Research on the Friction Stir Welding of Sc-Modified AA2519 Extrusion

Abstract

1. Introduction

2. Materials and Methods

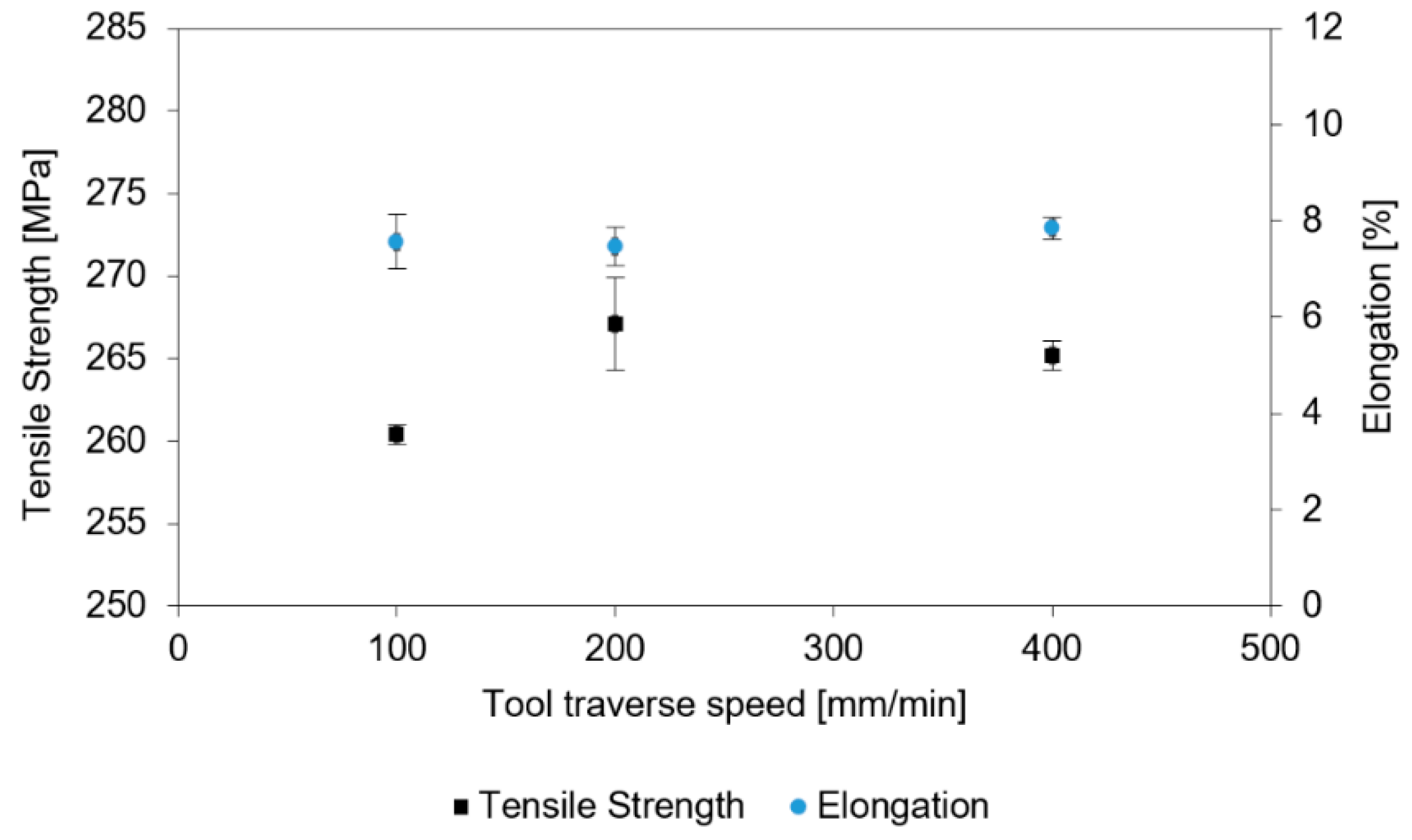

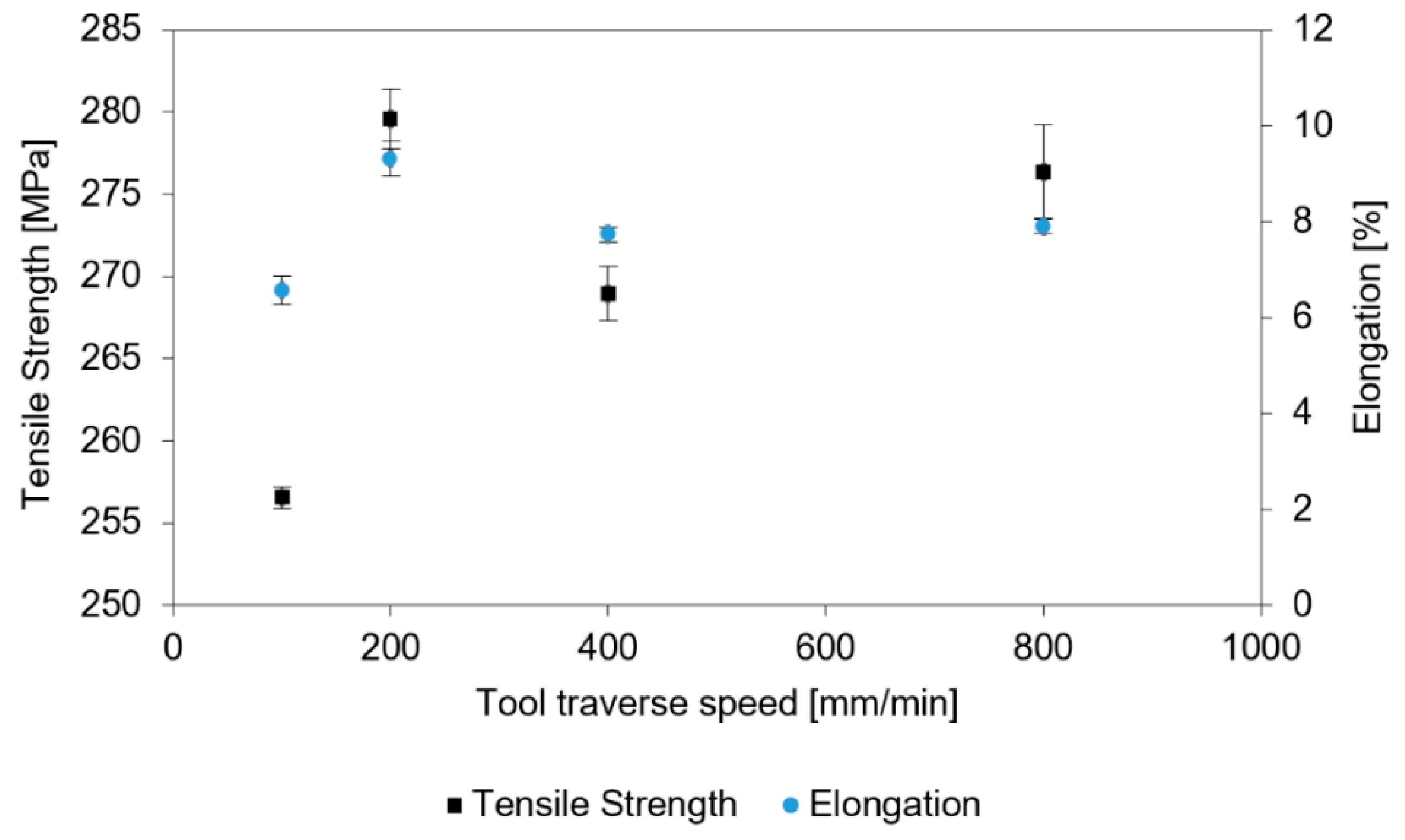

