Ductile Fracture Prediction for Ti6Al4V Alloy Based on the Shear-Modified GTN Model and Machine Learning

Abstract

1. Introduction

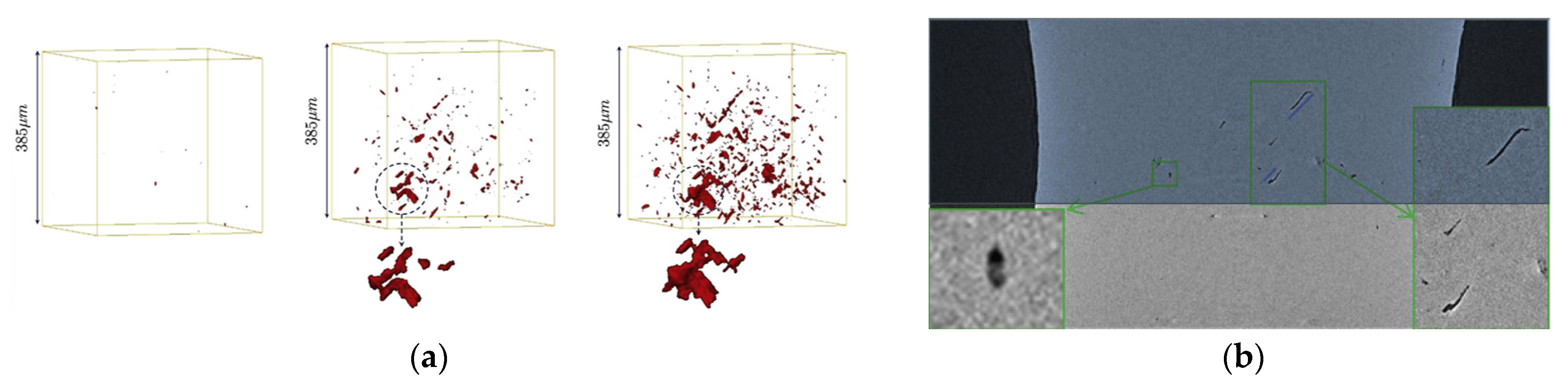

