Characterization of 17-4PH Single Tracks Produced at Different Parametric Conditions towards Increased Productivity of LPBF Systems—The Effect of Laser Power and Spot Size Upscaling

Abstract

1. Introduction

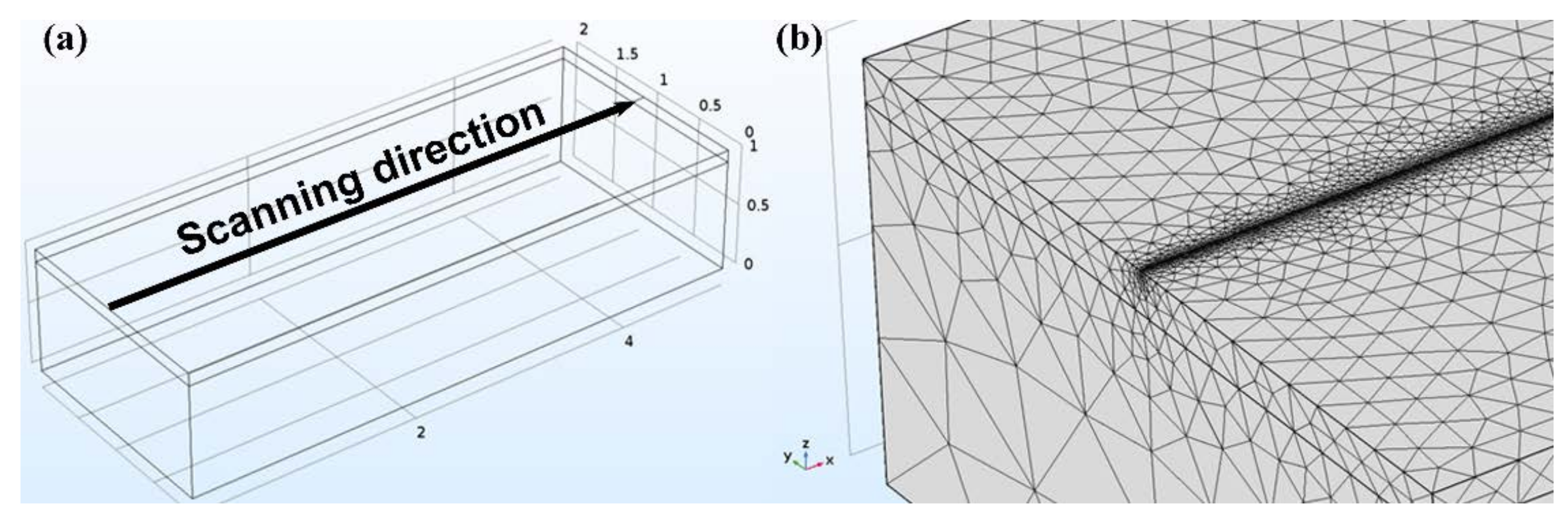

2. Materials and Methods

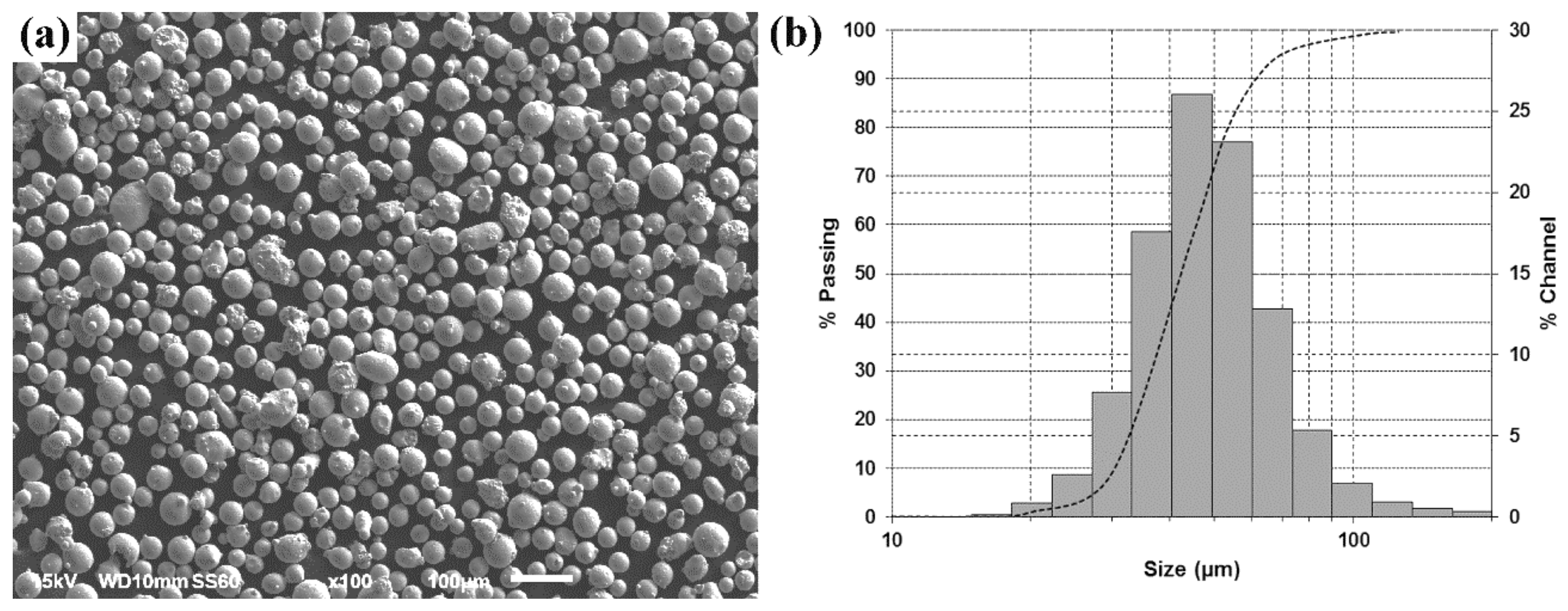

2.1. Material

2.2. Experimental Methods

3. Results and Discussion

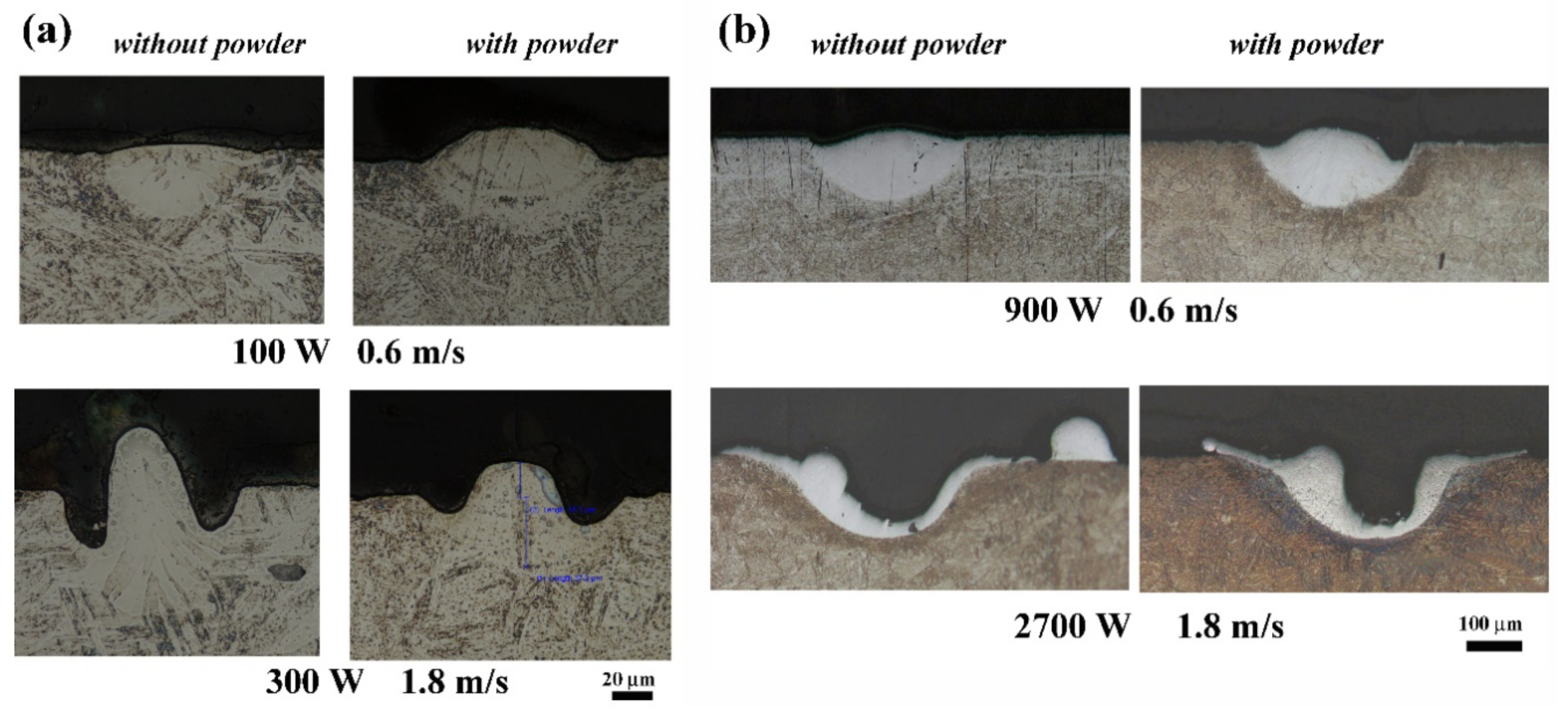

3.1. Surface Morphology and Melt Pool Profiles: Experimental Results

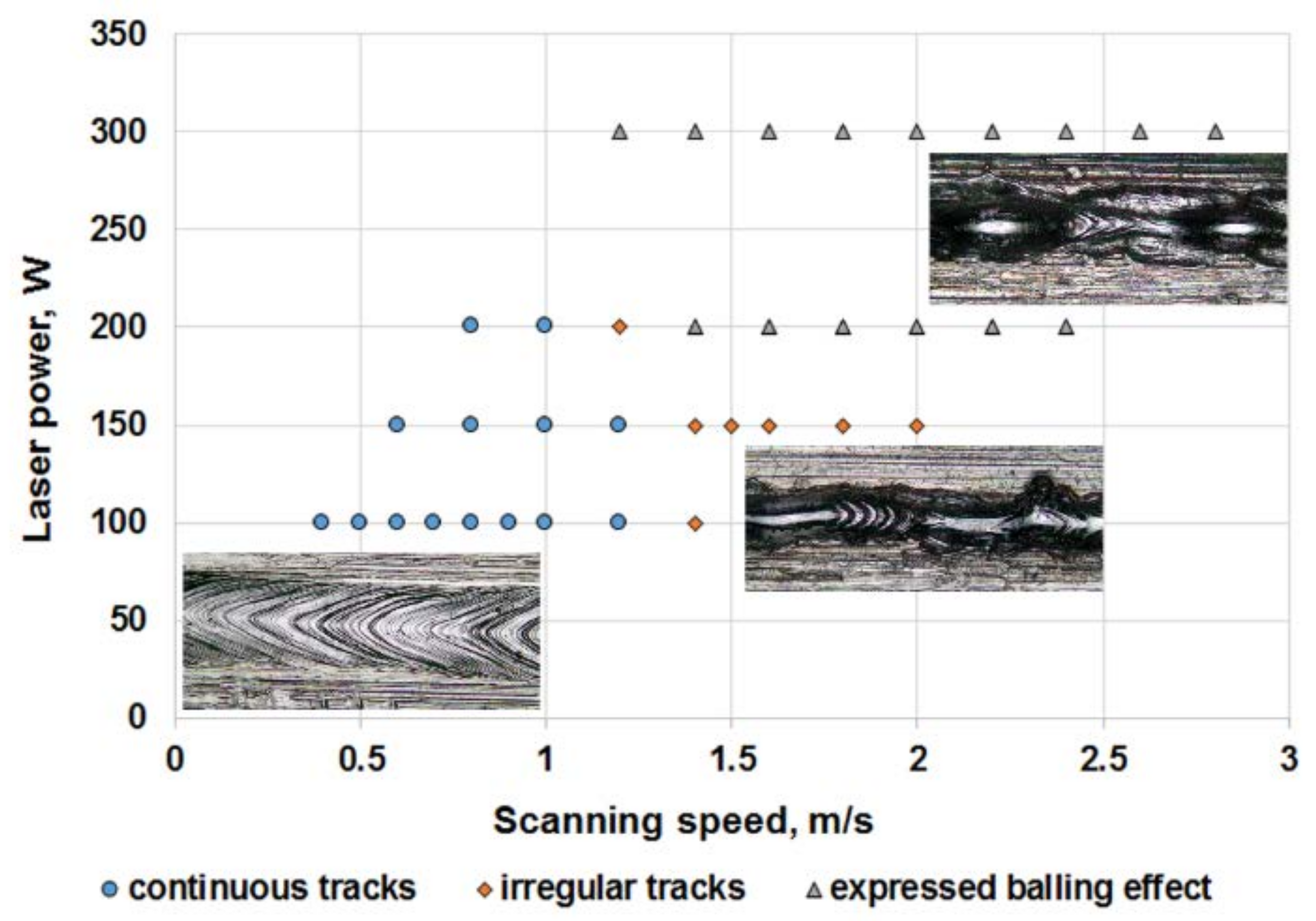

3.1.1. Low-Power System

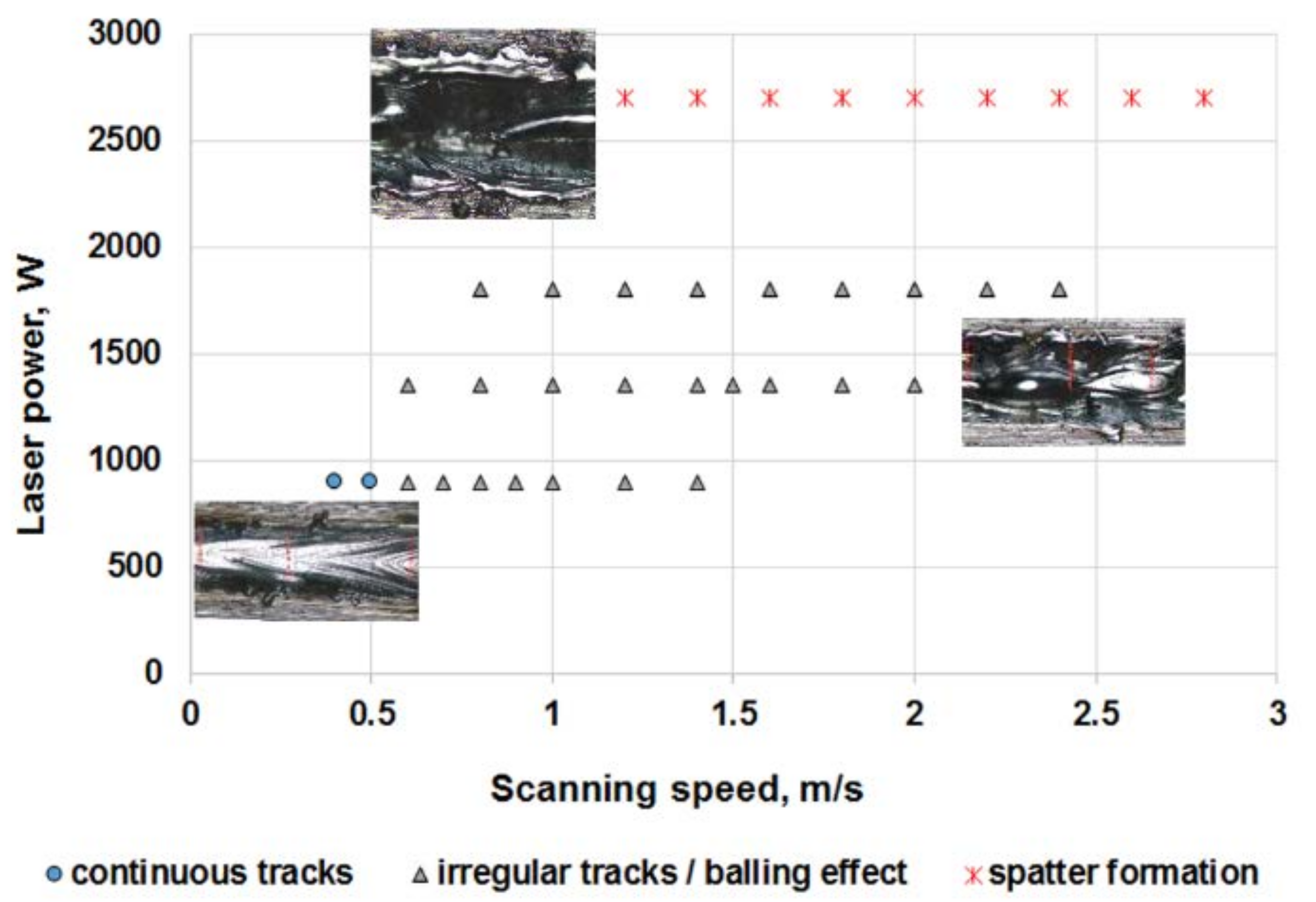

3.1.2. High-Power System

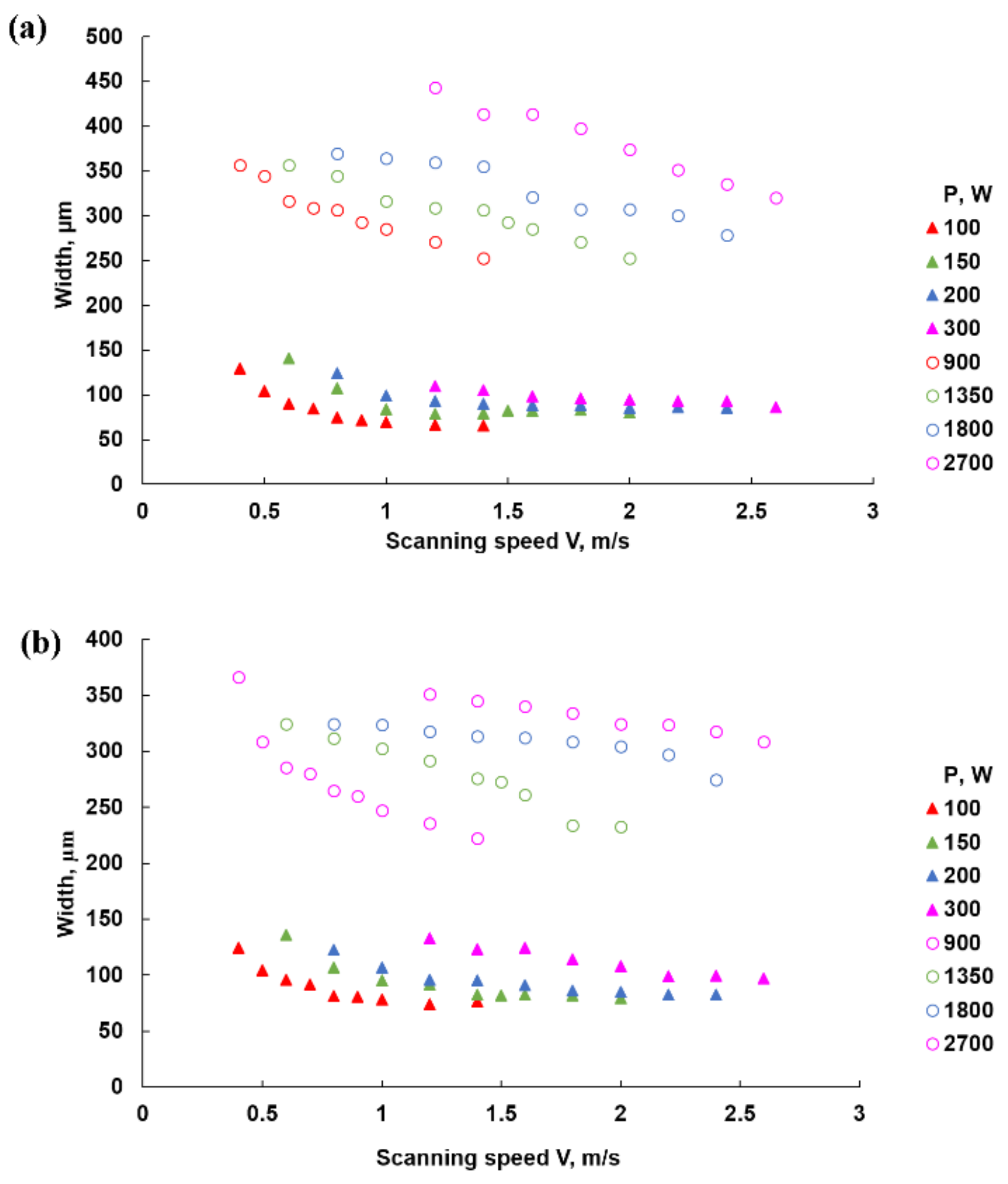

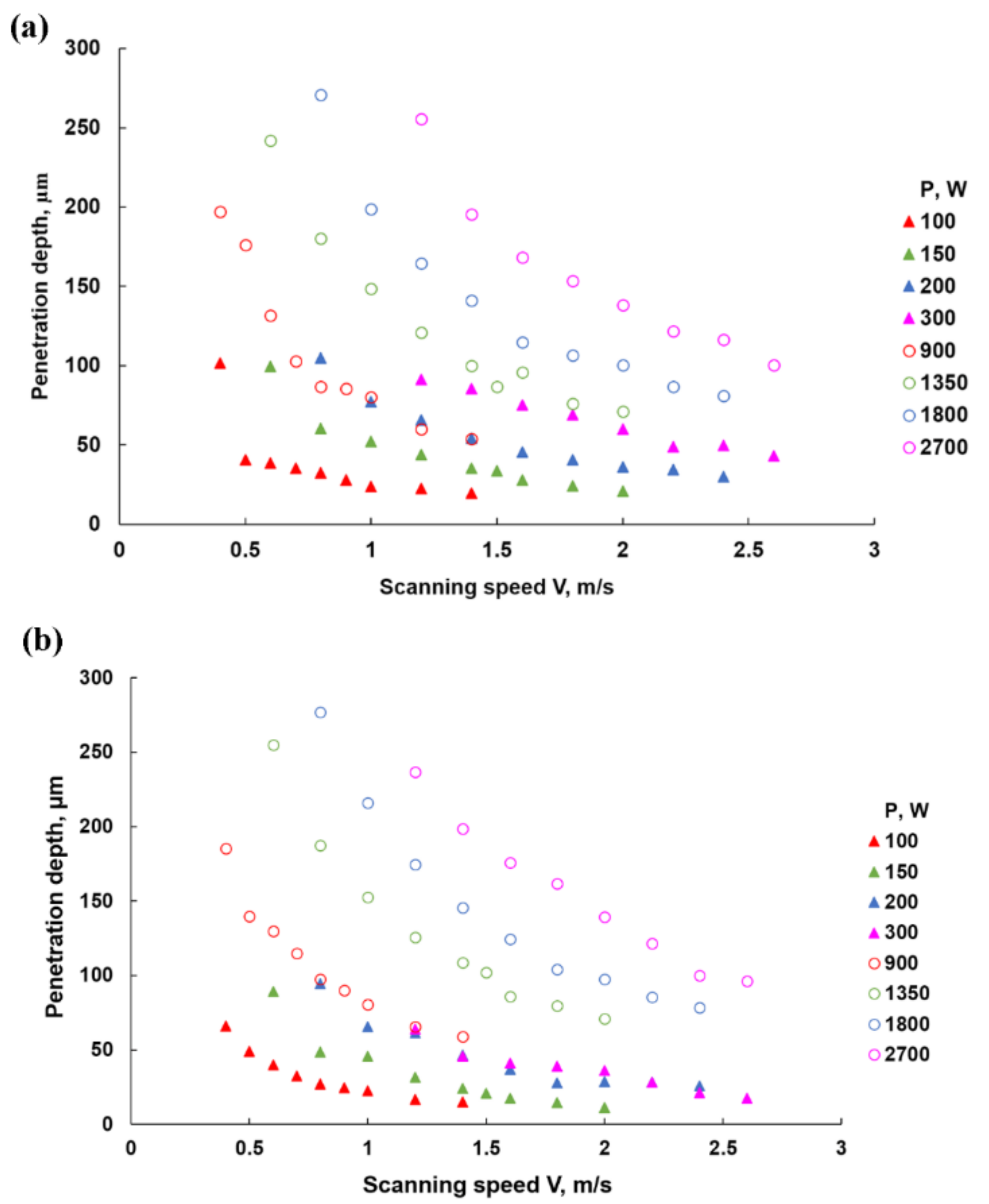

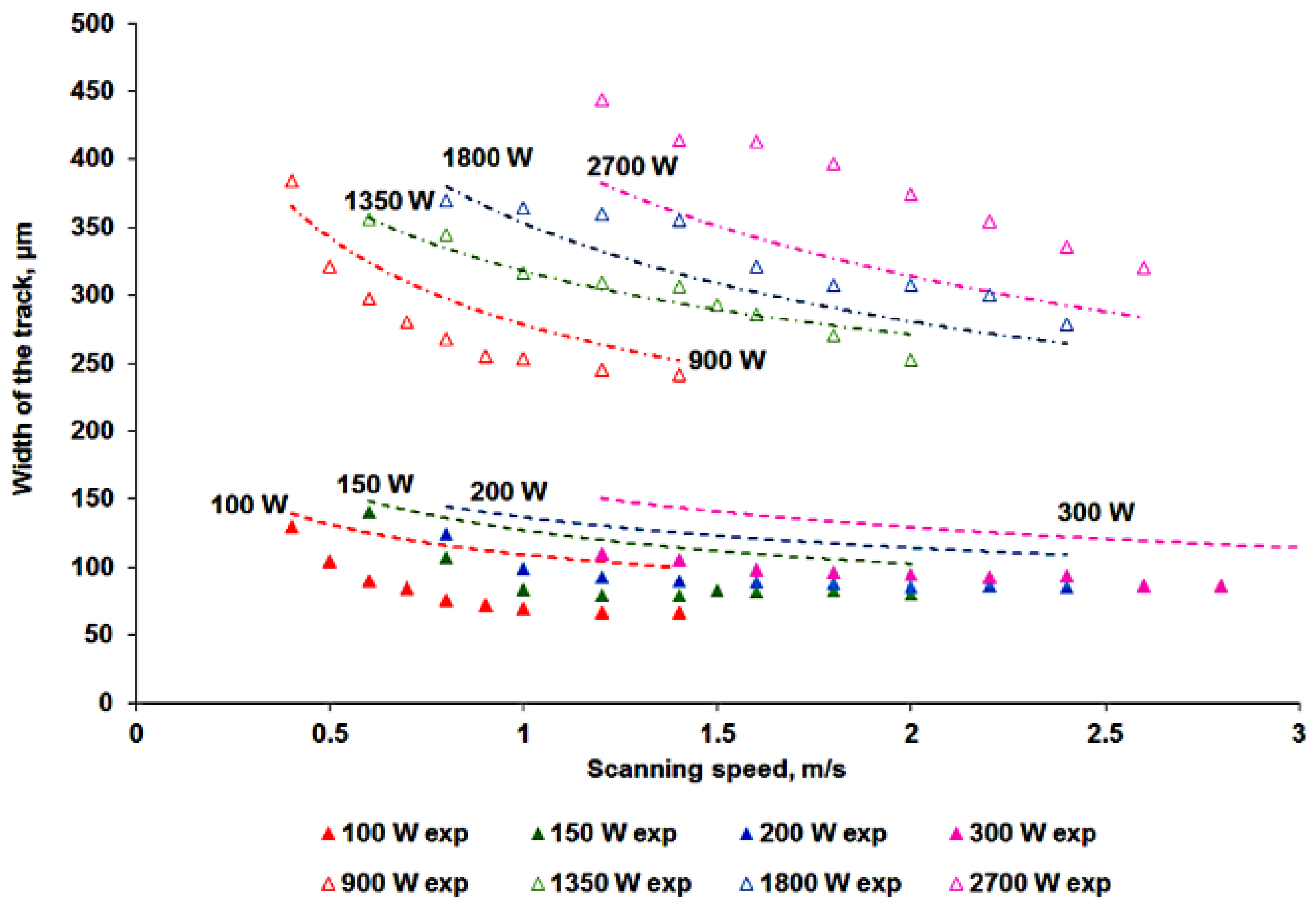

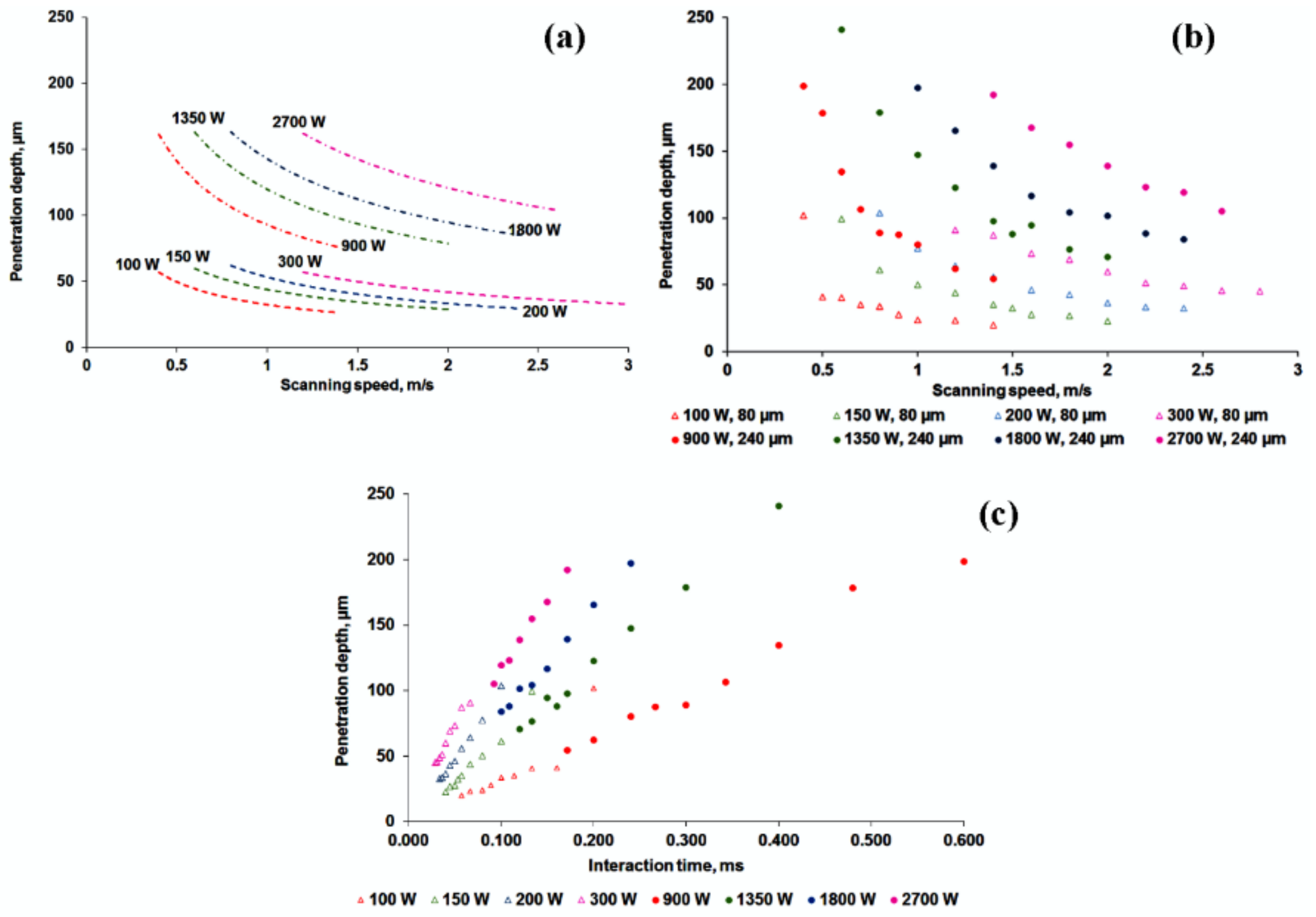

