A CPS-Based Simulation Platform for Long Production Factories

Abstract

:1. Introduction

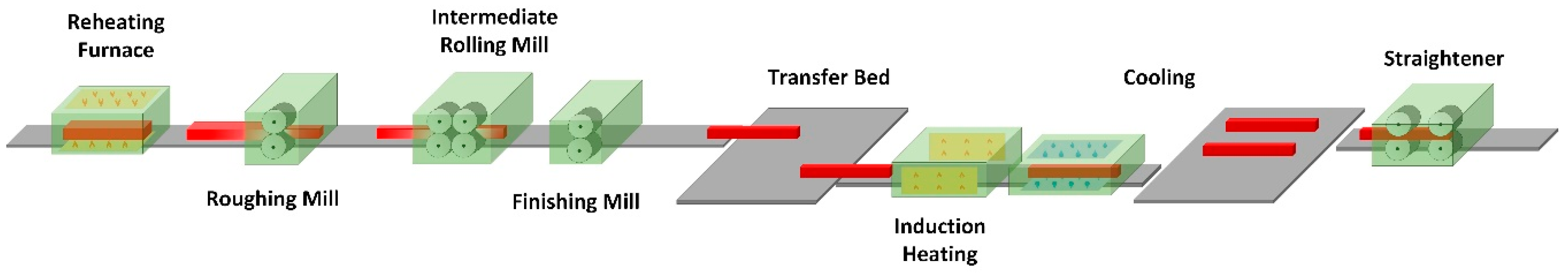

2. Long Products Manufacturing Process

- Reheating furnace;

- Roughing mill;

- Transfer bed;

- Induction heating;

- Active/passive cooling sections;

- Straightener.

2.1. Reheating Furnace

- Temperature evolution of the product;

- Decarburization (available as indirect measurement);

- Ambient temperature in each zone;

- Oxygen and gas percentage composition and flow;

- Product’s processing duration in each zone;

- Transport speed of the furnace.

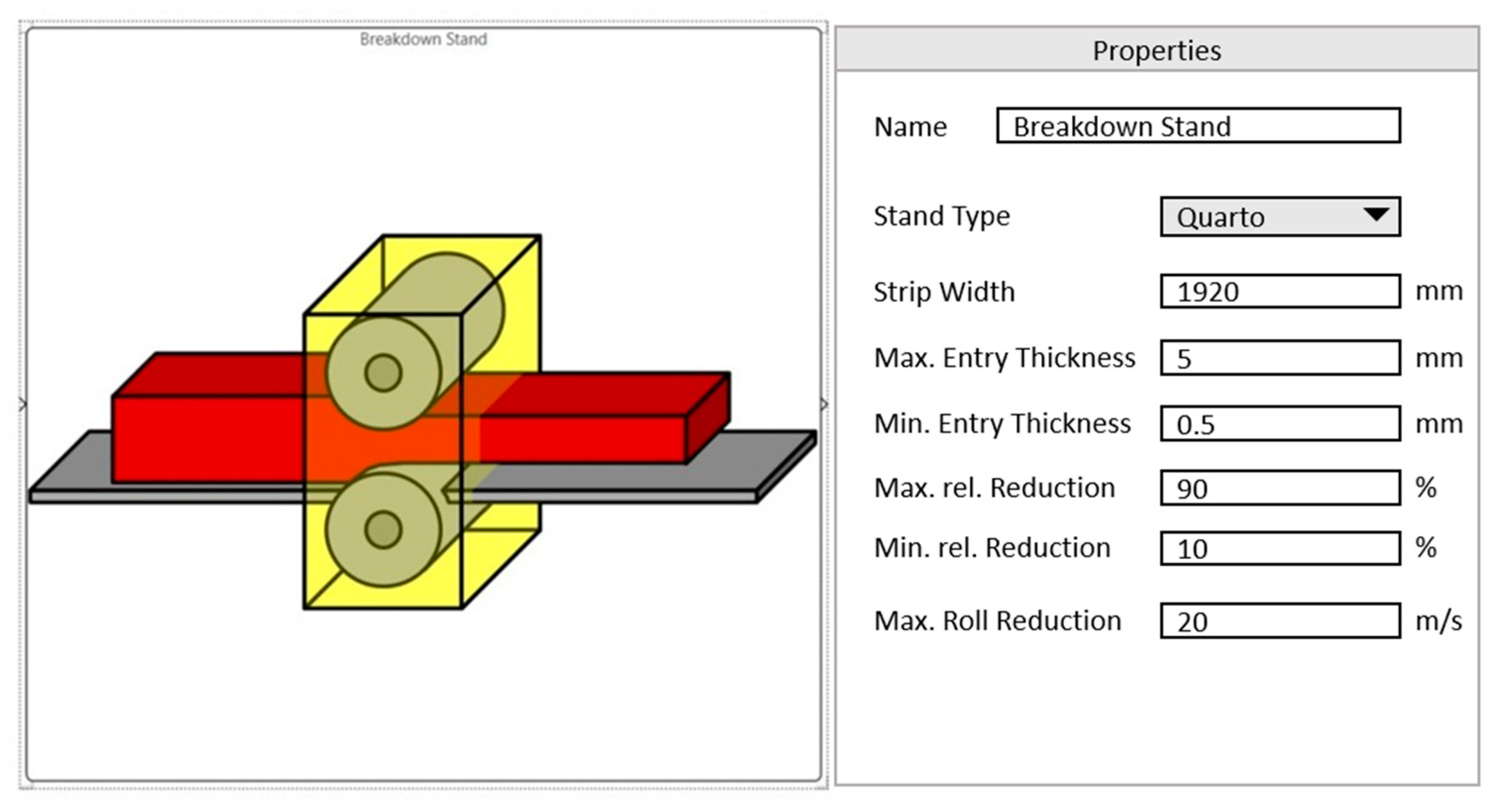

2.2. Rolling Section

- Temperature at the entry of each stand;

- Rolling forces and gaps;

- Rolling speeds;

- Rolling time.

