Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method

Abstract

1. Introduction

2. Experimental Procedure

2.1. Material

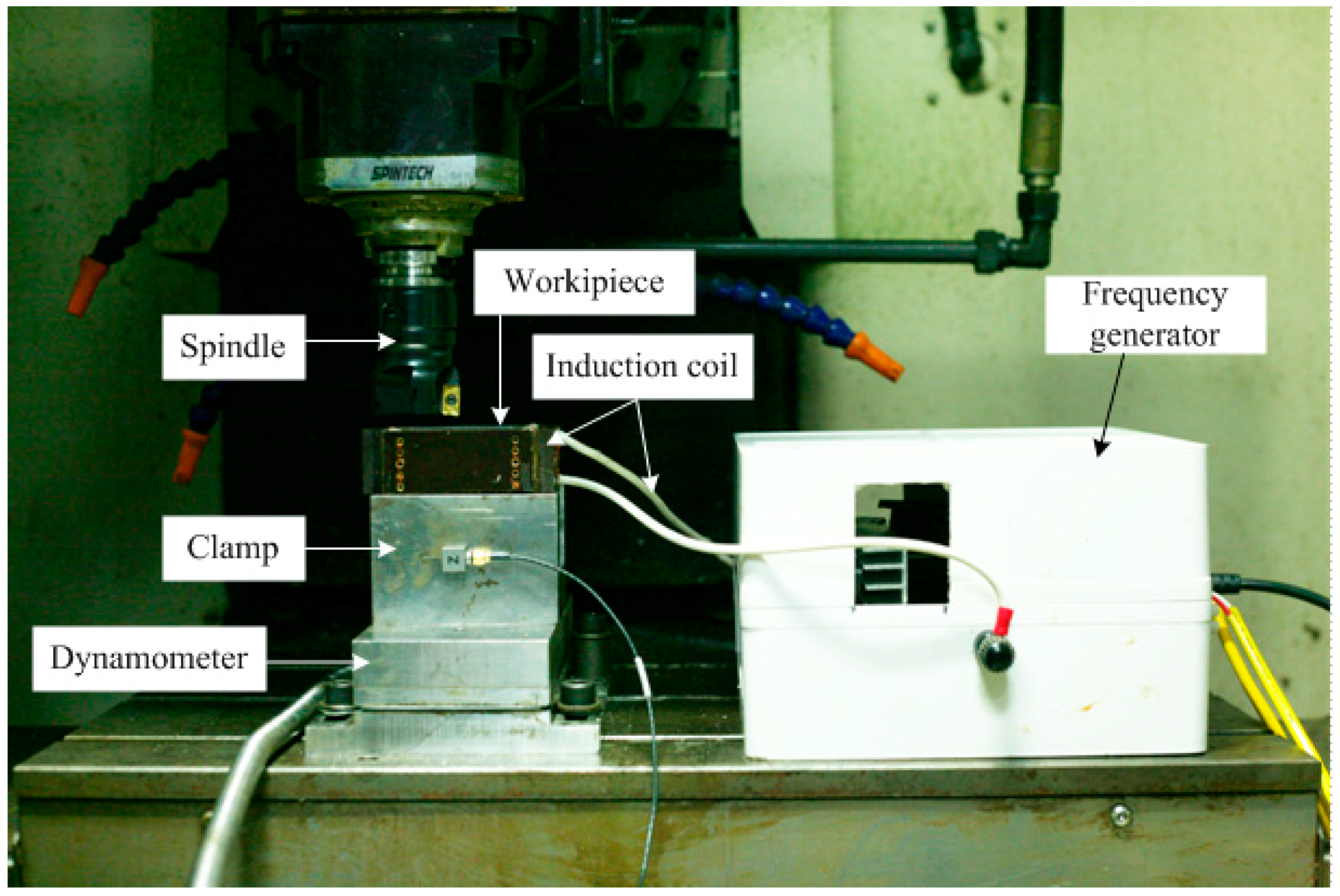

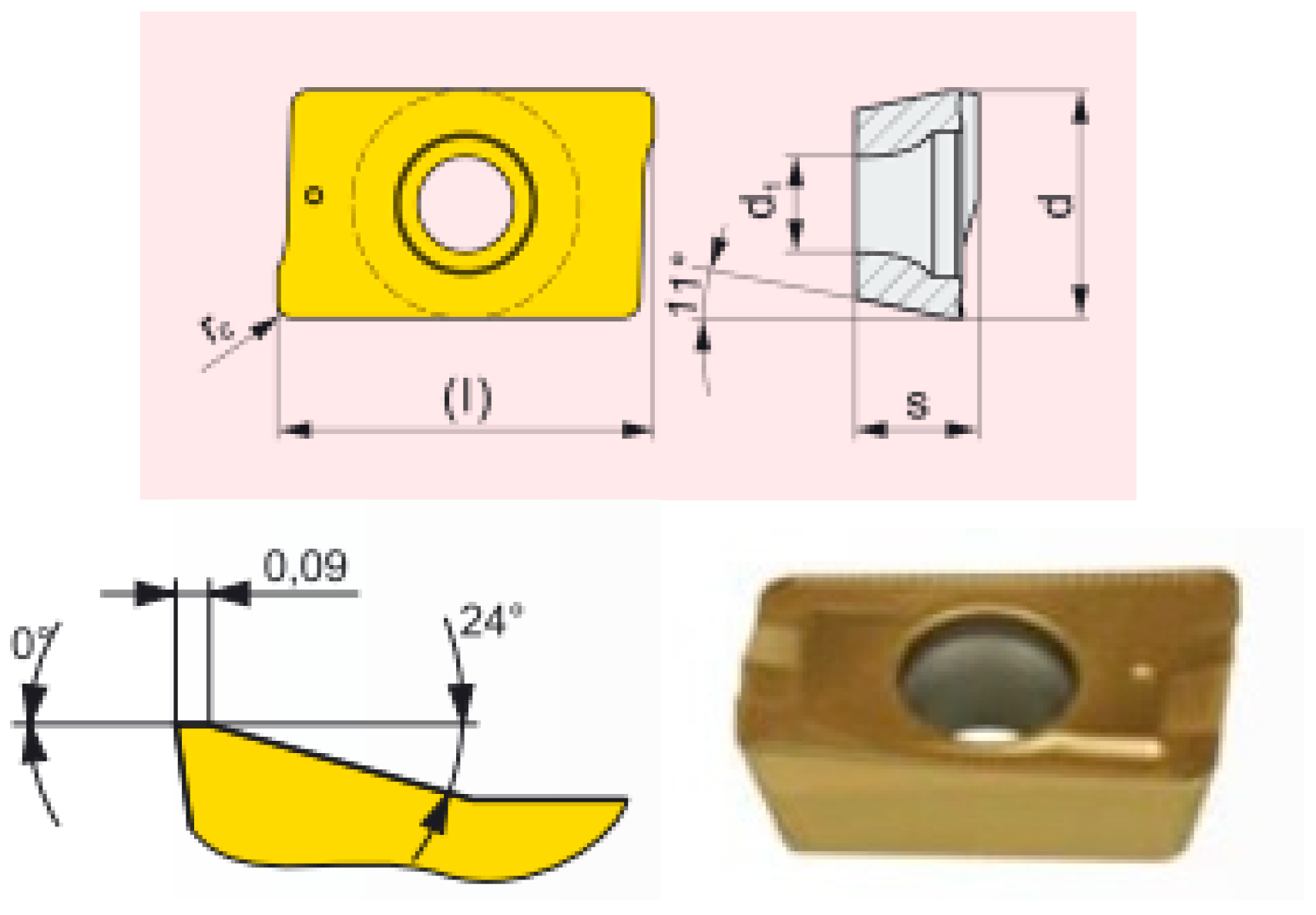

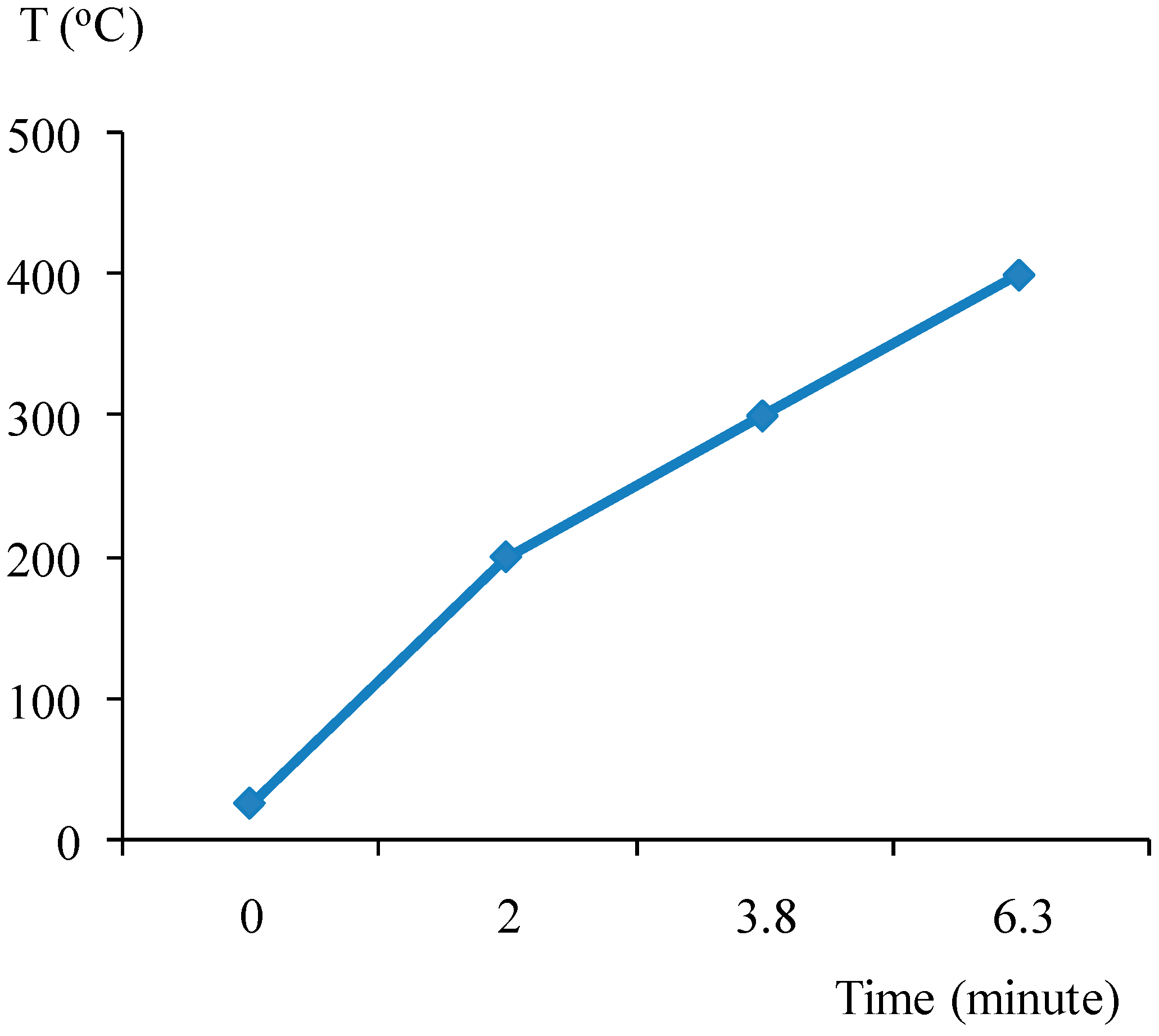

2.2. Experimental Setup

3. Design of Experiment

4. Results and Discussion

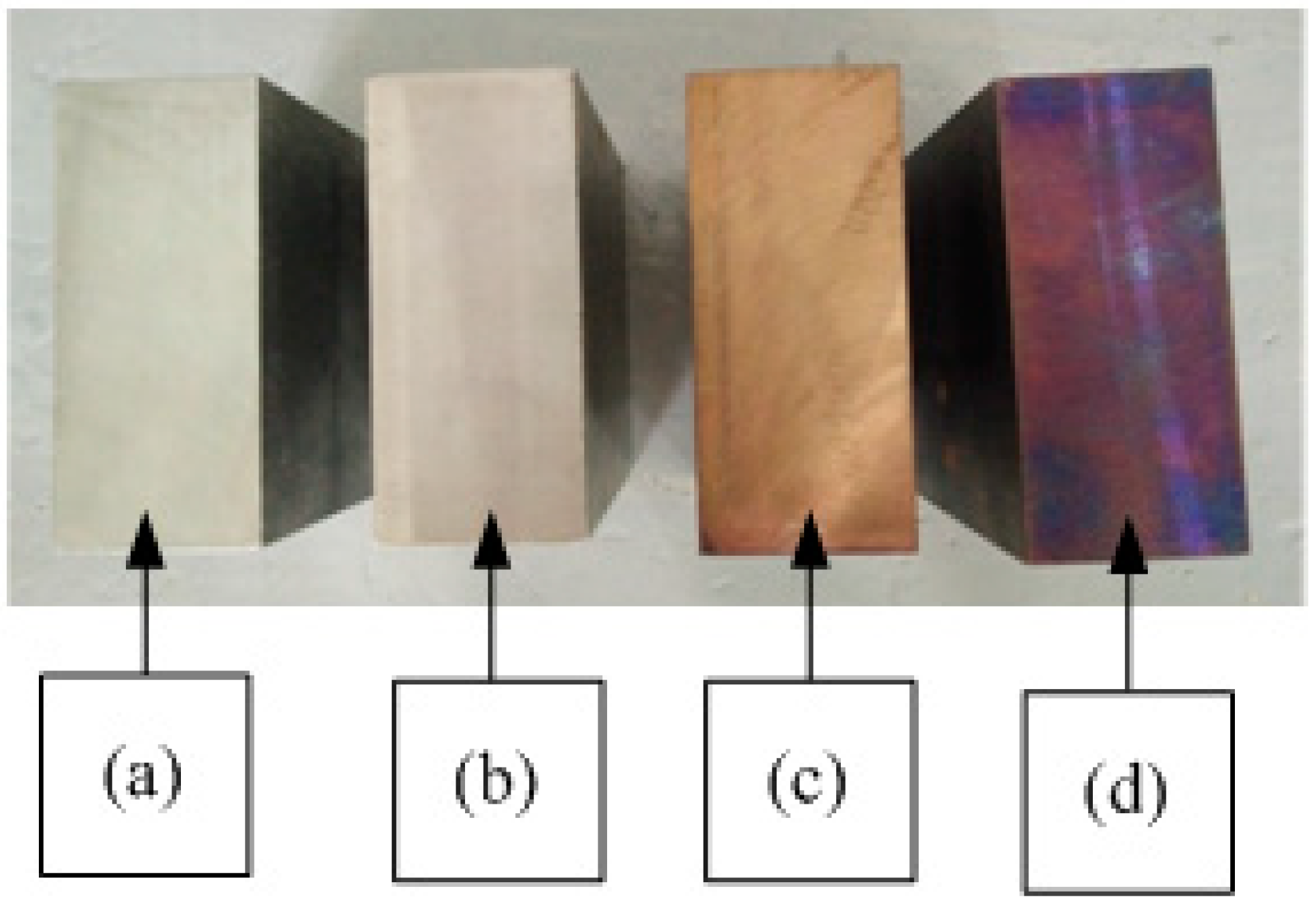

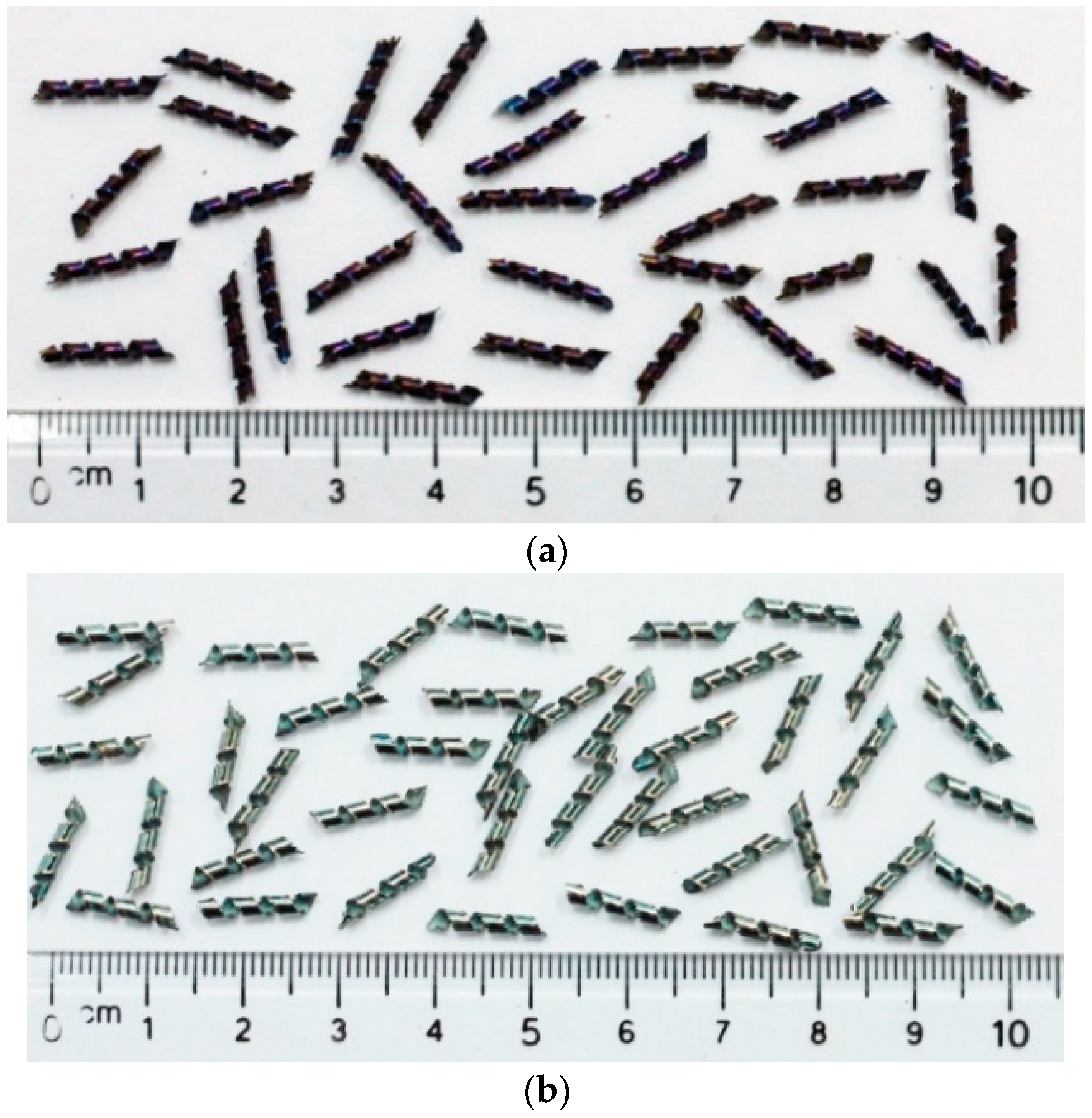

4.1. Chip Morphology