3.2. Parameters Affecting the Molten Pool Size

4. Summary and Conclusions

- The formation of continuous single tracks has a threshold character and depends on the process parameters. There are stability zones where the tracks formed are continuous and without defects, and instability zones where the tracks formed are irregular or in the form of beads, especially at higher scanning speeds and laser powers.

- A larger beam diameter and higher laser power can be used to form stable tracks when the scanning speed is reduced.

- The larger beam diameter and higher laser power result in a wider and deeper molten pool, which allows an increase in the hatch distance and the layer thickness.

- Numerical simulation has shown that a higher laser power leads to a longer molten pool, which can provoke instabilities.

- Excessive energy input leads to depression of the molten pool and spatter formation.

- The laser power and scanning speed exert the most influence on the width and penetration depth of the single track.

- The process of forming 3D objects will be more complicated. Thus, the next stage of the research should be devoted to the study of the influence of the layer thickness on single track formations and hatch distance on single layer formation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bourell, D.L.; Rosen, D.W.; Leu, M.C. The roadmap for additive manufacturing and its impact. 3D Print. Addit. Manuf. 2014, 1, 1. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Chang. 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Schleifenbaum, H.; Meiners, W.; Wissenbach, K.; Hinke, C. Individualized production by means of high power Selective Laser Melting. CIRP-JMST 2010, 2, 161–169. [Google Scholar] [CrossRef]

- Yadroitsava, I.; Els, J.; Booysen, G.; Yadroitsev, I. Peculiarities of single track formation from Ti6AL4V alloy at different laser power densities by selective laser melting. SAJIE 2015, 26, 86–95. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; GAO, M.; Zeng, X. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Chen, C.; Wu, Q.; Chen, X.; Lu, J. Performance of high layer thickness in selective laser melting of Ti6Al4V. Materials 2016, 9, 975. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, Y.; Shi, W.; Qi, B.; Yang, J.; Zhang, F.; Han, D.; Ma, Y. Research on high layer thickness