Microstructure and Mechanical Properties Change of Al7SiMgxEr (x: 0.03–0.1)

Abstract

1. Introduction

2. Materials and Methods

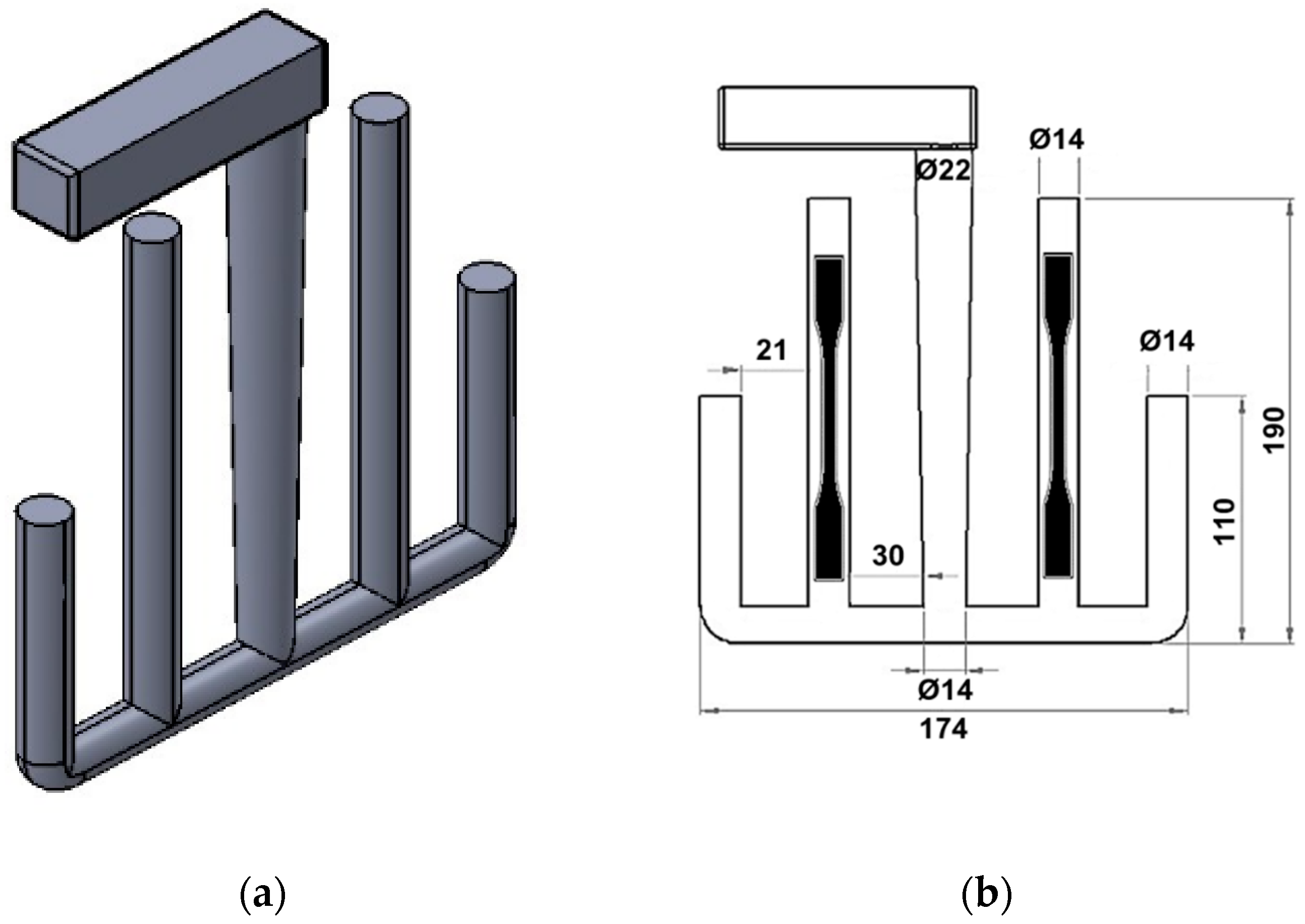

2.1. Sample Preparation

2.2. Determination of Mechanical Properties

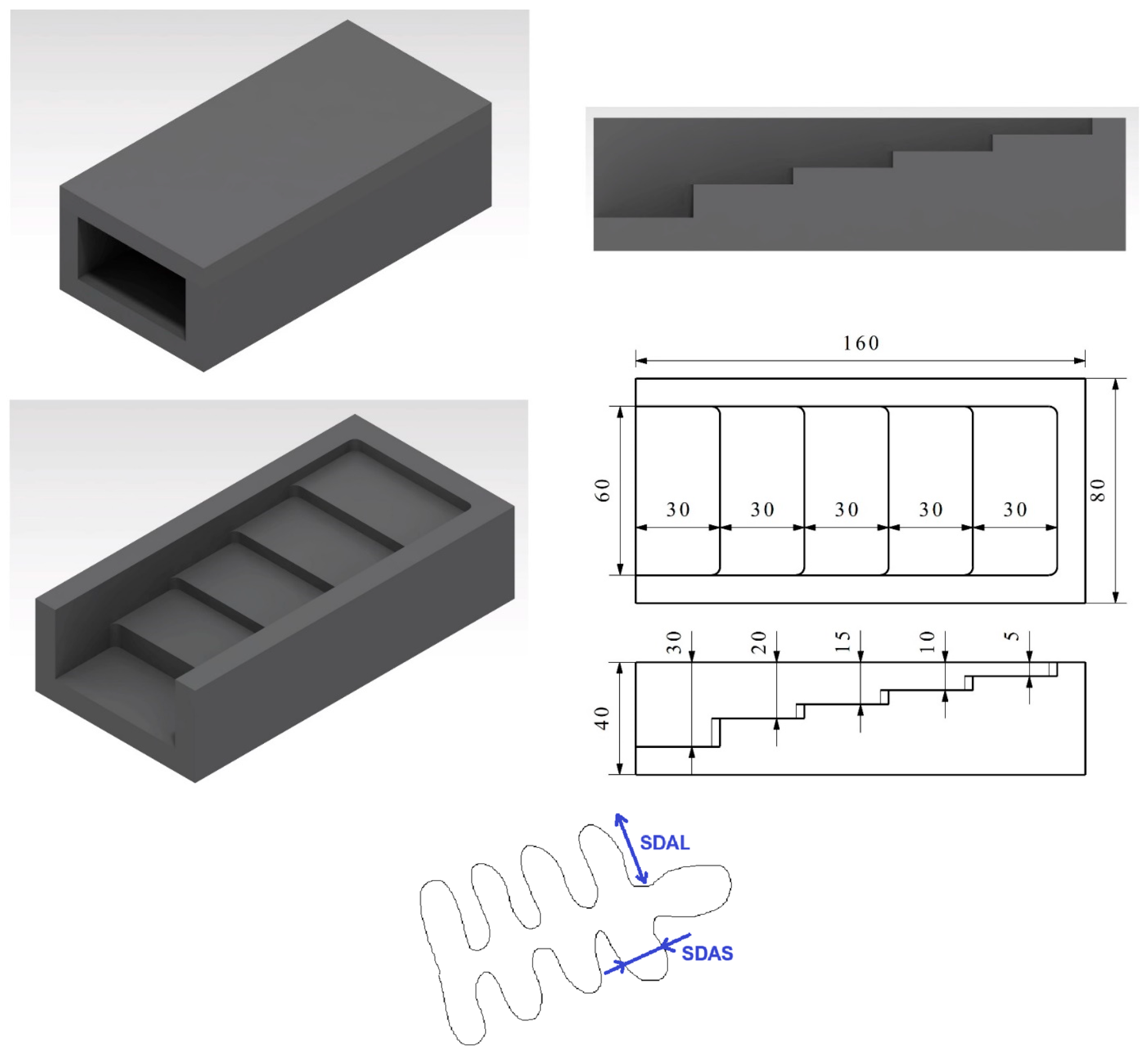

2.3. Solidification Test

3. Results

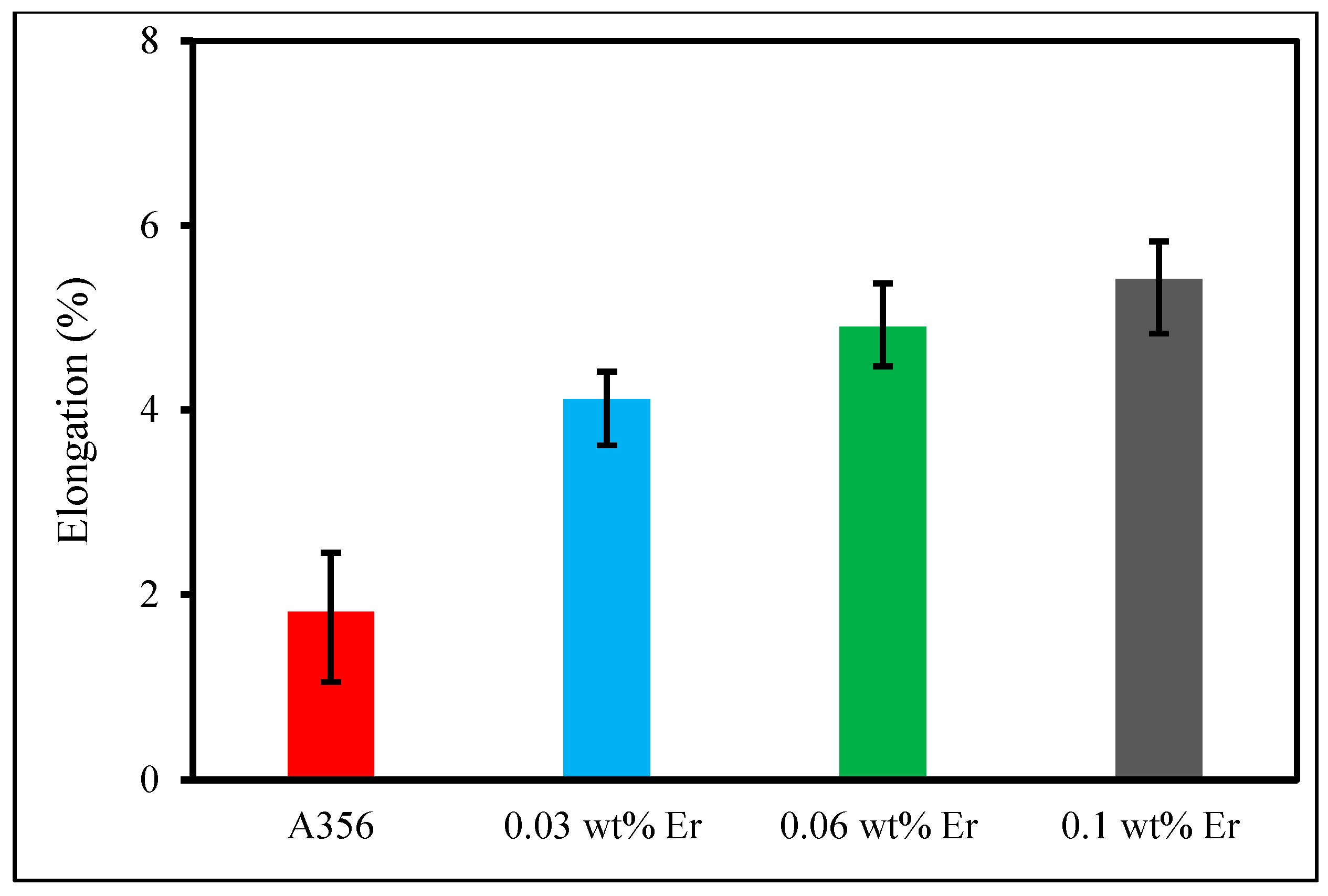

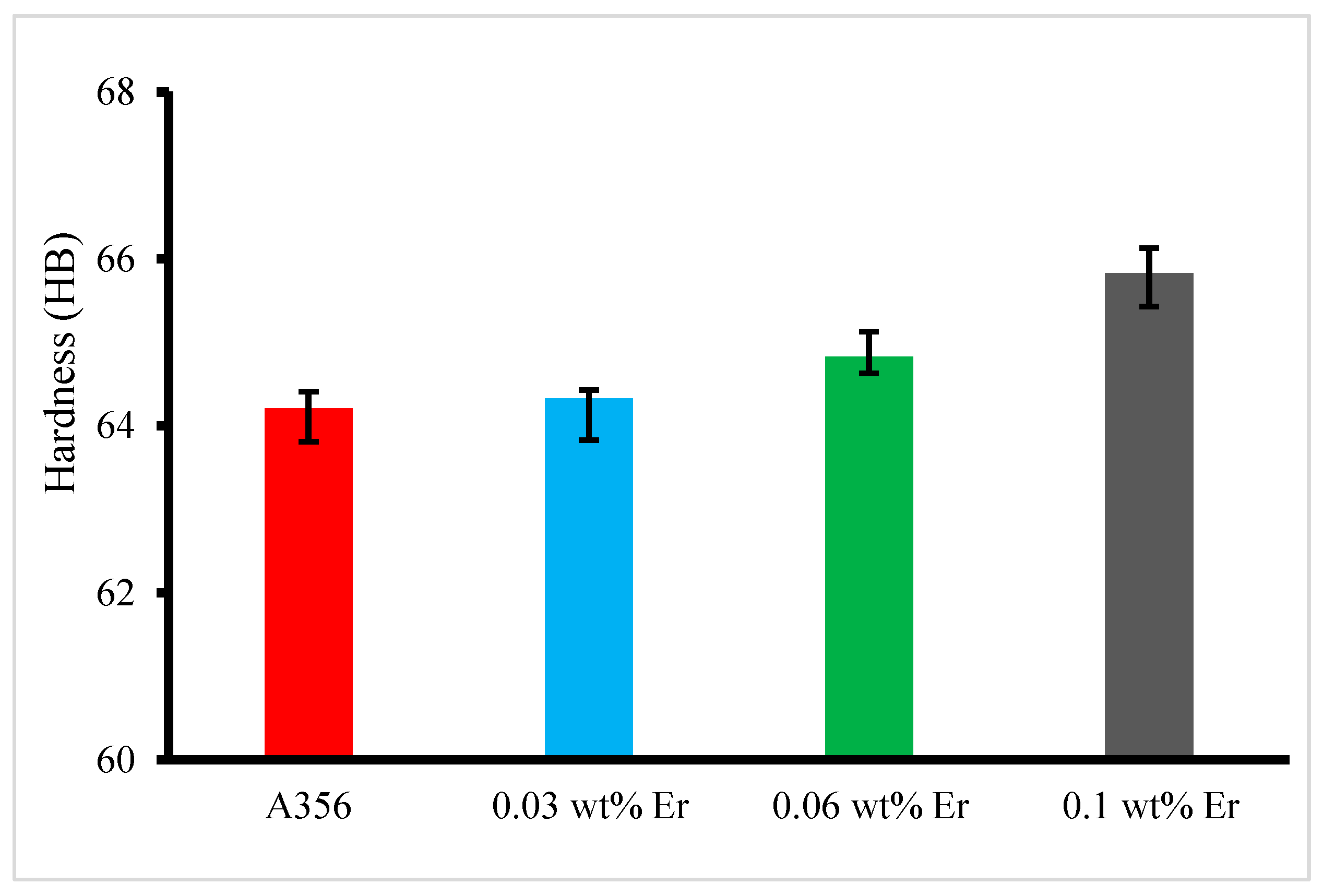

3.1. Mechanical Test Results

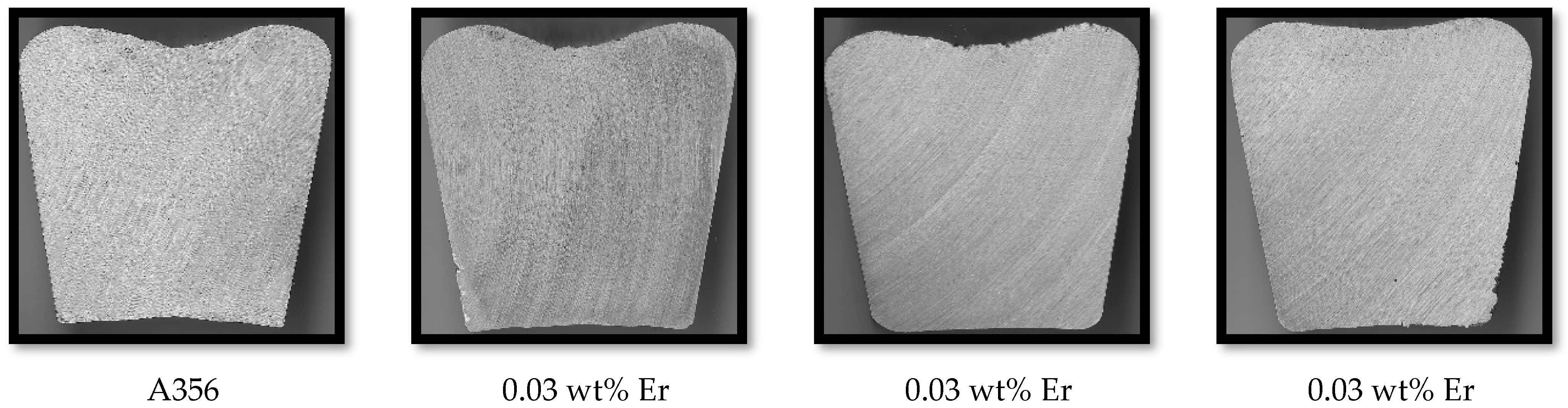

