A Microstructural Evaluation of Friction Stir Welded 7075 Aluminum Rolled Plate Heat Treated to the Semi-Solid State

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

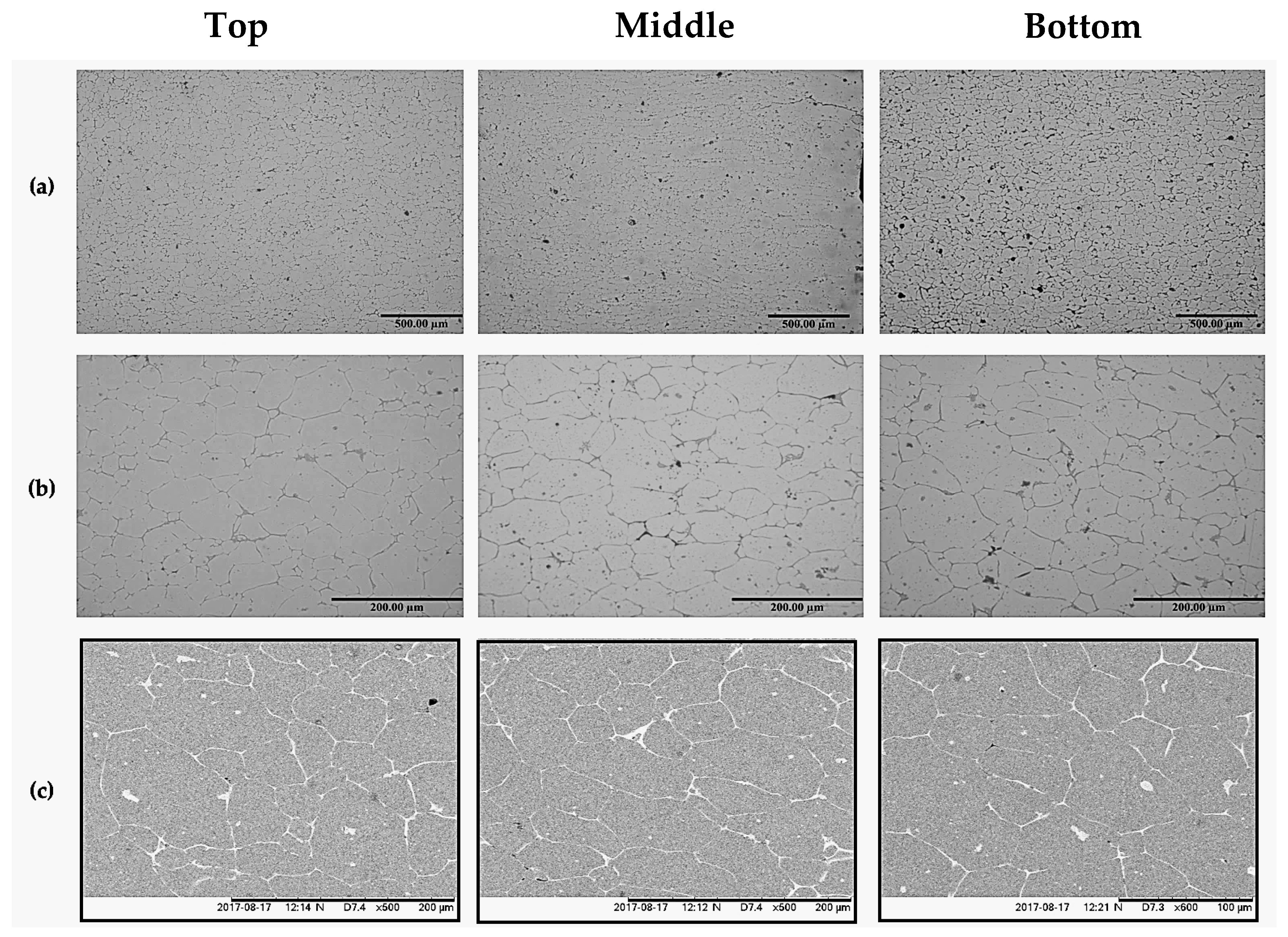

