In Situ Characterization of Inconel 718 Post-Dynamic Recrystallization within a Scanning Electron Microscope

Abstract

1. Introduction

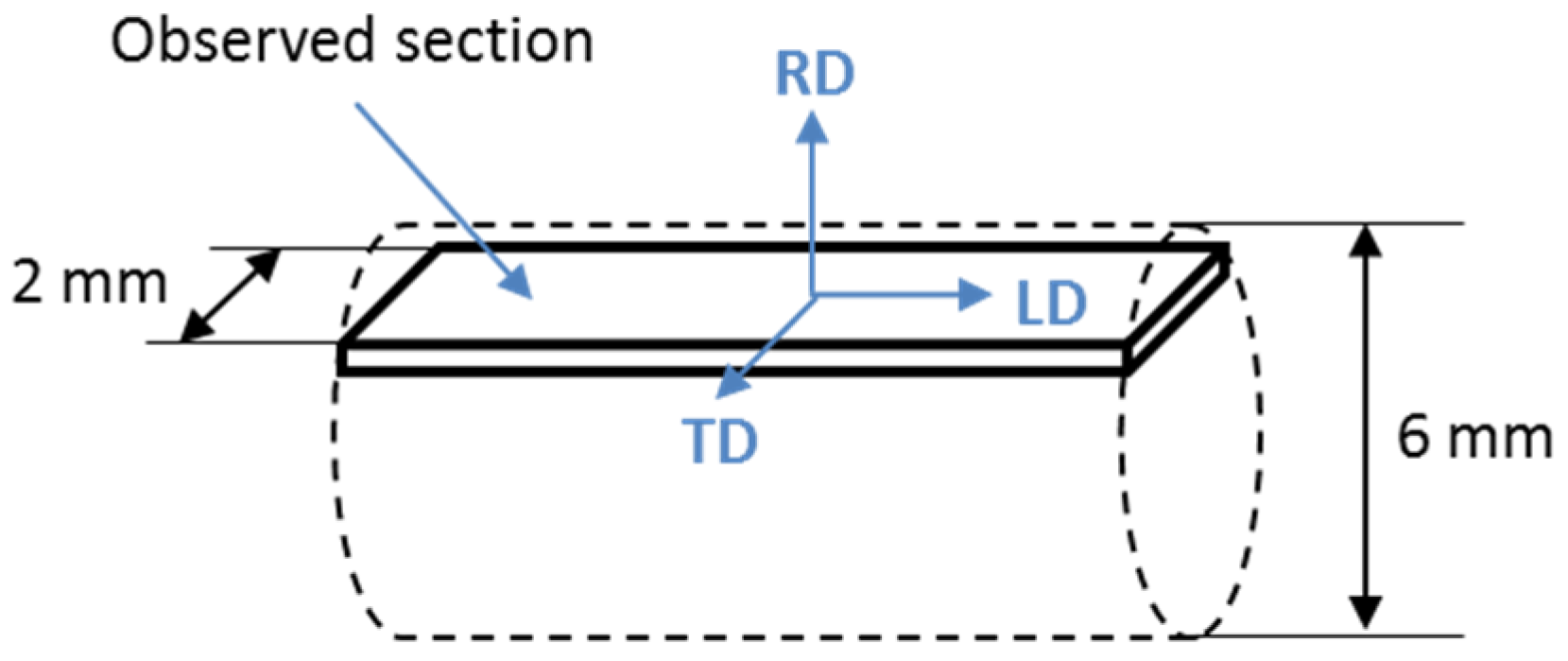

