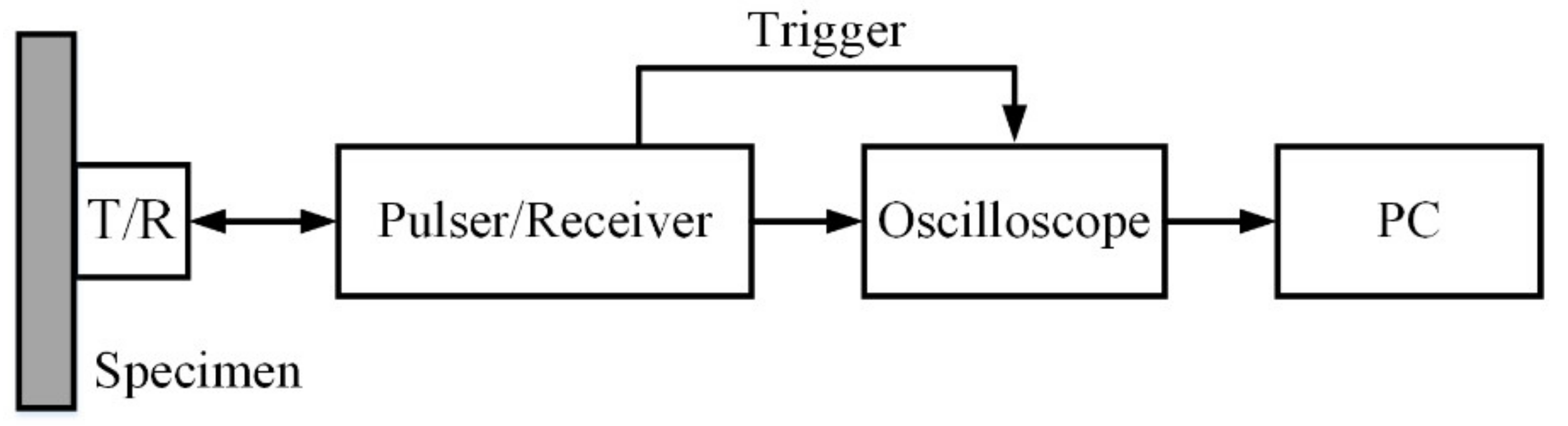

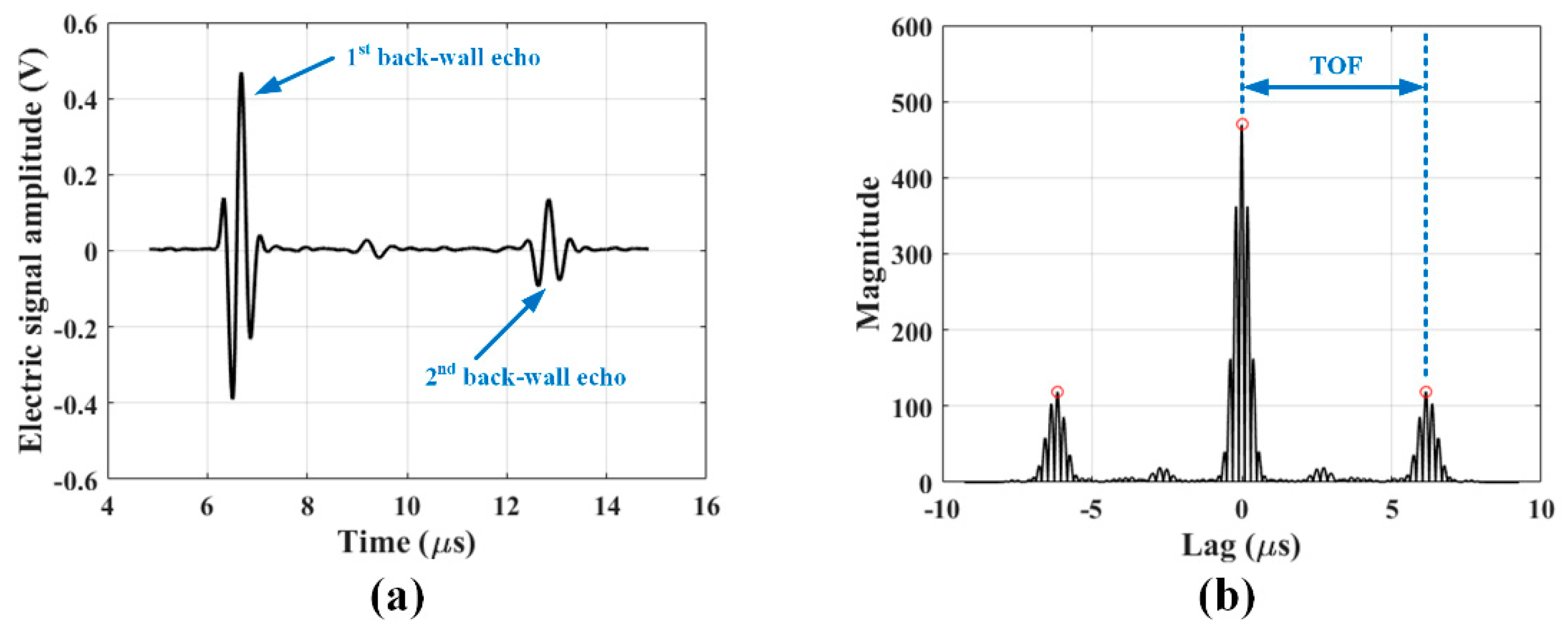

2.2. Ultrasonic Velocity and Attenuation Measurements

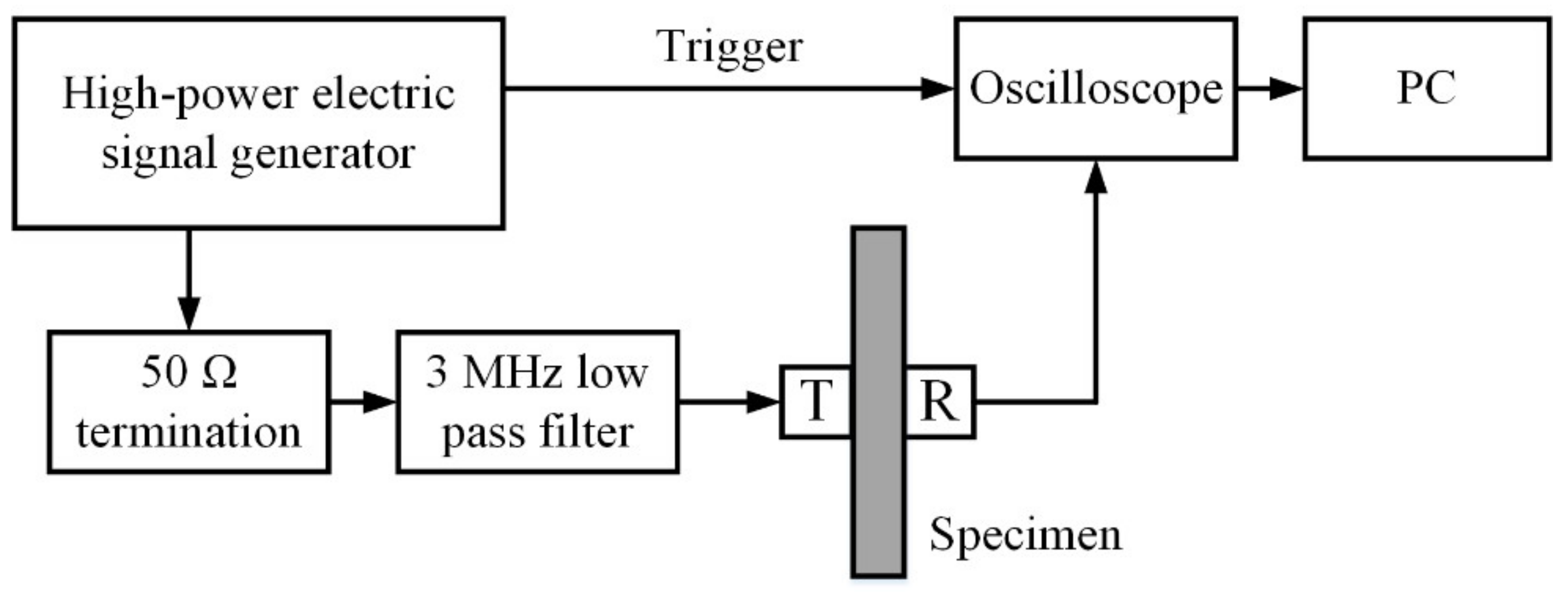

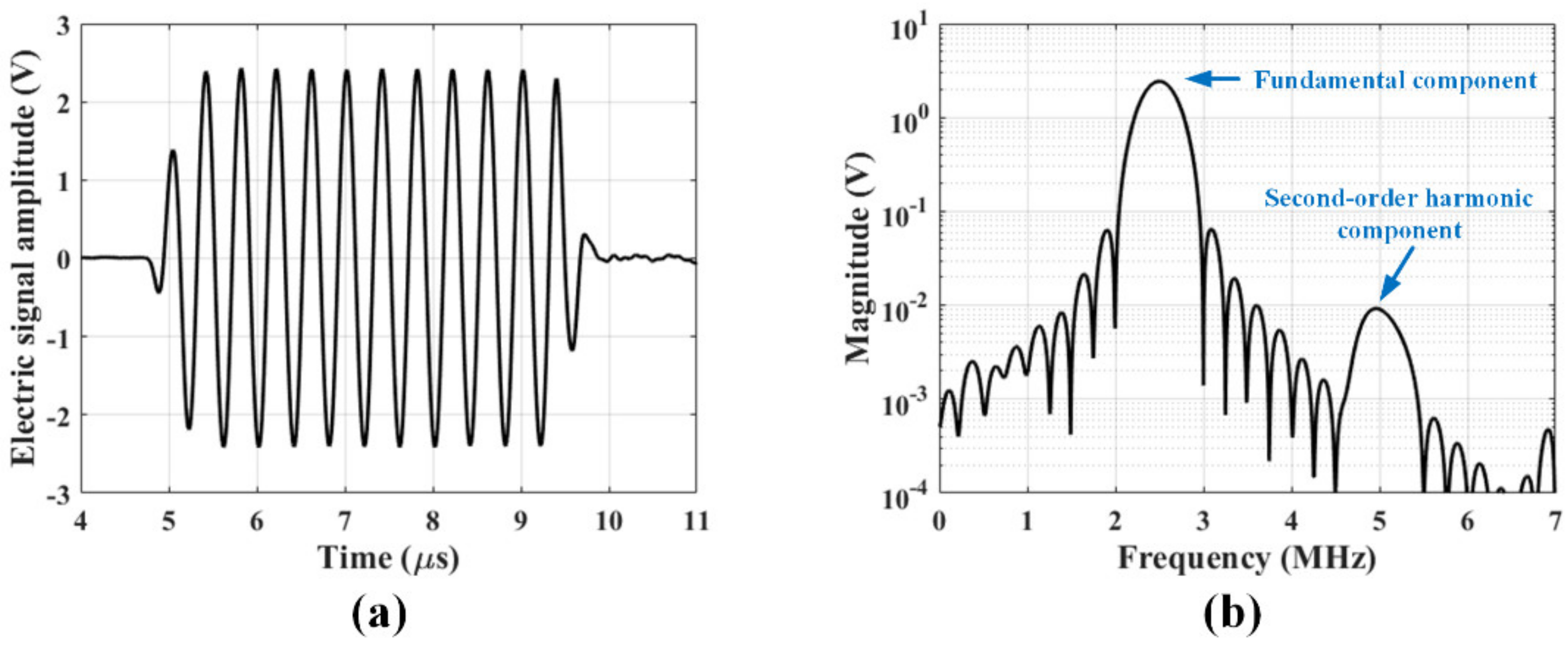

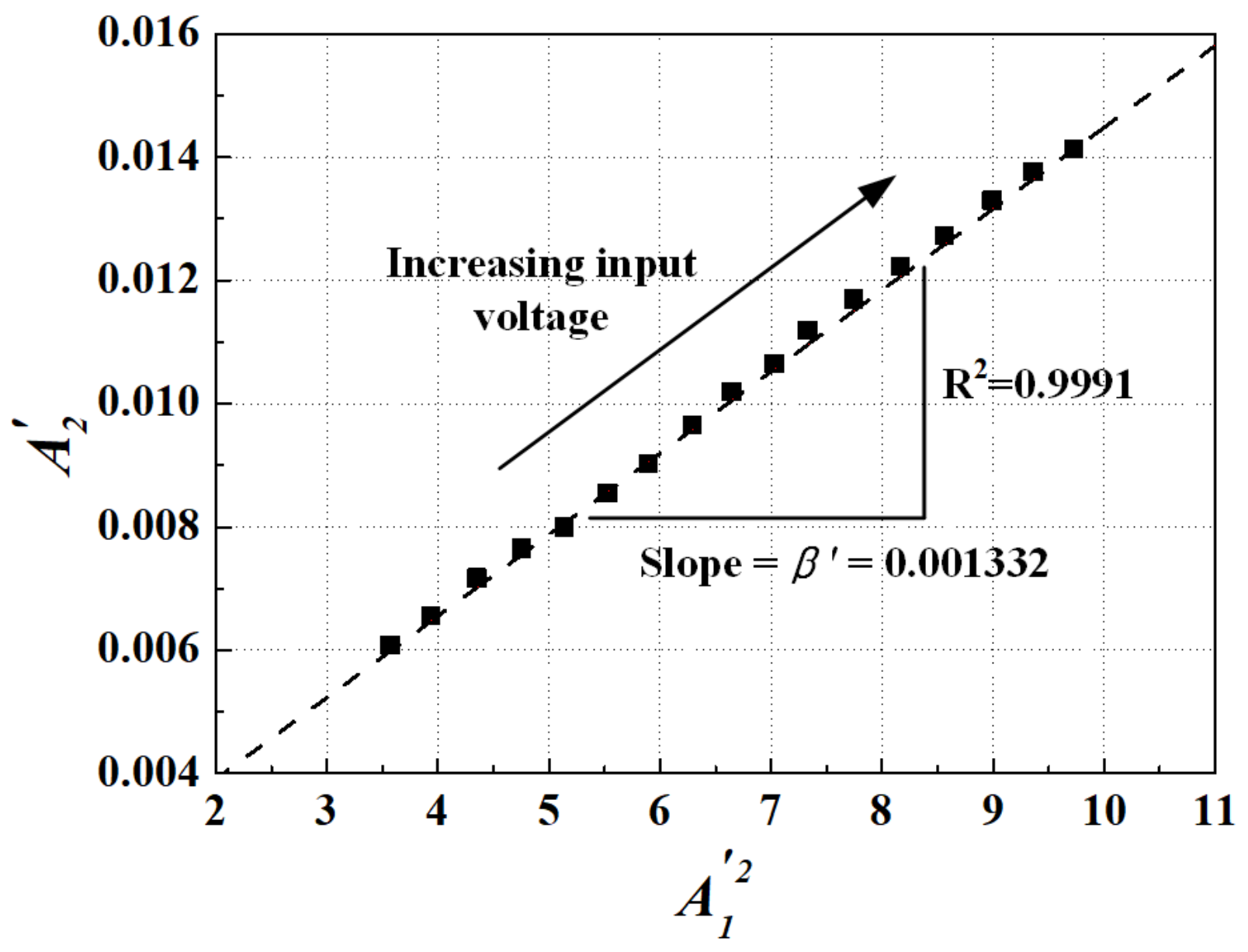

2.3. Nonlinear Ultrasonic Measurements

2.4. Mechanical Property Measurements

3. Experimental Results and Discussion

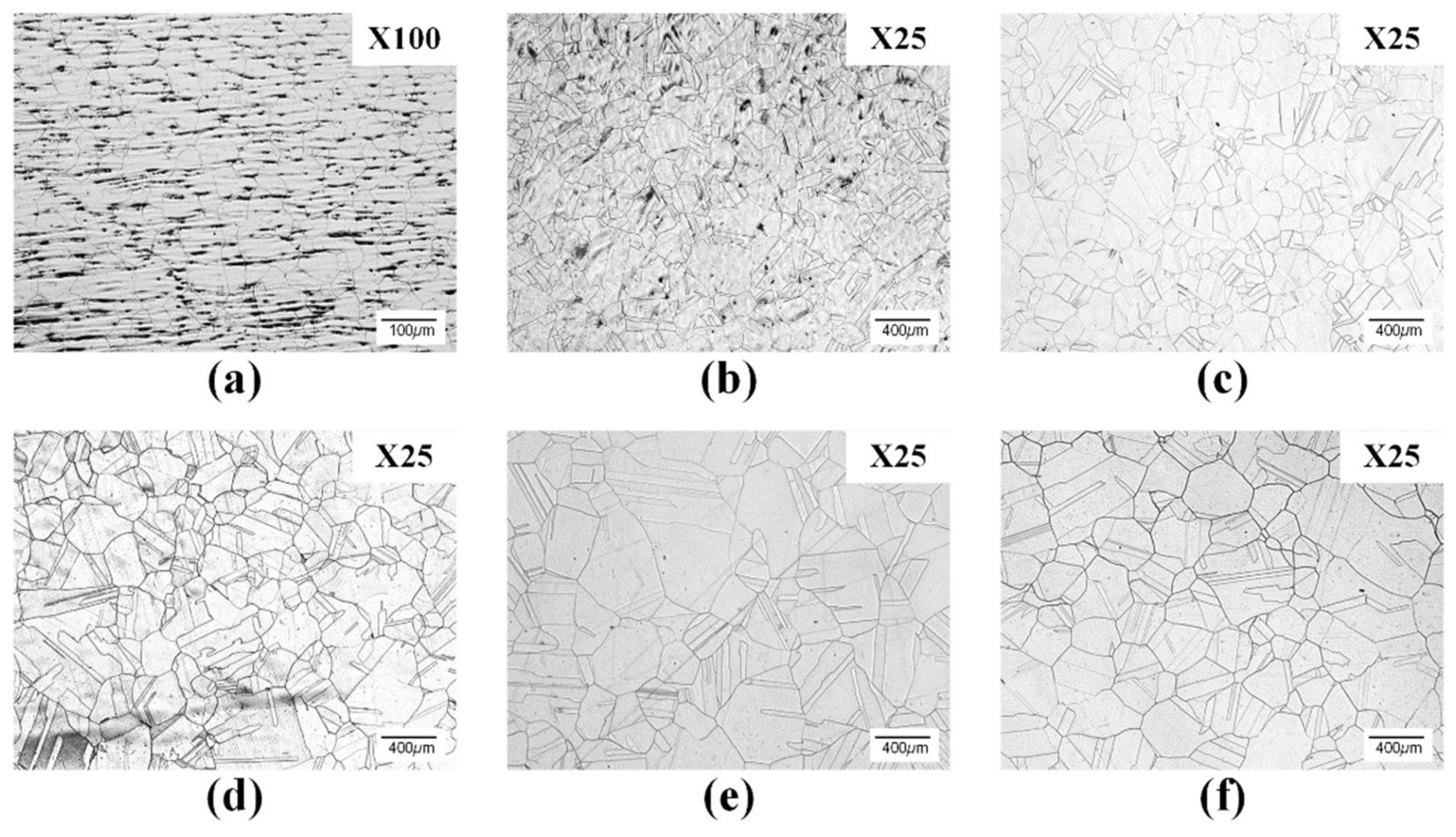

3.1. Grain Size

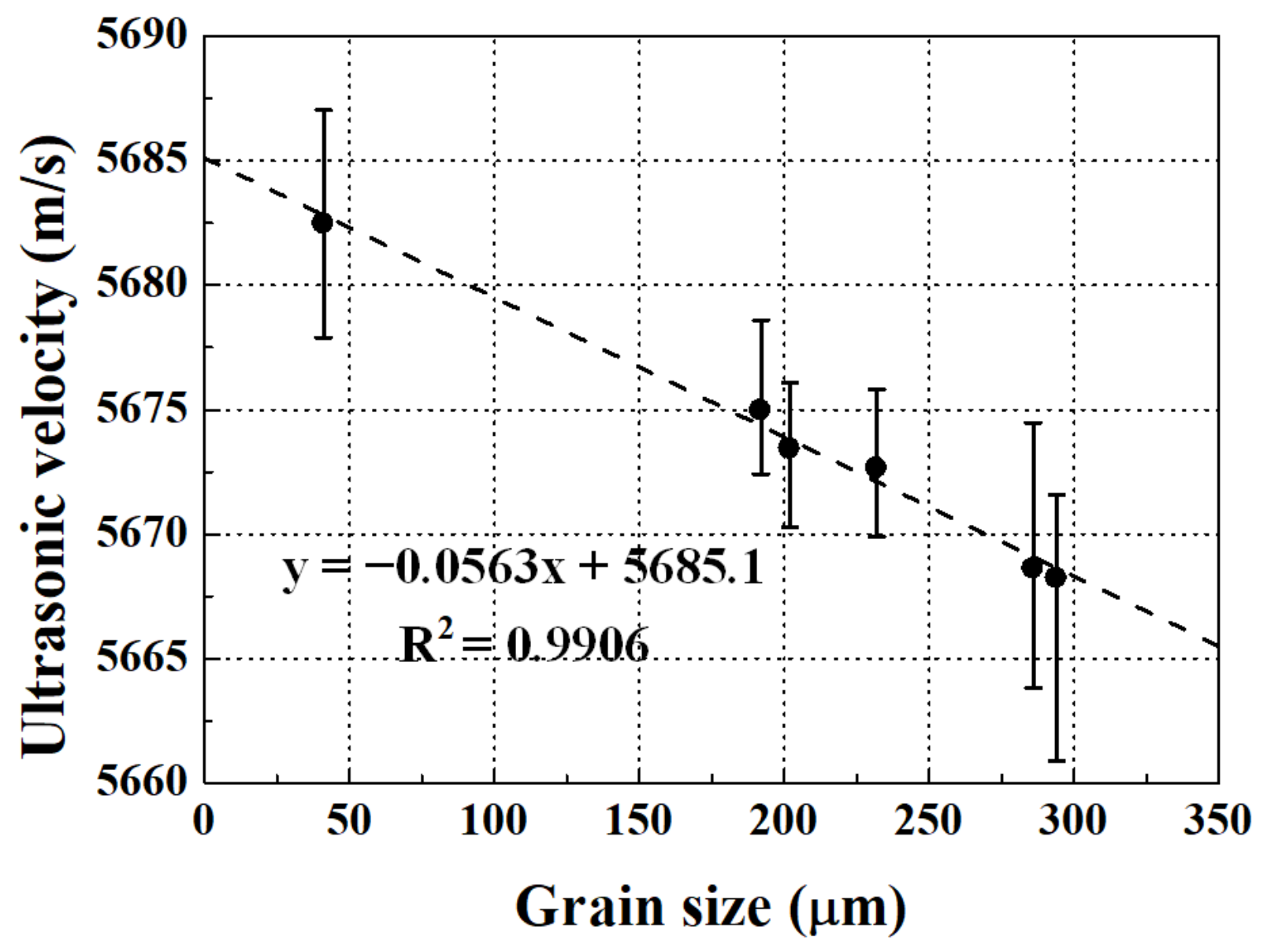

3.2. Ultrasonic Velocity vs. Grain Size

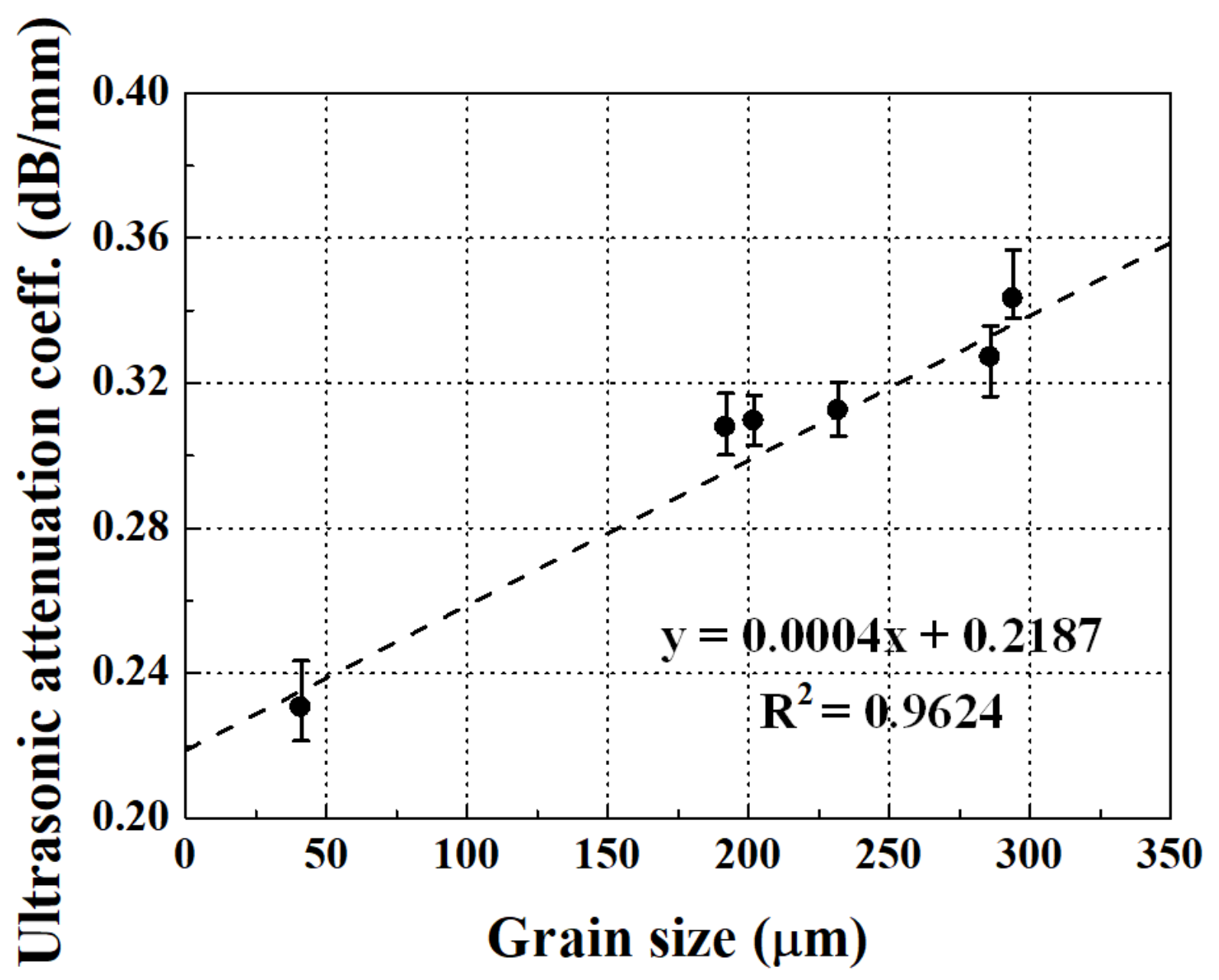

3.3. Ultrasonic Attenuation Coefficient vs. Gain Size

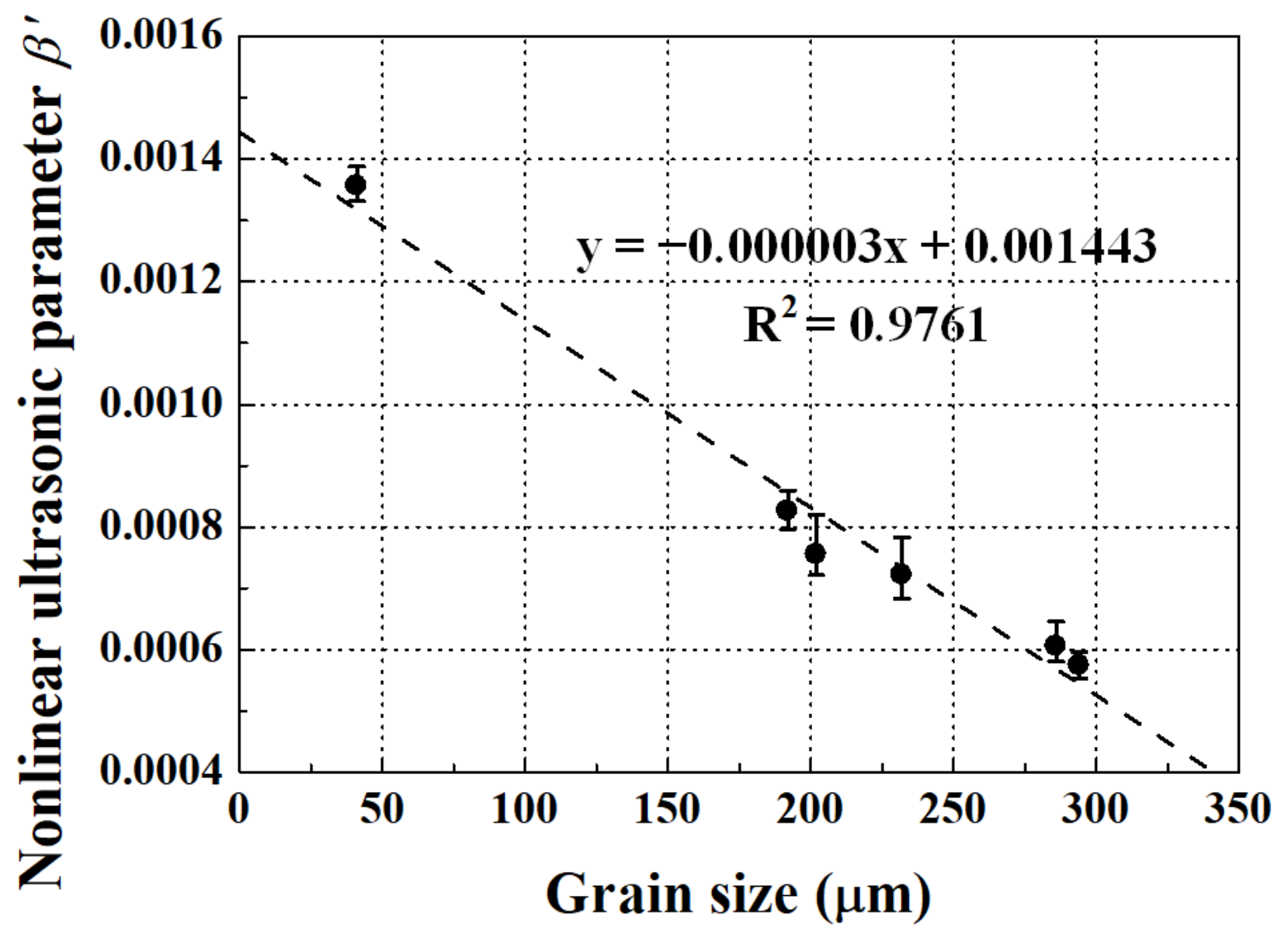

3.4. Nonlinear Ultrasonic Parameter vs. Grain Size

