Experimental Characterization of the Primary Stability of Acetabular Press-Fit Cups with Open-Porous Load-Bearing Structures on the Surface Layer

Abstract

1. Introduction

2. Materials and Methods

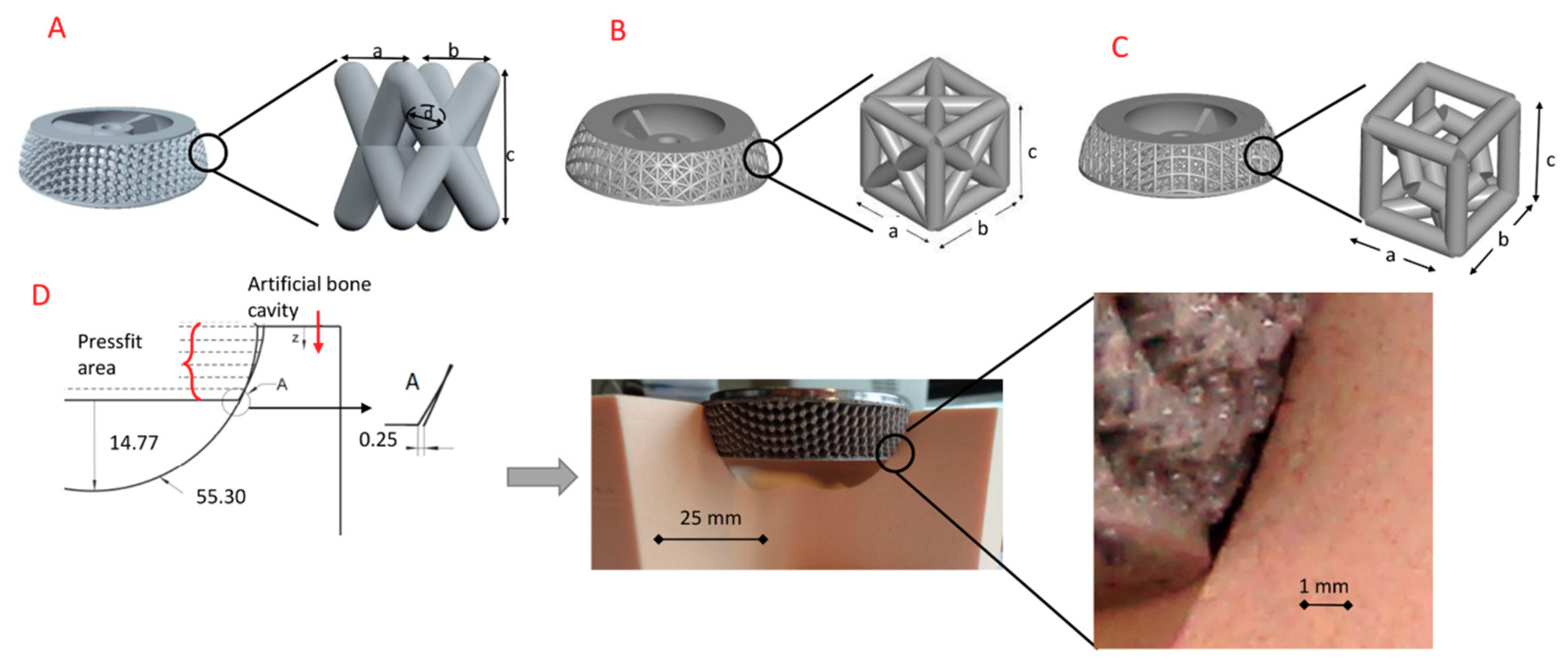

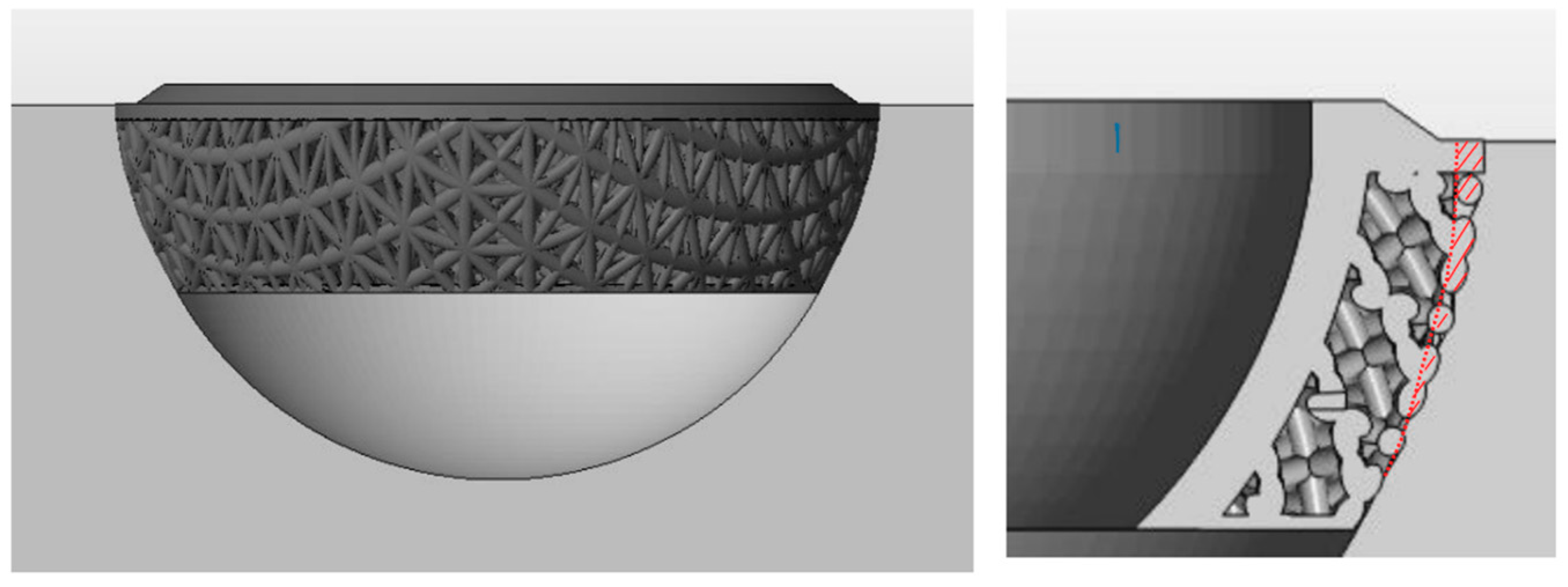

