A Study on the Influences of Welding Position on the Keyhole and Molten Pool Behavior in Laser Welding of a Titanium Alloy

Abstract

1. Introduction

2. Research Approaches

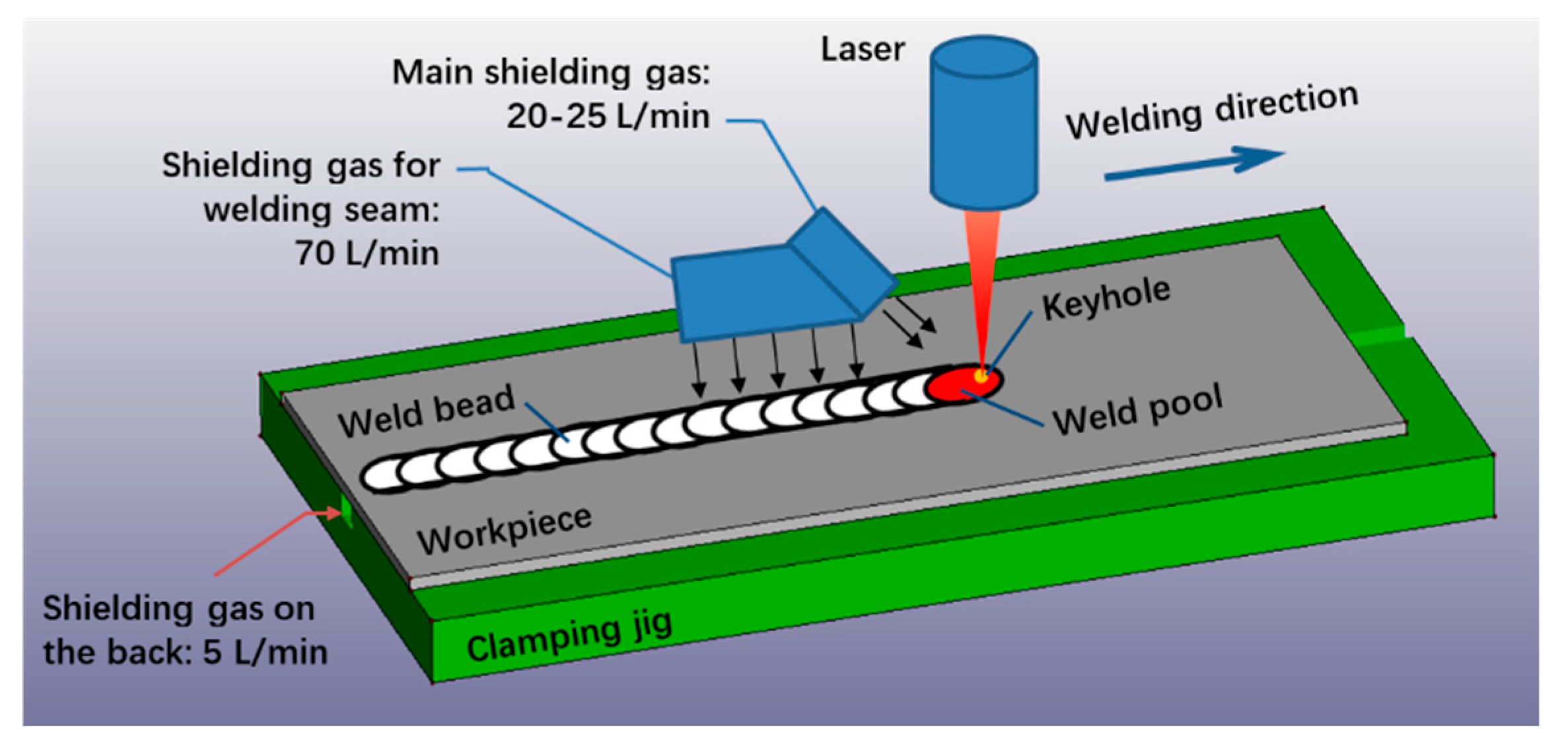

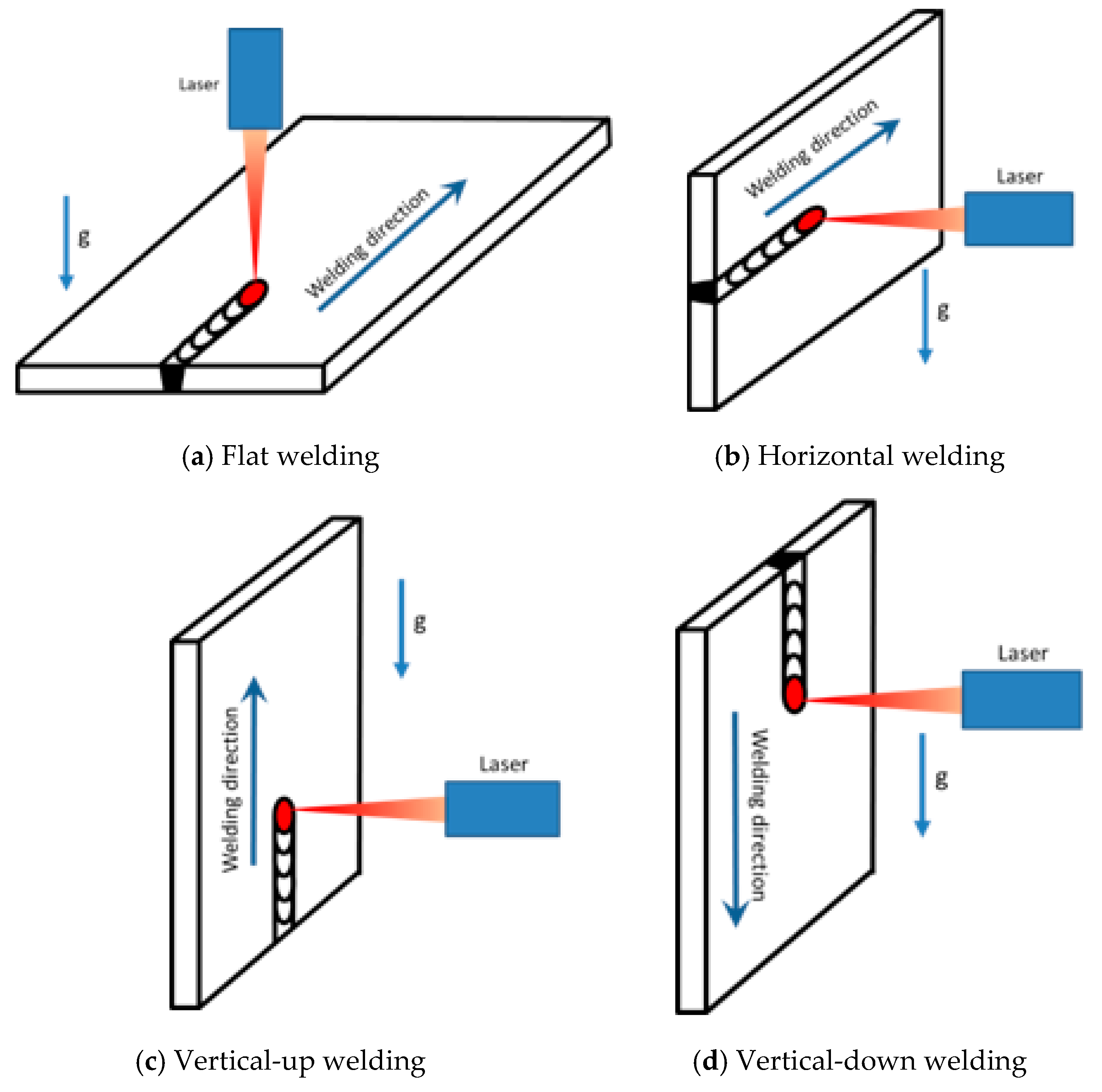

2.1. Experiments

2.2. Computational Fluid Dynamics (CFD) Numerical Modeling

2.2.1. Simplifications and Assumptions in Modeling

- (1)

- The fluid flow of the molten metal in weld pool was Newtonian, incompressible, and laminar.

- (2)

- The mass loss due to the metal vaporization was neglected.

- (3)

- Heat source and forces were applied directly on liquid and solid elements, but not on the vapor elements in the weld zone.

