An Introduction to Wear Degradation Mechanisms of Surface-Protected Metallic Components

Abstract

:1. Introduction

2. Synopsis of Experimental Techniques

- (1)

- Visual inspection and stereomicroscopic (Leica MS 5,Leica Microsystems GmbH, Wetzlar, Germany) and optical (Olympus BX60, Olympus Corporation, Tokyo, Japan) observations for determining the material’s failure areas that could provide information on the root cause, as well as areas that merit further laboratory examination.

- (2)

- Scanning electron microscopy (SEM, JEOL 840A, Jeol Ltd, Tokyo, Japan) coupled with elemental micro-analysis (EDS, OXFORD INCA 300, Oxford Instruments, Abingon, UK) and X-ray diffraction (XRD, Siemens D-800, Siemens AG, Munich, Germany) analysis of selected areas, for revealing the material’s flaws or transformations that accelerated failure.

- (3)

- Ball-on-disc tribological measurements (Centre Suiss d′ Electronique et de Microtechnique, CSEM SA, Neuchâtel, Switzerland), for evaluating the performance of wear-resistant protective coatings before service.

3. Case Study I: Failure of Lubricated Rolling Bearings

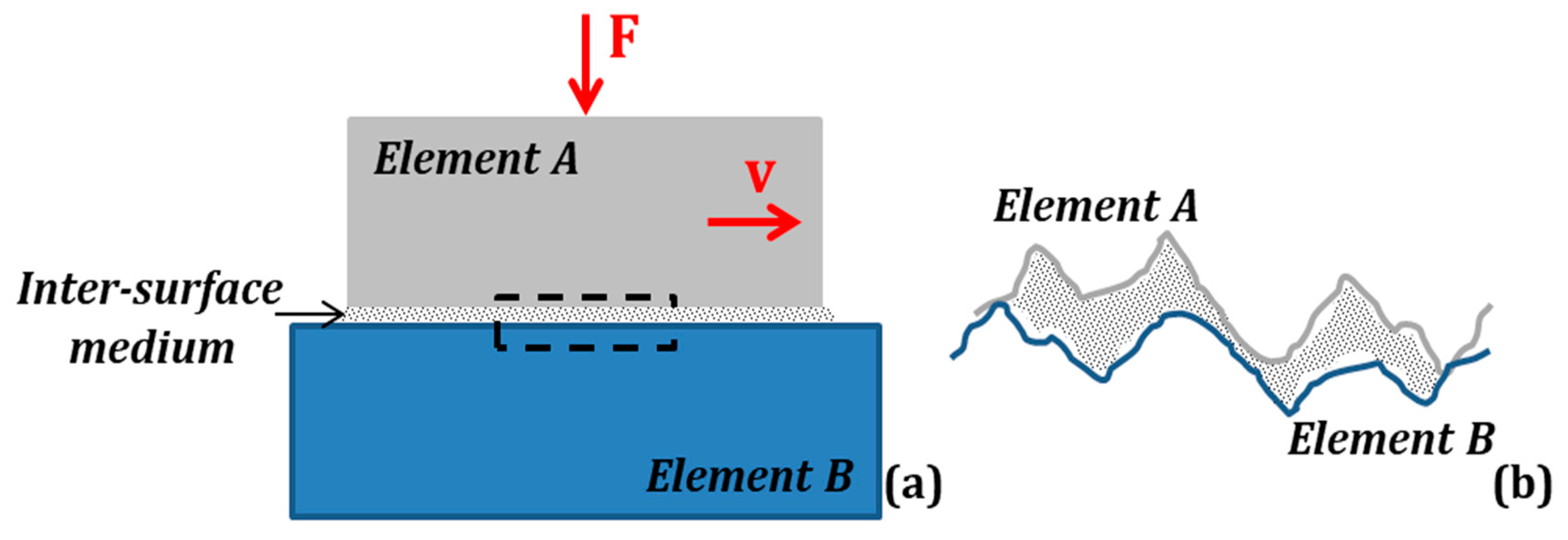

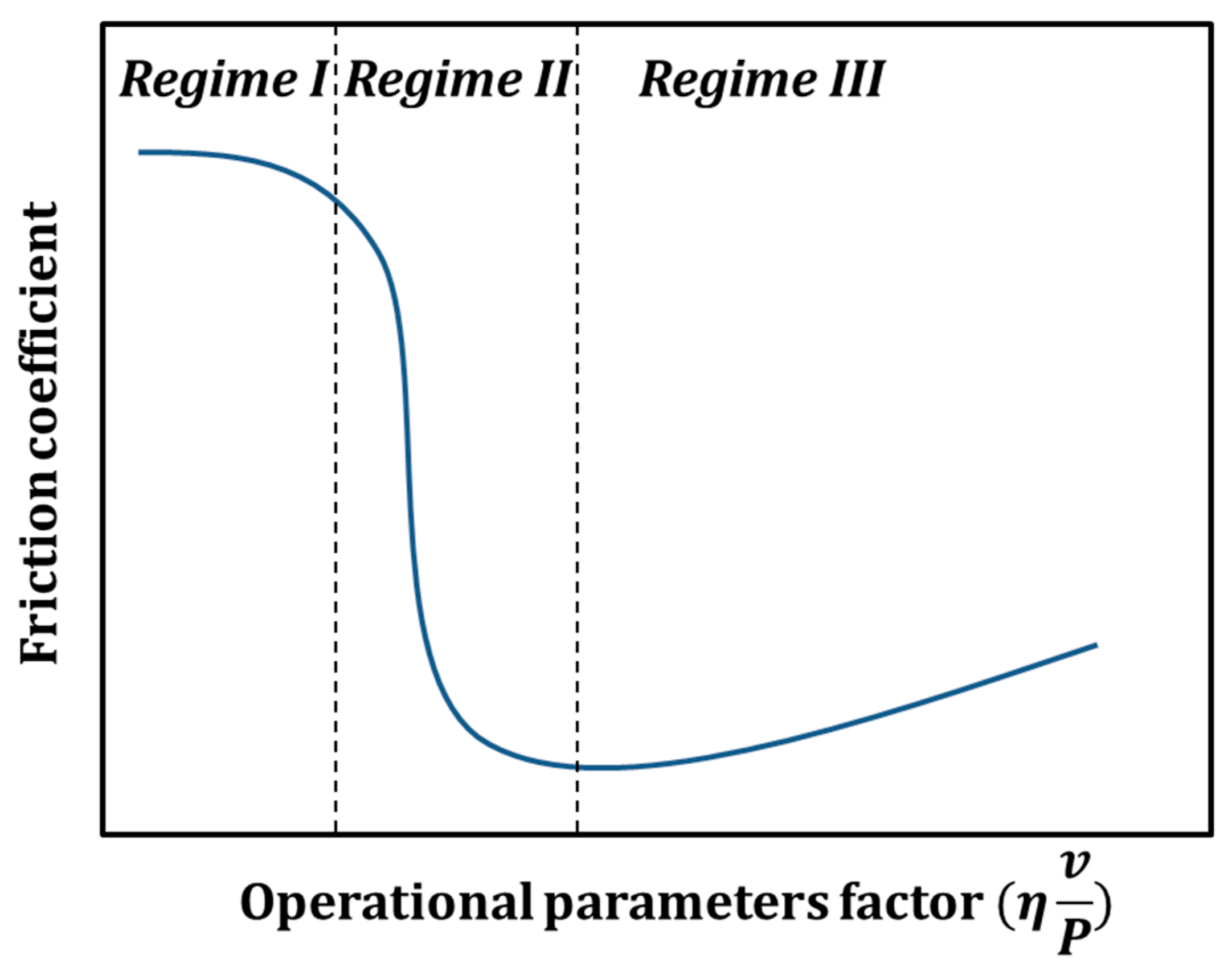

3.1. Fundamentals of Liquid Lubrication

- Within regime I, also known as boundary lubrication, the friction coefficient value tends to be similar to that under non-lubricating conditions. The thickness of the lubrication film is very thin, the load is taken on exclusively by the two solids and is transferred from the one to the other trough the contact between their surface asperities; thus, the rheological characteristics of the lubricant do not intervene and the lubrication efficacy depends only on the physicochemical characteristics of the liquid. These exactly “quasi-dry” lubrication conditions result in severe wear of the two solids.

- Within regime II, also known as mixed or partial elasto-hydrodynamic lubrication, the friction coefficient drops down to very low values. The thickness of the lubrication film is moderate, and the load is born by both the solid and the liquid film, depending on the thickness of the latter. The consecutive wear is moderate compared to that in regime I.

- Within regime III, also known as hydrodynamic lubrication, the friction coefficient values are slightly higher, the thickness of the lubrication film is significant enough to result in complete separation of the two solids and the load is transferred from the one to the other through the lubricant that should take on the entire load; thus, lubrication efficacy is depended only on the rheological characteristics of the liquid. In this case, the wear of the two non-in-contact solids is negligible.