4.2. Experimental Machining at Room Temperature

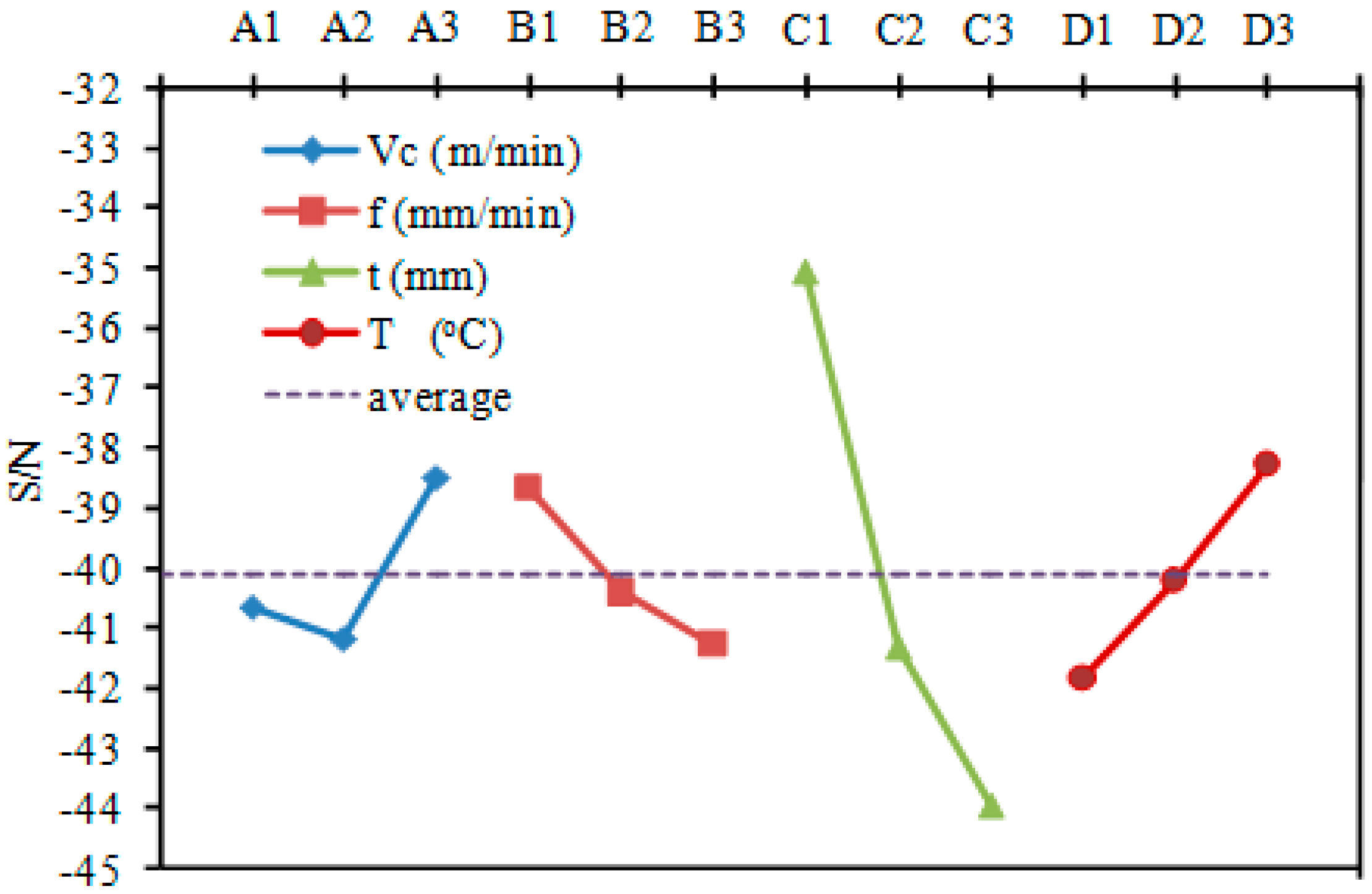

4.3. Experimental Machining at Elevated Temperatures

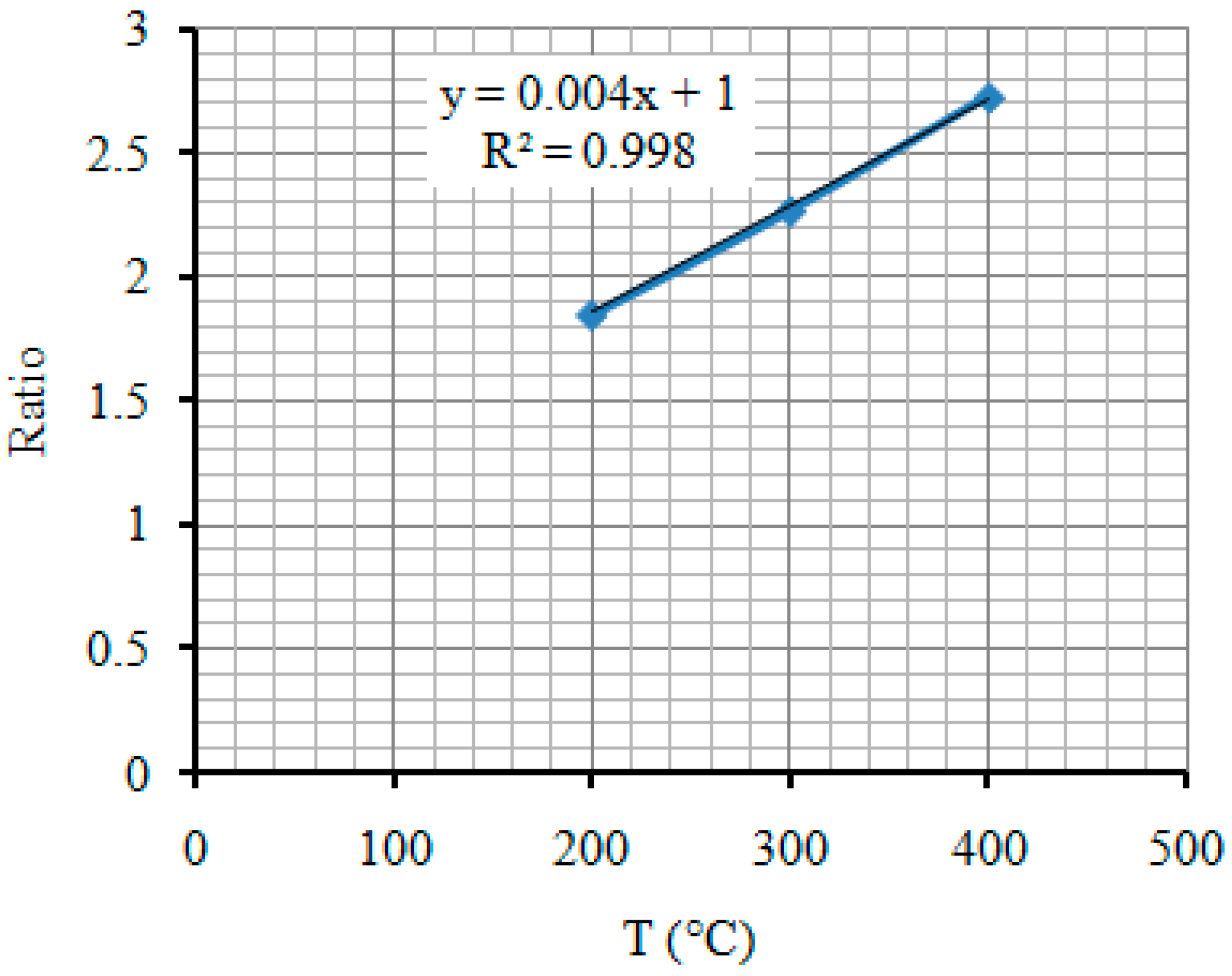

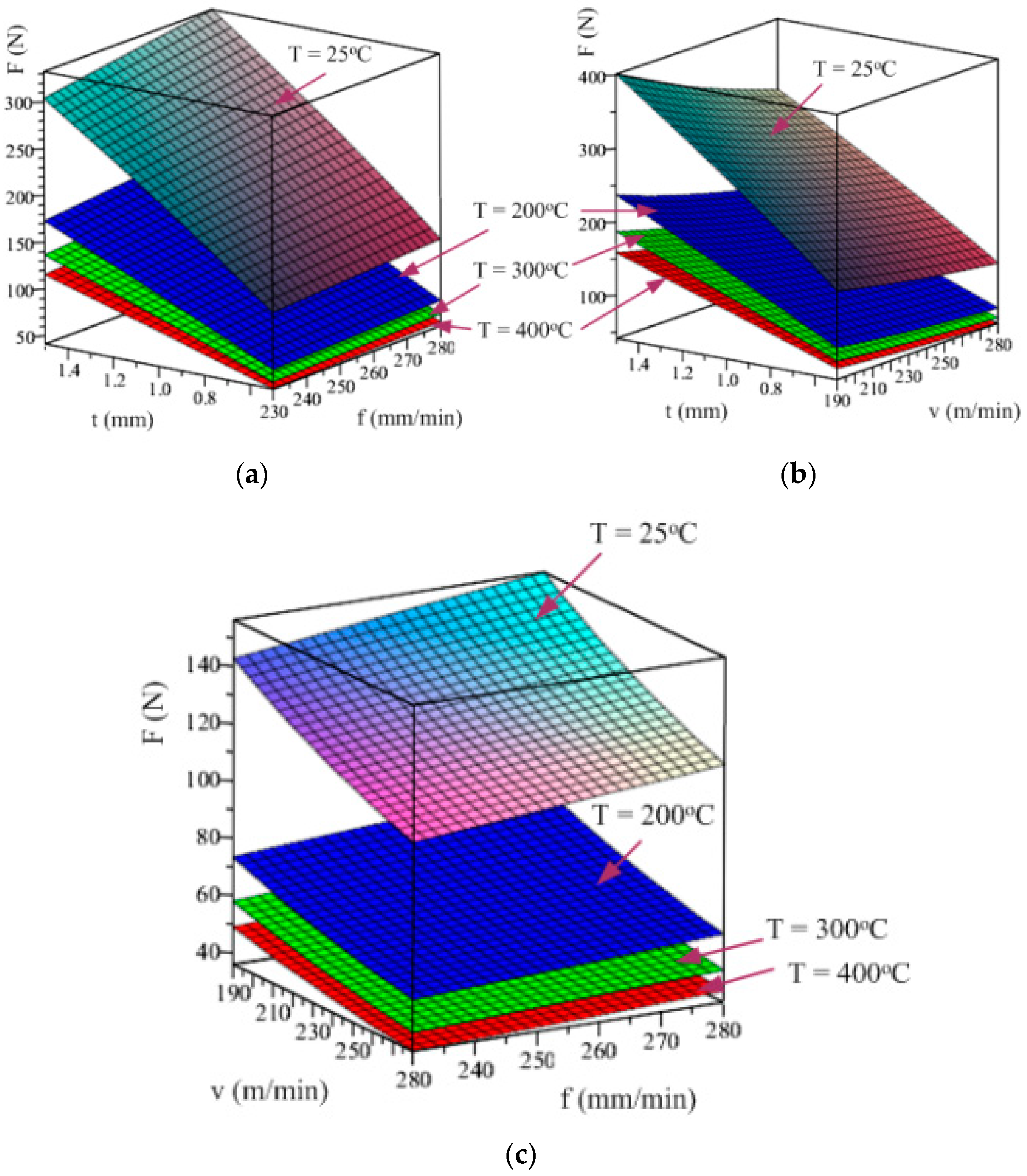

4.4. Establishing Cutting Force Model with Thermal-Assisted Machining

5. Conclusions

- Thermal-assisted process effect on chip morphology. The chip’s colour change in TAM with brighter colour while chip’s colour is violet-black in conventional machining.