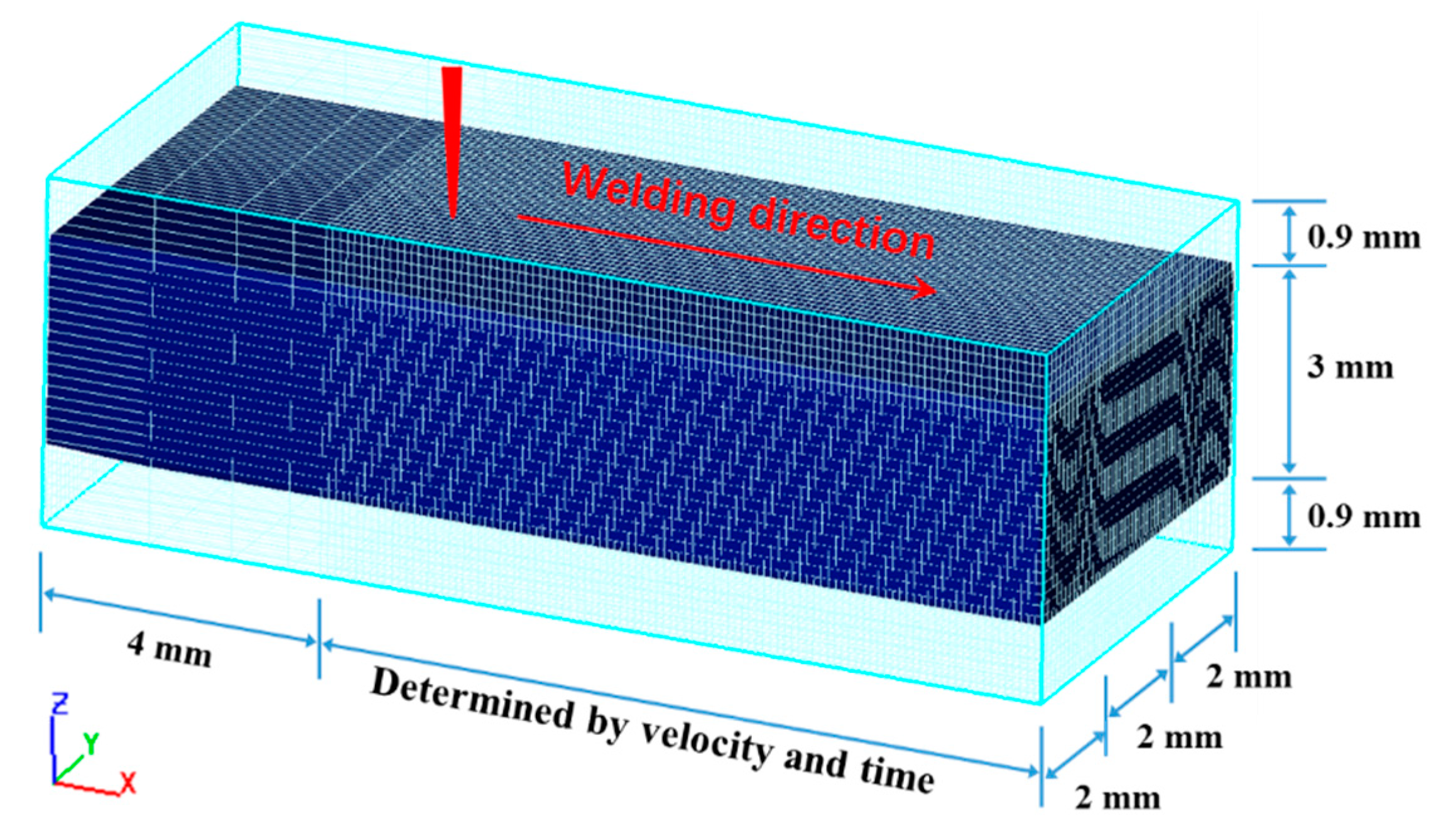

2.2.2. Computation Zone and Materials Property

2.2.3. Controlling Equations

Boundary Conditions

Heat Source Model

Force Models

Melting and Solidification Specification

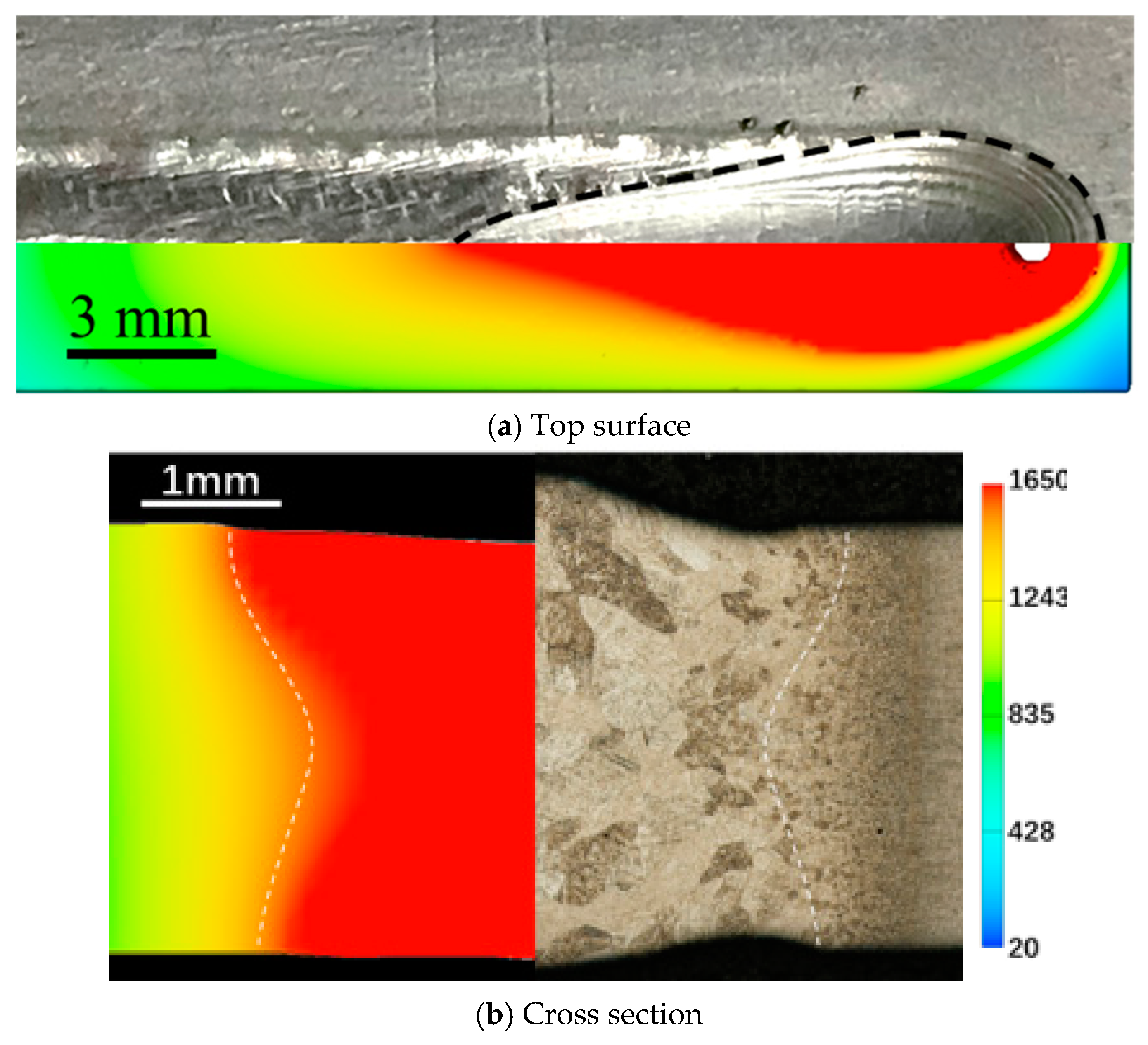

2.3. Validation of CFD Model

3. Results and Discussion