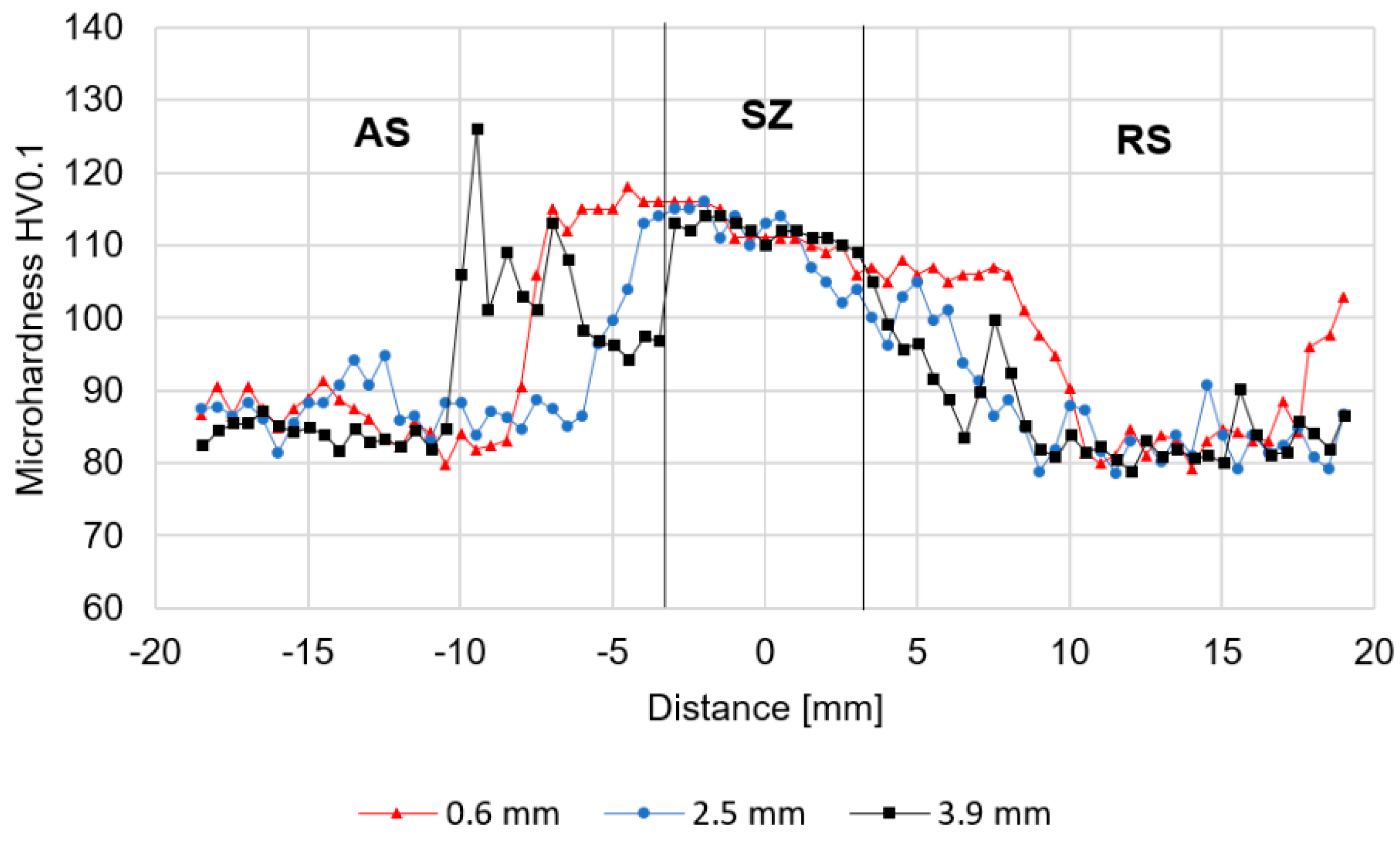

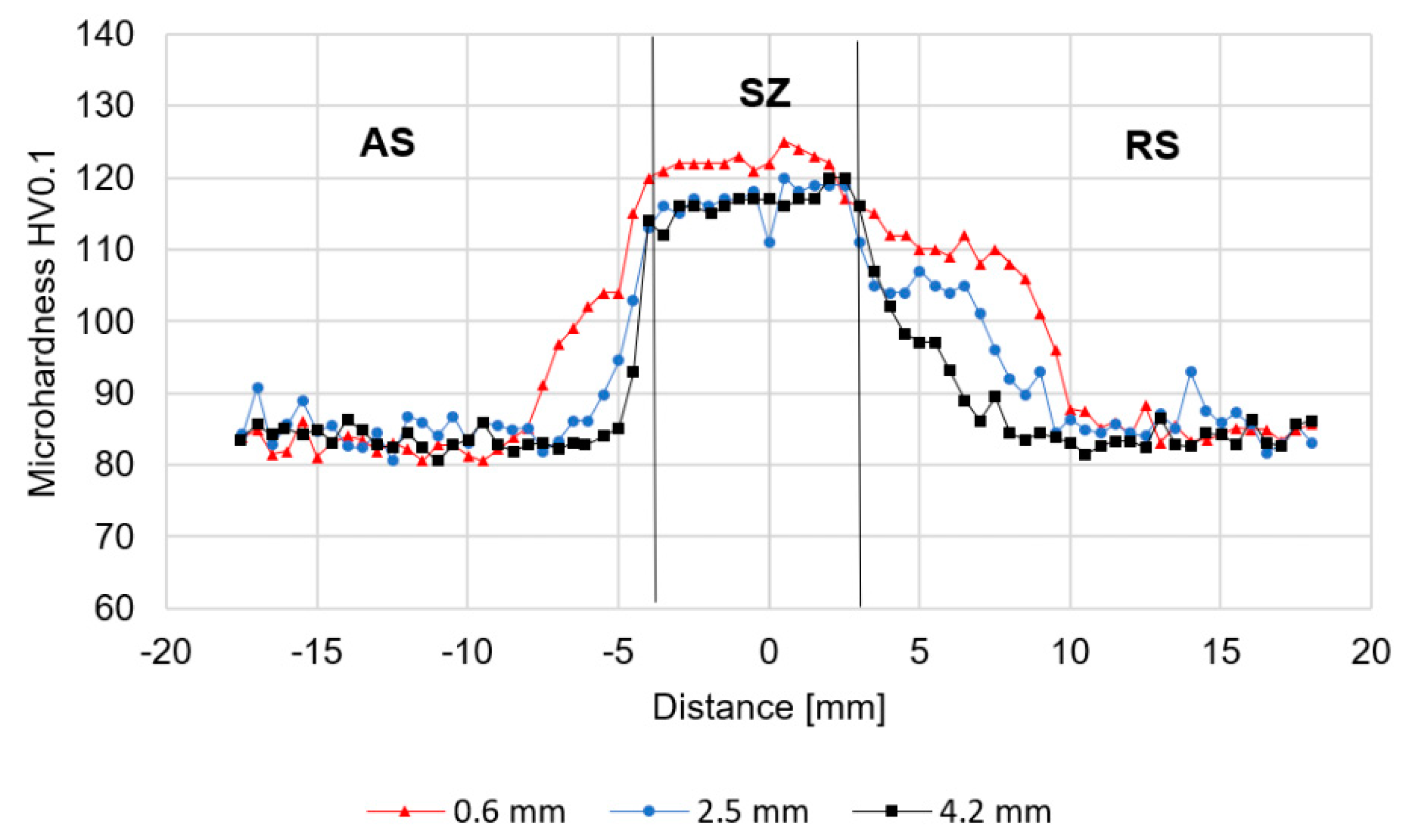

3. Results and Discussion

4. Conclusions

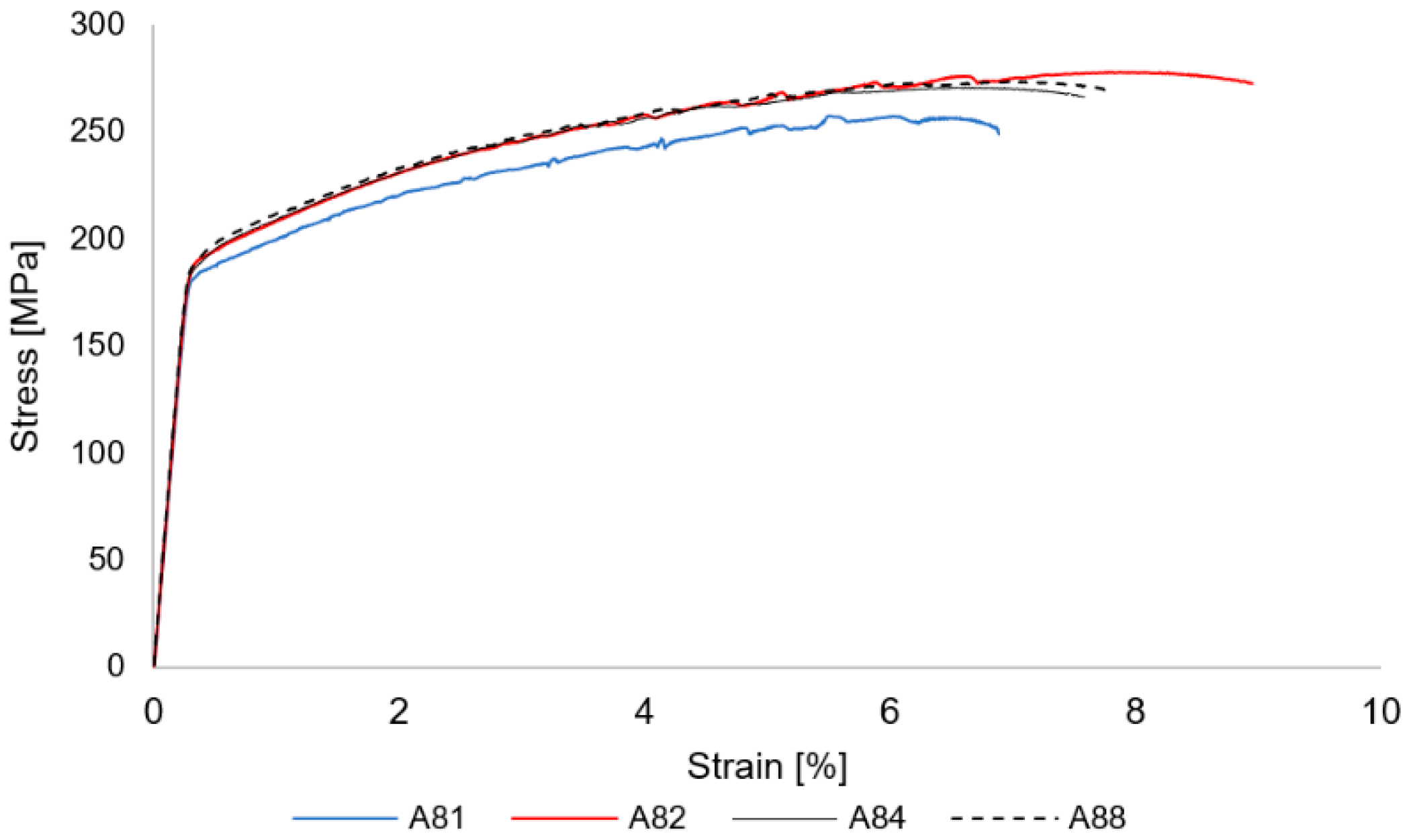