- It is observed that the maximum cutting forces reduction of 66.9% in TAM when compared to conventional machining.

- The optimal condition of parameters obtained for thermal-assisted machining are cutting speed of 280 m/min, feed rate of 230 mm/min, cutting depth of 0.5 mm, and temperature of 400 °C.

- A new method for predicting the cutting forces in thermal-assisted milling by induction heating of SKD11 is presented show good result when comparing with experimental data.

Author Contributions

Funding

Conflicts of Interest

References

- Shatarupa, G.; Gurav, P.; Rajiv, B.; Suvrna, P. A Review on Effect of Cutting Parameters in Hot Turning Operation on Surface Finish. Int. J. Eng. Dev. Res. 2016, 4, 55–61. [Google Scholar]

- Baili, M.; Wagner, V.; Dessein, G.; Sallaberry, J.; Lallement, D. An experimental investigation of hot machining with induction to improve Ti-5553 machinability. Appl. Mech. Mater. 2011, 62, 67–76. [Google Scholar] [CrossRef]

- Brecher, C.; Emonts, M.; Rosen, C.; Hermani, J. Laser-assisted Milling of Advanced Materials. Phys. Procedia 2011, 12, 599–606. [Google Scholar] [CrossRef]

- Germain, G.; Santo, P.D.; Lebrun, J.L. Comprehension of chip formation in laser assisted machining. Int. J. Mach. Tools Manuf. 2011, 51, 230–238. [Google Scholar] [CrossRef]