2. Materials and Methods

3. Results

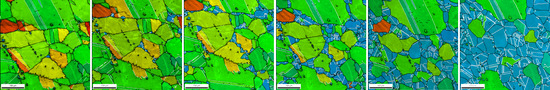

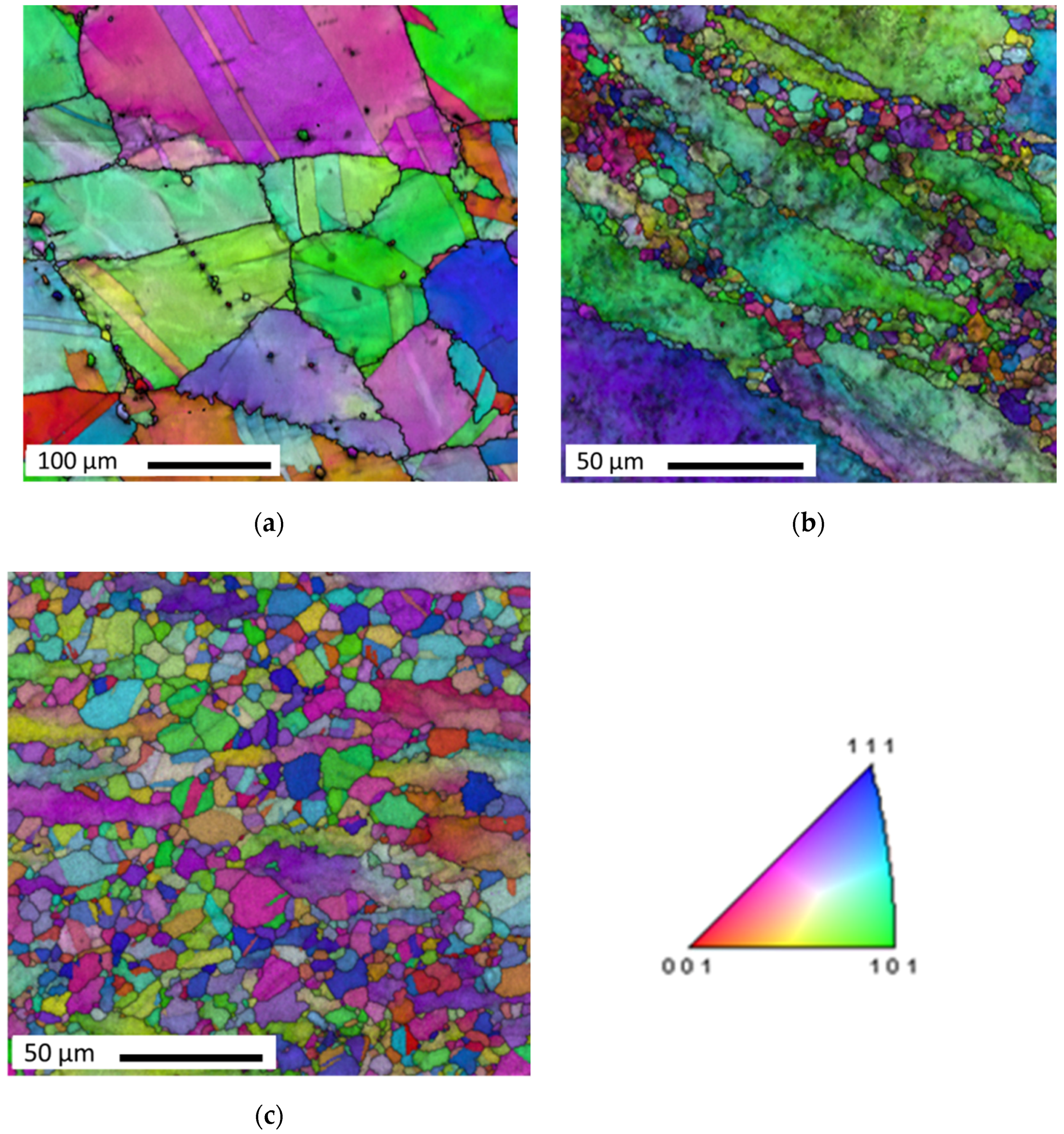

3.1. As-quenched Samples

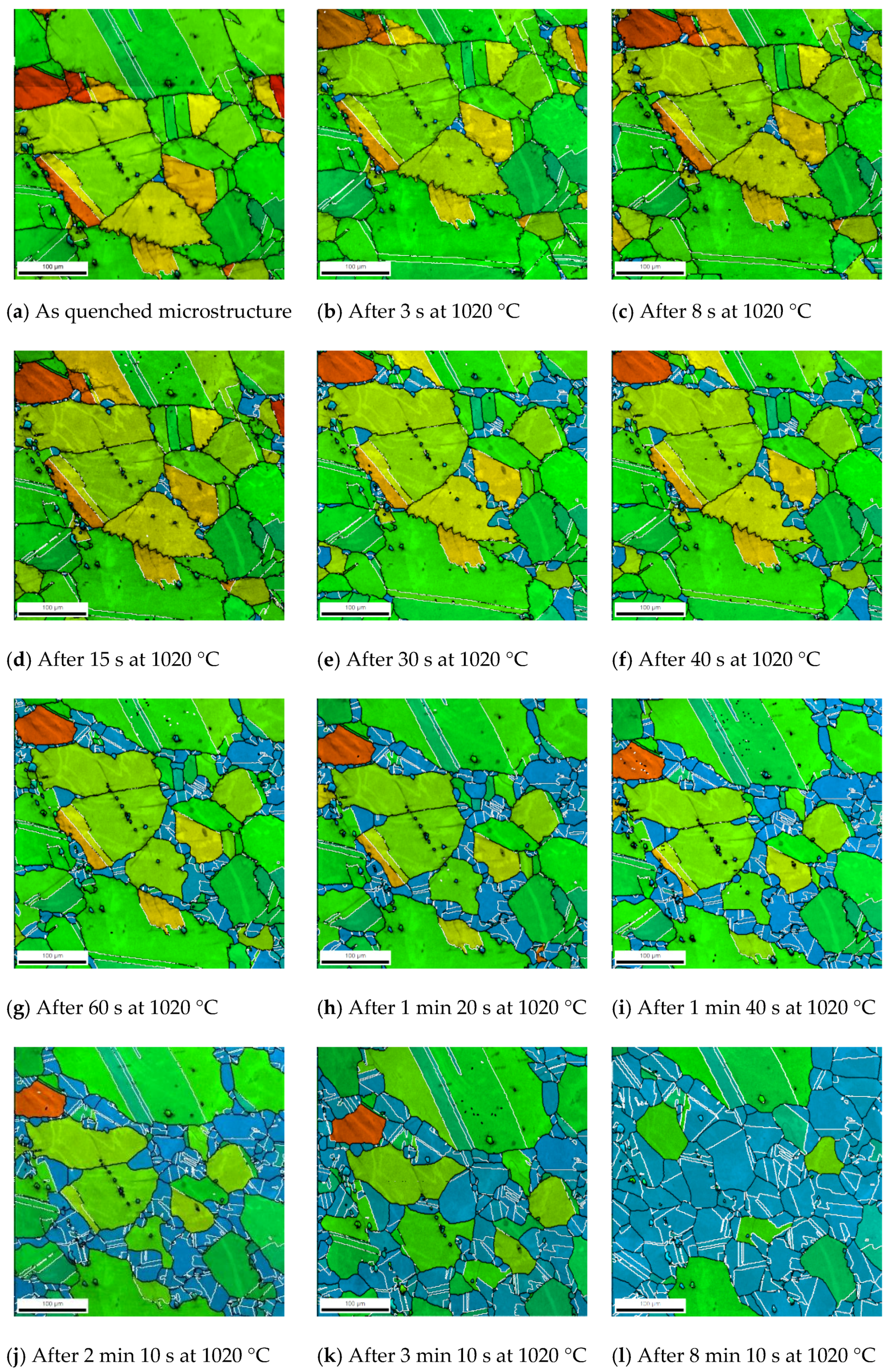