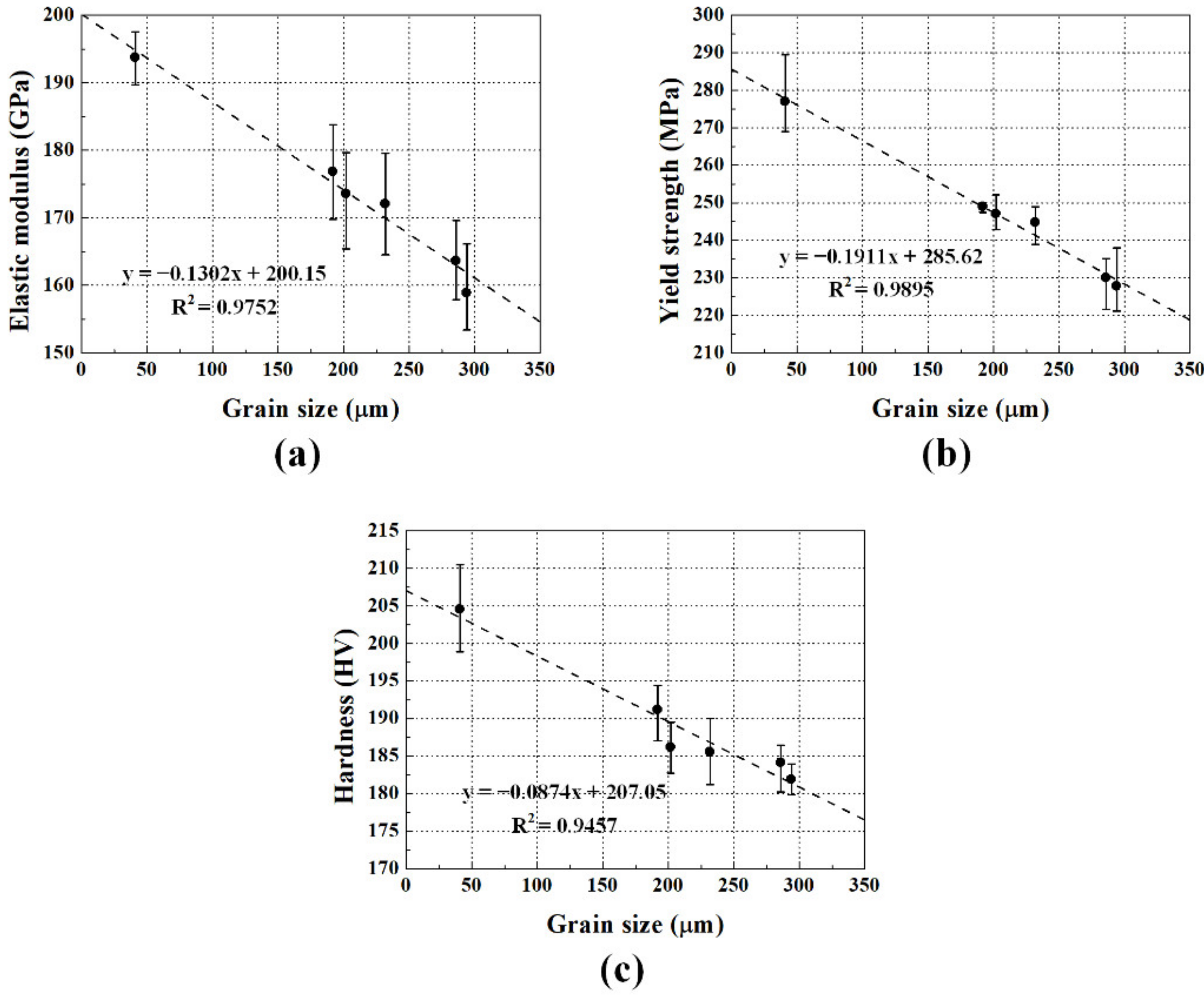

3.5. Mechanical Properties vs. Grain Size

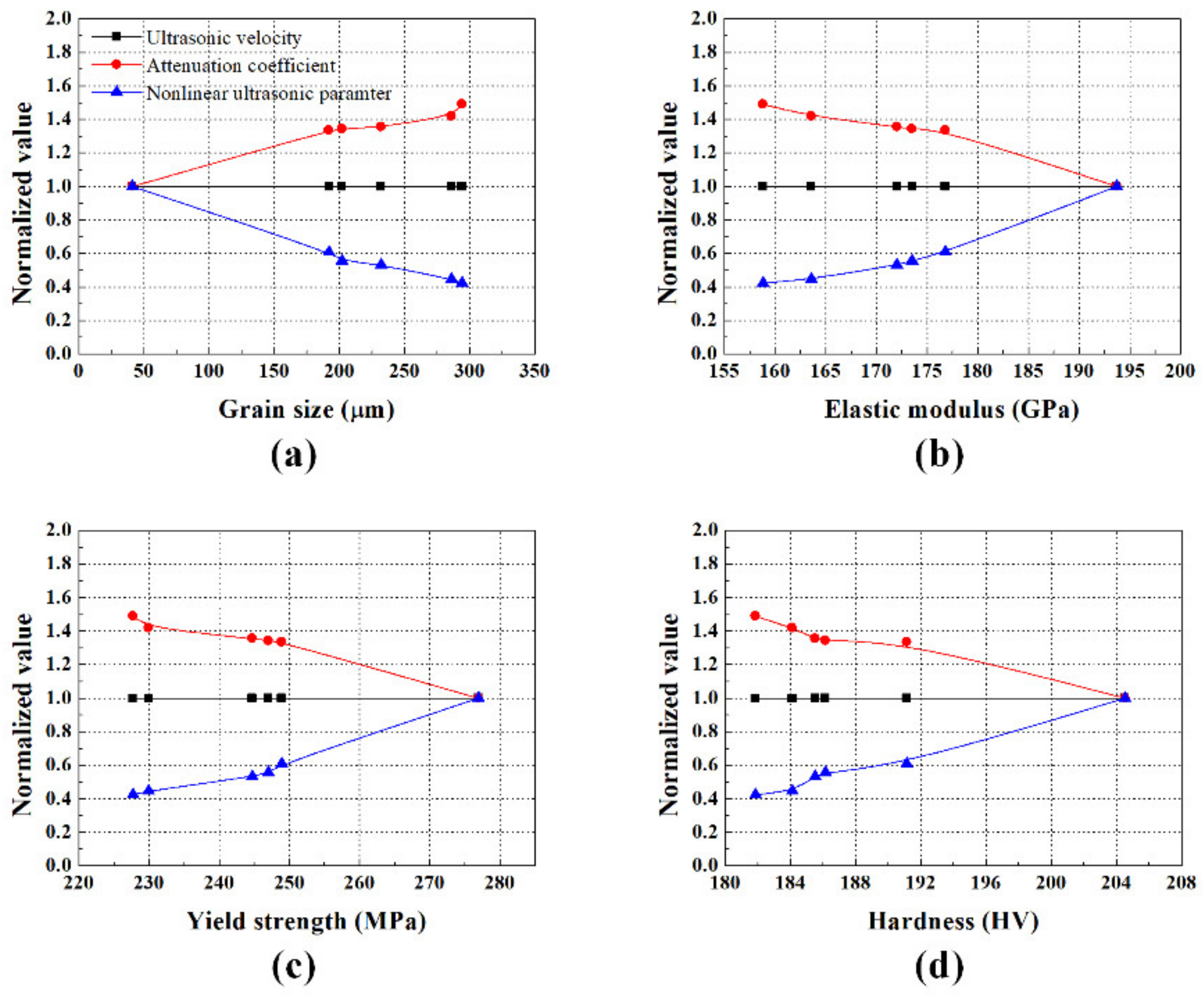

3.6. Summary

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, M.; Lomonosov, A.M.; Shen, Z.; Seo, H.; Jhang, K.Y.; Gusev, V.E.; Ni, C. Monitoring of thermal aging of aluminum alloy via nonlinear propagation of acoustic pulses generated and detected by lasers. Appl. Sci. 2019, 9, 1191. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Matori, K.A.; Ostovan, F.; Mustapha, F.; Zahari, N.I.; Oskoueian, A. On the correlation between microstructural evolution and ultrasonic properties: A review. J. Mater. Sci. 2015, 50, 2643–2665. [Google Scholar] [CrossRef]

