Interaction between Microalloying Additions and Phase Transformation during Intercritical Deformation in Low Carbon Steels

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

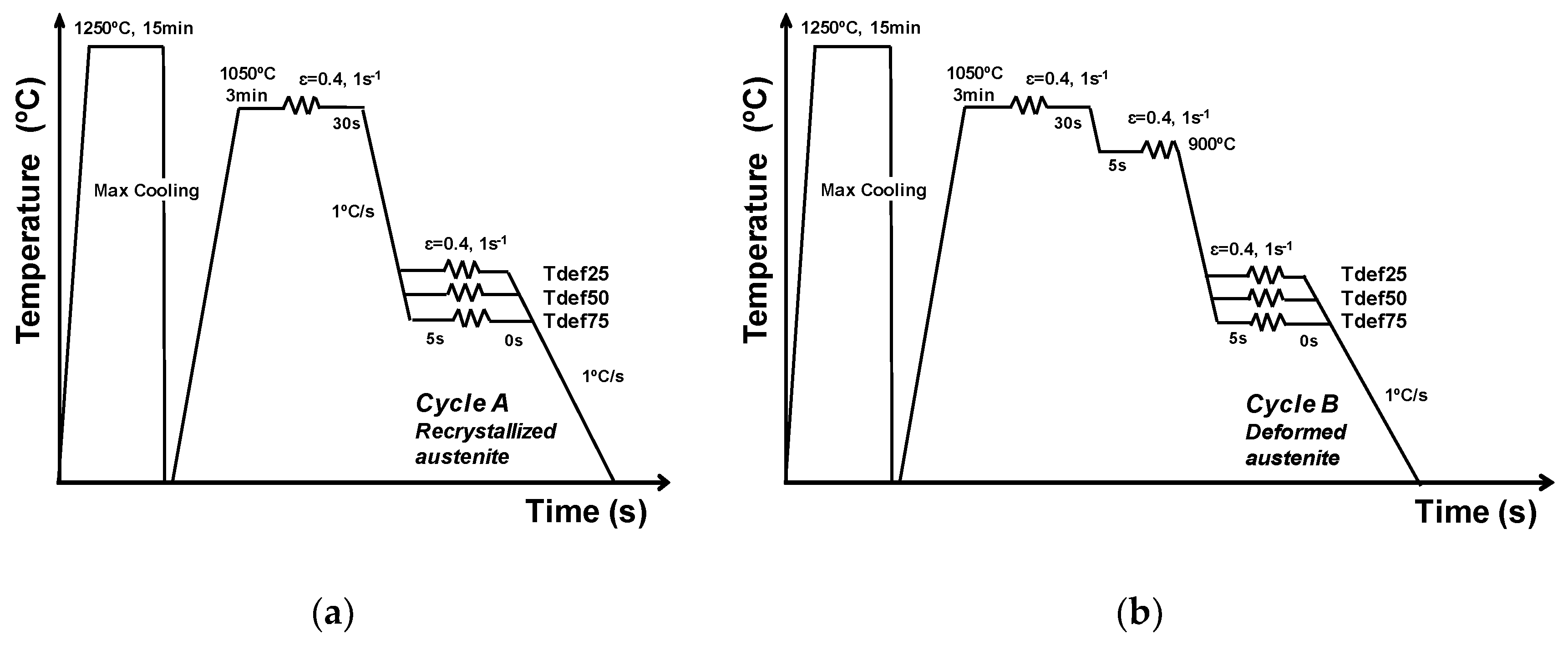

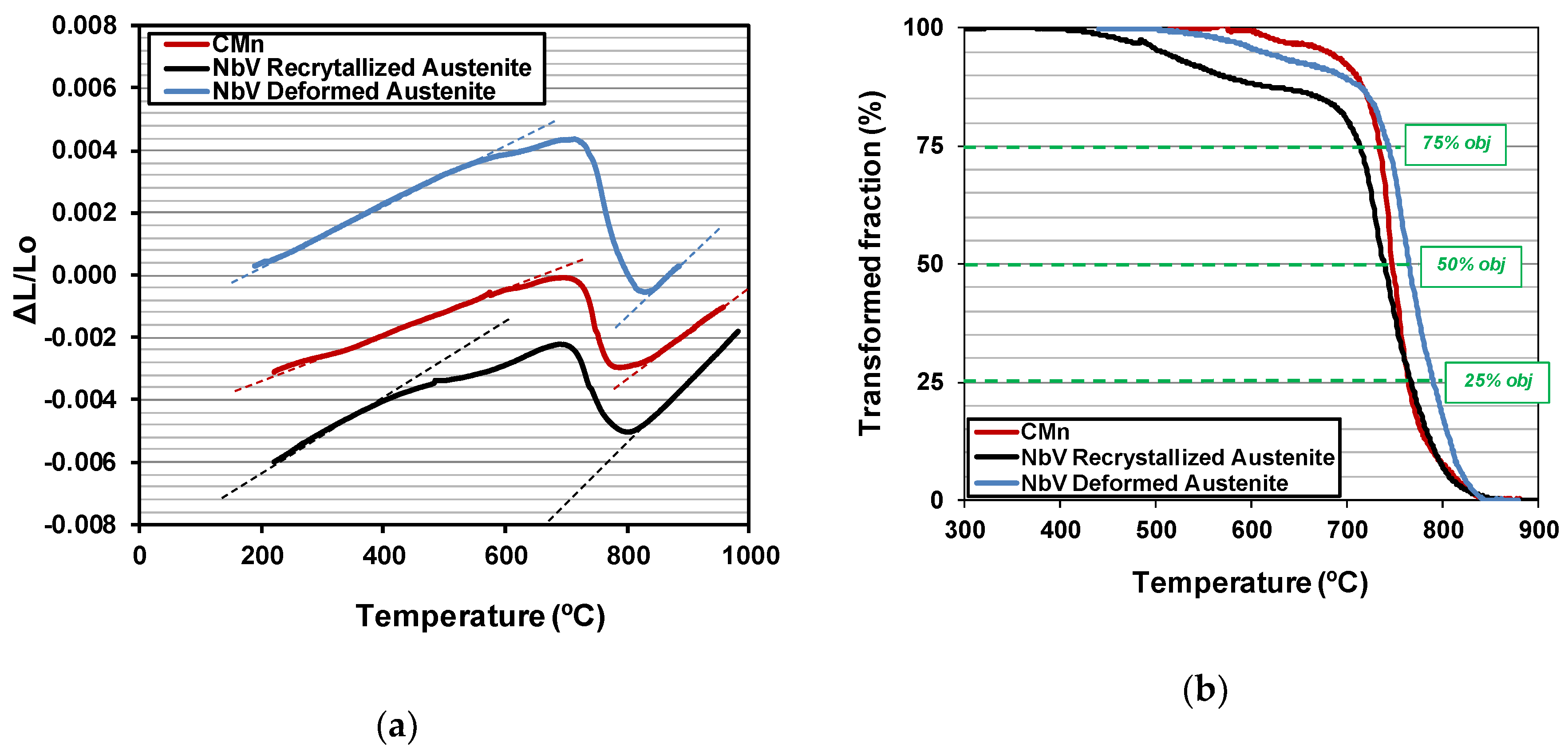

3.1. Definition of Deformation Temperatures

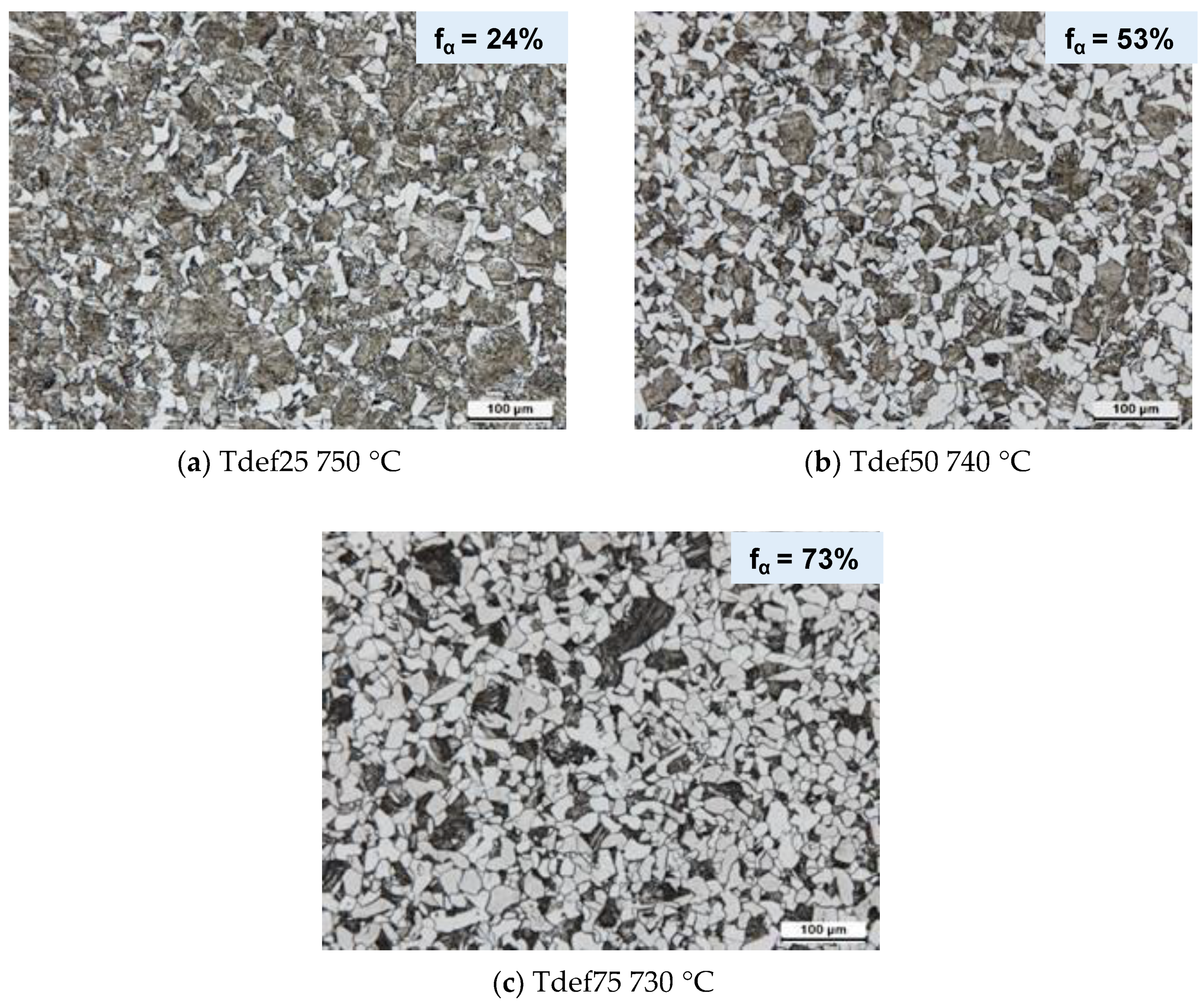

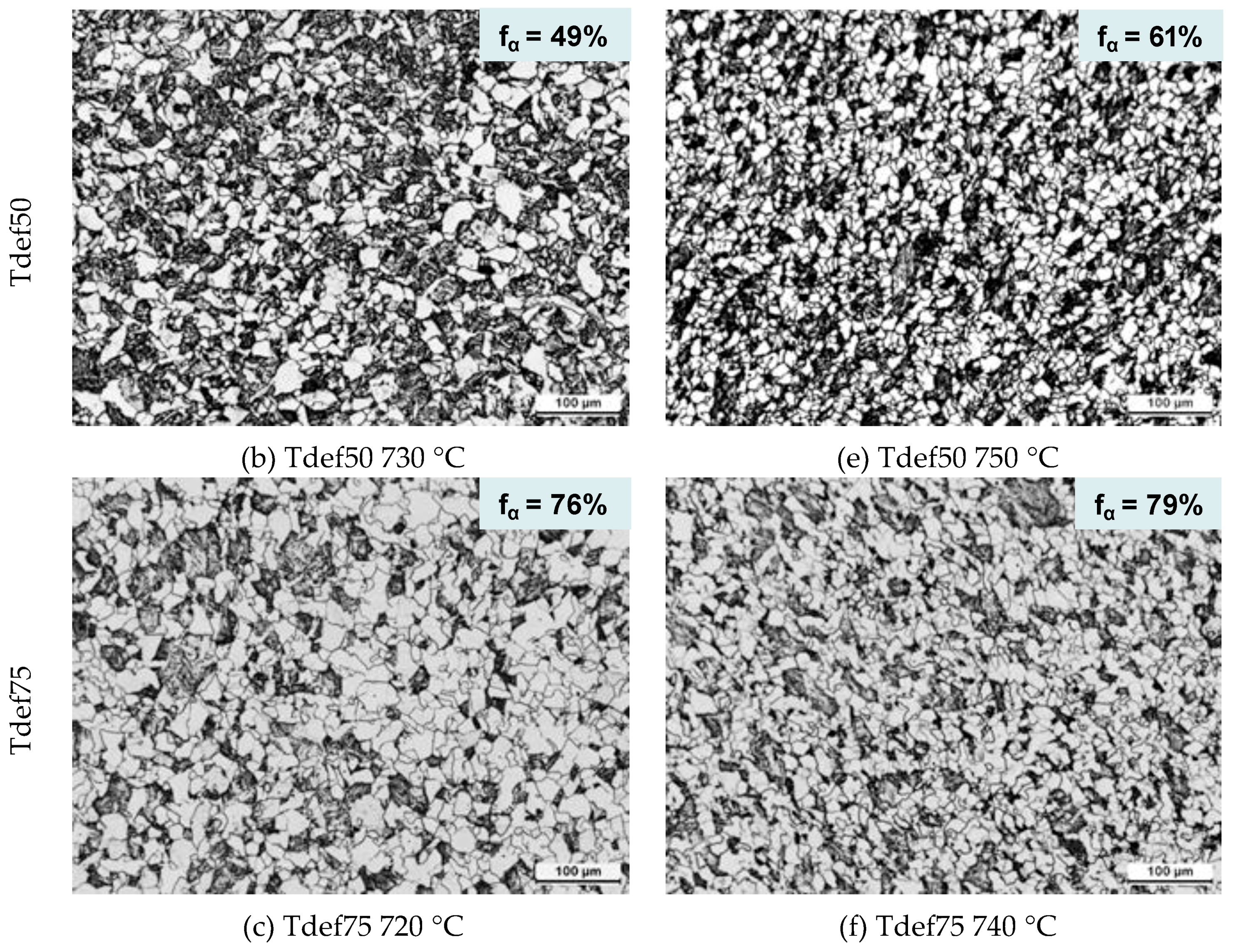

3.2. Microstructures at Room Temperature after Intercritical Deformation