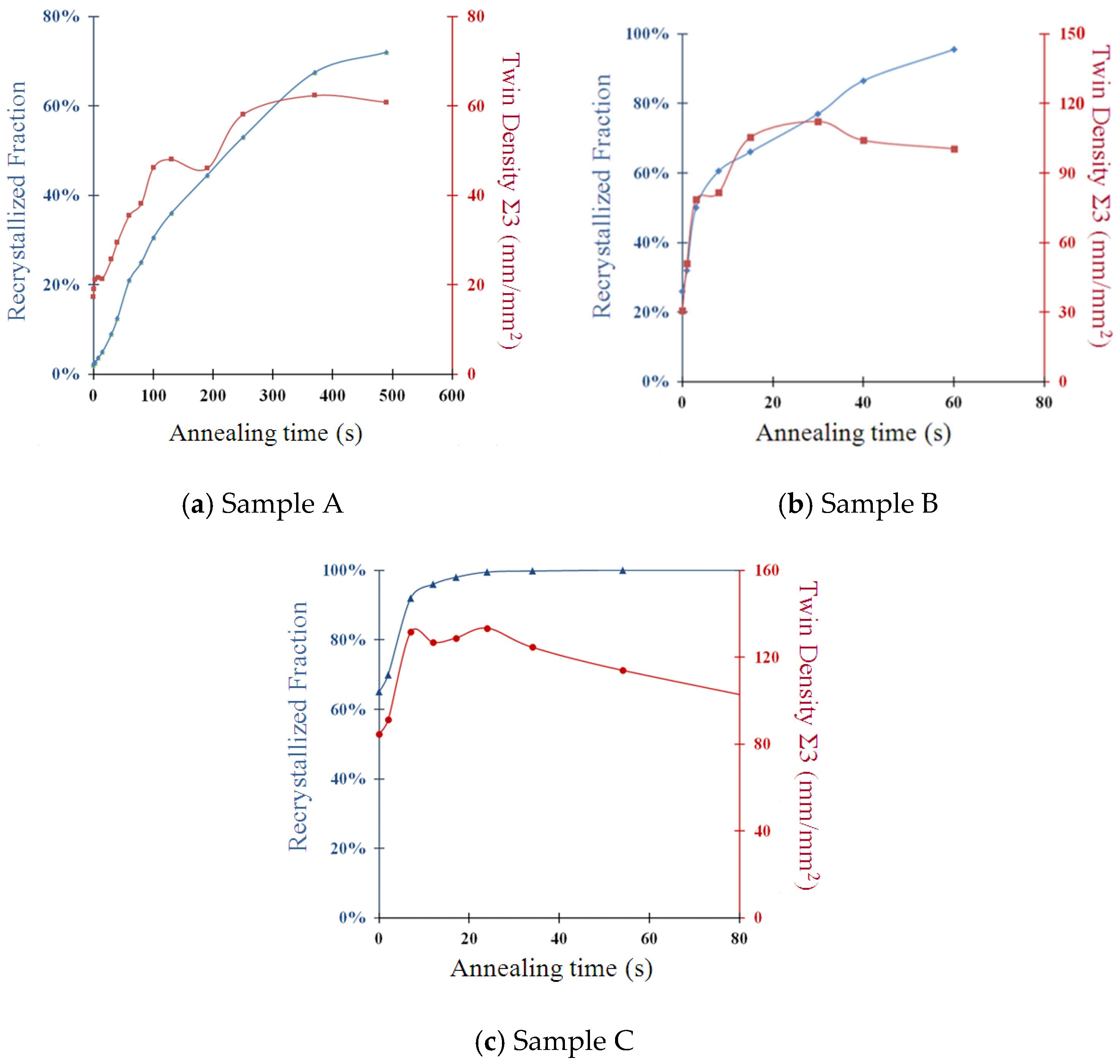

3.2. Post-dynamic Evolution Starting from a Very Low Dynamic Recrystallization (DRX) Volume Fraction (Sample A, 0.25 Strain, DRX 2%)