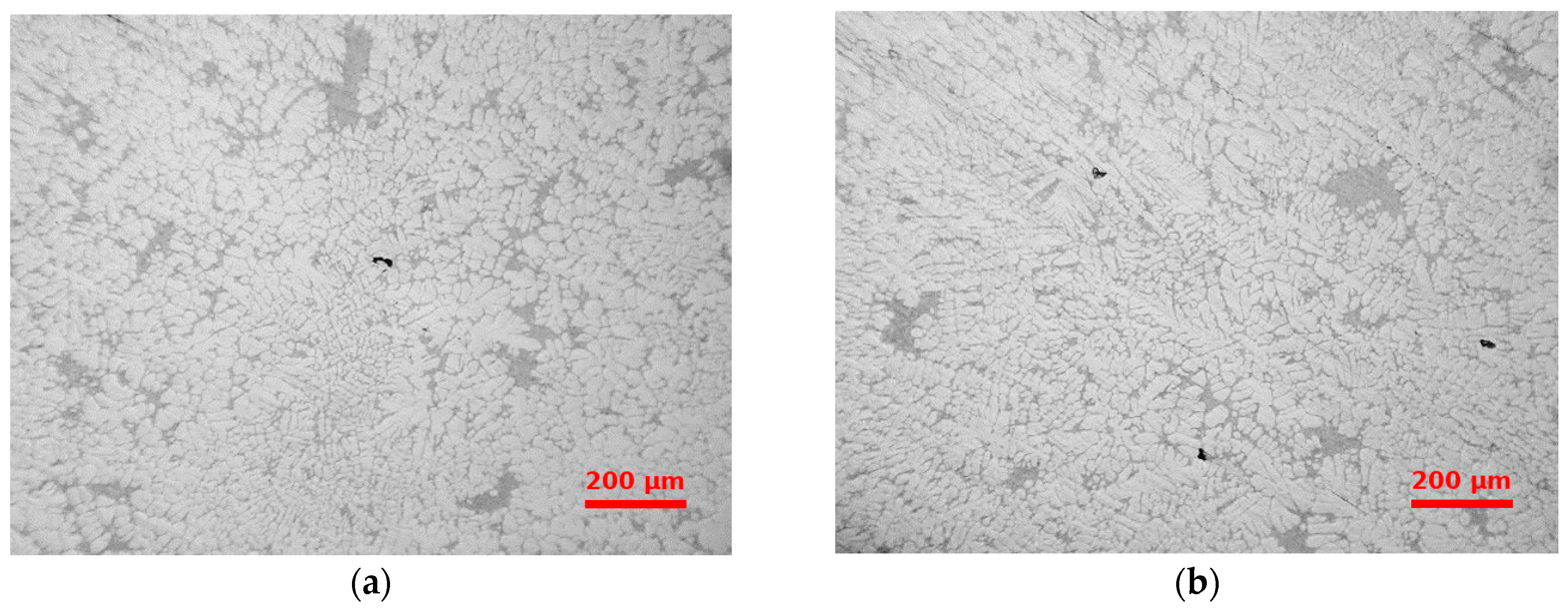

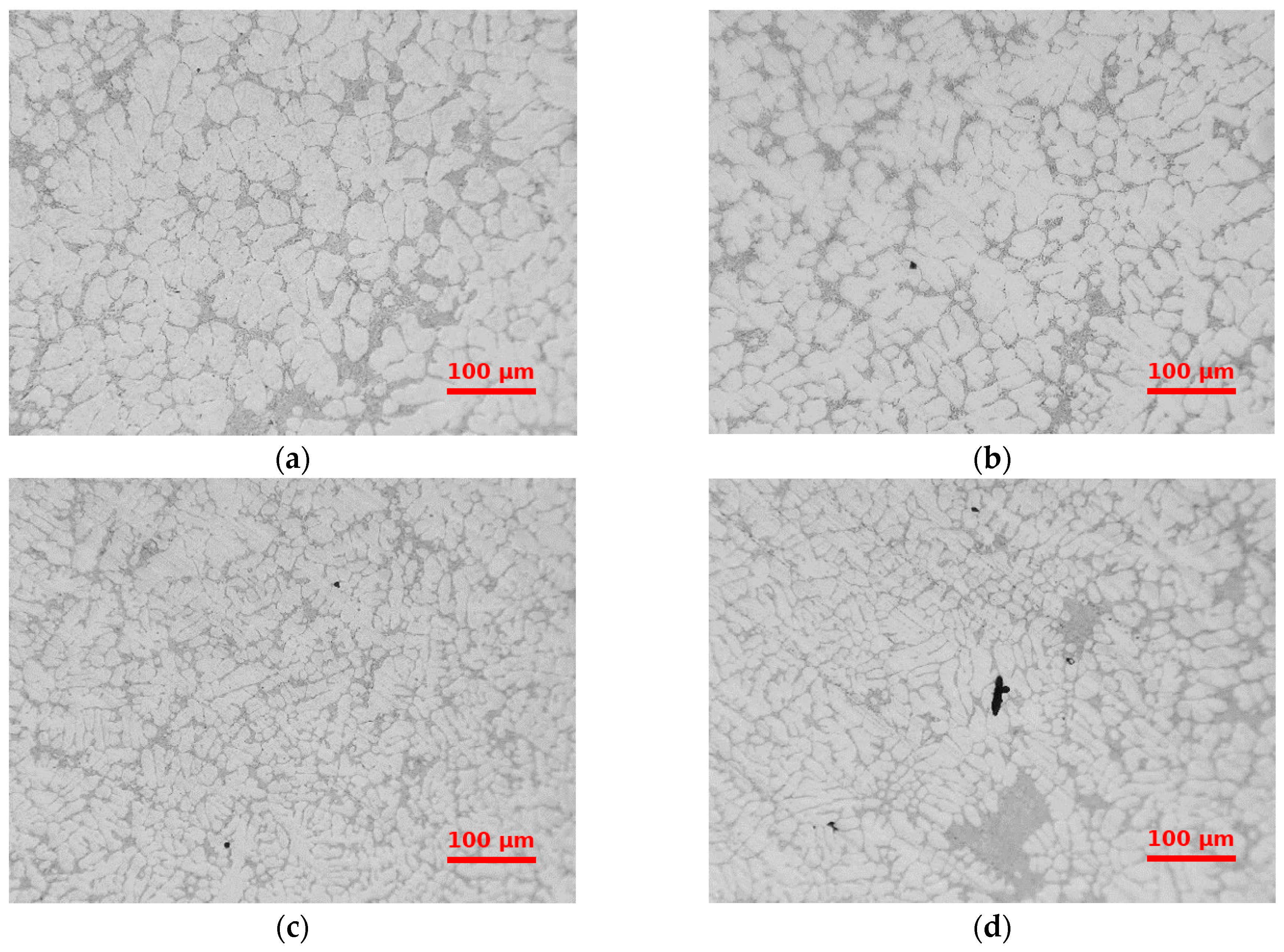

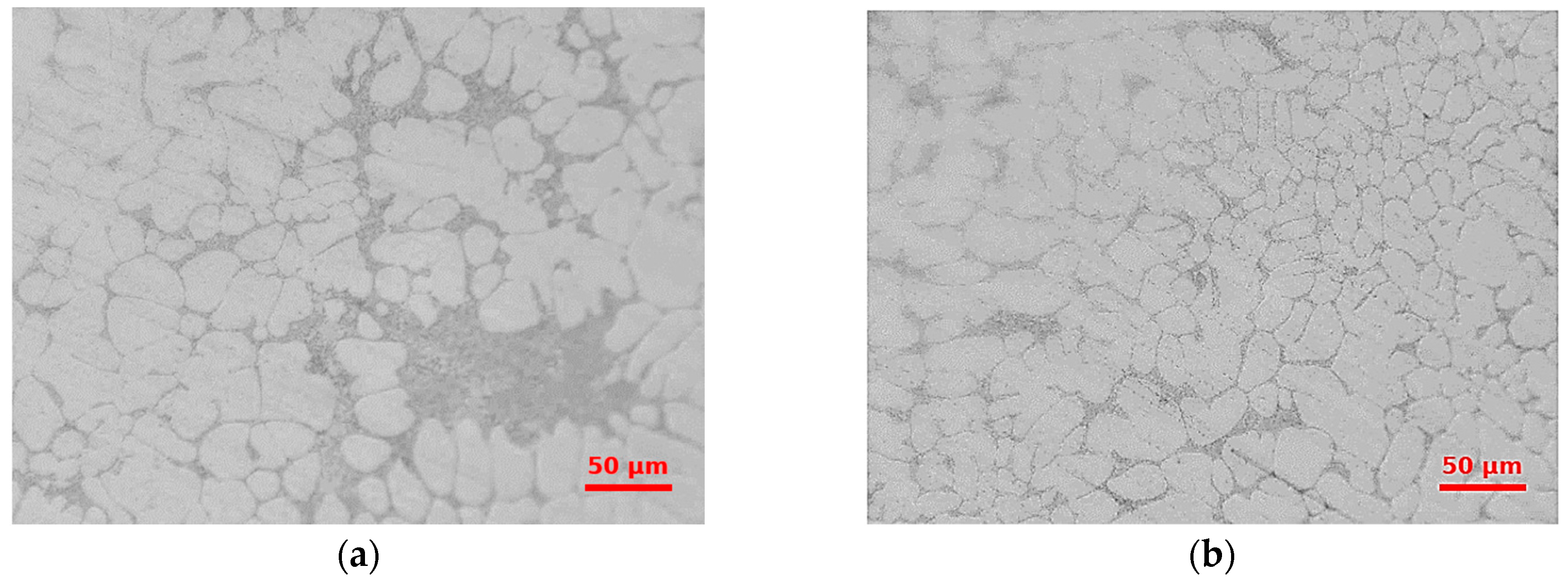

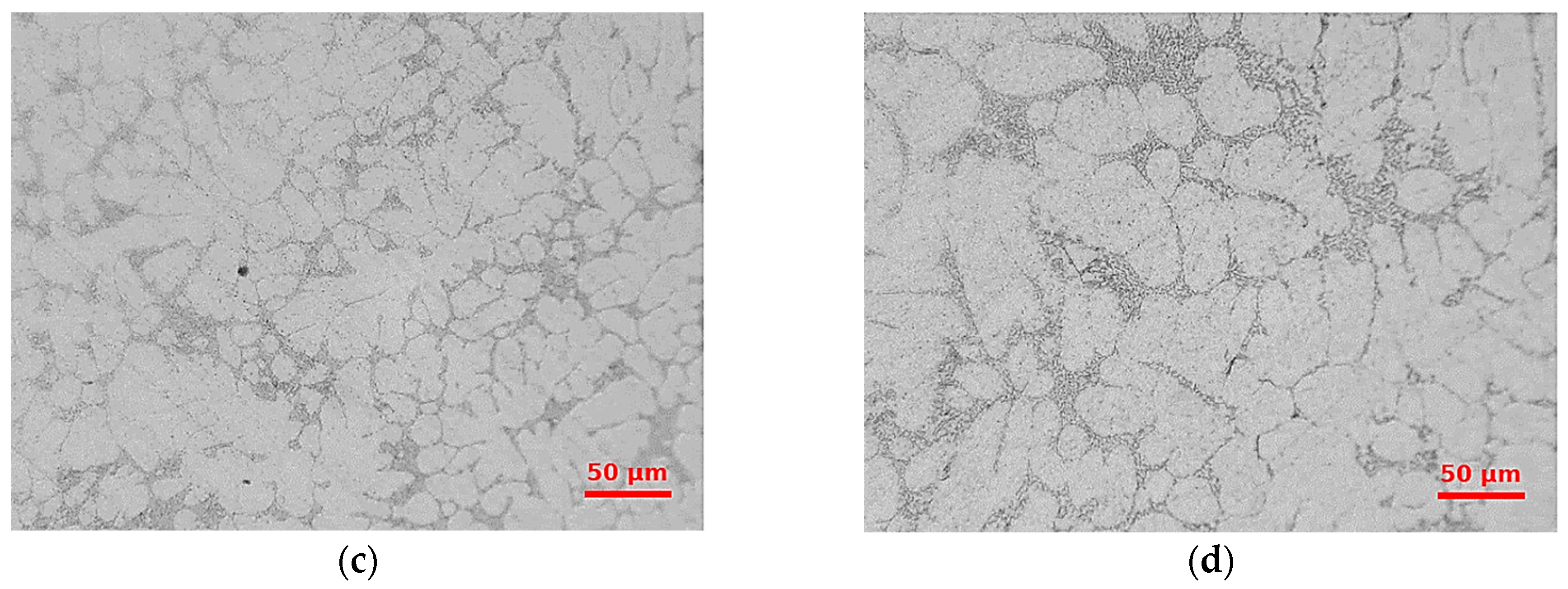

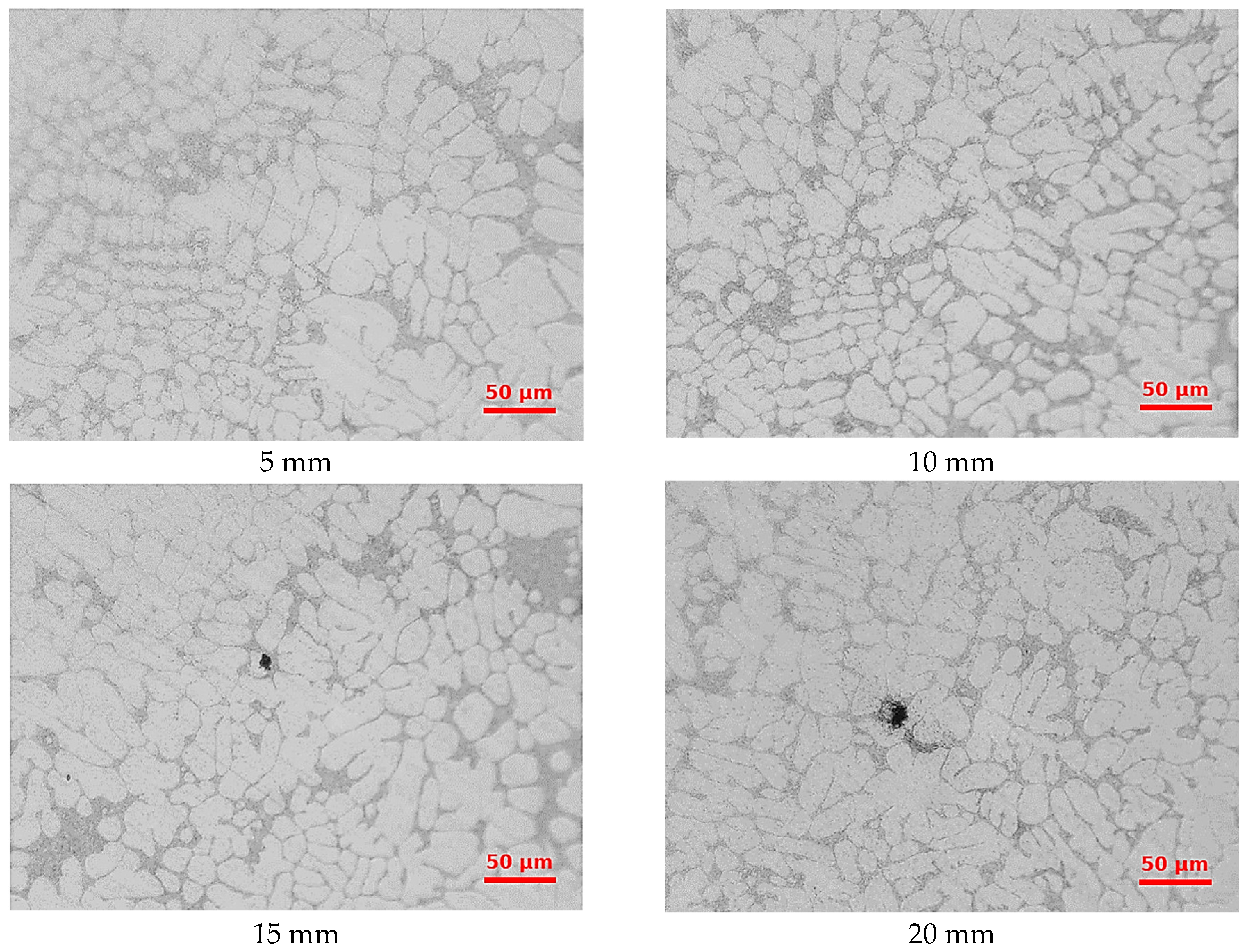

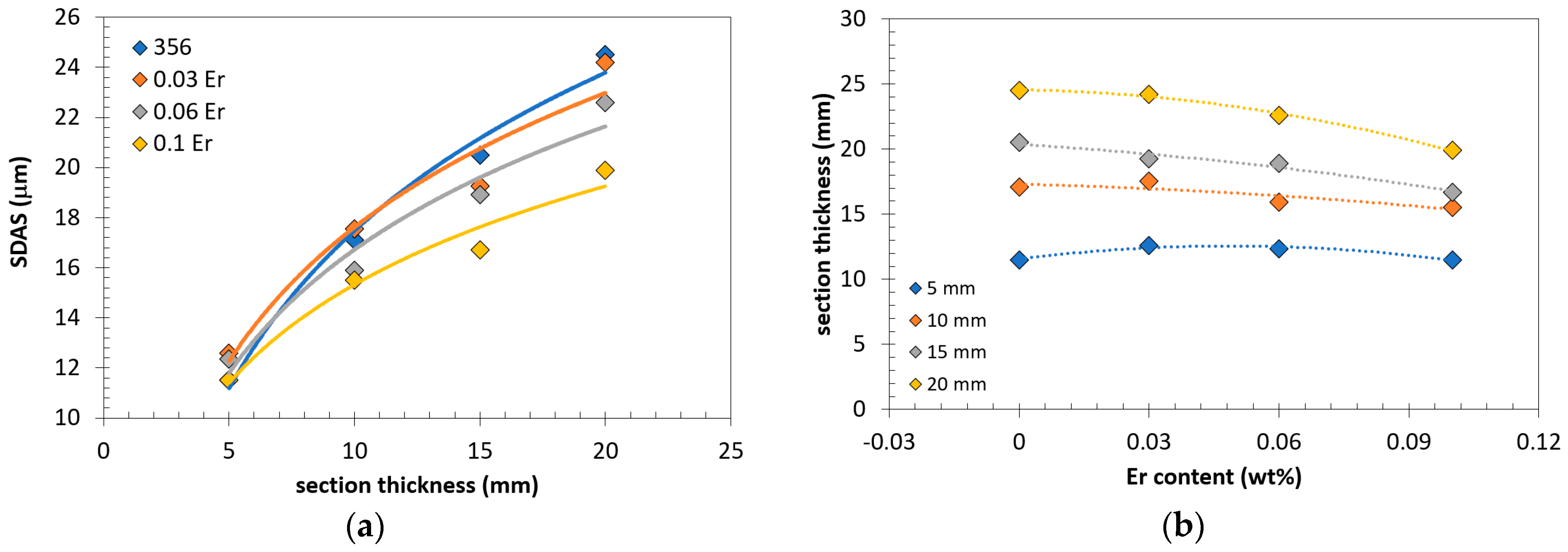

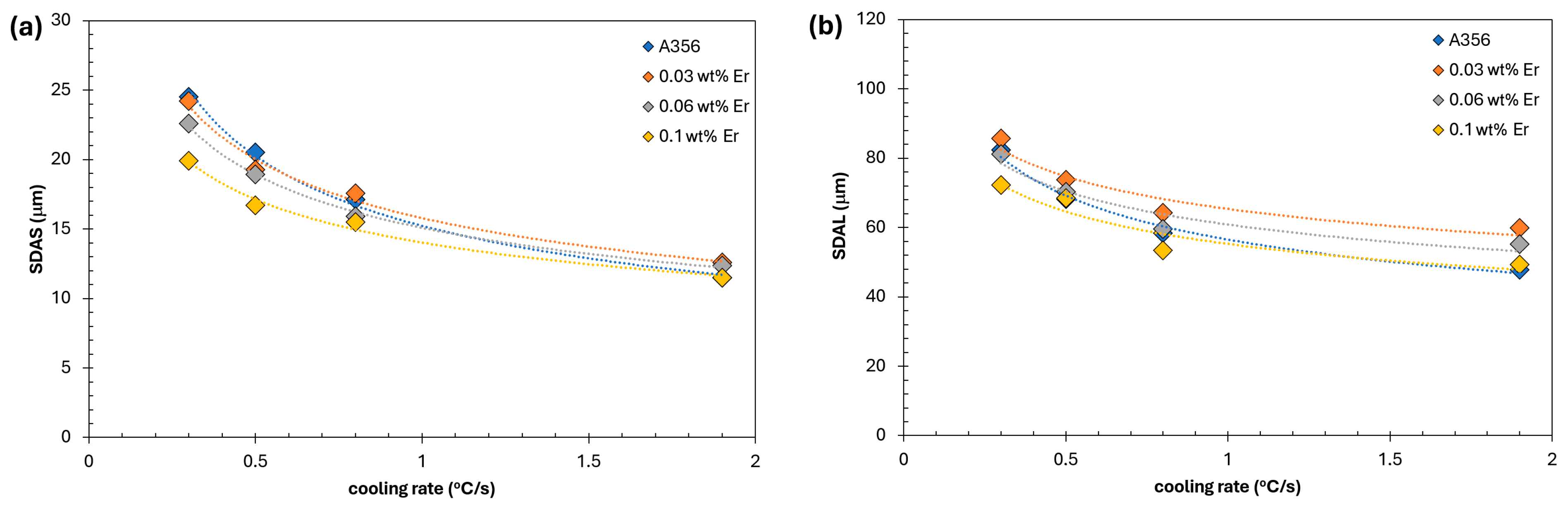

3.2. Microstructure Results

4. Conclusions

- The analyses clearly showed that Er addition has significant effects on the mechanical properties of A356 aluminum