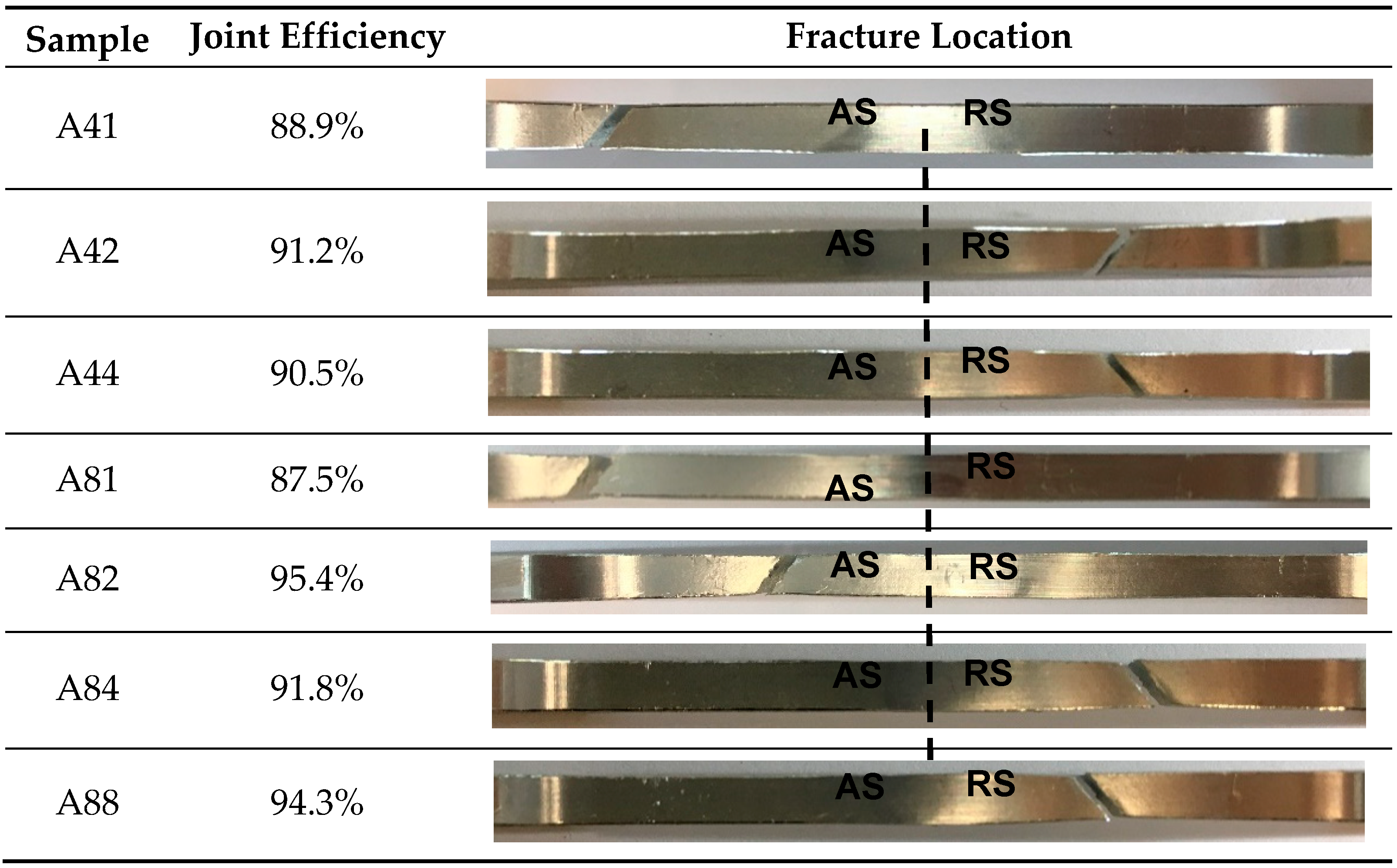

- Friction stir welding allows to obtain a high-quality joint of non-heat-treated Sc-modified AA2519 with the joint efficiency reaching 87–95%.