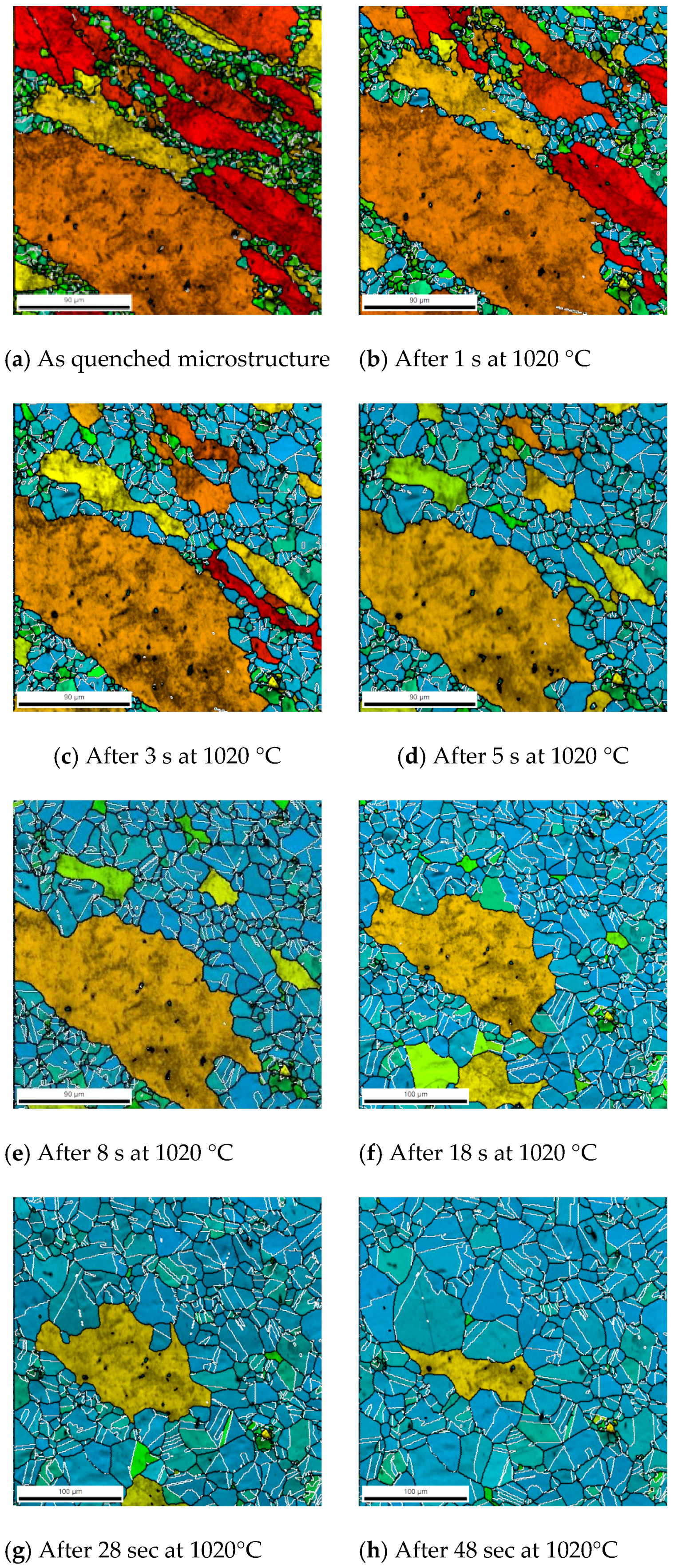

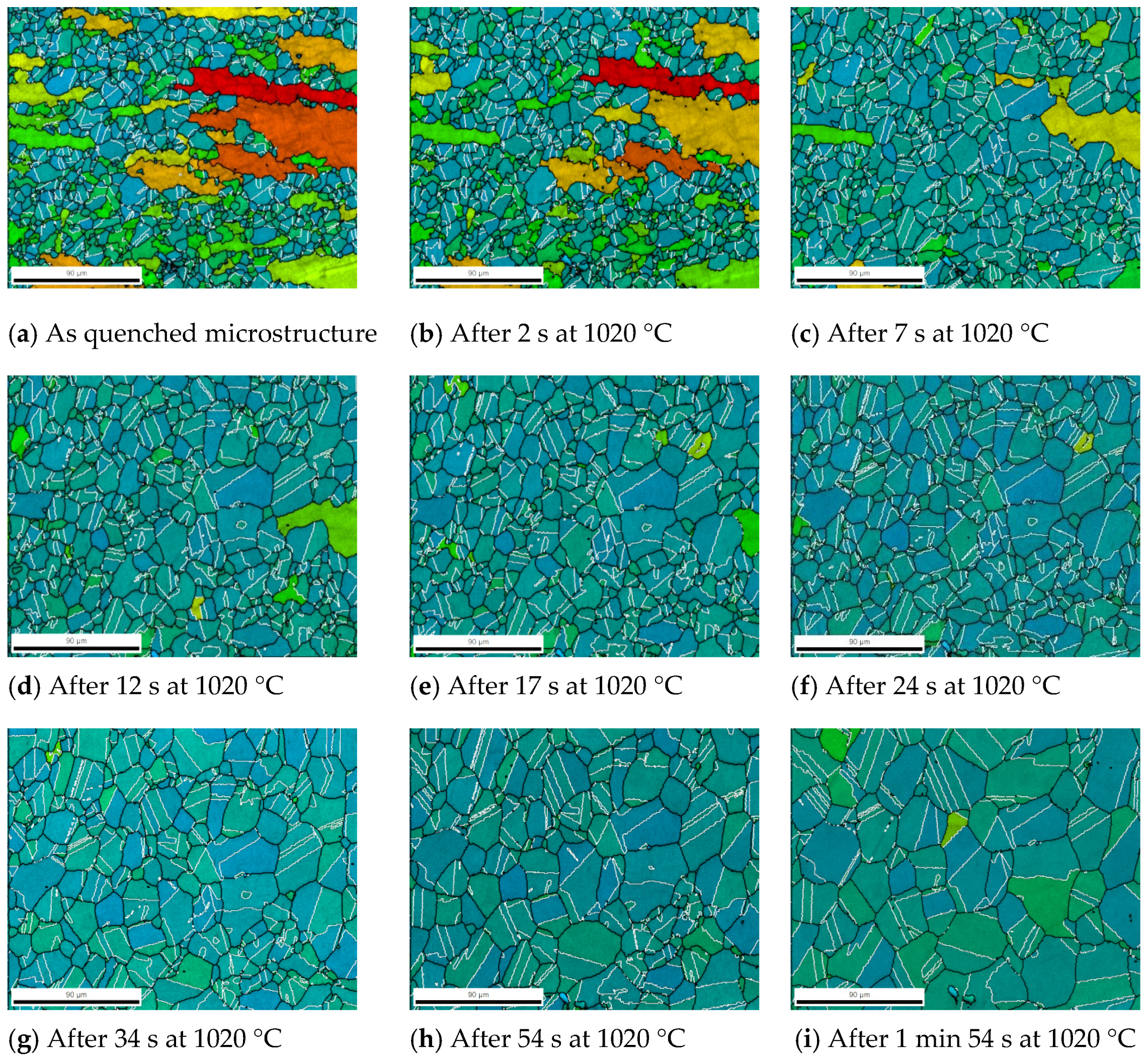

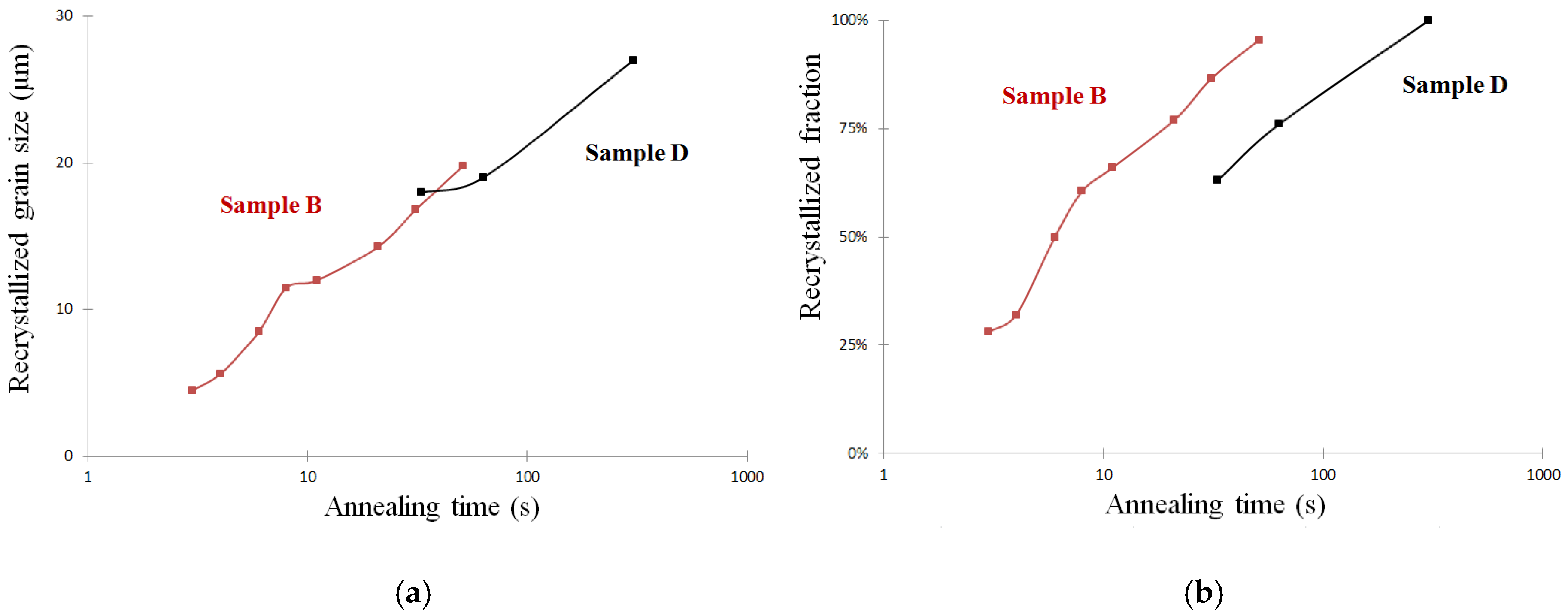

3.3. Post-dynamic Evolution Starting from Higher DRX Volume Fractions (Sample B, Strain 0.55, DRX 26%, and Sample C, Strain 2.0, DRX 65%)

4. Discussion

4.1. Validation of the Ability of the Sequential Annealing Procedure to Mimic Post-Dynamic Evolutions