alloy. While the tensile stress values were 141.5 MPa in the casting without Er addition, these values increased by at least 30% to 185.4 MPa in 0.03 wt% Er addition, 187.0 MPa in 0.06 wt% Er addition, and 187.8 MPa in 0.1 wt% Er addition.

- When the elongation values were examined, it was seen that the Er addition improved the ductility of the material. The elongation rate, which was 1.816% in the casting without the Er addition, increased 4 times to 4.1% with the addition of 0.03 wt% Er, to 4.9% with the addition of 0.06 wt% Er, and to 5.4 wt% with the addition of 0.1% Er.

- When looking at the toughness values, it was determined that Er addition made a significant contribution to the A356 alloy in a positive way in terms of mechanical properties. The toughness value, which was 2122 kJ/m3 in the alloy without Er addition, was determined as 6353 kJ/m3 with 0.03 wt% Er addition, 7758 kJ/m3 with 0.06 wt% Er addition, and 8966 kJ/m3 with 0.1 wt% Er addition.

- With regard to the cooling rate, the SDAS was not affected by Er content at 5 mm thickness; however, as the thickness was increased to 20 mm, the SDAS values were decreased logarithmically from 24 to 18 μm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sigworth, G.K. Grain Refining of Aluminum Casting Alloys: Unsolved Mysteries. Int. J. Met. 2024, 18, 1–30. [Google Scholar] [CrossRef]

- Uyan, T.Ç.; Otto, K.; Silva, M.S.; Vilaça, P.; Armakan, E. Industry 4.0 Foundry Data Management and Supervised Machine Learning in Low-Pressure Die Casting Quality Improvement. Int. J. Met. 2023, 17, 414–429. [Google Scholar] [CrossRef]

- Lazaro-Nebreda, J.; Patel, J.B.; Lordan, E.; Zhang, Y.; Karakulak, E.; Al-Helal, K.; Scamans, G.M.; Fan, Z. Degassing of Aluminum Alloy Melts by High Shear Melt Conditioning Technology: An Overview. Metals 2022, 12, 1772. [Google Scholar] [CrossRef]

