1. Introduction

Many investigations have been devoted to understanding the deformation behavior of magnesium and its alloys, because of their potential applications for lightweight materials in the aircraft and automotive industries, and for portable electronic devices [

1,

2]. Magnesium alloys have poor formability at room temperature, which can be attributed to the limited number of available slip systems [

3,

4]. <a> slip with a 1/3<11.0> Burgers vector on the close-packed (00.2) basal plane is the primary slip system in hexagonal close-packed (HCP) magnesium. Non-basal <a> slip on the {10.0} prismatic and {10.1} pyramidal plane has often been observed at higher stresses. While none of these slip modes can accommodate deformation along the c-axis, deformation twinning can provide limited deformation along the c-axis. {10.2}<10.1> extension twinning is commonly found during plastic deformation at room temperature in favorably oriented grains relative to the applied loading direction, leading to tension-compression yield asymmetry and strong plastic anisotropy in magnesium alloys [

5,

6,

7,

8]. When deformation twinning occurs, the lattice is reoriented approximately 86.3° relative to the parent lattice, resulting in pronounced changes in the crystallographic texture during deformation [

9,

10,

11,

12].

In situ neutron diffraction experiments have been employed extensively to study the plastic deformation behavior of magnesium alloys. The technique provides information on the distribution of internal stresses and strains among the various crystallographic orientations, as well as on bulk texture evolution caused by twinning [

13,

14,

15,

16,

17,

18,

19].