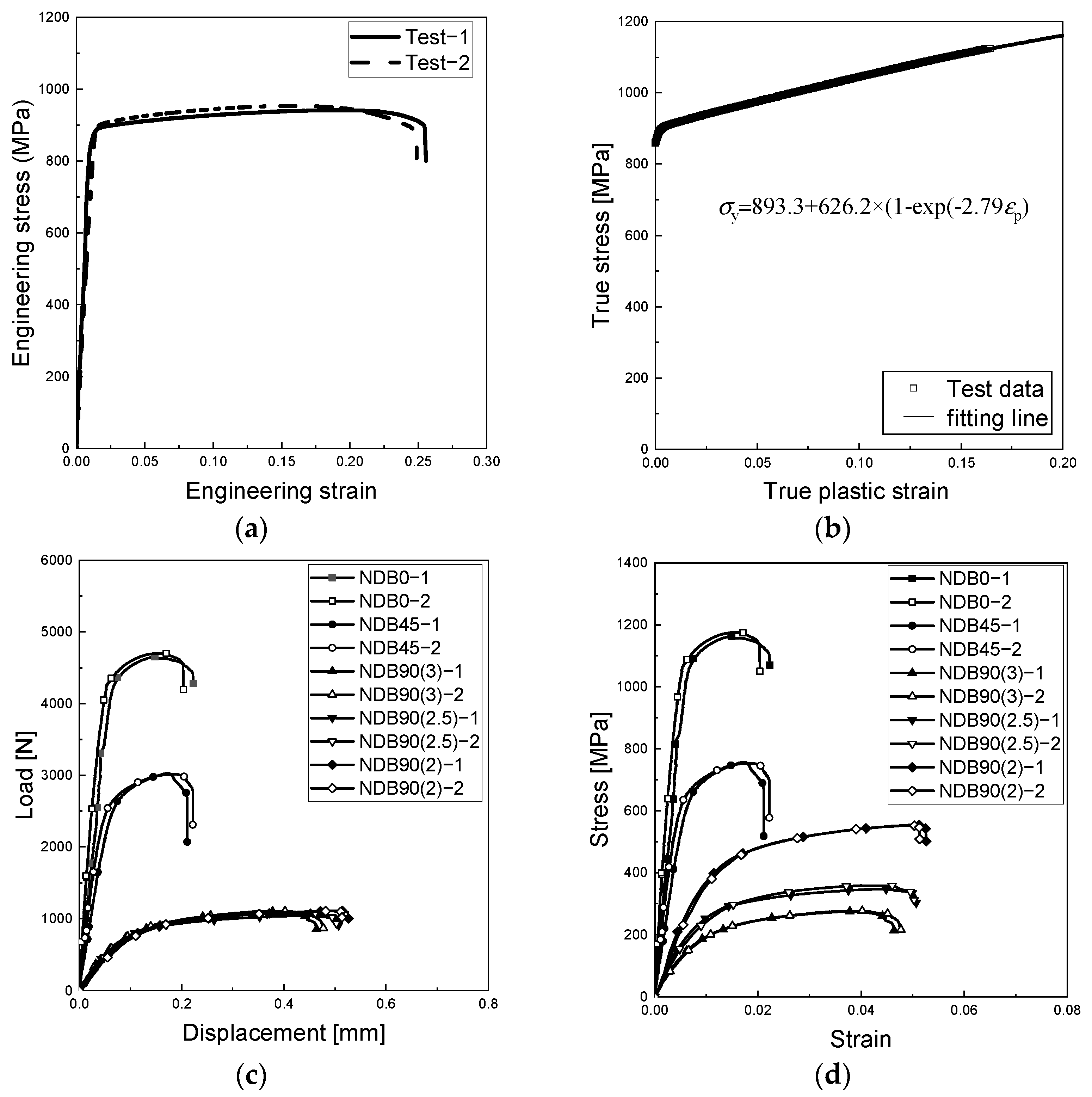

2. Materials and Methods

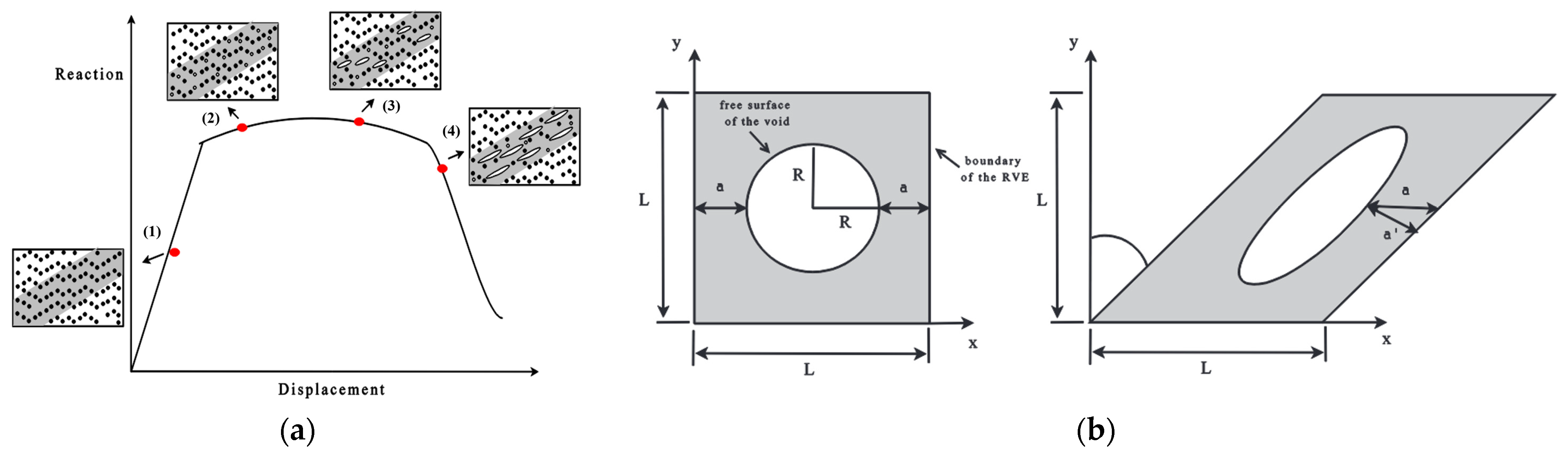

3. Shear-Modified GTN Model

4. Finite Element Analysis