fabricated of 316L by selective laser melting. Materials 2017, 10, 1055. [Google Scholar] [CrossRef] [PubMed]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured powder-bed laser-fused material. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Ferro, P.; Berto, F. Fatigue assessment of Ti-6Al-4V circular notched specimens produced by selective laser melting. Metals 2017, 7, 291. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.D.; Berto, F.; Razavi, S.M.J.; Ferreira, J.A.M.; Capela, C.; Santos, L.; Antunes, F. Low-Cycle Fatigue Behaviour of AISI 18Ni300 Maraging Steel Produced by Selective Laser Melting. Metals 2018, 8, 32. [Google Scholar] [CrossRef]

- Rausch, A.M.; Küng, V.E.; Pobel, C.; Markl, M.; Körner, C. Predictive Simulation of Process Windows for Powder Bed Fusion Additive Manufacturing: Influence of the Powder Bulk Density. Materials 2017, 10, 1117. [Google Scholar] [CrossRef] [PubMed]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties developed. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Guzanová, A.; Ižaríková, G.; Brezinová, J.; Živčák, J.; Draganovská, D.; Hudák, R. Influence of Build Orientation, Heat Treatment, and Laser Power on the Hardness of Ti6Al4V Manufactured Using the DMLS Process. Metals 2017, 7, 318. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Karthik, N.; Starr, T.; Stucker, B. Defect morphology in Ti-6Al-4V parts fabricated by selective laser melting and electron beam melting. In Proceedings of the 24rd Annual International Solid Freeform Fabrication Symposium: An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Mazumder, J.; Steen, W. Heat transfer model for CW laser material processing. J. Appl. Phys. 1980, 51, 941–947. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Hierarchical design principles of selective laser melting for high quality metallic objects. Addit. Manuf. 2015, 7, 45–56. [Google Scholar] [CrossRef]

- Childs, T.; Hauser, C.; Badrossamay, M. Mapping and modelling single scan track formation in direct metal selective laser melting. CIRP Ann. Manuf. Technol. 2004, 53, 191–194. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Tailoring surface quality through mass and momentum transfer modeling using a volume of fluid method in selective laser melting of TiC/AlSi10Mg powder. Int. J. Mach. Tools Manuf. 2015, 88, 95–107. [Google Scholar] [CrossRef]