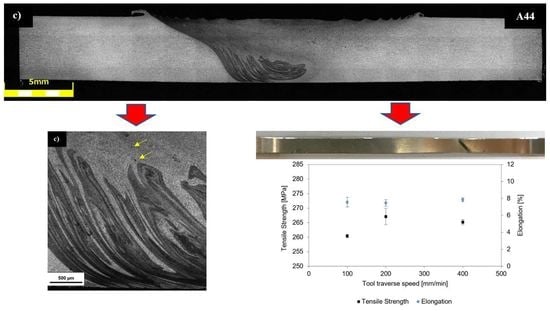

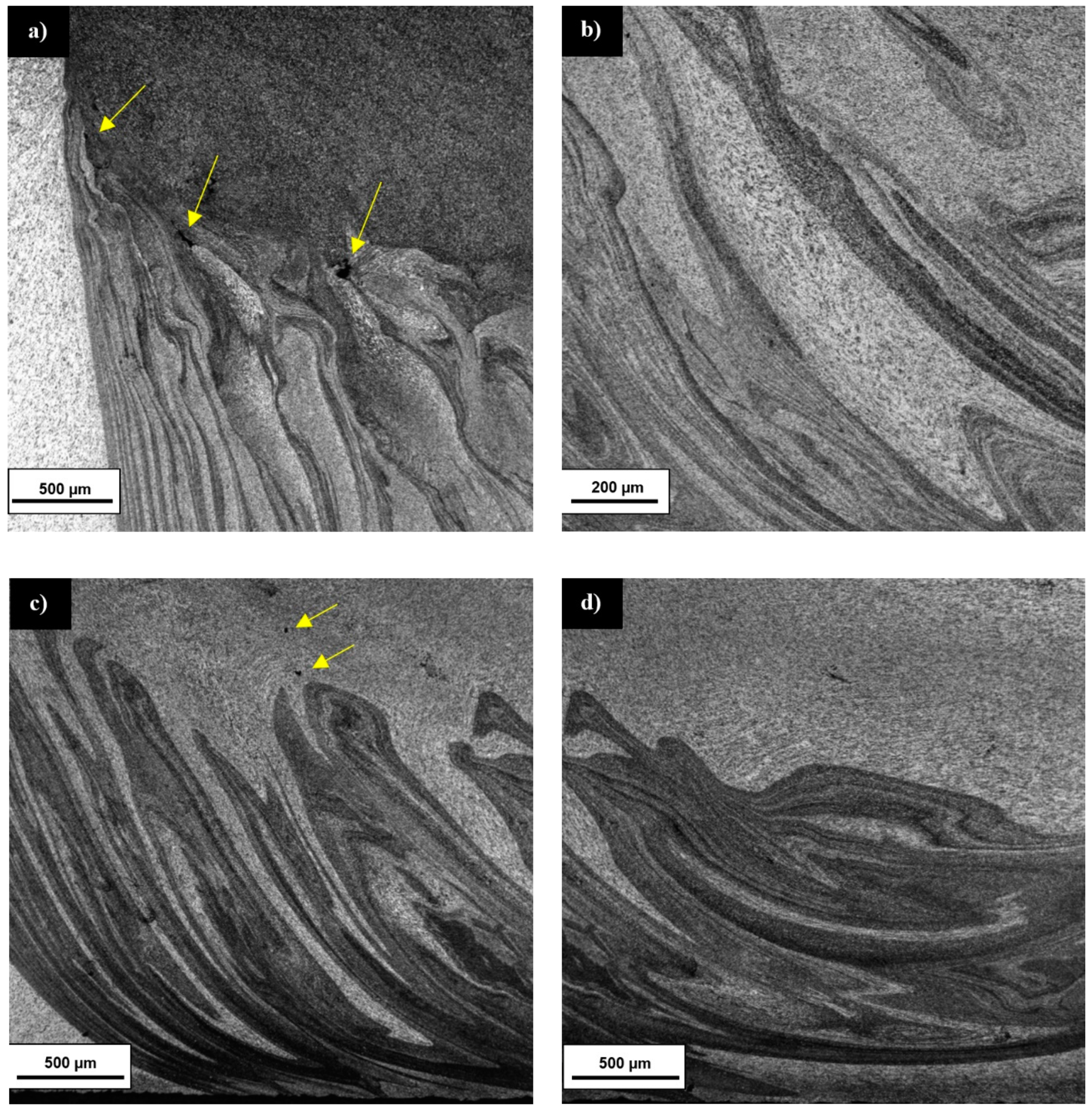

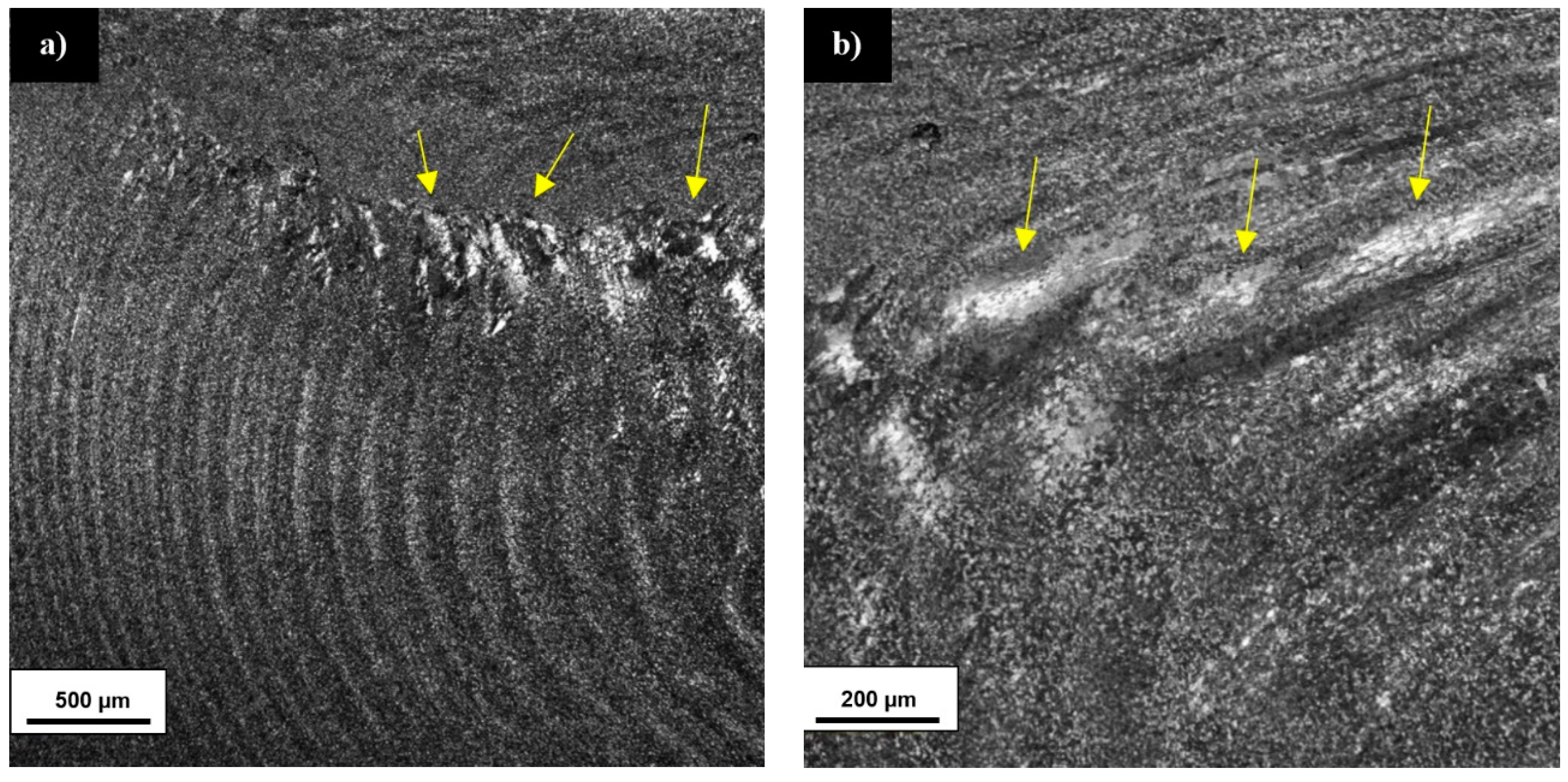

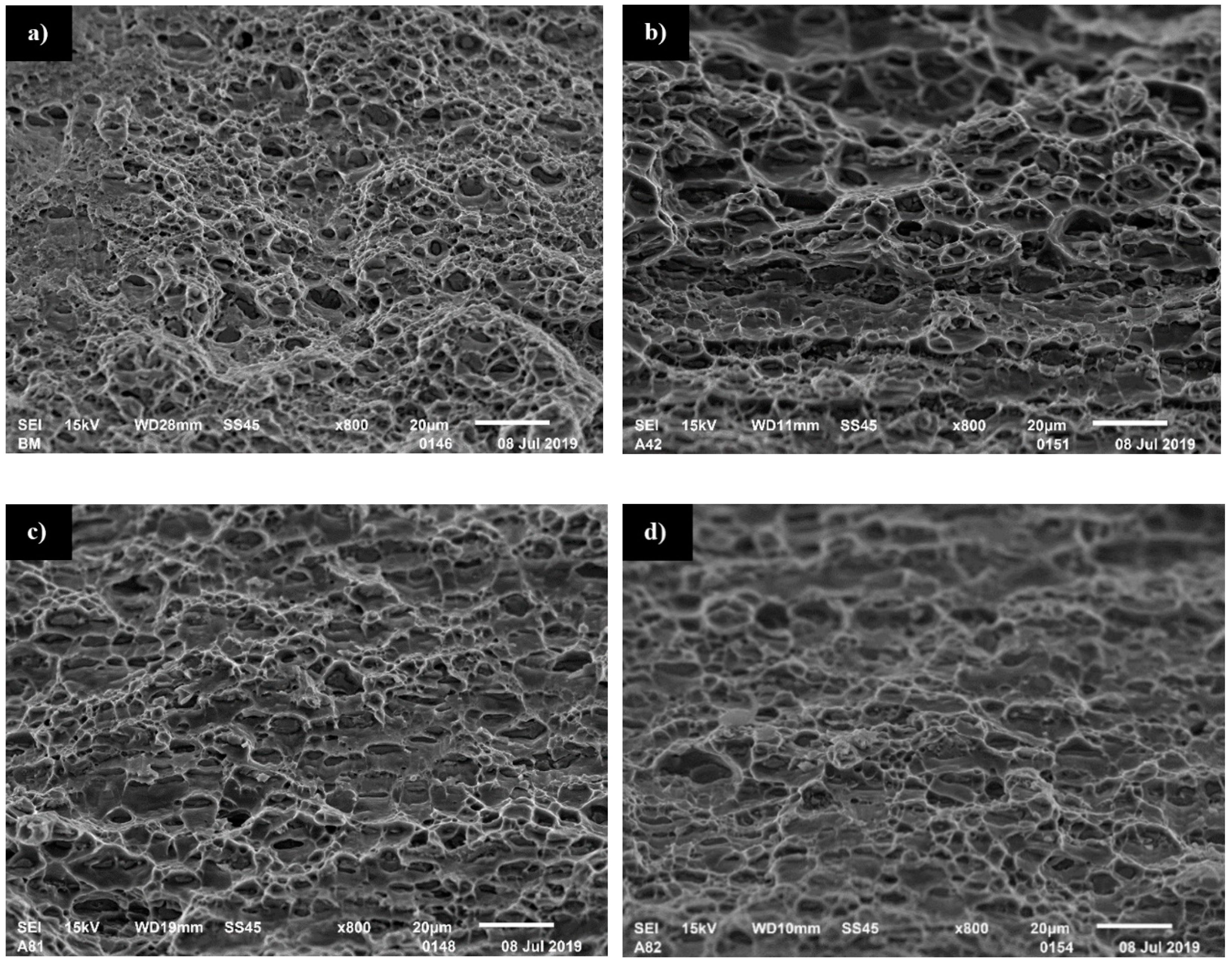

- The microstructure of the stir zone performed with the low ratio of the tool rotation speed to the tool traverse speed is characterized by the presence of defects (voids) and areas of deformed non-recrystallized grains.

- As the result of dynamic recrystallization, the microhardness of the joined material value of 86 HV0.1 increased to about 110–125 HV0.1 in the stir zone depending on the used welding parameters.

- Due to lack of the strengthening phase and low strain hardening of used alloy, the heat-affected zone is difficult to identify. The investigation of the fractured samples confirmed no presence of a significantly softened zone.

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, R.S.; Mahoney, M.W. Friction Stir Welding and Processing; ASM International: Materials Park, OH, USA, 2007; ISBN 978-0-87170-840-3. [Google Scholar]

- Radisavljevic, I.; Zikovic, A.; Radovic, N.; Grabulov, V. Influence of FSW parameters on formation quality and mechanical properties of Al 2042–T351 butt welded joints. Trans. Nonferrous Met. Soc. China 2013, 23, 3525–3539. [Google Scholar] [CrossRef]

- Çam, G.; Mistikoglu, S. Recent Developments in Friction Stir Welding of Al-alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Cabibbo, M.; Paoletti, C.; Ghat, M.; Archimede, F.; Simoncini, M. Post-FSW Cold-Rolling Simulation of ECAP Shear Deformation and Its Microstructure Role Combined to Annealing in a FSWed AA5754 Plate Joint. Materials 2019, 12, 1536. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wang, W.; Jin, X.; Rong, C.; Qin, Z. A Study on Microstructure and Mechanical Properties of Micro Friction Stir Welded Ultra-Thin Al-1060 Sheets by the Shoulderless Tool. Metals 2019, 9, 507. [Google Scholar] [CrossRef]

- Vijayakumar, S.; Balaji, J.; Ramesh, S.; Prince, L. Assessment of Microstructure and Mechanical Properties of Stir Zone Seam of Friction Stir Welded Magnesium AZ31B through Nano-SiC. Materials 2019, 12, 1044. [Google Scholar] [CrossRef]

- Ren, D.; Zeng, F.; Liu, Y.; Liu, L.; He, Z. Friction Stir Welding of 5754 Aluminum Alloy with Cover Sheet. Materials 2019, 12, 1765. [Google Scholar] [CrossRef] [PubMed]