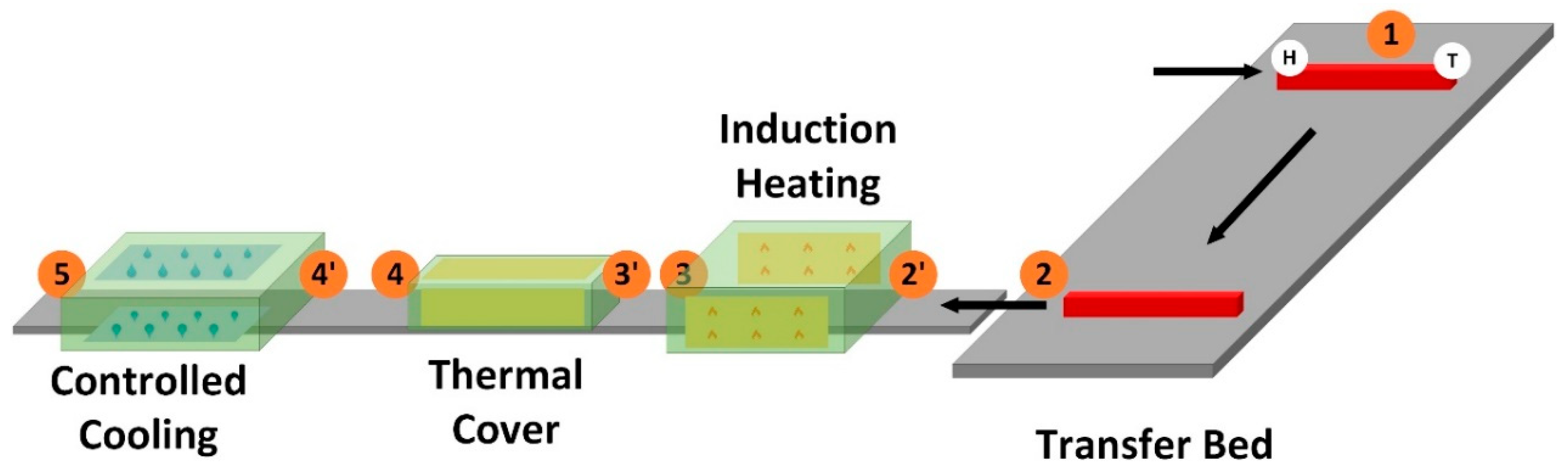

2.3. Transfer Bed

- Temperature at the entry and exit along the rail length;

- Duration at transfer bed;

- Transport speed.

2.4. Induction Heating

- Power injected by inductors;

- Temperature at the entry and exit of the induction section;

- Transport speed in specific inductors;

- Processing duration in specific inductors.

2.5. Cooling Section

- Water flow rates per zone and circuit;

- Fan speed and temperature;

- Speed in the cooling section;

- Duration in the cooling section;

- Temperatures in transition between zones;

- Temperatures at the entry and exit of the cooling section.

2.6. Straightener

- Rolling forces;

- Rolling speeds;

- Duration in the straightener.