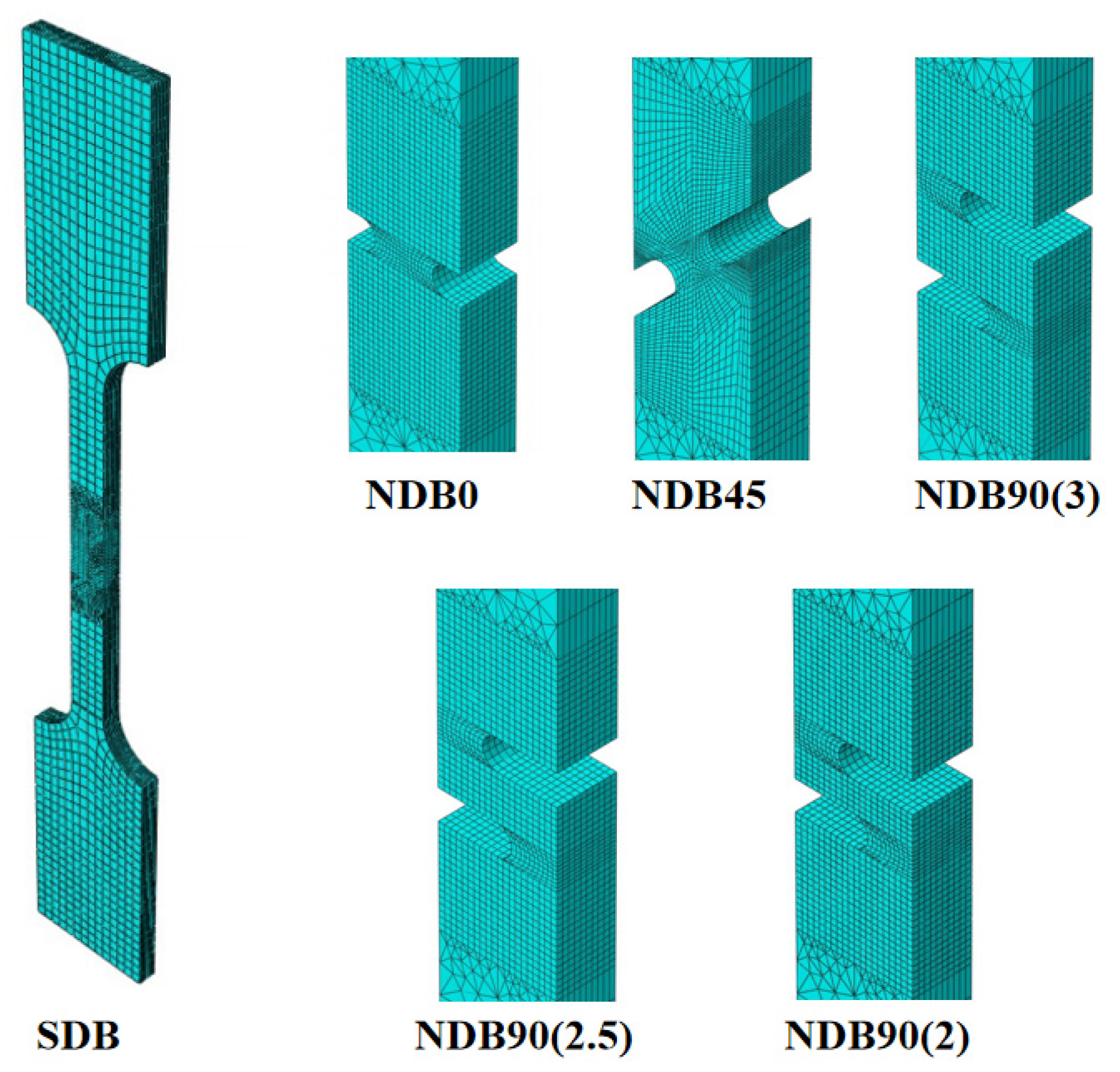

4.1. Finite Element Modeling

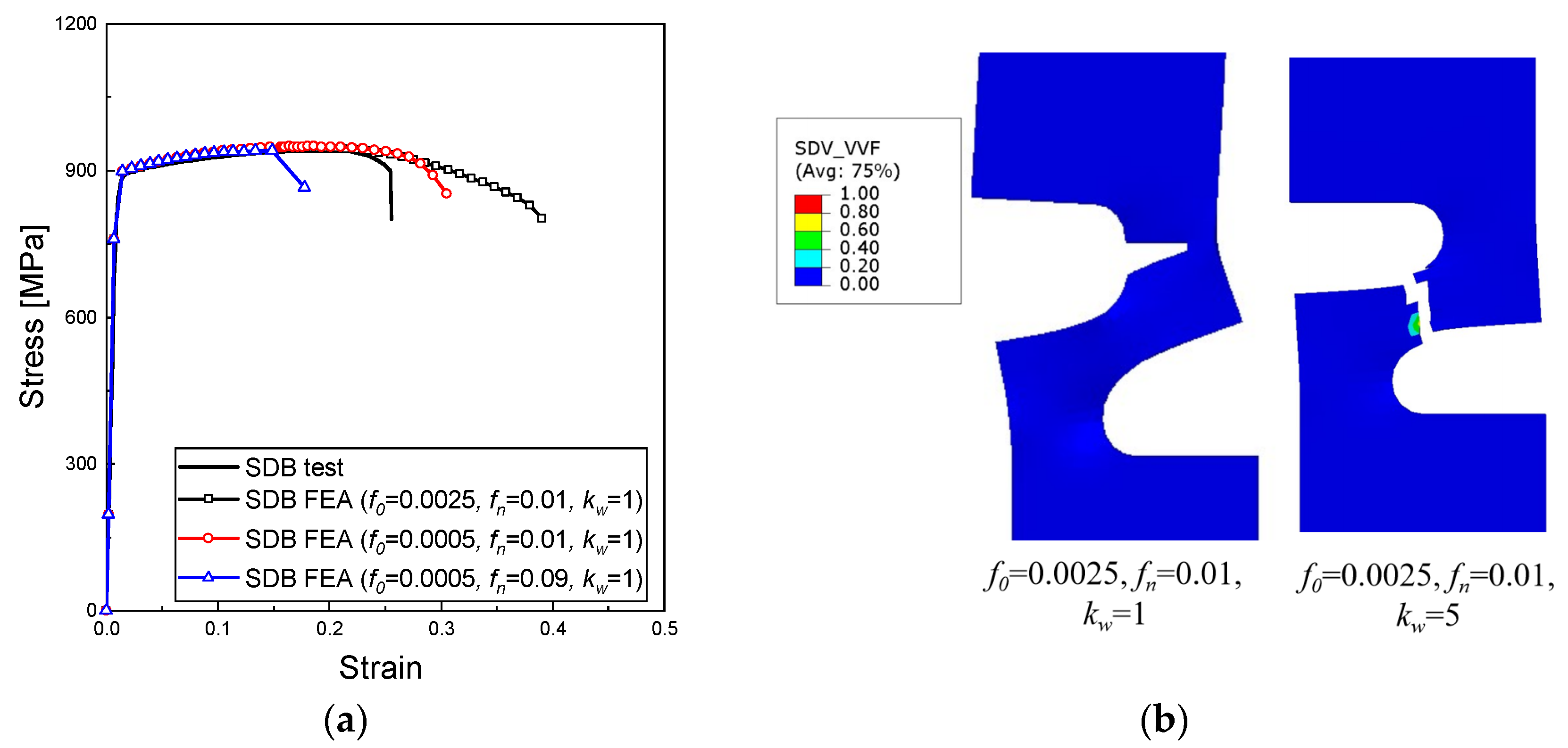

4.2. Determination of Parameters

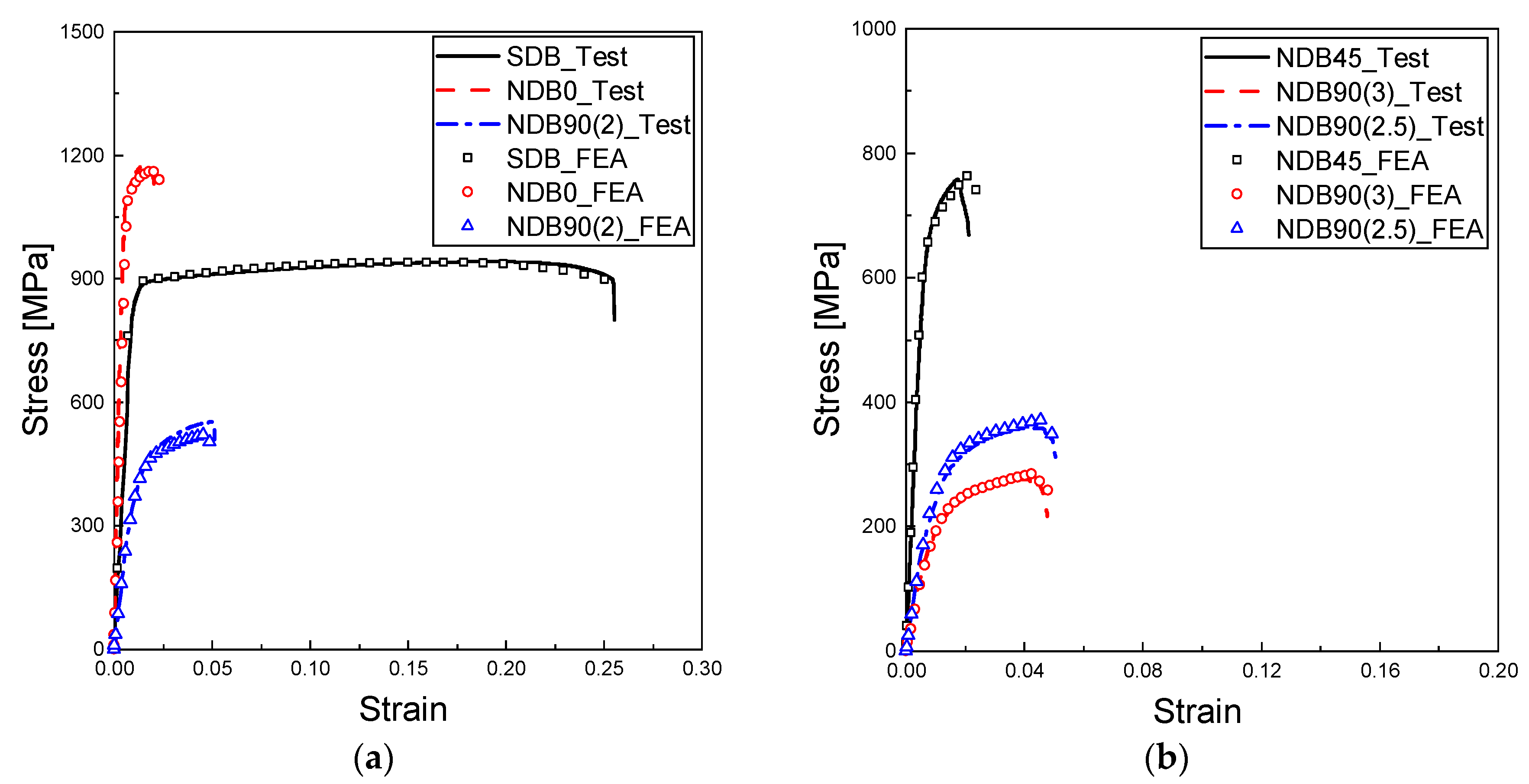

