Fabrication, Microstructure, and High-Temperature Mechanical Properties of a Novel Al-Si-Mg Based Composite Reinforced with Cu-Mn Binary Phase and Submicron Dispersoid

Abstract

1. Introduction

2. Materials and Methods

3. Results

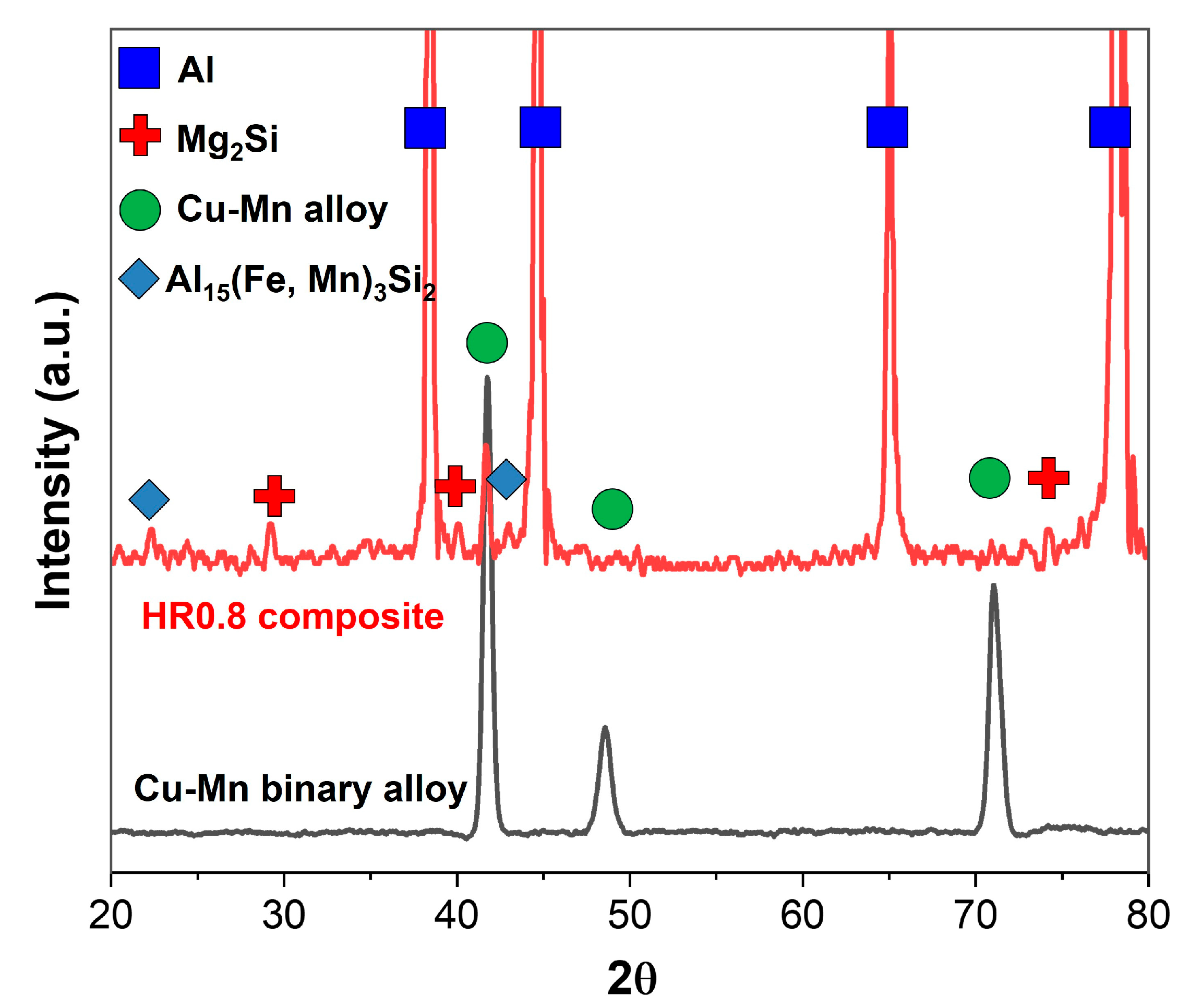

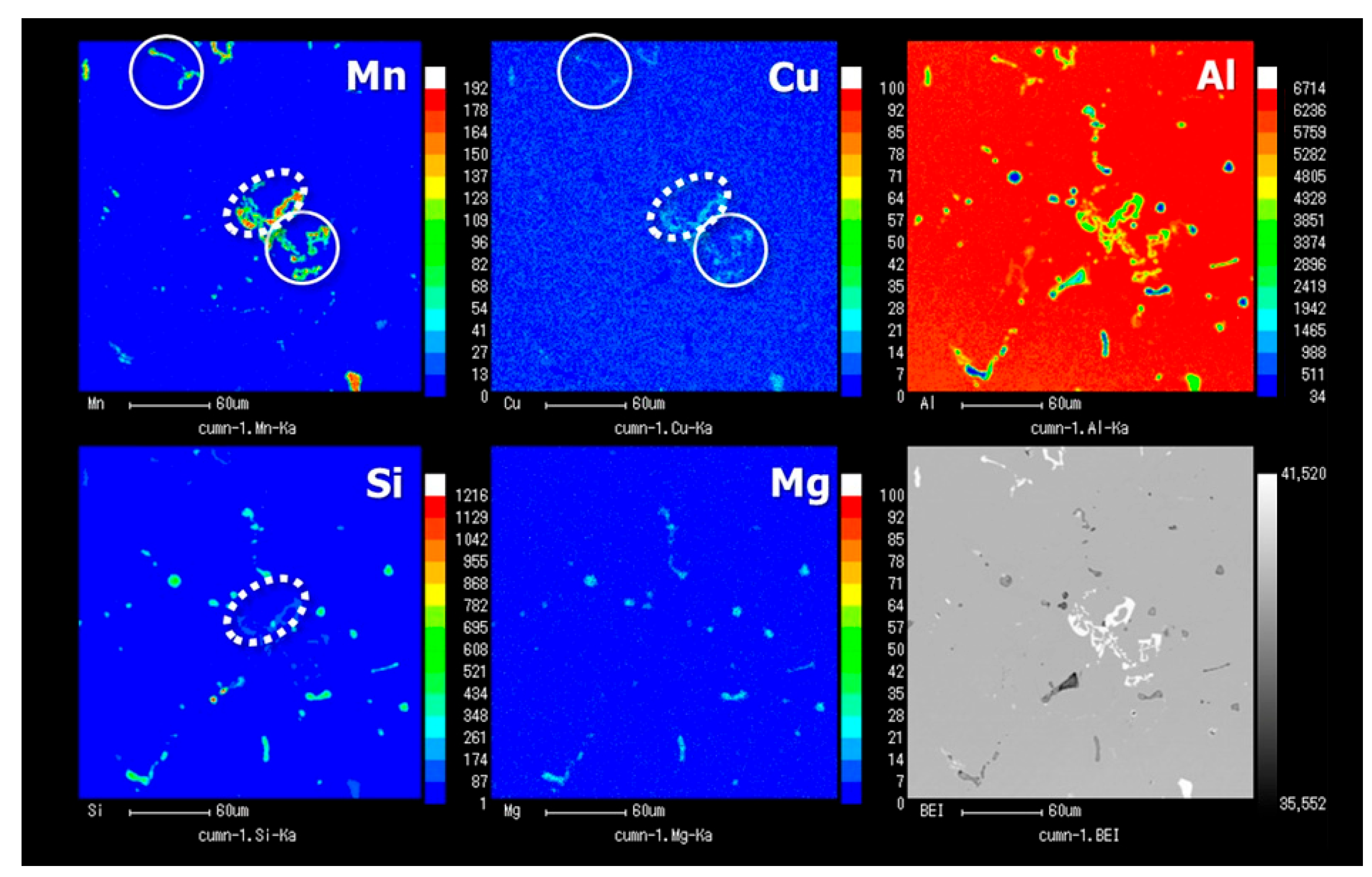

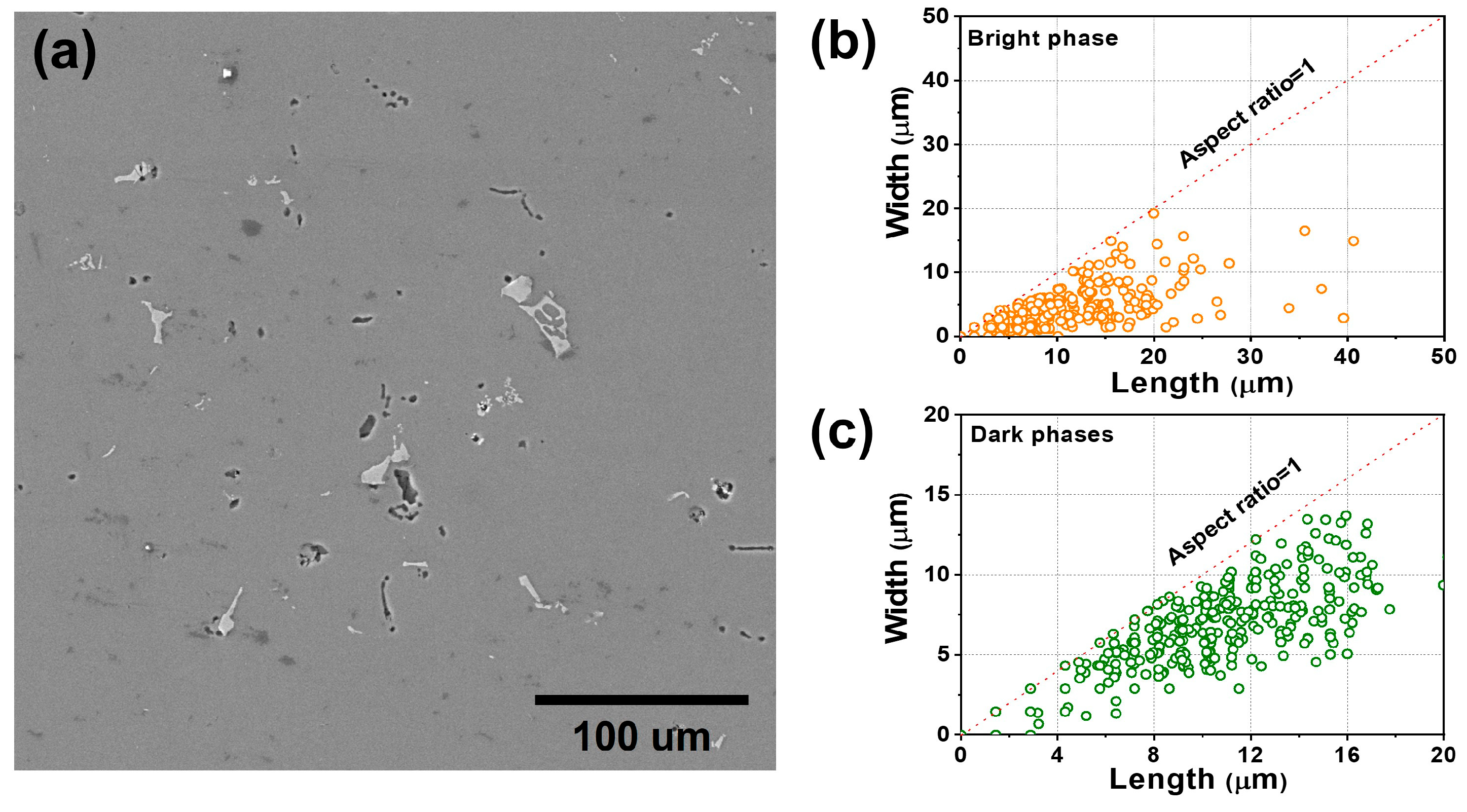

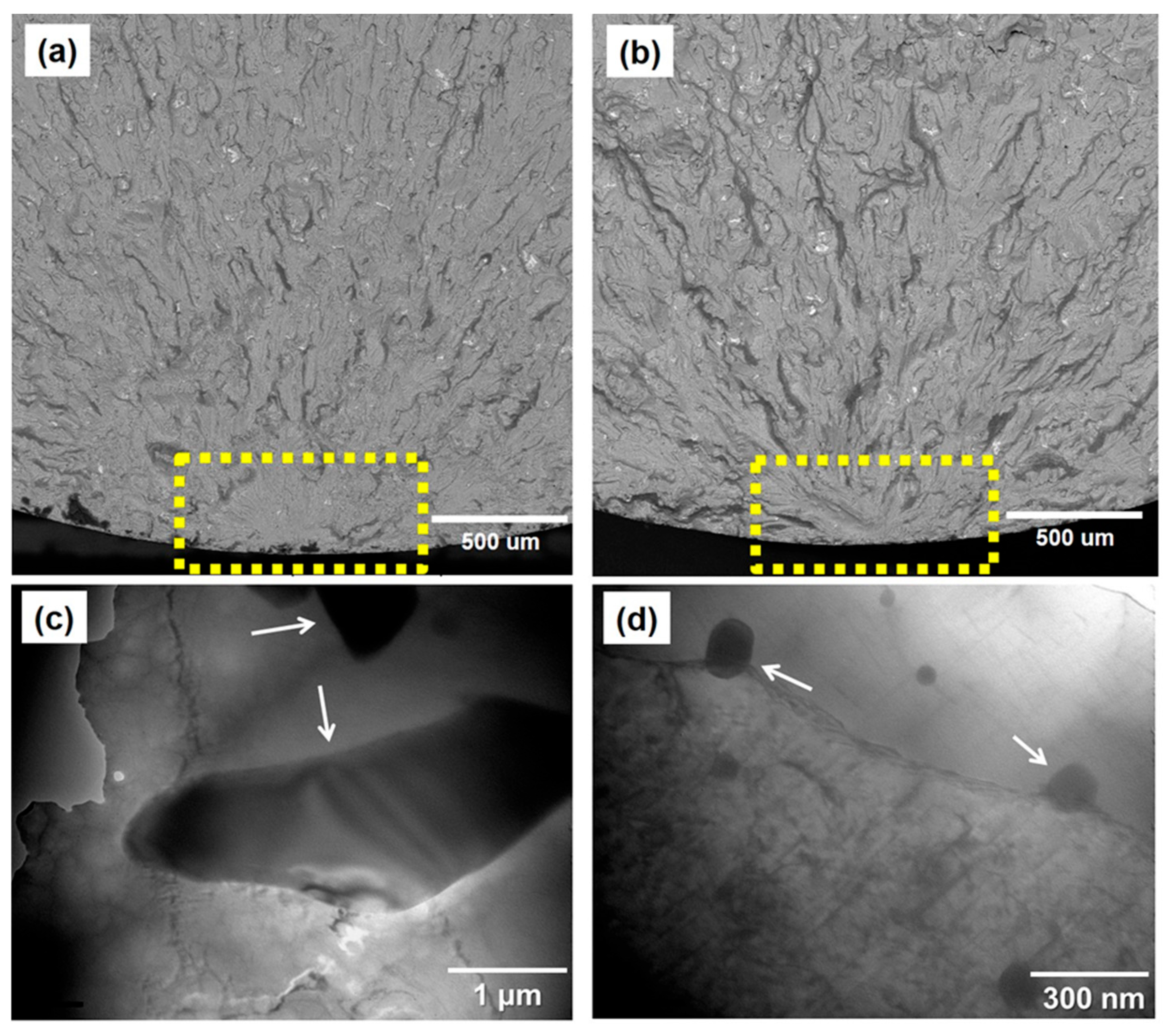

3.1. Microstructure and Phase Analysis

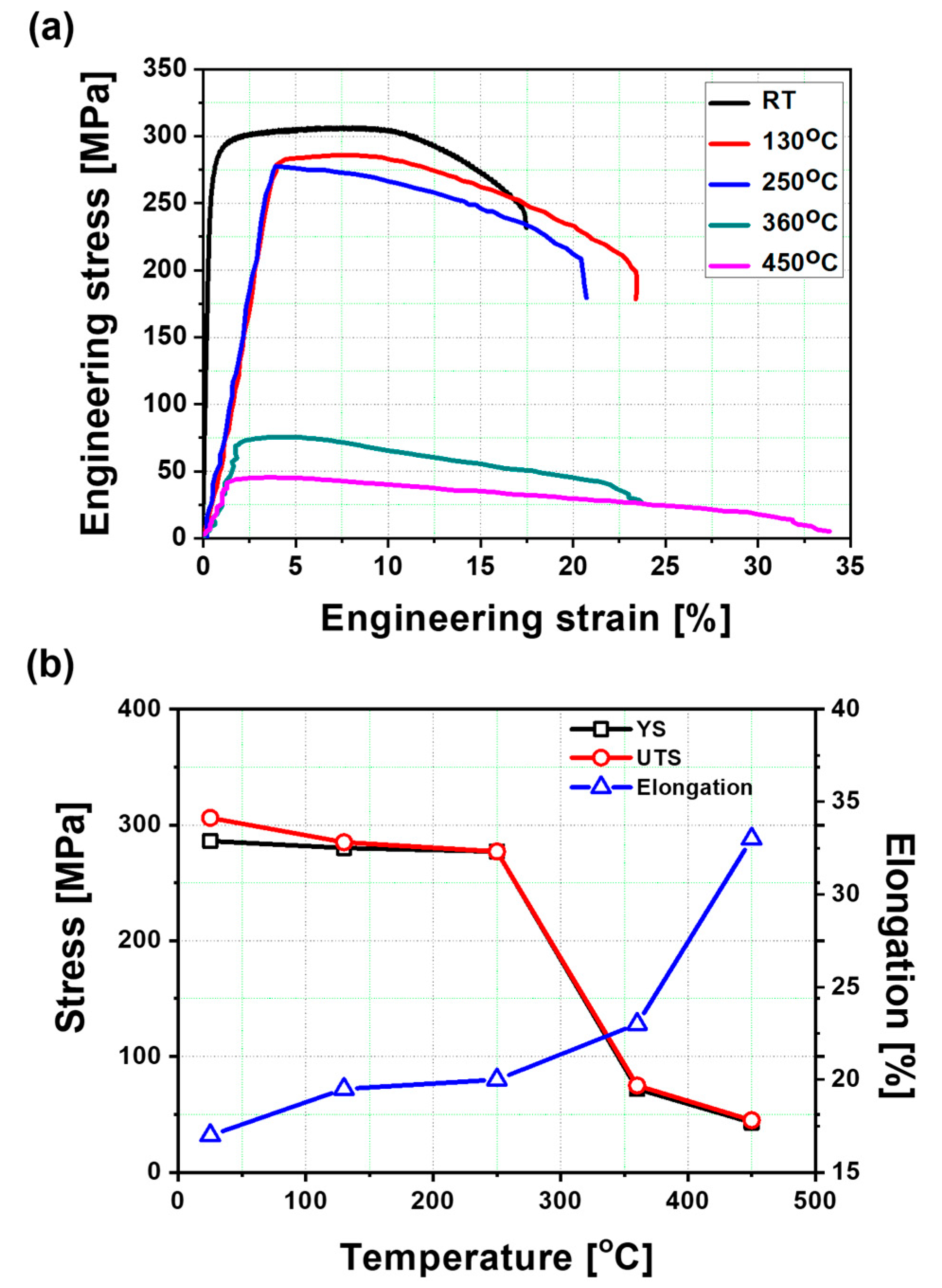

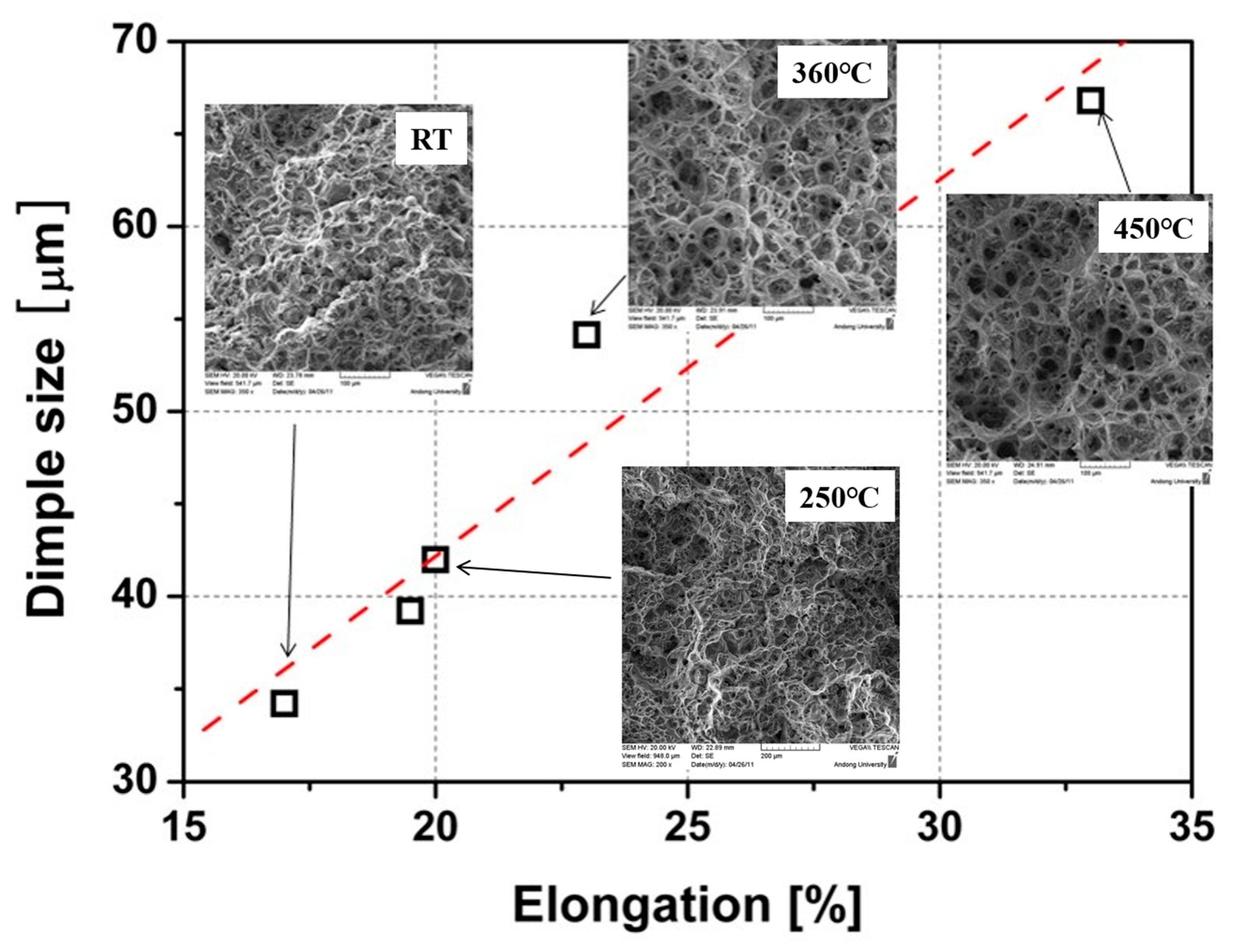

3.2. Room- and High-Temperature Tensile Properties

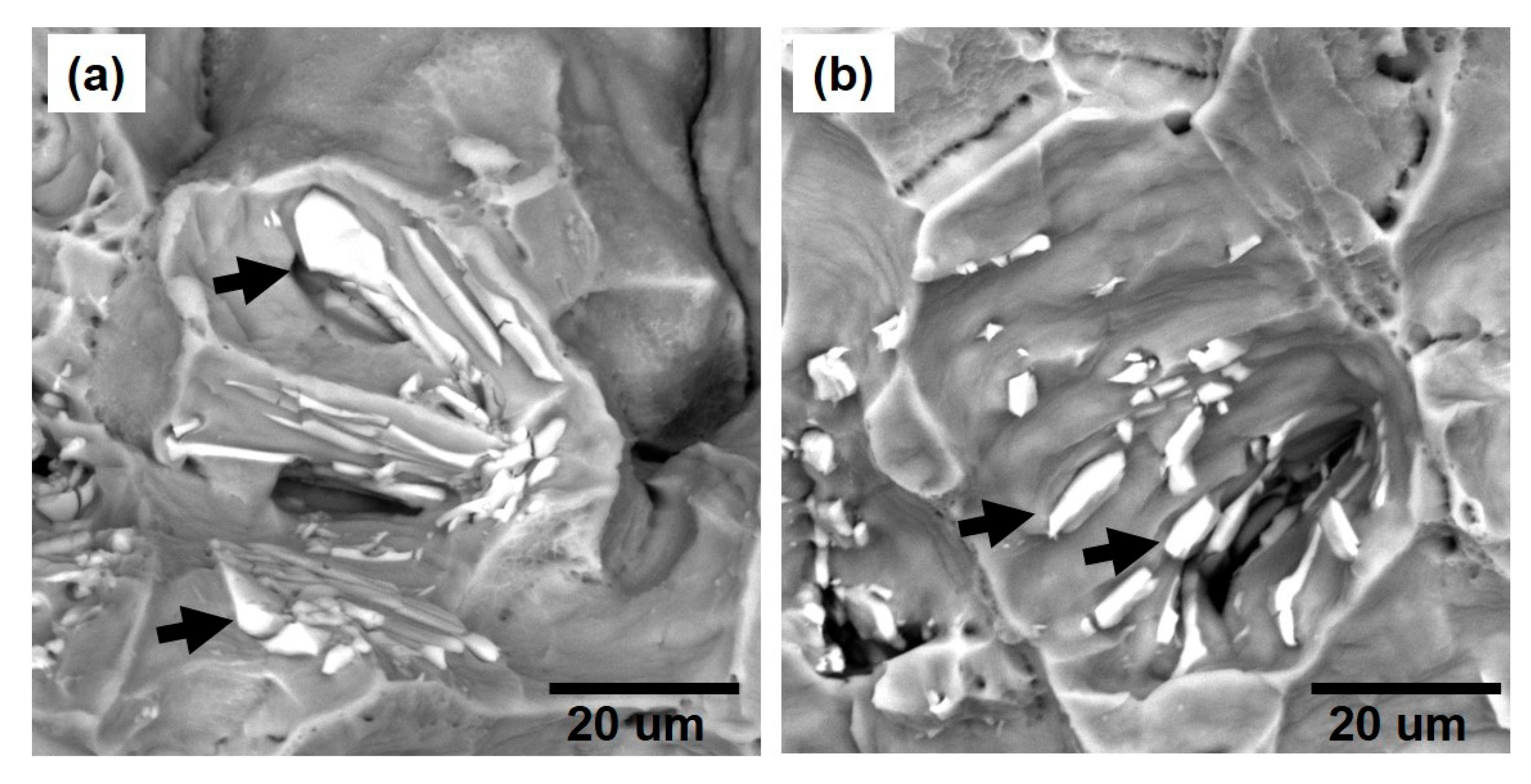

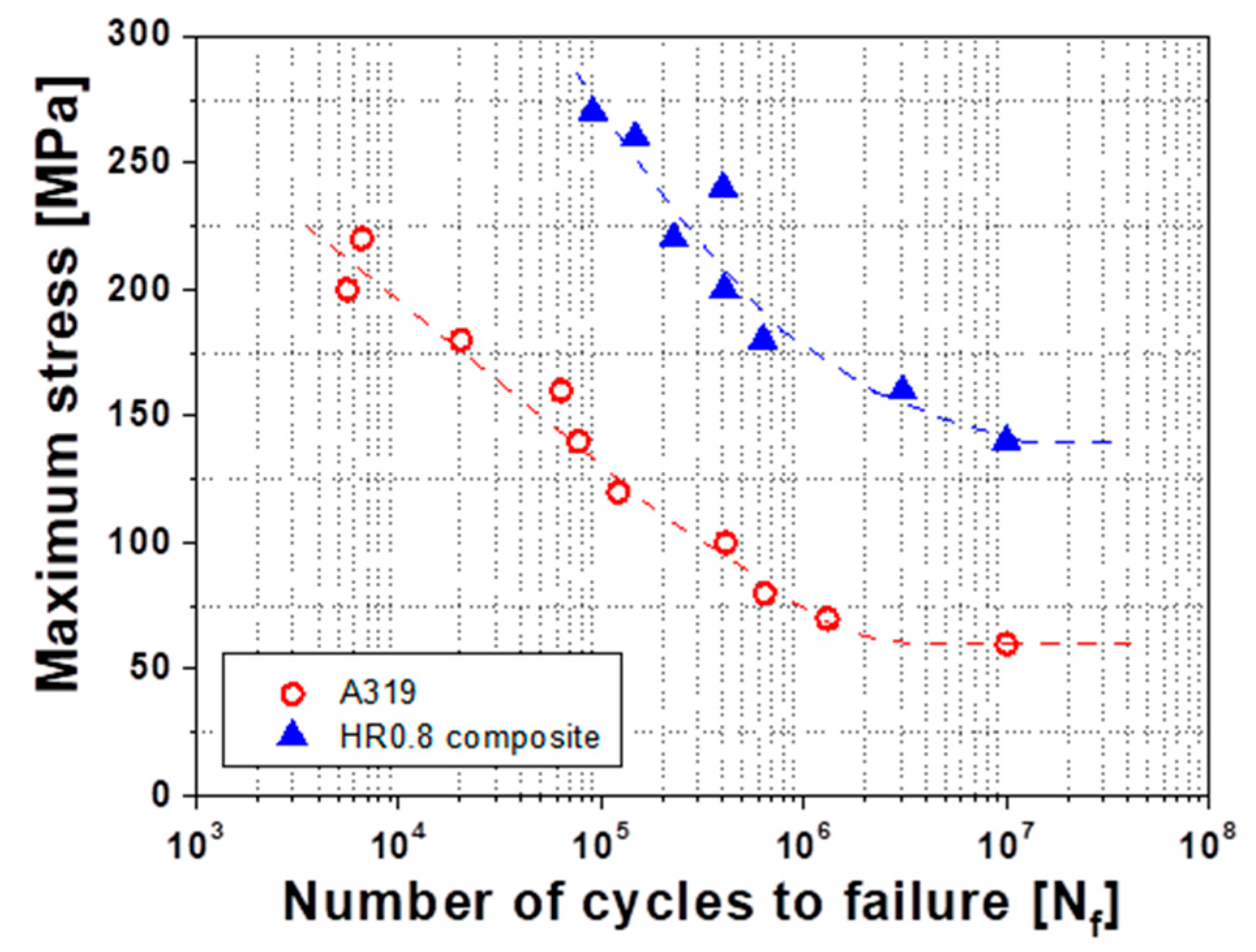

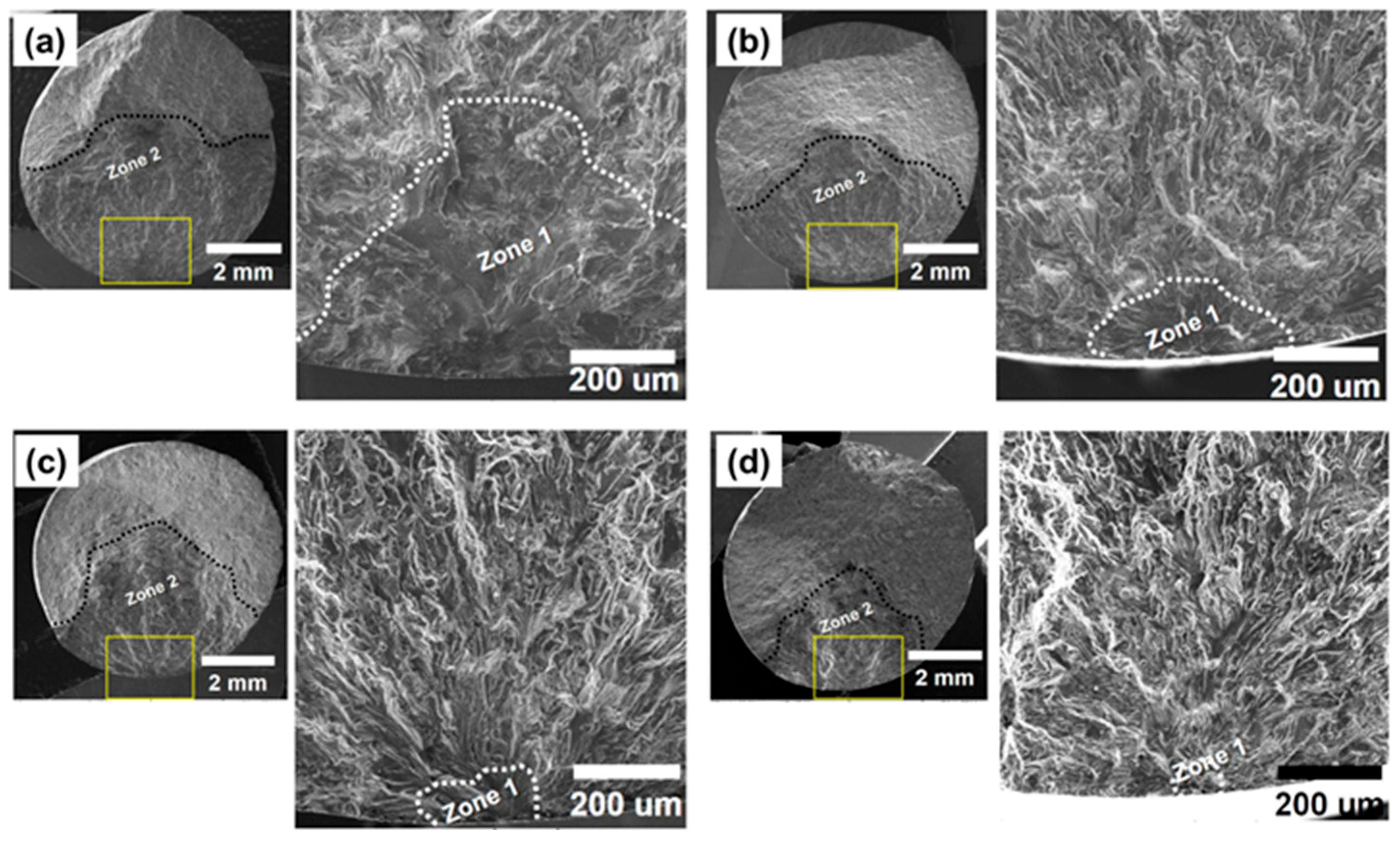

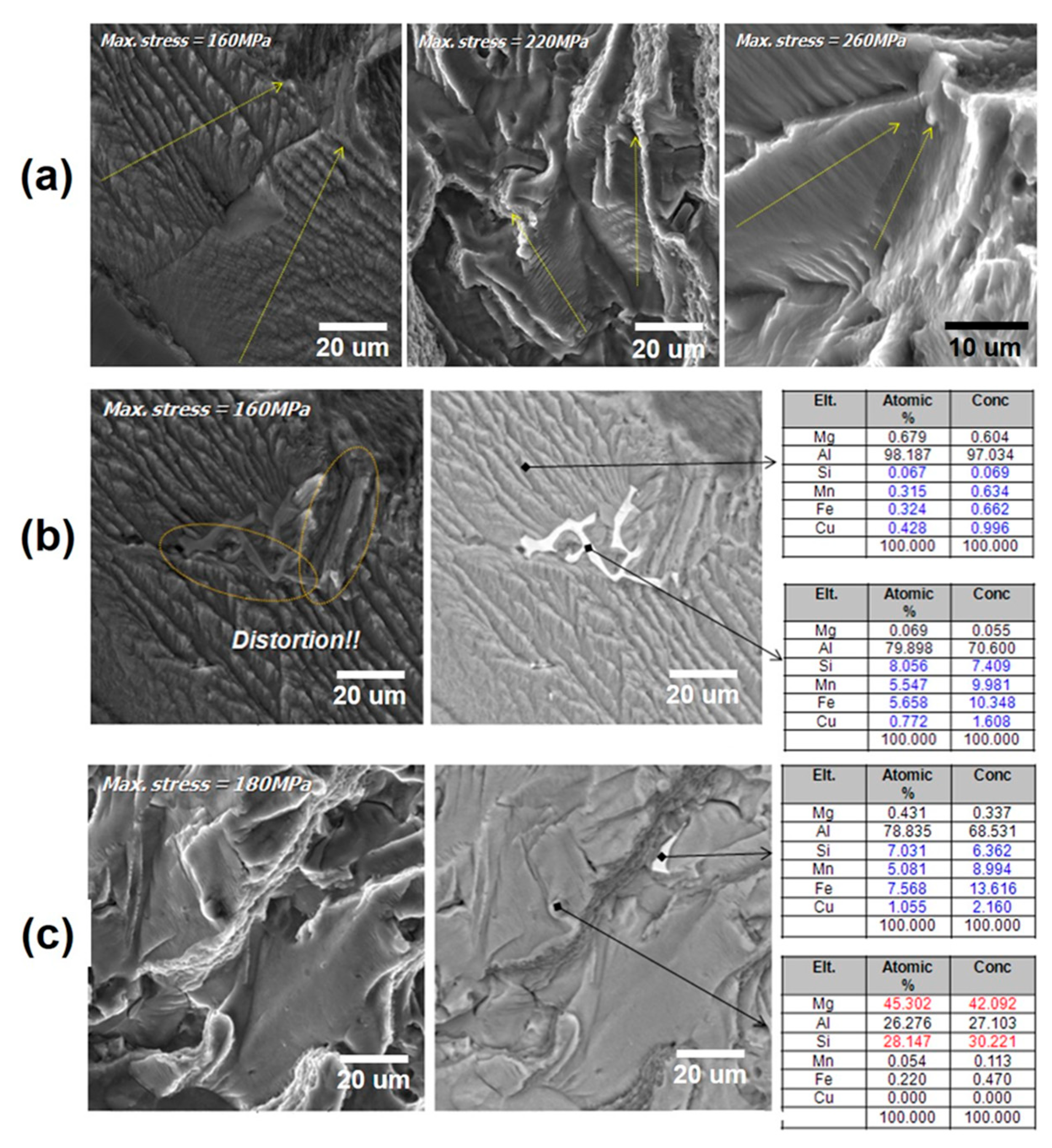

