Martensitic Transformation and Plastic Deformation of TiCuNiZr-Based Bulk Metallic Glass Composites

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

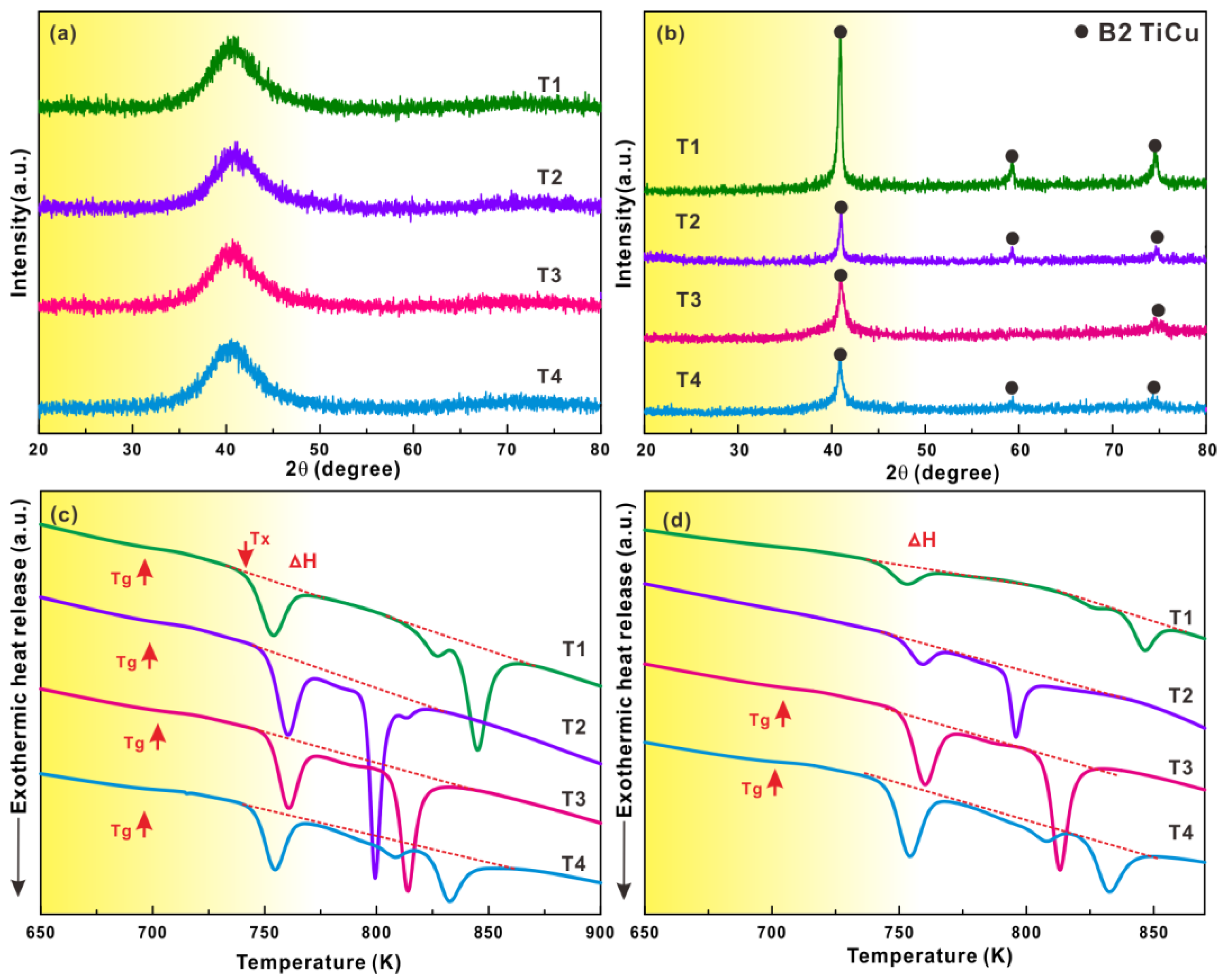

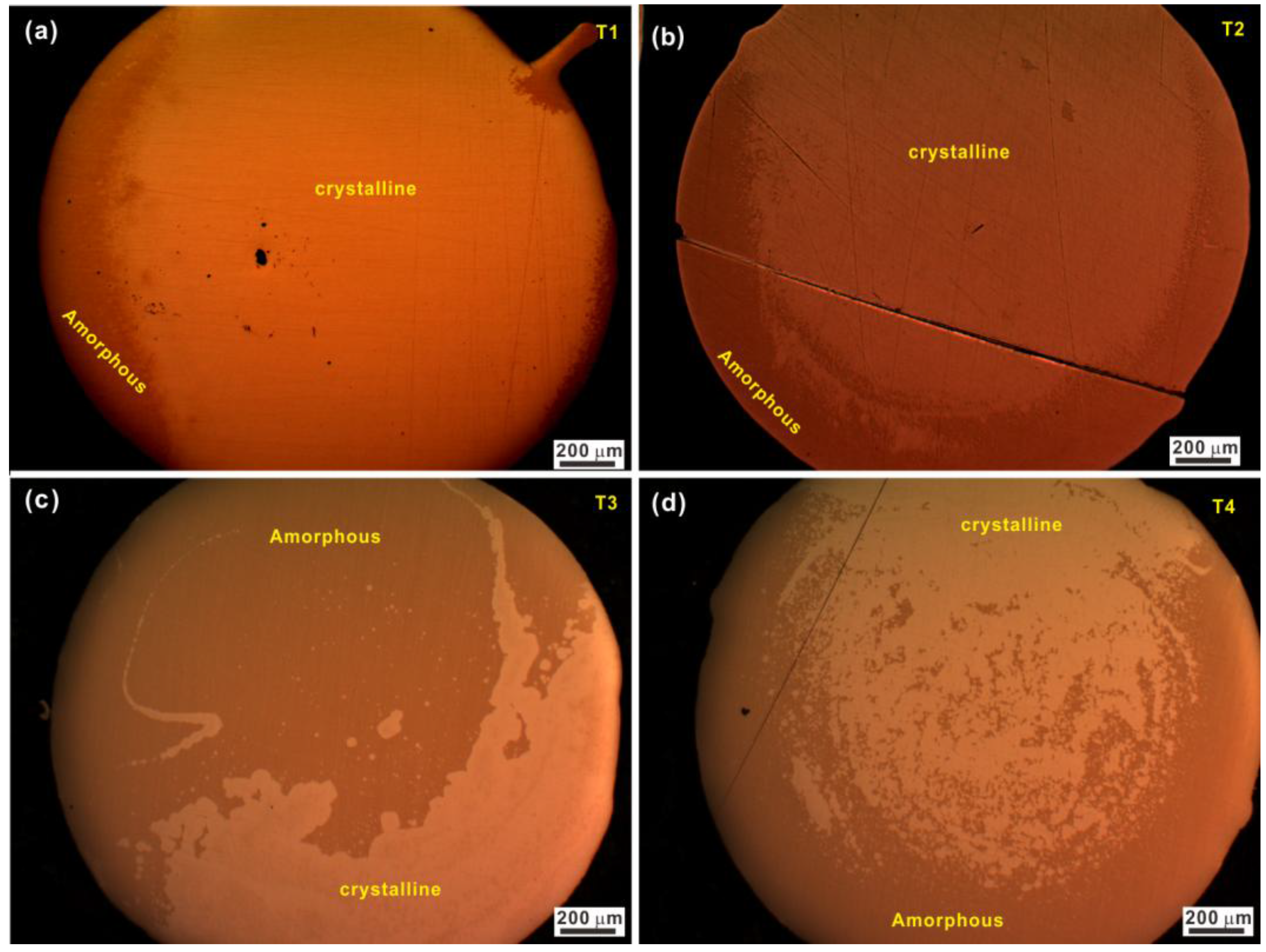

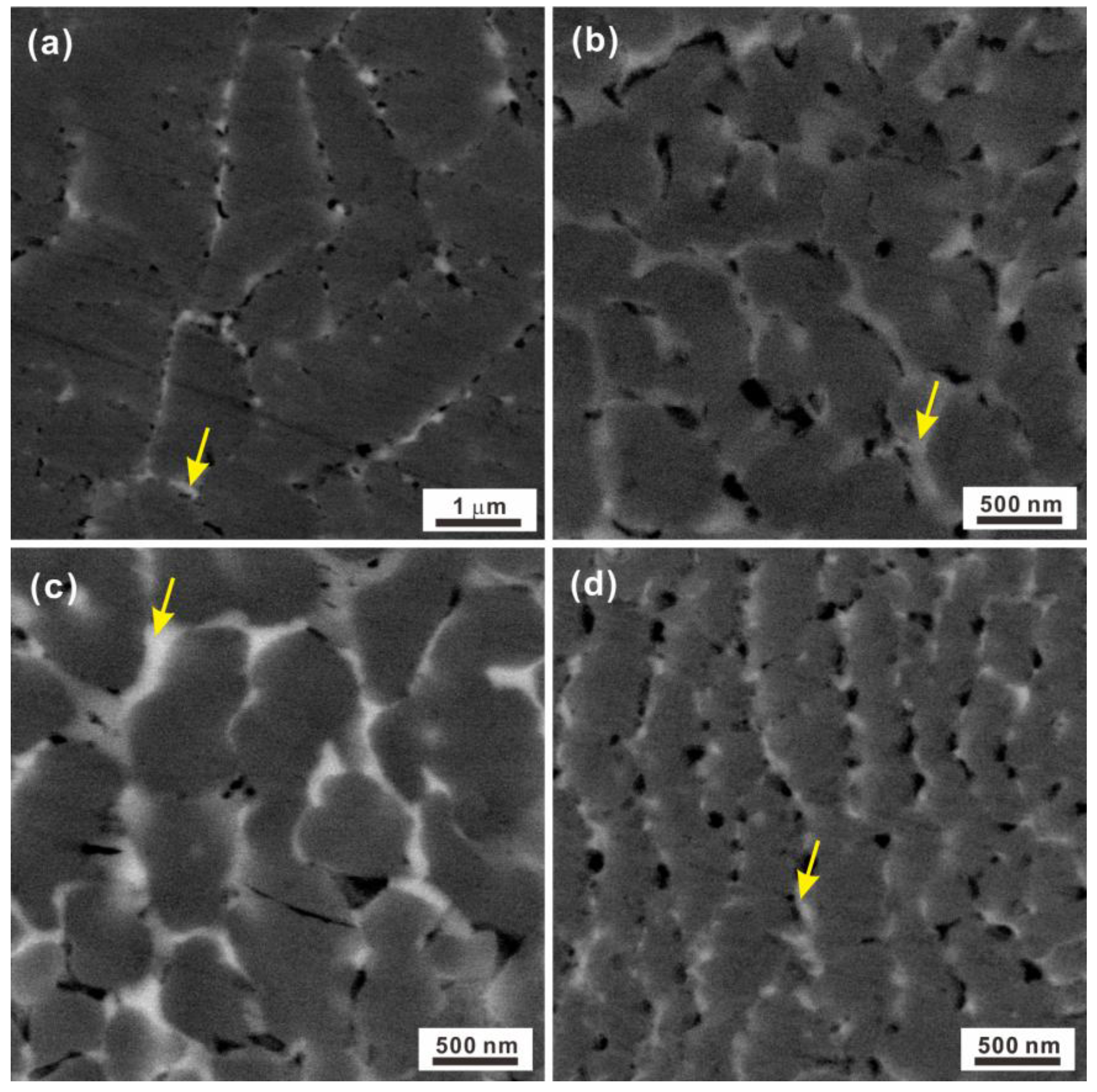

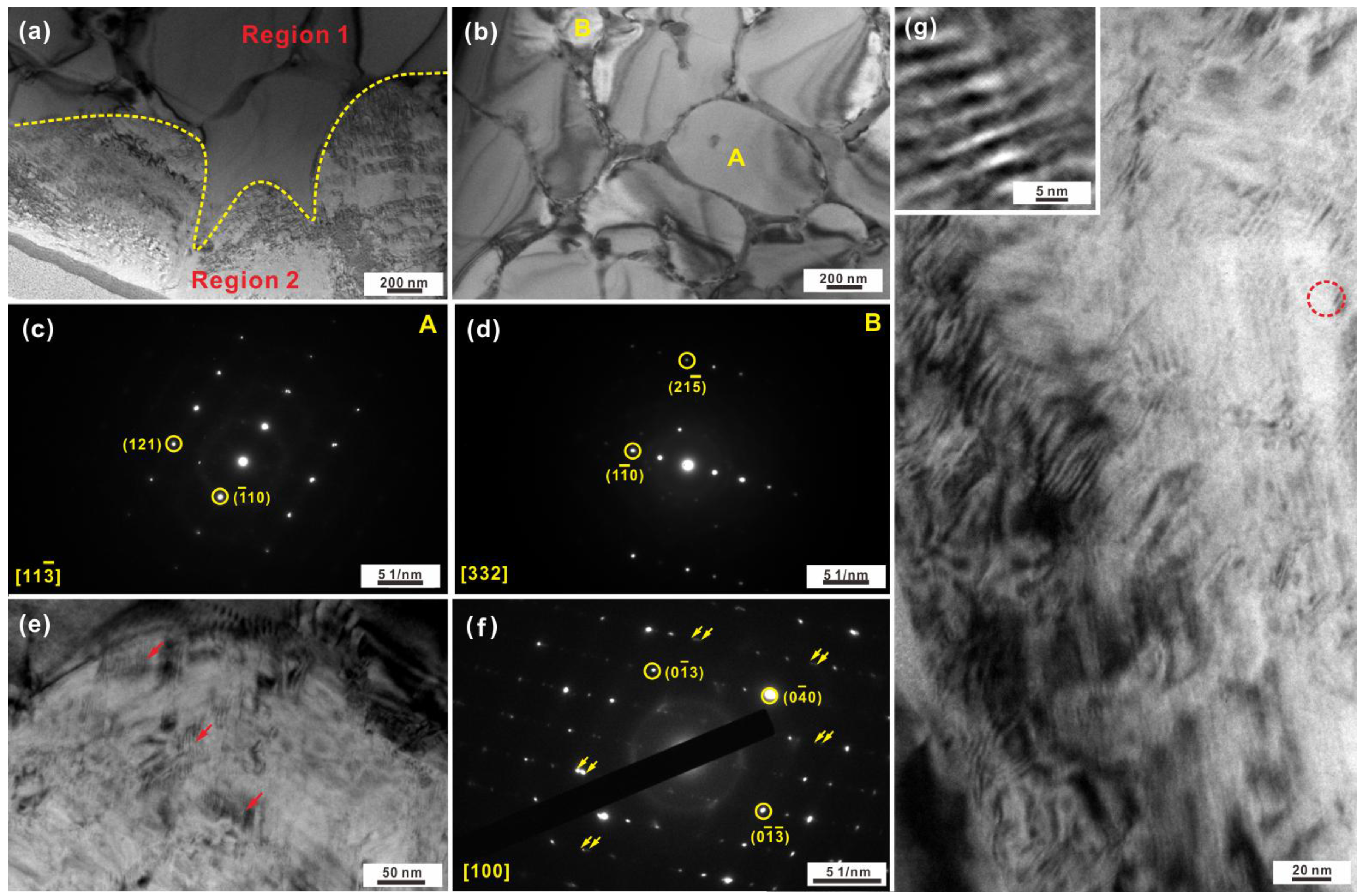

3.1. Phase Formation and Microstructural Features of Melt-Spun Ribbons and As-Cast Rods

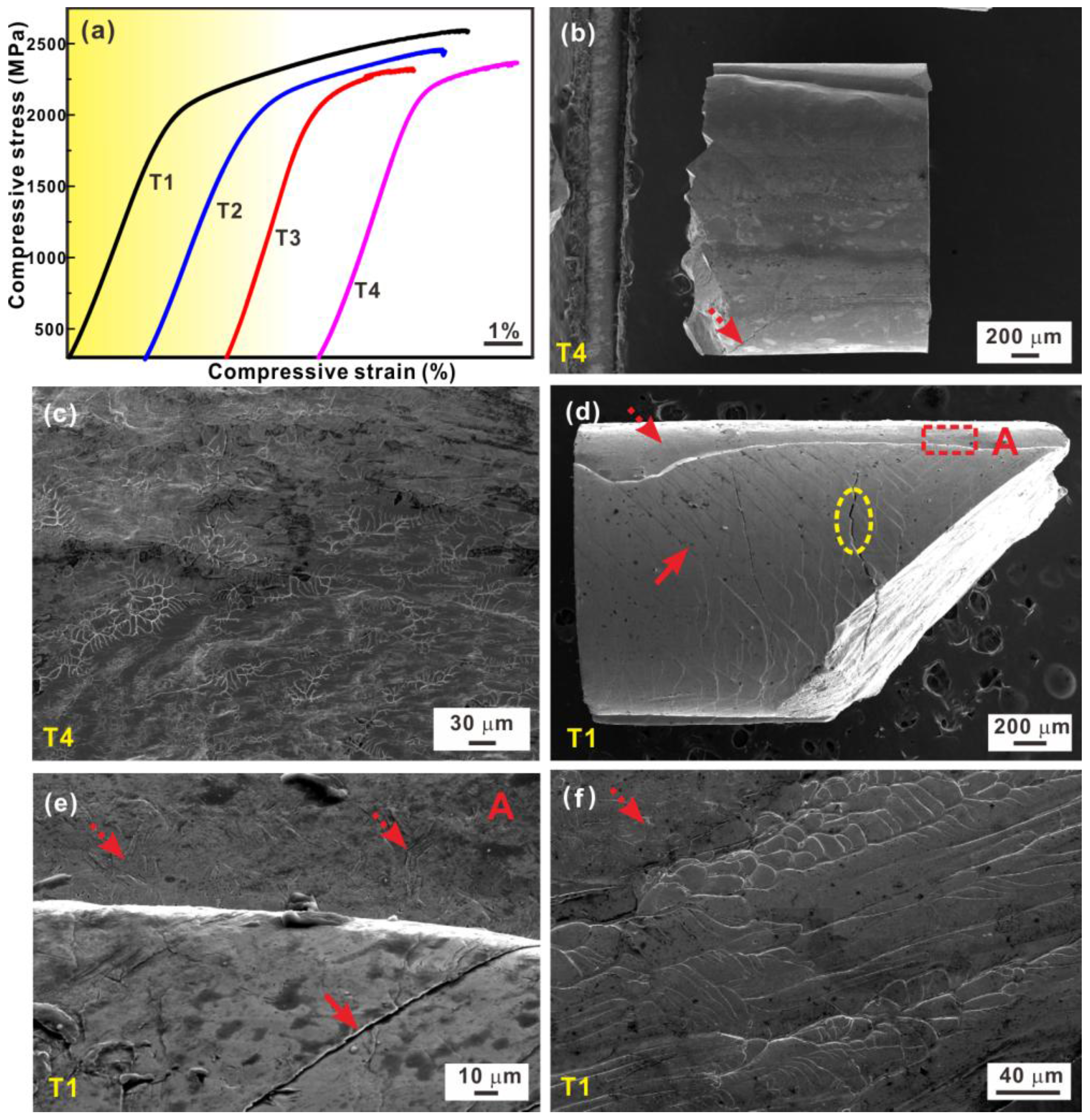

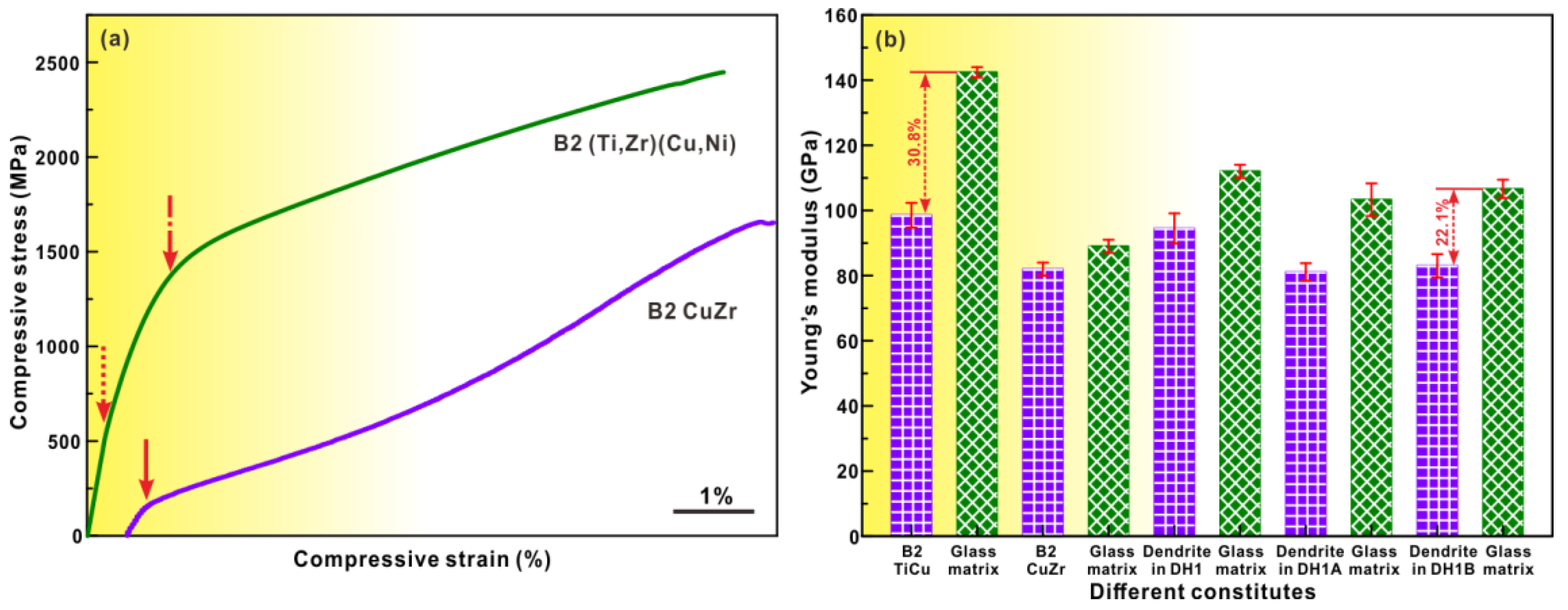

3.2. Mechanical Properties of the As-Cast Rods

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, W.T.; Park, E.S.; Mattern, N.; Eckert, J. Phase separation in metallic glasses. Prog. Mater. Sci. 2013, 58, 1103–1172. [Google Scholar] [CrossRef]