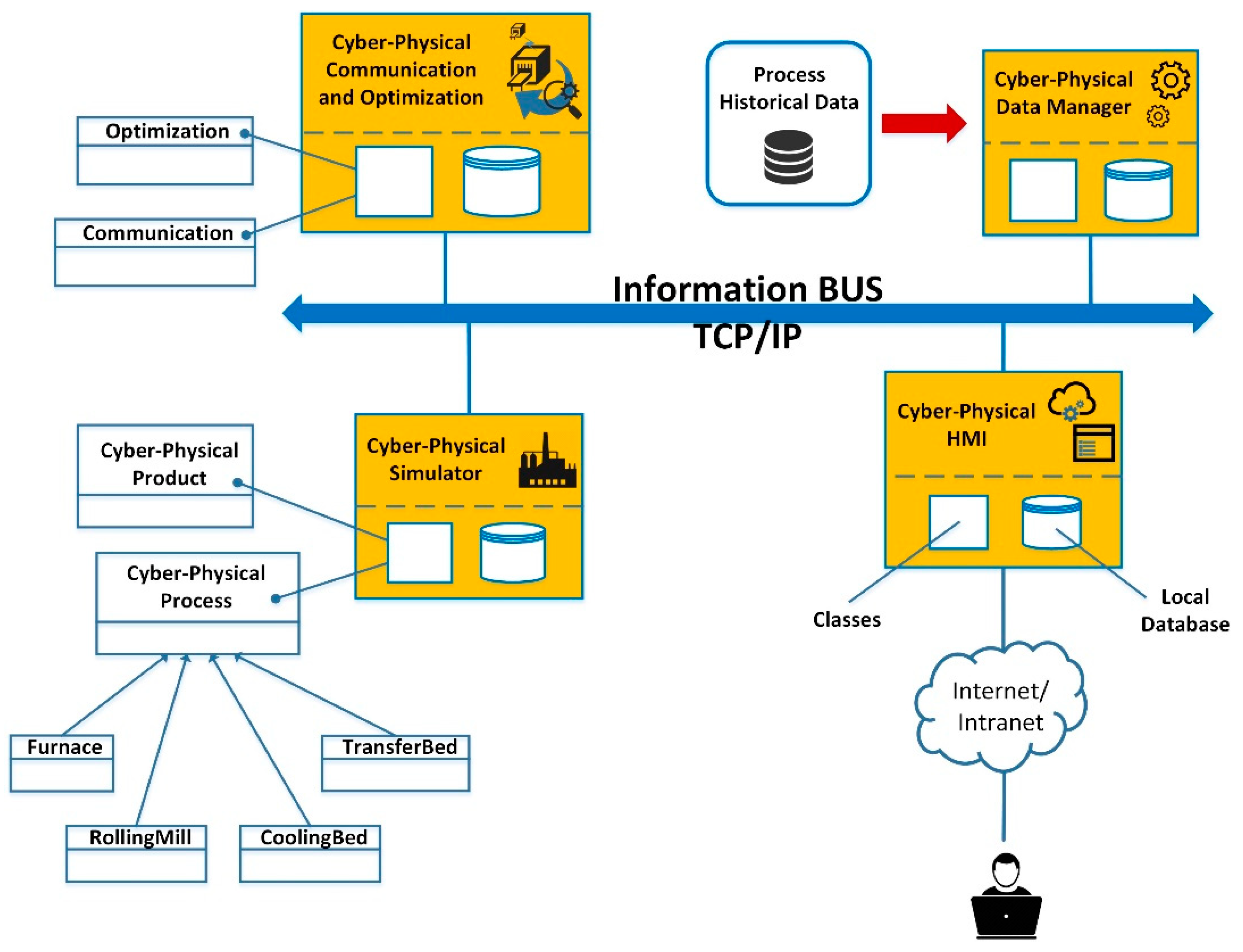

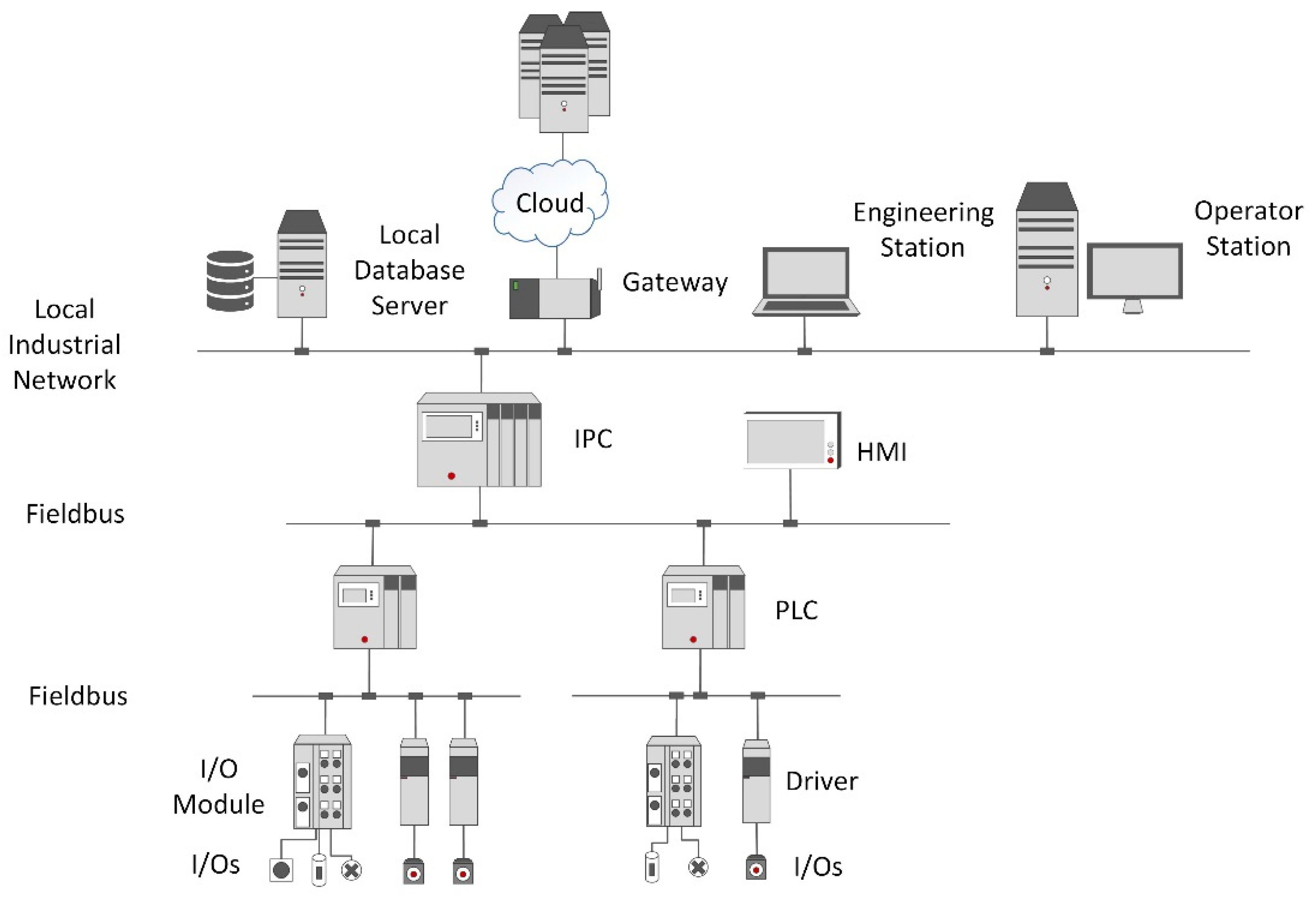

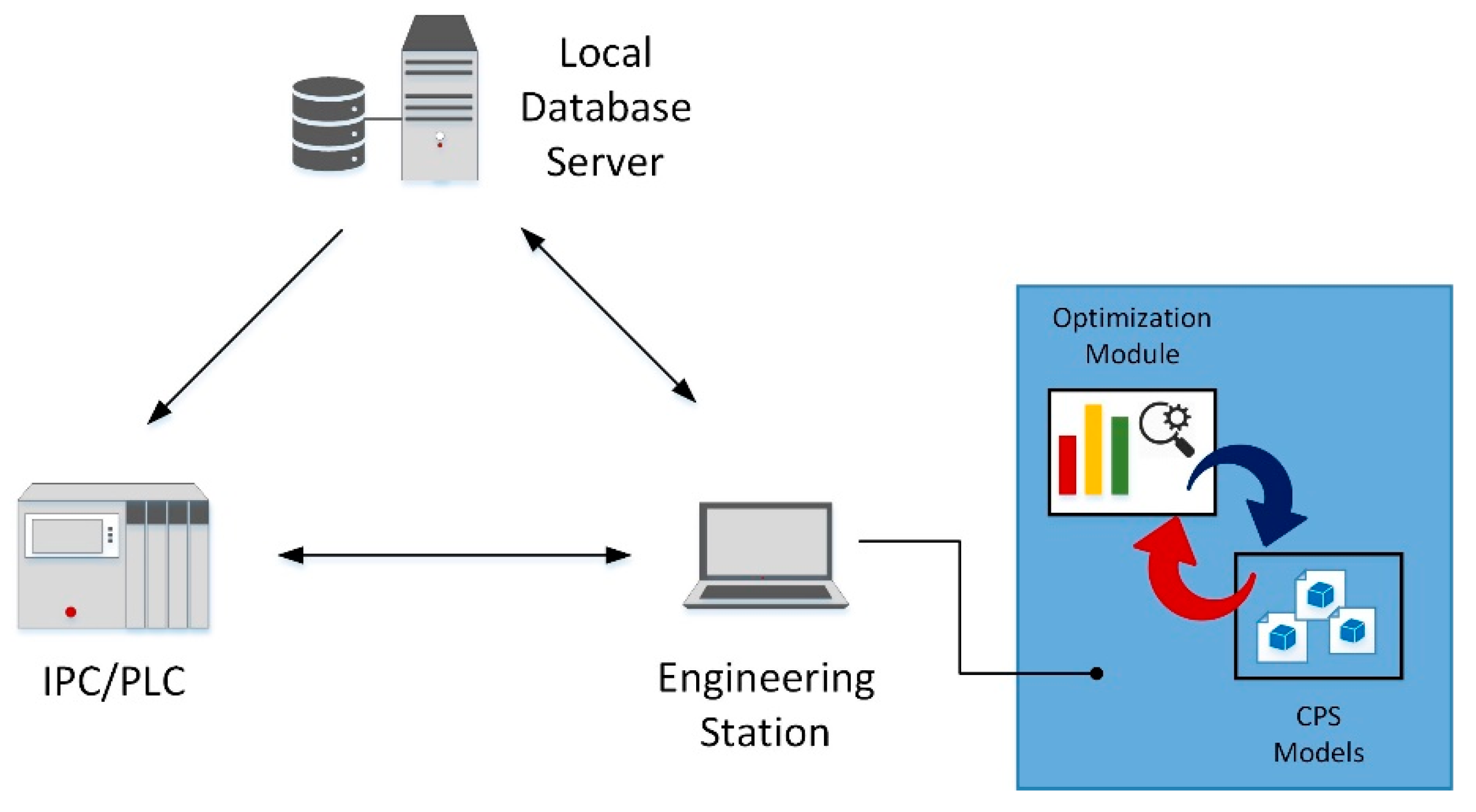

3. Cyber-Physical Production Optimization Systems Platform

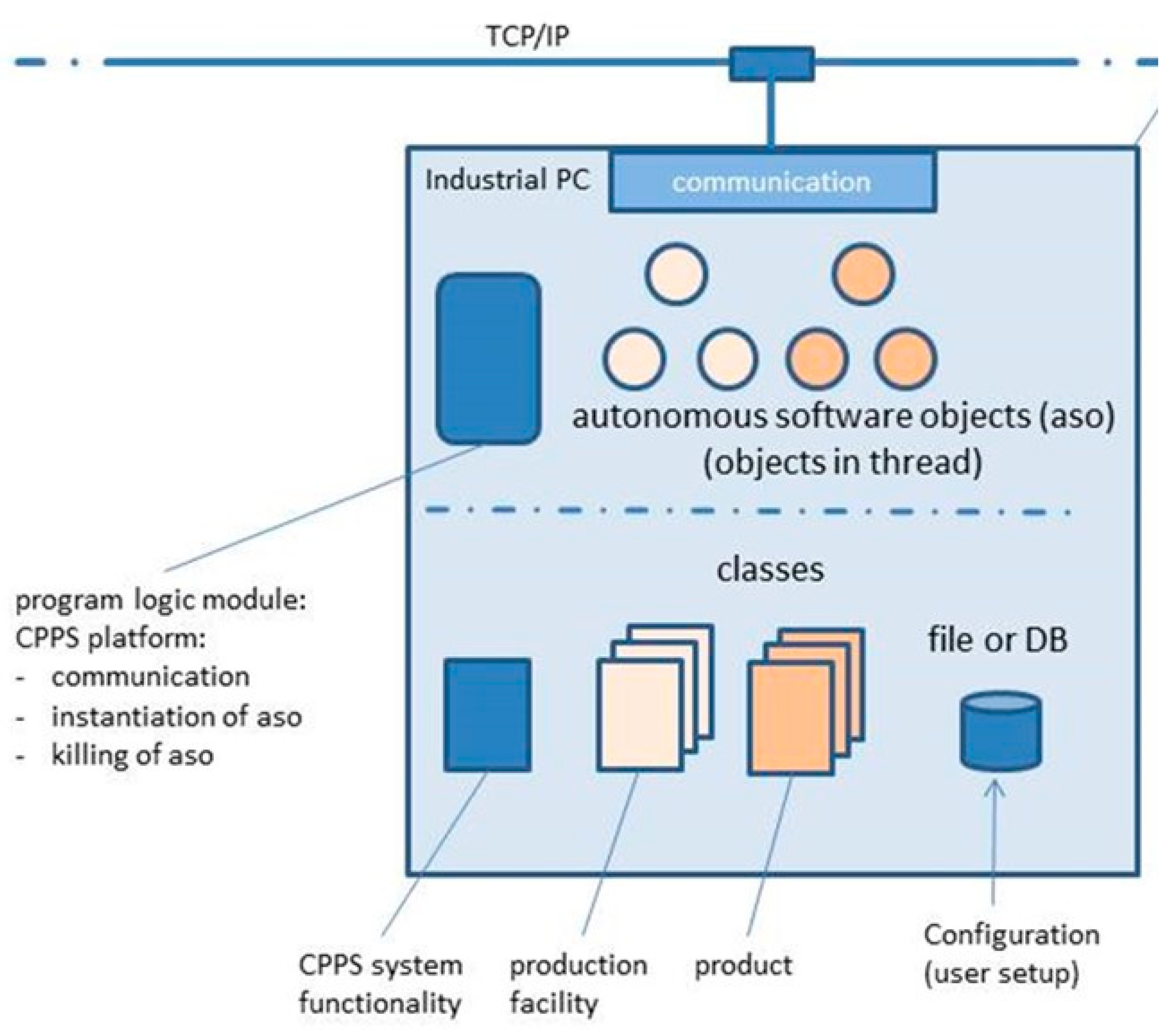

3.1. CPPS Architecture Design

- Integrated “garbage collection” system;

- Uses mainly advantages of real-time applicability from C++;

- Large standard libraries;

- Support of managed and integrated code blocks;

- Simple handling of DLL-implementation;

- Elegant implementation of properties and events;

- Integrated resource-management;

- High comfortability and integrity with Windows operating system;

- Simple definition of new data types;

- Possible integration of INTEL MKL library [21] for real-time processing;

- Elegant option for “embedded systems” for integration in industrial plants.

- Cyber-physical data management: A module containing functions devoted to the connection and querying of the database where historical process data are stored.

- Cyber-physical simulator: A module that runs plant simulations based on the status of the plant and a production plan provided by the user or by the cyber-physical communication and optimization module. The module is also composed of a cyber-physical product module and Cyber-physical process module. The first one enhances the product intelligence, it is continuously carried along by the respective product that is processed and includes product parameters, such as actual and target properties, logistic information regarding product process route, constraints, costs, etc. The second one implements the concept of the process line, the different sub-processes, such as the furnace, rolling mill, cooling, induction heating and transport are derived from this module.

- Cyber-physical communication and optimization: A module that provides the communication protocols between software modules and objects and is responsible for the overall through process global optimization based on multi-criteria strategies. Two sub-modules respectively implement communication and optimization separately.

- Cyber-physical Human Machine Interface (HMI): A module that shows all the relevant information of the modules (e.g., plant status, alarms, simulations and optimizations results, etc.) to the user. The module can be a web service or a local graphical user interface (GUI).

- Components and connectors for real-time monitoring and control.

- Architectural/physical models (thermal models, material-quality models, logistics/scheduling models).

- Elements for interaction between the cyber and the physical world.

3.2. Product Module

- Actual temperature profile:

- Actual properties (quality);

- Target properties;

- Control constraints (min/max temperature);

- Logistic information (previous, actual and following processing steps);

- Historical data.