- Gyarmati, G.; Kéri, Z.; Mende, T.; Molnár, D. Analysis of the Quality of Incoming AlSi9Mn Alloy Ingots. Int. J. Met. 2024, 18, 1723–1738. [Google Scholar] [CrossRef]

- Gyarmati, G.; Pálóczi, Á.; Somfai, D.; Ferenczi, T.; Mende, T.; Kéri, Z. Analysis of Different Commercial Solid Fluxes Used During the Rotary Degassing Melt Treatment of Casting Aluminum Alloys. Met. Mater. Trans. B 2025, 56, 782–797. [Google Scholar] [CrossRef]

- Zhang, Q.; Liljenfors, T.; Jansson, S.; Jonsson, S.; Jarfors, A.E. Effect of Na-based flux on melt quality assessment of 46,000 alloys. J. Mater. Res. Technol. 2023, 27, 1830–1842. [Google Scholar] [CrossRef]

- Zhang, Q.; Liljenfors, T.; Jonsson, S.; Jarfors, A.E. On the application of reduced pressure test for the prediction of ductility of 46000 alloy: Role of pore’s morphology and distribution. J. Mater. Res. Technol. 2024, 31, 927–934. [Google Scholar] [CrossRef]

- Olofsson, J.; Bogdanoff, T.; Tiryakioğlu, M. On the Competition between Pores and Hidden Entrainment Damage during In Situ Tensile Testing of Cast Aluminum Alloy Components. Metals 2024, 14, 1175. [Google Scholar] [CrossRef]

- Olofsson, J.; Bogdanoff, T.; Tiryakioğlu, M.; Bramann, H.; Sturm, J. The Effect of Hidden Damage on Local Process Variability in Al-10 Pct Si Alloy High-Pressure Die Castings. Met. Mater. Trans. B 2025, 56, 595–607. [Google Scholar] [CrossRef]

- Bogdanoff, T.; Tiryakioğlu, M. An In Situ Study of Short Crack Initiation and Propagation During Fatigue Testing of a Hot Isostatically Pressed Al-7%Si-0.5%Mg (A357-T6) Alloy Specimen. Materials 2024, 17, 5928. [Google Scholar] [CrossRef]

- Bogdanoff, T.; Tiryakioğlu, M.; Liljenfors, T.; Jarfors, A.E.W.; Seifeddine, S.; Ghassemali, E. On the Effectiveness of Rotary Degassing of Recycled Al-Si Alloy Melts: The Effect on Melt Quality and Energy Consumption for Melt Preparation. Sustainability 2023, 15, 5189. [Google Scholar] [CrossRef]

- Nogita Kazuhiro Stuart, D. McDonald, and Arne K. Dahle. Eutectic modification of Al-Si alloys with rare earth metals. Mater. Trans. 2004, 45, 323–326. [Google Scholar] [CrossRef]

- Wang, J.; Li, F. Effect of Sm + Er and Heat Treatment on As-Cast Microstructure and Mechanical Properties of 7055 Aluminum Alloy. Materials 2023, 16, 4846. [Google Scholar] [CrossRef]

- Qin, T.; Fan, B.; Yu, J.; Bu, C.; Zhang, J. Effect of Erbium Micro-Additions on Microstructures and Properties of 2024 Aluminum Alloy Prepared by Microwave Sintering. Crystals 2024, 14, 382. [Google Scholar] [CrossRef]

- Xia, Y.; Wang, D.; Jia, J.; Wu, J.; Wang, Z.; Li, X.; Yuan, W.; Huang, J. An investigation on the precipitated phases and mechanical properties of cerium modified 2024 aluminum alloy. Mater. Werkst. 2020, 51, 1267–1273. [Google Scholar] [CrossRef]

- Savchenkov, S.; Kosov, Y.; Bazhin, V.; Krylov, K.; Kawalla, R. Microstructural Master Alloys Features of Aluminum–Erbium System. Crystals 2021, 11, 1353. [Google Scholar] [CrossRef]

- Colombo, M.; Gariboldi, E.; Morri, A. Er addition to Al-Si-Mg-based casting alloy: Effects on microstructure, room and high temperature mechanical properties. J. Alloys Compd. 2017, 708, 1234–1244. [Google Scholar] [CrossRef]

- Sahin, H.; Dispinar, D. Effect of Rare Earth Elements Erbium and Europium Addition on Microstructure and Mechanical Properties of A356 (Al–7Si–0.3Mg) Alloy. Int. J. Met. 2023, 17, 2612–2621. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, Q.; Zhao, G.; Zhang, R. Effects of erbium modification on the microstructure and mechanical properties of A356 aluminum alloys. Mater. Sci. Eng. A 2015, 626, 102–107. [Google Scholar] [CrossRef]

- Wen, S.P.; Xing, Z.; Huang, H.; Li, B.; Wang, W.; Nie, Z. The effect of erbium on the microstructure and mechanical properties of Al–Mg–Mn–Zr alloy. Mater. Sci. Eng. A 2009, 516, 42–49. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, Z.; Yan, H.; Luo, C.; Li, H.; Xie, X.; Nie, Q.; Hu, Z. Modification and strengthening mechanism of high strength-toughness as-cast Al–11Si–3Cu alloy modified with minor Sr and Er content. Mater. Sci. Eng. A 2024, 903, 146670. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, Z.; Dong, H.; Wang, C.; Du, X. Effect of erbium on microstructure and mechanical properties of Al-Si-Mg-Cu alloy. Mater. Werkst. 2020, 51, 1389–1397. [Google Scholar] [CrossRef]

- Ou, L.; Xing, S.; Sun, T.; Zhao, B.; Yan, G. Effect of Mixed Rare Earth on the Iron Phase and Tensile Properties in Squeeze Casting 6066 Aluminum Alloys. Int. J. Met. 2024, 19, 1354–1368. [Google Scholar] [CrossRef]

- Li, M.; Shi, Z.; Wu, X.; Wang, H.; Liu, Y. Study of the Microstructure and Crack Evolution Behavior of Al-5Fe-1.5Er Alloy. Materials 2019, 12, 172. [Google Scholar] [CrossRef]

- Yuan, S.; Peng, J.; Wang, W.; Zhan, Y.; Zeng, J.; Gan, P.; Ji, J. Effects of Sc–Er Rare Earth on Solidification Microstructure and Mechanical Properties of A360 Alloy. Int. J. Met. 2024, 19, 1532–1545. [Google Scholar] [CrossRef]

- Pandee, P.; Patakham, U.; Limmaneevichitr, C. Microstructural evolution and mechanical properties of Al-7Si-0.3Mg alloys with erbium additions. J. Alloys Compd. 2017, 728, 844–853. [Google Scholar] [CrossRef]

- Schaffer, P.L.; Dahle, A.K. Settling behaviour of different grain refiners in aluminium. Mater. Sci. Eng. A 2005, 413–414, 373–378. [Google Scholar] [CrossRef]

- Gao, Z.; Li, H.; Lai, Y.; Ou, Y.; Li, D. Effects of minor Zr and Er on microstructure and mechanical properties of pure aluminum. Mater. Sci. Eng. A 2013, 580, 92–98. [Google Scholar] [CrossRef]