- Amin, K.M.N.; Binti, S.; Binti, M.; Lajis, M.A. Effects of workpiece preheating on surface roughness, chatter and tool performance during end milling of hardened steel D2. J. Mater. Process. Technol. 2007, 1, 466–470. [Google Scholar] [CrossRef]

- Thi-Hoa, P.; Thi-Bich, M.; Van-Canh, T.; Tien-Long, B.; Duc-Toan, N. A study on the cutting force and chip shrinkage coefficient in high-speed milling of A6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 177–188. [Google Scholar] [CrossRef]

- Ozler, L.; Inan, A.; Ozel, C. Theoretical and experimental determination of tool life in hot machining of austenitic manganese steel. Int. J. Mach. Tools Manuf. 2001, 41, 163–172. [Google Scholar] [CrossRef]

- Amin, K.M.N.; Ginta, T.L. Heat-Assisted Machining; Elsevier: Amsterdam, The Netherlands, 2014; Volume 11. [Google Scholar]

- Sadeghipour, K.; Dopkin, J.A.; Li, K. A computer aided finite element/experimental analysis of induction heating process of steel. Comput. Ind. 1996, 28, 195–205. [Google Scholar] [CrossRef]

- Pham, T.-H.; Mac, T.-B.; Tong, V.-C.; Banh, T.-L.; Nguyen, D.-T. Simulation and experimental studies to verify the effect of cutting parameters on chip shrinkage coefficient and cutting forces in machining of A6061 aluminum alloy. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Ginta, T.L.; Amin, A.K.M.N. Thermally-assisted end milling of titanium alloy Ti-6Al-4V using induction heating. Int. J. Mach. Mach. Mater. 2013, 14, 194–212. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. The Effect of a Laser Beam on Chip Formation during Machining of Ti6Al4V Alloy. Phys. Metall. Mater. Sci. 2010, 41, 1573–1581. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Rajurkar, K.P.; Fan, J.; Lei, S.; Shin, Y.C.; Petrescu, G. Hybrid machining of Inconel 718. Int. J. Mach. Tools Manuf. 2003, 43, 1391–1396. [Google Scholar] [CrossRef]

- Novak, J.W.; Shin, Y.C.; Incropera, F.P. Assessment of plasma enhanced machining for improved machinability of Inconel 718. J. Manuf. Sci. Eng. 1997, 119, 125–129. [Google Scholar] [CrossRef]

- Leshock, C.E.; Kim, J.-N.; Shin, Y.C. Plasma enhanced machining of Inconel 718: Modeling of workpiece temperature with plasma heating and experimental results. Int. J. Mach. Tools Manuf. 2001, 41, 877–897. [Google Scholar] [CrossRef]

- Shi, B.; Attia, H.; Vargas, R.; Tavakoli, S. Numerical and experimental investigation of laser-assisted machining of Inconel 718. Mach. Sci. Technol. 2008, 12, 498–513. [Google Scholar] [CrossRef]

- Dumitrescu, P.; Koshy, P.; Stenekes, J.; Elbestawi, M.A. High-power diode laser assisted hard turning AISI D2 tool steel. Int. J. Mach. Tools Manuf. 2006, 46, 2009–2016. [Google Scholar] [CrossRef]

- Rajagopal, S.; Plankenhorn, D.J.; Hill, V.L. Machining aerospace alloys with the aid of a 15 kW laser. J. Appl. Metalwork. 1982, 2, 170–184. [Google Scholar] [CrossRef]

- Ganta, V.; Chakradhar, D. Multi objective optimization of hot machining of 15-5PH stainless steel using grey relation analysis. Procedia Mater. Sci. 2014, 5, 1810–1818. [Google Scholar] [CrossRef]

- Muhammad, R.; Maurotto, A.; Demiral, M.; Roy, A.; Silberschmidt, V.V. Themelly enhanced ultrasonically assisted machining of Ti alloy. CIRP J. Manuf. Sci. Technol. 2014, 7, 159–167. [Google Scholar] [CrossRef]

- Amin, A.K.M.N. The effect of preheating of work material on chatter during end milling of medium carbon steel performed on a vertical machining center (VMC). J. Manuf. Sci. Eng. 2003, 125, 674–680. [Google Scholar] [CrossRef]

- Lajis, M.A.; Amin, A.K.M.N.; Karim, A.N.M.; Radzi, H.C.D.M.; Ginta, T.L. Hot machining of hardened steels with coated carbide inserts. Am. J. Eng. Appl. Sci. 2009, 2, 421–427. [Google Scholar] [CrossRef]

- Amin, A.K.M.N.; Talantov, N.V. Influence of the Instability of Chip Formation and Preheating of Work on Tool Life in Machining High Temperature Resistant Steel and Titanium Alloys. Mech. Eng. Res. Bull. 1986, 9, 52–62. [Google Scholar]

- Amin, A.K.M.N.; Saad, M.H.B.; Arif, M.D. Modeling & Optimization of Surface Roughness & Vibration Amplitude in Heat Assisted End Milling of SKD 11 Tool Steel using Ball Nose Tool. Adv. Mater. Res. 2012, 541, 799–803. [Google Scholar]

- Xavierarockiaraj, S.; Kuppan, P. Investigation of cutting forces, surface roughness and tool wear during Laser assisted machining of SKD11Tool steel. Procedia Eng. 2014, 97, 1657–1666. [Google Scholar] [CrossRef]

- Edwin, K.P.C.; Stanislaw, H.Z. An Introduction to Optimization, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Montgomery, D.C. Design, Analyses of Experiments, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1997. [Google Scholar]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. Evaluation of crygenic cooling and minimum quatity lubrication effects on machining GLARE laminates using design of experiments. J. Clean. Prod. 2016, 135, 533–548. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S. An investigation of burrs, chip formation, hole size, circularity and delamination during drilling operation of GLARE using ANOVA. J. Compos. Struct. 2017, 159, 745–760. [Google Scholar] [CrossRef]

- Nguyen, D.-T.; Kim, Y.-S. Combination of isotropic and kinematic hardening to predict fracture and improve press formability of a door hinge. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 224, 435–445. [Google Scholar] [CrossRef]

- Duc-Toan, N.; Young-Suk, K.; Dong-Won, J. Coupled thermomechanical finite element analysis to improve press formability for camera shape using AZ31B magnesium alloy sheet. Met. Mater. Int. 2012, 18, 583–595. [Google Scholar] [CrossRef]

- Du, S.; Chen, M.; Xie, L.; Zhu, Z.; Wang, X. Optimization of process parameters in the high-speed milling of titanium alloy TB17 for surface integrity by the Taguchi-Grey relational analysis method. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Taguchi, G. On-Line Quality Control during Production; Japan Standard Association: Tokyo, Japan, 1981. [Google Scholar]