2.1. Cup Design

2.2. Fabrication

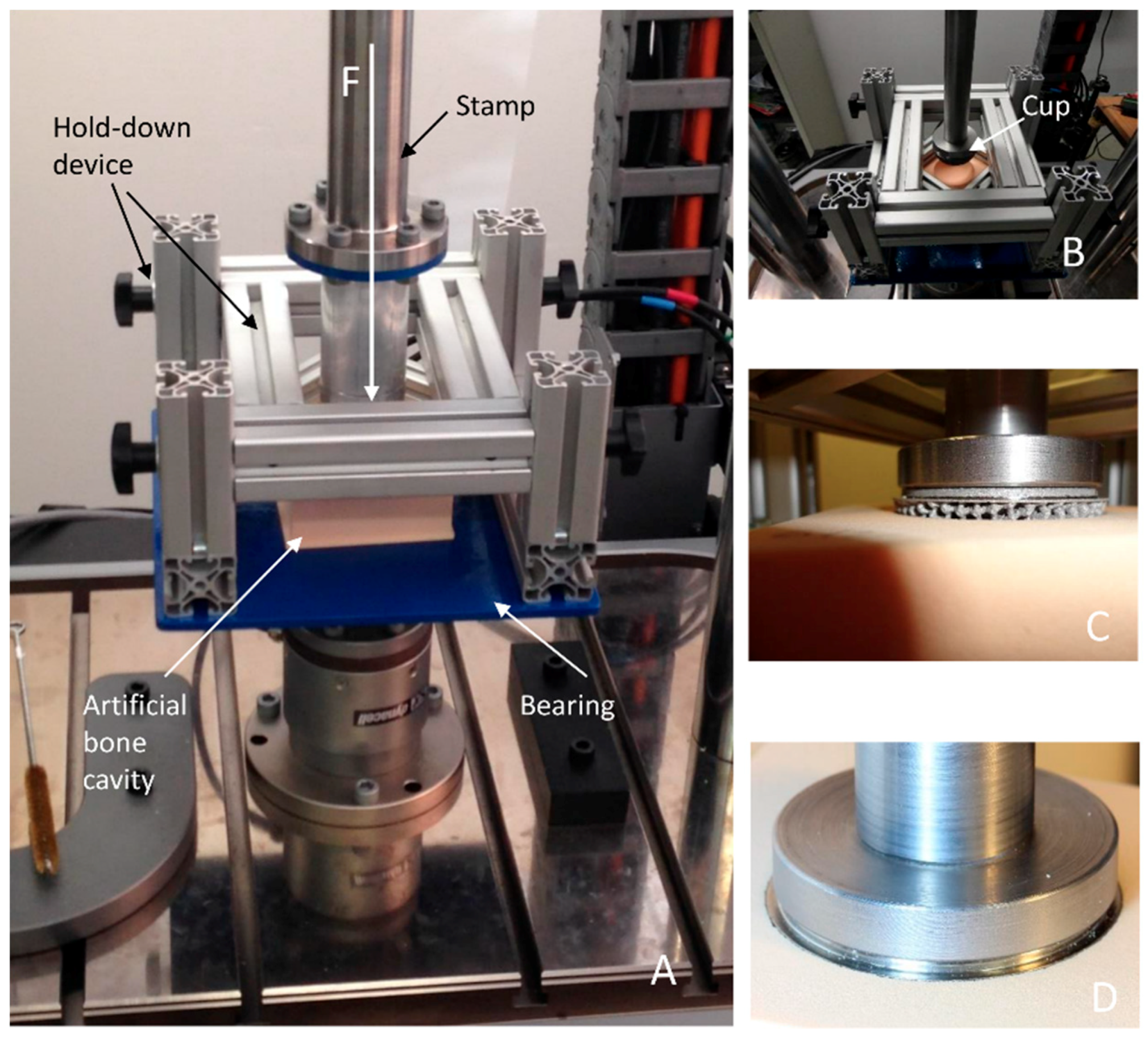

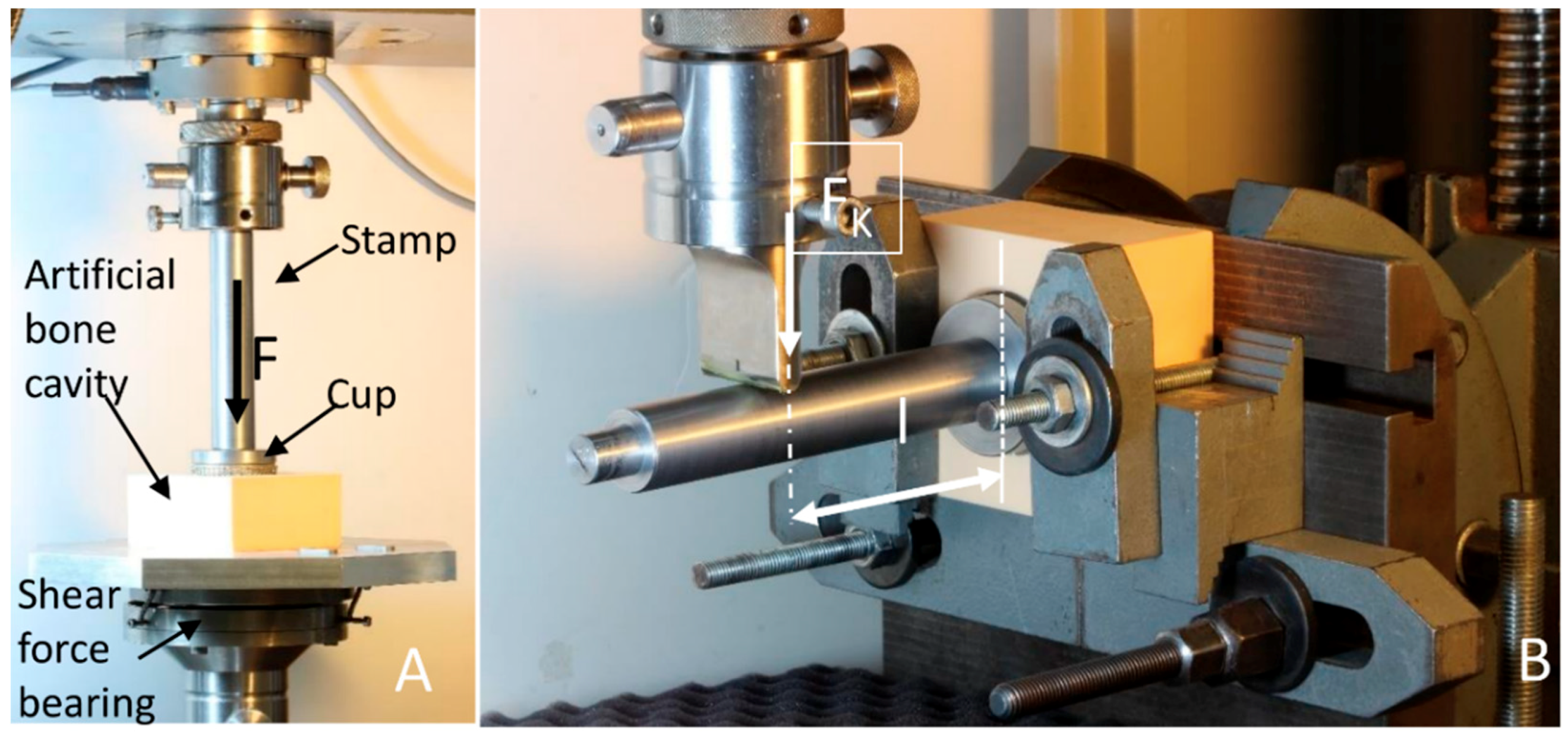

2.3. Measurements

2.4. Statistical Analysis

3. Results and Discussion

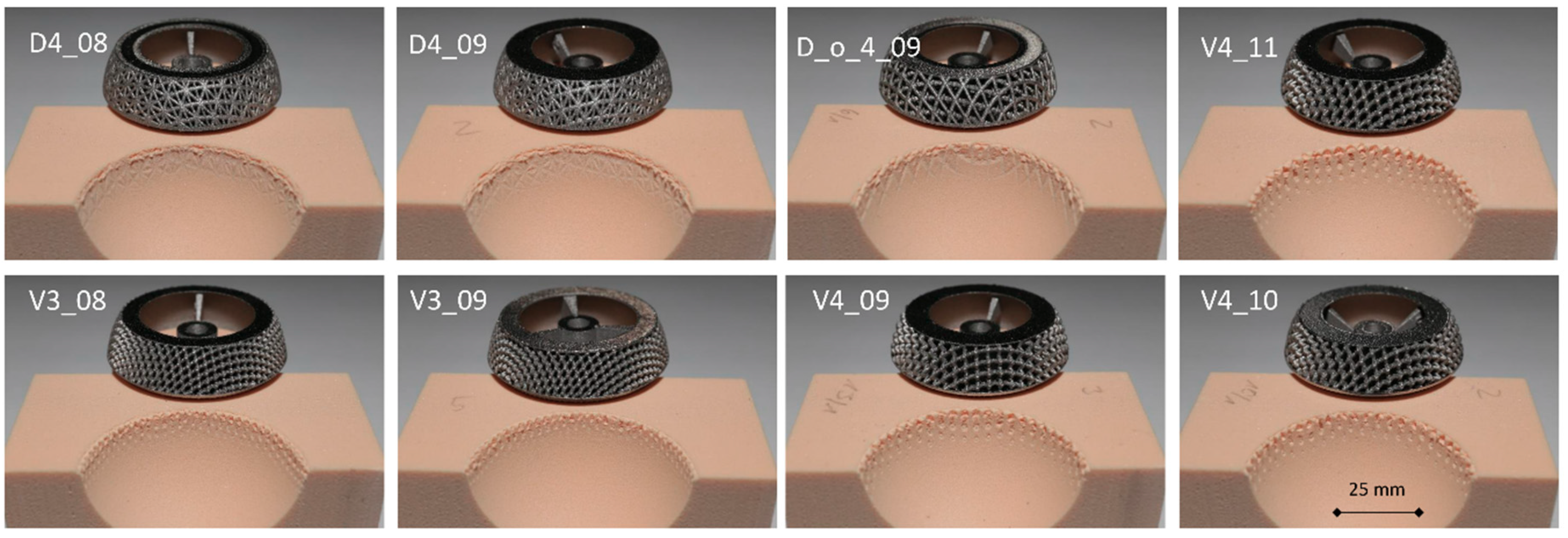

3.1. Accuracy of Fabricated Samples