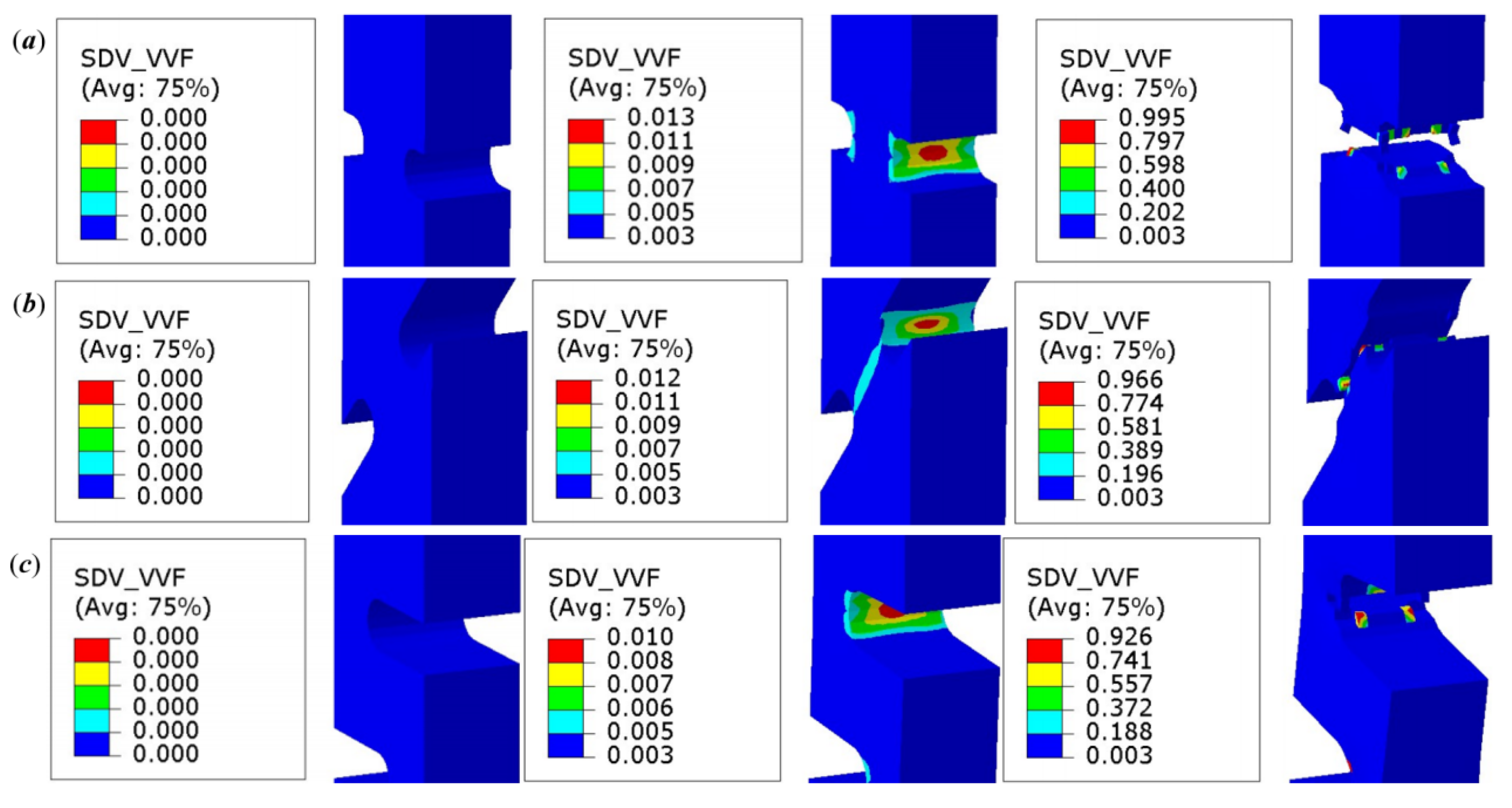

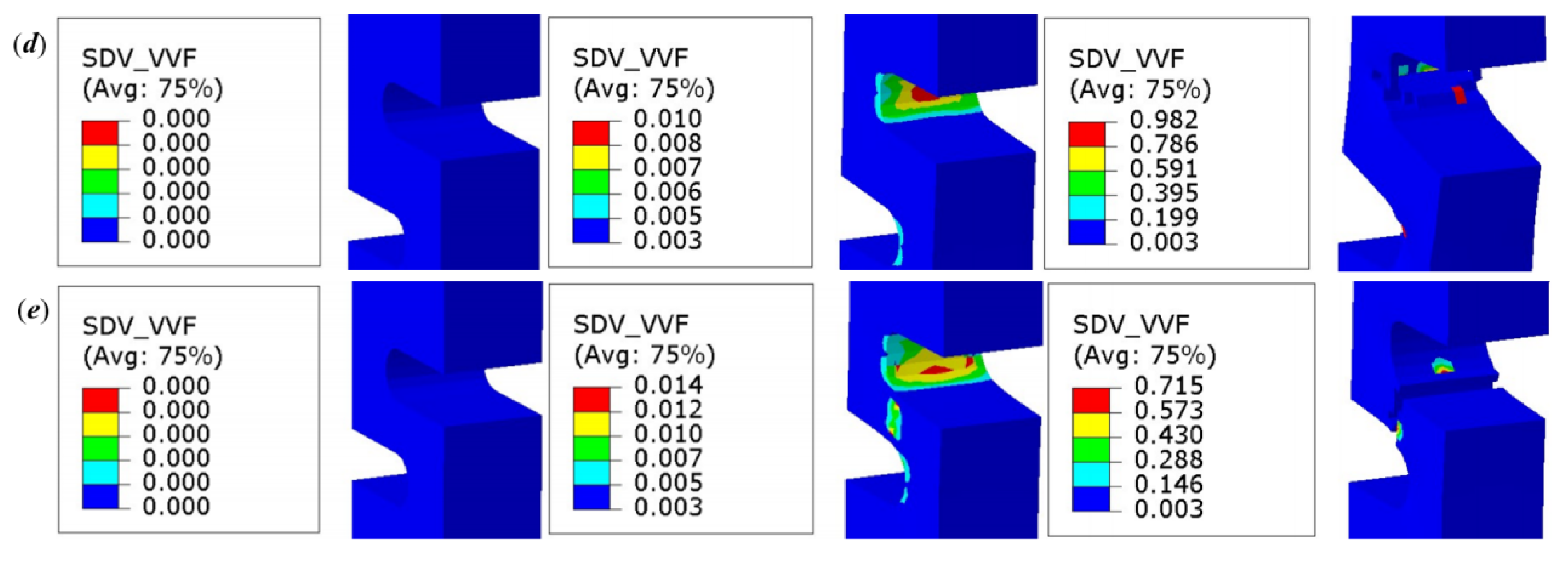

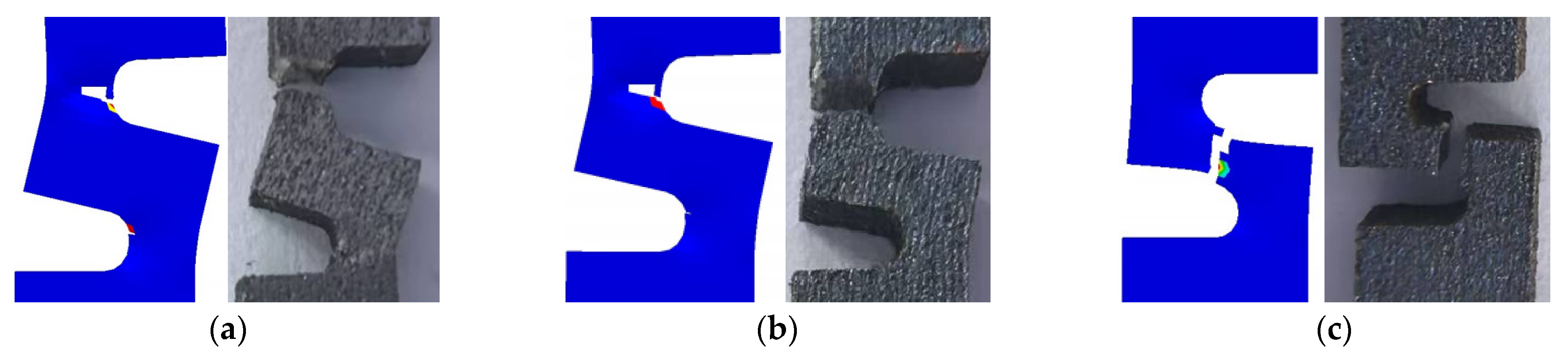

4.3. FEA Results and Discussions

5. Conclusions

- (1)