3.3. Process Module

3.4. Communication and Optimization Module

3.4.1. Communication Module

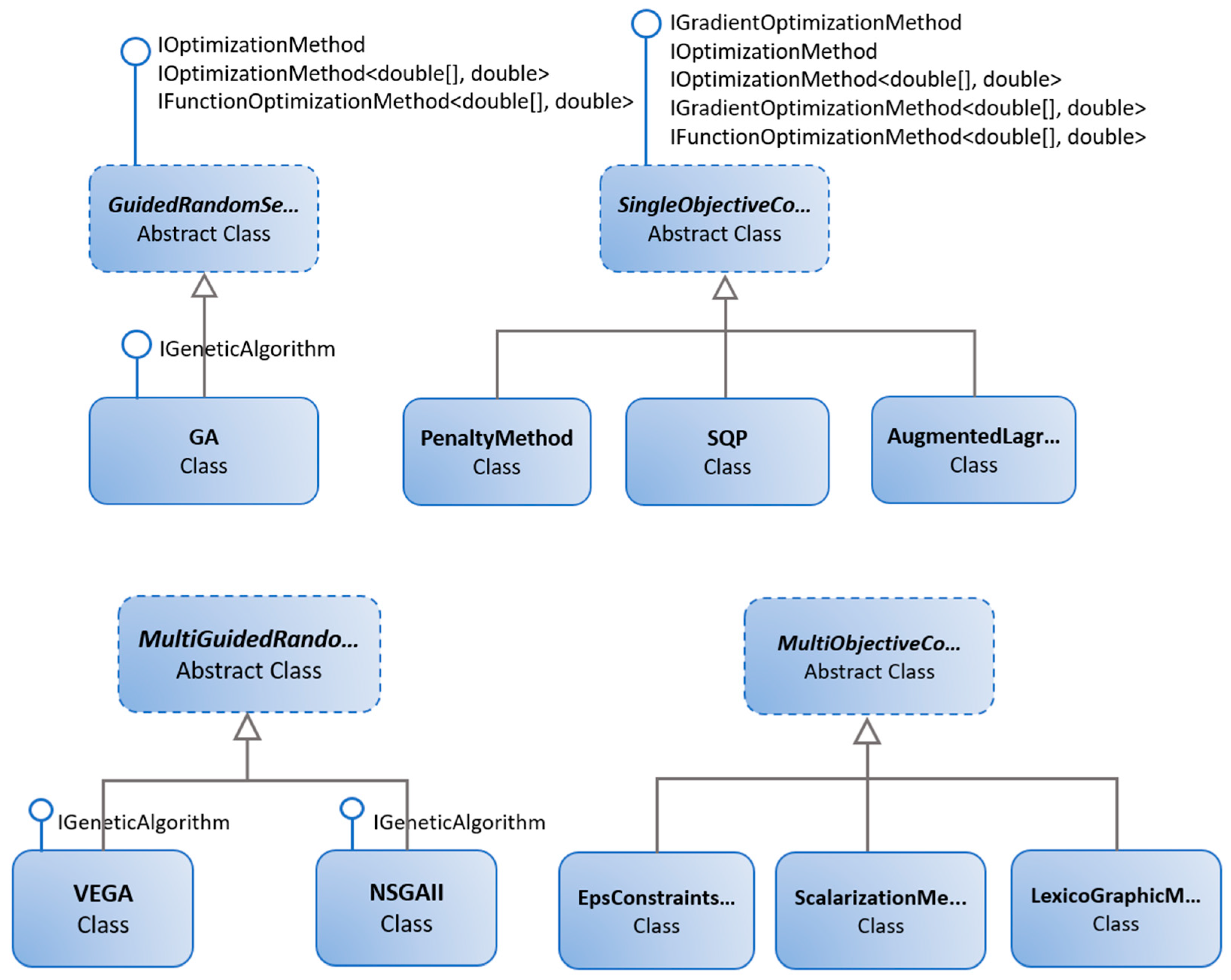

3.4.2. Optimization Module

- Penalty method: The constrained optimization is transformed into an unconstrained problem by penalizing the objective function for any violation of the constraints.

- Augmented Lagrangian method: A blend of both the penalty method and the Lagrangian multipliers method.

- Sequential quadratic programming (SQP) method: A quadratic subproblem is solved in every iteration where the objective function is approximated by a quadratic function and the constraints are linearized.

- Math.NET is an open-source initiative to build and maintain toolkits covering fundamental mathematics, targeting advanced as well as the daily needs of .Net developers. Some of the main libraries are Numerics, which aims at providing methods and algorithms for numerical computations in science, engineering and everyday use; Symbolics, a basic open-source computer algebra library; Filtering, which aims at providing a toolkit for digital signal processing; Spatial, which aims at becoming a geometry library.

- ALGLIB is a cross-platform numerical analysis and data processing library. It supports several programming languages (C++, C#, Delphi) and several operating systems (Windows and POSIX, including Linux). ALGLIB features include data analysis (e.g., classification/regression, statistics), optimization and nonlinear solvers, interpolation and linear/nonlinear least-squares fitting linear algebra (e.g., direct algorithms, Eigen Values Decomposition-EVD/Singular Value Decomposition-SVD), direct and iterative linear solvers, fast Fourier transform and many other algorithms.

- GeneticSharp.Net is a fast, extensible, multi-platform and multithreading C# genetic algorithm library that simplifies the development of applications using genetic algorithms (GAs). GeneticSharp.Net features include a definition of different kind of chromosomes (e.g., floating, integer, binary), fitness evaluation and population generation, several selection, mutation, crossover and reinsertion techniques, termination control.

- Accord.NET is a framework for scientific computing in .NET. The framework is comprised of multiple libraries encompassing a wide range of scientific computing applications, such as statistical data processing, machine learning, pattern recognition, including but not limited to, computer vision and computer audition. Some of the main libraries are Math, which contains a matrix extension library, along with a suite of numerical matrix decomposition methods, numerical optimization algorithms for constrained and unconstrained problems, special functions and other tools for scientific applications; Statistics, which contains probability distributions, statistical models and methods; MachineLearning, which contains techniques for regression, clustering and classification. Neuro which contains neural learning algorithms and neural network models.

- Single objective optimization algorithms. In particular, penalty method, augmented Lagrangian method, SQP and GA.

- Multi-objective optimization algorithms. In particular, scalarization method, lexicographic method, ε-constraint method, vector evaluated genetic algorithms (VEGA) and non-dominated sorting genetic algorithms II (NSGA-II).