- Greer, A.L.; Cheng, Y.Q.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R Rep. 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Egami, T.; Iwashita, T.; Dmowski, W. Mechanical properties of metallic glasses. Metals 2013, 3, 77–113. [Google Scholar] [CrossRef]

- Qiao, J.W.; Jia, H.; Liaw, P.K. Metallic glass matrix composites. Mater. Sci. Eng. R Rep. 2016, 100, 1–69. [Google Scholar] [CrossRef]

- Eckert, J.; Das, J.; Pauly, S.; Duhamel, C. Processing routes, microstructure and mechanical properties of metallic glasses and their composites. Adv. Eng. Mater. 2007, 9, 443–453. [Google Scholar] [CrossRef]

- Choi-Yim, H.; Busch, R.; Köster, U.; Johnson, W.L. Synthesis and characterization of particulate reinforced Zr57Nb5Al10Cu15.4Ni12.6 bulk metallic glass composites. Acta Mater. 1999, 47, 2455–2462. [Google Scholar] [CrossRef]

- Choi-Yim, H.; Johnson, W.L. Bulk metallic glass matrix composites. Appl. Phys. Lett. 1997, 71, 3808–3810. [Google Scholar] [CrossRef]

- Madge, V.S.; Louzguine-Luzgin, V.D.; Inoue, A.; Greer, L.A. Large compressive plasticity in a La-based glass-crystal composite. Metals 2013, 3, 41–48. [Google Scholar] [CrossRef]

- Kim, J.Y.; Scudino, S.; Kühn, U.; Kim, B.S.; Lee, M.H.; Eckert, J. Production and characterization of brass-matrix composites reinforced with Ni59Zr20Ti16Si2Sn3 glassy particles. Metals 2012, 2, 79–94. [Google Scholar] [CrossRef]

