Surface Roughness Investigation and Stress Modeling by Finite Element on Orthogonal Cutting of Copper

Abstract

1. Introduction

2. Experimental Work

2.1. Materials and Methods

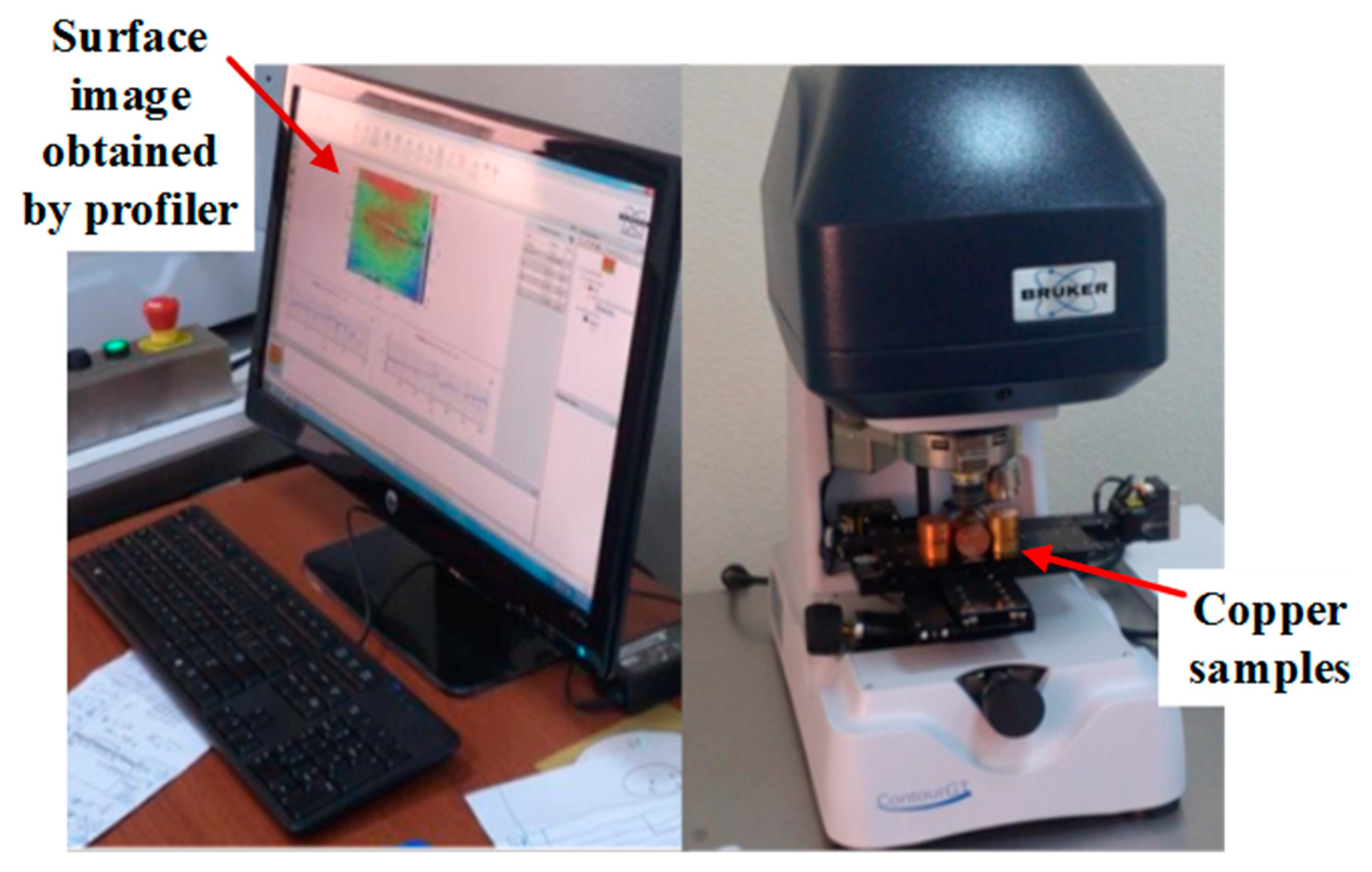

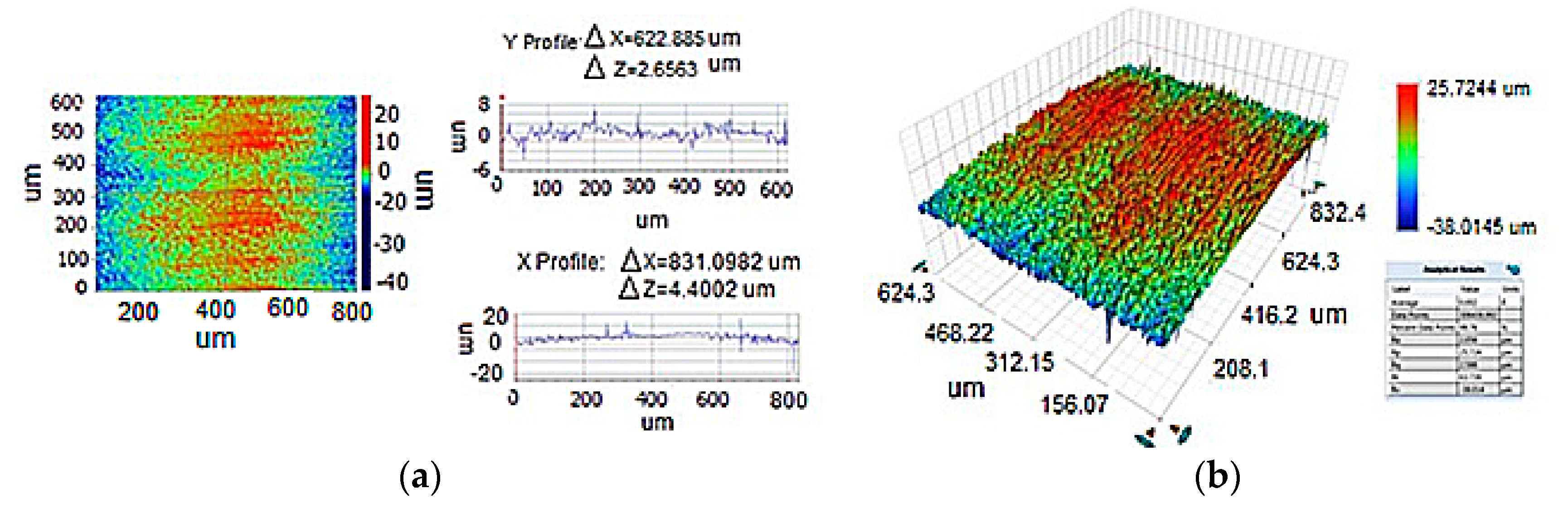