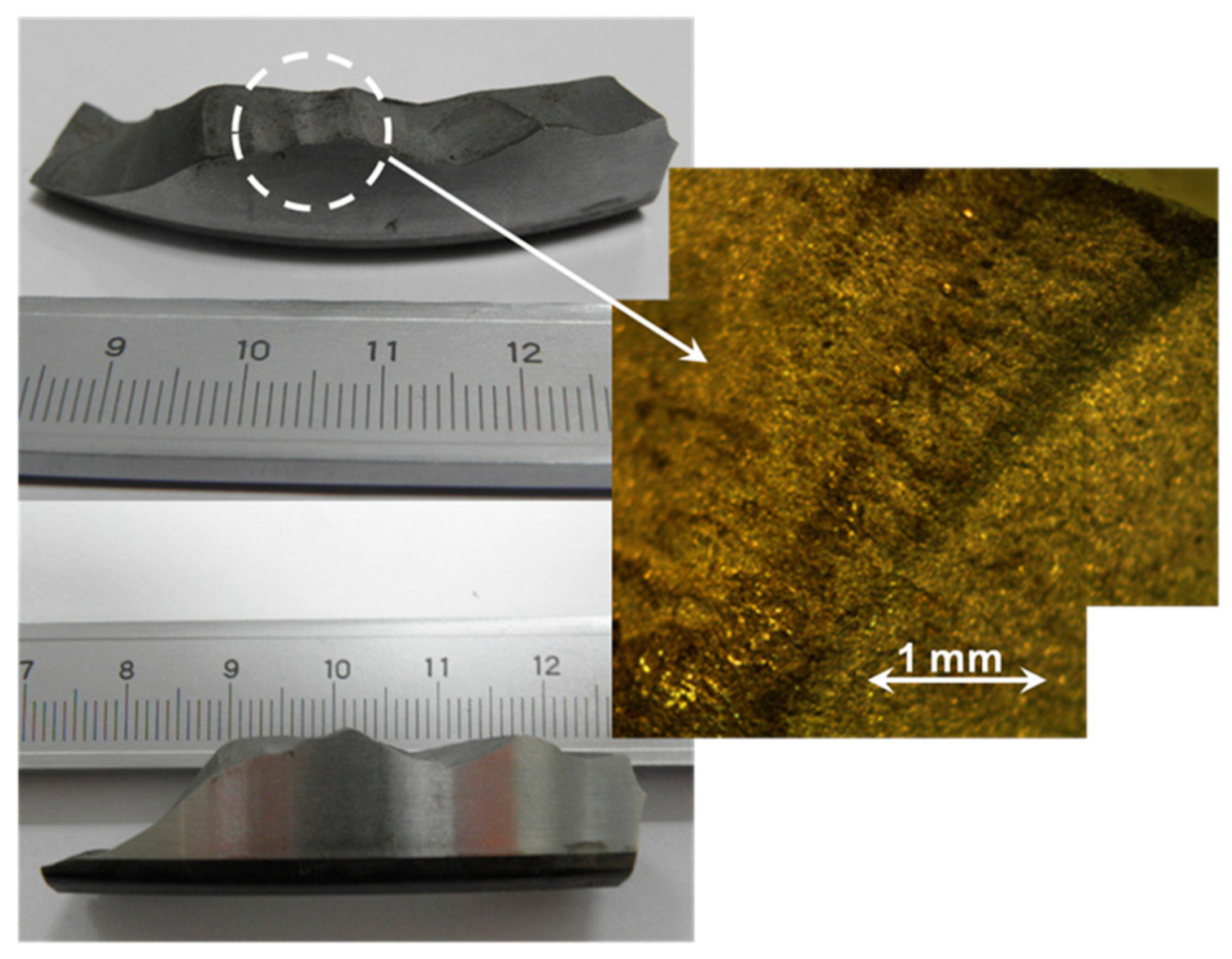

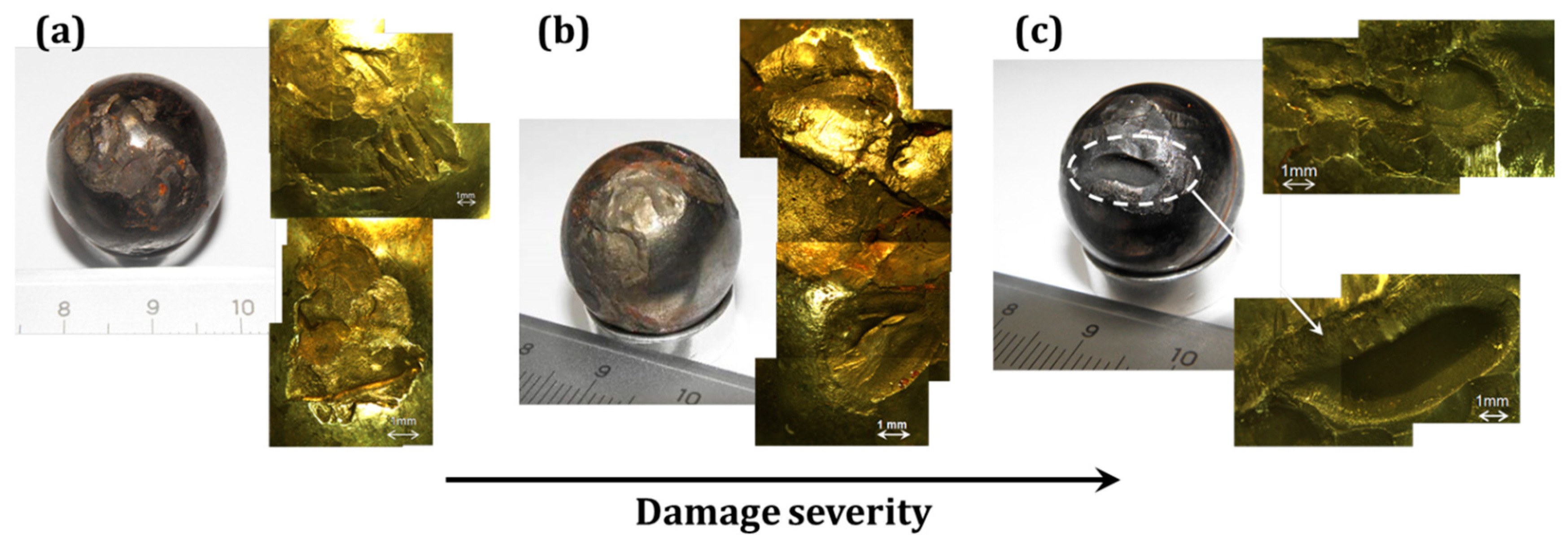

3.2. Catastrophic Failure of Rolling Bearings

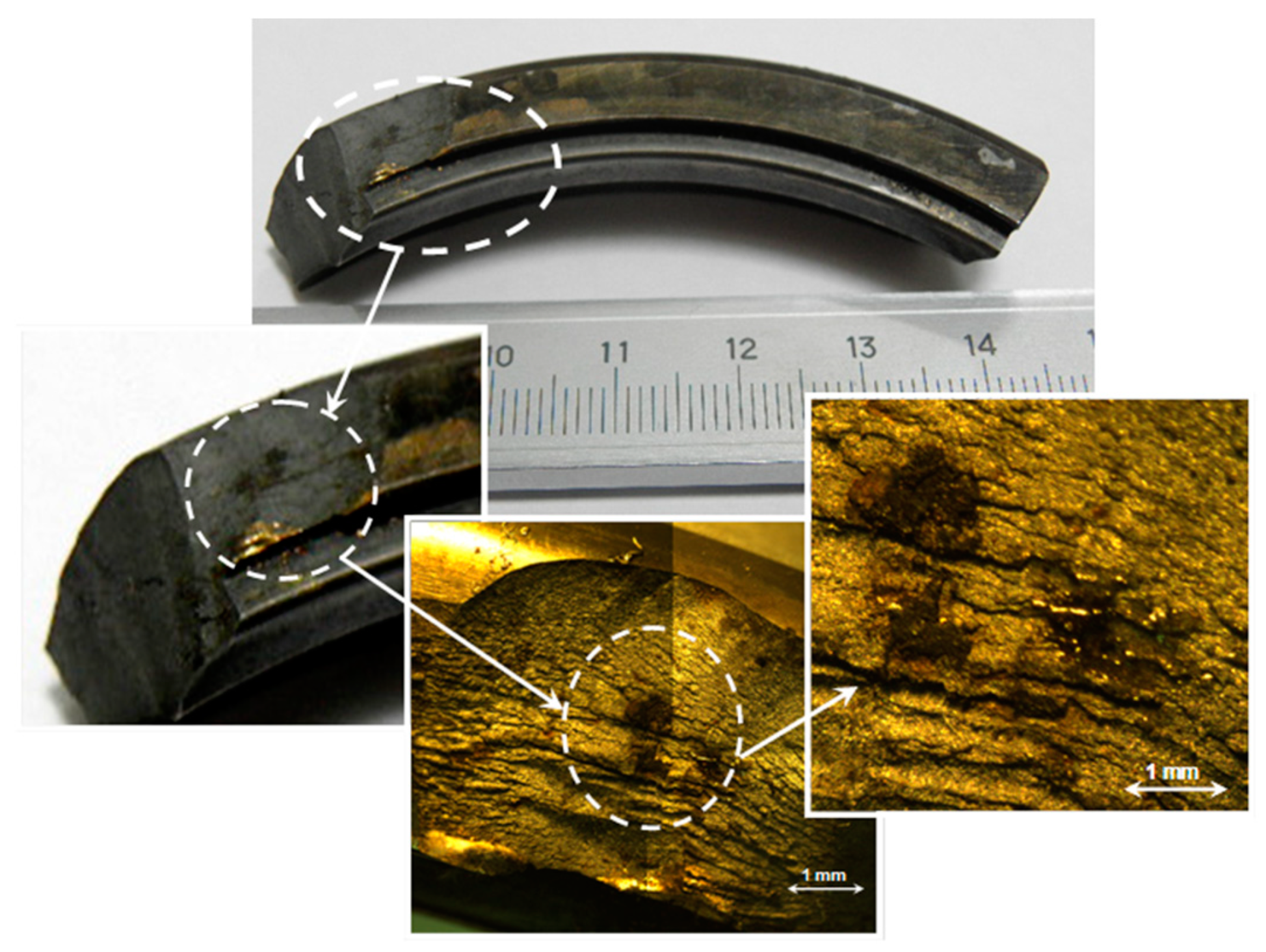

4. Case Study II: Failure of Nitrocarburized Sliding Bearings

4.1. Fundamentals of Nitrocarburizing

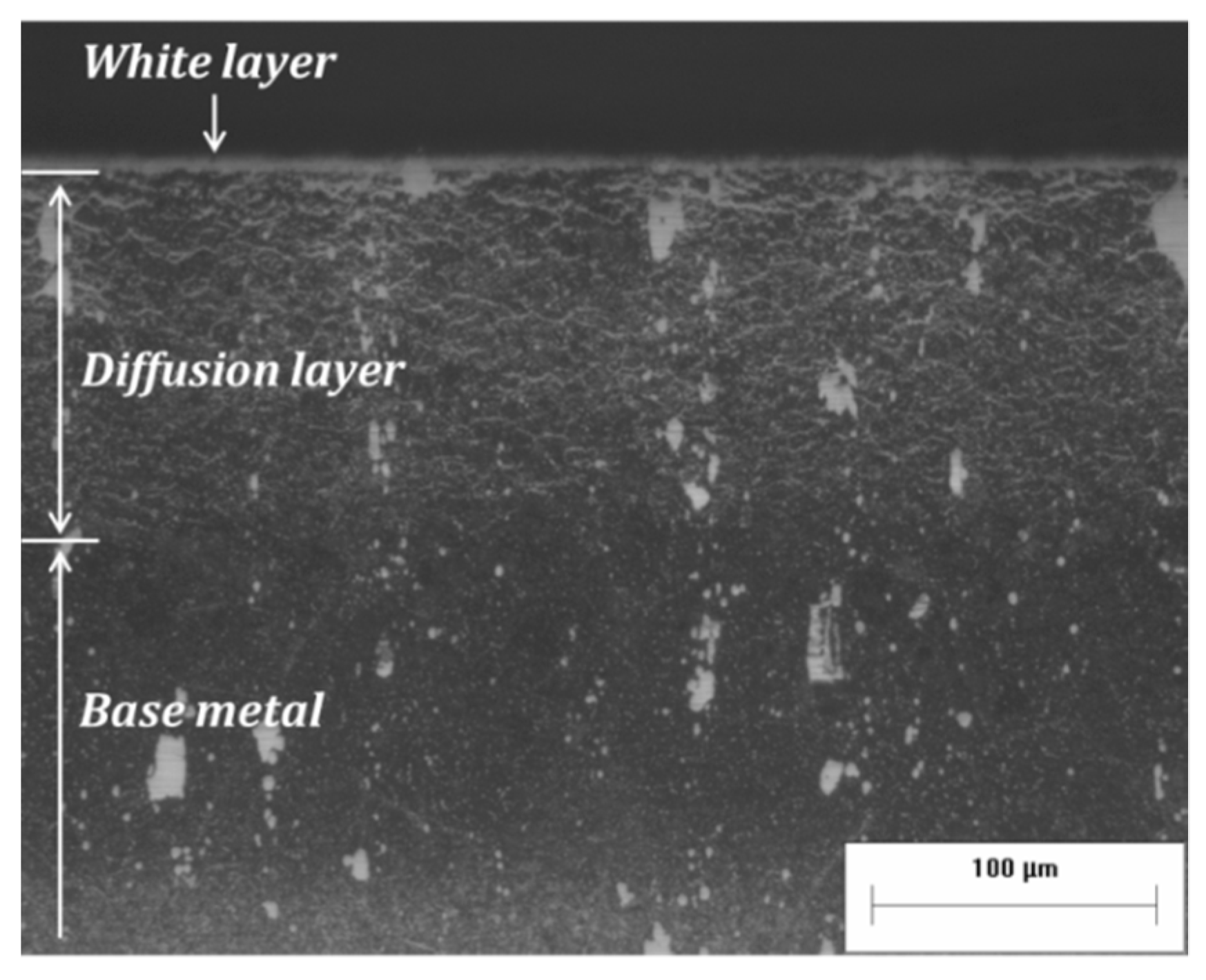

- (a)

- The outermost one is the product of the chemical reaction between the diffusing atoms and the iron of the base steel and consists mainly of ε-carbonitride Fe2-3 (C,N). This layer, known as white or compound layer, is the feature that provides high wear resistance to the underlying material. Although its thickness does not exceed 10 μm, the compound layer contributes to the decrease of specific wear even by an order of magnitude [17].

- (b)

- The layer underneath is formed via the in-depth nitrogen diffusion that leads, primarily, to α-(Fe,N) solid solution with a nitrogen content decreasing with increasing depth. In previous works [18], it was found that the thickness of this diffusion layer is strongly affected by the exact chemical composition of the steel grade, its level of prior thermal hardening, or cold working percentage. Although this layer does not affect the wear resistance, it results in a field of compressive stresses that have a positive effect on the fatigue performance of the treated components.