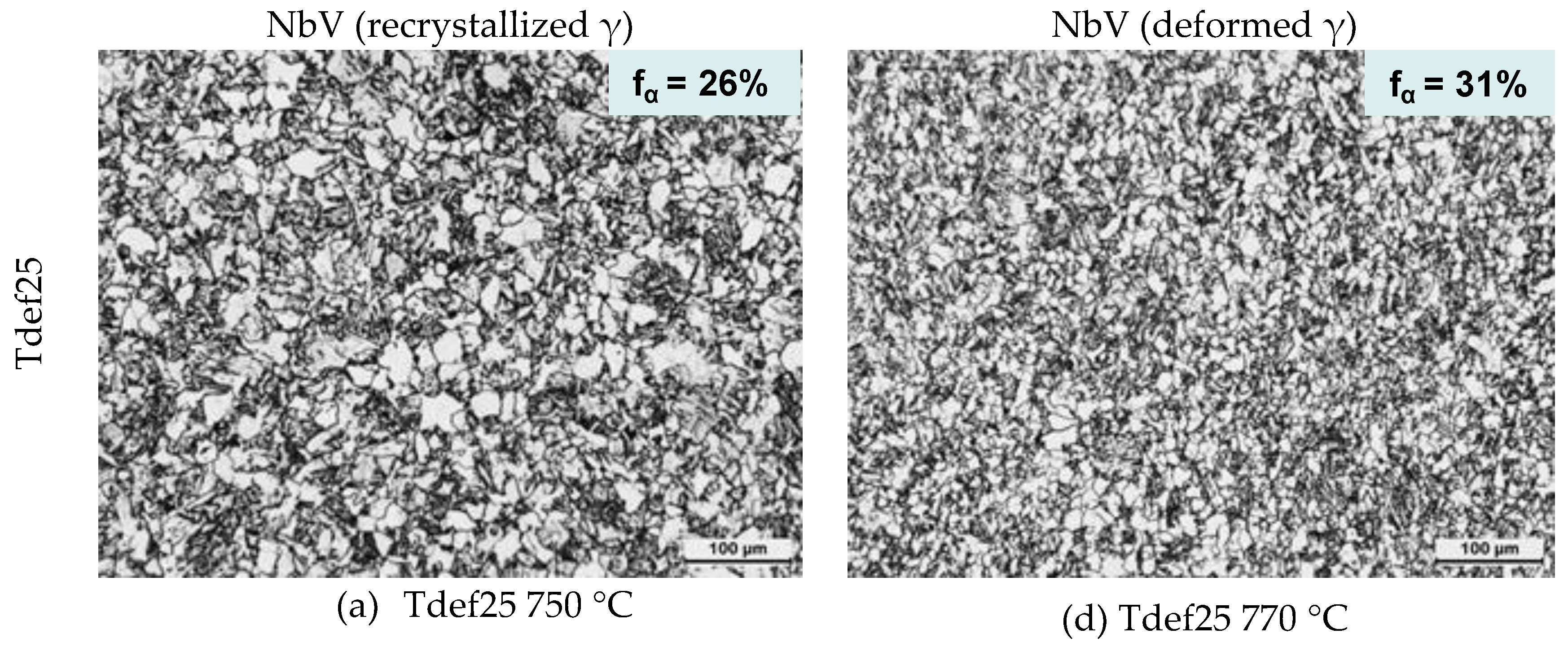

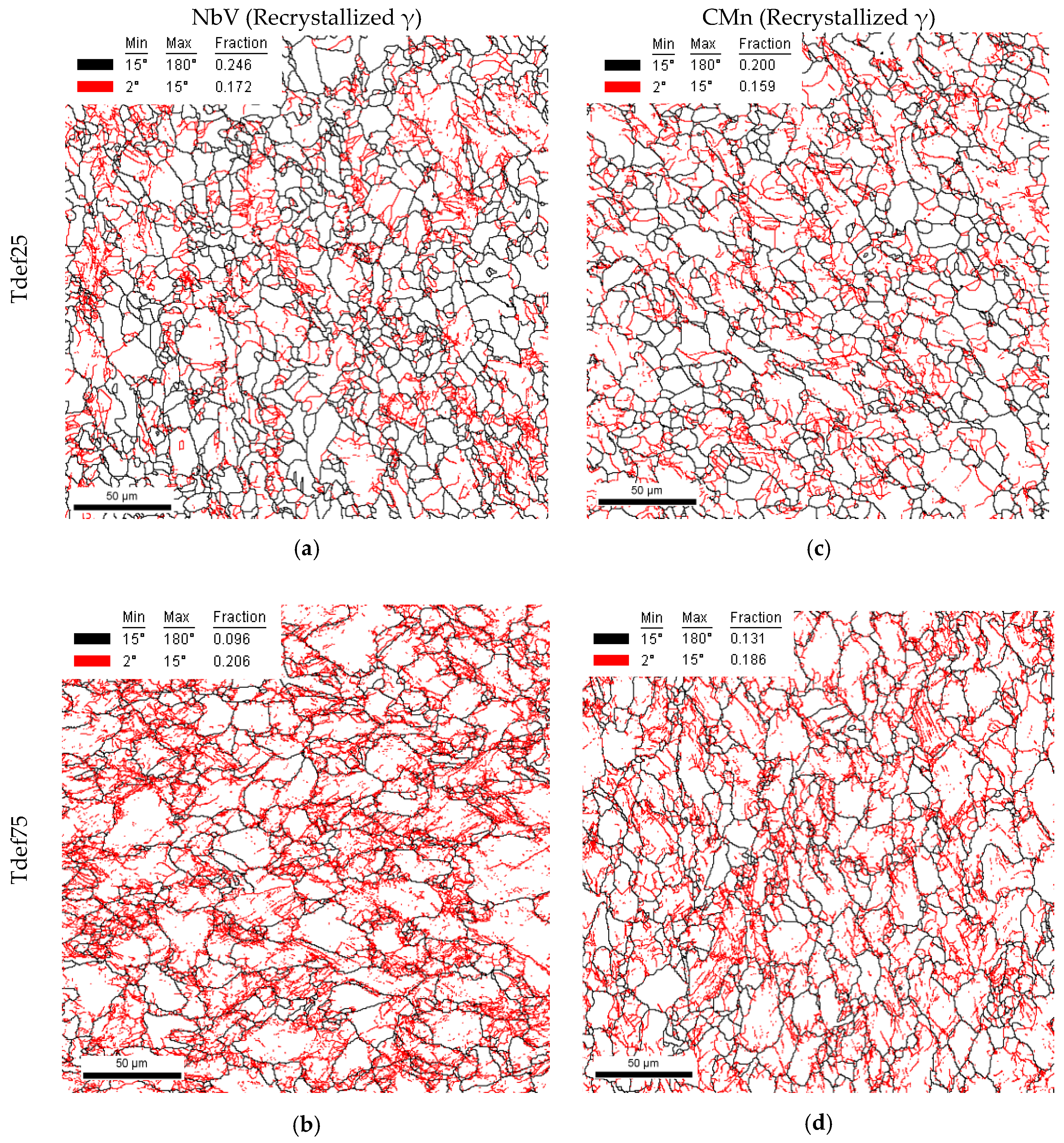

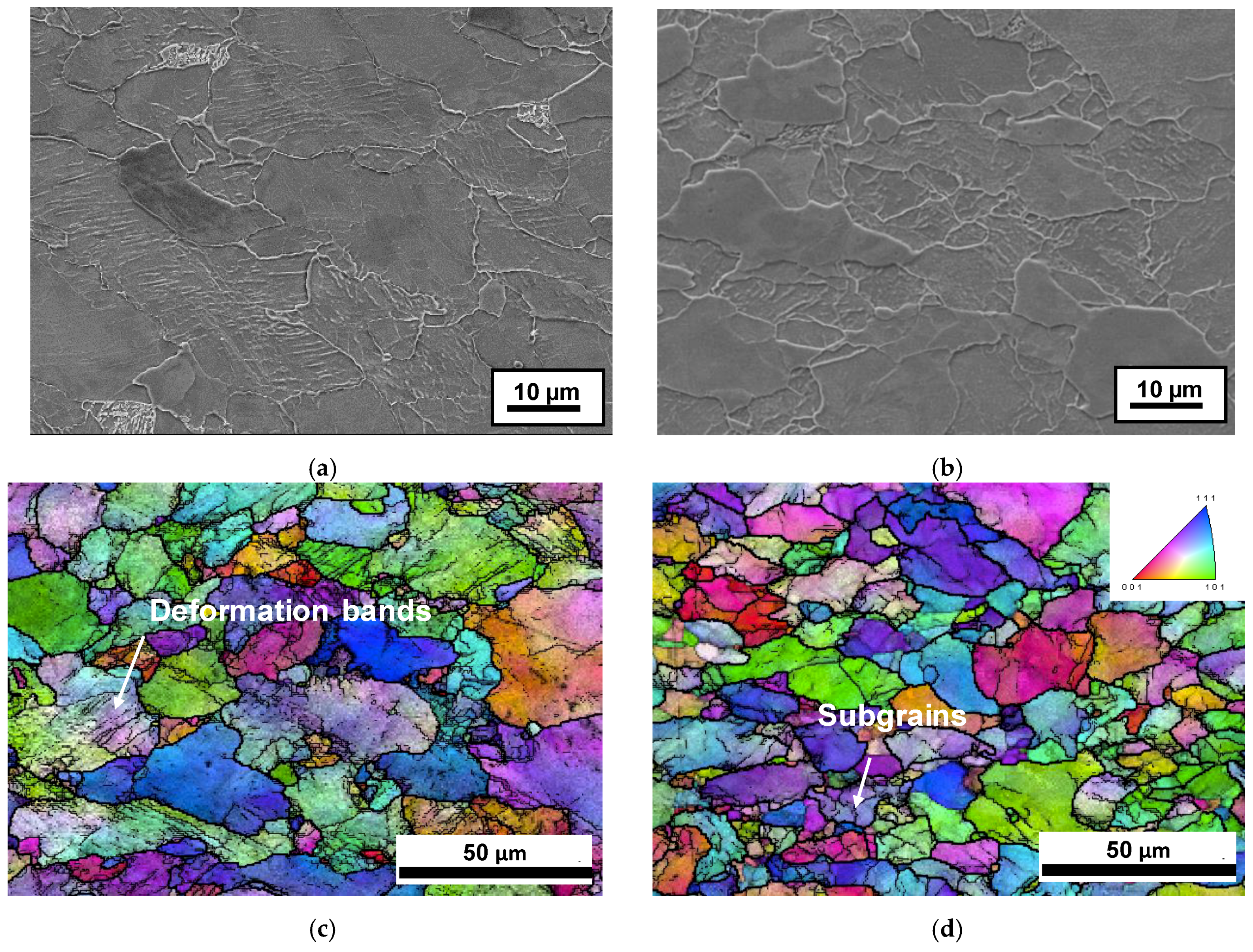

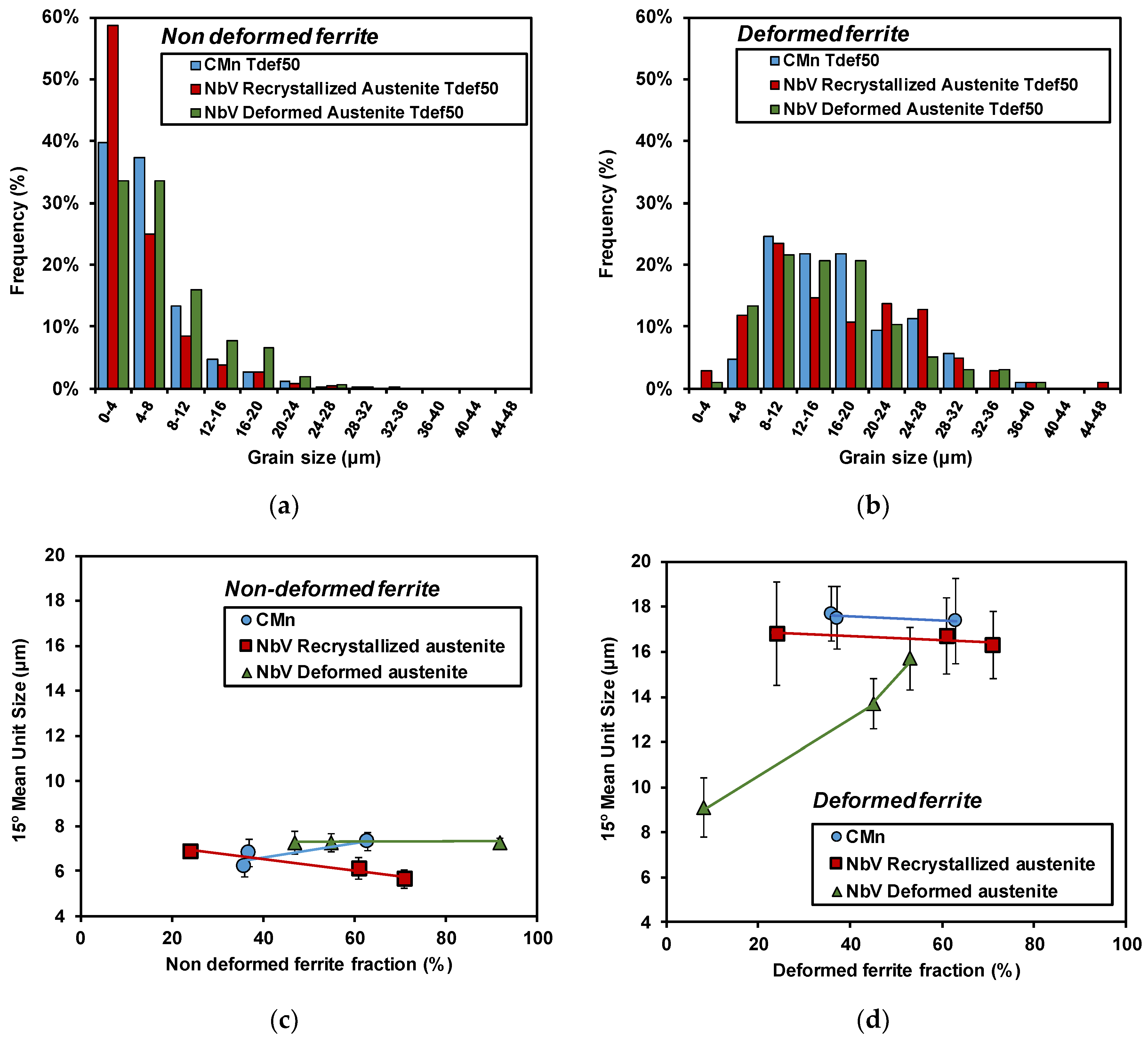

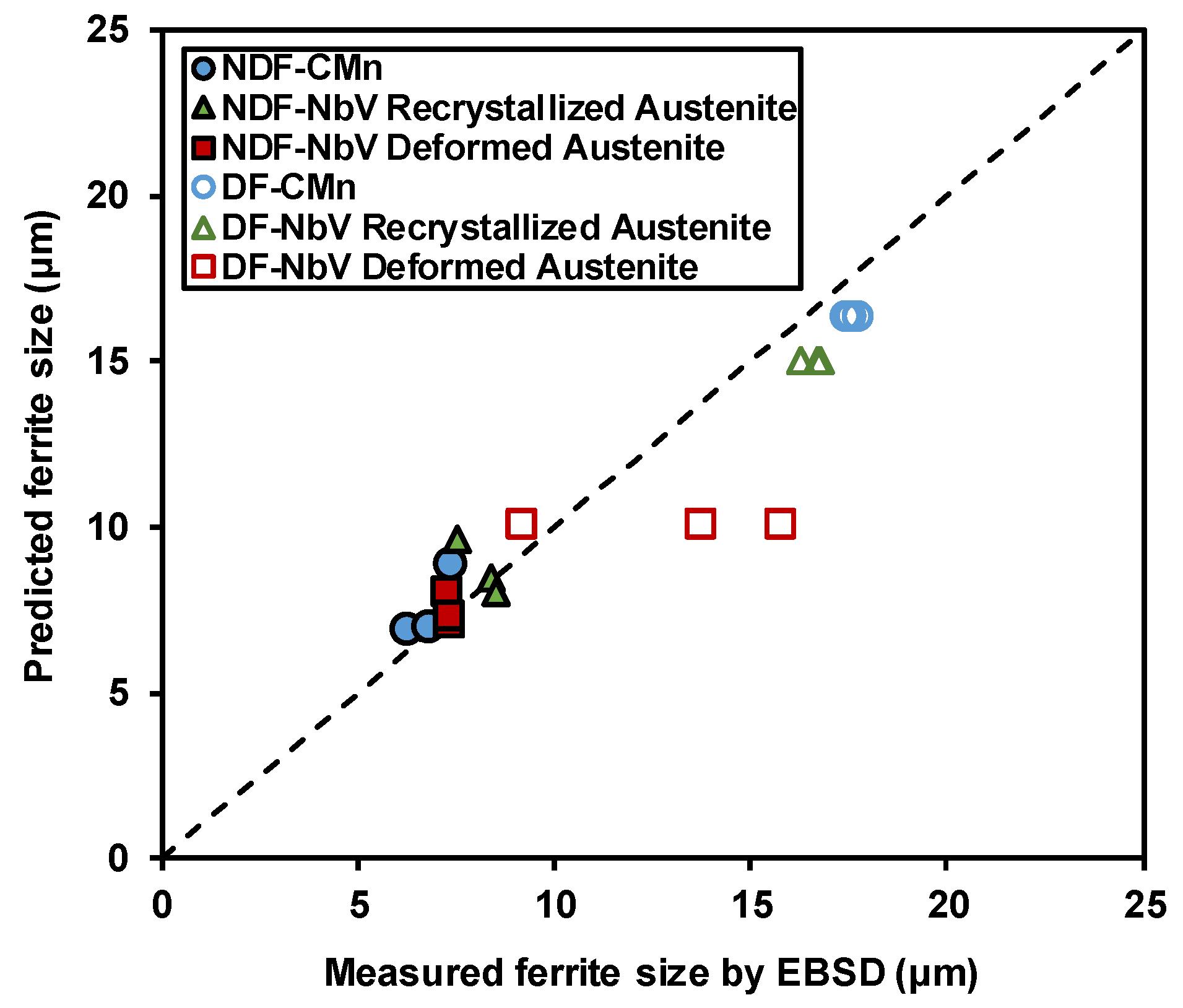

3.3. Effect of Austenite Conditioning and Addition of Microalloying Elements

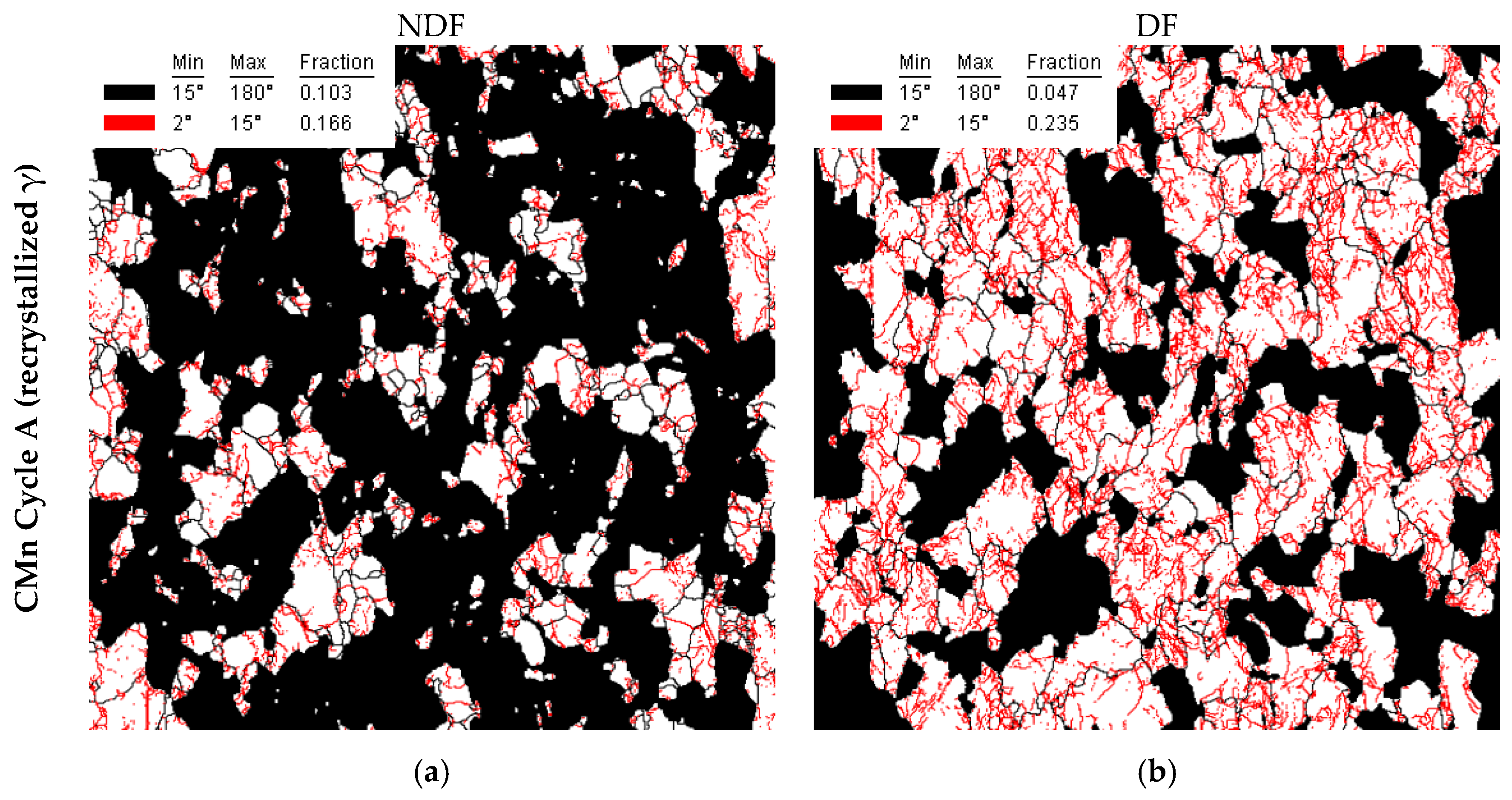

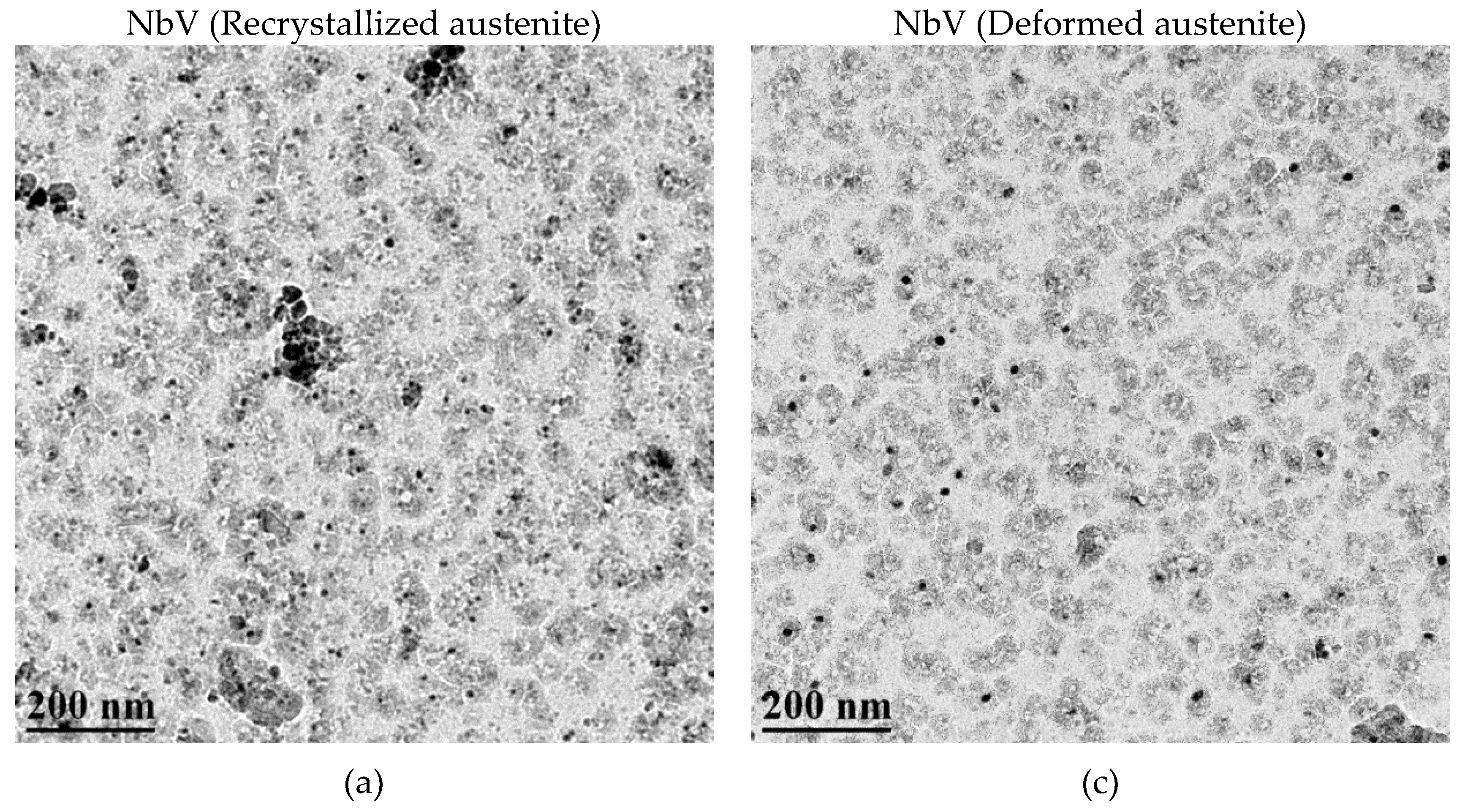

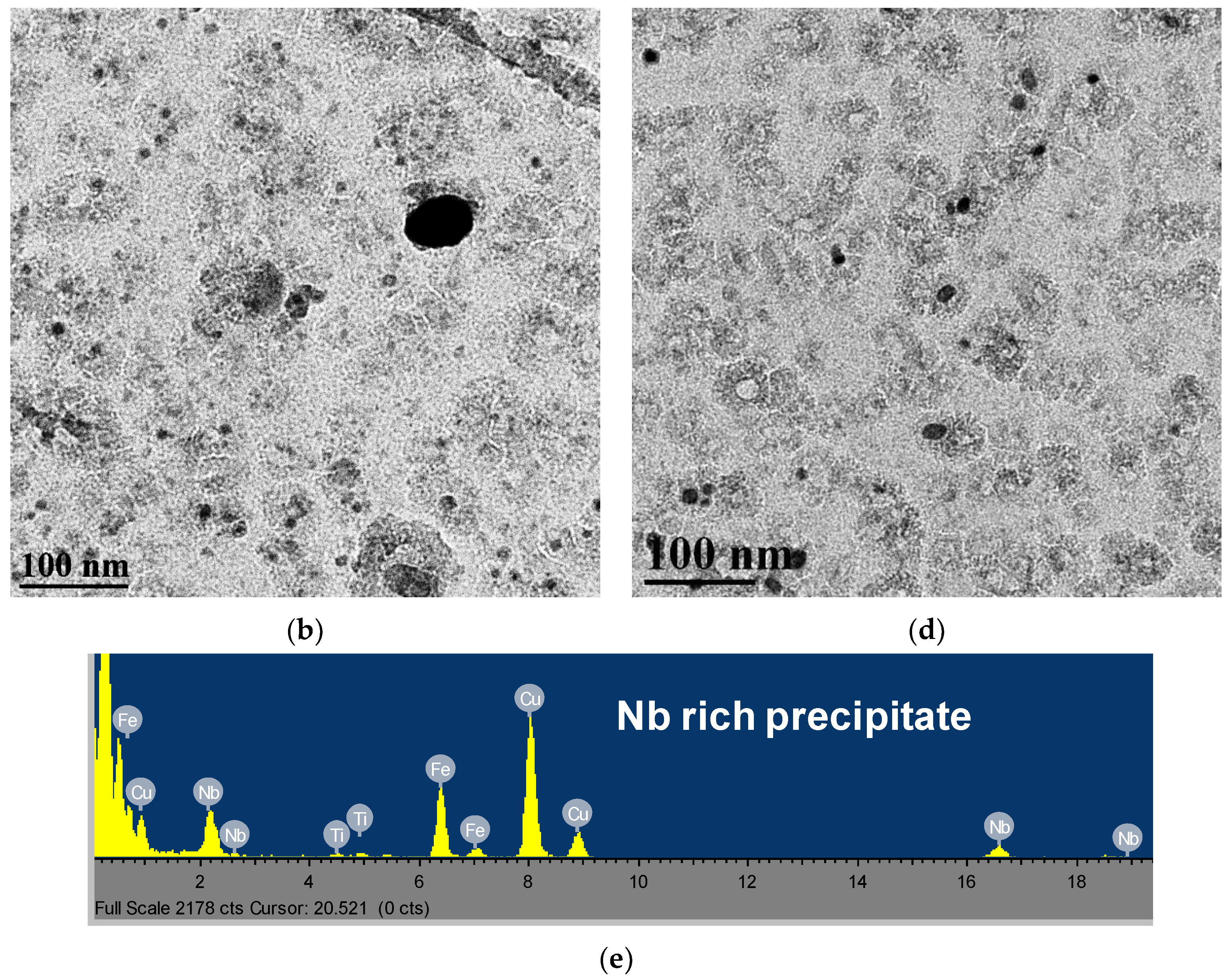