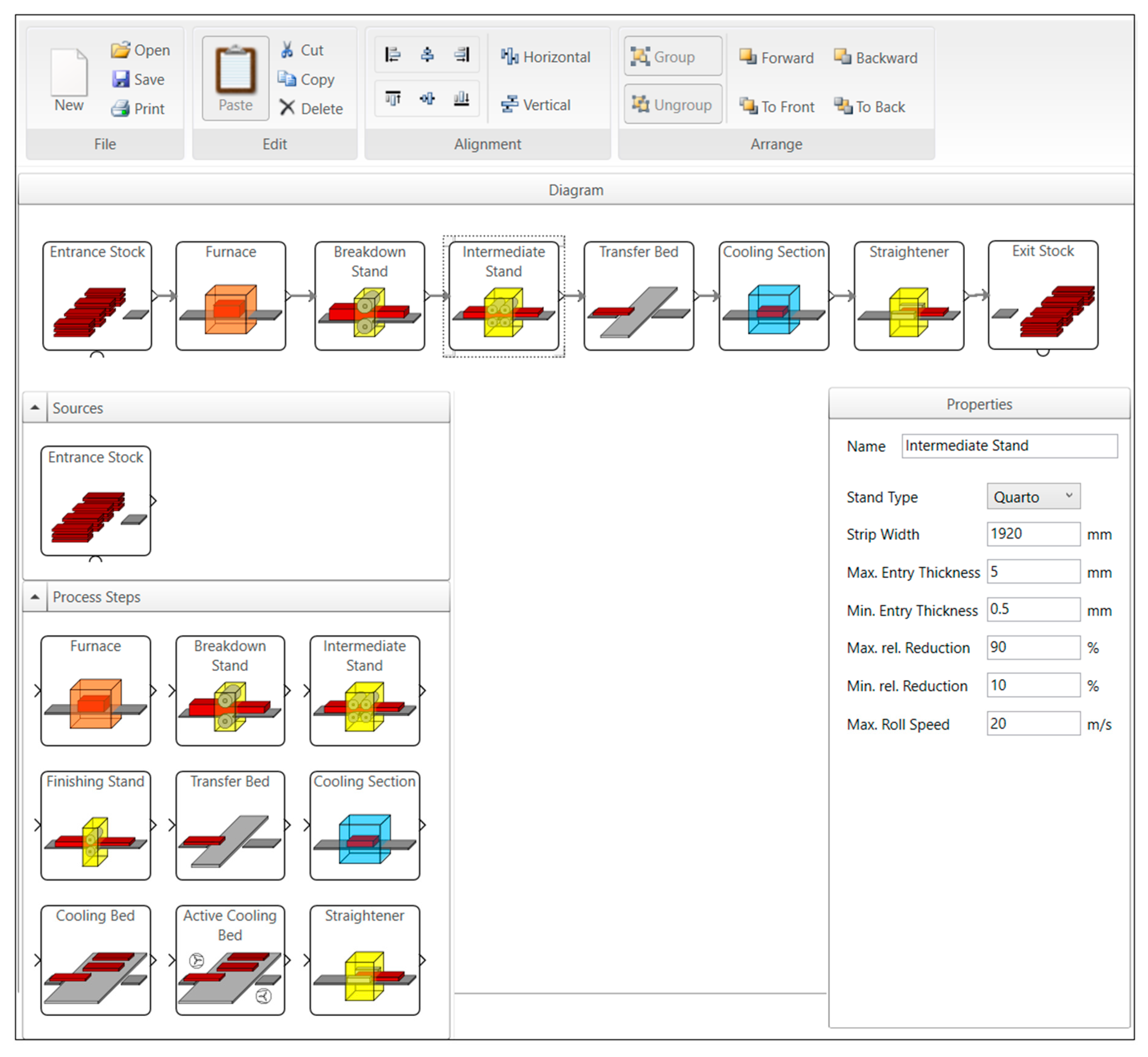

3.5. HMI Module

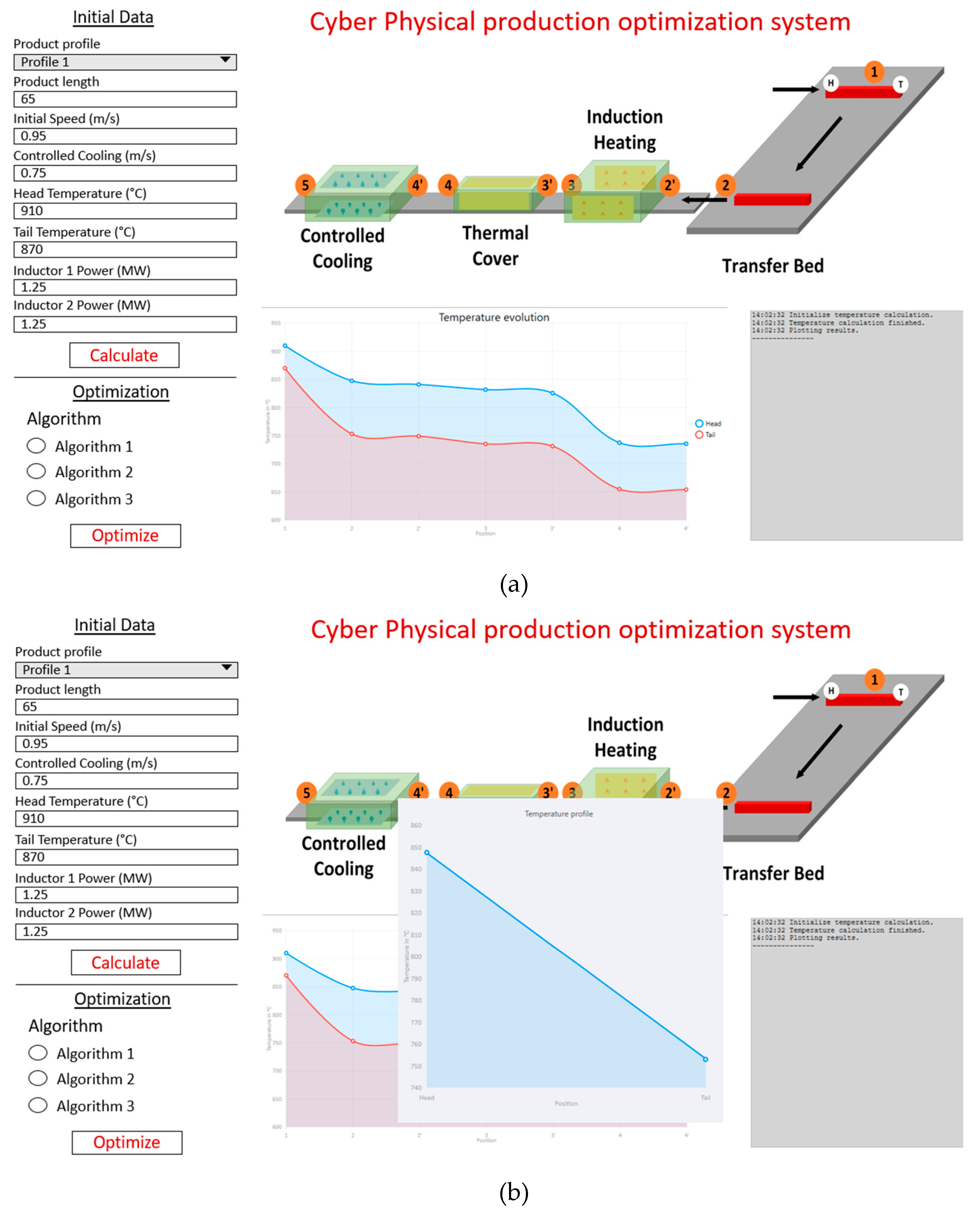

4. Results and Discussion

4.1. Induction-Heating System Optimization

- Transfer bed (1–2);

- Transport section with air cooling (2–2′);

- Induction furnace (2′–3);

- Transport section with air cooling (3–3′);

- Transport section covered by thermal insulator (3′–4);

- Transport section with air cooling (4–4′);

- Controlled cooling (4′–5).