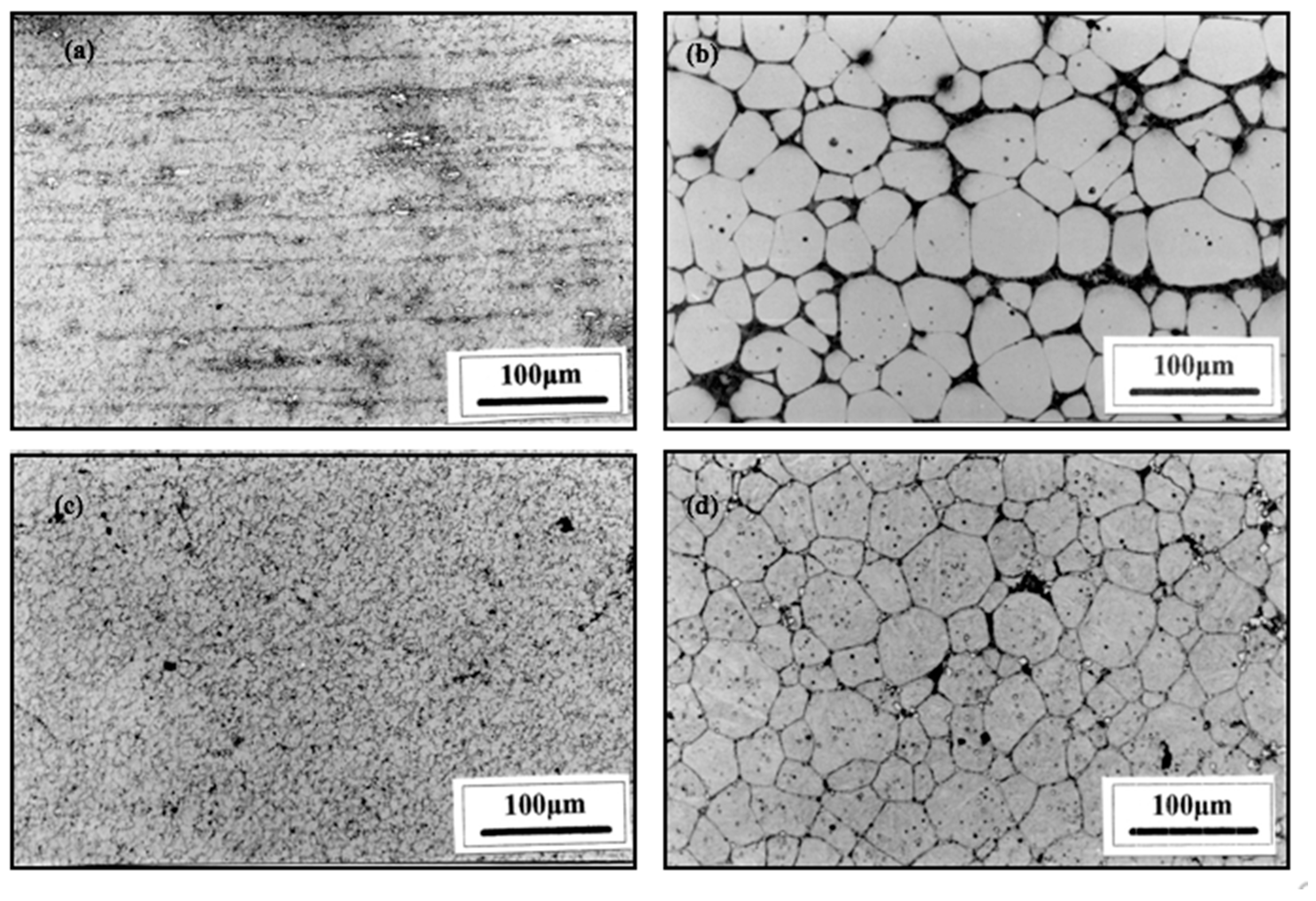

3.1. Microstructural Evolution of the Friction Stir Welded Plates

3.2. Post Welding Heat Treatment

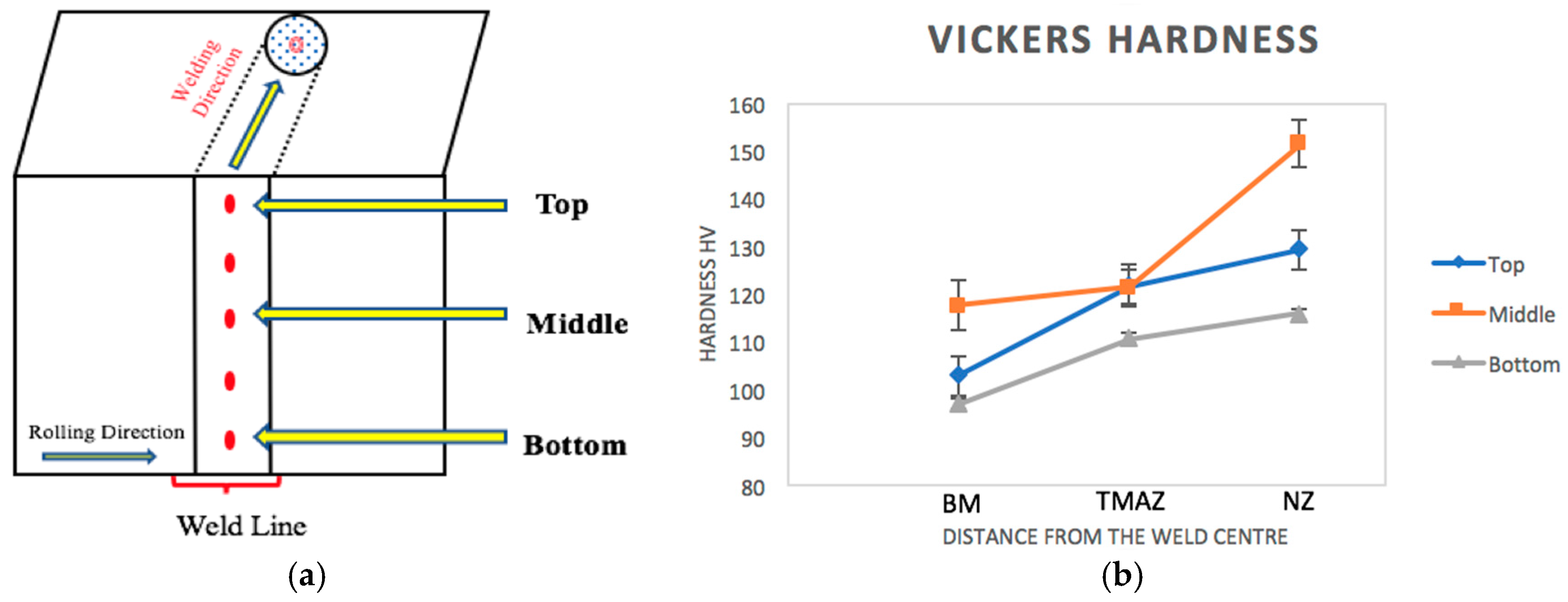

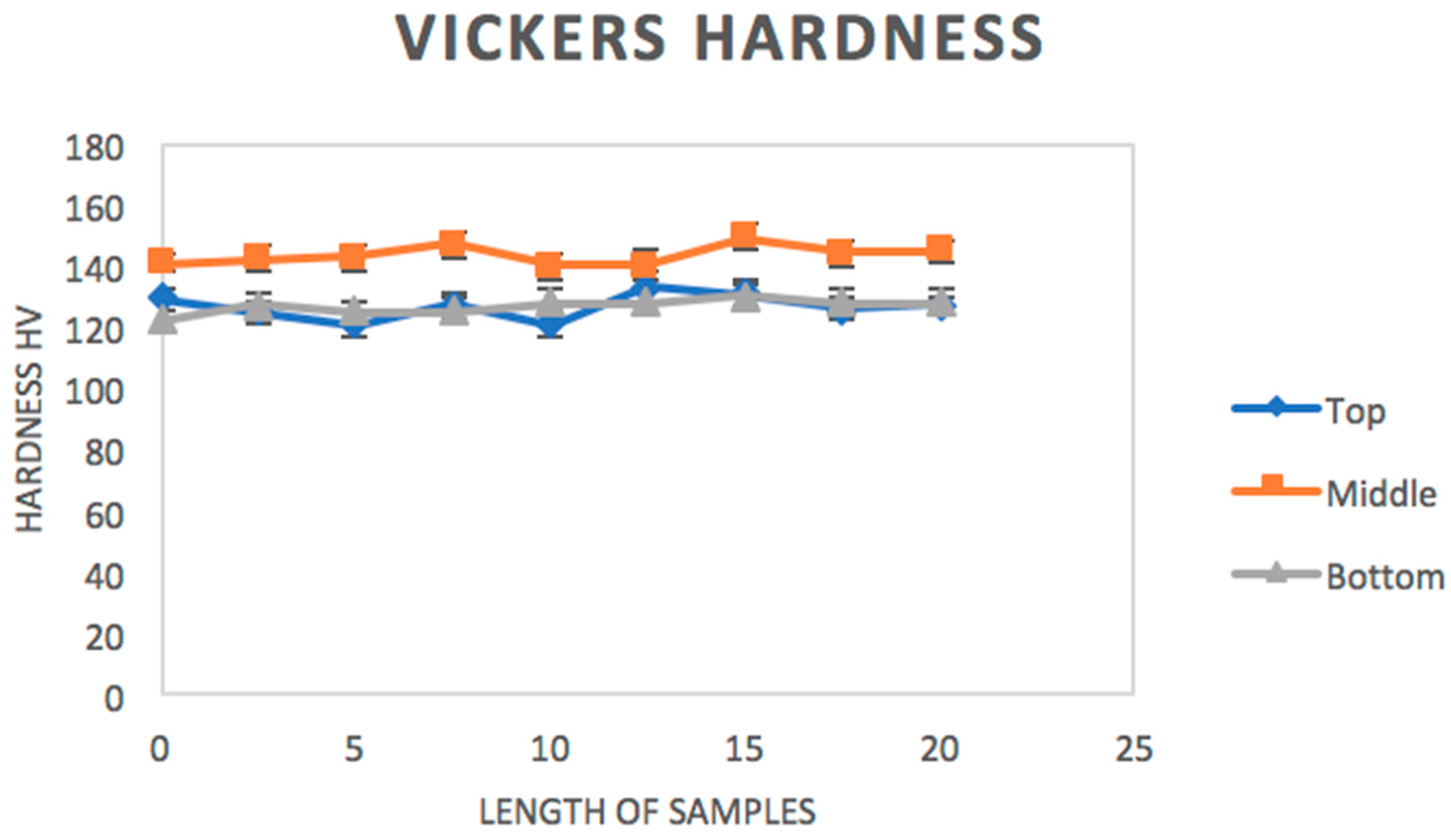

3.3. Vickers Hardness Results

4. Conclusions

- (a)

- The base metal consists of typical pancake-shaped grains elongated in the rolling direction but the grain size is significantly decreased in the nugget zone due to extensive plastic deformation that the materials undergo during FSW;

- (b)

- Grains start to grow throughout the material during heat treatment at 628 °C, resulting in uniform non-dendritic microstructures similar to those obtained by thixoforming;

- (c)