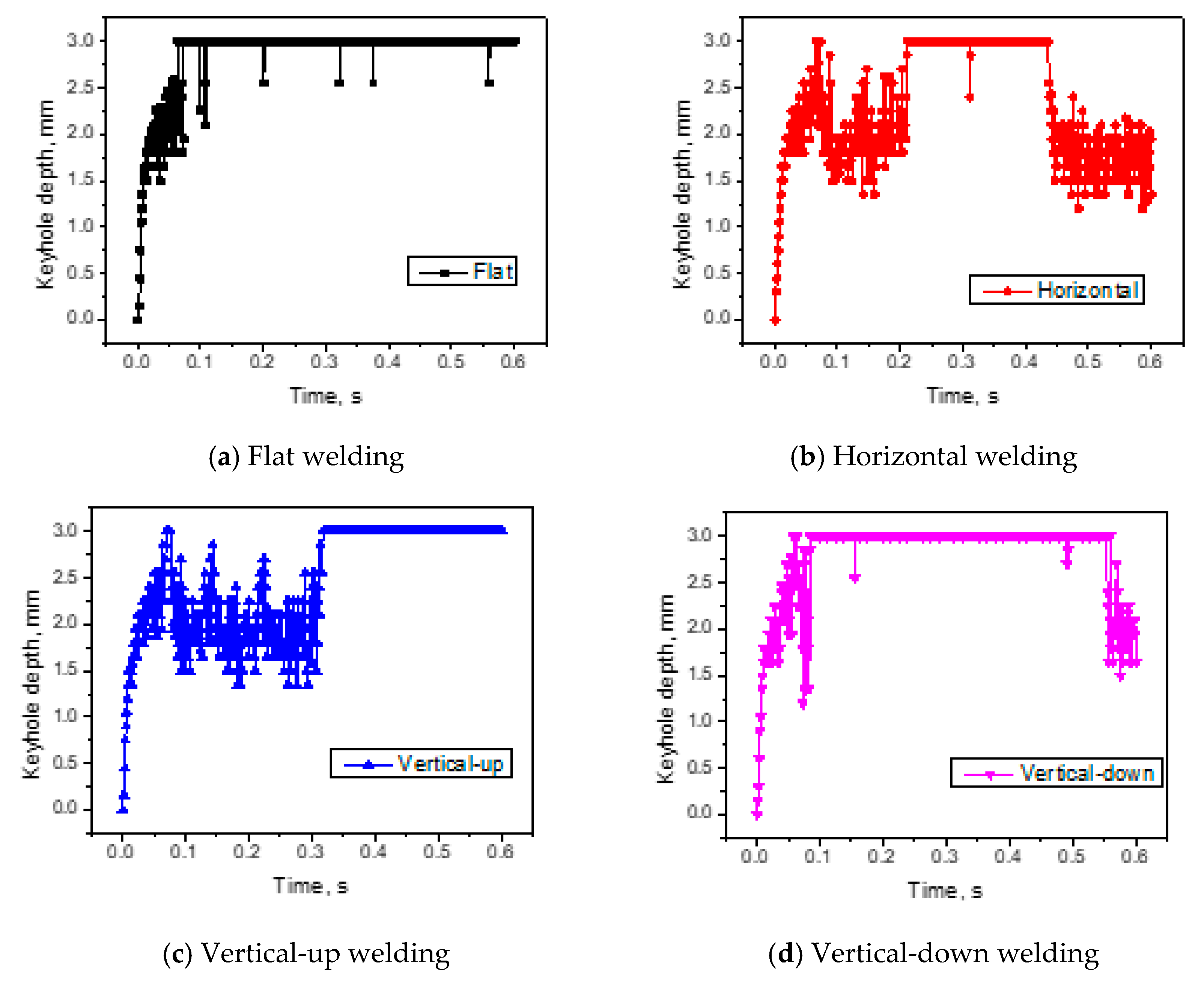

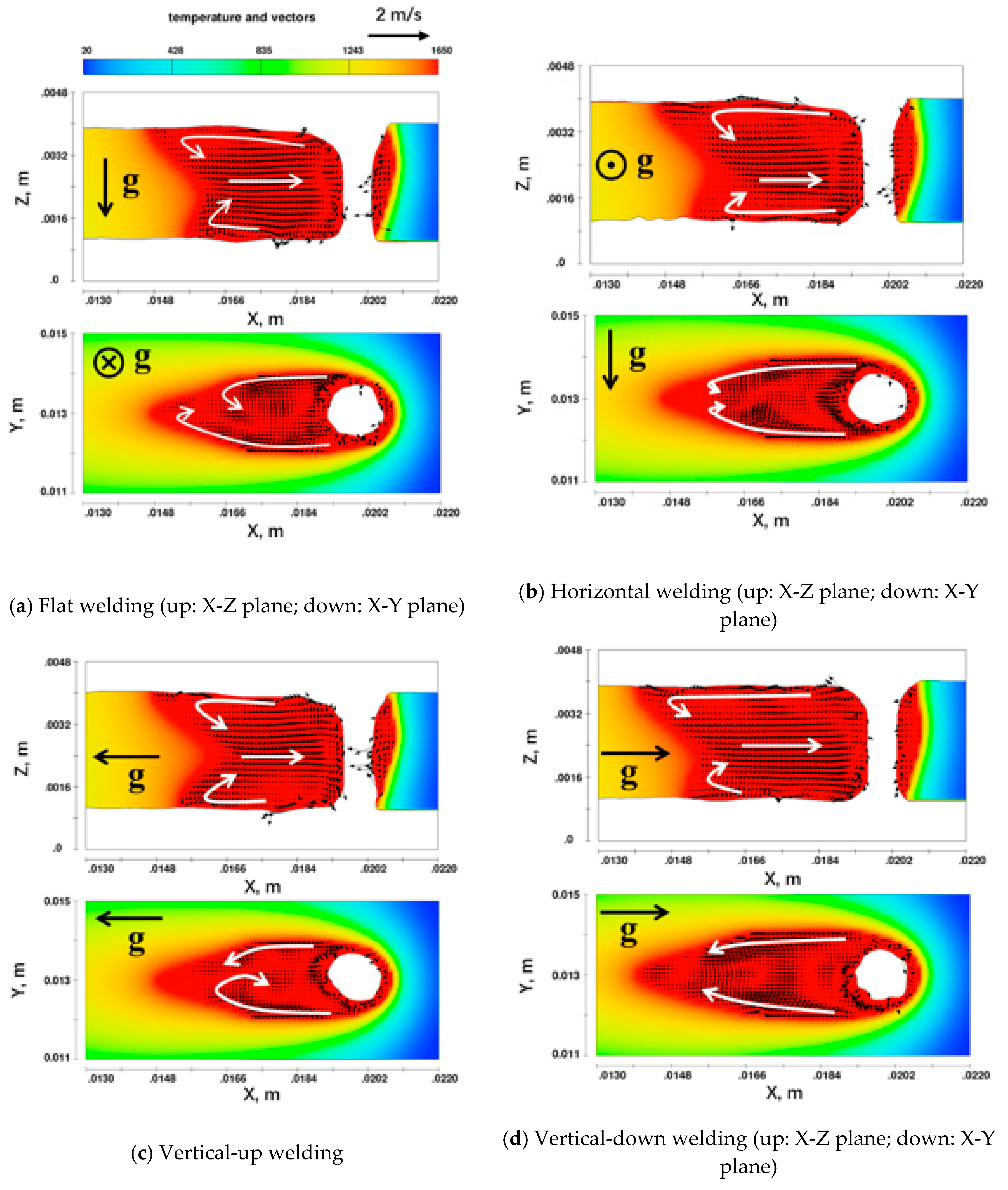

3.1. Keyholes and Weld Pool Behavior for Various Welding Positions with Small Heat Input

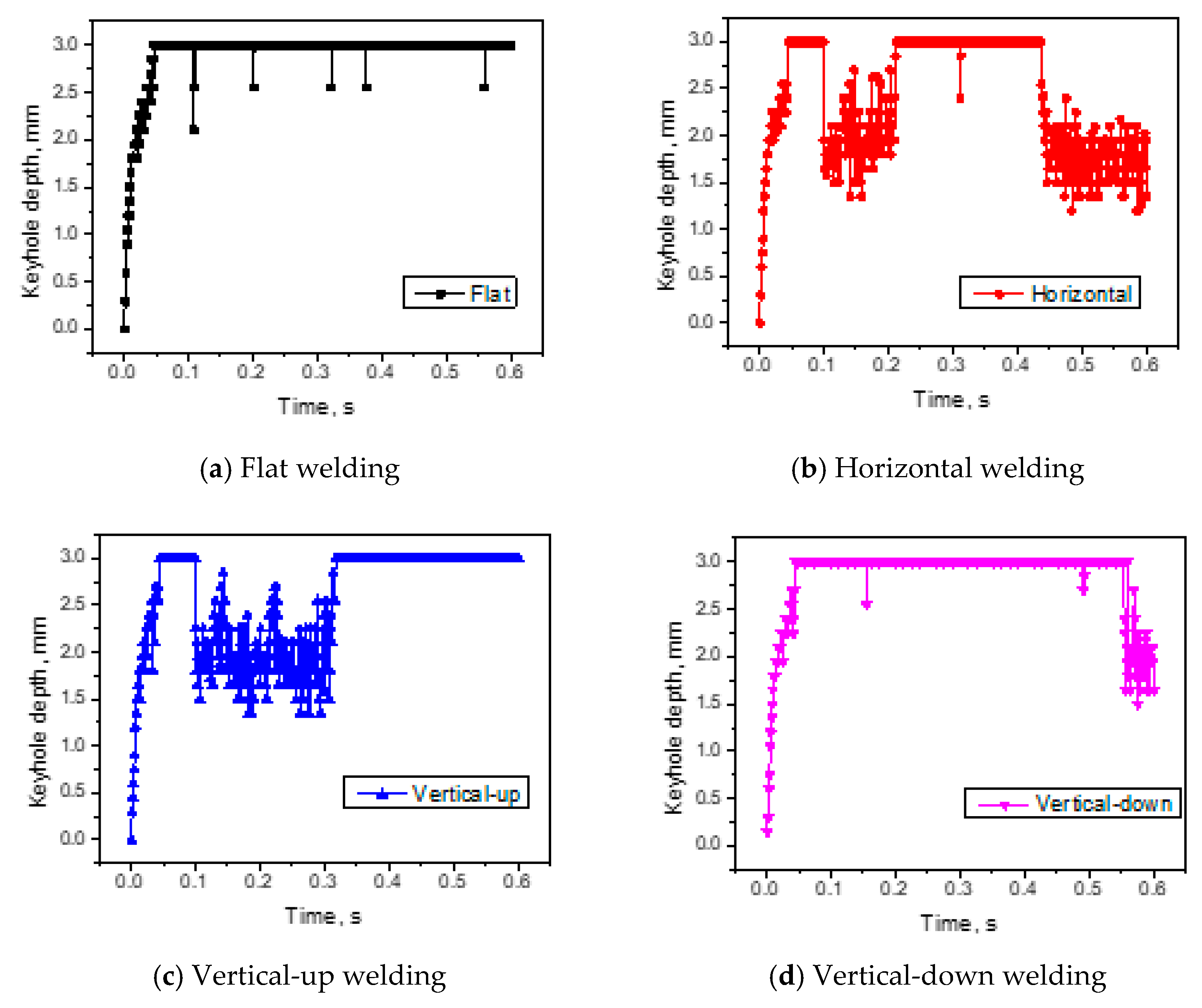

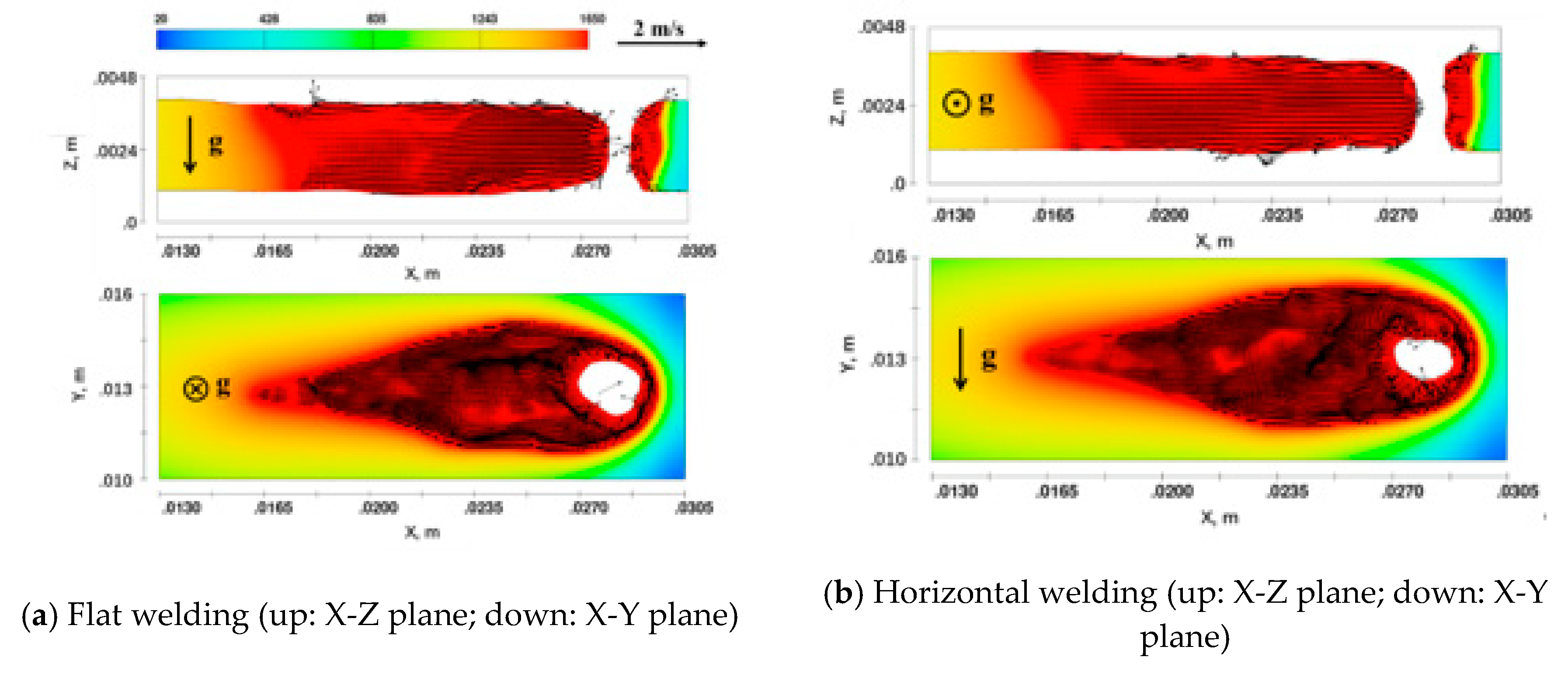

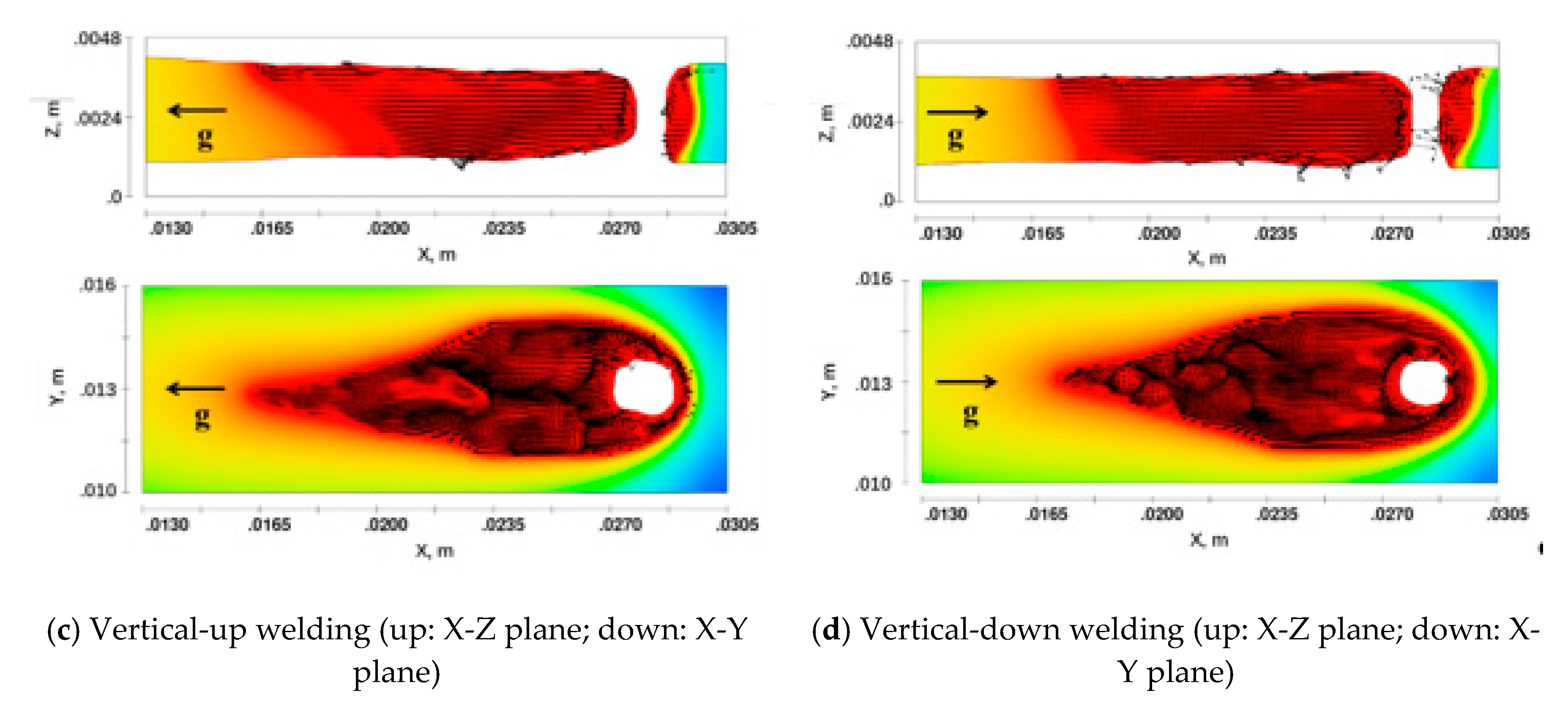