- Bu, F.; Wang, J.; Li, L.; Kou, H.; Xue, X.; Li, J. The effect of thermal cycling treatments on the thermal stability and mechanical properties of a Ti-based bulk metallic glass composite. Metals 2016, 6, 274. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Development of tough, low-density titanium-based bulk metallic glass matrix composites with tensile ductility. Proc. Natl. Acad. Sci. USA 2008, 105, 20136–20140. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Duan, G.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.W.; Sun, A.C.; Huang, E.W.; Zhang, Y.; Liaw, P.K.; Chuang, C.P. Tensile deformation micromechanisms for bulk metallic glass matrix composites: From work-hardening to softening. Acta Mater. 2011, 59, 4126–4137. [Google Scholar] [CrossRef]

- Narayan, R.L.; Singh, P.S.; Hofmann, D.C.; Hutchinson, N.; Flores, K.M.; Ramamurty, U. On the microstructure-tensile property correlations in bulk metallic glass matrix composites with crystalline dendrites. Acta Mater. 2012, 60, 5089–5100. [Google Scholar] [CrossRef]

- Hays, C.C.; Kim, C.P.; Johnson, W.L. Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 2000, 84, 2901–2904. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Cheng, J.L.; Liu, C.T. Large-sized Zr-based bulk-metallic-glass composite with enhanced tensile properties. Intermetallics 2012, 28, 25–33. [Google Scholar] [CrossRef]