- Hardness tests show that hardness in the NZ is higher than that in TMAZ and BM due to the ultra-fine grain structure attained in this area.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, J.F.; Peng, Z.W.; Li, C.X.; Jia, Z.Q.; Chen, W.J.; Zheng, Z.Q. Mechanical properties, corrosion behaviors and microstructures of 7075 aluminum alloy with various aging treatments. Trans. Nonferr. Met. Soc. China 2008, 18, 755–762. [Google Scholar] [CrossRef]

- Rachmat, R.S.; Takano, H.; Ikeya, N.; Kamado, S.; Kojima, Y. Application of Semi-Solid Forming to 2024 and 7075 Wrought Aluminum Billets Fabricated by EMC Process. Mater. Sci. Forum 2000, 329–330, 487–492. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Cerri, E.; Leo, P. Mechanical properties evolution during pos-welding-heat treatments of double lap friction stir welding joints. Mater. Des. 2011, 32, 3465–3475. [Google Scholar] [CrossRef]

- Flores, O.V.; Kennedy, C.; Murr, L.E.; Brown, D.; Pappu, S.; Nowak, B.M.; McClure, J.C. Microstructural issues in a friction stir-welded aluminum alloy. Scr. Mater. 1998, 38, 703–708. [Google Scholar] [CrossRef]

- Fadaeifard, F.; Matori, K.A.; Abd Aziz, S.; Zolkarnian, L.; Rahim, M.A.Z.B. Effects of the welding speed on the macrostructure, microstructure and mechanical properties of AA6061-T6 friction stir butt welds. J. Miner. Met. Mater. Soc. 2017, 7, 48. [Google Scholar] [CrossRef]

- Jata, K.V.; Sankaran, K.K.; Ruschau, J.J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. A 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Wang, G.; Yan, Z.; Zhang, H.; Zhang, X.; Liu, F.; Wang, X.; Su, Y. Improved properties of friction stir-welded AZ31 magnesium alloy by post-weld heat treatment. J. Mater. Sci. Technol. 2017, 33, 854–863. [Google Scholar] [CrossRef]

- Cam, G.; Mistikoglu, S. Recent developments in friction stir welding of Al-alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Pourali, M.; Abdollah-zadeh, A.; Saeid, T.; Kargar, F. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J. Alloys Compd. 2017, 715, 1–8. [Google Scholar] [CrossRef]

- Wang, Z.B.; He, Z.B.; Fan, X.B.; Zhou, L.; Lin, Y.L.; Yuan, S.J. High temperature deformation behavior of friction stir welded 2024-T4 aluminum alloy sheets. J. Mater. Process. Technol. 2017, 247, 184–191. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Abnormal grain growth in friction stir processed alloys. Scr. Mater. 2008, 58, 367–371. [Google Scholar] [CrossRef]

- Kapranos, P. Routes to Thixoformable Steel Starting Material, Thixoforming Steel; Shaker Verlag Publications: Aachen, Germany, 2010; ISBN 978-3-8322-9133-4. [Google Scholar]

- Mohammed, M.N.; Omar, M.Z.; Salleh, M.S.; Alhawari, K.S.; Kapranos, P. Semi-solid processing techniques for nondendritic feedstock production. Sci. World J. 2013, 2013, 752175. [Google Scholar] [CrossRef] [PubMed]

- Kirkwood, D.H.; Kapranos, P.; Young, K.P.; Suery, M.; Atkinson, H.V. Semi-Solid Metal Processing; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2010; p. 124. ISBN 978-3-642-00706-4. [Google Scholar]

- Chayong, S.; Atkinson, H.V.; Kapranos, P. Thixoforming 7075 Aluminum Alloy. Mater. Sci. Eng. A 2005, 390, 3–12. [Google Scholar] [CrossRef]

- Binesh, B.; Aghaie-Khafri, M. Phase evolution and mechanical behaviour of the semi-solid SIMA processed 7075 aluminum alloy. Metals 2016, 6, 42. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y.; Xiao, G.; Nie, X. Comparison of microstructural evolution of 7075 aluminum alloy fabricated by SIMA and RAP. J. Mater. Process. Technol. 2016, 238, 361–372. [Google Scholar] [CrossRef]