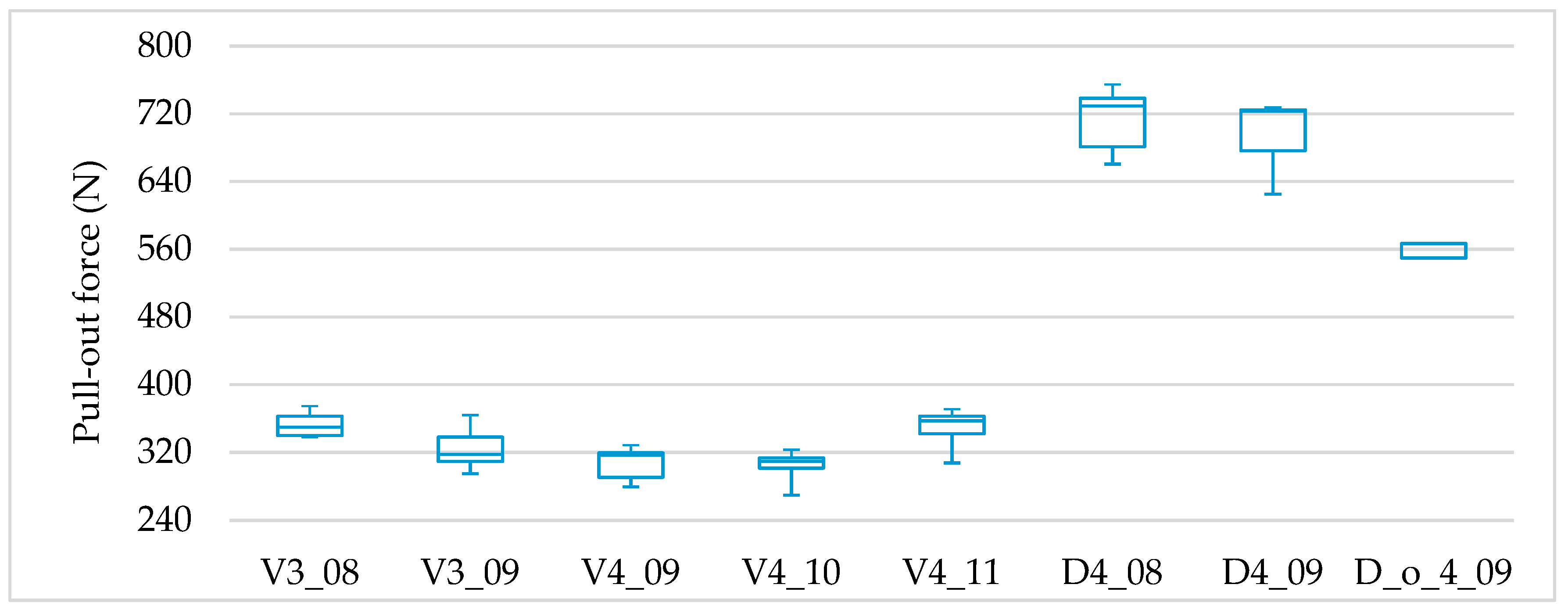

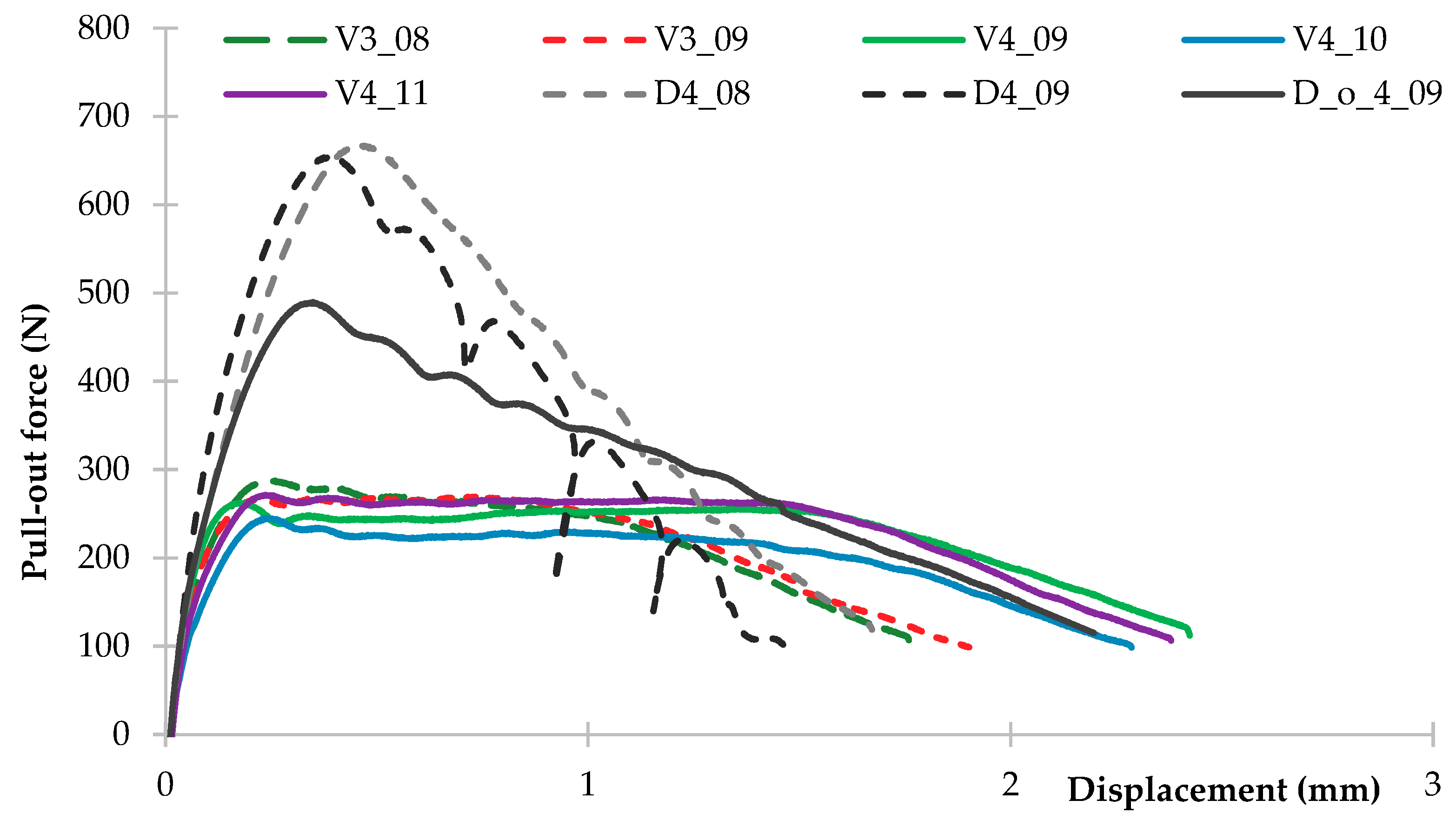

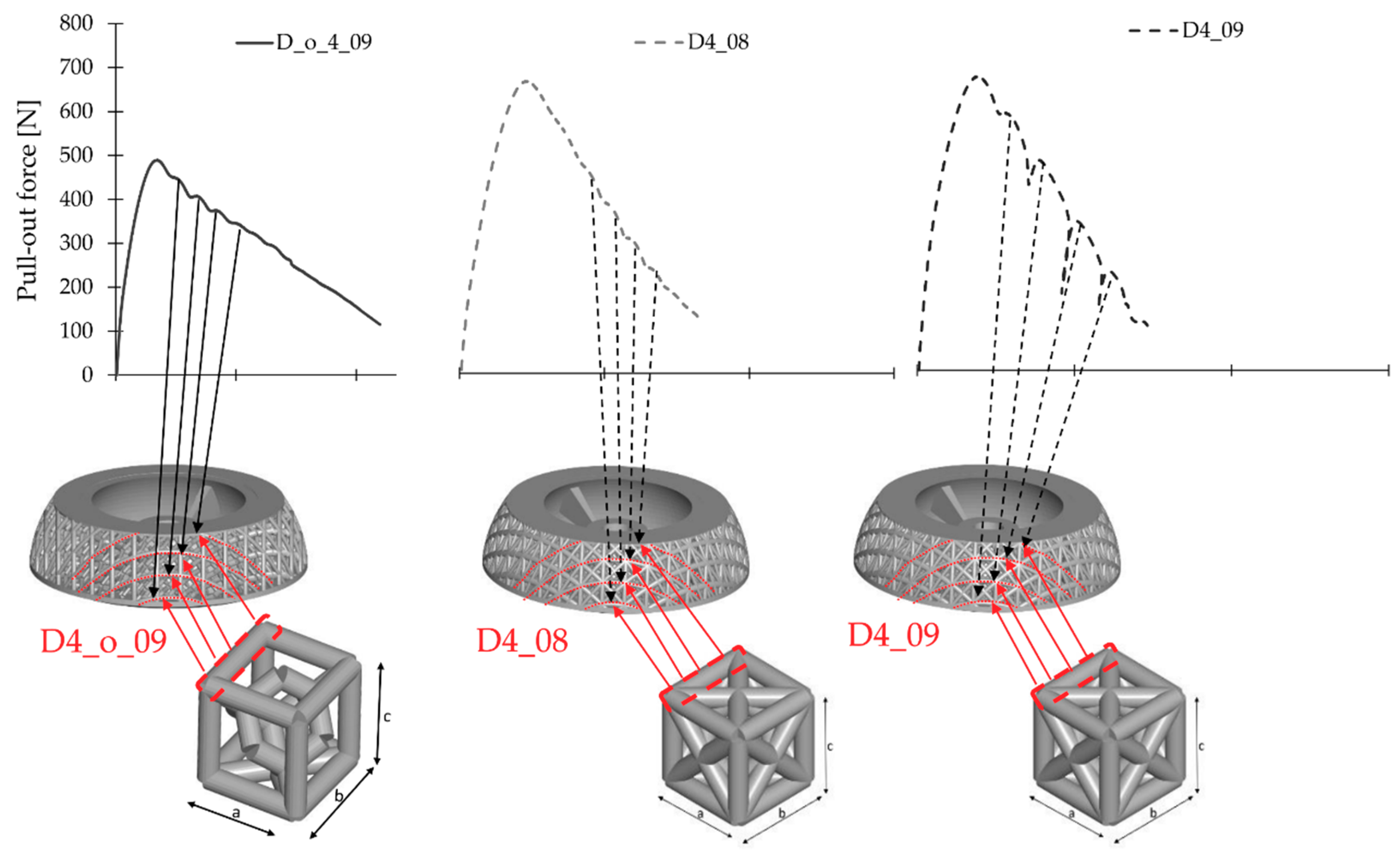

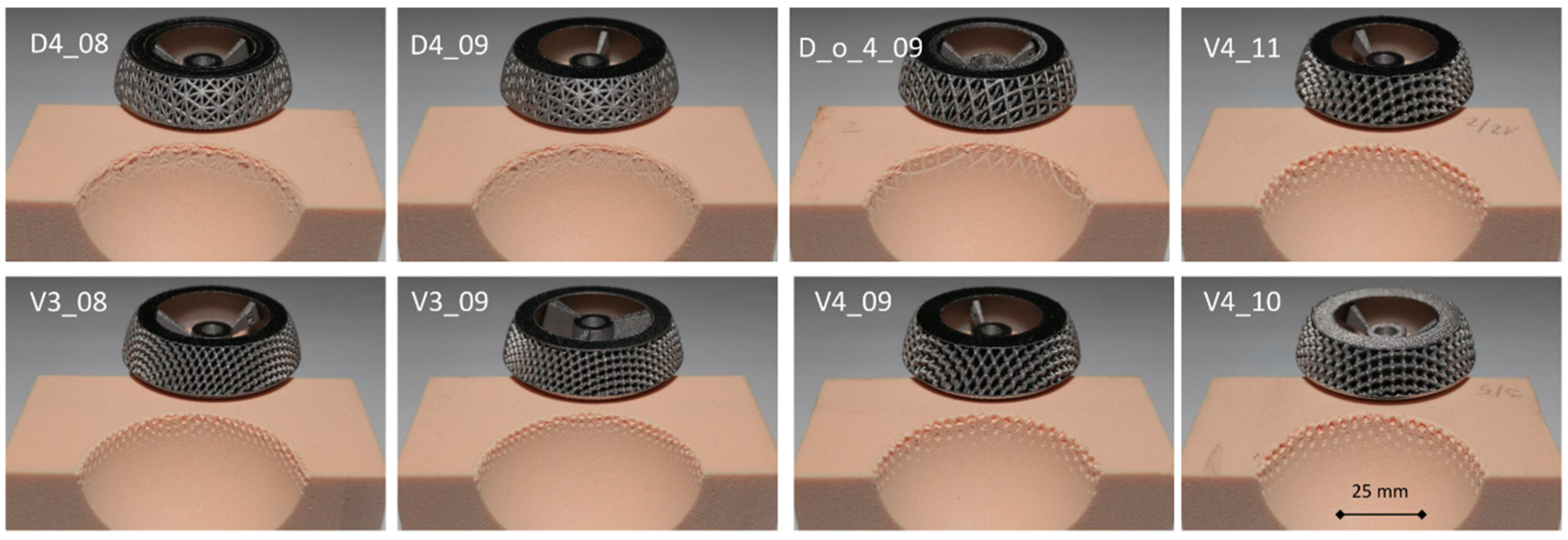

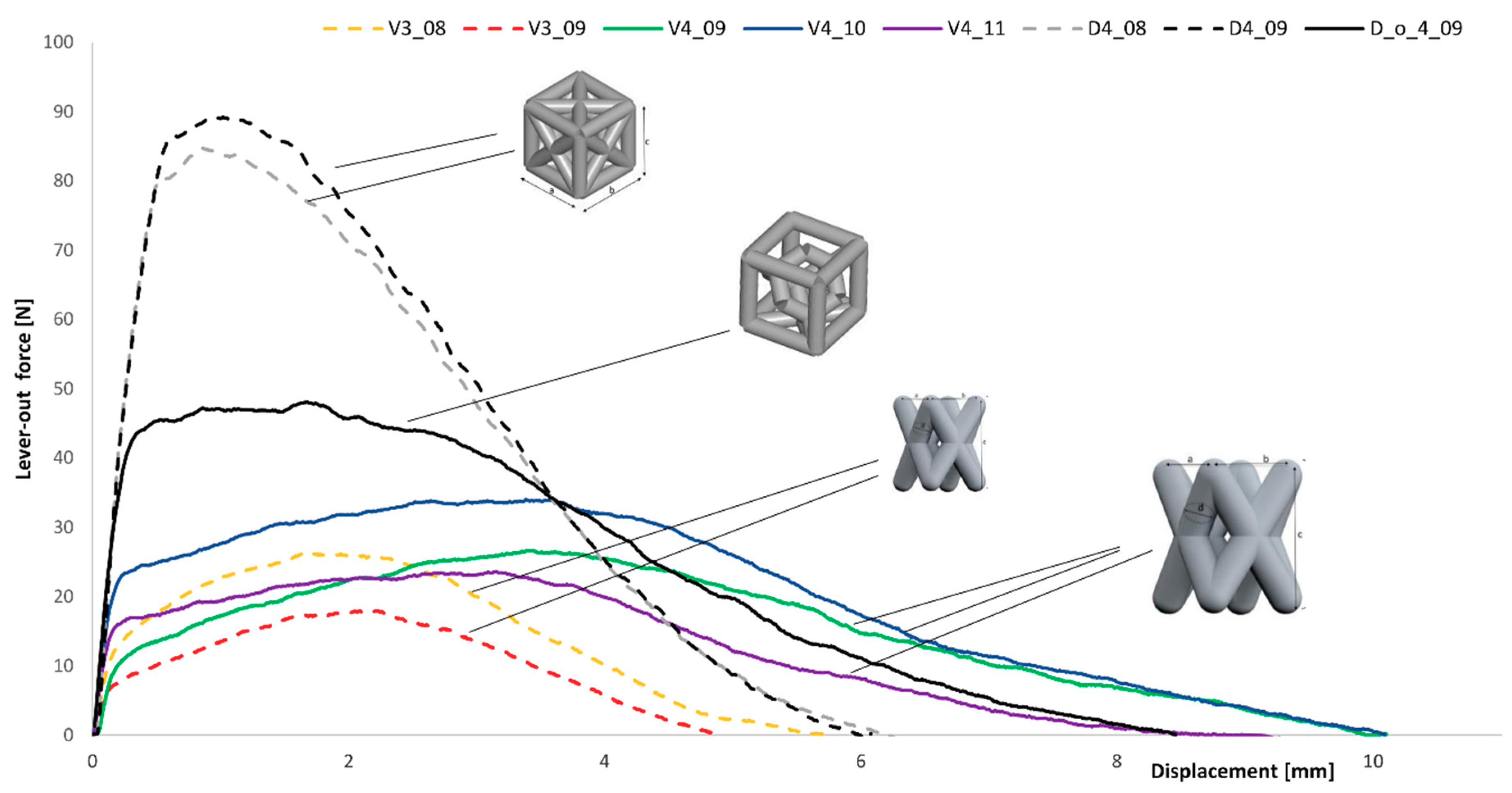

3.2. Pull-Out Force

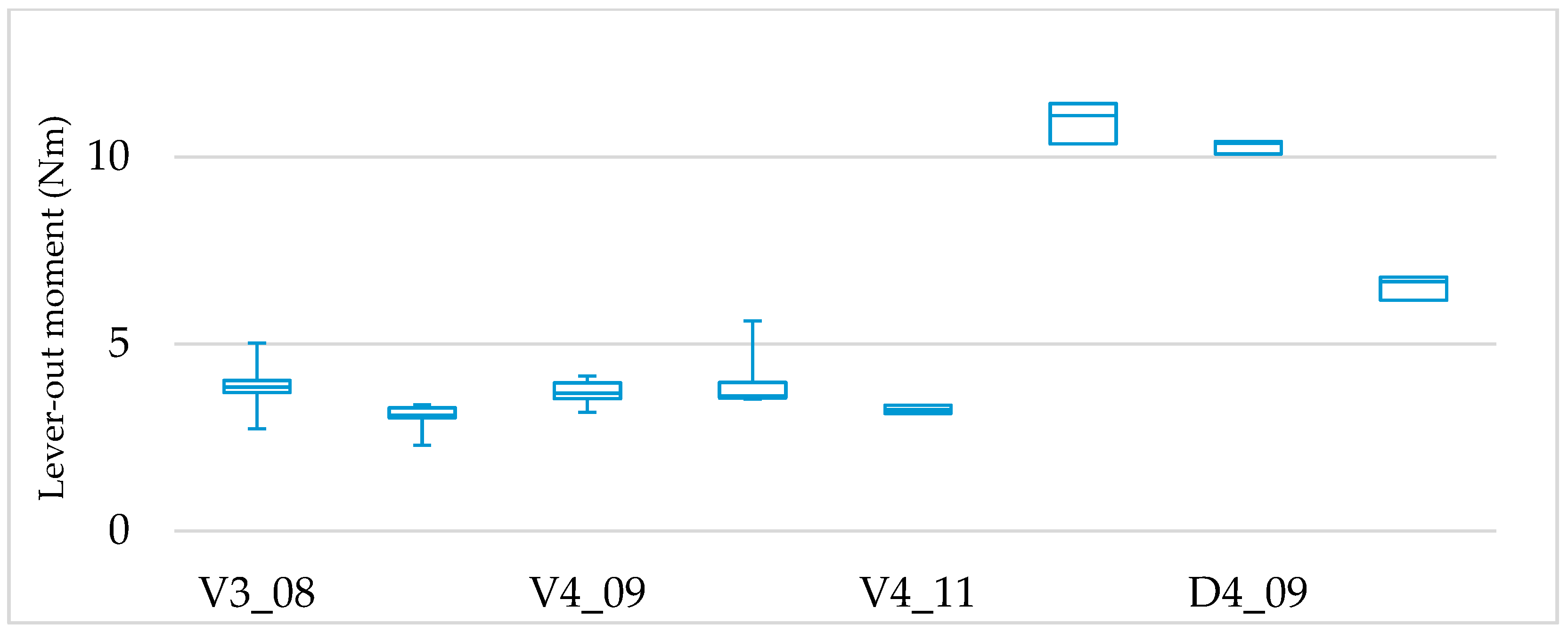