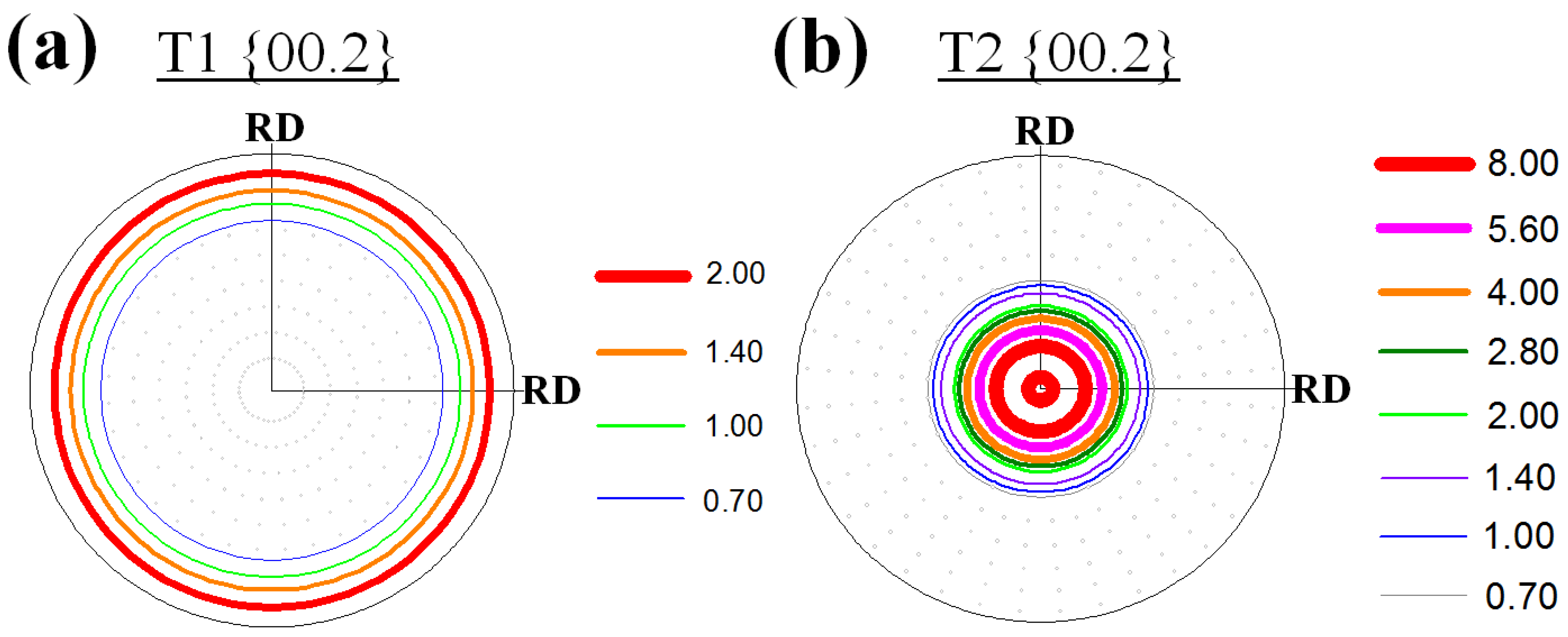

In the current work, neutron diffraction is used to study the plastic deformation behavior of a precipitation-hardened and extruded Mg-8.5wt.%Al alloy. Lattice strains and diffraction peak intensities for several grain orientations are monitored in situ during deformation to examine the evolution of the stress state and the occurrence of twinning and detwinning in various grain orientations. The loading paths consist of (i) compression followed by reverse tension and (ii) tension followed by reverse compression.