- Wang, C.; Xie, Y.; Zheng, L.; Qin, Z.; Tang, D.; Song, Y. Research on the Chip Formation Mechanism during the high-speed milling of hardened steel. Int. J. Mach. Tools Manuf. 2014, 79, 31–48. [Google Scholar] [CrossRef]

- Wang, C.; Ding, F.; Tang, D.; Zheng, L.; Li, S.; Xie, Y. Modeling and simulation of the high-speed milling of hardened steel SKD11 (62 HRC) based on SHPB technology. Int. J. Mach. Tools Manuf. 2016, 108, 13–26. [Google Scholar] [CrossRef]

| No. | Authors | Material | Tool | Heating Method | Results |

|---|---|---|---|---|---|

| 1 | Wang Z. Y. et al. [13] | Inconel 718 | Coated-carbide cutting inserts | Plasma Enhanced Machining (PEM) | The surface roughness decreased by 250%. The cutting forces reduced by approximately 30–50%. The tool life increased by 170% in comparing with conventional machining. |

| 2 | Novak J.W et al. [14] | Inconel 718 | WG-300 inserts aluminum oxide reinforced with silicon-carbide whiskers | Experimental results during conventional and plasma enhanced machining were compared. Several advantages of PEM were analyzed, including improvement of surface roughness by as much as a factor of 4, lower cutting forces by approximately 20% and extended tool life. | |

| 3 | Leshock C. E. et al. [15] | Inconel 718 | Coated-carbide cutting inserts | A numerical and experimental analysis of PEM were presented. A three-dimensional finite difference model was established to determine the temperatures distribution in a cylindrical workpiece. The results showed in good agreement with experimental data. Benefits of PEM were demonstrated in comparing with conventional machining, including 30% decreasing of the cutting force and 40% increase in tool life and two-fold improvement in surface roughness. | |

| 4 | Shi B. et al. [16] | Inconel 718 | Coated-carbide cutting inserts | Laser assisted machining (LAM) | The cutting forces decreased from 24% to 46% and chip thickness increased 40% during thermal-assisted machining at 800 °C. |

| 5 | Dumitrescu P. et al. [17] | AISI D2 tool steel | TiN–coated carbide insert | LAM of AISI D2 tool steel was studied using a high-power diode laser. The results showed that tool life was improved by as much as 100%, the cutting force was reduced, and laser heating wasn’t of significant thermal detriment to the machined surface. | |

| 6 | Rajagopal S. et al. [18] | Inconel-718 and Ti-6AI-4V | Ceramic tools for Inconel 718 and carbides for Ti-6Al-4V | LAM using a 15-kW continuous–wave laser was researched. The metal removal rate was significantly increase for both materials without aggravating either cutting force or tool wear, the gain in removal rate being 33 % for lnconel 718 and 100 % for Ti-6AI-4V. | |

| 7 | Ganta V. et al. [19] | 15-5PH stainless | K313 carbide cutting inserts | Oxy-acetylene gas flame | Material removal rate was maximum in TAM at 400 °C. The optimum cutting speed was 31 m/min to achieve the smallest roughness. |

| 8 | Muhammad R. et al. [20] | Ti-15333 | Cemented-carbide cutting inserts | Hot ultrasonically assisted turning (HUAT) | The cutting forces reduced 80–85% during HUAT at 300 °C. |

| 9 | Amin A. K. M. N et al. [21] | AISI 1040 | Coated-carbide cutting inserts | Induction heating | Preheating of the workpiece increased the tool life by 39% to 52%. The chatter and surface roughness reduced during TAM. |

| 10 | Lasis et al. [22] | AISI D2 hardened steel | Coated-carbide cutting inserts | The studied results presented the benefit of TAM of hardened steel components in reduced machining costs and lead times in comparing with conventional machining. 335 °C preheating temperature coupled with 40 m/min cutting speed, 1.0 mm depth of cutting and 0.02 mm/tooth resulted reduction in tool wear rate, maximum tool life of 188.55 min. The surface roughness was decreased. | |

| 11 | Amin A. K. M. N. et al. [23] | Resistant steel 3N-481 and titanium alloys BT3-1 | Cemented carbide tools | The influence of instability of chip formation and preheating of workpiece on tool life in TAM resistant steel and titanium alloys were researched. Results investigations showed the chip formation process was unstable in machining these alloys. Preheating of both the work materials leads to the decrease of tool wear and amplitude of vibration of the cutting forces. | |

| 12 | Amin A. K. M. N. et al. [24] | SKD11 | Coated-carbide cutting inserts | An investigation on TAM of SKD11 on VMC using ball nose was studied. The Design of Experiments was done in order to develop empirical mathematical models of vibration and surface roughness. The results showed that the surface roughness and vibration amplitude were reduced. Optimum temperatures support for machining process were between 400 °C and 500 °C. |

| C | Cr | Mo | Si | Mn | Ni | V |

|---|---|---|---|---|---|---|

| 1.4–1.6 | 11–13 | 0.7–1.2 | ≤0.6 | ≤0.6 | - | 0.15–0.3 |

| Johnson-Cook Flow Stress | |||

|---|---|---|---|

| Physical property | Value | J-C flow stress coefficient | Value |

| Density (kg/m3) | 8400 | A (Mpa) | 1766 |

| Poisson’s ratio | 0.3 | B (MPa) | 904 |

| Thermal expansion coefficient (10−6/K) | 11 | n | 0.39 |

| Melt temperature Tm (K) | 1733 | C | 0.012 |

| Specific heat (J/kg °C) | 461 | Tr (K) | 298 |

| Thermal conductivity coefficient (w/m·K) | 20.5 | m | 3.38 |

| Symbol | l (mm) | d (mm) | s (mm) | d1 (mm) | re (mm) |

|---|---|---|---|---|---|

| Value | 17 | 9.44 | 5.67 | 4.6 | 0.8 |

| No. | Control Parameter | Symbol | Unit | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|---|

| 1 | Cutting speed (A) | Vc | m/min | 190 | 235 | 280 |

| 2 | Feed rate (B) | f | mm/min | 230 | 305 | 380 |

| 3 | Cutting depth (C) | t | mm | 0.5 | 1.0 | 1.5 |

| 4 | Temperature (D) | T | °C | 200 | 300 | 400 |

| Exp. No | Experiment at Room Temperature | FR (N) | S/N | |||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | 1st | 2nd | 3rd | Average | ||