- Barabi, A.; Zarei Hanzaki, A.; Abedi, Hamid, R.; Anoushe, A.; Cho, J. The Correlation of Macrostructure, Microstructure, and Texture with Room Temperature Mechanical Properties of a Twinning-Induced Plasticity Automotive Steel after Friction Stir Spot Welding/Processing. Steel Res. Int. 2018, 89, 1800245. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M. Effect of the Tool Tilt Angle on the Heat Generation and the Material Flow in Friction Stir Welding. Metals 2019, 9, 28. [Google Scholar] [CrossRef]

- Kosturek, R.; Śnieżek, L.; Wachowski, M.; Torzewski, J. The Influence of Post-Weld Heat Treatment on the Microstructure and Fatigue Properties of Sc-Modified AA2519 Friction Stir-Welded Joint. Materials 2019, 12, 583. [Google Scholar] [CrossRef]

- Kosturek, R.; Wachowski, M.; Ślęzak, T.; Śnieżek, L.; Mierzyński, J.; Sobczak, U. Research on the friction stir welding of Titanium Grade 1. In Proceedings of the International Conference on Advanced Functional Materials and Composites (ICAFMC2018), MATEC Web of Conferences 242, Barcelona, Spain, 5–6 September 2018. [Google Scholar]

- Schaffer, G.B.; Sercombe, T.B.; Lumley, R.N. Liquid phase sintering of aluminium alloys. Mater. Chem. Phys. 2001, 67, 85–91. [Google Scholar] [CrossRef]

- Gödecke, T.; Sommer, F. Solidification behavior of the Al2Cu phase. Zeitschrift für Metallkunde 1996, 87, 581–586. [Google Scholar]

- Häusler, I.; Schwarze, C.; Bilal, M.; Ramirez, D.; Hetaba, W.; Kamachali, R.; Skrotzki, B. Precipitation of T1 and θ′ Phase in Al-4Cu-1Li-0.25Mn During Age Hardening: Microstructural Investigation and Phase-Field Simulation. Materials 2017, 10, 117. [Google Scholar] [CrossRef] [PubMed]

- Gündüz, M.; Çadırlı, E. Directional solidification of aluminium–copper alloys. Mater. Sci. Eng. A Struct. 2002, 327, 167–185. [Google Scholar] [CrossRef]

- Stoichev, N.V.; Yaneva, S.B.; Regel, L.L.; Videnskiy, I.V. Eutectic solidification of Al–Cu alloys influenced by convection. Adv. Space Res. 1998, 8, 171–174. [Google Scholar] [CrossRef]

- Sinha, V.C.; Kundu, S.; Chatterjee, S. Microstructure and mechanical properties of similar and dissimilar joints of aluminium alloy and pure copper by friction stir welding. Perspect. Sci. 2016, 8, 543–546. [Google Scholar] [CrossRef]