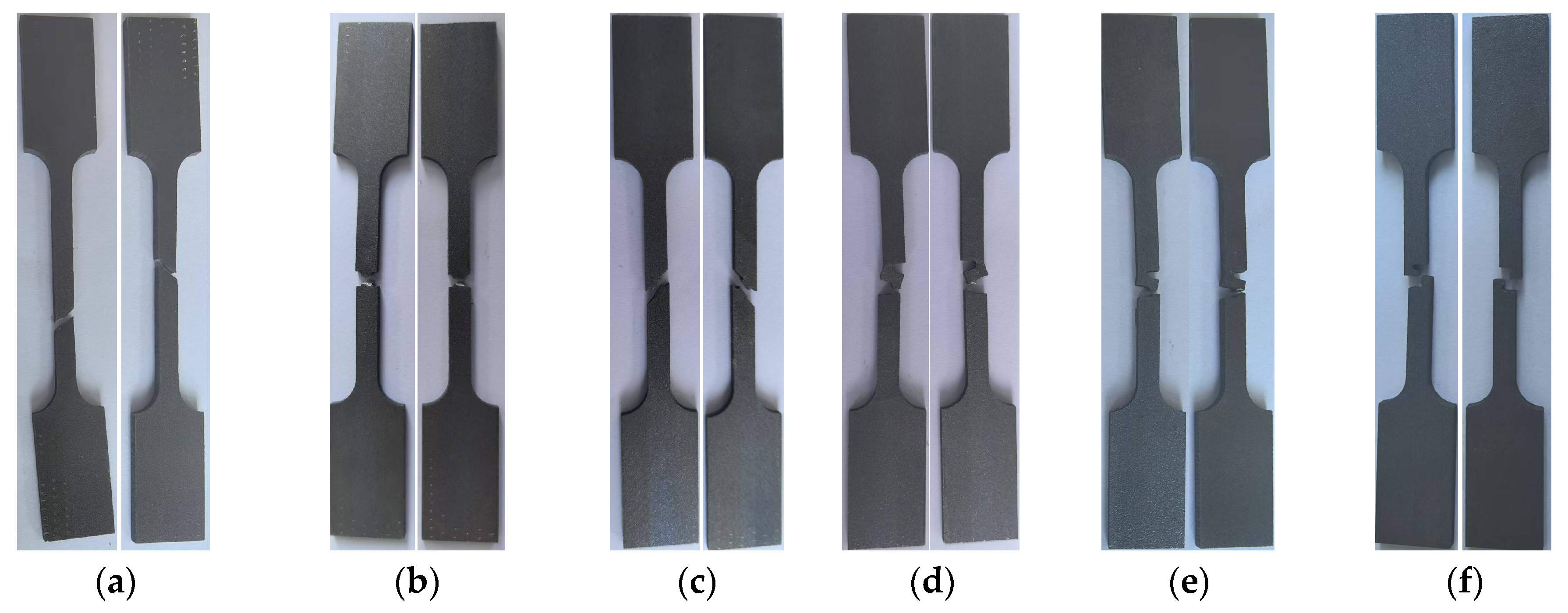

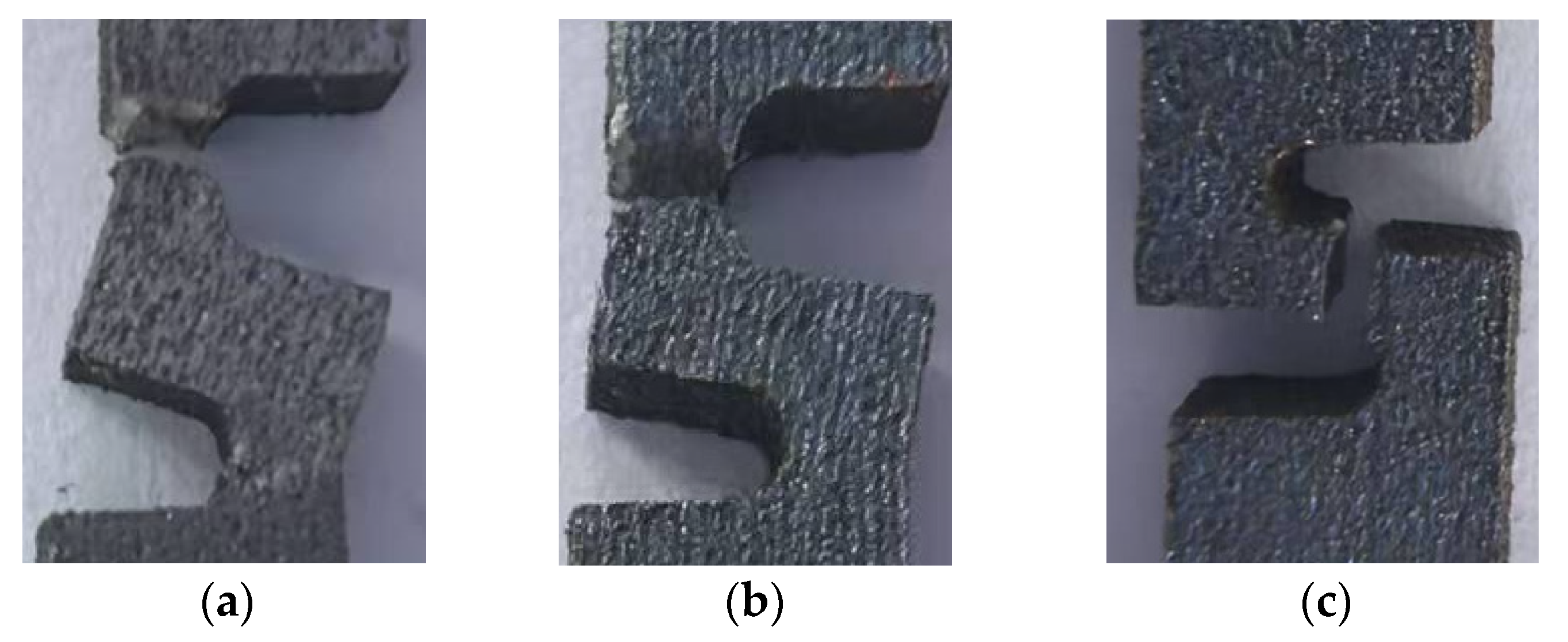

- Tensile tests were performed on specimens featuring various notch geometries to investigate their failure characteristics under different stress states. Specifically, within the NDB90 series, modifications to the cross-sectional area demonstrated two dominant failure mechanisms: tensile-dominated fracture at the notch sides, and shear-dominated failure at the center. These provide the experimental foundation for establishing the shear-modified GTN model and validating its efficacy.

- (2)

- The shear-modified GTN model involves multiple parameters requiring determination. In this study, the quantitative relationships between , , and were adopted, while the probability parameters governing void nucleation were established based on the relevant literature. The remaining parameters , , and were determined using a machine learning approach. FEA results obtained under various parameter combinations were utilized to construct a surrogate model via a BP neural network. Subsequently, an optimal combination of , , and was identified using a GA method.

- (3)

- FEA was performed on these specimens to simulate their failure behavior using the optimal parameters determined via machine learning. The fracture strain obtained from FEA for each specimen exhibited a maximum error of less than 10% when compared to the mean fracture strain measured experimentally. Furthermore, the stress–strain curves determined by FEA showed substantial agreement with those obtained from the tests. Additionally, the model effectively differentiated between failure modes and accurately predicted the fracture locations within the NDB90 specimen series. These results validate the efficacy of the proposed model in predicting the failure of Ti6Al4V titanium alloy structures under complex stress states. It should be noted, however, that the generalizability of the shear-modified GTN model and the identified parameters to other material systems has not been verified and may require further investigation and model adaptation. Nevertheless, the current model demonstrates strong potential for critical applications involving titanium components across aerospace, mechanical engineering, and marine structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Void volume fraction | |

| Yield function | |

| Huber–von Mises stress | |

| Yield stress of the material | |

| Hydrostatic stress | |

| Parameters relating to the hardening of the material | |