3. Results and Discussion

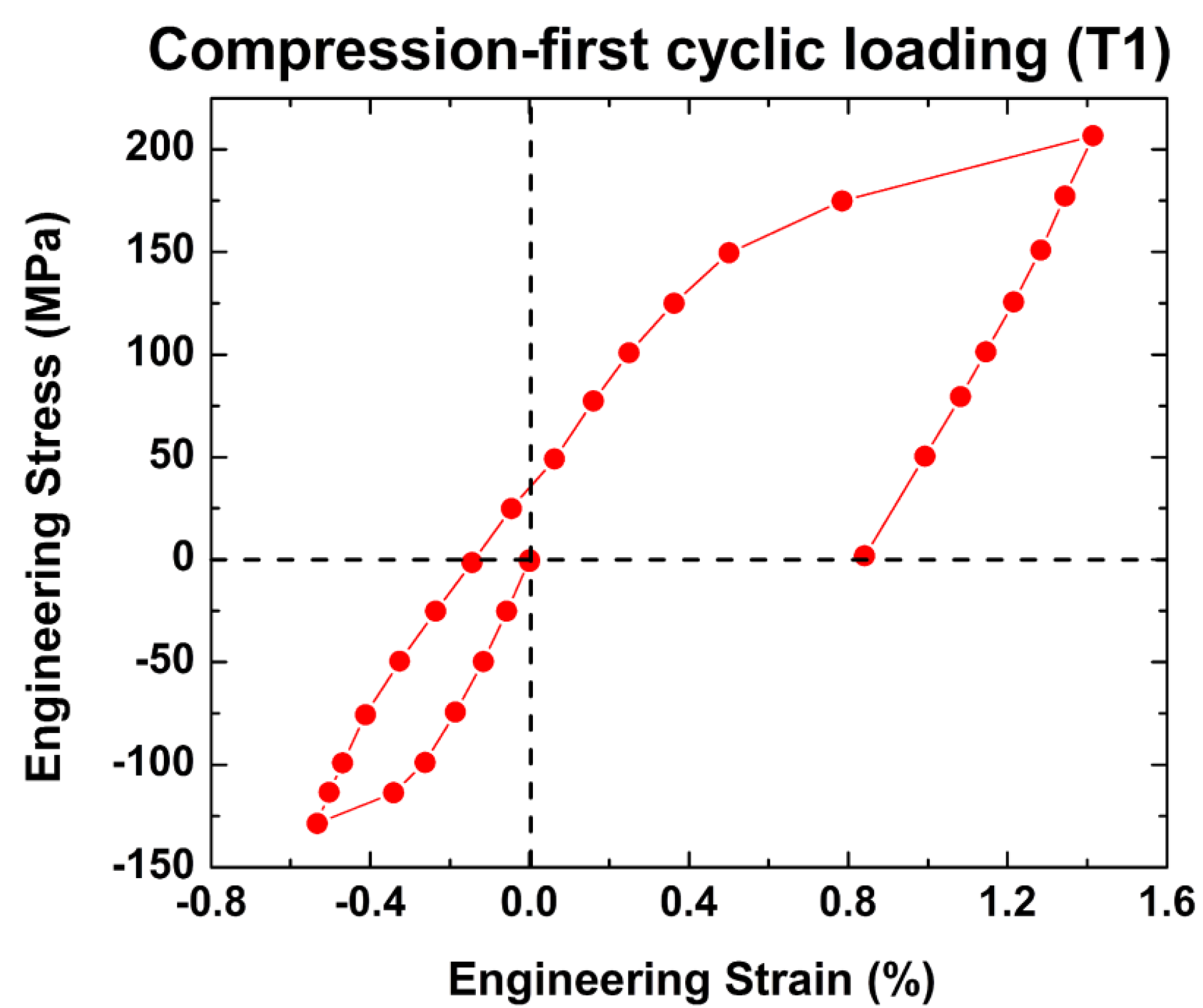

The macroscopic stress-strain response of the T1 sample subjected to compression followed by reverse tension is shown in

Figure 2.

The material yields at ~−100 MPa, at which the elastic-plastic transition is well underway, though plasticity is not fully developed. The non-linear macroscopic stress/strain behavior during unloading after compression is more significant than during unloading after tension.

Figure 2.

Macroscopic stress-strain response for the T1 sample. The symbols correspond to points in the loading history at which diffraction data were acquired.