- Zhang, L.; Li, W.Q.; Zhu, Z.W.; Fu, H.M.; Li, H.; Li, Z.K.; Zhang, H.W.; Wang, A.M.; Zhang, H.F. Distribution of Be in a Ti-based bulk metallic glass composite containing β-Ti. J. Mater. Sci. Technol. 2017, 33, 708–711. [Google Scholar] [CrossRef]

- Qin, Y.S.; Han, X.L.; Song, K.K.; Tian, Y.H.; Peng, C.X.; Wang, L.; Sun, B.A.; Wang, G.; Kaban, I.; Eckert, J. Local melting to design strong and plastically deformable bulk metallic glass composites. Sci. Rep. 2017, 7, 42518. [Google Scholar] [CrossRef] [PubMed]

- Song, K.K.; Han, X.L.; Pauly, S.; Qin, Y.S.; Kosiba, K.; Peng, C.X.; Gong, J.H.; Chen, P.X.; Wang, L.; Sarac, B.; et al. Rapid and partial crystallization to design ductile CuZr-based bulk metallic glass composites. Mater. Des. 2018, 139, 132–140. [Google Scholar] [CrossRef]

- Wu, F.F.; Chan, K.C.; Jiang, S.S.; Chen, S.H.; Wang, G. Bulk metallic glass composite with good tensile ductility, high strength and large elastic strain limit. Sci. Rep. 2014, 4, 5302. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Song, K.K.; Cao, C.D.; Li, R.; Wang, G.; Wu, Y.; Wan, F.; Ding, F.L.; Shi, Y.; Bai, X.J.; et al. Deformation-induced martensitic transformation in Cu-Zr-Zn bulk metallic glass composites. Metals 2015, 5, 2134–2147. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y.; Chen, G.; Liu, C.T.; Lu, Z. Bulk metallic glass composites with transformation-mediated work-hardening and ductility. Adv. Mater. 2010, 22, 2770–2773. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Qin, Y.; Qin, K.; Li, X.; Wang, S.; Mi, J.; Song, K.; Wang, L. Glass-forming ability and early crystallization kinetics of novel Cu-Zr-Al-Co. bulk metallic glasses. Metals 2016, 6, 225. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, D.; Li, Q.K.; Stoica, A.D.; Song, W.L.; Wang, H.; Liu, X.J.; Stoica, G.M.; Wang, G.Y.; An, K.; et al. Transformation-induced plasticity in bulk metallic glass composites evidenced by in-situ neutron diffraction. Acta Mater. 2017, 124, 478–488. [Google Scholar] [CrossRef]

- Gargarella, P.; Pauly, S.; Samadi Khoshkhoo, M.; Kühn, U.; Eckert, J. Phase formation and mechanical properties of Ti-Cu-Ni-Zr bulk metallic glass composites. Acta Mater. 2014, 65, 259–269. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, J.T.; Mun, S.C.; Kim, Y.S.; Park, H.J.; Na, Y.S.; Lim, K.R.; Park, J.M.; Kim, K.B. Influence of spherical particles and interfacial stress distribution on viscous flow behavior of Ti-Cu-Ni-Zr-Sn bulk metallic glass composites. Intermetallics 2017, 91, 90–94. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Wu, Y.; Zhou, J.; Wang, H.; Liu, X.J.; Lu, Z.P. Strong work-hardening behavior in a Ti-based bulk metallic glass composite. Scr. Mater. 2013, 69, 73–76. [Google Scholar] [CrossRef]

- Liu, D.; Zhu, Z.; Li, Z.; Zhang, L.; Fu, H.; Wang, A.; Li, H.; Zhang, H.; Wang, Y.; Zhang, H. Modulating work-hardening behaviors and tensile plasticity of in-situ formed ductile dendrite Ti-based bulk metallic glass composites with tailored dendrite composition. Scr. Mater. 2018, 146, 22–26. [Google Scholar] [CrossRef]

- Oh, Y.S.; Kim, C.P.; Lee, S.; Kim, N.J. Microstructure and tensile properties of high-strength high-ductility Ti-based amorphous matrix composites containing ductile dendrites. Acta Mater. 2011, 59, 7277–7286. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.F.; Li, W.Q.; Gemming, T.; Wang, P.; Bönisch, M.; Şopu, D.; Eckert, J.; Pauly, S. β-type Ti-based bulk metallic glass composites with tailored structural metastability. J. Alloys Compd. 2017, 708, 972–981. [Google Scholar] [CrossRef]

- Kim, K.B.; Zhang, X.F.; Yi, S.; Lee, M.H.; Das, J.; Eckert, J. Effect of local chemistry, structure and length scale of heterogeneities on the mechanical properties of a Ti45Cu40Ni7.5Zr5Sn2.5 bulk metallic glass. Philos. Mag. Lett. 2008, 88, 75–81. [Google Scholar] [CrossRef]

- Shen, J.; Huang, Y.; Sun, J. Plasticity of a TiCu-based bulk metallic glass: Effect of cooling rate. J. Mater. Res. 2007, 22, 3067–3074. [Google Scholar] [CrossRef]