3.3. Lever-Out Moment

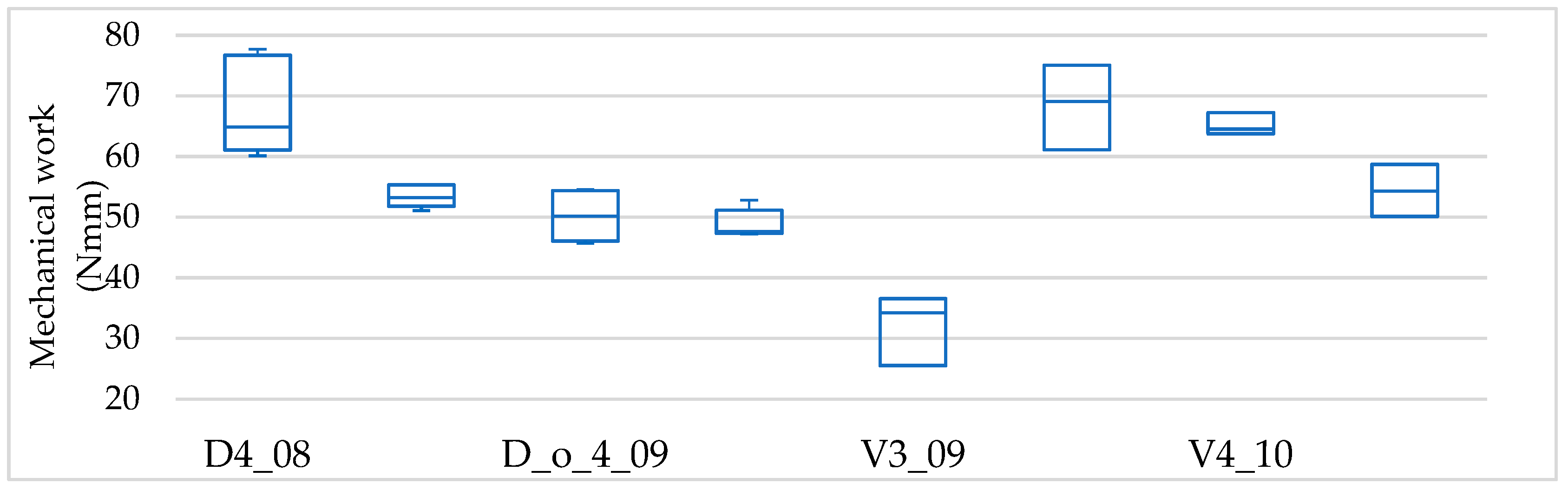

3.4. Lever-Out Momentmechanical Work

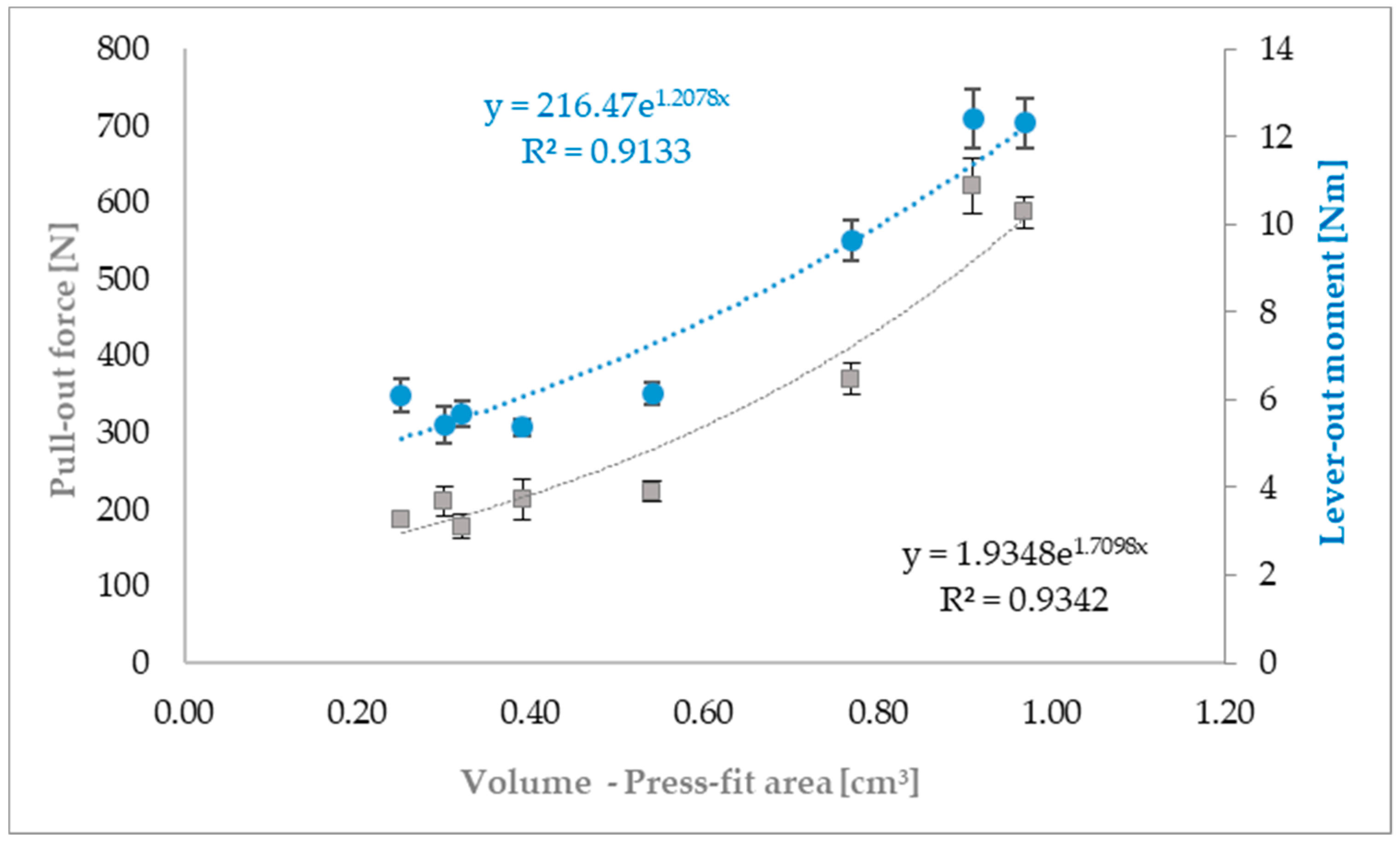

3.5. Correlations—Lever-Out Moment and Pull-Out Force Versus Volume of the Press-Fit Area

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Harrison, N.; Field, J.R.; Quondamatteo, F.; Curtin, W.; McHugh, P.E.; Mc Donnell, P. Preclinical trial of a novel surface architecture for improved primary fixation of cementless orthopaedic implants. Clin. Biomech. 2014, 29, 861–868. [Google Scholar] [CrossRef] [PubMed]