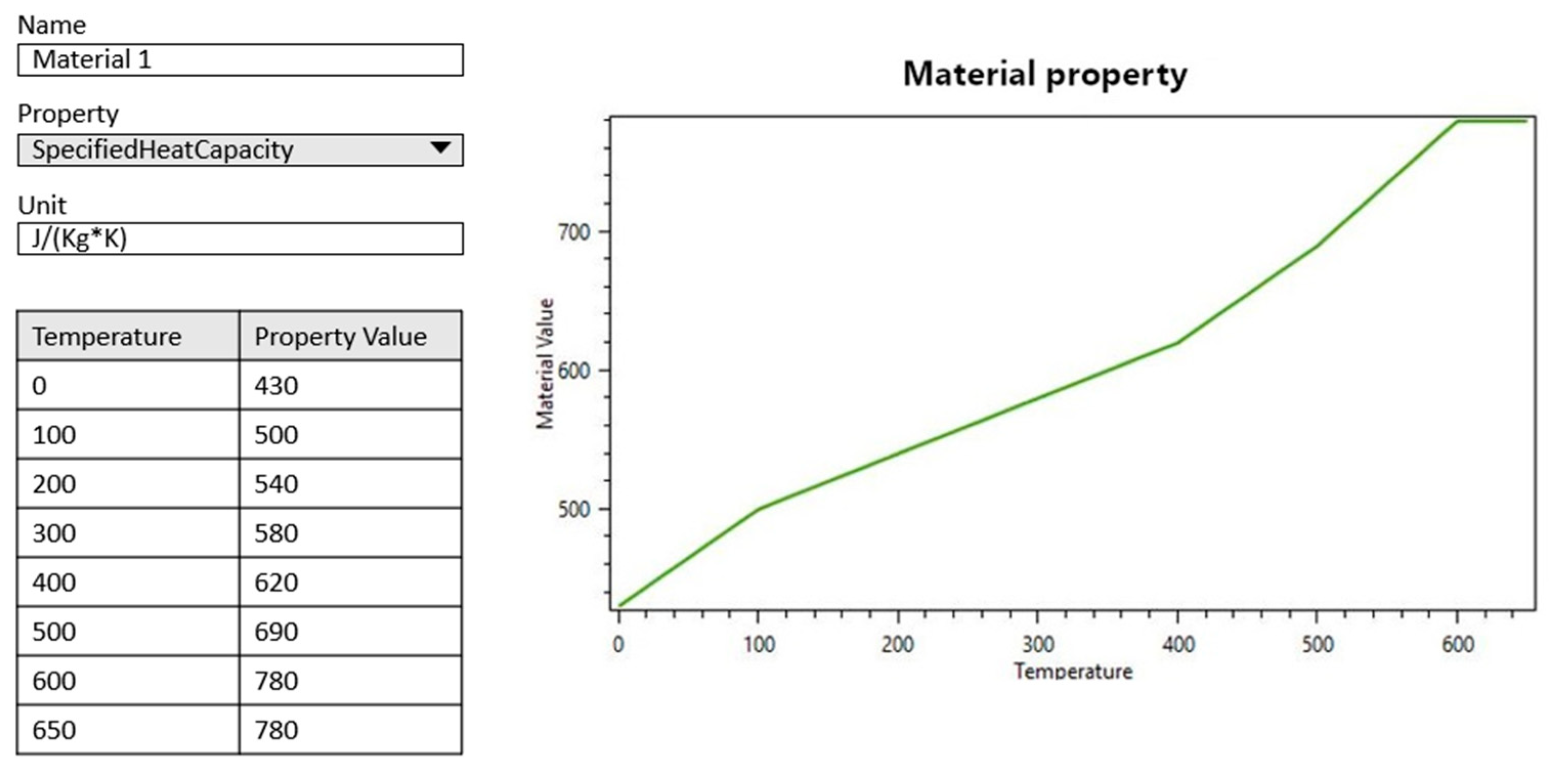

- Description of the geometry;

- Generation of the computing network;

- Definition of temperature-dependent material parameters;

- Definition of the thermal boundary conditions;

- Calculation of the thermal state of the useful material;

- Visualization of the results.

4.2. Setup Strategy for the Cyber-Physucal Production Optimization Systems

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online: https://ec.europa.eu/transparency/regdoc/rep/10102/2019/EN/SWD-2019-1-F1-EN-MAIN-PART-4.PDF (accessed on 23 July 2019).

- Biondi, M.; Saliba, S.; Harjunkoski, J. Production Optimization and Scheduling in a Steel Plant: Hot Rolling Mill. IFAC Proc. Vol. 2011, 44, 11750–11754. [Google Scholar] [CrossRef]

- Polzer, J.; Denker, J.; Hartman, H.G.; Lupinelli, M.; Martini, F.; Nastasi, G. Technology-Based Assistance System for Production Planning in Stainless Mills; European Union: Brussels, Belgium, 2015; ISBN 978-92-79-55072-0. [Google Scholar]

- Ema, L.; Peregrina, S.; Dischinger, N.; Queck, A.; Tavassi, M.; Murri, M.; Caporusso, R.A.; de la Fuente, D.; Helo, P. Optimisation of Stocks Management and Production Scheduling by Simulation of the Continuous Casting, Rolling and Finishing Departments; European Union: Brussels, Belgium, 2011; ISBN 978-92-79-20895-9. [Google Scholar]

- Yang, J.; Wang, B.; Zou, C.; Li, X.; Li, T.; Liu, Q. Optimal Charge Planning Model of Steelmaking Based on Multi-Objective Evolutionary Algorithm. Metals 2018, 8, 483. [Google Scholar] [CrossRef]

- Costa, P.; Altamirano, G.; Salinas, A.; González-González, D.S.; Goodwin, F. Optimization of the Continuous Galvanizing Heat Treatment Process in Ultra-High Strength Dual Phase Steels Using a Multivariate Model. Metals 2019, 9, 703. [Google Scholar] [CrossRef]

- Lee, A.; Seshia, A. Introduction to Embedded Systems, a Cyber-Physical Systems Approach, 2nd ed.; MIT Press: Cambridge, MA, USA, 2017; ISBN 978-0-262-53381-2. [Google Scholar]

- European Commission. Report from the Workshop on Cyber-Physical Systems: Uplifting Europe’s Innovation Capacity. Available online: http://ec.europa.eu/information_society/newsroom/cf/dae/document.cfm?doc_id=3948 (accessed on 22 July 2019).