- Rens, K.L.; Wipf, T.J.; Klaiber, F.W. Review of nondestructive evaluation techniques of civil infrastructure. J. Perform. Constr. Facil. 1997, 11, 152–160. [Google Scholar] [CrossRef]

- Lehto, P.; Remes, H.; Saukkonen, T.; Hänninen, H.; Romanoff, J. Influence of grain size distribution on the Hall–Petch relationship of welded structural steel. Mater. Sci. Eng. A 2014, 592, 28–39. [Google Scholar] [CrossRef]

- Aghaie-Khafri, M.; Honarvar, F.; Zanganeh, S. Characterization of grain size and yield strength in AISI 301 stainless steel using ultrasonic attenuation measurements. J. Nondestruct. Eval. 2012, 31, 191–196. [Google Scholar] [CrossRef]

- Palanichamy, P.; Joseph, A.; Jayakumar, T.; Raj, B. Ultrasonic velocity measurements for estimation of grain size in austenitic stainless steel. NDT E Int. 1995, 28, 179–185. [Google Scholar] [CrossRef]

- Li, W.; Chen, B.; Qing, X.; Cho, Y. Characterization of microstructural evolution by ultrasonic nonlinear parameters adjusted by attenuation factor. Metals 2019, 9, 271. [Google Scholar] [CrossRef]

- Wan, T.; Naoe, T.; Wakui, T.; Futakawa, M.; Obayashi, H.; Sasa, T. Effects of grain size on ultrasonic attenuation in type 316L stainless steel. Materials 2017, 10, 753. [Google Scholar] [CrossRef]

- Jhang, K.Y. Nonlinear ultrasonic techniques for nondestructive assessment of micro damage in material: A review. Int. J. Precis. Eng. Manuf. 2009, 10, 123–135. [Google Scholar] [CrossRef]