2.2. Surface Roughness Measurement

3. Simulation Model

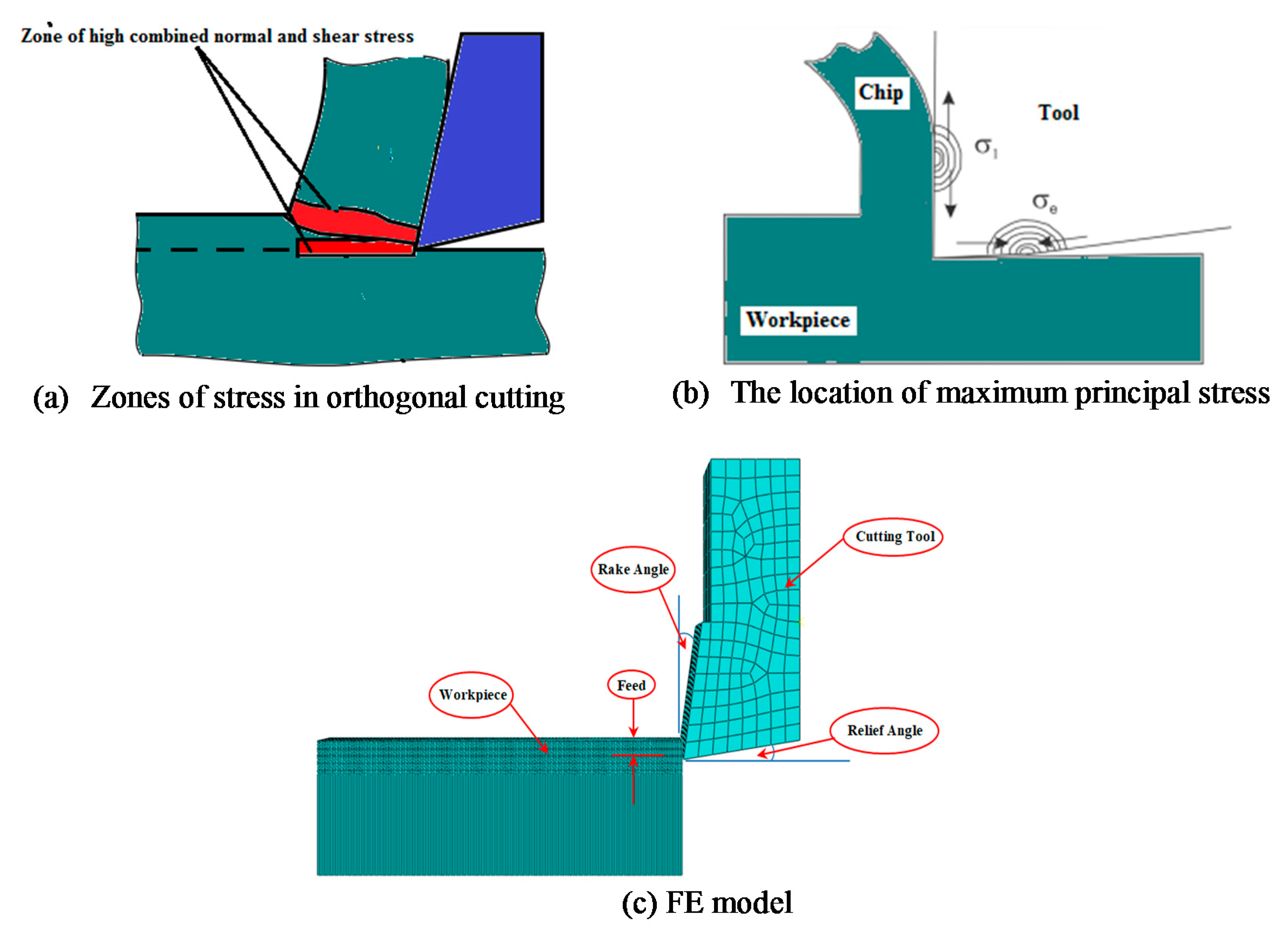

3.1. Finite Element Model

3.2. Material Properties for Modeling

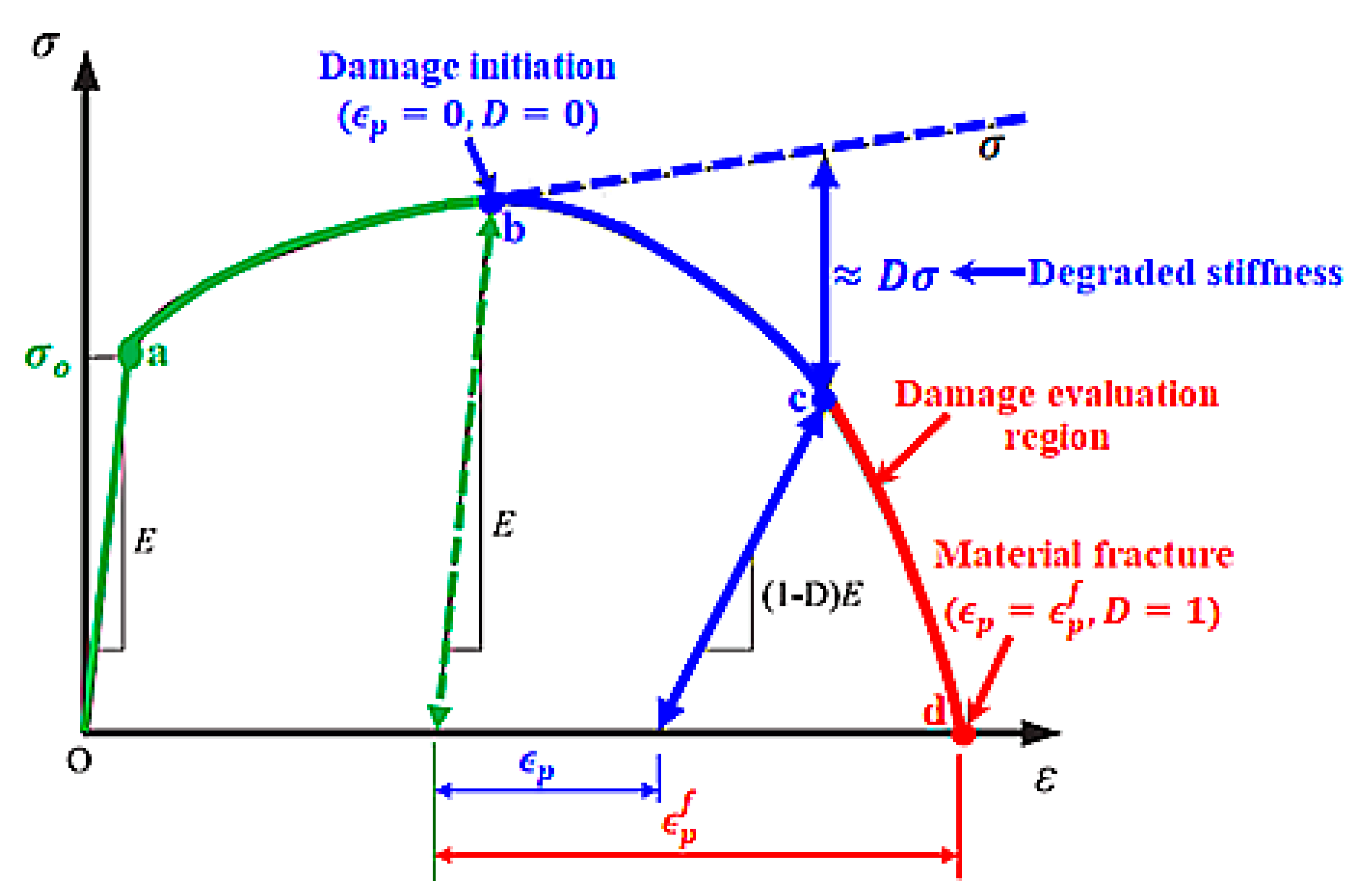

3.3. Material Modeling

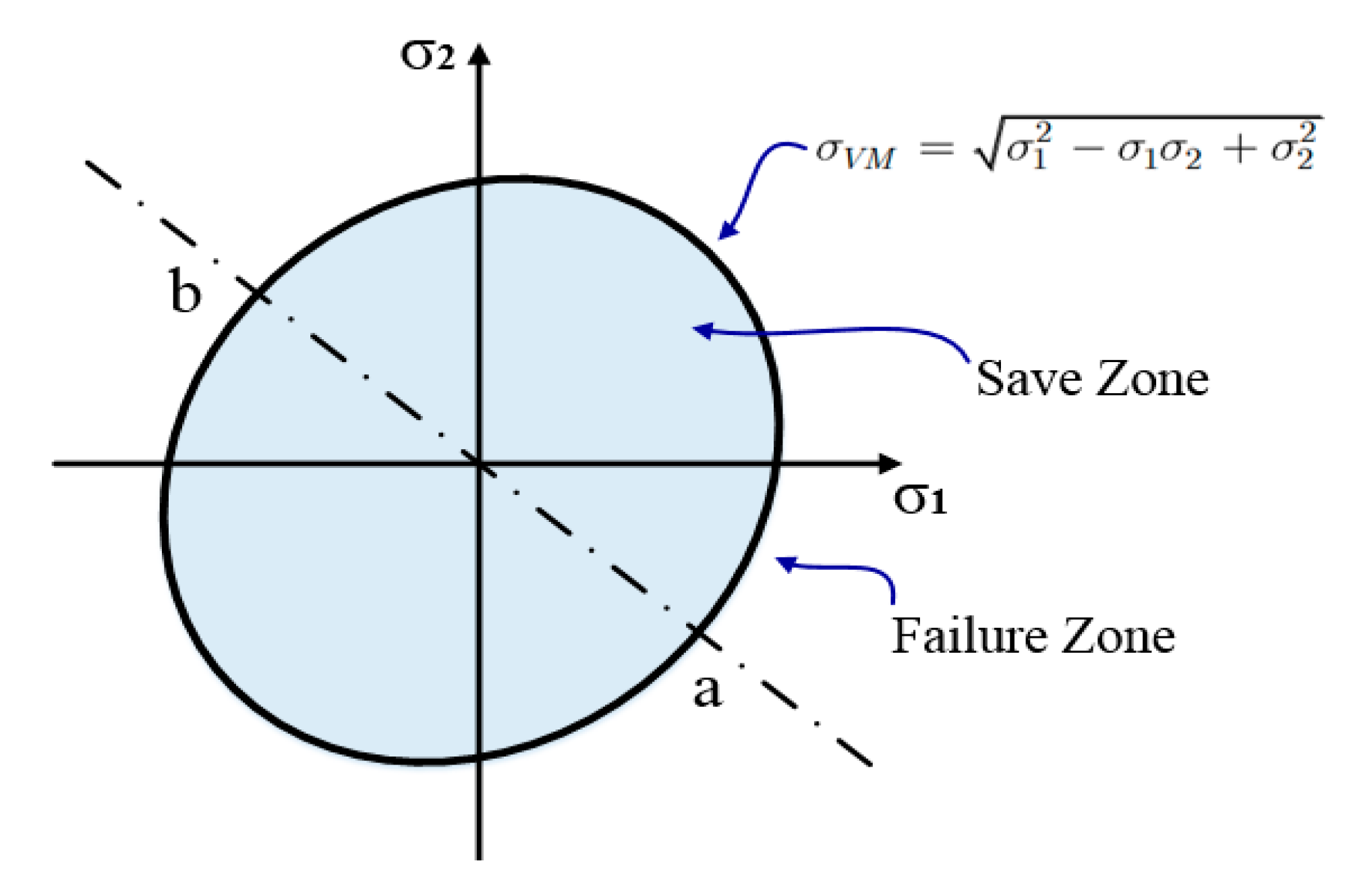

3.4. Von-Mises Stress Criterion