- Levine, B. A new era in porous metals: Applications in orthopaedics. Adv. Eng. Mater. 2008, 10, 788–792. [Google Scholar] [CrossRef]

- Murr, L.E. Open-cellular metal implant design and fabrication for biomechanical compatibility with bone using electron beam melting. J. Mech. Behav. Biomed. Mater. 2017, 76, 164–177. [Google Scholar] [CrossRef] [PubMed]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Tan, X.P.; Tan, Y.J.; Chow, C.S.L.; Tor, S.B.; Yeong, W.Y. Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater. Sci. Eng. C 2017, 76, 1328–1343. [Google Scholar] [CrossRef] [PubMed]

- Schulze, C.; Weinmann, M.; Schweigel, C.; Keßler, O.; Bader, R. Mechanical Properties of a Newly Additive Manufactured Implant Material Based on Ti-42Nb. Materials 2018, 11, 124. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Amato, K.N.; Li, S.J.; Tian, Y.X.; Cheng, X.Y.; Gaytan, S.M.; Martinez, E.; Shindo, P.W.; Medina, F.; Wicker, R.B. Microstructure and mechanical properties of open-cellular biomaterials prototypes for total knee replacement implants fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2011, 4, 1396–1411. [Google Scholar] [CrossRef] [PubMed]

- Do Prado, R.F.; De Oliveira, F.S.; Nascimento, R.D.; De Vasconcellos, L.M.R.; Carvalho, Y.R.; Cairo, C.A.A. Osteoblast response to porous titanium and biomimetic surface: In vitro analysis. Mater. Sci. Eng. C 2015, 52, 194–203. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M.; Xu, S. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 14. [Google Scholar] [CrossRef] [PubMed]

- Limmahakhun, S.; Oloyede, A.; Sitthiseripratip, K.; Xiao, Y.; Yan, C. Stiffness and strength tailoring of cobalt chromium graded cellular structures for stress-shielding reduction. Mater. Des. 2017, 114, 633–641. [Google Scholar] [CrossRef]

- Simoneau, C.; Terriault, P.; Jetté, B.; Dumas, M.; Brailovski, V. Development of a porous metallic femoral stem: Design, manufacturing, simulation and mechanical testing. Mater. Des. 2017, 114, 546–556. [Google Scholar] [CrossRef]

- Kumar, A.; Nune, K.C.; Murr, L.E.; Misra, R.D.K. Biocompatibility and mechanical behaviour of three-dimensional scaffolds for biomedical devices: Process-structure-property paradigm. Int. Mater. Rev. 2016, 61, 20–45. [Google Scholar] [CrossRef]

- Harrison, N.; McHugh, P.E.; Curtin, W.; Mc Donnell, P. Micromotion and friction evaluation of a novel surface architecture for improved primary fixation of cementless orthopaedic implants. J. Mech. Behav. Biomed. Mater. 2013, 21, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Jetté, B.; Brailovski, V.; Dumas, M.; Simoneau, C.; Terriault, P. Femoral stem incorporating a diamond cubic lattice structure: Design, manufacture and testing. J. Mech. Behav. Biomed. Mater. 2018, 77, 58–72. [Google Scholar] [CrossRef] [PubMed]

- Marin, E.; Fusi, S.; Pressacco, M.; Paussa, L.; Fedrizzi, L. Characterization of cellular solids in Ti6Al4V for orthopaedic implant applications: Trabecular titanium. J. Mech. Behav. Biomed. Mater. 2010, 3, 373–381. [Google Scholar] [CrossRef] [PubMed]

- Le Guéhennec, L.; Soueidan, A.; Layrolle, P.; Amouriq, Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent. Mater. 2007, 23, 844–854. [Google Scholar] [CrossRef] [PubMed]

- Khanna, R.; Kokubo, T.; Matsushita, T.; Nomura, Y.; Nose, N.; Oomori, Y.; Yoshida, T.; Wakita, K.; Takadama, H. Novel artificial hip joint: A layer of alumina on Ti-6Al-4V alloy formed by micro-arc oxidation. Mater. Sci. Eng. C 2015, 55, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Ramsden, J.J.; Allen, D.M.; Stephenson, D.J.; Alcock, J.R.; Peggs, G.N.; Fuller, G.; Goch, G. The design and manufacture of biomedical surface. CIRP Ann. Manuf. Technol. 2007, 56, 687–711. [Google Scholar] [CrossRef]

- Emmelmann, C.; Scheinemann, P.; Munsch, M.; Seyda, V. Laser additive manufacturing of modified implant surfaces with osseointegrative characteristics. Phys. Procedia 2011, 12, 375–384. [Google Scholar] [CrossRef]

- Paris, M.; Götz, A.; Hettrich, I.; Bidan, C.M.; Dunlop, J.W.C.; Razi, H.; Zizak, I.; Hutmacher, D.W.; Fratzl, P.; Duda, G.N.; et al. Scaffold curvature-mediated novel biomineralization process originates a continuous soft tissue-to-bone interface. Acta Biomater. 2017, 60, 64–80. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, C.; Li, C.; Qin, Y.; Zhong, L.; Chen, B.; Li, Z.; Liu, H.; Chang, F.; Wang, J. Analysis of factors influencing bone ingrowth into three-dimensional printed porous metal scaffolds: A review. J. Alloys Compd. 2017, 717, 271–285. [Google Scholar] [CrossRef]

- Schouman, T.; Schmitt, M.; Adam, C.; Dubois, G.; Rouch, P. Influence of the overall stiffness of a load-bearing porous titanium implant on bone ingrowth in critical-size mandibular bone defects in sheep. J. Mech. Behav. Biomed. Mater. 2016, 59, 484–496. [Google Scholar] [CrossRef] [PubMed]

- de Wild, M.; Zimmermann, S.; Rüegg, J.; Schumacher, R.; Fleischmann, T.; Ghayor, C.; Weber, F.E. Influence of microarchitecture on osteoconduction and mechanics of porous titanium Scaffolds generated by selective laser melting. 3D Print. Addit. Manuf. 2016, 3, 142–151. [Google Scholar] [CrossRef]

- Taniguchi, N.; Fujibayashi, S.; Takemoto, M.; Sasaki, K.; Otsuki, B. Effect of pore size on bone ingrowth into porous titanium implants. Mater. Sci. Eng. C 2016, 59, 690–701. [Google Scholar] [CrossRef] [PubMed]

- Jetté, B.; Brailovski, V.; Simoneau, C.; Dumas, M.; Terriault, P. Development and in vitro validation of a simplified numerical model for the design of a biomimetic femoral stem. J. Mech. Behav. Biomed. Mater. 2017, 77, 539–550. [Google Scholar] [CrossRef] [PubMed]

- Bellini, C.M.; Galbusera, F.; Ceroni, R.G.; Raimondi, M.T. Loss in mechanical contact of cementless acetabular prostheses due to post-operative weight bearing: A biomechanical model. Med. Eng. Phys. 2007, 29, 175–181. [Google Scholar] [CrossRef] [PubMed]

- Souffrant, R.; Zietz, C.; Fritsche, A.; Kluess, D.; Mittelmeier, W.; Bader, R. Advanced material modelling in numerical simulation of primary acetabular press-fit cup stability. Comput. Methods Biomech. Biomed. Engin. 2012, 15, 787–793. [Google Scholar] [CrossRef] [PubMed]

- Small, S.R.; Berend, M.E.; Howard, L.A.; Rogge, R.D.; Buckley, C.A.; Ritter, M.A. High initial stability in porous titanium acetabular cups: A biomechanical study. J. Arthroplast. 2013, 28, 510–516. [Google Scholar] [CrossRef] [PubMed]

- Udofia, I.; Liu, F.; Jin, Z.; Roberts, P.; Grigoris, P. The initial stability and contact mechanics of a press-fit resurfacing arthroplasty of the hip. J. Bone Jt. Surg. Br. 2007, 89, 549–556. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.-D.; Kim, T.-Y.; Rao, M.B.; Lee, S.-S.; Kim, I.-S. Revision total hip arthroplasty using a tapered, press-fit cementless revision stem in elderly patients. J. Arthroplast. 2011, 26, 1045–1049. [Google Scholar] [CrossRef] [PubMed]