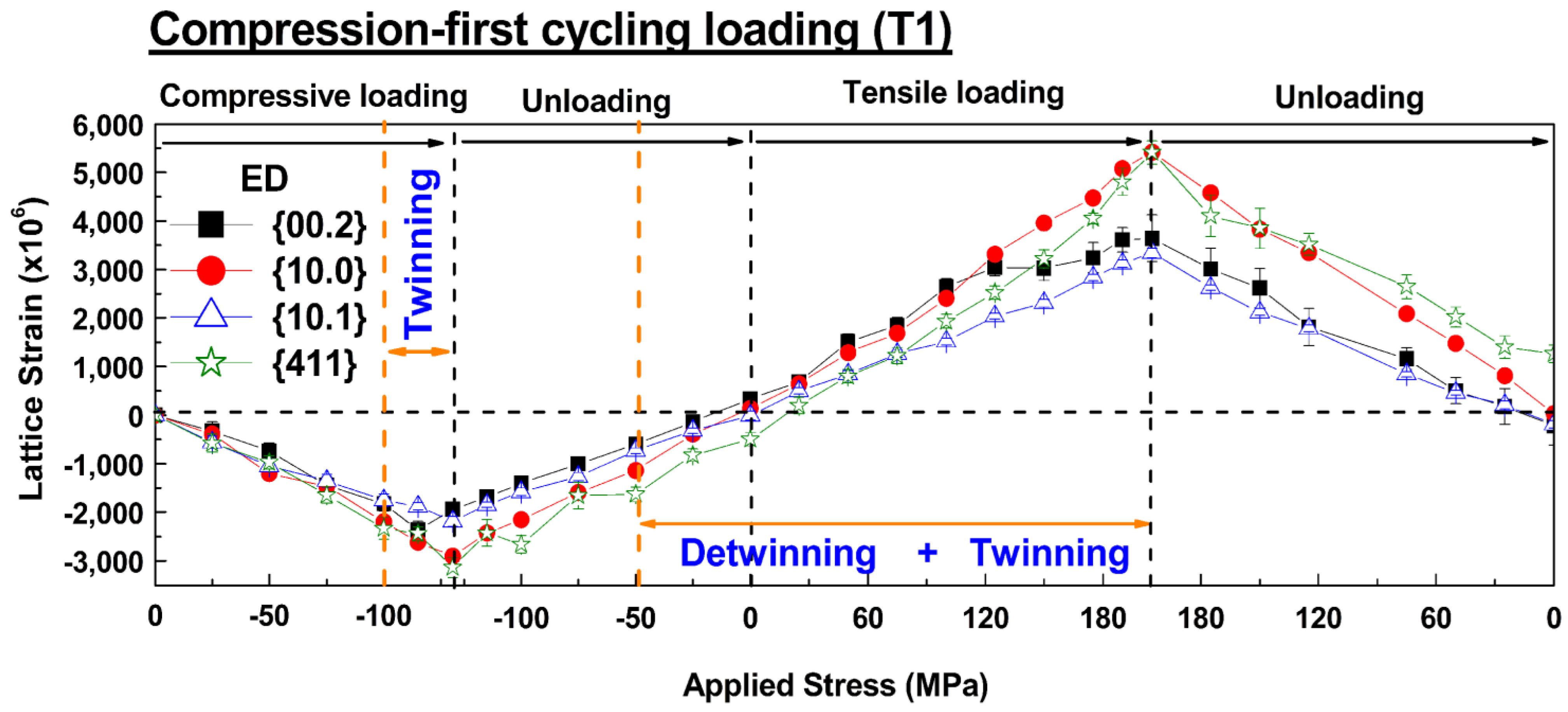

Figure 3 shows lattice strain evolution for four different families as a function of applied stress for the T1 sample subjected to compression followed by reverse tension (

Figure 2). The corresponding integrated intensity variations for all measured reflections are provided in

Figure 4 [

17]. A detailed discussion of the intensity variations in

Figure 4 is provided in [

17], based on which it is possible to identify the stress intervals over which twinning and detwinning occur. The twinning and detwinning intervals identified in

Figure 3 are based on this previous analysis.

Figure 3.

Lattice strain evolution for various grain families as a function of applied stress during the deformation shown in

Figure 2. The {

hk.l} plane normal is parallel to the applied loading direction, which is parallel to the extrusion direction (ED). The angles between the c-axis and the loading direction for the {00.2}, {10.0} and {10.1} families are 0°, 90° and 61.9°, respectively.

Figure 4.

Intensity variations for various grain families as a function of applied stress during the deformation shown in

Figure 2 [

17].

In

Figure 3, during the initial compressive loading step, the lattice strain increases linearly with applied stress for all four grain families up to ~−50 MPa. Beyond this stress, the lattice strain in the {10.1} family increases more slowly with applied stress compared with the other orientations, indicating that this family deforms plastically. The deformation mechanism is most likely basal <a> slip, which has the lowest critical resolved shear stress (CRSS) of all the commonly observed deformation modes, and for which the {10.1} family is favorably oriented. As the load increases beyond ~−100 MPa, the {00.2} and {10.0} lattice strains deviate from one another, corresponding to an increase in the {00.2} intensity and a concurrent decrease in the {10.0} intensity (see

Figure 4 [

17]). Despite being favorably oriented for {10.2}<10.1> extension twinning in compression, the strain in the {10.0} family increases linearly with the applied stress during the initial compressive loading step, resulting in almost zero residual strain upon unloading. On the other hand, the lattice strain in the {00.2} family, which is twin-related to the {10.0} grains, experiences relaxation during the final loading step, resulting in a slightly tensile residual strain at the end of unloading. The residual strain for the soft {10.1} family is slightly compressive, or zero. The strain in the β-Mg

17Al

12 precipitates ({411} reflection) increase linearly during loading, with no evidence of relaxation, resulting in relatively large compressive residual strains upon unloading. During unloading after compression, it was found that about 40% of the twinned volume detwins [

17]. This detwinning behavior is thought to contribute significantly to the non-linear behavior observed in

Figure 2.

During reverse loading in tension, the intensity data in

Figure 4 [

17] show that detwinning continues up to an applied stress of ~+100 MPa, after which the {00.2} minority grains undergo {10.2} extension twinning, as revealed by a decrease in the {00.2} intensity beyond ~100 MPa. The {00.2} and {10.1} families, favorably oriented for extension twinning and basal slip respectively, show stress relaxation during reverse tensile loading, resulting in slightly compressive residual strains upon unloading. Conversely, the lattice strain in the {100} family, which is not favorably oriented for basal slip or extension twinning, varies linearly throughout the test, resulting in negligible residual strain at the end of the test. The {411} precipitates accumulate high levels of lattice strain during the reverse tensile loading, but, unlike the {10.0} family, the precipitates show large tensile residual strains upon final unloading.