4. Results and Discussion

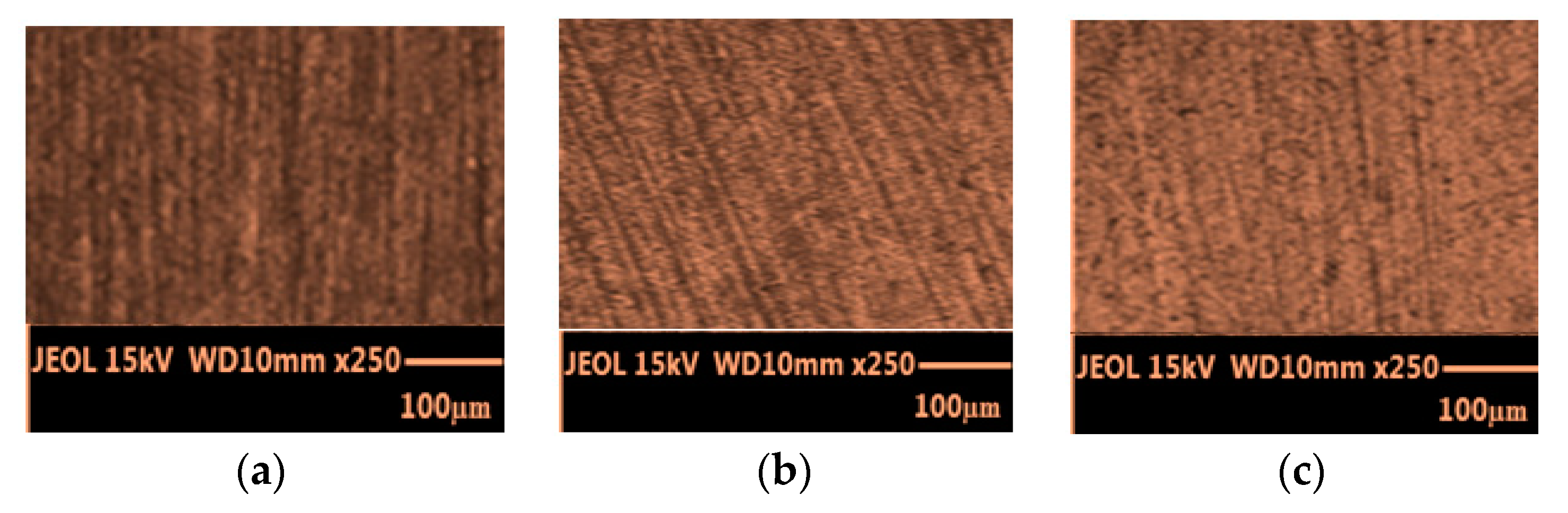

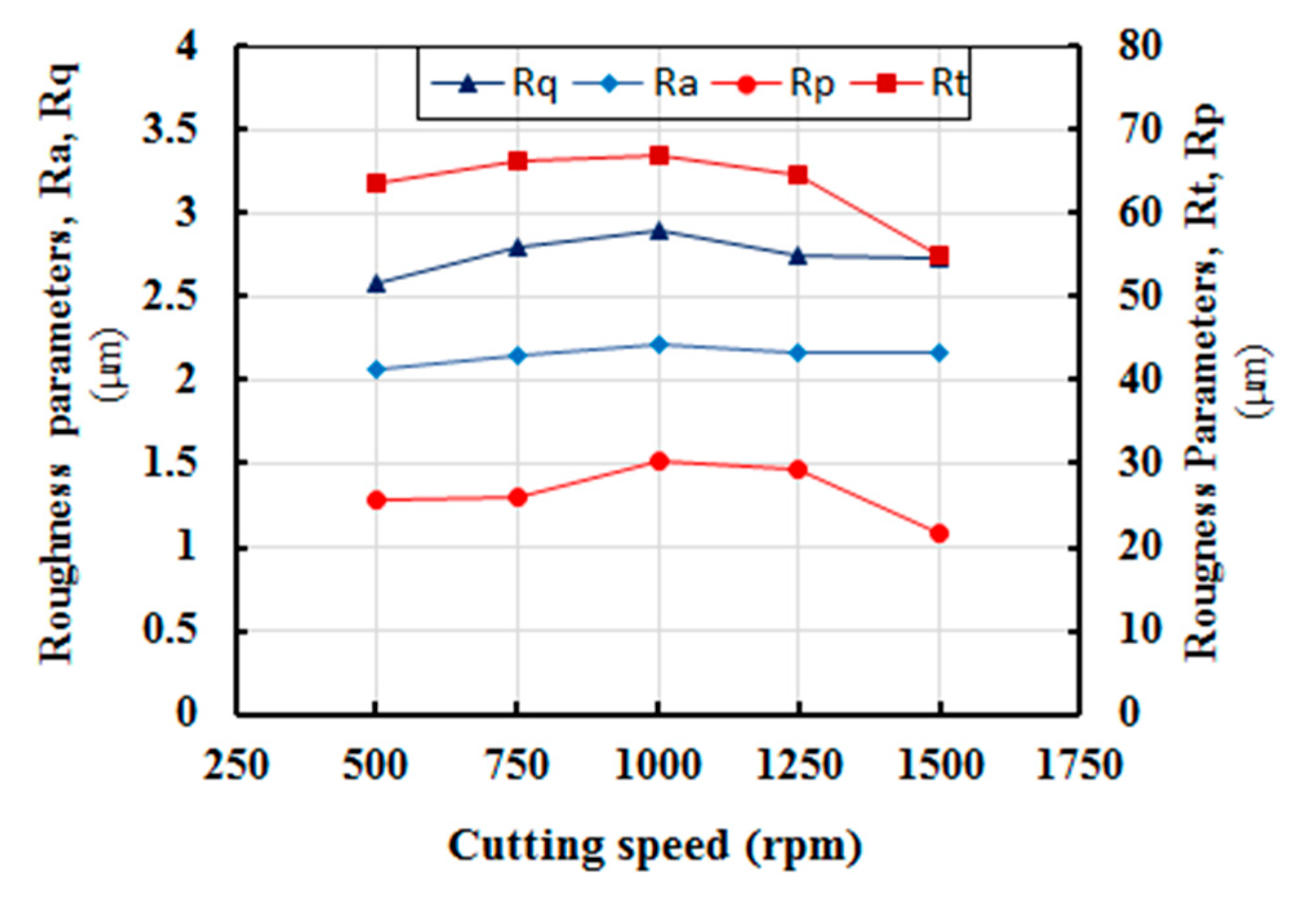

4.1. Microscopic Observations and Surface Roughness Results

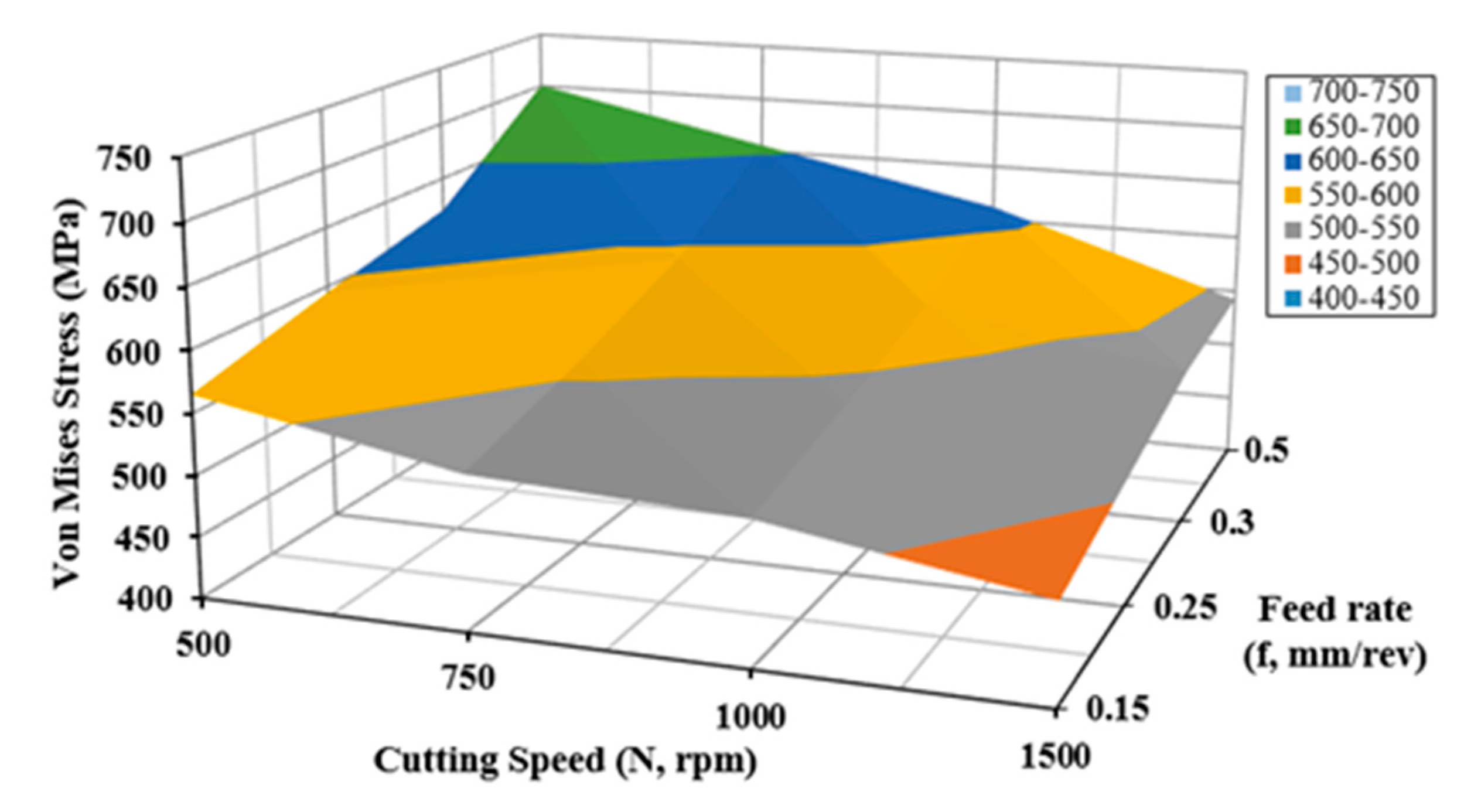

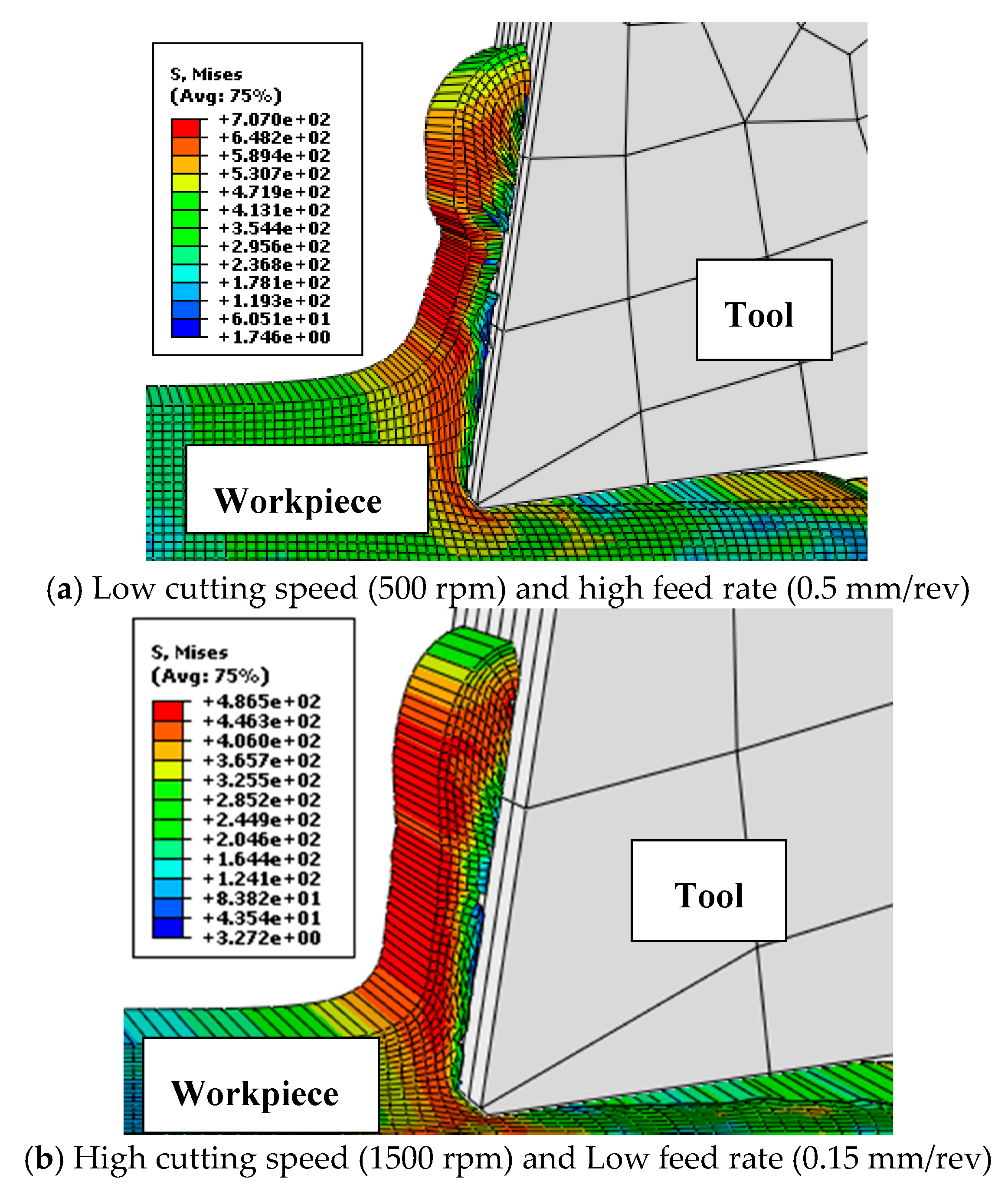

4.2. Results of Simulation Model

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hatem, H. Study the Effect of Cutting Conditions for turning process on the Machined Surface. Nahrain Univ. Coll. Eng. J. 2011, 14, 61–66. [Google Scholar]

- Ashvin, J.; Nanavati, J.I. Optimization of machining parameters for turning operations based on response surface methodology. Measurement 2013, 46, 1521–1529. [Google Scholar]

- Sarosh, M.; Jahanzaib, M.; Mumtaz, J.; Sarfraz, S. Investigation of Electric Discharge Machining Parameters to Minimize Surface Roughness. Pak. J. Sci. 2016, 68, 315–325. [Google Scholar]

- Charles, S.; Arunachalam, V.P. Property Analysis and Mathematical modeling of machining properties of Aluminum alloy hybrid composites produced by liquid metallurgy techniques. Indian J. Eng. Mater. Sci. 2004, 11, 473–480. [Google Scholar]