- Chanlalit, C.; Fitzsimmons, J.S.; Shukla, D.R.; An, K.-N.; O’Driscoll, S.W. Micromotion of plasma spray versus grit-blasted radial head prosthetic stem surfaces. J. Shoulder Elb. Surg. 2011, 20, 717–722. [Google Scholar] [CrossRef] [PubMed]

- Le Cann, S.; Galland, A.; Rosa, B.; Le Corroller, T.; Pithioux, M.; Argenson, J.N.; Chabrand, P.; Parratte, S. Does surface roughness influence the primary stability of acetabular cups? A numerical and experimental biomechanical evaluation. Med. Eng. Phys. 2014, 36, 1185–1190. [Google Scholar] [CrossRef] [PubMed]

- Goriainov, V.; Jones, A.; Briscoe, A.; New, A.; Dunlop, D. Do the cup surface properties influence the initial stability? J. Arthroplast. 2014, 29, 757–762. [Google Scholar] [CrossRef] [PubMed]

- Gebert, A.; Peters, J.; Bishop, N.E.; Westphal, F.; Morlock, M.M. Influence of press-fit parameters on the primary stability of uncemented femoral resurfacing implants. Med. Eng. Phys. 2009, 31, 160–164. [Google Scholar] [CrossRef] [PubMed]

- Ries, M.D.; Harbaugh, M.; Shea, J.; Lambert, R. Effect of cementless acetabular cup geometry on strain distribution and press-fit stability. J. Arthroplast. 1997, 12, 207–212. [Google Scholar] [CrossRef]

- Adler, E.; Stuchin, S.A.; Kummer, F.J. Stability of press-fit acetabular cups. J. Arthroplast. 1992, 7, 295–301. [Google Scholar] [CrossRef]

- Macdonald, W.; Carlsson, L.V.; Charnley, G.J.; Jacobsson, C.M. Press-fit acetabular cup fixation: Principles and testing. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1999, 213, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Morlock, M.; Götzen, N.; Sellenschloh, K. Bestimmung der Primärstabilität von künstlichen Hüftpfannen. In DVM Bericht 314—Eigenschaften und Prüftechniken mechanisch Beanspruchter Implantate; DVM: Berlin, Germany, 2002; pp. 221–229. [Google Scholar]

- Toossi, N.; Adeli, B.; Timperley, A.J.; Haddad, F.S.; Maltenfort, M.; Parvizi, J. Acetabular components in total hip arthroplasty: Is there evidence that cementless fixation is better? J. Bone Jt. Surg. 2013, 95, 168–174. [Google Scholar] [CrossRef] [PubMed]

- Roth, A.; Winzer, T.; Sander, K.; Anders, J.O.; Venbrocks, R.-A. Press fit fixation of cementless cups: How much stability do we need indeed? Arch. Orthop. Trauma Surg. 2006, 126, 77–81. [Google Scholar] [CrossRef] [PubMed]

- Tabata, T.; Kaku, N.; Hara, K.; Tsumura, H. Initial stability of cementless acetabular cups: Press-fit and screw fixation interaction—An in vitro biomechanical study. Eur. J. Orthop. Surg. Traumatol. 2015, 25, 497–502. [Google Scholar] [CrossRef] [PubMed]

- Takao, M.; Nakamura, N.; Ohzono, K.; Sakai, T.; Nishii, T.; Sugano, N. The results of a press-fit-only technique for acetabular fixation in hip dysplasia. J. Arthroplast. 2011, 26, 562–568. [Google Scholar] [CrossRef] [PubMed]

- Amirouche, F.; Solitro, G.; Broviak, S.; Gonzalez, M.; Goldstein, W.; Barmada, R. Factors influencing initial cup stability in total hip arthroplasty. Clin. Biomech. 2014, 29, 1177–1185. [Google Scholar] [CrossRef] [PubMed]

- Clarke, H.J.; Jinnah, R.H.; Warden, K.E.; Cox, Q.G.; Curtis, M.J. Evaluation of acetabular stability in uncemented prostheses. J. Arthroplast. 1991, 6, 335–340. [Google Scholar] [CrossRef]

- Klanke, J.; Partenheimer, A.; Westermann, K. Biomechanical qualities of threaded acetabular cups. Int. Orthop. 2002, 26, 278–282. [Google Scholar] [CrossRef] [PubMed]

- Baleani, M.; Fognani, R.; Toni, A. Initial stability of a cementless acetabular cup design: Experimental investigation on the effect of adding fins to the rim of the cup. Artif. Organs. 2001, 25, 664–669. [Google Scholar] [CrossRef] [PubMed]

- Olory, B.; Havet, E.; Gabrion, A.; Vernois, J.; Mertl, P. Comparative in vitro assessment of the primay stbility of cementless press-fit acetabular cups. Acta Orthop. Belg. 2004, 70, 31–37. [Google Scholar] [PubMed]

- Fritsche, A.; Zietz, C.; Teufel, S.; Kolp, W.; Tokar, I.; Mauch, C.; Mittelmeier, W.; Bader, R. In-vitro and in-vivo investigations of the impaction and pull-out behavior of metal-backed acetabular cups. Br. Ed. Soc. Bone Jt. Surg. 2011, 93, 406. [Google Scholar]

- Weißmann, V.; Boss, C.; Bader, R.; Hansmann, H. A novel approach to determine primary stability of acetabular press-fit cups. J. Mech. Behav. Biomed. Mater. 2018, 80, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Markhoff, J.; Wieding, J.; Weissmann, V.; Pasold, J.A.; Jonitz-Heincke, R. Bader, Influence of different three-dimensional open porous titanium scaffold designs on human osteoblasts behavior in static and dynamic cell investigations. Materials 2015, 8, 5490–5507. [Google Scholar] [CrossRef] [PubMed]

- Weißmann, V.; Bader, R.; Hansmann, H.; Laufer, N. Influence of the structural orientation on the mechanical properties of selective laser melted Ti6Al4V open-porous scaffolds. Mater. Des. 2016, 95, 188–197. [Google Scholar] [CrossRef]

- Weißmann, V.; Wieding, J.; Hansmann, H.; Laufer, N.; Wolf, A.; Bader, R. Specific yielding of selective laser-melted Ti6Al4V open-porous scaffolds as a function of unit cell design and dimensions. Metals 2016, 6, 166. [Google Scholar] [CrossRef]

- Weißmann, V.; Hansmann, H.; Bader, R.; Laufer, N. Influence of the Structural Orientation on the Mechanical Properties of Selective Laser Melted TiAL6V4 Open-Porous Scaffold. In Proceedings of the 13th Rapid Tech Conference Erfurt, Erfurt, Germany, 14–16 June 2016. [Google Scholar]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Rashed, M.G.; Ashraf, M.; Mines, R.A.W.; Hazell, P.J. Metallic microlattice materials: A current state of the art on manufacturing, mechanical properties and applications. Mater. Des. 2016, 95, 518–533. [Google Scholar] [CrossRef]

- Suard, M.; Martin, G.; Lhuissier, P.; Dendievel, R.; Vignat, F.; Blandin, J.J.; Villeneuve, F. Mechanical equivalent diameter of single struts for the stiffness prediction of lattice structures produced by Electron Beam Melting. Addit. Manuf. 2015, 8, 124–131. [Google Scholar] [CrossRef]

- Weißmann, V.; Drescher, P.; Bader, R.; Seitz, H.; Hansmann, H.; Laufer, N. Comparison of single Ti6Al4V struts made using selective laser melting and electron beam melting subject to part orientation. Metals 2017, 7, 91. [Google Scholar] [CrossRef]

- Triantaphyllou, A.; Giusca, C.L.; Macaulay, G.D.; Roerig, F.; Hoebel, M.; Leach, R.K.; Tomita, B.; Milne, K.A. Surface texture measurement for additive manufacturing. Surf. Topogr. Metrol. Prop. 2015, 3, 024002. [Google Scholar] [CrossRef]

- Frosch, K.; Barvencik, F.; Viereck, V.; Lohmann, C.H.; Dresing, K.; Breme, J.; Brunner, E.; Stürmer, K.M. Growth behavior, matrix production, and gene expression of human osteoblasts in defined cylindrical titanium channels. J. Biomed. Mater. Res. Part A 2004, 68, 325–334. [Google Scholar] [CrossRef] [PubMed]

- Knychala, J.; Bouropoulos, N.; Catt, C.J.; Katsamenis, O.L.; Please, C.P.; Sengers, B.G. Pore geometry regulates early stage human bone marrow cell tissue formation and organization. Ann. Biomed. Eng. 2013, 41, 917–930. [Google Scholar] [CrossRef] [PubMed]

- Kienapfel, H.; Sprey, C.; Wilke, A.; Griss, P. Implant fixation by bone ingrowth. J. Arthroplast. 1999, 14, 355–368. [Google Scholar] [CrossRef]