4.2. Post-dynamic Recrystallization Mechanisms and Kinetics

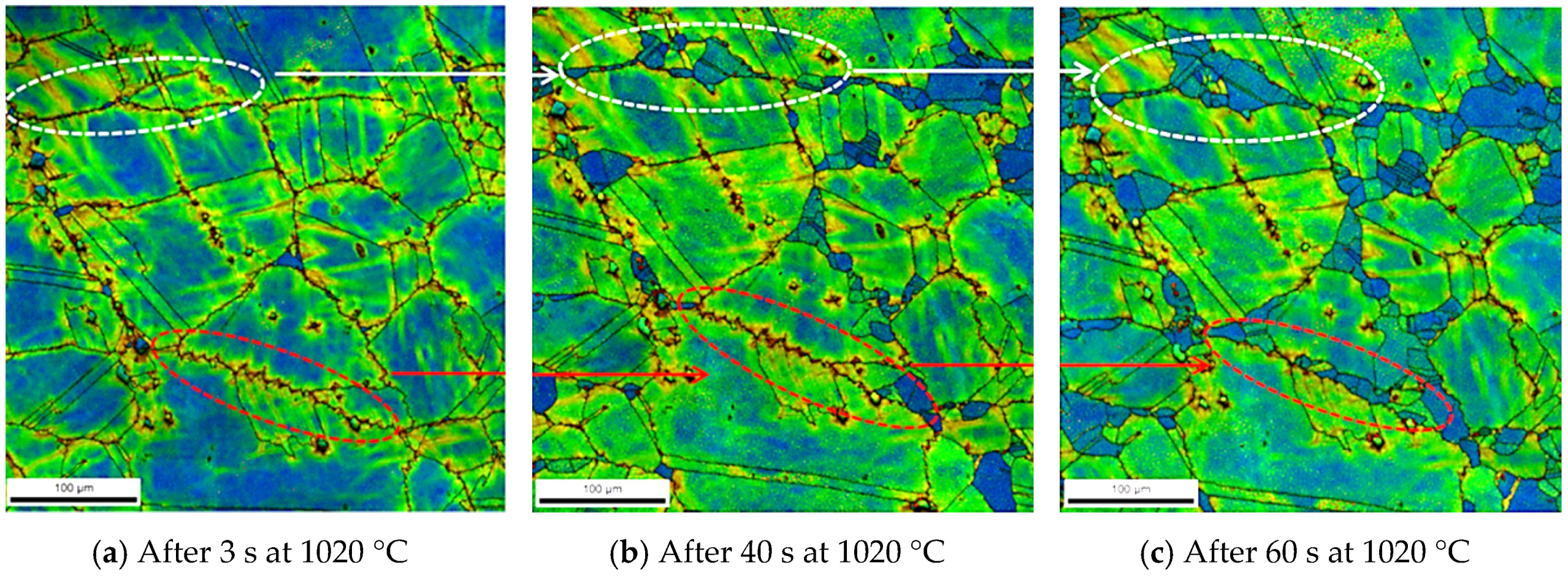

4.3. Post-dynamic Evolution of Twin Boundaries

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Luton, M.J.; Sellars, C.M. Dynamic recrystallization in nickel and nickel-iron alloys during high temperature deformation. Acta Metall. 1969, 17, 1033–1043. [Google Scholar] [CrossRef]

- Zhou, L.X.; Baker, T.N. Effects of dynamic and metadynamic recrystallization on microstructures of wrought IN-718 due to hot deformation. Mater. Sci. Eng. A 1995, 196, 89–95. [Google Scholar] [CrossRef]

- Guest, R.P.; Tin, S. The dynamic and metadynamic recrystallization of IN718. In Proceedings of the 6th International Symposium on Superalloys 718, 625, 706 and Derivatives, Pittsburgh, PA, USA, 17–20 May 2005. [Google Scholar]