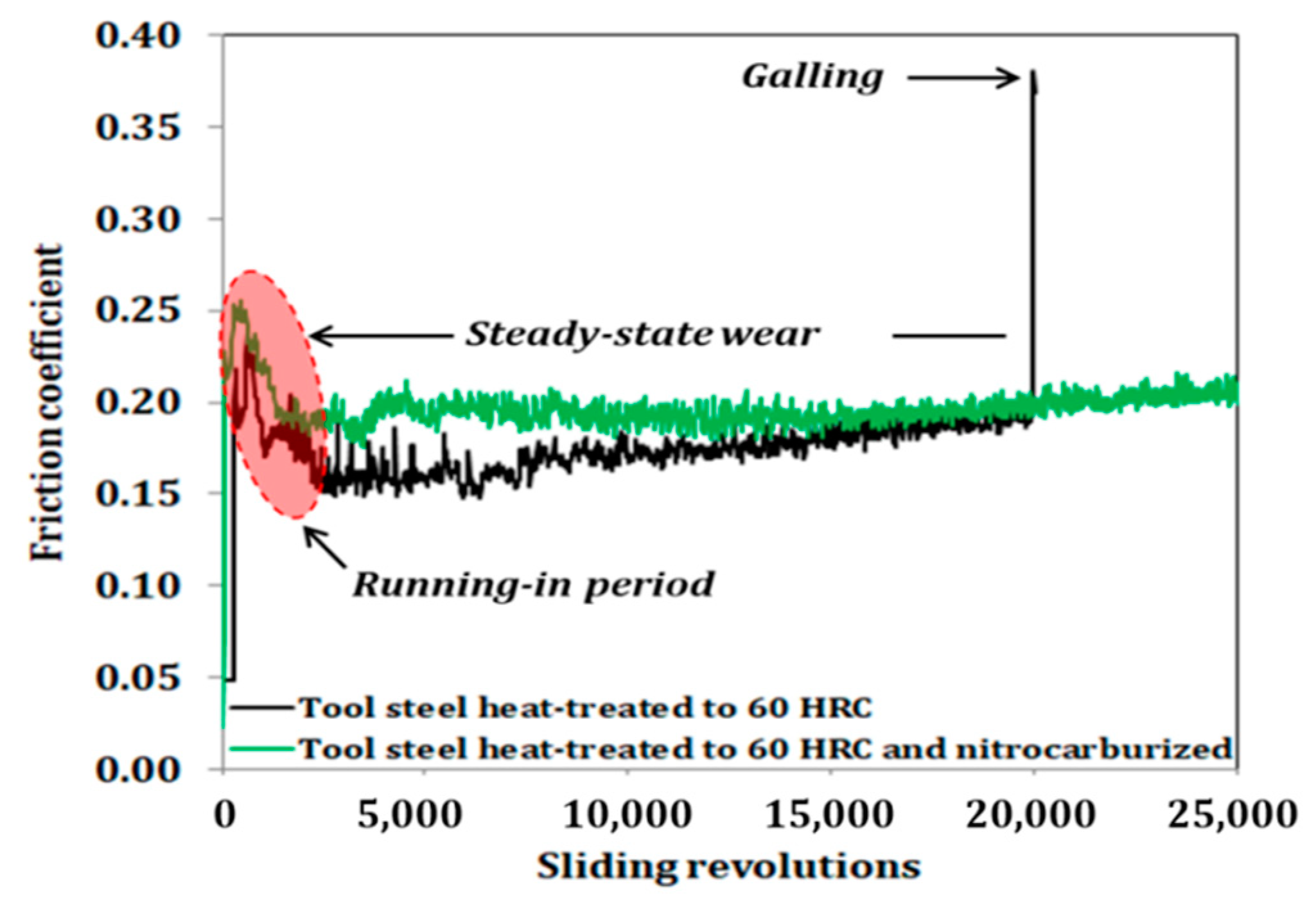

4.2. Degradation of Nitriding Layers and Acceleration of Base Metal Failure

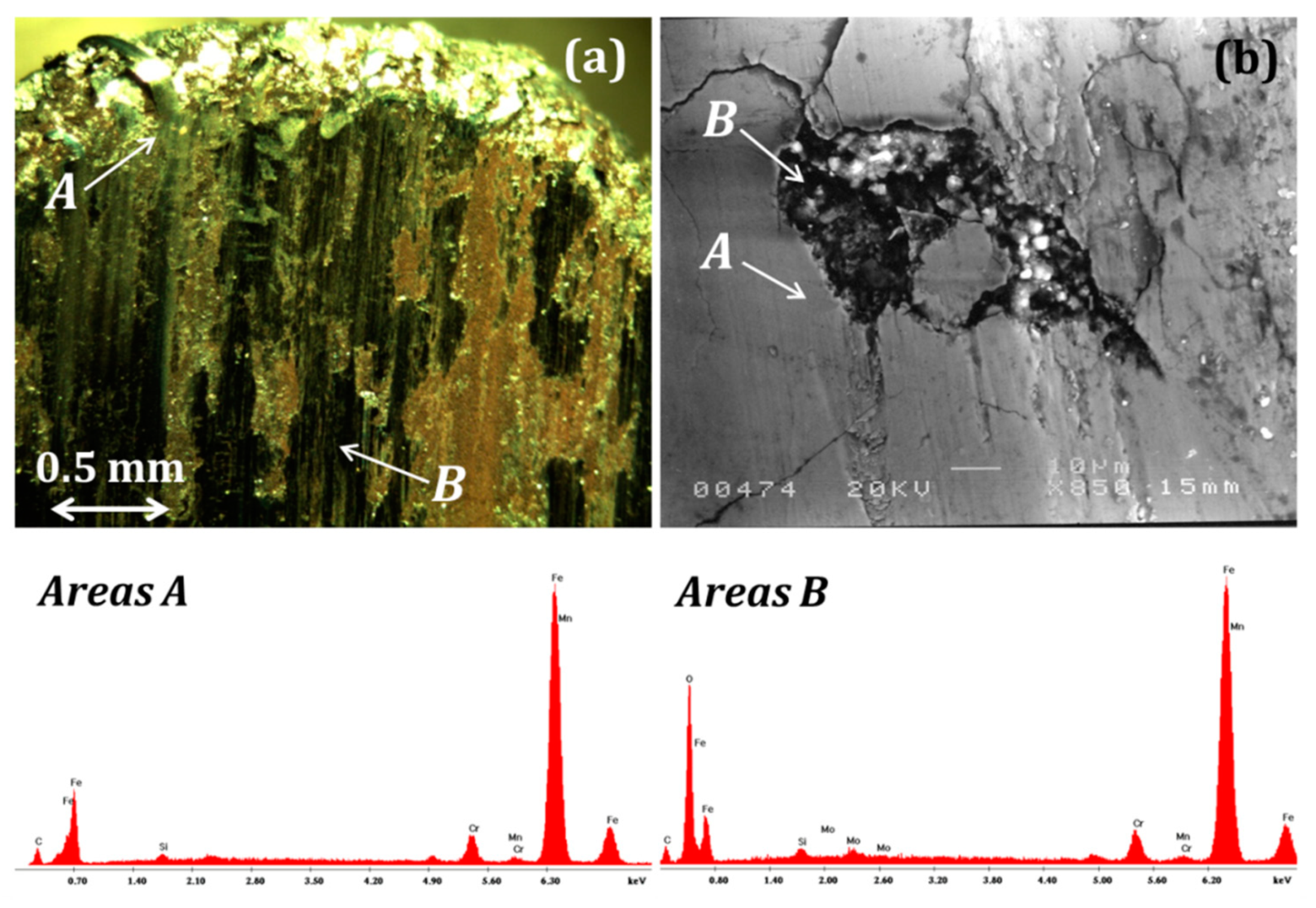

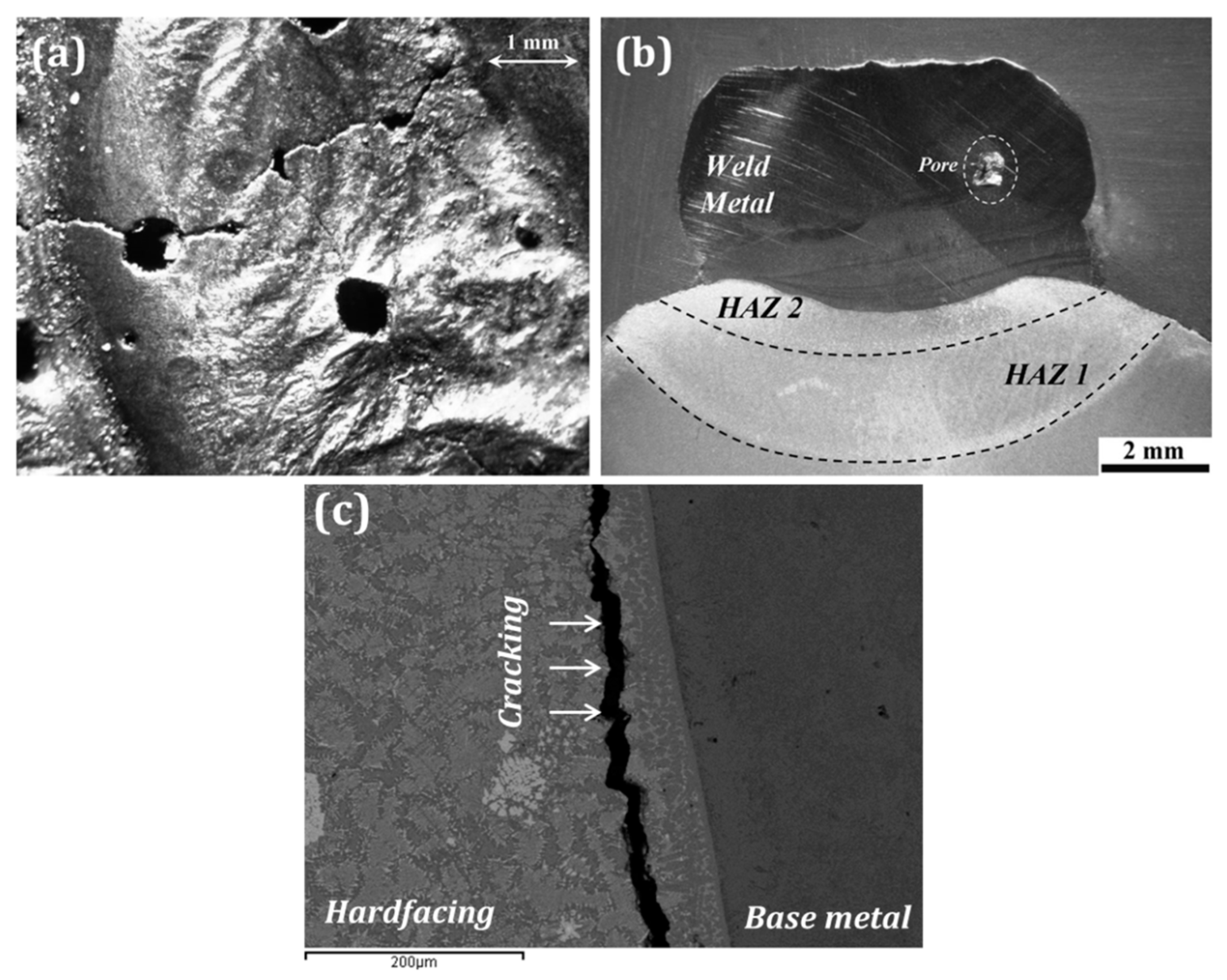

5. Case Study III: Failure of Wear-Resistant Hardfacing Overlayers