3.3. High-Temperature High-Cycle Fatigue Properties

4. Discussion

4.1. Strengthening Mechanisms at Room Temperature (RT)

4.2. Strengthening Mechanisms at Elevated Temperatures

4.3. Strengthening Mechanisms Under High-Temperature Cyclic Loading

5. Conclusions

- Microstructure analysis confirmed the presence of micron-sized Cu-Mn binary, eutectic Mg2Si, and Al15(Fe, Mn)3Si2 phases, submicron-sized α-Al(Mn, Fe)Si dispersoids, and nano-sized precipitates in the microstructure of the composite in a T6 temper.

- The newly developed composite demonstrated improved mechanical properties compared to commonly used heat-resistant Al alloys. At room temperature, it exhibits a yield strength (YS) of 287 MPa and a maximum tensile strength (TS) of 306 MPa, with an elongation of 17%, attributed mainly to Orowan strengthening from nano-sized precipitates and submicron dispersoids, along with load transfer and dislocation density strengthening from micron-sized Cu-Mn binary solid solution phases, and grain boundary strengthening.

- Moreover, the novel composite maintained a YS of 277 MPa up to 250 °C, with a slight increase in elongation. The improved thermal stability is attributed to the presence of submicron dispersoids and micron-sized (Cu-Mn binary and Al15(Fe, Mn)3Si2) phases pinning the dislocations as well as grain boundaries.