- Guo, W.; Chen, X.; Liu, P.; Yu, G.; Fu, S.; Fan, J.; Zhou, H.; Liu, H. Effects of Er Additions on the Microstructure, Mechanical Properties, and Electrical Conductivity of the Al-0.4 Fe-0.05 Si Alloy. Adv. Eng. Mater. 2021, 23, 2000955. [Google Scholar] [CrossRef]

- Peeratatsuwan, C.; Pandee, P.; Patakham, U.; Limmaneevichitr, C. Effect of erbium on the rheocast quality index of A356 semisolid feedstock. Mater. Sci. Technol. 2021, 37, 424–438. [Google Scholar] [CrossRef]

- Khrustalyov, A.P.; Kozulin, A.A.; Zhukov, I.A.; Nikitin, P.Y.; Sachkov, V.I.; Vorozhtsov, A.B. Effect of Al3Er Particles on the Structure, Mechanical Properties, and Fracture of AA5056 Alloy After Casting and Deformation Treatment. JOM 2021, 73, 3858–3865. [Google Scholar] [CrossRef]

- Baysal, E.; Koçar, O.; Kahrıman, F.; Köklü, U. Investigation of Microstructure, Hardness, Corrosion and Machinability Properties of Commercially Pure Aluminum alloyed with Rare-Earth Elements. Int. J. Met. 2025, 19, 1–21. [Google Scholar] [CrossRef]

- Gursoy, O.; Colak, M.; Tur, K.; Dispinar, D. Characterization of properties of Vanadium, Boron and Strontium addition on HPDC of A360 alloy. Mater. Chem. Phys. 2021, 271, 124931. [Google Scholar] [CrossRef]

- Çolak, M.; Yalçin, Ö. Investigation of the Effect of Niobium Addition on Fluidity and Mechanical Properties in Casting of Aluminum Alloys. Int. J. Met. 2025. [Google Scholar] [CrossRef]

- Çeker, M.; Çolak, M. Investigation of the Effect of Vanadium Addition on Mechanical Properties in A356 Aluminum Casting Alloys. Int. J. Met. 2024. [Google Scholar] [CrossRef]

- ASTM E10; Standard Test Method for Brinell Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- Erzi, E.; Gürsoy, Ö.; Yüksel, Ç.; Colak, M.; Dispinar, D. Determination of acceptable quality limit for casting of A356 aluminium alloy: Supplier’s quality index (SQI). Metals 2019, 9, 957. [Google Scholar] [CrossRef]

- Patel, D.N.; Sutaria, M.P. Effect of Trace Rare Earth Er Addition on Microstructure and Tensile Properties of 319 Al-Si-Cu Alloy. Int. J. Met. 2022, 16, 2199–2209. [Google Scholar] [CrossRef]

- Çolak, M.; Arslan, I. Investigation of the effect of the addition of grain refiner and modifier addition on wear properties in sand and permanent mould casting of A357 and A380 aluminium alloys. Int. J. Cast Met. Res. 2022, 35, 17–23. [Google Scholar] [CrossRef]

- Uslu, E.; Tiğli, A.; Çolak, M. The effect of cooling plate, mechanical vibration, and grain refinement on the microstructure and hardness of A380 produced by sand mold. Int. J. Cast Met. Res. 2024, 37, 108–116. [Google Scholar] [CrossRef]

- Çolak, M. Modification of eutectic Al–Si alloys by Sr and CuSn5. Mater. Res. Express 2019, 6, 1065a2. [Google Scholar] [CrossRef]

- Sheykh-Jaberi, F.; Cockcroft, S.; Maijer, D.; Phillion, A. Comparison of the semi-solid constitutive behaviour of A356 and B206 aluminum foundry alloys. J. Mater. Process. Technol. 2019, 266, 37–45. [Google Scholar] [CrossRef]

- Jeon, J.; Bae, D. Effect of cooling rate on the thermal and electrical conductivities of an A356 sand cast alloy. J. Alloys Compd. 2019, 808, 151756. [Google Scholar] [CrossRef]

- Samuel, A.M.; Zedan, Y.; Doty, H.W.; Songmene, V.; Samuel, F.H. Role of the Addition of La and Ce on the Cooling Characteristics and Porosity Formation in A356 and A413 Alloys. Int. J. Met. 2022, 16, 553–572. [Google Scholar] [CrossRef]

| Alloys | Fe | Si | Cu | Mn | Mg | Zn | Ti | Er | Al |

|---|---|---|---|---|---|---|---|---|---|

| A356 standard | ≤0.20 | 6.5–7.5 | ≤0.20 | ≤0.10 | 0.25–045 | ≤0.10 | 0.10–0.20 | - | Remain |

| A356 | 0.121 | 6.74 | 0.012 | 0.015 | 0.261 | 0.0276 | 0.116 | 0.001 | Remain |

| A356 + 0.03 wt% Er | 0.112 | 6.71 | 0.011 | 0.019 | 0.277 | 0.0295 | 0.109 | 0.028 | Remain |

| A356 + 0.06 wt% Er | 0.136 | 6.68 | 0.016 | 0.027 | 0.312 | 0.0595 | 0.112 | 0.059 | Remain |

| A356 + 0.1 wt% Er | 0.093 | 6.84 | 0.014 | 0.023 | 0.293 | 0.0393 | 0.123 | 0.102 | Remain |

| Alloys | UTS (MPa) | YS (MPa) | Elongation % | Toughness (kJ/m3) |

|---|---|---|---|---|

| A356 | 141.5 | 91.4 | 1.8 | 2122.7 |

| A356 + 0.03 wt% Er | 185.4 | 93.0 | 4.1 | 6353.2 |

| A356 + 0.06 wt% Er | 187.1 | 92.7 | 4.9 | 7758.0 |

| A356 + 0.1 wt% Er | 187.9 | 91.8 | 5.4 | 8966.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colak, M.; Muhammed, E.A.; Turkmen, M.; Dispinar, D. Microstructure and Mechanical Properties Change of Al7SiMgxEr (x: 0.03–0.1). Metals 2025, 15, 969. https://doi.org/10.3390/met15090969

Colak M, Muhammed EA, Turkmen M, Dispinar D. Microstructure and Mechanical Properties Change of Al7SiMgxEr (x: 0.03–0.1). Metals. 2025; 15(9):969. https://doi.org/10.3390/met15090969

Chicago/Turabian StyleColak, Murat, Enes Aydin Muhammed, Mustafa Turkmen, and Derya Dispinar. 2025. "Microstructure and Mechanical Properties Change of Al7SiMgxEr (x: 0.03–0.1)" Metals 15, no. 9: 969. https://doi.org/10.3390/met15090969

APA StyleColak, M., Muhammed, E. A., Turkmen, M., & Dispinar, D. (2025). Microstructure and Mechanical Properties Change of Al7SiMgxEr (x: 0.03–0.1). Metals, 15(9), 969. https://doi.org/10.3390/met15090969