- Khan, S.Z.; Khan, T.M.; Joya, Y.F.; Khan, M.A.; Ahmed, S.; Shah, A. Assessment of material properties of AISI 316L stainless steel using non-destructive testing. Nondestruct. Test. Eval. 2016, 31, 360–370. [Google Scholar] [CrossRef]

- ASTM E494-15, Standard Practice for Measuring Ultrasonic Velocity in Materials; ASTM International: West Conshohocken, PA, USA, 2015.

- Hirsekorn, S. The scattering of ultrasonic waves by polycrystals. J. Acoust. Soc. Am. 1982, 72, 1021–1031. [Google Scholar] [CrossRef]

- Bouda, A.B.; Lebaili, S.; Benchaala, A. Grain size influence on ultrasonic velocities and attenuation. NDT E Int. 2003, 36, 1–5. [Google Scholar] [CrossRef]

- Vijayalakshmi, K.; Muthupandi, V.; Jayachitra, R. Influence of heat treatment on the microstructure, ultrasonic attenuation and hardness of SAF 2205 duplex stainless steel. Mater. Sci. Eng. A 2011, 529, 447–451. [Google Scholar] [CrossRef]

- Kwun, S.I.; Hong, S.T.; Choo, W.Y. Ultrasonic nondestructive evaluation of microstructure and strength of carbon steels. J. Mater. Sci. Lett. 2000, 19, 1453–1456. [Google Scholar] [CrossRef]

- ASTM E664-93, Standard Practice for the Measurement of the Apparent Attenuation of Longitudinal Ultrasonic Waves by Immersion Method; ASTM International: West Conshohocken, PA, USA, 2000.

- Papadakis, E.P. Rayleigh and stochastic scattering of ultrasonic waves in steel. J. Appl. Phys. 1963, 34, 265–269. [Google Scholar] [CrossRef]

- Botvina, L.R.; Fradkin, L.J.; Bridge, B. A new method for assessing the mean grain size of polycrystalline materials using ultrasonic NDE. J. Mater. Sci. 2000, 35, 4673–4683. [Google Scholar] [CrossRef]

- Ahn, B.; Lee, S.S.; Hong, S.T.; Kim, H.C.; Kang, S.J.L. Application of the acoustic resonance method to evaluate the grain size of low carbon steels. NDT E Int. 1999, 32, 85–89. [Google Scholar] [CrossRef]

- Dubois, M.; Militzer, M.; Moreau, A.; Bussière, J.F. A new technique for the quantitative real-time monitoring of austenite grain growth in steel. Scr. Mater. 2000, 42, 867–874. [Google Scholar] [CrossRef]

- Moghanizadeh, A.; Farzi, A. Effect of heat treatment on an AISI 304 austenitic stainless steel evaluated by the ultrasonic attenuation coefficient. Mater. Test. 2016, 58, 448–452. [Google Scholar] [CrossRef]