- Yan, W.; Ge, W.; Qian, Y.; Lin, S.; Zhou, B.; Liu, W.K.; Lin, F.; Wagner, G.J. Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater. 2017, 134, 324–333. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of metal powder layers in laser powder bed fusion processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Das, S. Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- Wei, P.S. The physics of weld bead defects. In Welding Processes; Kovacevic, R., Ed.; InTech: London, UK, 2012; pp. 395–414. [Google Scholar]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Yadroitsev, I. Selective Laser Melting: Direct Manufacturing of 3D-Objects by Selective Laser Melting of Metal Powders; Lambert Academic Publishing: Saarbrücken, Germany, 2009. [Google Scholar]

| Parameter | Low-Power System | High-Power System |

|---|---|---|

| Beam diameter, 2r0 (µm) | 80 | 240 |

| Laser power, P (W) | 100–300 | 900–2700 |

| Scanning speed, V (m/s) | 0.4–2.8 | 0.4–2.8 |

| Laser-matter interaction time, 2r0/V (µs) | 200–29 | 600–86 |

| Laser power density, P/(π·r02) (kW/mm2) | 19.9–59.7 | 19.9–59.7 |

| Linear energy input, P/V (J/m) | 35.7–750 | 321–6750 |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. | Partial η2 |

|---|---|---|---|---|---|---|

| Corrected Model | 5,471,735.346 a | 139 | 39,365.002 | 968.846 | 0.000 | 0.998 |

| Intercept | 14,999,811.89 | 1 | 14,999,811.89 | 369,173.171 | 0.000 | 0.999 |

| P | 5,301,134.139 | 7 | 757,304.877 | 18,638.677 | 0.000 | 0.998 |

| V | 191,424.337 | 15 | 12,761.622 | 314.087 | 0.000 | 0.944 |

| P × powder | 45,185.119 | 7 | 6455.017 | 158.87 | 0.000 | 0.799 |

| P × V | 37,439.075 | 47 | 796.576 | 19.605 | 0.000 | 0.767 |

| P × V × powder | 14,765.419 | 47 | 314.158 | 7.732 | 0.000 | 0.565 |

| Powder | 12,016.96 | 1 | 12,016.96 | 295.76 | 0.000 | 0.514 |

| V × powder | 4340.016 | 15 | 289.334 | 7.121 | 0.000 | 0.276 |

| Error | 11,376.632 | 280 | 40.631 | - | - | - |

| Total | 22,832,609.23 | 420 | - | - | - | - |

| Corrected Total | 5,483,111.978 | 419 | - | - | - | - |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. | Partial η2 |

|---|---|---|---|---|---|---|

| Corrected Model | 1,569,172.893 a | 139 | 11,289.014 | 1639.041 | 0.000 | 0.999 |

| Intercept | 2,916,511.823 | 1 | 2,916,511.823 | 423,445.601 | 0.000 | 0.999 |

| P | 1,211,746.604 | 7 | 173,106.658 | 25,133.192 | 0.000 | 0.998 |

| V | 509,356.538 | 15 | 33,957.103 | 4930.2 | 0.000 | 0.996 |

| P × V | 137,073.879 | 47 | 2916.466 | 423.439 | 0.000 | 0.986 |

| P × powder | 9250.968 | 7 | 1321.567 | 191.877 | 0.000 | 0.827 |

| P × V × powder | 5023.967 | 47 | 106.893 | 15.52 | 0.000 | 0.723 |

| Powder | 3650.127 | 1 | 3650.127 | 529.958 | 0.000 | 0.654 |

| V × powder | 2279.275 | 15 | 151.952 | 22.062 | 0.000 | 0.542 |

| Error | 1928.52 | 280 | 6.888 | - | - | - |

| Total | 482,8881.17 | 420 | - | - | - | - |

| Corrected Total | 1,571,101.413 | 419 | - | - | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makoana, N.W.; Yadroitsava, I.; Möller, H.; Yadroitsev, I. Characterization of 17-4PH Single Tracks Produced at Different Parametric Conditions towards Increased Productivity of LPBF Systems—The Effect of Laser Power and Spot Size Upscaling. Metals 2018, 8, 475. https://doi.org/10.3390/met8070475

Makoana NW, Yadroitsava I, Möller H, Yadroitsev I. Characterization of 17-4PH Single Tracks Produced at Different Parametric Conditions towards Increased Productivity of LPBF Systems—The Effect of Laser Power and Spot Size Upscaling. Metals. 2018; 8(7):475. https://doi.org/10.3390/met8070475

Chicago/Turabian StyleMakoana, Nkutwane Washington, Ina Yadroitsava, Heinrich Möller, and Igor Yadroitsev. 2018. "Characterization of 17-4PH Single Tracks Produced at Different Parametric Conditions towards Increased Productivity of LPBF Systems—The Effect of Laser Power and Spot Size Upscaling" Metals 8, no. 7: 475. https://doi.org/10.3390/met8070475

APA StyleMakoana, N. W., Yadroitsava, I., Möller, H., & Yadroitsev, I. (2018). Characterization of 17-4PH Single Tracks Produced at Different Parametric Conditions towards Increased Productivity of LPBF Systems—The Effect of Laser Power and Spot Size Upscaling. Metals, 8(7), 475. https://doi.org/10.3390/met8070475