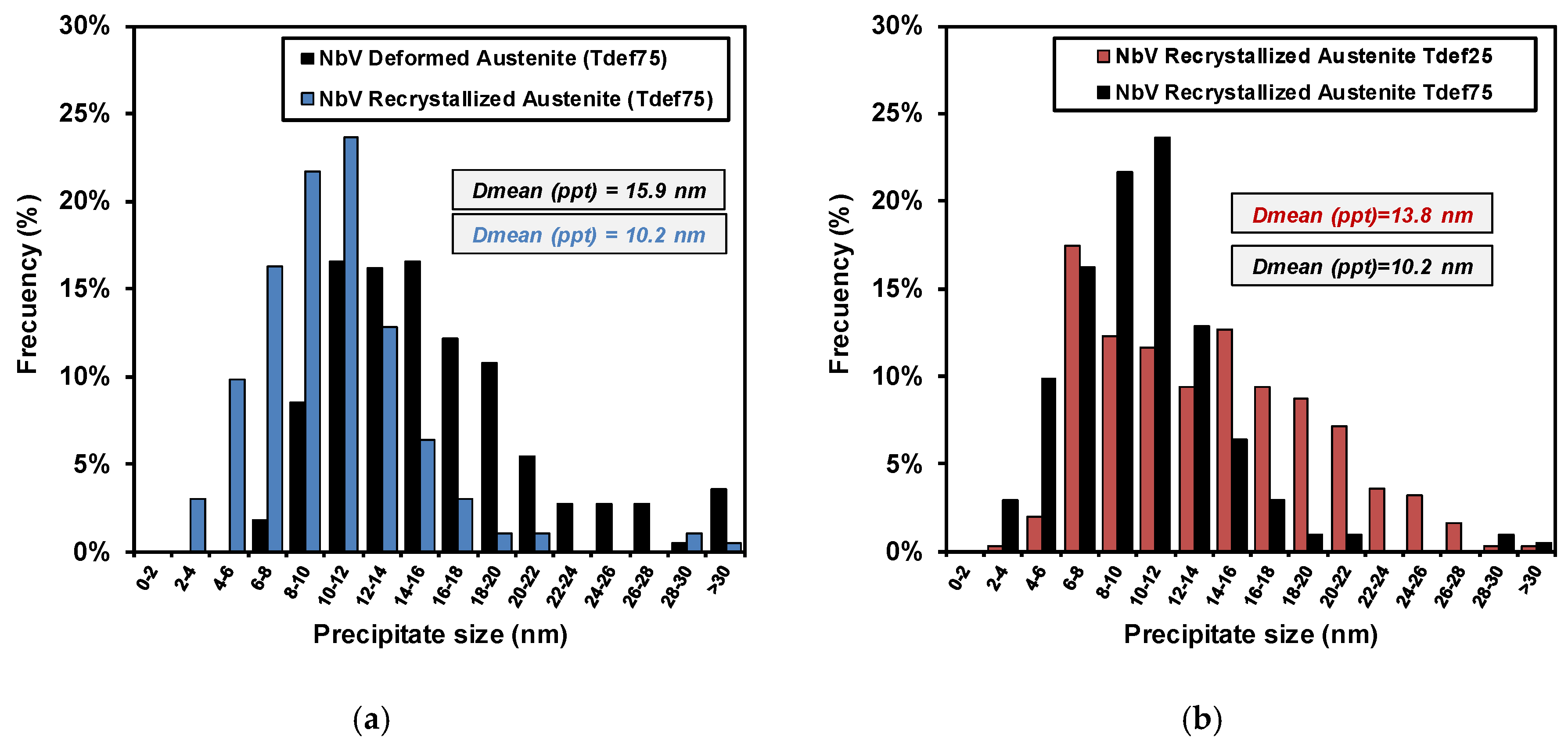

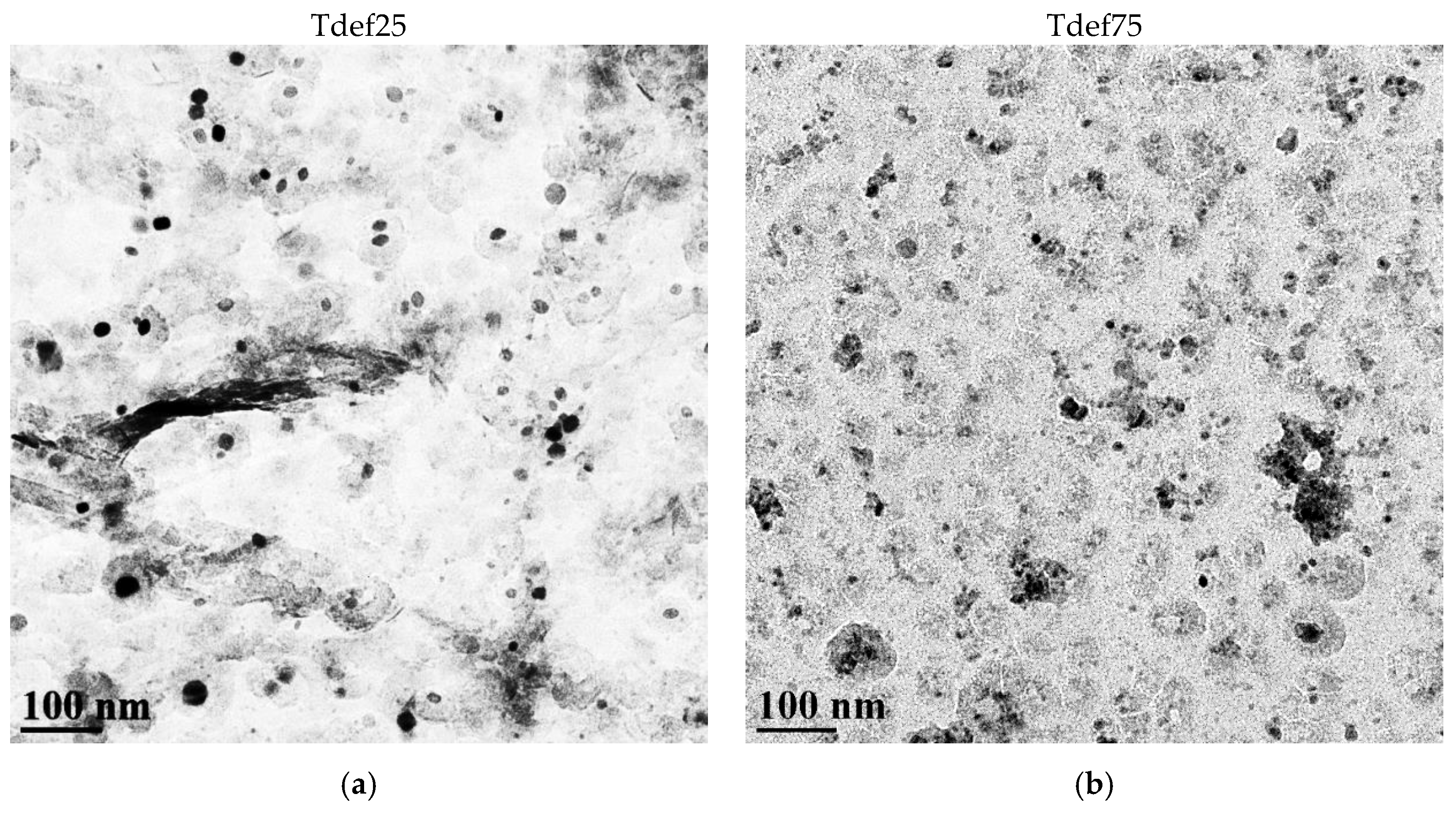

3.4. Interaction between Precipitation, Nb in Solution, and Intercritically Deformed Ferrite

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Humphreys, A.O.; Liu, D.; Toroghinejad, M.R.; Essadiqi, E.; Jonas, J.J. Warm rolling behaviour of low carbon steels. Mater. Sci. Technol. 2003, 19, 709–714. [Google Scholar] [CrossRef]