- Monostori, L. Cyber-Physical Production Systems: Roots, Expectations and R&D Challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar]

- Engell, S.; Paulen, R.; Reniers, M.A.; Sonntag, C.; Thompson, H. Core Research and Innovation Areas in Cyber-Physical Systems of Systems. In Cyber Physical Systems. Design, Modeling, and Evaluation; Mousavi, M., Berger, C., Eds.; Springer: Cham, Switzerland, 2015; Volume 9361, ISBN 978-3-319-25140-0. [Google Scholar] [CrossRef]

- Leitão, P.; Barbosa, J.; Papadopoulou, M.E.; Venieris, I.S. Standardization in Cyber-Physical Systems: The ARUM Case. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 2988–2993. [Google Scholar] [CrossRef]

- acatech. Cyber Physical Systems—Driving force for innovation in mobility, health, energy and production. In Acatech POSITION PAPER; acatech, Ed.; Springer: Berlin, Germany, 2011; ISBN 978-3-642-29089-3. [Google Scholar] [CrossRef]

- Sun, J.; Peng, W.; Ding, J.; Li, X.; Zhang, D. Key Intelligent Technology of Steel Strip Production through Process. Metals 2018, 8, 597. [Google Scholar] [CrossRef]

- Iannino, V.; Vannocci, M.; Vannucci, M.; Colla, V.; Neuer, M. A Multi-Agent Approach for the Self-Optimization of Steel Production. Int. J. Simul. Syst. Sci. Technol. 2018, 19, 20:1–20:6. [Google Scholar] [CrossRef]

- Ebel, A.; Neuer, M.; Matskanis, N.; Mouton, S.; Marchiori, F.; Pietrosanti, C.; Papiez, A.; Rößiger, M.; Goldenberg, N.; Mathis, G.; et al. Integrated Intelligent Manufacturing for Steel Industries; European Union: Brussels, Belgium, 2017; ISBN 978-92-79-65607-1. [Google Scholar]

- Hoffmann, M.; Kreisköther, K.; Büscher, C.; Meisen, T.; Kampker, A.; Schilberg, D.; Jeschke, S. Optimized Factory Planning and Process Chain Formation Using Virtual Production Intelligence. In Enabling Manufacturing Competitiveness and Economic Sustainability; Zaeh, M., Ed.; Springer: Cham, Switzerland, 2014; pp. 153–158. ISBN 978-3-319-02053-2. [Google Scholar] [CrossRef]

- Arnu, D.; Yaqub, E.; Mocci, C.; Colla, V.; Neuer, M.; Fricout, G.; Renard, X.; Mozzati, C.; Gallinari, P. A Reference Architecture for Quality Improvement in Steel Production. In Data Science—Analytics and Applications; Haber, P., Lampoltshammer, T., Mayr, M., Eds.; Springer Vieweg: Wiesbaden, Germany, 2017; pp. 85–90. ISBN 978-3-658-19286-0. [Google Scholar]

- Shardt, Y.A.W.; Mehrkanoon, S.; Zhang, K.; Yang, X.; Suykens, J.; Ding, S.X.; Peng, K. Modelling the strip thickness in hot steel rolling mills using least-squares support vector machines. Can. J. Chem. Eng. 2018, 96, 171–178. [Google Scholar] [CrossRef]

- Delange, J.; Feiler, P. Incremental latency analysis of heterogeneous cyber-physical systems. In Proceedings of the 3rd IEEE International Workshop on Real-Time and Distributed Computing in Emerging Applications (RTSS), Rome, Italy, 2 December 2014. [Google Scholar]

- European Computer Manufacturers Association (ECMA). Standard ECMA-335: Common Language Infrastructure (CLI). Available online: https://www.ecma-international.org/publications/files/ECMA-ST/ECMA-335.pdf (accessed on 23 July 2019).

- Intel. Intel Math Kernel Library. Available online: https://software.intel.com/en-us/mkl (accessed on 23 July 2019).

- Fielding, R.T. Architectural Styles and the Design of Network-Based Software Architectures. Ph.D. Thesis, University of California, Irvine, CA, USA, 2000. [Google Scholar]

- European Computer Manufacturers Association (ECMA). Standard ECMA-262: ECMAScript 2016 Language Specification. Available online: https://www.ecma-international.org/publications/files/ECMA-ST/Ecma-262.pdf (accessed on 23 July 2019).

- World Wide Web Consortium (W3C). Extensible Markup Language (XML) 1.0 (5th Edition). Available online: https://www.w3.org/TR/xml/ (accessed on 23 July 2019).

- Bazaraa, M.S.; Sherali, H.D.; Shetty, C.M. Nonlinear Programming: Theory and Algorithms, 3rd ed.; Wiley: Hoboken, NJ, USA, 2006; ISBN 978-0-471-48600-8. [Google Scholar]

- Nocedal, J.; Wright, S. Numerical Optimization, 2nd ed.; Springer: New York, NY, USA, 2006; ISBN 978-0-387-30303-1. [Google Scholar] [CrossRef]

- Yang, X.-S. Engineering Optimization: An Introduction with Metaheuristic Applications; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-58246-6. [Google Scholar]

- Souza, C.R. The Accord.NET Framework. Available online: http://accord-framework.net (accessed on 23 July 2019).

- Giacomelli, D. GeneticSharp. Available online: https://github.com/giacomelli/GeneticSharp/ (accessed on 23 July 2019).

- Steinke, P. Finite-Elemente-Methode: Rechnergestützte Einführung, 5th ed.; Springer Vieweg: Wiesbaden, Germany, 2015. [Google Scholar]

- Denker, J.; Göttsche, M. Setup- and Furnace Control System for Hybrid Heating Systems for Flexibilizing and Improving Efficiency of the Process Industry (SmartHeating); Project Funded by EU and EFRE (Europäischer Fonds für Regionale Entwicklung); EU: Brussels, Belgium; EFRE: Brussels, Belgium, 2018. [Google Scholar]

- Steinböck, A. Model-Based Control and Optimization of a Continuous Slab Reheating Furnace; Shaker Verlag: Herzogenrath, Germany, 2011. [Google Scholar]

- Jankowski, T.A.; Pawley, N.H.; Gonzales, L.M.; Ross, C.A.; Jurney, J.D. Approximate analytical solution for induction heating of solid cylinders. Appl. Math. Model. 2016, 40, 2770–2782. [Google Scholar] [CrossRef]

- International Society of Automation ISA-95, Enterprise Control System Integration. Available online: https://www.isa.org/isa95/ (accessed on 23 July 2019).

| Variables | Barrier (MALAB) | GA (MATLAB) | Penalty (Opt. Module) | GA (Opt. Module) |

|---|---|---|---|---|

| 0.4416 | 0.4414 | 0.4416 | 0.4416 | |

| 0.4416 | 0.4418 | 0.4416 | 0.4416 | |

| 0 | 0 | 0 | 0.004 | |

| 0.11 | 0.18 | 0.04 | 0.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iannino, V.; Colla, V.; Denker, J.; Göttsche, M. A CPS-Based Simulation Platform for Long Production Factories. Metals 2019, 9, 1025. https://doi.org/10.3390/met9101025

Iannino V, Colla V, Denker J, Göttsche M. A CPS-Based Simulation Platform for Long Production Factories. Metals. 2019; 9(10):1025. https://doi.org/10.3390/met9101025

Chicago/Turabian StyleIannino, Vincenzo, Valentina Colla, Joachim Denker, and Marc Göttsche. 2019. "A CPS-Based Simulation Platform for Long Production Factories" Metals 9, no. 10: 1025. https://doi.org/10.3390/met9101025

APA StyleIannino, V., Colla, V., Denker, J., & Göttsche, M. (2019). A CPS-Based Simulation Platform for Long Production Factories. Metals, 9(10), 1025. https://doi.org/10.3390/met9101025