5.1. Hardfacing Overlayers Elaborated via Melting and Resolidification

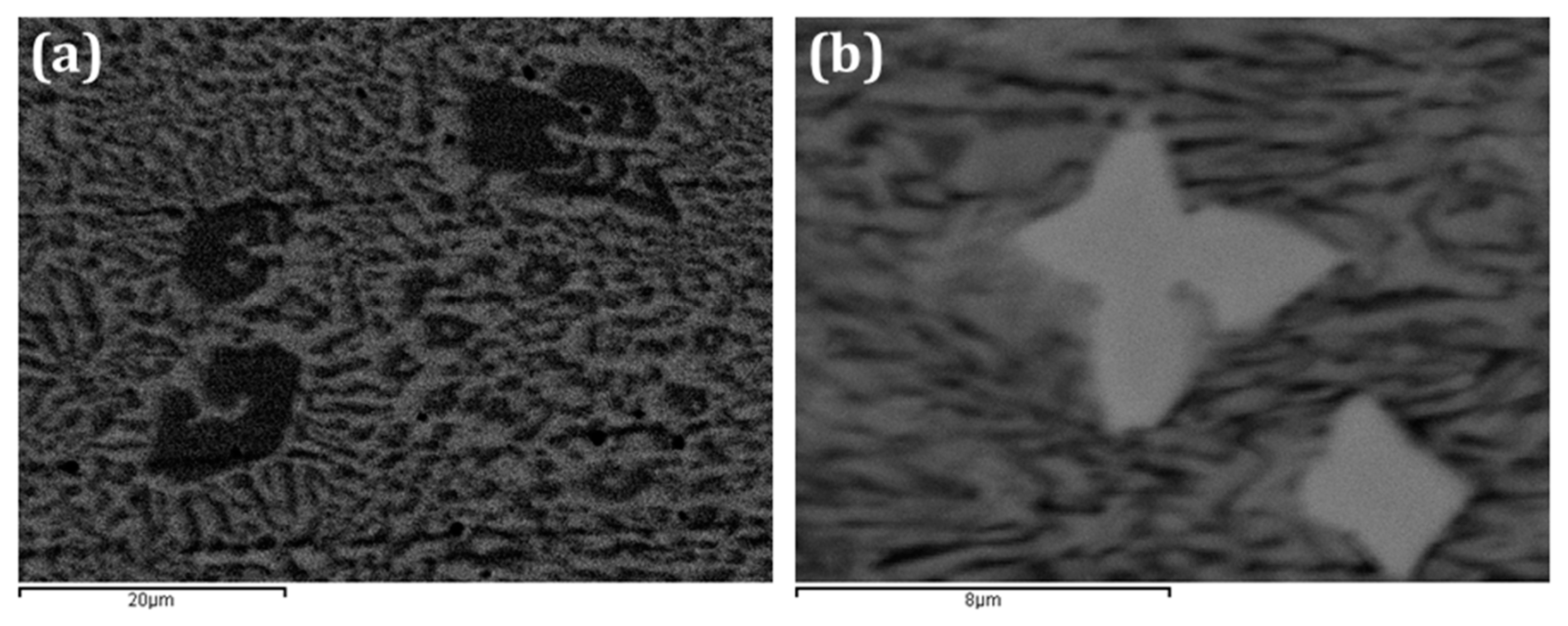

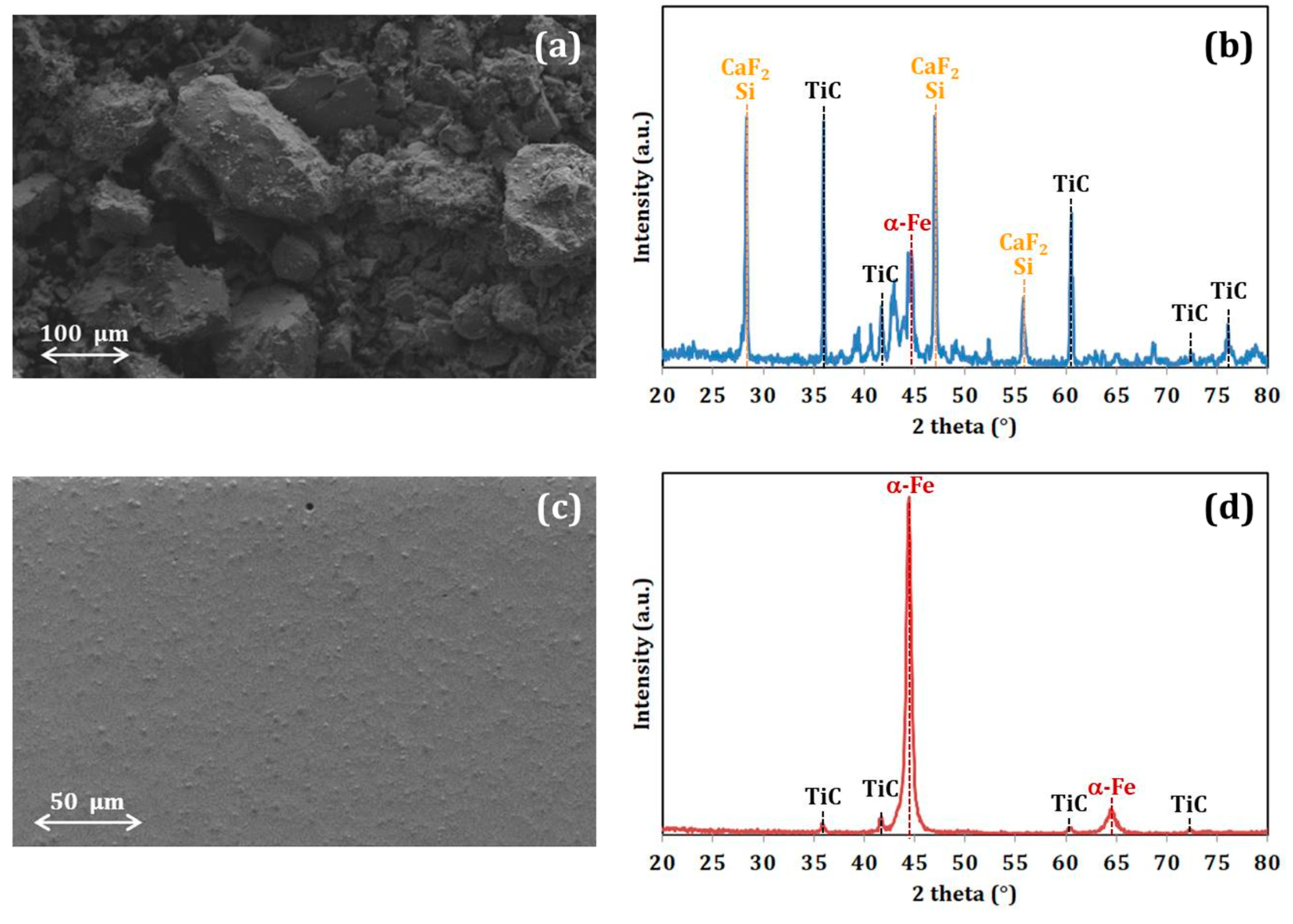

5.2. Performance of TiC-Based Composite Overlayers Produced via FCAW Technique

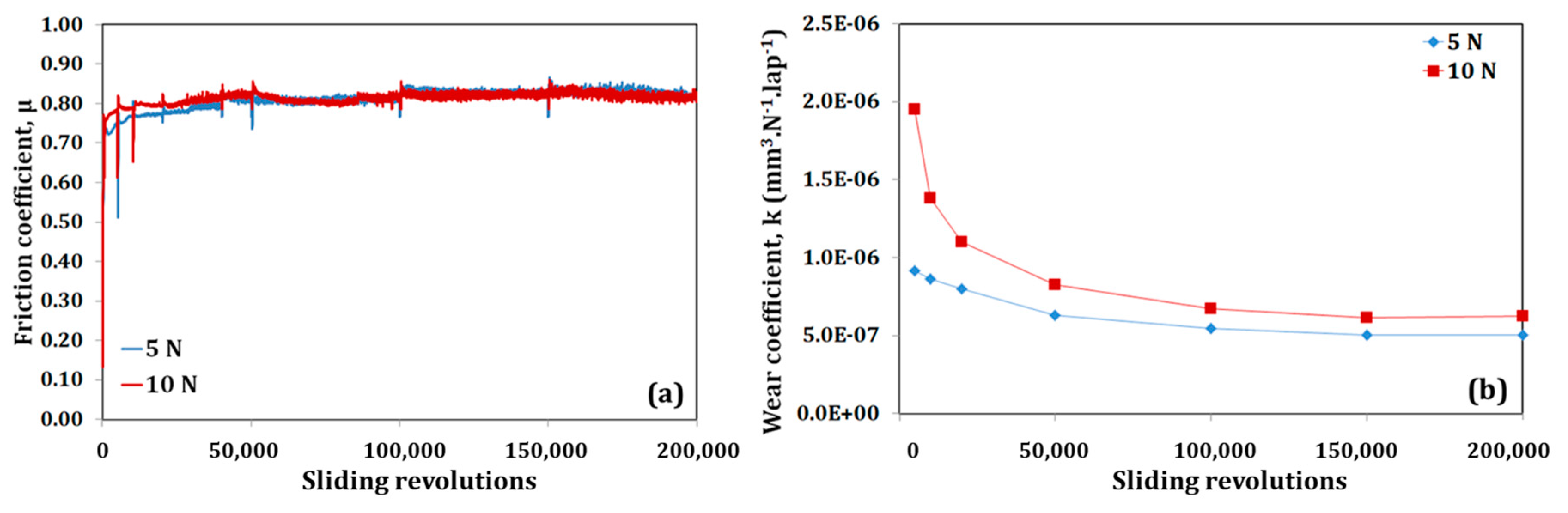

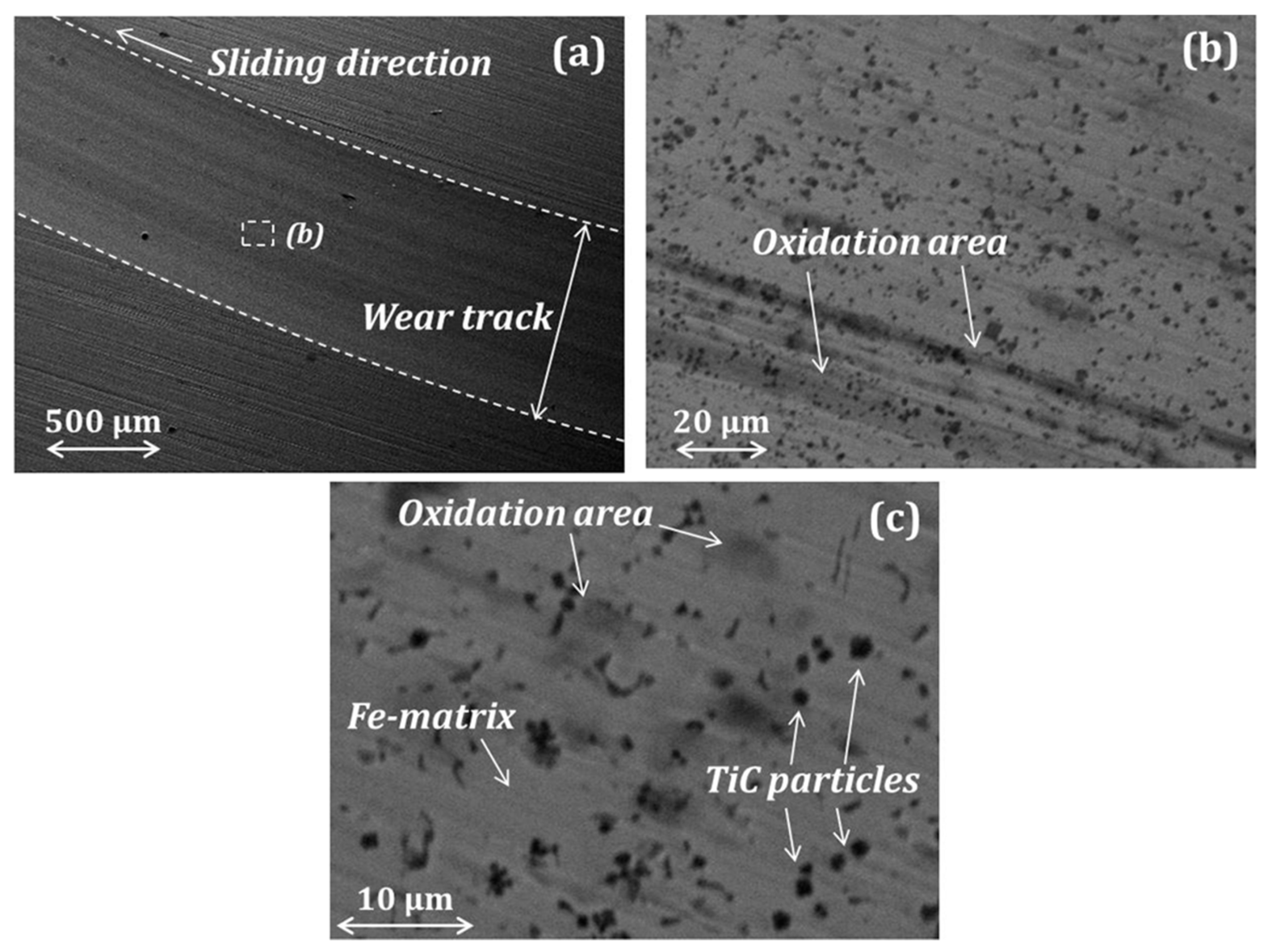

- (a)

- The conventional FCAW deposits, enhanced by TiC particles of finer size, exhibit a rather metallic nature, with high friction coefficient values, tending towards those of a typical tool steel [17] and the relevant wear micro-mechanisms, involving polishing and oxidation of the metallic matrix.

- (b)