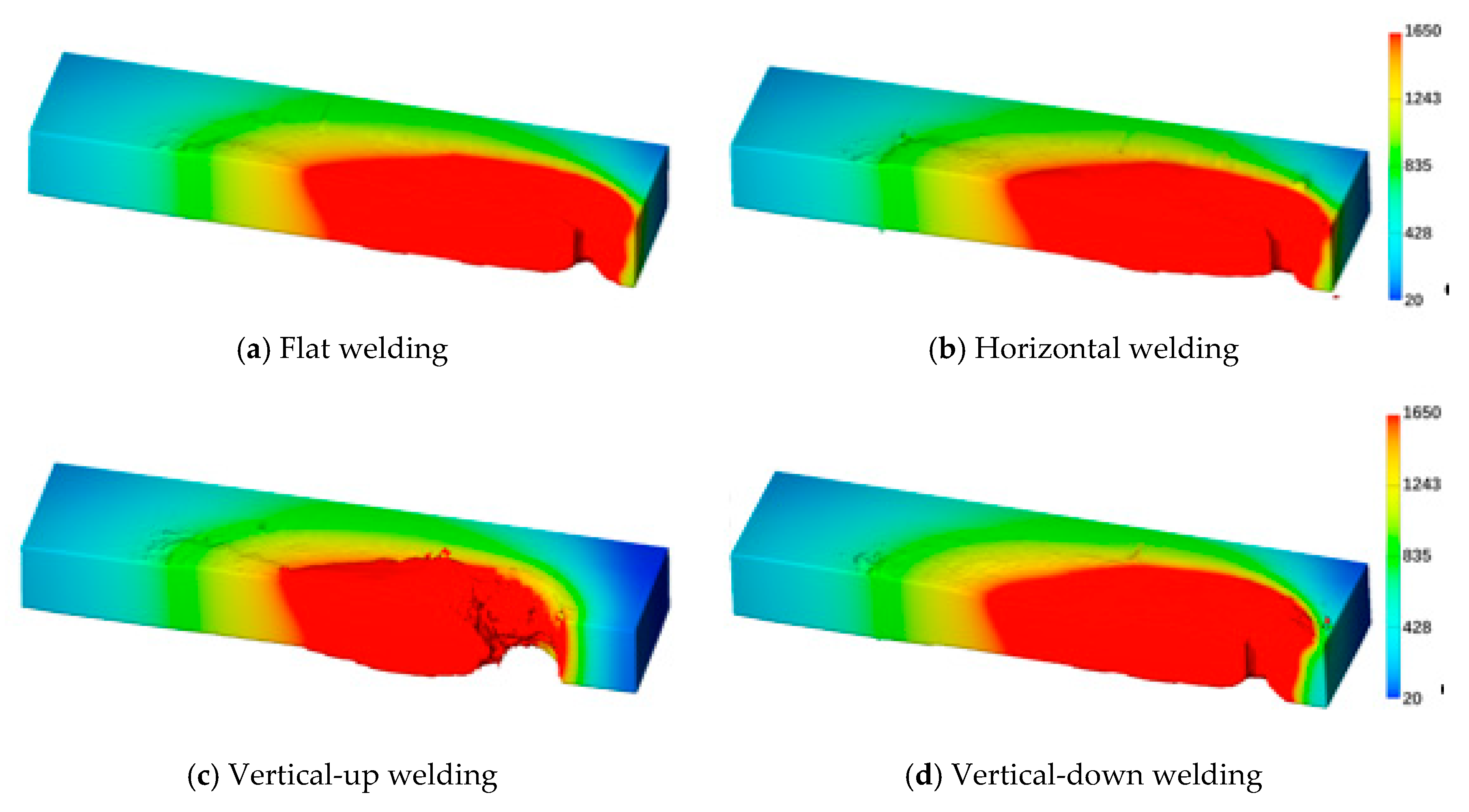

3.2. Keyholes and Weld Pool Behavior for Various Welding Positions with Large Heat Input

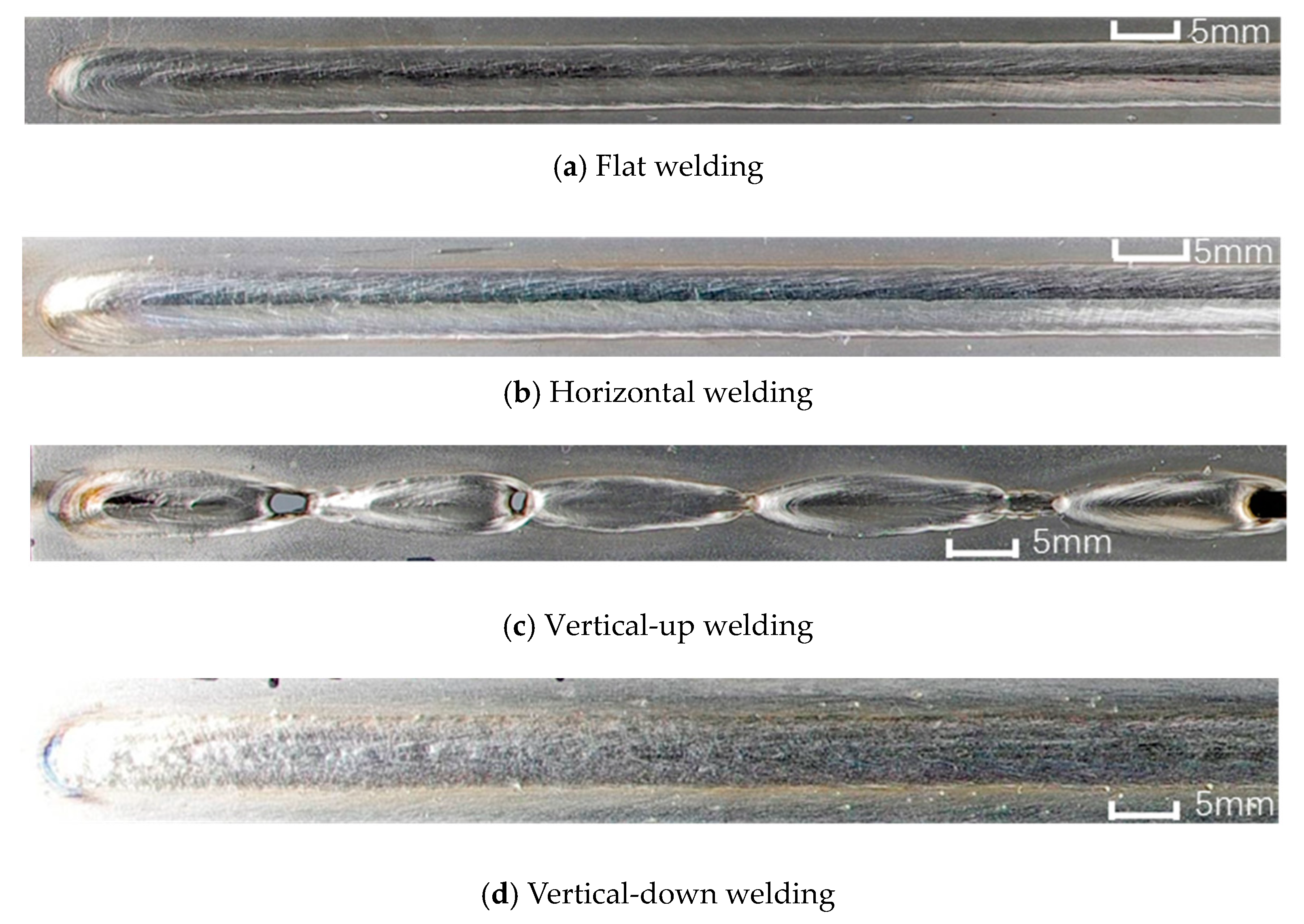

3.3. Laser Welding with too High a Heat Input

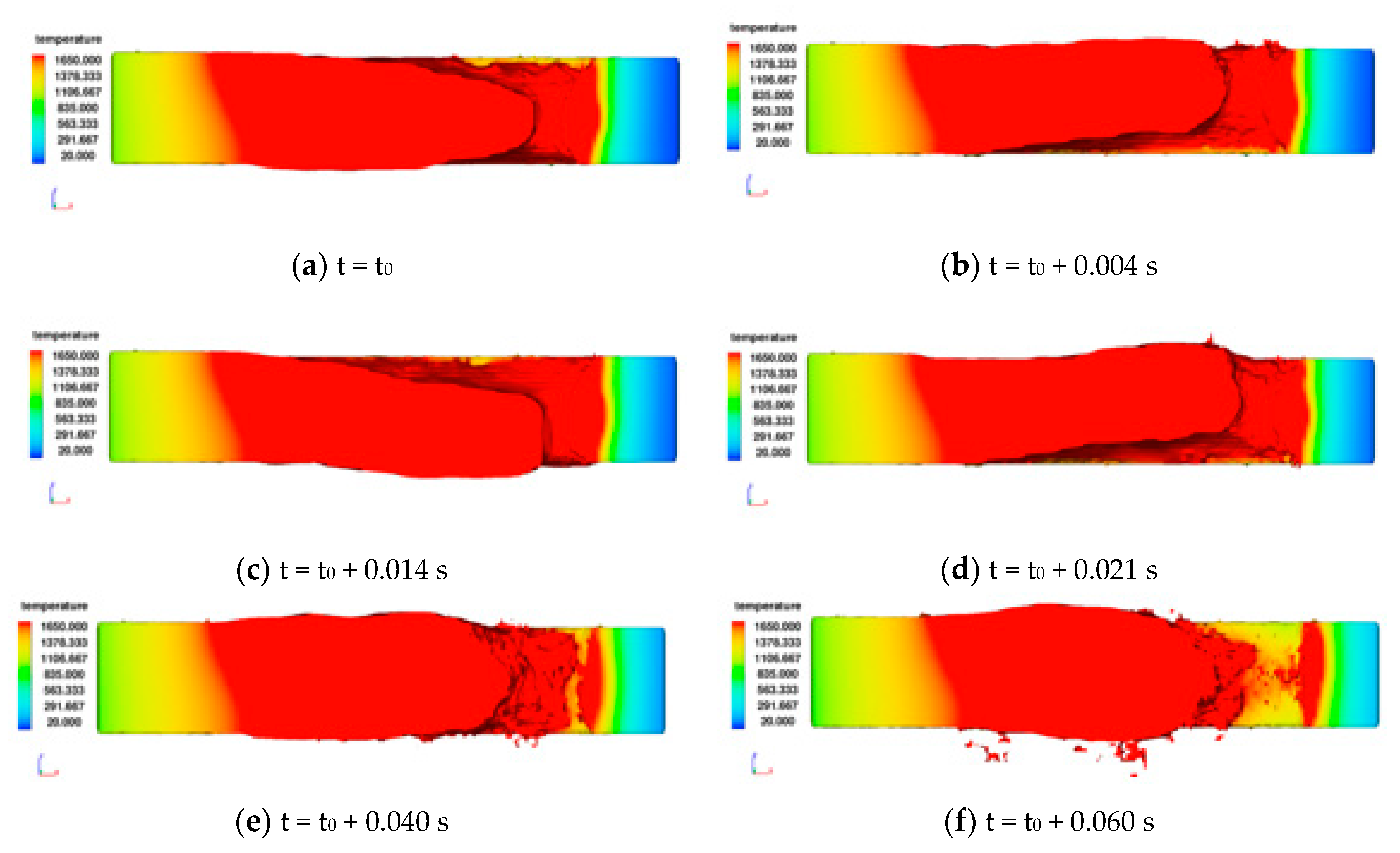

3.4. Formation Process of Burn-Through Holes in Vertical-Up Welding

4. Conclusions

- (1)

- As for the four welding positions studied in the study, the stability of keyhole is the best for flat welding, moderate for vertical-up and vertical-down welding, and the worst for horizontal welding. Increasing heat input may increase the keyhole stability by increasing laser power and decreasing welding speed.

- (2)

- When heat input is small, the influence of welding position is negligible on the keyhole and weld-pool behavior; when the heat input is large, the influences of gravity on the molten metal become significant, especially when the vertical welding positions are used.

- (3)

- When too high a heat input is used in vertical-up welding, the molten metal around the keyhole will oscillate and break away from the weld pool, which will lead to separation of molten metal near the keyhole and result in burn-through holes in welds.