- Wang, G.; Liu, Y.H.; Yu, P.; Zhao, D.Q.; Pan, M.X.; Wang, W.H. Structural evolution in TiCu-based bulk metallic glass with large compressive plasticity. Appl. Phys. Lett. 2006, 89, 251909. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, J.T.; Park, H.J.; Kim, Y.S.; Suh, J.Y.; Na, Y.S.; Lim, K.R.; Park, J.M.; Kim, K.B. Gradual martensitic transformation of B2 phase on TiCu-based bulk metallic glass composite during deformation. Intermetallics 2016, 75, 1–7. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, J.T.; Park, H.J.; Suh, J.Y.; Lim, K.R.; Na, Y.S.; Park, J.M.; Kim, K.B. Work-hardening and plastic deformation behavior of Ti-based bulk metallic glass composites with bimodal sized B2 particles. Intermetallics 2015, 62, 36–42. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, J.T.; Lee, M.W.; Park, J.M.; Lee, M.H.; Kim, B.S.; Park, J.Y.; Seo, Y.; Suh, J.Y.; Yu, P.; et al. Combinatorial influence of bimodal size of B2 TiCu compounds on plasticity of Ti-Cu-Ni-Zr-Sn-Si bulk metallic glass composites. Metall. Mater. Trans. A 2014, 45, 2376–2381. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Song, K.K.; Pauly, S.; Zhang, Y.; Li, R.; Gorantla, S.; Narayanan, N.; Kühn, U.; Gemming, T.; Eckert, J. Triple yielding and deformation mechanisms in metastable Cu47.5Zr47.5Al5 composites. Acta Mater. 2012, 60, 6000–6012. [Google Scholar] [CrossRef]

- Hermann, H.; Kokotin, V.; Eckert, J. Locally fluctuating cooling rate as possible reason for non-crystalline plasticity in metallic glasses. Europhys. Lett. 2012, 98, 16003. [Google Scholar] [CrossRef]

- Pauly, S.; Liu, G.; Wang, G.; Kühn, U.; Mattern, N.; Eckert, J. Microstructural heterogeneities governing the deformation of Cu47.5Zr47.5Al5 bulk metallic glass composites. Acta Mater. 2009, 57, 5445–5453. [Google Scholar] [CrossRef]

- Fu, X.L.; Li, Y.; Schuh, C.A. Mechanical properties of metallic glass matrix composites: Effects of reinforcement character and connectivity. Scr. Mater. 2007, 56, 617–620. [Google Scholar] [CrossRef]

- Glicksman, M.E. Principles of Solidification: An Introduction to Modern Casting and Crystal Growth Concepts, 1st ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Gargarella, P.; Pauly, S.; Khoshkhoo, M.S.; Kiminami, C.S.; Kühn, U.; Eckert, J. Improving the glass-forming ability and plasticity of a TiCu-based bulk metallic glass composite by minor additions of Si. J. Alloys Compd. 2016, 663, 531–539. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Wu, Y.; Zhou, J.; Song, W.L.; Cao, D.; Wang, H.; Liu, X.J.; Lu, Z.P. Effects of Sn addition on phase formation and mechanical properties of TiCu-based bulk metallic glass composites. Intermetallics 2013, 42, 68–76. [Google Scholar] [CrossRef]

- Chen, T.H.; Hsu, Y.K. Mechanical properties and microstructural of biomedical Ti-based bulk metallic glass with Sn addition. Comput. Mater. Sci. 2016, 117, 584–589. [Google Scholar] [CrossRef]

- Gargarella, P.; Pauly, S.; Song, K.K.; Hu, J.; Barekar, N.S.; Samadi Khoshkhoo, M.; Teresiak, A.; Wendrock, H.; Kühn, U.; Ruffing, C.; et al. Ti-Cu-Ni shape memory bulk metallic glass composites. Acta Mater. 2013, 61, 151–162. [Google Scholar] [CrossRef]

- Yang, S.; Li, D.; Li, X.C.; Zhang, Z.Z.; Zhang, S.F.; He, L. Composition dependence of the microstructure and mechanical behavior of Ti-Zr-Cu-Pd-Sn-Nb bulk metallic glass composites. Intermetallics 2017, 90, 1–8. [Google Scholar] [CrossRef]

- Schryvers, D.; Firstov, G.S.; Seo, J.W.; Van Humbeeck, J.; Koval, Y.N. Unit cell determination in CuZr martensite by electron microscopy and X-ray diffraction. Scr. Mater. 1997, 36, 1119–1125. [Google Scholar] [CrossRef]

- Xi, X.K.; Zhao, D.Q.; Pan, M.X.; Wang, W.H.; Wu, Y.; Lewandowski, J.J. Fracture of brittle metallic glasses: Brittleness or plasticity. Phys. Rev. Lett. 2012, 109, 245506. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, H.; Wu, H.H.; Zhang, Z.Y.; Hui, X.D.; Chen, G.L.; Ma, D.; Wang, X.L.; Lu, Z.P. Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties. Acta Mater. 2011, 59, 2928–2936. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, D.Q.; Song, W.L.; Wang, H.; Zhang, Z.Y.; Ma, D.; Wang, X.L.; Lu, Z.P. Ductilizing bulk metallic glass composite by tailoring stacking fault energy. Phys. Rev. Lett. 2012, 109, 245506. [Google Scholar] [CrossRef] [PubMed]