- The new composite also exhibited excellent high-temperature high-cycle fatigue properties and showed a high-cycle fatigue limit of 140 MPa at 130 °C, which is ~2.3 times higher than that of the A319 alloy. A fractography study revealed that the secondary particles hindered the movement of dislocations, thus delaying crack initiation under cyclic loading at high temperatures. Additionally, Cu-Mn binary and Al15(Fe, Mn)3Si2 phases were also found to be effective in reducing the crack propagation rate by hindering the movement of the propagated crack.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AMCs | Aluminum matrix composites |

| HEAs | High-entropy alloys |

| SEM | Scanning electron microscope |

| EDS | Energy dispersive spectroscopy |

| EPMA | Electron probe micro analysis |

| TEM | Transmission electron microscopy |

| YS | Yield strength |

| UTS | Ultimate tensile strength |

| EL | Elongation |

| RT | Room temperature |

| BSE | Backscattered electron |

| PFZs | Precipitate-free zones |

References

- Cai, Q.; Lordan, E.; Wang, S.; Liu, G.; Mendis, C.L.; Chang, I.T.H.; Ji, S. Die-Cast Multicomponent near-Eutectic and Hypoeutectic Al–Si–Ni–Fe–Mn Alloys: Microstructures and Mechanical Properties. Mater. Sci. Eng. A 2023, 872, 144977. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, X.; Le, P.; Liao, Y.; He, G.; Wang, Q.; He, Q. Effect of Heat Treatment and Loading Path on Non-Proportional Fatigue Behavior and Fracture Characteristics of an Al-Si Casting Alloy. J. Mater. Eng. Perform. 2023, 32, 4325–4337. [Google Scholar] [CrossRef]

- Lin, B.; Fan, T.; Li, H.; Zhao, Y.; Zhang, W.; Liu, K. Microstructure and High Temperature Tensile Properties of Al–Si–Cu–Mn–Fe Alloys Prepared by Semi-Solid Thixoforming. Trans. Nonferrous Met. Soc. China 2021, 31, 2232–2249. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Fan, T. Three-Dimensional Network Structure and Mechanical Properties of Al-Cu-Ni-Fe Cast Alloys with Gd Micro-Addition. Metall. Mater. Trans. A 2021, 52, 2613–2629. [Google Scholar] [CrossRef]

- Sun, J.; Zeng, G.; Rao, D.; Wang, Y.; Yang, Y.; Pan, L.; Hu, Z. Microstructure and Tensile Properties of a Cast Eutectic Al–Si–Cu Alloy Modified by Zr and V. Met. Mater. Int. 2021, 27, 5436–5449. [Google Scholar] [CrossRef]