- Kawai, T.; Takemoto, M.; Fujibayashi, S.; Tanaka, M.; Akiyama, H.; Nakamura, T.; Matsuda, S. Comparison between alkali heat treatment and sprayed hydroxyapatite coating on thermally-sprayed rough Ti surface in rabbit model: Effects on bone-bonding ability and osteoconductivity. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 103, 1069–1081. [Google Scholar] [CrossRef] [PubMed]

- Grimal, Q.; Haupert, S.; Mitton, D.; Vastel, L.; Laugier, P. Assessment of cortical bone elasticity and strength: Mechanical testing and ultrasound provide complementary data. Med. Eng. Phys. 2009, 31, 1140–1147. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M.; Nakai, M. Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Int. J. Biomater. 2011, 2011. [Google Scholar] [CrossRef] [PubMed]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Humbeeck, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4 V lattice structures. Addit. Manuf. 2014, 5, 6–13. [Google Scholar] [CrossRef]

- Goldman, A.H.; Armstrong, L.C.; Owen, J.R.; Wayne, J.S.; Jiranek, W.A. Does increased coefficient of friction of highly porous metal increase initial stability at the acetabular interface? J. Arthroplast. 2016, 31, 721–726. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, S.M.; Campoli, G.; Amin Yavari, S.; Sajadi, B.; Wauthle, R.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J. Mech. Behav. Biomed. Mater. 2014, 34, 106–115. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Heredia, M.A.; Goyenvalle, E.; Aguado, E.; Pilet, P.; Leroux, C.; Dorget, M.; Weiss, P.; Layrolle, P. Bone growth in rapid prototyped porous titanium implants. J. Biomed. Mater. Res. Part A 2008, 85, 664–673. [Google Scholar] [CrossRef] [PubMed]

- Hedayati, R.; Sadighi, M.; Mohammadi-Aghdam, M.; Zadpoor, A.A. Mechanics of additively manufactured porous biomaterials based on the rhombicuboctahedron unit cell. J. Mech. Behav. Biomed. Mater. 2016, 53, 272–294. [Google Scholar] [CrossRef] [PubMed]

- Gollwitzer, R.; Gradinger, H. Ossäre Integration; Springer Medizin Verlag: Heidelberg, Germany, 2006. [Google Scholar]

- Swarts, E.; Bucher, T.A.; Phillips, M.; Yap, F.H.X. Does the ingrowth surface make a difference? A retrieval study of 423 cementless acetabular components. J. Arthroplast. 2015, 30, 706–712. [Google Scholar] [CrossRef] [PubMed]

| Unit Cell | Twisted (V) | Combined (D) | Combined Open (D_o) | |||||

|---|---|---|---|---|---|---|---|---|

|  |  | ||||||

| Dimension | V4_09 | V4_10 | V4_11 | V3_09 | V3_08 | D4_09 | D4_08 | D_o_4_09 |

| Width-a (mm) | 2.83 | 2.83 | 2.83 | 2.12 | 2.12 | 4.00 | 4.00 | 4.00 |

| Depth-b (mm) | 2.83 | 2.83 | 2.83 | 2.12 | 2.12 | 4.00 | 4.00 | 4.00 |

| Height-c (mm) | 4.00 | 4.00 | 4.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 |

| Strut diameter-d (mm) | 0.90 | 1.00 | 1.10 | 0.90 | 0.80 | 0.90 | 0.80 | 0.90 |

| Porosity-Structure area (%) | 72.50 | 67.40 | 60.60 | 58.80 | 65.50 | 61.10 | 66.90 | 74.80 |

| Volume-Press-fit area (cm3) | 0.30 | 0.39 | 0.25 | 0.32 | 0.54 | 0.97 | 0.91 | 0.77 |

| Parameter | Description | Unit | Process Parameter |

|---|---|---|---|

| P | Laser power | W | 275 |

| v | Scan speed | mm/s | 805 |

| d | Hatch spacing | µm | 120 |

| t | Layer thickness | µm | 50 |

| Name | Press-Fit Cup | Artificial Bone Cavity | Press-Fit (mm) | ||

|---|---|---|---|---|---|

| Best Fit Circle (mm) | Roundness (mm) | Best Fit Circle (mm) | Roundness (mm) | ||

| V3_08 | 55.32 | 0.26 | 53.18 ± 0.02 | 0.14 ± 0.02 | 2.13 ± 0.02 |

| V3_09 | 55.47 | 0.17 | 53.34 ± 0.02 | 0.13 ± 0.04 | 2.13 ± 0.01 |

| V4_09 | 54.90 | 0.29 | 52.68 ± 0.01 | 0.15 ± 0.01 | 2.16 ± 0.01 |

| V4_10 | 55.03 | 0.02 | 52.87 ± 0.01 | 0.14 ± 0.02 | 2.15 ± 0.01 |

| V4_11 | 55.20 | 0.28 | 53.07 ± 0.01 | 0.12 ± 0.01 | 2.13 ± 0.01 |

| D4_08 | 54.98 | 0.30 | 52.87 ± 0.01 | 0.14 ± 0.01 | 2.11 ± 0.01 |

| D4_09 | 55.04 | 0.11 | 52.87 ± 0.01 | 0.14 ± 0.01 | 2.17 ± 0.01 |

| D_o_4_09 | 55.03 | 0.25 | 52.87 ± 0.01 | 0.14 ± 0.01 | 2.16 ± 0.01 |

| Cupversion | D4_09 | D_o_4_09 | V3_08 | V3_09 | V4_09 | V4_10 | V4_11 |

|---|---|---|---|---|---|---|---|

| D4_08 | N.S. | 0.00438 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| D4_09 | - | 0.00193 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| D_o_4_09 | - | - | <0.001 | 0.0006 | <0.001 | <0.001 | <0.001 |

| V3_08 | - | - | - | N.S. | N.S. | 0.0242 | N.S. |

| V3_09 | - | - | - | - | N.S. | N.S. | N.S. |

| V4_09 | - | - | - | - | - | N.S. | N.S. |

| V4_10 | - | - | - | - | - | - | N.S. |

| Cupversion | D4_09 | D_o_4_09 | V3_08 | V3_09 | V4_09 | V4_10 | V4_11 |

|---|---|---|---|---|---|---|---|

| D4_08 | N.S. | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| D4_09 | - | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| D_o_4_09 | - | - | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| V3_08 | - | - | - | 0.04619 | N.S. | N.S. | 0.04649 |

| V3_09 | - | - | - | - | N.S. | N.S. | N.S. |

| V4_09 | - | - | - | - | - | N.S. | N.S. |

| V4_10 | - | - | - | - | - | - | N.S. |

| Cupversion | D4_09 | D_o_4_09 | V3_08 | V3_09 | V4_09 | V4_10 | V4_11 |

|---|---|---|---|---|---|---|---|

| D4_08 | N.S. | N.S. | N.S. | 0.04296 | N.S. | N.S. | N.S. |

| D4_09 | - | N.S. | N.S. | 0.01733 | N.S. | N.S. | N.S. |

| D_o_4_09 | - | - | N.S. | N.S. | N.S. | N.S. | N.S. |

| V3_08 | - | - | - | N.S. | N.S. | N.S. | N.S. |

| V3_09 | - | - | - | - | 0.01595 | 0.03089 | 0.01335 |

| V4_09 | - | - | - | - | - | N.S. | N.S. |

| V4_10 | - | - | - | - | - | - | N.S. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weißmann, V.; Boss, C.; Schulze, C.; Hansmann, H.; Bader, R. Experimental Characterization of the Primary Stability of Acetabular Press-Fit Cups with Open-Porous Load-Bearing Structures on the Surface Layer. Metals 2018, 8, 839. https://doi.org/10.3390/met8100839

Weißmann V, Boss C, Schulze C, Hansmann H, Bader R. Experimental Characterization of the Primary Stability of Acetabular Press-Fit Cups with Open-Porous Load-Bearing Structures on the Surface Layer. Metals. 2018; 8(10):839. https://doi.org/10.3390/met8100839

Chicago/Turabian StyleWeißmann, Volker, Christian Boss, Christian Schulze, Harald Hansmann, and Rainer Bader. 2018. "Experimental Characterization of the Primary Stability of Acetabular Press-Fit Cups with Open-Porous Load-Bearing Structures on the Surface Layer" Metals 8, no. 10: 839. https://doi.org/10.3390/met8100839

APA StyleWeißmann, V., Boss, C., Schulze, C., Hansmann, H., & Bader, R. (2018). Experimental Characterization of the Primary Stability of Acetabular Press-Fit Cups with Open-Porous Load-Bearing Structures on the Surface Layer. Metals, 8(10), 839. https://doi.org/10.3390/met8100839