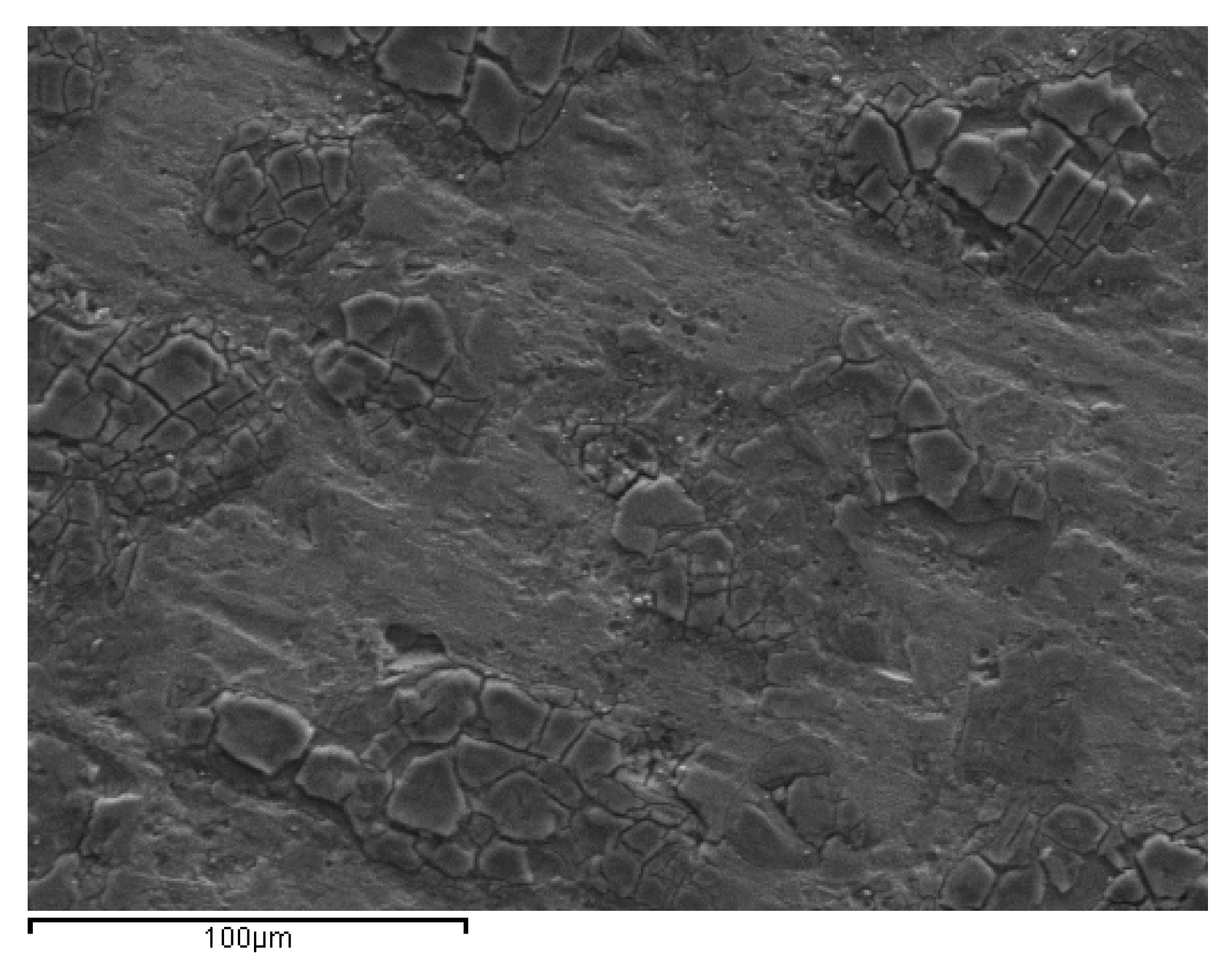

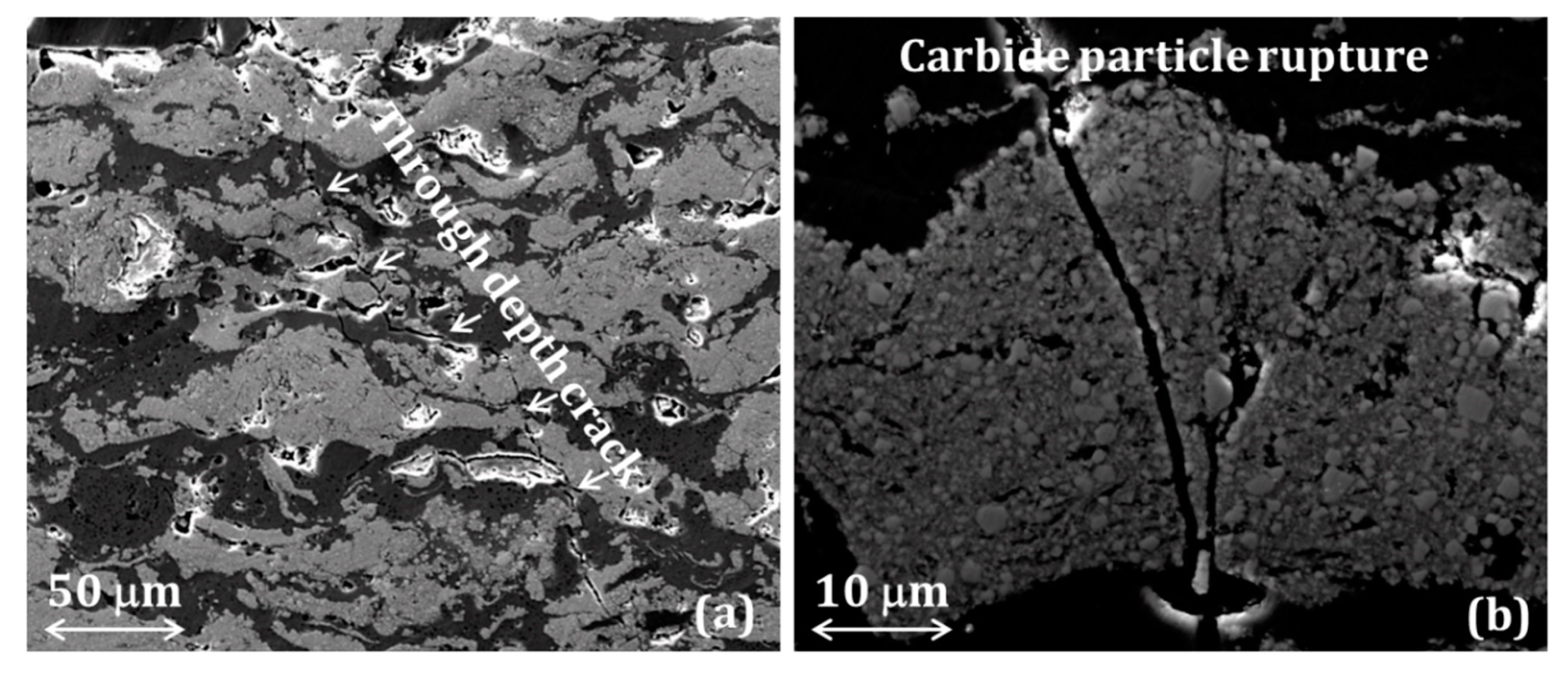

- The solar surface layers, enhanced by TiC particles of larger size, exhibit the typical nature of a ceramic-particle-reinforced metal (CPRM) composite, with the ceramic phase playing the predominant role in the low friction coefficient values. The wear micro-mechanism is a clear superposition of the plastic deformation of the metallic matrix and the micro-fragmentation of the carbides, leading finally to exfoliation (Figure 15).

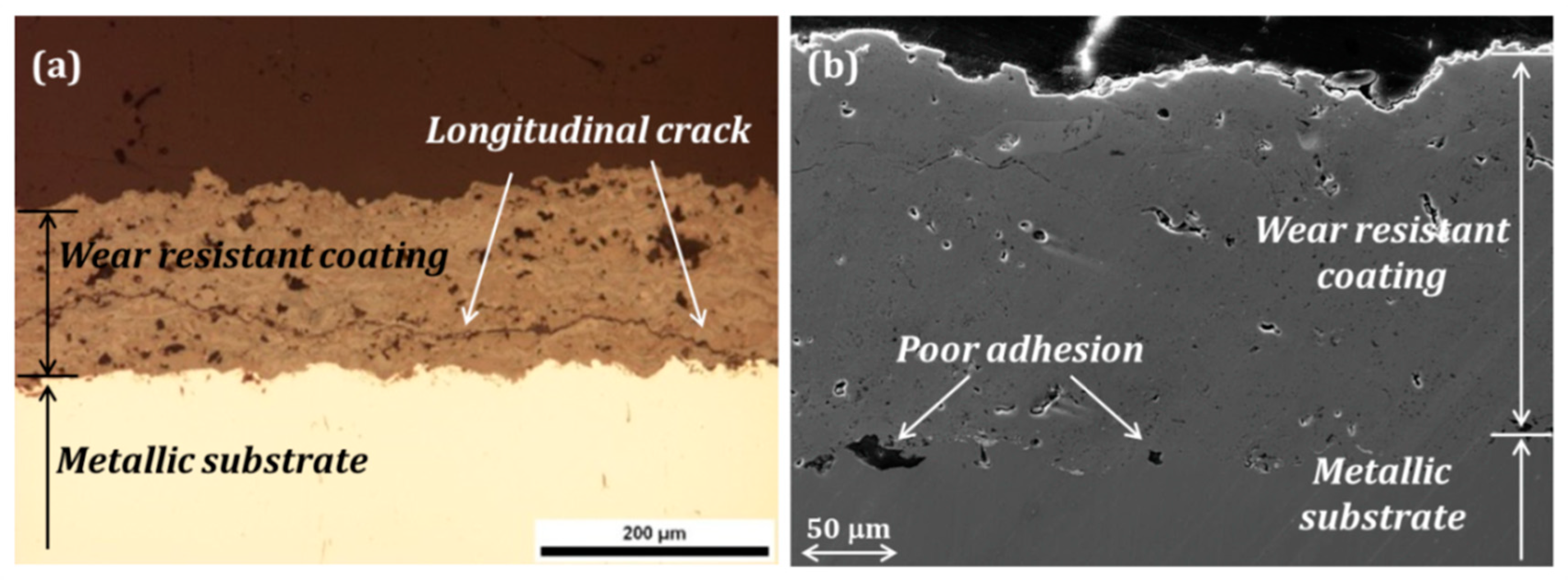

6. Case Study IV: Failure of Wear-Resistant Thermal-Sprayed Ceramic Coatings

7. Epilogue

Funding

Acknowledgments

Conflicts of Interest

References

- Williams, J.A. Engineering Tribology, 1st ed.; Oxford University Press Inc.: New York, NY, USA, 1994. [Google Scholar]

- Friction, Lubrication and Wear Technology; ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 18.

- Zum Gahr, K.-H. Microstructure and Wear of Materials, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Holmberg, K.; Matthews, A. Coatings Tribology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Heat Treating; ASM Handbook; ASM International: Materials Park, OH, USA, 1991; Volume 4.

- Surface Engineering; ASM Handbook; ASM International: Materials Park, OH, USA, 1994; Volume 5.

- Fauchais, P.L.; Heberlein, J.V.R.; Boulos, M.I. Thermal Stray Fundamentals: From Power to Part, 1st ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Stribeck, R. Die Wesentlichen Eigenschaften der Gleit-und Rollenlager. Z. Ver. Deul. Zng. 1902, 46, 180. [Google Scholar]

- Avitzur, B. Boundary and hydrodynamic lubrication. Wear 1990, 139, 49–76. [Google Scholar] [CrossRef]

- Avitzur, B. Modelling the effect of lubrication on friction behavior. Lubr. Sci. 1990, 2, 99–132. [Google Scholar] [CrossRef]

- Vrčeka, A.; Hultqvista, T.; Baubetb, Y.; Marklunda, P.; Larssona, R. Micro-pitting damage of bearing steel surfaces under mixed lubrication conditions: Effects of roughness, hardness and ZDDP additive. Tribol. Int. 2019, 138, 239–249. [Google Scholar] [CrossRef]

- Ancellotti, S.; Fontanari, V.; Dallago, M.; Benedetti, M. A novel experimental procedure to reproduce the load history at the crack tip produced by lubricated rolling sliding contact fatigue. Eng. Fract. Mech. 2018, 192, 129–147. [Google Scholar] [CrossRef]

- Stolarski, T.A.; Tobe, S. Rolling Contacts, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Pye, D. Practical Nitriding and Ferritic Nitrocarburizing; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Pantazopoulos, G.A. Tufftriding and Tennifer Surface Treatment. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.W., Eds.; Springer: Boston, MA, USA, 2013. [Google Scholar]