- Simielli, E.A.; Yue, S.; Jonas, J.J. Recrystallization kinetics of microalloyed steels deformed in the intercritical region. Met. Trans. A 1992, 23, 597–608. [Google Scholar] [CrossRef]

- Kwon, O.; De Ardo, A.J. Interactions between recrystallization and precipitation in hot-deformed microalloyed steels. Acta Mater. 1991, 39, 529–538. [Google Scholar] [CrossRef]

- Dunne, D.P.; Feng, B.; Chandra, T. The effect of Ti and Ti-Nb additions on α formation and restoration during intercritical rolling and holding of C-Mn structural steels. ISIJ Int. 1991, 31, 1354–1361. [Google Scholar] [CrossRef]

- Smith, A.; Luo, H.; Hanlon, D.N.; Sietsma, J.; Van Der Zwaag, S. Recovery processes in the ferrite phase in C–Mn steel. ISIJ Int. 2004, 44, 1188–1194. [Google Scholar] [CrossRef]

- Eghbali, B. Microstructural development in a low carbon Ti microalloyed steel during deformation within the ferrite region. Mat. Sci. Eng. A 2008, 480, 84–88. [Google Scholar] [CrossRef]

- Mayo, U.; Isasti, N.; Jorge-Badiola, D.; Rodriguez-Ibabe, J.M.; Uranga, P. An EBSD-based methodology for the characterization of intercritically deformed low carbon steel. Mat. Charact. 2019, 147, 31–42. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M. EBSD image quality mapping. Microsc. Microanal. 2006, 12, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Llanos, L.; Pereda, B.; Jorge-Badiola, D.; Rodriguez-Ibabe, J.M.; López, B. Study of recrystallization in high manganese steels by means of the EBSD technique. Mat. Sci. Forum 2013, 753, 443–448. [Google Scholar] [CrossRef]

- Olasolo, M.; Uranga, P.; Rodriguez-Ibabe, J.M.; López, B. Effect of austenite microstructure and cooling rate on transformation characteristics in a low carbon Nb–V microalloyed Steel. Mater. Sci. Eng. A 2011, 528, 2559–2569. [Google Scholar] [CrossRef]