| Function of the void volume fraction | |

| Void volume fraction | |

| Initial void volume fraction of the material | |

| Critical void volume fraction for void coalescence | |

| Void growth accelerated factor | |

| Void volume fraction at final failure of the material | |

| Increment of void volume fraction by nucleation of new voids at material defects | |

| Increment of void volume fraction by growth of voids pre-existing in the material | |

| Possible nucleated void volume fraction | |

| Equivalent plastic strain of the matrix | |

| Average equivalent plastic strain during nucleation | |

| Standard deviation of the nucleation strain | |

| Plastic strain tensor | |

| Second-order unit vector | |

| Shear-induced increment of void volume fraction | |

| Shear damage parameter | |

| Deviatoric stress tensor | |

| Third invariant of the deviatoric stress tensor | |

| Stress state weighting function | |

| Fitness function | |

| RMSE | Root mean square error |

| SDB | Smooth dog bone specimen |

| NDB0, NDB45 | Notched dog bone specimens with 0°/45° notch |

| NDB90(3), NDB90(2.5), NDB90(2) | Notched dog bone specimens with 90° notch and 3/2.5/2 mm notch spacing |

| Fracture strains for NDB0, SDB, and NDB90(2) specimens predicted by BP surrogate models | |

| Fracture strains for NDB0, SDB, and NDB90(2) specimens obtained from tests |

References

- Wu, X.; Lu, Y.; Wang, M.; Wen, M.; Fu, L.; Ma, S.; Shan, A. Comparative Study the Effect of β-Phase Ratio on Mechanical Properties of Ti-4Al-2.5V-1.5Fe and Ti-6Al-4V Alloys by Heavy Warm Rolling Followed by Annealing. J. Alloys Compd. 2025, 1033, 181274. [Google Scholar] [CrossRef]

- Seo, S.; Jung, M.; Park, J. Microstructure Control for Enhancing the Combination of Strength and Elongation in Ti-6Al-4V through Heat Treatment. Metals 2024, 14, 985. [Google Scholar] [CrossRef]

- Xiong, Y.; Duan, W. Predictive Capability Evaluation of Micrograph-Driven Deep Learning for Ti6Al4V Alloy Tensile Strength under Varied Preprocessing Strategies. Metals 2025, 15, 586. [Google Scholar] [CrossRef]

- Čolić, K.; Kostić, S.M.; Sedmak, S.; Gubeljak, N.; Grbović, A. Structural Integrity and Life Assessment of Ti-6Al-4V Orthopaedic Implants. Metals 2025, 15, 333. [Google Scholar] [CrossRef]

- Zhang, T.; Lu, K.; Zhang, Z.; Shang, X.; Wang, Q. Experimental Investigations on Parameter Identification and Failure Predictions of Titanium Alloy by Gurson–Tvergaard–Needleman Model. Theor. Appl. Fract. Mech. 2023, 127, 104058. [Google Scholar] [CrossRef]