- Cavaliere, P.; Nobile, R.; Panella, F.W.; Squilla, A. Mechanical and microstructural behaviour of 2024-7075 aluminium sheets joined by friction stir welding. Int. J. Mach. Tools Manuf. 2006, 46, 588–594. [Google Scholar] [CrossRef]

- Motohashi, Y. Grain refinement process in commercial 7075-T6 aluminum alloy under friction stir welding and superplasticity. Mater. Werksttech 2008, 39, 275–278. [Google Scholar] [CrossRef]

- Keydon, S.; Veeredhi, R. Recent developments in micro friction stir welding: A review. In Proceedings of the 2nd International Manufacturing Engineering Conference (iMEC), Kuala Lumpur, Malaysia, 12–14 November 2015; Hamedon, Z., Ed.; IOP Conference Series: Materials Science and Engineering. IOP Publishing Ltd.: Bristol, UK, 2016; Volume 114, p. 012036. [Google Scholar] [CrossRef]

- Rafi, H.K.; Jonak Ram, G.D.; Phanikumar, G.; Prasad Rao, K. Microstructure and tensile properties of friction welded aluminum alloy AA 7075-T6. Mater. Des. 2010, 31, 2375–2380. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Threadgill, P.L.; Addison, A.C. Solid state joining of metals by linear friction welding: A literature review. Mater. Sci. Technol. 2010, 27, 2–12. [Google Scholar] [CrossRef]

- Maalekian, M. Friction welding–Critical assessment of literature. Sci. Technol. Weld. Join. 2007, 12, 738–759. [Google Scholar] [CrossRef]

- Kumar, A.; Sandan Kumar, S.; Pal, K.; Mula, S. Effect of process parameters on microstructural evolution, mechanical properties and corrosion behaviour of friction stir processed Al 7075 alloy. J. Mater. Eng. Perform. 2017, 26, 1122–1134. [Google Scholar] [CrossRef]

- Camacho, A.M.; Atkinson, H.V.; Kapranos, P.; Argent, B.B. Thermodynamic Predictions of Wrought Alloy Compositions Amenable to Semi-Solid Processing. Acta Mater. 2003, 51, 2319–2330. [Google Scholar] [CrossRef]

- Leatham, A. Spray Forming: Alloys, Products and Markets. J. Miner. Met. Mater. Soc. 1999, 51. [Google Scholar] [CrossRef]

| Alloy | Cu | Zn | Mg | Mn | Cr | Ti | Si | Fe | Zr | B | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7075 | 0.94 | 4.52 | 2.24 | <0.01 | 0.22 | 0.05 | 0.02 | <0.01 | <0.01 | <0.01 | Bal. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azadi Chegeni, A.; Kapranos, P. A Microstructural Evaluation of Friction Stir Welded 7075 Aluminum Rolled Plate Heat Treated to the Semi-Solid State. Metals 2018, 8, 41. https://doi.org/10.3390/met8010041

Azadi Chegeni A, Kapranos P. A Microstructural Evaluation of Friction Stir Welded 7075 Aluminum Rolled Plate Heat Treated to the Semi-Solid State. Metals. 2018; 8(1):41. https://doi.org/10.3390/met8010041

Chicago/Turabian StyleAzadi Chegeni, Ava, and Platon Kapranos. 2018. "A Microstructural Evaluation of Friction Stir Welded 7075 Aluminum Rolled Plate Heat Treated to the Semi-Solid State" Metals 8, no. 1: 41. https://doi.org/10.3390/met8010041

APA StyleAzadi Chegeni, A., & Kapranos, P. (2018). A Microstructural Evaluation of Friction Stir Welded 7075 Aluminum Rolled Plate Heat Treated to the Semi-Solid State. Metals, 8(1), 41. https://doi.org/10.3390/met8010041