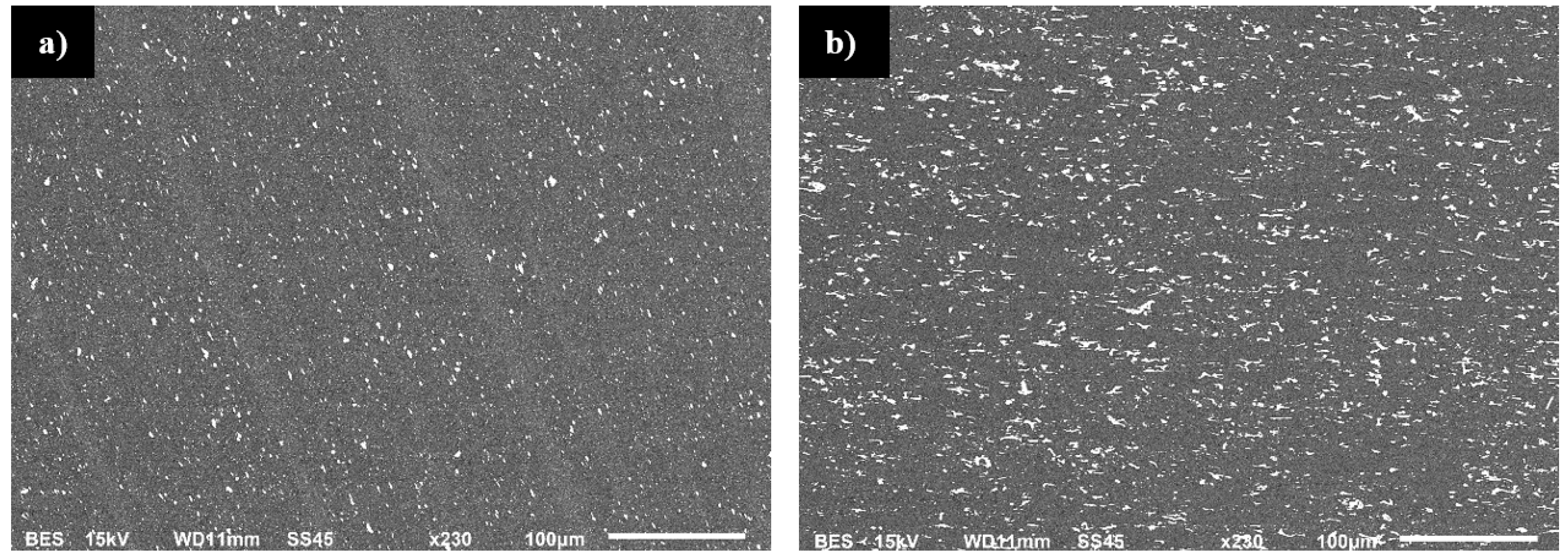

- Cao, G.; Kou, S. Friction Stir Welding of 2219 Aluminum: Behavior of (Al2Cu) particles. Weld. J. 2005, 84, 1–7. [Google Scholar]

- Hsu, C.J.; Kao, P.W.; Ho, N.J. Ultrafine-grained Al–Al2Cu composite produced in situ by friction stir processing. Scr. Mater. 2005, 53, 341–345. [Google Scholar] [CrossRef]

- Liang, X.; Li, H.; Li, Z.; Hong, T.; Ma, B.; Liu, S.; Liu, Y. Study on the microstructure in a friction stir welded 2519-T87 Al alloy. Mater. Des. 2012, 35, 603–608. [Google Scholar] [CrossRef]

- Rao, C.V.; Reddy, G.M.; Rao, K.S. Microstructure and pitting corrosion resistance of AA2219 Al–Cu alloy friction stir welds—Effect of tool profile. Def. Technol. 2015, 11, 123–131. [Google Scholar] [CrossRef]

- Babu, S.; Elangovan, K.; Balasubramanian, V. Optimizing friction stir welding parameters to maximize tensile strength of AA2219 aluminum alloy joints. Met. Mater. Int. 2009, 15, 321–330. [Google Scholar] [CrossRef]

- Starke, E.A., Jr.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Fisher, J.; James, J. Aluminum alloy 2519 in military vehicles. Mater. Sci. Forum 2002, 160, 43–46. [Google Scholar]

- Wachowski, M.; Kosturek, R.; Śnieżek, L.; Mróz, S.; Gloc, M.; Krawczyńska, A.; Malek, M. Analysis of the microstructure of an AZ31/AA1050/AA2519 laminate produced using the explosive-welding method. Mater. Tehnol. 2019, 53, 239–243. [Google Scholar] [CrossRef]

- Wachowski, M.; Fras, T.; Kosturek, R.; Śnieżek, L.; Szachogluchowicz, I.; Grzelak, K. The Effect of Hypervelocity Impact Loading on Explosively Welded Ti/Al/Al Plate. In Proceedings of the 2018 International Conference on Materials Science and Manufacturing Engineering (MSME 2018), Paris, France, 8–10 November 2018; Volume 253. [Google Scholar]

- Zakharov, V.V. Combined alloying of aluminium alloys with scandium and zirconium. Met. Sci. Heat Treat. 2014, 56, 281–286. [Google Scholar] [CrossRef]

- Davydov, V.G.; Elagin, V.I.; Zakharov, V.V.; Rostova, T.D. Alloying aluminium alloys with scandium and zirconium additives. Met. Sci. Heat Treat. 1996, 38, 347–352. [Google Scholar] [CrossRef]

- Zakharov, V.V. Effect of Scandium on the structure and properties of aluminium alloys. Met. Sci. Heat Treat. 2003, 45, 246. [Google Scholar] [CrossRef]

- Jia, Z.H.; Røyset, J.; Solberg, J.K.; Liu, Q. Formation of precipitates and recrystallization resistance in Al–Sc–Zr alloys. Trans. Nonferrous Met. Soc. China 2012, 22, 1866–1871. [Google Scholar] [CrossRef]

- Feng, J.C.; Chen, Y.; Liu, H. Effects of post-weld heat treatment on microstructure and mechanical properties of friction stir welded joints of 2219-O aluminium alloy. Mater. Sci. Eng. A Struct. 2006, 22, 86–90. [Google Scholar] [CrossRef]

- Suenger, S.; Kreissle, M.; Kahnert, M.; Zaeh, M.F. Influence of Process Temperature on Hardness of Friction Stir Welded High Strength Aluminum Alloys for Aerospace Applications. Procedia CIRP 2014, 24, 120–124. [Google Scholar] [CrossRef]

- Khan, N.Z.; Bajaj, D.; Siddiquee, A.N.; Khan, Z.A.; Abidi, M.H.; Umer, U.; Alkhalefah, H. Investigation on Effect of Strain Rate and Heat Generation on Traverse Force in FSW of Dissimilar Aerospace Grade Aluminium Alloys. Materials 2019, 12, 1641. [Google Scholar] [CrossRef]

- Sajuri, Z.; Selamat, N.M.; Baghdadi, A.H.; Kokabi, A.H.; Junaidi, S. Effect of Rolling on Strength of Friction Stir Welded Joint of Aluminium Alloys. Jurnal Kejuruteraan SI 2018, 1, 9–15. [Google Scholar] [CrossRef]

- Mehtedi, M.E.; Archimede, F.; Panaccio, L.; Simoncini, M. Design of Stamping Processes of Pinless FSWed Thin Sheets in AA1050 Alloy for Motomotive Applications Using FEM. Procedia Eng. 2017, 183, 213–218. [Google Scholar] [CrossRef]

- Simoncini, M.; Archimede, F.; Panaccio, L. Bending and Stamping Processes of FSWed Thin Sheets in AA1050 Alloy. Key Eng. Mater. 2014, 622–623, 459–466. [Google Scholar] [CrossRef]

- Haghshenas, M.; Gerlich, A.P. Joining of automotive sheet materials by friction-based welding methods: A review. Eng. Sci. Technol. Int. J. 2018, 21, 130–148. [Google Scholar] [CrossRef]

- De Filippis, L.; Serio, L.; Palumbo, D.; De Finis, R.; Galietti, U. Optimization and characterization of the Friction Stir Welded Sheets of AA 5754-H111: Monitoring of the quality of joints with thermographic techniques. Materials 2017, 9, 122. [Google Scholar] [CrossRef] [PubMed]

- De Filippis, L.A.C.; Serio, L.M.; Facchini, F.; Mummolo, G.; Ludovico, A.D. Prediction of the Vickers Microhardness and Ultimate Tensile Strength of AA5754 H111 Friction Stir Welding Butt Joints Using Artificial Neural Network. Materials 2016, 9, 915. [Google Scholar] [CrossRef] [PubMed]