- Shin, Y.C.; Coker, S.A. Surface Roughness Measure by Ultrasonic Sensing for in Process Monitoring. J. Eng. Ind. 1995, 117, 439–447. [Google Scholar] [CrossRef]

- Shoba, C.; Ramanaiah, N.; Rao, D.N. Optimizing the Machining Parameters for Minimum Surface Roughness in Turning Al/6% SiC/6% RHA Hybrid Composites. Procedia Mater. Sci. 2015, 10, 220–229. [Google Scholar] [CrossRef]

- Suresh, P.V.S.; Rao, P.V.; Deshmukh, S.G. A genetic algorithmic approach for optimization of surface roughness prediction model. Int. J. Mach. Tools Manuf. 2002, 42, 675–680. [Google Scholar] [CrossRef]

- Davim, J.P. A note on the determination of optimal cutting conditions for surface finish obtained in turning using design of experiments. J. Mater. Process. Technol. 2001, 116, 305–308. [Google Scholar] [CrossRef]

- Gouveia, R.M.; Silva, F.J.G.; Reis, P.; Baptista, A.P.M. Machining Duplex Stainless Steel: Comparative Study Regarding End Mill Coated Tools. Coatings 2016, 6, 51. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiCp metal matrix composites, part 1. Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Shyha, I.; Gariani, S.; El-Sayed, M.A.; Huo, D. Analysis of Microstructure and Chip Formation When Machining Ti-6Al-4V. Metals 2018, 8, 185. [Google Scholar] [CrossRef]

- Bhushan, R.K.; Kumar, S.; Das, S. Effect of machining parameters on surface roughness and tool wear for 7075 Al alloy SiC composite. Int. J. Adv. Manuf. Technol. 2010, 50, 459–469. [Google Scholar] [CrossRef]

- Ozben, T.; Kilickap, E.; Cakir, O. Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J. Mater. Process. Technol. 2008, 198, 220–225. [Google Scholar] [CrossRef]

- Thiele, J.; Melkote, S. Effect of innovative geometry and workpiece hardness on surface generation in the finish hard turning of AISI 52100 Steel. J. Mater. Process. Technol. 1999, 94, 216–226. [Google Scholar] [CrossRef]

- Aouici, H.; Yallese, M.A.; Fnides, B.; Mabrouki, T. Machinability investigation in hard turning of AISI H11 hot work steel with CBN tool. Mechanika 2010, 6, 71–77. [Google Scholar]

- Shashi Kiran, G.; Prasanna, N.D. Machinability Studies on Copper Based Alloy Optimization of Control Parameters in Turning Operation Using Taguchi Method. Int. J. Eng. Res. Technol. 2013, 2, 1248–1255. [Google Scholar]

- Papanikolaou, M.; Frank, M.; Drikakis, D. Effects of surface roughness on shear viscosity. Phys. Rev. 2017, 95, 33108. [Google Scholar] [CrossRef] [PubMed]

- Fnides, B.; Aouici, H.; Yallese, M.A. Cutting forces and surface roughness in hard turning of hot work steel X38CrMoV5-1 using mixed ceramic. J. Mech. 2008, 2, 73–78. [Google Scholar]

- Sundara Murthy, K.; Rajendran, I. A study on optimization of cutting parameters and prediction of surface roughness in end milling of aluminum under MQL machining. Int. J. Mach. Mach. Mater. 2010, 7, 112–128. [Google Scholar]

- Bacaria, J.L.; Dalverny, O.; Pantale, O.; Rakotomalala, R.; Caperaa, S. 2D and 3D Numerical Models of Metal Cutting with Damage Effects. Comput. Methods Appl. Mech. Eng. 2004, 193, 4383–4399. [Google Scholar]

- Sivararnakrishnaiah, M.; Nanda, K.P. Effect of Cutting Speed in Turning Process using Finite Element Modeling. Int. J. Latest Trends Eng. Technol. 2016, 7, 32–36. [Google Scholar]

- Xuebin, L.; Xibin, W.; Chongning, L.; Sanpeng, D. Finite Element Simulation of the Orthogonal Cutting Based on Abaqus. Adv. Mater. Res. 2013, 821–822, 1410–1413. [Google Scholar]

- Kun, H.; Wenyu, Y.; Qilin, C. Analytical model of stress field in workpiece machined surface layer in orthogonal cutting. Int. J. Mech. Sci. 2015, 103, 127–140. [Google Scholar]

- Irfan, O.M.; Mukras, S.M.S.; Al-Mufadi, F.A.; Djavanroodi, F. Surface Modelling of Nanostructured Copper Subjected to Erosion-Corrosion. Metals 2017, 7, 155. [Google Scholar] [CrossRef]

- Mahajan, K.A.; Sadaiah, M.; Gawande, S.H. Experimental Investigations of Surface Roughness on OFHC Copper by Diamond Turning Machine. Int. J. Eng. Sci. Technol. 2010, 2, 5215–5220. [Google Scholar]

- Available online: http://www.circuitinsight.com/pdf/measuring_copper_surface_roughness_ipc.pdf (accessed on 20 February 2018).