- Bengochea, R.; Lopez, B.; Gutierrez, I. Microstructural evolution during the austenite-to-ferrite transformation from deformed austenite. Metall. Mater. Trans. A 1998, 29, 417–426. [Google Scholar] [CrossRef]

- Petrov, R.; Kestens, L.; Houbaert, Y. Characterization of the microstructure and transformation behaviour of strained and nonstrained austenite in Nb–V-alloyed C–Mn steel. Mater. Charact. 2004, 53, 51–61. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). ASTM E-562 Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Isasti, N.; Jorge-Badiola, D.; Taheri, M.L.; López, B.; Uranga, P. Effect of composition and deformation on coarse-grained austenite transformation in nb-mo microalloyed steels. Met. Trans. A 2011, 42, 3729–3742. [Google Scholar] [CrossRef]

- Isasti, N.; Jorge-Badiola, D.; Taheri, M.L.; Uranga, P. Phase transformation study in Nb-Mo microalloyed steels using dilatometry and EBSD quantification. Metall. Mater. Trans. A 2013, 44, 3552–3563. [Google Scholar] [CrossRef]

- Cizek, P.; Wynne, B.P.; Davies, C.H.J.; Muddle, B.C.; Hodgson, P.D. Effect of composition and austenite deformation on the transformation characteristics of low-carbon and ultralow-carbon microalloyed steels. Met. Trans. A 2002, 33, 1331–1349. [Google Scholar] [CrossRef]

- Krauss, G.; Thompson, S.W. Ferritic microstructures in continuously cooled low- and ultralow-carbon steels. ISIJ Int. 1995, 35, 937–945. [Google Scholar] [CrossRef]

- Bengochea, R.; López, B.; Gutierrez, I. Influence of the prior austenite microstructure on the transformation products obtained for C-Mn-Nb steels after continuous cooling. ISIJ Int. 1999, 39, 583–591. [Google Scholar] [CrossRef]

- Cizek, P.; Wynne, B.P.; Davies, C.H.J.; Hodgson, P.D. The effect of simulated thermomechanical processing on the transformation behavior and microstructure of a low-carbon mo-nb linepipe steel. Met. Trans. A 2015, 46, 407–425. [Google Scholar] [CrossRef]

- Tamura, I.; Sekine, H.; Tanaka, T.; Ouchi, C. Thermomechanical Processing of High-Strength Low-Alloy Steels; Butterworth and Company: London, UK, 1988. [Google Scholar]

- Speich, G.R.; Cuddy, L.J.; Gordon, C.R.; DeArdo, A.J. Phase Transformations in Ferrous Alloys; Marder, A.R., Goldstein, J.I., Eds.; TMS-AIME: Warrendale, PA, USA, 1983; pp. 341–389. [Google Scholar]

- Sellars, C.M.; Beynon, J.H. Proceedings of the Conference on High Strength Low Alloy Steels; Dunee, D., Chandra, T., Eds.; South Coast Printers: Wollongong, Australia, 1984; p. 142. [Google Scholar]

- Gibbs, R.K.; Parker, B.A.; Hodgson, P. Low-carbon steels for the 90’s. In Proceedings of the International Symposium on Low-Carbon Steels for the 90s; Asfahani, R., Tiher, G., Eds.; The Minerals, Metals and Materials Society: Pittsburgh, PA, USA, 1993; p. 173. [Google Scholar]

- García-Riesco, P.M.; Uranga, P.; López, B.; Rodriguez-Ibabe, J.M. Modelling the austenite to ferrite phase transformation in low carbon microalloyed steels in terms of grain size distributions. In Proceedings of the International Conference on Solid-Solid Phase Transformations in Inorganic Materials 2015, PTM’2015, Whistler, BC, Canada, 28 June–3 July 2015; pp. 917–924. [Google Scholar]

- Hernandez, D.; López, B.; Rodriguez-Ibabe, J.M. Ferrite grain size refinement in vanadium microalloyed structural steels. Mater. Sci. Forum 2015, 500, 411–418. [Google Scholar] [CrossRef]

- Vandermerr, R.A.; Juul Jensen, D. Microstructural path and temperature dependence of recrystallization in commercial aluminum. Acta Mater. 2001, 49, 2083–2094. [Google Scholar] [CrossRef]

| Steels | C | Mn | Si | Cr | V | Ti | Al | Nb | N |

|---|---|---|---|---|---|---|---|---|---|

| CMn | 0.063 | 1.53 | 0.25 | 0.012 | 0.005 | 0.002 | 0.035 | 0.002 | 0.003 |

| NbV | 0.062 | 1.52 | 0.25 | 0.012 | 0.034 | 0.002 | 0.038 | 0.056 | 0.004 |

| Steel and Austenite Condition | 25% Ferrite | 50% Ferrite | 75% Ferrite | ||||

|---|---|---|---|---|---|---|---|

| Tdef25 (°C) | Measured fα | Tdef50 (°C) | Measured fα | Tdef75 (°C) | Measured fα | ||

| NbV | Cycle A recrystallized γ | 750 | 26% | 730 | 49% | 720 | 76% |

| Cycle B deformed γ | 770 | 31% | 750 | 61% | 740 | 79% | |

| CMn | Cycle A recrystallized γ | 750 | 24.3% | 740 | 53.3% | 730 | 73.1% |

| Ferrite Family | Condition | Ferrite Content Prior to Deformation (%) | Mean Austenite Size, dγ (µm) | εacc | (°C/s) | dα Predicted (µm) by Equation (1) |

|---|---|---|---|---|---|---|

| DF | CMn | 37 | 73 | 0 | 1 | 16.4 |

| 64 | 73 | 0 | 1 | 16.4 | ||

| 63 | 73 | 0 | 1 | 16.4 | ||

| NbV recrystallized austenite | 24 | 55 | 0 | 1 | 15 | |

| 61 | 55 | 0 | 1 | 15 | ||

| 71 | 55 | 0 | 1 | 15 | ||

| NbV deformed austenite | 8 | 55 | 0.4 | 1 | 10.1 | |

| 53 | 55 | 0.4 | 1 | 10.1 | ||

| 45 | 55 | 0.4 | 1 | 10.1 | ||

| NDF | CMn | 37 | 36 | 0.4 | 1 | 8.9 |

| 64 | 16 | 0.4 | 1 | 7.0 | ||

| 63 | 16 | 0.4 | 1 | 7.0 | ||

| NbV recrystallized austenite | 24 | 47 | 0.4 | 1 | 9.6 | |

| 61 | 31 | 0.4 | 1 | 8.4 | ||

| 71 | 26 | 0.4 | 1 | 8.0 | ||

| NbV deformed austenite | 8 | 52 | 0.8 | 1 | 8.1 | |

| 53 | 35 | 0.8 | 1 | 7.1 | ||

| 45 | 38 | 0.8 | 1 | 7.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayo, U.; Isasti, N.; Rodriguez-Ibabe, J.M.; Uranga, P. Interaction between Microalloying Additions and Phase Transformation during Intercritical Deformation in Low Carbon Steels. Metals 2019, 9, 1049. https://doi.org/10.3390/met9101049

Mayo U, Isasti N, Rodriguez-Ibabe JM, Uranga P. Interaction between Microalloying Additions and Phase Transformation during Intercritical Deformation in Low Carbon Steels. Metals. 2019; 9(10):1049. https://doi.org/10.3390/met9101049

Chicago/Turabian StyleMayo, Unai, Nerea Isasti, Jose M. Rodriguez-Ibabe, and Pello Uranga. 2019. "Interaction between Microalloying Additions and Phase Transformation during Intercritical Deformation in Low Carbon Steels" Metals 9, no. 10: 1049. https://doi.org/10.3390/met9101049

APA StyleMayo, U., Isasti, N., Rodriguez-Ibabe, J. M., & Uranga, P. (2019). Interaction between Microalloying Additions and Phase Transformation during Intercritical Deformation in Low Carbon Steels. Metals, 9(10), 1049. https://doi.org/10.3390/met9101049