- (4)

- A moderate heat input should be taken in positional laser welding of titanium alloys, which is high enough to generate a stable keyhole, but not too high in order to guarantee formation quality.

Author Contributions

Funding

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium Alloys for Aerospace Applications. In Titanium and Titanium Alloys: Fundamentals and Applications; Christoph, L., Manfred, P., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Goussain, J.C.; Becker, A.; Chehaibou, A.; Leca, P. Heavy-section welding with very high power laser beams: The challenge. In Proceedings of the SPIE–The International Society for Optical Engineering, Munich, Germany, 16–20 June 1997. [Google Scholar]

- Shen, X.F.; Li, L.; Guo, W.; Teng, W.H.; He, W.P. Comparison of processing window and porosity distribution in laser welding of 10 mm thick 30CrMnSiA ultrahigh strength between flat (1G) and horizontal (2G) positions. J. Laser Appl. 2016, 28, 022418. [Google Scholar] [CrossRef]

- Guo, W.; Liu, Q.; Francis, J.A.; Crowther, D.; Thompson, A.; Liu, Z.; Li, L. Comparison of laser welds in thick section S700 high-strength steel manufactured in flat (1G) and horizontal (2G) positions. CIRP Ann. Manuf. Technol. 2015, 64, 197–200. [Google Scholar] [CrossRef]

- Sohail, M.; Han, S.W.; Na, S.J.; Gumenyuk, A.; Rethmeier, M. Numerical investigation of energy input characteristics for high-power fiber laser welding at different positions. Int. J. Adv. Manuf. Technol. 2015, 80, 931–946. [Google Scholar] [CrossRef]

- Chang, B.H.; Yuan, Z.; Pu, H.T.; Li, H.G.; Cheng, H.; Du, D.; Shan, J.G. A comparative study on the laser welding of Ti6Al4V alloy sheets in flat and horizontal positions. Appl. Sci. 2017, 7, 376. [Google Scholar] [CrossRef]

- Chang, B.H.; Yuan, Z.; Pu, H.T.; Li, H.G.; Cheng, H.; Du, D.; Shan, J.G. Study of gravity effects on titanium laser welding in the vertical position. Materials 2017, 10, 1031. [Google Scholar] [CrossRef] [PubMed]

- Katayama, S.; Mizutani, M.; Matsunawa, A. Development of porosity prevention procedures during laser welding. In Proceedings of the lamp 2002 International Congress on Laser Advanced Materials Processing, Osaka, Japan, 27–31 May 2002. [Google Scholar]

- Wu, D.S.; Hua, X.M.; Huang, L.J.; Zhao, J. Numerical simulation of spatter formation during fiber laser welding of 5083 aluminum alloy at full penetration condition. Opt. Laser Technol. 2018, 100, 157–164. [Google Scholar] [CrossRef]

- Huang, L.J.; Hua, X.M.; Wu, D.S.; Li, F. Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel. J. Mater. Process. Technol. 2018, 252, 421–431. [Google Scholar] [CrossRef]

- Wu, D.S.; Hua, X.M.; Li, F.; Huang, L.J. Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int. J. Heat Mass Transf. 2017, 113, 730–740. [Google Scholar] [CrossRef]

- Pang, S.Y.; Chen, L.L.; Zhou, J.X.; Yin, Y.J.; Chen, T. A three-dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding. J. Phys. D Appl. Phys. 2011, 44, 025301. [Google Scholar] [CrossRef]

- Pang, S.Y.; Chen, W.D.; Wang, W. A quantitative model of keyhole instability induced porosity in laser welding of titanium alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 2808–2818. [Google Scholar] [CrossRef]

- Wen, P.; Yelkenci, D.; Chen, J.H.; Chang, B.H.; Du, D.; Shan, J.G. Numerical analysis of the effect of welding positions on formation quality during laser welding of TC4 titanium alloy parts in aerospace industry. J. Laser Appl. 2019, 31, 022401. [Google Scholar] [CrossRef]

- Chang, B.H.; Allen, C.; Blackburn, J.; Hilton, P.; Du, D. Fluid flow characteristics and porosity behavior in full penetration laser welding of a titanium alloy. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2015, 46, 906–918. [Google Scholar] [CrossRef]

- Jin, X.Z.; Li, L.J.; Zhang, Y. A study on fresnel absorption and reflections in the keyhole in deep penetration laser welding. J. Phys. D Appl. Phys. 2002, 35, 2304–2310. [Google Scholar] [CrossRef]

| Elements | C | H | O | N | Fe | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| Content, wt% | 0.05 | 0.011 | 0.19 | 0.03 | 0.20 | 5.8 | 4.0 | Bal. |

| Number | Laser Power, kW | Welding Speed, mm/s | Defocusing Distance, mm | Heat Input, J/mm |

|---|---|---|---|---|

| Set 1 | 3.0 | 35 | 0 | 85.7 (Small) |

| Set 2 | 4.0 | 25 | 0 | 160 (Large) |

| Set 3 | 4.2 | 20 | 0 | 210 (Too high) |

| Material Property | Values |

|---|---|

| Density ρ, kg/m3 | 4420 |

| Viscosity μ, kg/(m⋅s) | 0.00325 |

| Specific Heat Cp, J/(kg⋅K) | 546 |

| Thermal Conductivity λ, W/(m⋅K) | 34.6 |

| Melting Temperature Tm, °C | 1650 |

| Melting enthalpy ΔHsl, J/kg | |

| Evaporation temperature Tv, °C | 3287 |

| Evaporation enthalpy ΔHv, J/kg | |

| Surface tension coefficient Pσ, N/m |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, B.; Yuan, Z.; Cheng, H.; Li, H.; Du, D.; Shan, J. A Study on the Influences of Welding Position on the Keyhole and Molten Pool Behavior in Laser Welding of a Titanium Alloy. Metals 2019, 9, 1082. https://doi.org/10.3390/met9101082

Chang B, Yuan Z, Cheng H, Li H, Du D, Shan J. A Study on the Influences of Welding Position on the Keyhole and Molten Pool Behavior in Laser Welding of a Titanium Alloy. Metals. 2019; 9(10):1082. https://doi.org/10.3390/met9101082

Chicago/Turabian StyleChang, Baohua, Zhang Yuan, Hao Cheng, Haigang Li, Dong Du, and Jiguo Shan. 2019. "A Study on the Influences of Welding Position on the Keyhole and Molten Pool Behavior in Laser Welding of a Titanium Alloy" Metals 9, no. 10: 1082. https://doi.org/10.3390/met9101082

APA StyleChang, B., Yuan, Z., Cheng, H., Li, H., Du, D., & Shan, J. (2019). A Study on the Influences of Welding Position on the Keyhole and Molten Pool Behavior in Laser Welding of a Titanium Alloy. Metals, 9(10), 1082. https://doi.org/10.3390/met9101082