- Simulia. Abaqus Analysis User’s Manual, Volume IV: Elements; Dassault Systèmes Simulia Corp.: Johnston, RI, USA, 2016; pp. 29.6.1–29.6.10. [Google Scholar]

- Feng, B. Effects of surface roughness on scratch resistance and stress-strain fields during scratch tests. AIP Adv. 2017, 7, 35217. [Google Scholar] [CrossRef]

- Kiener, D.; Motz, C.; Schoberl, T.; Jenko, M.; Dehm, G. Determination of Mechanical Properties of Copper at the Micron Scale. Adv. Eng. Mater. 2006, 8, 1119–1125. [Google Scholar] [CrossRef]

- Wedberg, D.; Svoboda, A.; Lindgren, L.-E. Modelling high strain rate phenomena in metal cutting simulation. Model. Simul. Mater. Sci. Eng. 2012, 20, 1–19. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Villar, A.; Ugarte, D.; Marya, S. Serrated chip prediction in Finite Element modeling of the chip formation process. Mach. Sci. Technol. 2007, 11, 367–390. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture Characteristics of Three Metals Subjected to Various Strains, strain Rates, Temperature, and Pressures. Eng. Fract. Mech. J. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Agmell, M.; Ahadi, A.; Stahl, J.E. The Link between Plasticity Parameters and Process Parameters in Orthogonal Cutting. Procedia CIRP 2013, 8, 224–229. [Google Scholar] [CrossRef]

- Zouhar, J.; Piska, M. Modelling the orthogonal machining process using cutting tools with different geometry. MM Sci. J. 2008, 48/49, 1–4. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Xu, C. Evaluation of ductile fracture models in finite element simulation of metal cutting processes. J. Manuf. Sci. Eng. 2014, 136, 1–14. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z. Shear localization sensitivity analysis for Johnson–Cook constitutive parameters on serrated chips in high speed machining of Ti6Al4V. Simul. Model. Pract. Theory 2015, 55, 63–76. [Google Scholar] [CrossRef]

- Wang, K. Calibration of the Johnson-Cook Failure Parameters as the Chip Separation Criterion in the Modeling of the Orthogonal Metal Cutting Process. Master’s Thesis, McMaster University, Hamilton, ON, Canada, 2016; pp. 47–50. [Google Scholar]

- Bendarma, A.; Jankowiak, T.; Rusinek, A.; Klosak, M. Experimental and numerical analysis of aluminum alloy AW5005 behavior subjected to tension and perforation under dynamic loading. J. Theor. Appl. Mech. 2017, 55, 1219–1233. [Google Scholar] [CrossRef]

- ABAQUS. Abaqus/Explicit User’s Manuals; Version 6.11; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2011. [Google Scholar]

- Barber, J.R. Intermediate Mechanics of Materials, 2nd ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Irfan, O.M.; Al-Mufadi, F.; Al-Shataif, Y.; Djavanroodi, F. Effect of Equal Channel Angular Pressing (ECAP) on Erosion-Corrosion of Pure Copper. Appl. Sci. 2017, 7, 1250. [Google Scholar] [CrossRef]

- Biermann, D.; Hollmann, F. Thermal Effects in Complex Machining Processes; Springer International Publishing AG: Basel, Switzerland, 2018; p. 127. [Google Scholar]

- Biermann, D.; Liedschulte, M. Plasma-assisted turning of hard alloys on an iron base with PKB. Ind. Diam. Rundsch. 1994, 28, 71–77. [Google Scholar]

- Astakhov, V.P. Effects of the cutting feed, depth of cut, and work piece (bore) diameter on the tool wear rate. Int. J. Adv. Manuf. Technol. 2007, 34, 631–640. [Google Scholar] [CrossRef]

- Agmell, M.; Ahadi, A.; Gutnichenko, O.; Stahl, J. The influence of tool micro-geometry on stress distribution in turning operations of AISI 4140 by FE analysis. Int. J. Adv. Manuf. Technol. 2017, 89, 3109–3122. [Google Scholar] [CrossRef]

| Group | Constant Cutting Condition | Samples | Changed Cutting Condition | ||||

|---|---|---|---|---|---|---|---|

| Sample No. | |||||||

1 | 2 | 3 | 4 | 5 | |||

| A | N = 750, dc = 0.5 | f, (mm/rev) | 0.05 | 0.10 | 0.15 | 0.25 | 0.35 |

| B | ƒ = 0.5, dc = 0.5 | N, (rpm) | 500 | 750 | 1000 | 1250 | 1500 |

| C | ƒ = 0.5, N = 750 | dc, (mm) | 0.10 | 0.15 | 0.25 | 0.5 | 1.0 |

| Property | Value |

|---|---|

| Young’s modulus (E) | 117 GPa |

| Poisson’s ratio (ν) | 0.33 |

| Density (ρ) | 8950 Kg/m3 |

| Yield stress (σyo) | 112 MPa |

| A | B | C | n | m |

|---|---|---|---|---|

| 90 MPa | 292 MPa | 0.025 | 0.31 | 1.09 |

| D1 | D2 | D3 | D4 | D5 |

|---|---|---|---|---|

| 0.54 | 4.89 | −3.03 | 0.014 | 1.12 |

| Parameter | Objective | Optimum Cutting Conditions | ||

|---|---|---|---|---|

| Von Mises (σV.M.) stress | Minimum | N, (rpm) | f, (mm/rev) | dc, (mm) |

| 1500 | 0.15 | 0.5 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zein, H.; Irfan, O.M. Surface Roughness Investigation and Stress Modeling by Finite Element on Orthogonal Cutting of Copper. Metals 2018, 8, 418. https://doi.org/10.3390/met8060418

Zein H, Irfan OM. Surface Roughness Investigation and Stress Modeling by Finite Element on Orthogonal Cutting of Copper. Metals. 2018; 8(6):418. https://doi.org/10.3390/met8060418

Chicago/Turabian StyleZein, Hussein, and Osama M. Irfan. 2018. "Surface Roughness Investigation and Stress Modeling by Finite Element on Orthogonal Cutting of Copper" Metals 8, no. 6: 418. https://doi.org/10.3390/met8060418

APA StyleZein, H., & Irfan, O. M. (2018). Surface Roughness Investigation and Stress Modeling by Finite Element on Orthogonal Cutting of Copper. Metals, 8(6), 418. https://doi.org/10.3390/met8060418