- Wang, Y.; Shao, W.Z.; Zhen, L.; Yang, L.; Zhang, X.M. Flow behavior and microstructures of superalloy 718 during high temperature deformation. Mater. Sci. Eng. A 2008, 497, 479–486. [Google Scholar] [CrossRef]

- De Jaeger, J.; Solas, D.; Baudin, T.; Fandeur, O.; Schmitt, J.H.; Rey, C. Inconel 718 recrystallization in the delta supersolvus domain. Adv. Mater. Res. 2011, 409, 751–756. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Shao, W.; Zhen, L.; Zhang, B.Y. Hot deformation behavior of delta-processed superalloy 718. Mater. Sci. Eng. A 2011, 528, 3218–3227. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Zhou, H.; Lu, Z.; Zhao, C.; Yang, X. Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation. Mater. Design 2015, 80, 51–62. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M.; Cabrera, J.M.; Calvo, J. Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater. Sci. Eng. A 2016, 678, 137–152. [Google Scholar] [CrossRef]

- Roberts, W.; Ahlblom, B. A nucleation criterion for dynamic recrystallization during hot working. Acta Metall. 1978, 26, 801–813. [Google Scholar] [CrossRef]

- Brand, A.J.; Karhausen, K.; Kopp, R. Microstructural simulation of nickel base alloy Inconel 718 in production of turbine discs. Mater. Sc. Technol. 1996, 12, 963–969. [Google Scholar] [CrossRef]

- Huang, D.; Wu, W.T.; Lambert, D.; Semiatin, S.L. Computer simulation of microstructure evolution during hot forging of Waspaloy and nickel alloy 718. In Proceedings of the Fifth International Symposium on Superalloys 718, 625, 706, and Derivatives, Pittsburgh, PA, USA, 17–20 June 2001. [Google Scholar]

- Na, Y.S.; Yeom, J.T.; Park, N.K.; Lee, J.Y. Simulation of microstructures for Alloy 718 blade forging using 3D FEM simulator. J. Mater. Proc. Technol. 2003, 141, 337–342. [Google Scholar] [CrossRef]

- Guest, R.P.; Tin, S. Modelling Microstructural Transformations of Nickel Base Superalloy IN 718 during Hot Deformation. In Proceedings of the 6th International Symposium on Superalloys 718, 625, 706 and Derivatives, Pittsburgh, PA, USA, 17–20 May 2005. [Google Scholar]

- Furrer, D.; Goetz, R.; Shen, G. Modeling and simulation of Alloy 718 microstructure and mechanical properties. In Proceedings of the 7th international symposium on Superalloy 718 & Derivatives, Pittsburgh, PA, USA, 10–13 October 2010. [Google Scholar]

- Zouari, M.; Bozzolo, N.; Logé, R.E. Mean field modeling of dynamic and post-dynamic recrystallization during hot deformation of Inconel 718 in the absence of δ-phase particles. Mater. Sci. Eng. A 2016, 655, 408–424. [Google Scholar] [CrossRef]

- Medeiros, S.C.; Prasad, Y.V.R.K.; Frazier, W.G.; Srinivasan, R. Microstructural modeling of metadynamic recrystallization in hot working of IN 718 superalloy. Mater. Sci. Eng. A 2000, 293, 198–207. [Google Scholar] [CrossRef]

- Zouari, M.; Logé, R.E.; Beltran, O.; Rousselle, S.; Bozzolo, N. Multipass forging of Inconel 718 in the delta-Supersolvus domain: Assessing and modeling microstructure evolution. In Proceedings of the 2nd European Symposium on Superalloys and their Applications, Giens, France, 10–16 May 2014. [Google Scholar]

- He, D.G.; Lin, Y.C.; Chen, M.S.; Li, L. Kinetics equations and microstructural evolution during metadynamic recrystallization in a nickel-based superalloy with δ phase. J. Alloys Compd. 2017, 690, 971–978. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Djaic, R.A.P.; Jonas, J.J. Static recrystallization of austenite between intervals of hot working. J. Iron Steel Inst. 1972, 210, 256–261. [Google Scholar]

- Tang, X.; Wang, B.; Ji, H.; Fu, X.; Xiao, W. Behaviour and modeling of microstructure evolution during metadynamic recrystallization in a Ni-based superalloy. Mater. Sci. Eng. A 2016, 675, 192–203. [Google Scholar] [CrossRef]

- Lehockey, E.M.; Palumbo, G.; Lin, P. Improving the weldability and service performance of nickel-and iron-based superalloys by grain boundary engineering. Metall. Mater. Trans. A 1998, 29, 3069–3079. [Google Scholar] [CrossRef]

- Krupp, U.; Kane, W.M.; Liu, X.; Dueber, O.; Laird, C.; McMahon, C.J. The effect of grain-boundary-engineering-type processing on oxygen-induced cracking of IN718. Mater. Sci. Eng. A 2003, 349, 213–217. [Google Scholar] [CrossRef]

- Krupp, U.; Wagenhuber, P.G.; Kane, W.M.; McMahon, C.J. Improving resistance to dynamic embrittlement and intergranular oxidation of nickel based superalloys by grain boundary engineering type processing. Mater. Sc. Technol. 2005, 21, 1247–1254. [Google Scholar] [CrossRef]