- Brink, T.; Peterlechner, M.; Rösner, H.; Albe, K.; Wilde, G. Influence of crystalline nanoprecipitates on shear-band propagation in Cu-Zr-based metallic glasses. Phys. Rev. Appl. 2016, 5, 054005. [Google Scholar] [CrossRef]

- Narayan, R.; Boopathy, K.; Sen, I.; Hofmann, D.; Ramamurty, U. On the hardness and elastic modulus of bulk metallic glass matrix composites. Scr. Mater. 2010, 63, 768–771. [Google Scholar] [CrossRef]

- Corteen, J.; Rainforth, M.; Todd, I. A mathematical approach to transformation toughening in bulk metallic glasses. Scr. Mater. 2011, 65, 524–527. [Google Scholar] [CrossRef]

- Pauly, S.; Liu, G.; Gorantla, S.; Wang, G.; Kühn, U.; Kim, D.H.; Eckert, J. Criteria for tensile plasticity in Cu-Zr-Al bulk metallic glasses. Acta Mater. 2010, 58, 4883–4890. [Google Scholar] [CrossRef]

- Okulov, I.V.; Soldatov, I.V.; Sarmanova, M.F.; Kaban, I.; Gemming, T.; Edstrøm, K.; Eckert, J. Flash joule heating for ductilization of metallic glasses. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhou, S.; Wang, X. Effects of rare earth addition on microstructure and mechanical properties of a Fe-15Mn-1.5Al-0.6C TWIP steel. Mater. Sci. Eng. A 2014, 608, 106–113. [Google Scholar] [CrossRef]

- Khaund, A.K.; Nicholson, P.S. Fracture of a brittle composite: Influence of elastic mismatch and interfacial bonding. J. Mater. Sci. 1980, 15, 177–187. [Google Scholar] [CrossRef]

- Murali, P.; Bhandakkar, T.K.; Cheah, W.L.; Jhon, M.H.; Gao, H.; Ahluwalia, R. Role of modulus mismatch on crack propagation and toughness enhancement in bioinspired composites. Phys. Rev. E 2011, 84, 015102. [Google Scholar] [CrossRef] [PubMed]

- He, M.Y.; Evans, A.G.; Hutchinson, J.W. Crack deflection at an interface between dissimilar elastic materials: Role of residual stresses. Int. J. Solids Struct. 1994, 31, 3443–3455. [Google Scholar] [CrossRef]

| Composition | Tg (K) | Tx (K) | ΔTrg (K) | fc1 (vol. %) | fc2 (vol. %) |

|---|---|---|---|---|---|

| T1 | 689 ± 3 | 743 ± 1 | 54 ± 4 | 83.7 ± 5.8 | 85.5 ± 5.5 |

| T2 | 693 ± 3 | 751 ± 1 | 58 ± 4 | 86.9 ± 6.1 | 70.0 ± 5.5 |

| T3 | 692 ± 3 | 752 ± 1 | 60 ± 4 | 44.0 ± 7.9 | 37.7 ± 5.5 |

| T4 | 687 ± 3 | 746 ± 1 | 59 ± 4 | 38.5 ± 8.6 | 37.4 ± 5.5 |

| Composition | Yield Strength (MPa) | Fracture Strength (MPa) | Plastic Strain (%) |

|---|---|---|---|

| T1 | 1915 ± 45 | 2590 ± 45 | 7.7 ± 1.0 |

| T2 | 1890 ± 35 | 2456 ± 35 | 5.3 ± 0.9 |

| T3 | 1974 ± 15 | 2311 ± 15 | 2.6 ± 0.5 |

| T4 | 2127 ± 15 | 2364 ± 15 | 2.4 ± 0.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Song, K.; Han, X.; Xing, H.; Li, X.; Wang, S.; Kim, J.T.; Chawake, N.; Maity, T.; Wang, L.; et al. Martensitic Transformation and Plastic Deformation of TiCuNiZr-Based Bulk Metallic Glass Composites. Metals 2018, 8, 196. https://doi.org/10.3390/met8030196

Sun H, Song K, Han X, Xing H, Li X, Wang S, Kim JT, Chawake N, Maity T, Wang L, et al. Martensitic Transformation and Plastic Deformation of TiCuNiZr-Based Bulk Metallic Glass Composites. Metals. 2018; 8(3):196. https://doi.org/10.3390/met8030196

Chicago/Turabian StyleSun, Honggang, Kaikai Song, Xiaoliang Han, Hui Xing, Xuelian Li, Shenghai Wang, Jeong Tae Kim, Niraj Chawake, Tapabrata Maity, Li Wang, and et al. 2018. "Martensitic Transformation and Plastic Deformation of TiCuNiZr-Based Bulk Metallic Glass Composites" Metals 8, no. 3: 196. https://doi.org/10.3390/met8030196

APA StyleSun, H., Song, K., Han, X., Xing, H., Li, X., Wang, S., Kim, J. T., Chawake, N., Maity, T., Wang, L., & Eckert, J. (2018). Martensitic Transformation and Plastic Deformation of TiCuNiZr-Based Bulk Metallic Glass Composites. Metals, 8(3), 196. https://doi.org/10.3390/met8030196