- Kim, S.; Kam, D.-H.; Lee, K.-A. Characterization of the Microstructure and Mechanical Properties of Ti-6Al-4V Alloy Fabricated by Wire-Arc Additive Manufacturing: Insights into Fracture Behavior and Strengthening Mechanism. Mater. Sci. Eng. A 2025, 939, 148399. [Google Scholar] [CrossRef]

- Yang, X.; Li, Y.; Jiang, W.; Duan, M.; Chen, D.; Li, B. Ductile Fracture Prediction of Additive Manufactured Ti6Al4V Alloy Based on an Extended GTN Damage Model. Eng. Fract. Mech. 2021, 256, 107989. [Google Scholar] [CrossRef]

- Dhar, S.; Dixit, P.M.; Sethuraman, R. A Continuum Damage Mechanics Model for Ductile Fracture. Int. J. Press. Vessels Pip. 2000, 77, 335–344. [Google Scholar] [CrossRef]

- Chaboche, J.L. Continuum Damage Mechanics: Part I—General Concepts. J. Appl. Mech. 1988, 55, 59–64. [Google Scholar] [CrossRef]

- Chaboche, J.L. Continuum Damage Mechanics: Part II—Damage Growth, Crack Initiation, and Crack Growth. J. Appl. Mech. 1988, 55, 65–72. [Google Scholar] [CrossRef]

- Lemaitre, J. A Continuous Damage Mechanics Model for Ductile Fracture. J. Eng. Mater. Technol. 1985, 107, 83–89. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the Cup-Cone Fracture in a Round Tensile Bar. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of Voids on Shear Band Instabilities under Plane Strain Conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Yan, R.; Xin, H.; Veljkovic, M. Ductile Fracture Simulation of Cold-Formed High Strength Steel Using GTN Damage Model. J. Constr. Steel Res. 2021, 184, 106832. [Google Scholar] [CrossRef]

- Kanvinde, A.M.; Deierlein, G.G. The Void Growth Model and the Stress Modified Critical Strain Model to Predict Ductile Fracture in Structural Steels. J. Struct. Eng. 2006, 132, 1907–1918. [Google Scholar] [CrossRef]

- Yu, F.; Hendry, M.T.; Jar, P.-Y.B.; Li, S.; Li, Z. A Coupled Stress-Triaxiality-Dependent Damage Viscoplasticity Model on Crack Initiation and Propagation in High-Strength Rail Steel. Theor. Appl. Fract. Mech. 2020, 109, 102769. [Google Scholar] [CrossRef]

- Wang, H.; Shen, T.; Yu, F.; Zheng, R. Ductile Fracture of Hydrostatic-stress-insensitive Metals Using a Coupled Damage-plasticity Model. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 967–982. [Google Scholar] [CrossRef]

- Gonçalves, P.T.; Arteiro, A.; Rocha, N. End-to-End Simulation of Linerless Composite Pressure Vessels Using 3D Continuum Damage Models. J. Compos. Sci. 2024, 8, 504. [Google Scholar] [CrossRef]

- Bonora, N. A Nonlinear CDM Model for Ductile Failure. Eng. Fract. Mech. 1997, 58, 11–28. [Google Scholar] [CrossRef]

- Fang, B.; Lu, A.; Sun, J.; Li, X.; Shen, T. The Simulation of Extremely Low Cycle Fatigue Fracture Behavior for Pipeline Steel (X70) Based on Continuum Damage Model. Metals 2023, 13, 1238. [Google Scholar] [CrossRef]

- Kachanov, L.M. Rupture Time under Creep Conditions. Int. J. Fract. 1999, 97, 11–18. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, J.; Shen, F.; Li, D.; Münstermann, S.; Han, W.; Huang, S.; Li, T. Ductile Fracture Prediction of HPDC Aluminum Alloy Based on a Shear-Modified GTN Damage Model. Eng. Fract. Mech. 2023, 291, 109541. [Google Scholar] [CrossRef]

- Li, Y.; Sun, X.; Hu, X.; Cheng, Y.; Xue, F. Uncoupled Ductile Fracture Initiation Model for 5052 Aluminum Alloy with Machine Learning Assisted Identification of the Material Parameters. Eng. Fract. Mech. 2025, 320, 111090. [Google Scholar] [CrossRef]

- Peng, Z.; Zhao, H.; Li, X. New Ductile Fracture Model for Fracture Prediction Ranging from Negative to High Stress Triaxiality. Int. J. Plast. 2021, 145, 103057. [Google Scholar] [CrossRef]

- Wei, M.; Lai, X.; Cheng, S.; Ye, X.; Gang, T.; Chen, L. The Extended GTN Model for Stiffness Degradation Prediction Based on Voids Evolution Mechanism. Mater. Today Commun. 2025, 45, 112361. [Google Scholar] [CrossRef]

- Min, F.; Gao, K.; Zhang, X.; Wei, W.; Qi, P.; Wu, X.; Wen, S.; Huang, H.; Nie, Z.; Zhou, D. A Shear Modified GTN Model Based on Stress Degradation Method for Predicting Ductile Fracture. Model. Simul. Mater. Sci. Eng. 2023, 31, 85004. [Google Scholar] [CrossRef]

- Malcher, L.; Andrade Pires, F.M.; César De Sá, J.M.A. An Extended GTN Model for Ductile Fracture under High and Low Stress Triaxiality. Int. J. Plast. 2014, 54, 193–228. [Google Scholar] [CrossRef]

- Min, F.; Gao, K.; Huang, H.; Wen, S.; Wu, X.; Nie, Z.; Zhou, D.; Gao, X. Application of the Modified GTN Model in Predicting Taylor Impact Fracture of 7XXX Aluminum Alloy. Comput. Struct. 2024, 301, 107457. [Google Scholar] [CrossRef]

- Peng, Z.; Zhao, H.; Li, X.; Yuan, L.; Zhu, T. Ductile Fracture of X80 Pipeline Steel over a Wide Range of Stress Triaxialities and Lode Angles. Eng. Fract. Mech. 2023, 289, 109470. [Google Scholar] [CrossRef]

- Zhang, K.; Badreddine, H.; Saanouni, K. Ductile Fracture Prediction Using Enhanced CDM Model with Lode Angle-Dependency for Titanium Alloy Ti-6Al-4V at Room Temperature. J. Mater. Process. Technol. 2020, 277, 116462. [Google Scholar] [CrossRef]