- Psyllaki, P.; Kefalonikas, G.; Pantazopoulos, G.; Sideris, J.; Antoniou, S. Microstructure and tribological behaviour of liquid nitrocarburized tool steels. Surf. Coat. Tech. 2002, 162, 67–78. [Google Scholar] [CrossRef]

- Karamboiki, C.-M.; Mourlas, A.; Psyllaki, P.; Sideris, J. Influence of microstructure on the sliding wear behavior of nitrocarburized tool steels. Wear 2013, 303, 560–568. [Google Scholar] [CrossRef]

- Pantazopoulos, G.; Psyllaki, P. An overview on the tribological behaviour of nitro-carburised steels for various industrial applications. Tribol. Ind. 2015, 37, 299–308. [Google Scholar]

- Psyllaki, P.; Stamatiou, K.; Iliadis, I.; Mourlas, A.; Asteris, P.; Vaxevanidis, N. Surface treatment of tool steels against galling failure. MATEC 2018, 188, 04024. [Google Scholar] [CrossRef]

- Cavaleri, L.; Asteris, P.G.; Psyllaki, P.P.; Douvika, M.G.; Skentou, A.D.; Vaxevanidis, N.M. Prediction of surface treatment effects on the tribological performance of tool steels using artificial neural networks. Appl. Sci. 2019, 9, 2788. [Google Scholar] [CrossRef]

- Rasool, G.; Stack, M.M. Wear maps for TiC composite based coatings deposited on 303 stainless steel. Tribol. Int. 2014, 74, 93–102. [Google Scholar] [CrossRef] [Green Version]

- Chaidemenopoulos, N.; Psyllaki, P.; Pavlidou, E.; Vourlias, G. Aspects on carbides transformations of Fe-based hardfacing deposits. Surf. Coat. Tech. 2019, 357, 651–661. [Google Scholar] [CrossRef]

- Bourithis, L.; Papaefthymiou, S.; Papadimitriou, G.D. Plasma transferred arc boriding of a low carbon steel: Microstructure and wear properties. Appl. Surf. Sci. 2002, 200, 203–218. [Google Scholar] [CrossRef]

- Bourithis, L.; Papadimitriou, G.D. The effect of microstructure and wear conditions on the wear resistance of steel metal matrix composites fabricated with PTA alloying technique. Wear 2009, 266, 1155–1164. [Google Scholar] [CrossRef]

- Pantelis, D.; Tissandier, A.; Manolatos, P.; Ponthiaux, P. Formation of wear resistant Al-SiC composite by laser melt-particle injection process. Mater. Sci. Tech. 1995, 11, 299–303. [Google Scholar] [CrossRef]

- Pantelis, D.; Michaud, H.; de Freitas, M. Wear behaviour of laser surface hardfaced steels with tungsten carbide powder injection. Surf. Coat. Tech. 1993, 57, 123–131. [Google Scholar] [CrossRef]

- Mourlas, A.; Pavlidou, E.; Vourlias, G.; Rodríguez, J.; Psyllaki, P. Concentrated solar energy for in-situ elaboration of wear-resistant composite layers. Part I: TiC and chromium carbide surface enrichment of common steels. Surf. Coat. Tech. 2019, 377, 124882. [Google Scholar] [CrossRef]

- Aranke, O.; Algenaid, W.; Awe, S.; Joshi, S. Coatings for automotive gray cast iron brake discs: A review. Coatings 2019, 9, 552. [Google Scholar] [CrossRef]

- Basu, B.; Kalin, M. Tribology of Ceramics and Composites, 1st ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Pantelis, D.; Psyllaki, P.; Alexopoulos, N. Tribological behaviour of plasma-sprayed Al2O3 coatings under severe wear conditions. Wear 2000, 237, 197–204. [Google Scholar] [CrossRef]

- Psyllaki, P.; Jeandin, M.; Pantelis, D. Microstructure and wear mechanisms of thermal-sprayed alumina coatings. Mater. Lett. 2001, 47, 77–82. [Google Scholar] [CrossRef]

- Kekes, D.; Psyllaki, P.; Vardavoulias, M.; Vekinis, G. Wear micro-mechanisms of composite WC-Co/Cr-NiCrFeBSiC coatings. Part II: Cavitation erosion. Tribol. Ind. 2014, 36, 375–383. [Google Scholar]

- Kekes, D.; Psyllaki, P.; Vardavoulias, M. Wear micro-mechanisms of composite WC-Co/Cr-NiCrFeBSiC coatings. Part I: Dry sliding. Tribol. Ind. 2014, 36, 361–374. [Google Scholar]

- Verdon, C.; Karimi, A.; Martin, J.-L. A study of high velocity oxy-fuel thermally sprayed tungsten carbide based coatings. Part 1: Microstructures. Mat. Sci. Eng. A Struct. 1998, 246, 11–24. [Google Scholar] [CrossRef]

- Liao, H.; Normand, B.; Coddet, C. Influence of coating microstructure on the abrasive wear resistance of WC/Co cermet coatings. Surf. Coat. Tech. 2000, 124, 235–242. [Google Scholar] [CrossRef]

- Sahraoui, T.; Fenineche, N.-E.; Montavon, G.; Coddet, C. Structure and wear behaviour of HVOF sprayed Cr3C2-NiCr and WC-Co coatings. Mater. Des. 2003, 24, 309–313. [Google Scholar] [CrossRef]

- Morks, M.F.; Gao, Y.; Fahim, N.F.; Yingqing, F.U.; Shoeib, M.A. Influence of binder materials on the properties of low power plasma sprayed cermet coatings. Surf. Coat. Tech. 2005, 199, 66–71. [Google Scholar] [CrossRef]

- Lee, C.W.; Han, J.H.; Yoon, J.; Shin, M.C.; Kwun, S.I. A study on powder mixing for high fracture toughness and wear resistance of WC-Co-Cr coatings sprayed by HVOF. Surf. Coat. Tech. 2010, 204, 2223–2229. [Google Scholar] [CrossRef]

- Venter, A.M.; Oladijo, O.P.; Luzin, V.; Cornish, L.A.; Sacks, N. Performance characterization of metallic substrates coated by HVOF WC-Co. Thin Solid Films 2013, 549, 330–339. [Google Scholar] [CrossRef]

- Psyllaki, P.; Mourlas, A.; Vourlias, G.; Pavlidou, E.; Vardavoulias, M. Influence of microstructure flaws on the tribological performance of Cr-based thermal-sprayed ceramic coatings. Ceram. Int. 2019, 45, 19360–19369. [Google Scholar] [CrossRef]

| Category | Representative Lubricants | Main Applications |

|---|---|---|

| Solid-State Lubrication | Graphite; Phyllomorphous Minerals | Dies and Molds for Metal Forming and Shaping |

| Liquid-State Lubrication | Oil-Based; Water-Based | Engines and Tool-Machines for Metals Machining |

| Gas-State Lubrication | Air | Dental Equipment |

| Technique | Representative Wear-Resistant Surface Layers | Main Applications |

|---|---|---|

| Thermochemical Treatments | Nitriding and nitrocarburizing | Forming, Cutting tools, Dies, Gears, Shafts, Clutches |

| Welding; High-power laser | Carbide-reinforced Fe-based composites | Heavily-loaded surfaces |

| Thermal Spraying | Oxides (Al2O3; TiO2, YSZ); WC-, Cr3C2 based CerMets | Medical implants Heavily-loaded surfaces |

| Physical or Chemical Vapor Deposition (PVD or CVD) | TiN; TiC; BN; Diamond; DLC | Cutting tools |

| Metallization/Plating | Cr-, Ni- coatings | Automotive parts |

| Applied Load | Friction Coefficient, µ | Wear Coefficient, k (mm−3.N−1.laps−1) | ||

|---|---|---|---|---|

| FCAW Deposits | CSE Overlayers | FCAW Deposits | CSE Overlayers | |

| 5 N | 0.78 ± 0.02 | 0.43 ± 0.02 | (5.45 ± 0.31) × 10-7 | (3.26 ± 0.41) × 10-7 |

| 10 N | 0.78 ± 0.02 | 0.46 ± 0.02 | (6.84 ± 0.49) × 10-7 | (4.18 ± 0.42) × 10-7 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Psyllaki, P.P. An Introduction to Wear Degradation Mechanisms of Surface-Protected Metallic Components. Metals 2019, 9, 1057. https://doi.org/10.3390/met9101057

Psyllaki PP. An Introduction to Wear Degradation Mechanisms of Surface-Protected Metallic Components. Metals. 2019; 9(10):1057. https://doi.org/10.3390/met9101057

Chicago/Turabian StylePsyllaki, Pandora P. 2019. "An Introduction to Wear Degradation Mechanisms of Surface-Protected Metallic Components" Metals 9, no. 10: 1057. https://doi.org/10.3390/met9101057

APA StylePsyllaki, P. P. (2019). An Introduction to Wear Degradation Mechanisms of Surface-Protected Metallic Components. Metals, 9(10), 1057. https://doi.org/10.3390/met9101057