- Tan, L.; Sridharan, K.; Allen, T.R. Effect of thermomechanical processing on grain boundary character distribution of a Ni-based superalloy. J. Nucl. Mater. 2007, 371, 171–175. [Google Scholar] [CrossRef]

- Gabb, T.P.; Telesman, J.; Garg, A.; Lin, P.; Provenzano, V.; Heard, R.; Miller, H.M. Grain Boundary Engineering the Mechanical Properties of Allvac 718 Plus Superalloy. In Proceedings of the 7th international symposium on Superalloy 718 & Derivatives, Pittsburgh, PA, USA, 10–13 October 2010. [Google Scholar]

- Souaï, N.; Bozzolo, N.; Nazé, L.; Chastel, Y.; Logé, R.E. About the possibility of grain boundary engineering via hot-working in a nickel-base superalloy. Script. Mater. 2010, 62, 851–854. [Google Scholar] [CrossRef]

- Bozzolo, N.; Souaï, N.; Logé, R.E. Evolution of microstructure and twin density during thermomechanical processing in a γ-γ’ nickel-based superalloy. Acta Mater. 2012, 60, 5056–5066. [Google Scholar] [CrossRef]

- Li, B.; Tin, S. The role of deformation temperature and strain on grain boundary engineering of Inconel 600. Mater. Sci. Eng. A 2014, 603, 104–113. [Google Scholar] [CrossRef]

- Detrois, M.; Rotella, J.; Goetz, R.L.; Helmink, R.C.; Tin, S. Grain boundary engineering of powder processed Ni-base superalloy RR1000: Influence of the deformation parameters. Mater. Sci. Eng. A 2015, 627, 95–105. [Google Scholar] [CrossRef]

- Watanabe, T. Grain boundary engineering: Historical perspective and future prospects. J. Mater. Sci. 2011, 46, 4095–4115. [Google Scholar] [CrossRef]

- Bozzolo, N.; Jacomet, S.; Logé, R.E. Fast in-situ annealing stage coupled with EBSD: A suitable tool to observe quick recrystallization mechanisms. Mater. Charact. 2012, 70, 28–32. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, B.; Bernacki, M.; Rohrer, G.S.; Rollett, A.D.; Bozzolo, N. Annealing twin development during recrystallization and grain growth in pure nickel. Mater. Sci. Eng. A 2014, 597, 295–303. [Google Scholar] [CrossRef]

- Carpenter, H.; Tamura, S. The formation of twinned metallic crystals. Proc. R. Soc. London 1926, 113, 161–182. [Google Scholar] [CrossRef]

- Fullman, R.L.; Fisher, J.C. Formation of annealing twins during grain growth. J. Appl. Phys. 1951, 22, 1350–1355. [Google Scholar] [CrossRef]

- Gleiter, H. The formation of annealing twins. Acta Metall. 1969, 17, 1421–1428. [Google Scholar] [CrossRef]

- Jin, Y.; Bernacki, M.; Agnoli, A.; Lin, B.; Rohrer, G.S.; Rollett, A.D.; Bozzolo, N. Evolution of the annealing twin density during δ-supersolvus grain growth in the nickel-based superalloy Incone 718. Metals 2015, 6, 5–18. [Google Scholar] [CrossRef]

- Lin, B.; Jin, Y.; Hefferan, C.M.; Li, S.F.; Lind, J.; Suter, R.M.; Bernacki, M.; Bozzolo, N.; Rollett, A.D.; Rohrer, G.S. Observation of annealing twin nucleation at triple lines in nickel during grain growth. Acta Mater. 2015, 99, 63–68. [Google Scholar] [CrossRef]

.

.

.

.

.

.

.

.

.

.

.

.

.

.

| Ni | Fe | Cr | Nb | Mo | Ti,Al,Co | Other |

|---|---|---|---|---|---|---|

| 54.0% | 17.8% | 18.0% | 5.3% | 3.0% | 1.49% | <0.5% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zouari, M.; Logé, R.E.; Bozzolo, N. In Situ Characterization of Inconel 718 Post-Dynamic Recrystallization within a Scanning Electron Microscope. Metals 2017, 7, 476. https://doi.org/10.3390/met7110476

Zouari M, Logé RE, Bozzolo N. In Situ Characterization of Inconel 718 Post-Dynamic Recrystallization within a Scanning Electron Microscope. Metals. 2017; 7(11):476. https://doi.org/10.3390/met7110476

Chicago/Turabian StyleZouari, Meriem, Roland E. Logé, and Nathalie Bozzolo. 2017. "In Situ Characterization of Inconel 718 Post-Dynamic Recrystallization within a Scanning Electron Microscope" Metals 7, no. 11: 476. https://doi.org/10.3390/met7110476

APA StyleZouari, M., Logé, R. E., & Bozzolo, N. (2017). In Situ Characterization of Inconel 718 Post-Dynamic Recrystallization within a Scanning Electron Microscope. Metals, 7(11), 476. https://doi.org/10.3390/met7110476