- Mini, R.S.; Balasubramaniam, K.; Ravindran, P. An experimental investigation on the influence of annealed microstructure on wave propagation. Exp. Mech. 2015, 55, 1023–1030. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, F. Fatigue damage evaluation of austenitic stainless steel using nonlinear ultrasonic waves in low cycle regime. J. Appl. Phys. 2014, 115, 204906. [Google Scholar] [CrossRef]

- Nam, T.; Choi, S.; Lee, T.; Jhang, K.; Kim, C. Acoustic nonlinearity of narrowband laser-generated surface waves in the bending fatigue of Al6061 alloy. J. Korean Phys. Soc. 2010, 57, 1212–1217. [Google Scholar]

- Kim, J.; Jacobs, L.J.; Qu, J.; Littles, J.W. Experimental characterization of fatigue damage in a nickel-base superalloy using nonlinear ultrasonic waves. J. Acoust. Soc. Am. 2006, 120, 1266–1273. [Google Scholar] [CrossRef]

- Balasubramaniam, K.; Valluri, J.S.; Prakash, R.V. Creep damage characterization using a low amplitude nonlinear ultrasonic technique. Mater. Charact. 2011, 62, 275–286. [Google Scholar] [CrossRef]

- Valluri, J.S.; Balasubramaniam, K.; Prakash, R.V. Creep damage characterization using non-linear ultrasonic techniques. Acta Mater. 2010, 58, 2079–2090. [Google Scholar] [CrossRef]

- Xiang, Y.; Deng, M.; Xuan, F. Thermal degradation evaluation of HP40Nb alloy steel after long term service using a nonlinear ultrasonic technique. J. Nondestruct. Eval. 2014, 33, 279–287. [Google Scholar] [CrossRef]

- Xiang, Y.; Deng, M.; Xuan, F.; Liu, C. Experimental study of thermal degradation in ferritic Cr-Ni alloy steel plates using nonlinear Lamb waves. NDT E Int. 2011, 44, 768–774. [Google Scholar] [CrossRef]

- Kim, C.; Park, I.; Jhang, K. Nonlinear ultrasonic characterization of thermal degradation in ferritic 2.25Cr-1Mo steel. NDT E Int. 2009, 42, 204–209. [Google Scholar] [CrossRef]

- Choi, S.; Seo, H.; Jhang, K. Noncontact evaluation of acoustic nonlinearity of a laser-generated surface wave in a plastically deformed aluminum alloy. Res. Nondestruct. Eval. 2015, 26, 13–22. [Google Scholar] [CrossRef]

- Punnose, S.; Mukhopadhyay, A.; Sarkar, R.; Kumar, V. Characterisation of microstructural damage evolution during tensile deformation of a near-α titanium alloy: Effects of microtexture. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2014, 607, 476–481. [Google Scholar] [CrossRef]

- Cantrell, J.H.; Yost, W.T. Nonlinear ultrasonic characterization of fatigue microstructures. Int. J. Fatigue 2001, 23, 487–490. [Google Scholar] [CrossRef]

- Hikata, A.; Chick, B.B.; Elbaum, C. Dislocation contribution to the second harmonic generation of ultrasonic waves. J. Appl. Phys. 1965, 36, 229–236. [Google Scholar] [CrossRef]

- Choi, S.; Lee, P.; Jhang, K.Y. A Pulse inversion-based nonlinear ultrasonic technique using a single-cycle longitudinal wave for evaluating localized material degradation in plates. Int. J. Precis. Eng. Manuf. 2019, 20, 549–558. [Google Scholar] [CrossRef]

- Matlack, K.H.; Bradley, H.A.; Thiele, S.; Kim, J.; Wall, J.J.; Jung, H.; Qu, J.; Jacobs, L.J. Nonlinear ultrasonic characterization of precipitation in 17-4PH stainless steel. NDT E Int. 2015, 71, 8–15. [Google Scholar] [CrossRef]

- Kim, C.; Lissenden, C.J. Precipitate contribution to the acoustic nonlinearity in nickel-based superalloy. Chin. Phys. Lett. 2009, 26, 086107. [Google Scholar] [CrossRef]

- Hurley, D.C.; Balzar, D.; Purtscher, P.T.; Hollman, K.W. Nonlinear ultrasonic parameter in quenched martensitic steels. J. Appl. Phys. 1998, 83, 4584–4588. [Google Scholar] [CrossRef]

- ASTM E112-13, Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM E8/E8M-16a, Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E384-17, Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 2017.

| Holding Time (h) | ASTM Grain Size No. G | Average Grain Size (μm) |

|---|---|---|

| 0 | 6.3 | 41 |

| 1 | 1.8 | 192 |

| 5 | 1.7 | 202 |

| 10 | 1.3 | 232 |

| 25 | 0.7 | 286 |

| 34 | 0.6 | 294 |

| Item | v (m/s) | α (dB/mm) | β′ |

|---|---|---|---|

| Sensitivity to grain size (1/um) | −0.00001 | 0.0018 | −0.0023 |

| Sensitivity to elastic modulus (1/GPa) | 0.00008 | −0.0135 | 0.0168 |

| Sensitivity to yield strength (1/MPa) | 0.00005 | −0.0093 | 0.0116 |

| Sensitivity to hardness (1/HV) | 0.0001 | −0.02 | 0.0252 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.; Ryu, J.; Kim, J.-S.; Jhang, K.-Y. Comparison of Linear and Nonlinear Ultrasonic Parameters in Characterizing Grain Size and Mechanical Properties of 304L Stainless Steel. Metals 2019, 9, 1279. https://doi.org/10.3390/met9121279

Choi S, Ryu J, Kim J-S, Jhang K-Y. Comparison of Linear and Nonlinear Ultrasonic Parameters in Characterizing Grain Size and Mechanical Properties of 304L Stainless Steel. Metals. 2019; 9(12):1279. https://doi.org/10.3390/met9121279

Chicago/Turabian StyleChoi, Sungho, Juyoung Ryu, Jae-Seung Kim, and Kyung-Young Jhang. 2019. "Comparison of Linear and Nonlinear Ultrasonic Parameters in Characterizing Grain Size and Mechanical Properties of 304L Stainless Steel" Metals 9, no. 12: 1279. https://doi.org/10.3390/met9121279

APA StyleChoi, S., Ryu, J., Kim, J.-S., & Jhang, K.-Y. (2019). Comparison of Linear and Nonlinear Ultrasonic Parameters in Characterizing Grain Size and Mechanical Properties of 304L Stainless Steel. Metals, 9(12), 1279. https://doi.org/10.3390/met9121279