- Limodin, N.; Dahdah, N.; Wang, L.; El Bartali, A.; Witz, J.-F.; Buffiere, J.-Y.; Charkaluk, E. Characterisation of 3D Strain Heterogeneity at the Microstructure Scale during Low Cycle Fatigue of an AlSi7Cu3Mg Alloy at 250 °C. Int. J. Fatigue 2023, 172, 107476. [Google Scholar] [CrossRef]

- Mohammed, A.A. Original Articles. Rev. Afr. Polit. Econ. 2003, 30, 479–510. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.F.; Niroumand, B. Fatgiue Behavior of Metal Matrix Nanocomposites. Ceram. Int. 2020, 46, 23326–23336. [Google Scholar] [CrossRef]

- Azadi, M.; Bahmanabadi, H.; Gruen, F.; Winter, G. Evaluation of Tensile and Low-Cycle Fatigue Properties at Elevated Temperatures in Piston Aluminum-Silicon Alloys with and without Nano-Clay-Particles and Heat Treatment. Mater. Sci. Eng. A 2020, 788, 139497. [Google Scholar] [CrossRef]

- Shettar, M.; Sharma, S.; M C, G.; H M, V.; Ranjan, R.; Doddapaneni, S. Individual and Combined Effects of Reinforcements on Fractured Surface of Artificially Aged Al6061 Hybrid Composites. J. Compos. Sci. 2023, 7, 91. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, K.; Gao, T.; Liu, G.; Sun, Q.; Liu, X.; Liu, S. A New Measure to Enhance the Heat-Resistant (4TiC + 5AlN)/Al Composite by Multi-Scale Fe/Mn Enrichment Effect. J. Alloys Compd. 2023, 952, 170019. [Google Scholar] [CrossRef]

- Azizi, A.; Zangeneh, S.; Mojtahedi, M.; Rasaee, S. Hot Deformation Behavior and Microstructure of Ni-Cu Rich Al-Si AA4032 Alloy. J. Alloys Compd. 2023, 940, 168934. [Google Scholar] [CrossRef]

- Sun, Y.; Li, C.; Zhou, Z.; An, R.; Yu, L.; Liu, Y. The Strengthening Role of Micro-Sized Phases and Nano-Precipitates in Al–Mg2Si–Cu(–Ni) Alloys at 25 °C and 350 °C. J. Mater. Res. Technol. 2023, 24, 2514–2521. [Google Scholar] [CrossRef]

- Zohoor, M.; Besharati Givi, M.K.; Salami, P. Effect of Processing Parameters on Fabrication of Al–Mg/Cu Composites via Friction Stir Processing. Mater. Des. 2012, 39, 358–365. [Google Scholar] [CrossRef]

- Farajollahi, R.; Jamshidi Aval, H.; Jamaati, R. Evaluating of the Microstructure, Texture, and Mechanical Properties of AA2024-Al3NiCu Composites Fabricated by the Stir Casting Process. CIRP J. Manuf. Sci. Technol. 2022, 37, 204–218. [Google Scholar] [CrossRef]

- Selvakumar, S.; Dinaharan, I.; Palanivel, R.; Babu, B.G. Development of Stainless Steel Particulate Reinforced AA6082 Aluminum Matrix Composites with Enhanced Ductility Using Friction Stir Processing. Mater. Sci. Eng. A 2017, 685, 317–326. [Google Scholar] [CrossRef]

- Georgarakis, K.; Dudina, D.V.; Kvashnin, V.I. Metallic Glass-Reinforced Metal Matrix Composites: Design, Interfaces and Properties. Materials 2022, 15, 8278. [Google Scholar] [CrossRef]

- Rezaei, M.R.; Albooyeh, A.; Shayestefar, M.; Shiraghaei, H. Microstructural and Mechanical Properties of a Novel Al-Based Hybrid Composite Reinforced with Metallic Glass and Ceramic Particles. Mater. Sci. Eng. A 2020, 786, 139440. [Google Scholar] [CrossRef]

- Luo, K.; Xiong, H.; Zhang, Y.; Gu, H.; Li, Z.; Kong, C.; Yu, H. AA1050 Metal Matrix Composites Reinforced by High-Entropy Alloy Particles via Stir Casting and Subsequent Rolling. J. Alloys Compd. 2022, 893, 162370. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Li, Z.; Wang, X.; Fan, X.; Liu, J. Formation of Transition Layer and Its Effect on Mechanical Properties of AlCoCrFeNi High-Entropy Alloy/Al Composites. J. Alloys Compd. 2019, 780, 558–564. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, H.; Dong, P.; Yan, Z.; Wang, W. A Study on the Formation of Multiple Intermetallic Compounds of Friction Stir Processed High Entropy Alloy Particles Reinforced Al Matrix Composites. Mater. Charact. 2022, 183, 111646. [Google Scholar] [CrossRef]

- Wu, C.-Y.; Wu, C.-T.; Lee, W.-H.; Chang, S.-C.; Wang, Y.-L. A Study on Annealing Mechanisms with Different Manganese Contents in CuMn Alloy. J. Alloys Compd. 2012, 542, 118–123. [Google Scholar] [CrossRef]

- Lee, H.-Y.; He, C.-W.; Lee, Y.-C.; Wu, D.-C. A Study on the Characteristics of Cu–Mn–Dy Alloy Resistive Thin Films. Coatings 2019, 9, 118. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, X.P.; Tang, Y.; You, W.X.; Xu, Y.G. Microstructure and Properties of Mn-Cu-Based Damping Alloys Prepared by Ball Milling and Hot-Press Sintering. J. Mater. Eng. Perform. 2019, 28, 2641–2648. [Google Scholar] [CrossRef]

- Chen, C.; Li, J.; Ji, P.; Guo, W.; Liu, B.; Xue, H.; Li, X.; Zhao, D.; Yin, F. Microstructure and Damping Property of Mn-Cu Damping Alloy by Induction Brazing and Different Heat Treating. Mater. Lett. 2023, 330, 133312. [Google Scholar] [CrossRef]

- ASTM E8/E8M-21; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E21-20; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E466-21; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM B26/B26M-18e1; Standard Specification for Aluminum-Alloy Sand Castings. ASTM International: West Conshohocken, PA, USA, 2018.

- Liu, F.-Z.; Qin, J.; Li, Z.; Yu, C.-B.; Zhu, X.; Nagaumi, H.; Zhang, B. Precipitation of Dispersoids in Al–Mg–Si Alloys with Cu Addition. J. Mater. Res. Technol. 2021, 14, 3134–3139. [Google Scholar] [CrossRef]

- Zandbergen, M.W.; Xu, Q.; Cerezo, A.; Smith, G.D.W. Study of Precipitation in Al–Mg–Si Alloys by Atom Probe Tomography I. Microstructural Changes as a Function of Ageing Temperature. Acta Mater. 2015, 101, 136–148. [Google Scholar] [CrossRef]

- Baruah, M.; Borah, A. Processing and Precipitation Strengthening of 6xxx Series Aluminium Alloys: A Review. Int. J. Mater. Sci. 2020, 1, 40–48. [Google Scholar] [CrossRef]

- Shah, A.W.; Ha, S.-H.; Yoon, Y.-O.; Kim, S.K. Heat Treatment of Al–Mg–Si–Mn Alloys with Varying Mg/Si Ratio. In Light Metals 2022; Springer: Cham, Switzerland, 2022; pp. 199–206. [Google Scholar]