- Tamjidy, M.; Hang Tuah Baharudin, B.T.; Paslar, S.; Matori, K.A.; Sulaiman, S.; Fadaeifard, F. Multi-Objective Optimization of Friction Stir Welding Process Parameters of AA6061-T6 and AA7075-T6 Using a Biogeography Based Optimization Algorithm. Materials 2017, 10, 533. [Google Scholar] [CrossRef]

- Padhy, G.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Seung-Ju, S.; Jungseok, K.; Woo, L.; Jae Yong, L.; Yohan, G.; Young, K. Influence of Friction Stir Welding on Mechanical Properties of Butt Joints of AZ61 Magnesium Alloy. Adv. Mater. Sci. Eng. 2017, 2017, 7381403. [Google Scholar] [CrossRef]

- Sabari, S.S.; Malarvizhi, V.; Balasubramanian, V. Influences of tool traverse speed on tensile properties of air cooled and water cooled friction stir welded AA2519-T87 aluminium alloy joints. J. Mater. Process. Technol. 2016, 237, 286–300. [Google Scholar] [CrossRef]

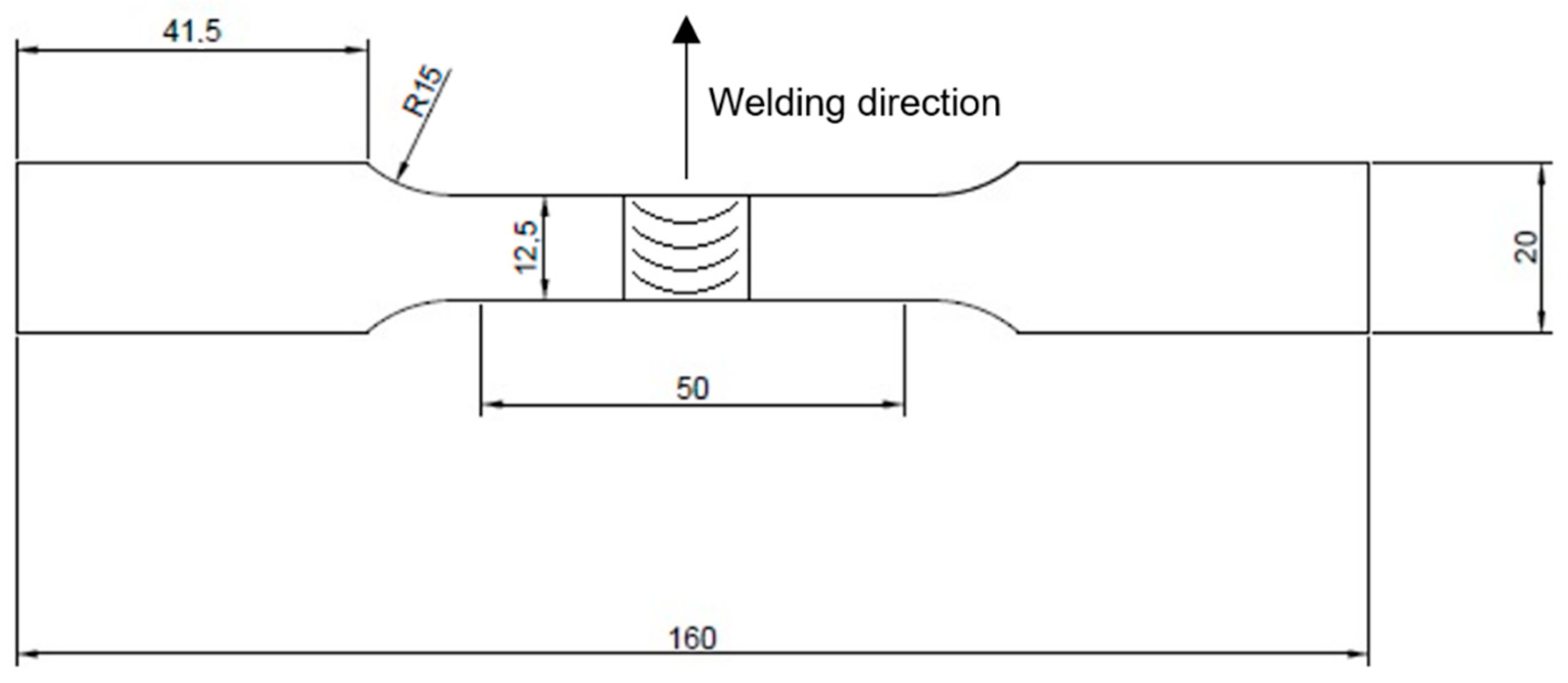

- ASTM. ASTM Standard E8/E8M—13a: Standard Test. Methods for Tension Testing of Metallic Materials; ASTM: West Conshoboken, PA, USA, 2013. [Google Scholar]

- Ravi Raja, A.; Yusufzai, M.Z.; Vashista, M. Characterization of advancing and retreating weld of friction stir welding of aluminium. In Proceedings of the ICAMM 2016, Bangkok, Thailand, 29–30 October 2016; pp. 3–8. [Google Scholar]

- Tufaro, L.; Manzoni, I.; Svoboda, H. Effect of Heat Input on AA5052 Friction Stir Welds Characteristics. Proc. Mater. Sci. 2015, 8, 914–923. [Google Scholar] [CrossRef]

- Prangnell, P.; Heason, C. Grain structure formation during friction stir welding observed by the ‘stop action technique’. Acta Mater. 2005, 53, 3179–3192. [Google Scholar] [CrossRef]

- De Meer, S.; Drury, M.R.; Bresser, J.H.P.; Pennock, G.M. Current issues and new developments in deformation mechanisms, rheology and tectonics. Geol. Soc. Lond. Spec. Publ. 2002, 200, 1–27. [Google Scholar] [CrossRef]

- Fan, X.; Li, M.; Li, D.; Shao, Y.; Zhang, S.; Peng, Y. Dynamic recrystallisation and dynamic precipitation in AA6061 aluminium alloy during hot deformation. Mater. Sci. Technol. 2014, 30, 1263–1272. [Google Scholar] [CrossRef]

- Jones, J.M.; Humphreys, J.F. Interaction of recrystallization and precipitation: The effect of Al3Sc on the recrystallization behaviour of deformed aluminium. Acta Mater. 2003, 51, 2149–2159. [Google Scholar] [CrossRef]

- Salih, O.S.; Neate, N.; Ou, H.; Sun, W. Influence of process parameters on the microstructural evolution and mechanical characterisations of friction stir welded Al–Mg–Si alloy. J. Mater. Process. Technol. 2019, 275, 116366. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.; Sterling, J.C. Microstructure evolution during FSW/FSP of high strength aluminum alloys. Mat. Sci. Eng. A Struct. 2005, 405, 277–286. [Google Scholar] [CrossRef]

- Staron, P.; Koçak, M.; Williams, S. Residual stresses in friction stir welded Al sheets. Appl. Phys. A 2002, 74, 1161. [Google Scholar] [CrossRef]

- Sabari, S.; Malarvizhi, S.; Balasubramanian, V. Characteristics of FSW and UWFSW joints of AA2519-T87 aluminium alloy: Effect of tool rotation speed. J. Manuf. Process. 2016, 22, 278–289. [Google Scholar] [CrossRef]

| Fe | Si | Cu | Zn | Ti | Mn | Mg | Ni | Zr | Sc | V | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.11 | 0.08 | 6.32 | 0.05 | 0.08 | 0.17 | 0.33 | 0.02 | 0.19 | 0.16 | 0.10 | Base |