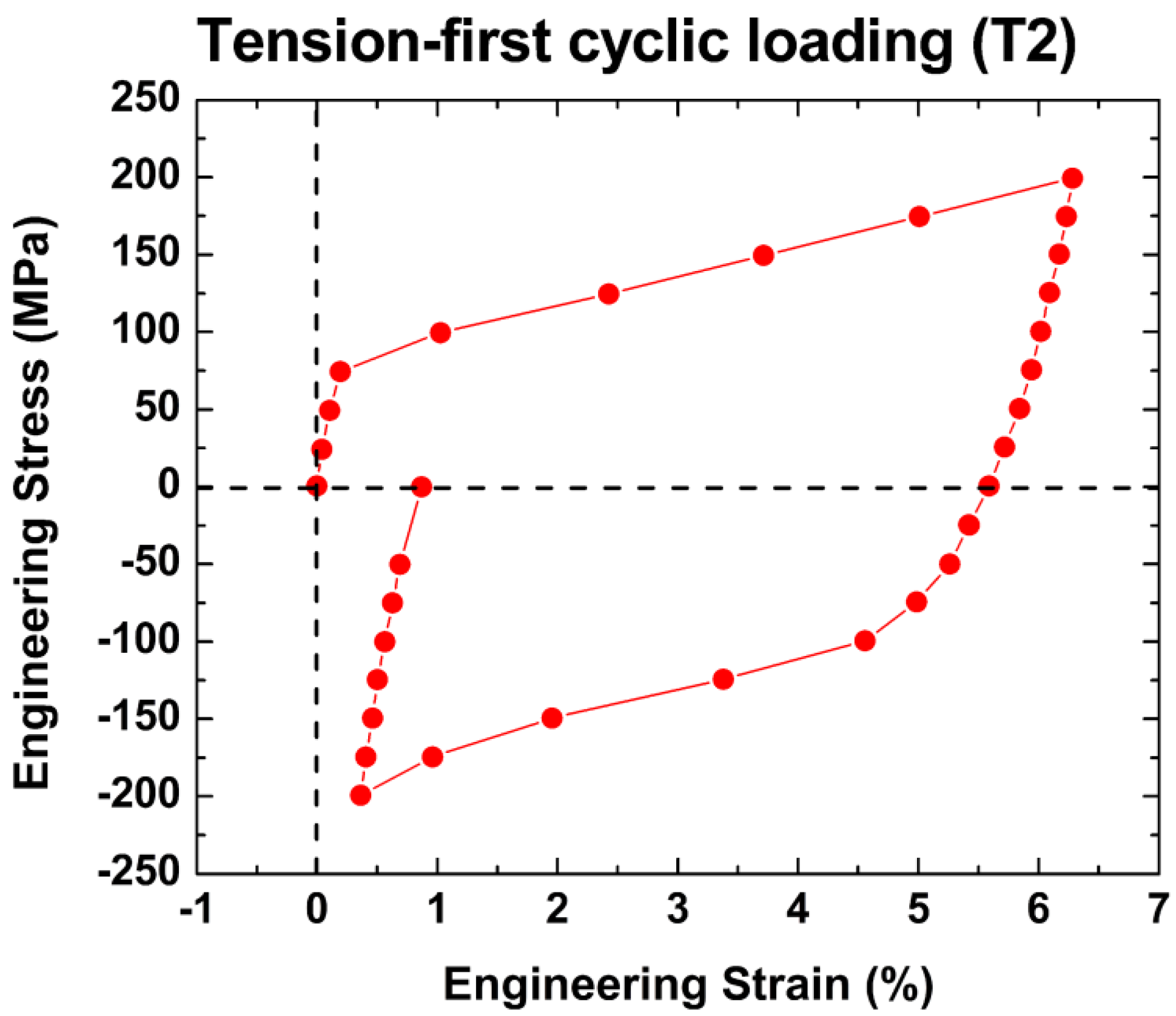

Figure 5 shows the macroscopic stress-strain response for the T2 sample subjected to tension followed by reverse compression. The initial stress-strain response is linear up to an applied stress of ~75 MPa, after which the slope decreases as the material starts to yield. During unloading after tension and reloading in compression, the stress-strain response is clearly non-linear. The material undergoes general yielding in compression at ~−50 MPa. The unloading behavior at the end of the test is also clearly non-linear, but the effect is less significant than the non-linear behavior after compression for T1 (

Figure 2).