- Asghar, G.; Peng, L.; Fu, P.; Yuan, L.; Liu, Y. Role of Mg2Si Precipitates Size in Determining the Ductility of A357 Cast Alloy. Mater. Des. 2020, 186, 108280. [Google Scholar] [CrossRef]

- Taylor, J.A. Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Chanyathunyaroj, K.; Patakham, U.; Kou, S.; Limmaneevichitr, C. Microstructural Evolution of Iron-Rich Intermetallic Compounds in Scandium Modified Al-7Si-0.3Mg Alloys. J. Alloys Compd. 2017, 692, 865–875. [Google Scholar] [CrossRef]

- Puncreobutr, C.; Phillion, A.B.; Fife, J.L.; Rockett, P.; Horsfield, A.P.; Lee, P.D. In Situ Quantification of the Nucleation and Growth of Fe-Rich Intermetallics during Al Alloy Solidification. Acta Mater. 2014, 79, 292–303. [Google Scholar] [CrossRef]

- Xu, S.; Khanlari, K.; Lin, B.; Fan, T.; Xia, S.; Achouri, I.E.; Zhang, W.; Jiang, Y. Effects of Fe-Addition as a Beneficial Modifying Element on the Microstructure and Mechanical Properties of an Al–Si–Cu–Mg–Ni–Mn Piston Alloy. Metallogr. Microstruct. Anal. 2023, 12, 401–412. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, D.; Wu, S.; Xie, S.; Wang, H.; Wang, M.; Zhang, W.; Sun, Z.; Ke, Y.; Wang, S.; et al. Influence of Fe-Rich Phases and Precipitates on the Mechanical Behaviour of Al-Cu-Mn-Fe-Sc-Zr Alloys Studied by Synchrotron X-Ray and Neutron. J. Mater. Sci. Technol. 2023, 158, 226–241. [Google Scholar] [CrossRef]

- Du, H.; Zhang, S.; Zhang, B.; Tao, X.; Yao, Z.; Belov, N.; van der Zwaag, S.; Liu, Z. Ca-Modified Al–Mg–Sc Alloy with High Strength at Elevated Temperatures Due to a Hierarchical Microstructure. J. Mater. Sci. 2021, 56, 16145–16157. [Google Scholar] [CrossRef]

- Li, J.; Zhao, K.; Ren, L.; Xie, K.; Li, D.; Liu, S.; Liu, X. Microstructure Evolution, Mechanical Properties, and Strengthening Mechanisms of Heat-Resistant Al-Based Composite Reinforced by a Combination of AlN and TiN Particles. J. Mater. Res. Technol. 2023, 24, 5628–5641. [Google Scholar] [CrossRef]

- Hatch, J.E. (Ed.) Aluminum: Properties and Physical Metallurgy; ASM International: Metals Park, OH, USA, 1984. [Google Scholar]

- Wang, B.B.; An, X.H.; Xue, P.; Liu, F.C.; Ni, D.R.; Xiao, B.L.; Liu, Y.D.; Ma, Z.Y. Grain Size Effects on High Cycle Fatigue Behaviors of Pure Aluminum. Int. J. Fatigue 2023, 170, 107556. [Google Scholar] [CrossRef]

- He, C.; Wei, J.; Li, Y.; Zhang, Z.; Tian, N.; Qin, G.; Zuo, L. Improvement of Microstructure and Fatigue Performance of Wire-Arc Additive Manufactured 4043 Aluminum Alloy Assisted by Interlayer Friction Stir Processing. J. Mater. Sci. Technol. 2023, 133, 183–194. [Google Scholar] [CrossRef]

- Sepe, R.; Giannella, V.; Razavi, N.; Berto, F. Characterization of Static, Fatigue and Fracture Behaviour of the Aluminium-Lithium Alloy Al-Li 2198-T851. Int. J. Fatigue 2023, 166, 107265. [Google Scholar] [CrossRef]

- Vysotskiy, I.; Malopheyev, S.; Rahimi, S.; Mironov, S.; Kaibyshev, R. Unusual Fatigue Behavior of Friction-Stir Welded Al–Mg–Si Alloy. Mater. Sci. Eng. A 2019, 760, 277–286. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, Y.; Gao, X.; Wu, Y.; Hutchinson, C. Training High-Strength Aluminum Alloys to Withstand Fatigue. Nat. Commun. 2020, 11, 5198. [Google Scholar] [CrossRef] [PubMed]

- Hagen, A.B.; Wenner, S.; Bjørge, R.; Wan, D.; Marioara, C.D.; Holmestad, R.; Ringdalen, I.G. Local Mechanical Properties and Precipitation Inhomogeneity in Large-Grained Al–Mg–Si Alloy. Mater. Sci. Eng. A 2023, 872, 144222. [Google Scholar] [CrossRef]

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | ||||

|---|---|---|---|---|---|---|

| A319 | HR0.8 | A319 | HR0.8 | A319 | HR0.8 | |

| R.T | 155 ± 6.9 | 286 ± 10.1 | 210 ± 15.1 | 306 ± 16.1 | 2 ± 0.4 | 17 ± 3.0 |

| 130 °C | 157 ± 5.1 | 280 ± 8.5 | 225 ± 12.5 | 285 ± 15.2 | 3 ± 0.7 | 19.5 ± 2.5 |

| 250 °C | 150 ± 2.8 | 277 ± 6.8 | 160 ± 13.5 | 277 ± 10.5 | 2 ± 0.4 | 20 ± 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.-S.; Shah, A.W.; Kim, J.-P.; Sung, S.-Y.; Lee, K.-A.; Jeon, M.-S. Fabrication, Microstructure, and High-Temperature Mechanical Properties of a Novel Al-Si-Mg Based Composite Reinforced with Cu-Mn Binary Phase and Submicron Dispersoid. Metals 2025, 15, 958. https://doi.org/10.3390/met15090958

Kim K-S, Shah AW, Kim J-P, Sung S-Y, Lee K-A, Jeon M-S. Fabrication, Microstructure, and High-Temperature Mechanical Properties of a Novel Al-Si-Mg Based Composite Reinforced with Cu-Mn Binary Phase and Submicron Dispersoid. Metals. 2025; 15(9):958. https://doi.org/10.3390/met15090958

Chicago/Turabian StyleKim, Kyu-Sik, Abdul Wahid Shah, Jin-Pyung Kim, Si-Young Sung, Kee-Ahn Lee, and Min-Su Jeon. 2025. "Fabrication, Microstructure, and High-Temperature Mechanical Properties of a Novel Al-Si-Mg Based Composite Reinforced with Cu-Mn Binary Phase and Submicron Dispersoid" Metals 15, no. 9: 958. https://doi.org/10.3390/met15090958

APA StyleKim, K.-S., Shah, A. W., Kim, J.-P., Sung, S.-Y., Lee, K.-A., & Jeon, M.-S. (2025). Fabrication, Microstructure, and High-Temperature Mechanical Properties of a Novel Al-Si-Mg Based Composite Reinforced with Cu-Mn Binary Phase and Submicron Dispersoid. Metals, 15(9), 958. https://doi.org/10.3390/met15090958