- Nahshon, K.; Hutchinson, J.W. Modification of the Gurson Model for Shear Failure. Eur. J. Mech. A. Solids 2008, 27, 1–17. [Google Scholar] [CrossRef]

- Xue, L. Constitutive Modeling of Void Shearing Effect in Ductile Fracture of Porous Materials. Eng. Fract. Mech. 2008, 75, 3343–3366. [Google Scholar] [CrossRef]

- Zhai, Q.; Tang, R.; Liu, Z.; Zhu, P. A Novel Method for Predicting Mechanical Properties of Megacasting Alloy Based on the Modified GTN Model and Machine Learning. Eng. Fail. Anal. 2025, 174, 109536. [Google Scholar] [CrossRef]

- Ding, X.; Wei, X.; Zhang, X.; Hou, Y.; Zhao, F. Ductile Fracture Prediction of Titanium Foil Based on Shear-Modified GTN Damage Model Considering Size Effect. Eng. Fract. Mech. 2025, 323, 111200. [Google Scholar] [CrossRef]

- Tian, H.; Zhao, J.; Zhao, R.; He, W.; Meng, B.; Wan, M. The Modified GTN Model for Fracture of Nickel-Based Superalloys Considering Size Effect and Healing Effect in Pulsed Current Assisted Deformation. Int. J. Plast. 2023, 167, 103656. [Google Scholar] [CrossRef]

- Yildiz, R.A.; Yilmaz, S. Experimental Investigation of GTN Model Parameters of 6061 al Alloy. Eur. J. Mech. A. Solids 2020, 83, 104040. [Google Scholar] [CrossRef]

- Gholipour, H.; Biglari, F.R.; Nikbin, K. Experimental and Numerical Investigation of Ductile Fracture Using GTN Damage Model on In-Situ Tensile Tests. Int. J. Mech. Sci. 2019, 164, 105170. [Google Scholar] [CrossRef]

- Cao, T.-S.; Maire, E.; Verdu, C.; Bobadilla, C.; Lasne, P.; Montmitonnet, P.; Bouchard, P.-O. Characterization of Ductile Damage for a High Carbon Steel Using 3D X-Ray Micro-Tomography and Mechanical Tests—Application to the Identification of a Shear Modified GTN Model. Comput. Mater. Sci. 2014, 84, 175–187. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Yang, X.; Jiang, W.; Guan, L. Efficient Parameters Identification of a Modified GTN Model of Ductile Fracture Using Machine Learning. Eng. Fract. Mech. 2021, 245, 107535. [Google Scholar] [CrossRef]

- Zhang, T.; Shuai, Y.; Wang, H.; Wang, J.; Lv, Z.; Zhang, Y.; Tian, Y.; Shuai, J.; Zhang, L. An Efficient Method for Determining the Constitutive Relationships of Pipeline Girth Welded Joints Based on Micro-Area Material Testing and Machine Learning. Int. J. Press. Vessels Pip. 2025, 217, 105570. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, X.; Hu, Y.; Chu, J.; Kan, Q.; Kang, G. Machine Learning-Based Constitutive Parameter Identification for Crystal Plasticity Models. Mech. Mater. 2025, 203, 105263. [Google Scholar] [CrossRef]

- Marques, A.E.; Parreira, T.G.; Pereira, A.F.G.; Ribeiro, B.M.; Prates, P.A. Machine Learning Applications in Sheet Metal Constitutive Modelling: A Review. Int. J. Solids Struct. 2024, 303, 113024. [Google Scholar] [CrossRef]

- Benseddiq, N.; Imad, A. A Ductile Fracture Analysis Using a Local Damage Model. Int. J. Press. Vessels Pip. 2008, 85, 219–227. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Thaulow, C.; Èdegard, J. A Complete Gurson Model Approach for Ductile Fracture. Eng. Fract. Mech. 2000, 67, 155–168. [Google Scholar] [CrossRef]

- Zhou, Y.; Shen, T.; Du, J. Simulation Analysis and Optimization Design of Dome Structure in Filament Wound Composite Shells. Polymers 2025, 17, 1421. [Google Scholar] [CrossRef]

| Element | Al | V | Fe | C | Sn | O | N | Ti |

|---|---|---|---|---|---|---|---|---|

| Wt (%) | 5.8~6.5 | 3.8~4.5 | ≤0.30 | ≤0.08 | ≤0.07 | 0.10~0.15 | ≤0.05 | rest |

| Parameter | |||

|---|---|---|---|

| Range | 0.0005–0.005 | 0.01–0.09 | 1–5 |

| Parameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| value | 1 | 1.5 | 0.0032 | 0.044 | 0.156 | 0.383 | 0.3 | 0.1 | 3.25 |

| Specimen | Surrogate-Predicted Strain | FEA-Predicted Strain | Error (%) |

|---|---|---|---|

| SDB | 0.2510 | 0.250 | 0.4 |

| NDB0 | 0.0226 | 0.0230 | 1.8 |

| NDB90(2) | 0.0491 | 0.0486 | 1.0 |

| Specimen | Mean Experimental Strain (±STD) | FEA-Predicted Strain | Error (%) |

|---|---|---|---|

| SDB | 0.2522 ± 0.0034 | 0.250 | 0.8 |

| NDB0 | 0.0212 ± 0.0010 | 0.0230 | 8.5 |

| NDB90(2) | 0.0521 ± 0.0007 | 0.0486 | 6.7 |

| NDB45 | 0.0217 ± 0.0006 | 0.0238 | 9.7 |

| NDB90(2.5) | 0.0505 ± 0.0002 | 0.0484 | 4.2 |

| NDB90(3) | 0.0471 ± 0.0006 | 0.0478 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, T.; Li, B.; Fang, Y. Ductile Fracture Prediction for Ti6Al4V Alloy Based on the Shear-Modified GTN Model and Machine Learning. Metals 2025, 15, 995. https://doi.org/10.3390/met15090995

Shen T, Li B, Fang Y. Ductile Fracture Prediction for Ti6Al4V Alloy Based on the Shear-Modified GTN Model and Machine Learning. Metals. 2025; 15(9):995. https://doi.org/10.3390/met15090995

Chicago/Turabian StyleShen, Tao, Biao Li, and Yuxuan Fang. 2025. "Ductile Fracture Prediction for Ti6Al4V Alloy Based on the Shear-Modified GTN Model and Machine Learning" Metals 15, no. 9: 995. https://doi.org/10.3390/met15090995

APA StyleShen, T., Li, B., & Fang, Y. (2025). Ductile Fracture Prediction for Ti6Al4V Alloy Based on the Shear-Modified GTN Model and Machine Learning. Metals, 15(9), 995. https://doi.org/10.3390/met15090995