| Yield Strength | Tensile Strength | Elongation |

|---|---|---|

| 207 MPa | 293 MPa | 16.1% |

| Shoulder Profile | Spiral |

|---|---|

| Shoulder diameter | 19 mm |

| Pin profile | Threaded and tapered with three spiral flutes |

| Pin length | 4.8 mm |

| Pin diameter | 6.5–8.7 mm |

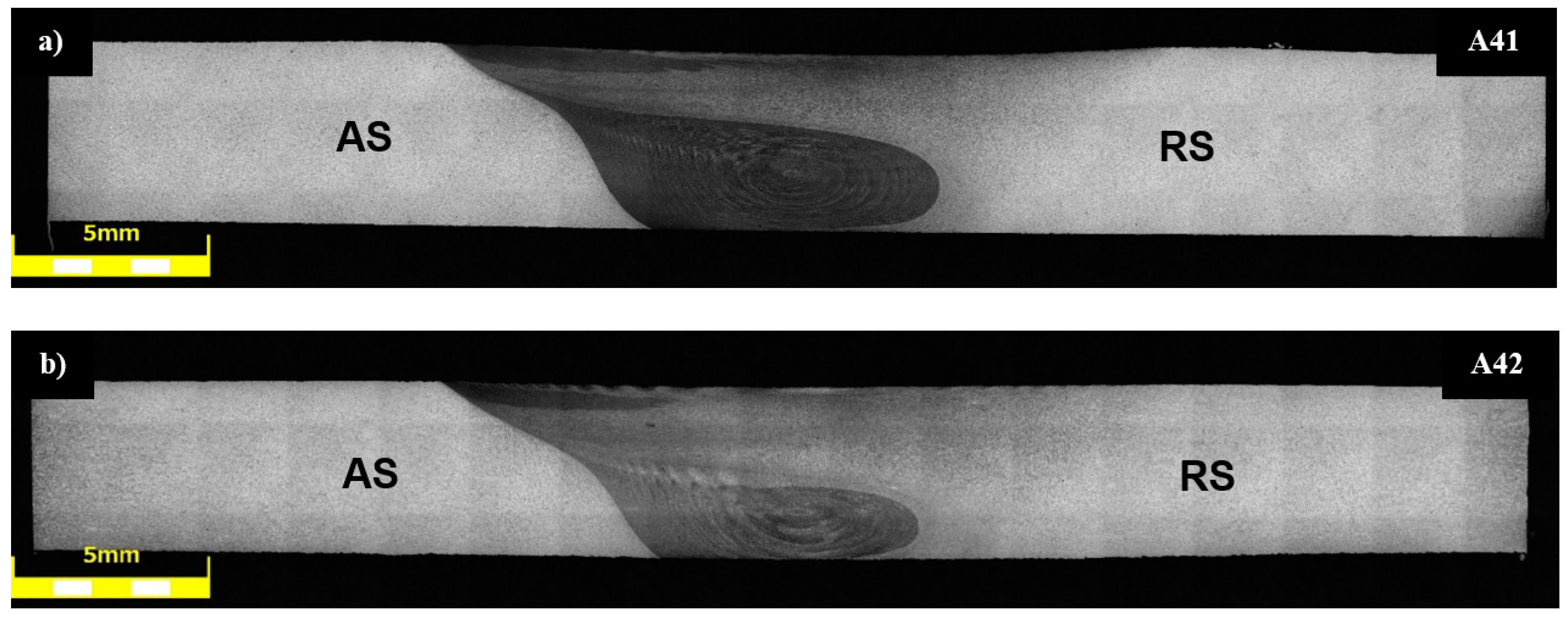

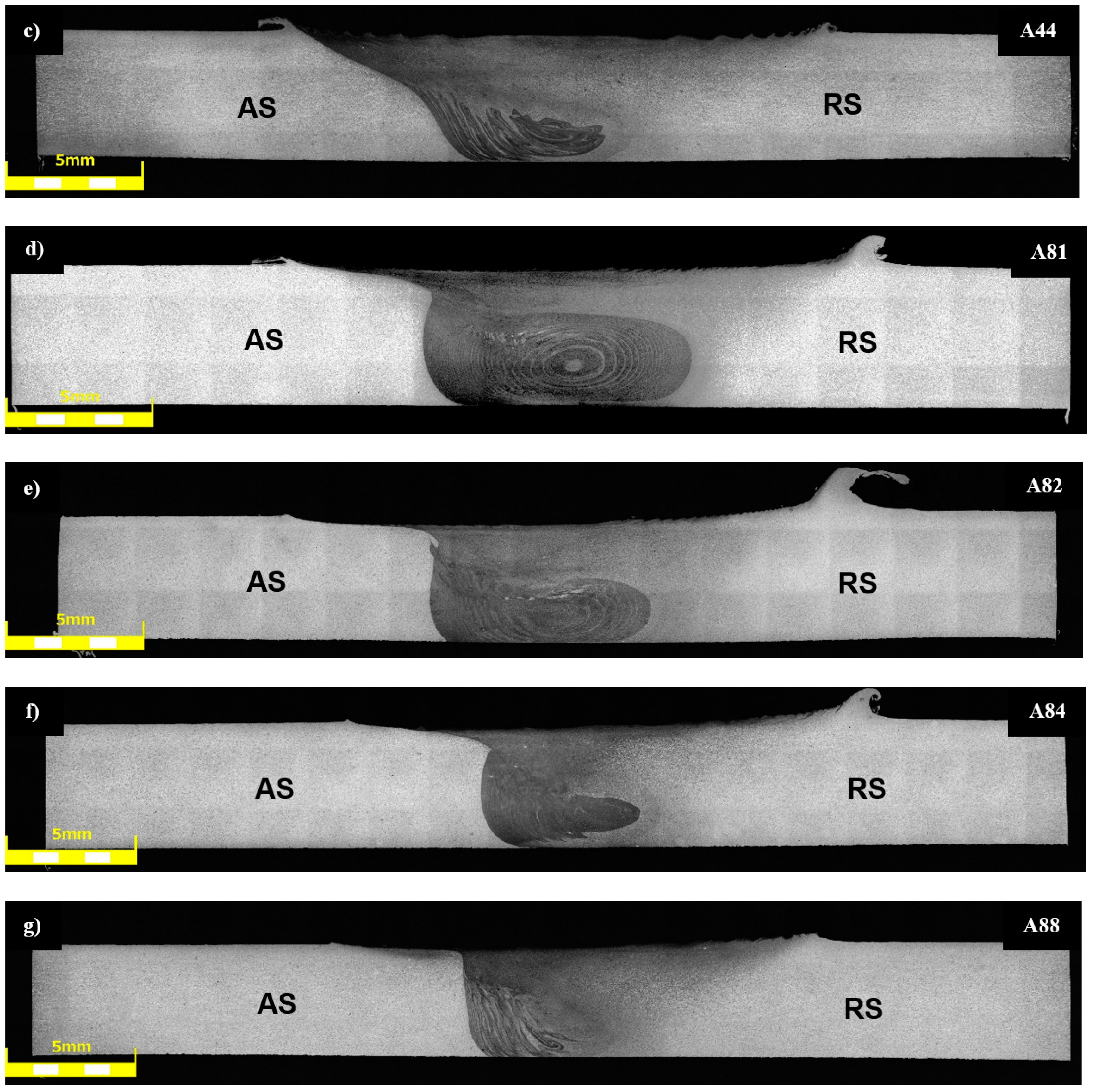

| Sample Designation | Tool Rotation Speed (ω) (rpm) | Tool Traverse Speed (v) (mm/min) | Heat Input (Q) Ratio ω/v |

|---|---|---|---|

| A41 | 400 | 100 | 4 |

| A42 | 400 | 200 | 2 |

| A44 | 400 | 400 | 1 |

| A81 | 800 | 100 | 8 |

| A82 | 800 | 200 | 4 |

| A84 | 800 | 400 | 2 |

| A88 | 800 | 800 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosturek, R.; Śnieżek, L.; Torzewski, J.; Wachowski, M. Research on the Friction Stir Welding of Sc-Modified AA2519 Extrusion. Metals 2019, 9, 1024. https://doi.org/10.3390/met9101024

Kosturek R, Śnieżek L, Torzewski J, Wachowski M. Research on the Friction Stir Welding of Sc-Modified AA2519 Extrusion. Metals. 2019; 9(10):1024. https://doi.org/10.3390/met9101024

Chicago/Turabian StyleKosturek, Robert, Lucjan Śnieżek, Janusz Torzewski, and Marcin Wachowski. 2019. "Research on the Friction Stir Welding of Sc-Modified AA2519 Extrusion" Metals 9, no. 10: 1024. https://doi.org/10.3390/met9101024

APA StyleKosturek, R., Śnieżek, L., Torzewski, J., & Wachowski, M. (2019). Research on the Friction Stir Welding of Sc-Modified AA2519 Extrusion. Metals, 9(10), 1024. https://doi.org/10.3390/met9101024