| 1 | 1 | 1 | 1 | 138.12 | 134.87 | 134.95 | 135.98 | −42.6695 |

| 2 | 1 | 2 | 2 | 292.56 | 299.67 | 303.83 | 298.69 | −49.5043 |

| 3 | 1 | 3 | 3 | 432.86 | 425.13 | 444.20 | 434.06 | −52.7510 |

| 4 | 2 | 1 | 2 | 218.3 | 211.45 | 211.20 | 213.65 | −46.5941 |

| 5 | 2 | 2 | 3 | 349.96 | 362.79 | 367.75 | 360.17 | −51.1301 |

| 6 | 2 | 3 | 1 | 163.78 | 157.92 | 159.69 | 160.46 | −44.1074 |

| 7 | 3 | 1 | 3 | 262.76 | 268.19 | 257.05 | 262.67 | −48.3881 |

| 8 | 3 | 2 | 1 | 119.78 | 120.43 | 116.09 | 118.77 | −41.4940 |

| 9 | 3 | 3 | 2 | 238.18 | 241.89 | 237.96 | 239.34 | −47.5804 |

| Exp. No | Experiment at Elevated Temperature | FR (N) | S/N | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | 1st | 2nd | 3rd | Average | ||

| 1 | 1 | 1 | 1 | 1 | 60.286 | 61.965 | 64.364 | 62.205 | −35.8765 |

| 2 | 1 | 2 | 2 | 2 | 129.768 | 132.879 | 127.104 | 129.917 | −42.2733 |

| 3 | 1 | 3 | 3 | 3 | 157.198 | 149.546 | 158.676 | 155.140 | −43.8145 |

| 4 | 2 | 1 | 2 | 3 | 93.124 | 89.865 | 87.754 | 90.248 | −39.1087 |

| 5 | 2 | 2 | 3 | 1 | 228.178 | 219.897 | 226.810 | 224.962 | −47.0422 |

| 6 | 2 | 3 | 1 | 2 | 71.899 | 76.124 | 74.018 | 74.014 | −37.3862 |

| 7 | 3 | 1 | 3 | 2 | 109.765 | 110.9 | 115.540 | 112.068 | −40.9897 |

| 8 | 3 | 2 | 1 | 3 | 39.123 | 38.935 | 39.710 | 39.256 | −31.8781 |

| 9 | 3 | 3 | 2 | 1 | 130.895 | 135.267 | 136.612 | 134.258 | −42.5588 |

| Parameter | Mean of Multiple S/N Ratio | Sum of Squares | Contribution (%) | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| A | −48.308 | −47.277 | −45.821 * | 9.371 | 8.087 |

| B | −45.884 * | −47.376 | −48.146 | 7.938 | 6.850 |

| C | −42.757 * | −47.893 | −50.756 | 98.56 | 85.062 |

| Parameter | Mean of Multiple S/N Ratio | Sum of Squares | Contribution (%) | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| A | −40.65 | −41.18 | −38.48 * | 12.332 | 7.370 |

| B | −38.66 * | −40.40 | −41.25 | 10.491 | 6.269 |

| C | −35.05 * | −41.31 | −43.95 | 125.459 | 74.973 |

| D | −41.83 | −40.22 | −38.27 * | 19.055 | 11.386 |

| Trial | FR (N) | T (°C) | FT (N) | ΔF (%) |

|---|---|---|---|---|

| 1 | 135.98 | 200 | 62.205 | 54.3 |

| 2 | 298.69 | 300 | 129.917 | 56.5 |

| 3 | 434.06 | 400 | 155.140 | 64.3 |

| 4 | 213.65 | 400 | 90.248 | 57.8 |

| 5 | 360.17 | 200 | 224.962 | 37.5 |

| 6 | 160.46 | 300 | 74.014 | 53.9 |

| 7 | 262.67 | 300 | 112.068 | 57.3 |

| 8 | 118.77 | 400 | 39.256 | 66.9 |

| 9 | 239.34 | 200 | 134.258 | 43.9 |

| No. | T (°C) | Average Ratio |

|---|---|---|

| 1 | 200 | 1.85 |

| 2 | 300 | 2.27 |

| 3 | 400 | 2.73 |

| Exp. No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| ΔFT (%) | 27.4 | 0.6 | 10.1 | 7.3 | 14.6 | 5 | 8.9 | 21 | 0.1 |

| Exp. No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| ΔFT (%) | 23.6 | 4 | 5.2 | 16.7 | 4.2 | 18.4 | 8.7 | 2 | 5.4 |

| Exp. No | S/N Ratio | ||

|---|---|---|---|

| Method 1 | Method 2 | Method 3 | |

| 1 | −24.6373 | −20.9968 | −23.3397 |

| 2 | 2.125087 | −4.05212 | −14.2712 |

| 3 | −23.9383 | −27.0762 | −18.175 |

| 4 | −16.4083 | −20.9676 | −23.5718 |

| 5 | −30.3401 | −27.8572 | −19.5419 |

| 6 | −11.4257 | −20.4168 | −22.6809 |

| 7 | −19.9561 | −16.4373 | −19.8295 |

| 8 | −18.3414 | −7.60736 | 2.217361 |

| 9 | 15.30213 | 4.028598 | −17.2207 |

| m value | −14.18 | −15.7092 | −17.3793 |

| mjn | Method 1 | Method 2 | Method 3 |

|---|---|---|---|

| mj1 | −13.2251 | −14.9418 | −20.0341 |

| mj2 | −9.75223 | −13.6354 | −18.9272 |

| mj3 | −19.5627 | −18.5504 | −13.1765 |

| Method | T (°C) | SS | ||

|---|---|---|---|---|

| 200 °C | 300 °C | 400 °C | ||

| 1 | 2.7356 | 58.8154 | 86.9196 | 148.4706 |

| 2 | 21.1444 | 7.1885 | 52.9903 | 81.3232 |

| 3 | 1.7667 | 12.9019 | 24.2171 | 38.8857 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mac, T.-B.; Dinh, V.-C.; Banh, T.-L.; Nguyen, D.-T. Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method. Metals 2018, 8, 992. https://doi.org/10.3390/met8120992

Mac T-B, Dinh V-C, Banh T-L, Nguyen D-T. Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method. Metals. 2018; 8(12):992. https://doi.org/10.3390/met8120992

Chicago/Turabian StyleMac, Thi-Bich, Van-Chien Dinh, Tien-Long Banh, and Duc-Toan Nguyen. 2018. "Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method" Metals 8, no. 12: 992. https://doi.org/10.3390/met8120992

APA StyleMac, T.-B., Dinh, V.-C., Banh, T.-L., & Nguyen, D.-T. (2018). Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method. Metals, 8(12), 992. https://doi.org/10.3390/met8120992