Figure 5.

Macroscopic stress-strain response for the T2 sample. The symbols correspond to points in the loading history at which diffraction data were acquired.

Lattice strain and integrated intensity variations for four different grain orientations as a function of applied stress are shown in

Figure 6 for the T2 sample subjected to tension followed by reverse compression.

During initial loading in tension, the lattice strain varies linearly with applied stress for all four grain orientations up to ~50 MPa showing the same slope, as expected based on the near elastic isotropy of magnesium. Beyond ~50 MPa, the {10.2} and {10.3} strains increase more slowly with stress, indicating that these grains undergo plastic deformation, most likely by basal <a> slip (

Figure 6a), which is the easiest slip system to activate in Mg-Al alloys, and for which these grain families are favorably oriented. Beyond ~75 MPa, the lattice strain behavior of the {00.2} family deviates from its initial linear behavior, corresponding to a decrease in intensity for the {00.2} peak in

Figure 6b, and macroscopic yielding in

Figure 5. The {00.2} family, which represents a large fraction of the microstructure, has the basal pole aligned 0° relative to the applied loading direction. It is thus favorably oriented for {10.2} extension twinning in tension, which results in the observed decrease in intensity. Likewise, the changes in the {11.0} and {10.3} intensities for 75 < σ (MPa) < 200 are due to {10.2} extension twinning in the {10.3} families, as the two families are twin-related.

Figure 6.

(

a) Lattice strain evolution and (

b) intensity variations for various grain families as functions of applied stress during the deformation shown in

Figure 5. The {

hk.l} plane normal is parallel to the applied loading direction, which is parallel to the extrusion direction (ED).

Figure 6a shows that the {10.2}, {10.3} and {00.2} families, which deform plastically by either basal slip or extension twinning during the initial tensile portion of the test, undergo stress relaxation, resulting in compressive residual strains upon unloading. On the other hand, the {11.0} family, which is unfavorably oriented for both extension twinning and basal slip, accumulates much higher lattice strains during tensile loading, resulting in slightly tensile residual strains at the end of unloading. In the compression stage of the test, the {10.2} and {10.3} families, which are favorably oriented for basal slip, accumulate relatively low levels of lattice strain during loading, resulting in small tensile residual strains at the end of the test. Conversely, the residual strain in the hard {00.2} family is slightly compressive, or zero. The {11.0} family presents an interesting case—despite being favorably oriented for extension twinning in compression, it still accumulates large lattice strains during loading, resulting in slightly negative (or zero) residual lattice strain at the end of the test. This lack of a significant relaxation effect associated with twinning is consistent with the behavior of the {10.0} family during the initial compressive loading step in T1, and is in marked contrast to the behavior of the {00.2} family in both textures, in which strong relaxation effects are associated with twinning. This difference in behavior between the {10.0}/{11.0} and {00.2} orientations may be due to the fact that extension twinning is activated by compression normal to the c-axis in the {10.0} and {11.0} family, but by tension parallel to the c-axis in the {00.2} family.

During unloading after tension, the intensities of all four reflections change little (the {00.2} and {10.3} intensities increase slightly), indicating that the twinned material generated during tension does not undergo significant detwinning. During reverse loading in compression, however, the twinned volume within the {00.2} family, which contributes to the {10.0} signal, is favorably oriented to detwin in compression. Thus, in reverse compression, detwinning starts at an applied stress of ~−50 MPa and continues up to an applied stress of −200 MPa, as revealed by the increase in the {00.2} intensity (

Figure 6b). However, the {00.2} intensity at the start of the test is not fully recovered at −200 MPa. During unloading after the compressive portion of the test, the {00.2} peak intensity does not change, suggesting that the non-linear behavior observed in

Figure 5 is not related to the behavior of deformation twins, but rather to dislocation phenomena. This behavior is likely due to the fact that almost all traces of twinning are gone when the highest compressive stress is reached, such that little material is favorably oriented for either twinning or detwinning when the final unloading starts.