Thermal Characterisation of Hybrid Laser Welds Made of Conventionally and Additively Soft Martensitic Steel 1.4313

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

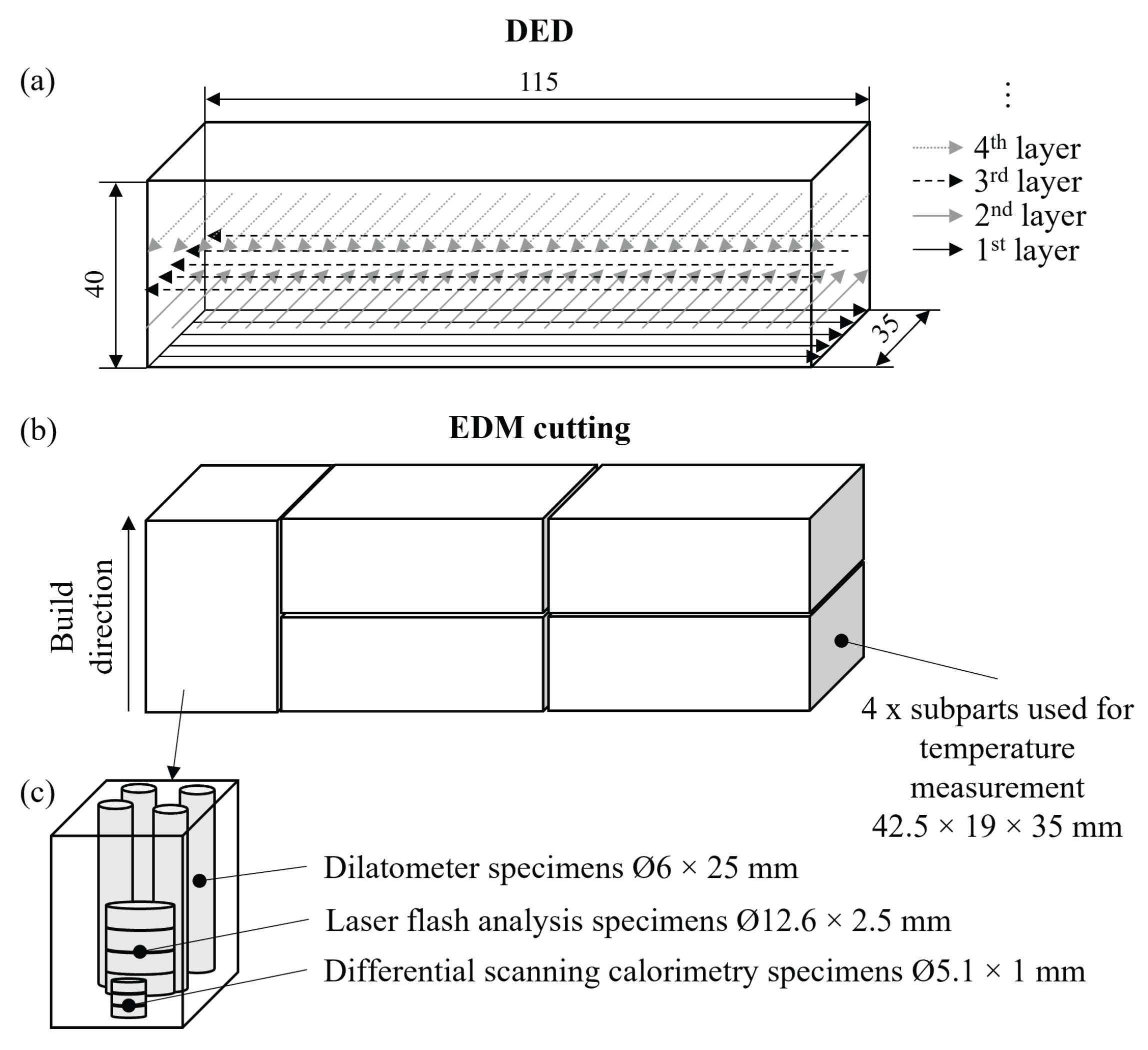

2.2. Sample Manufacturing

2.3. Material Properties

2.4. Microstructure

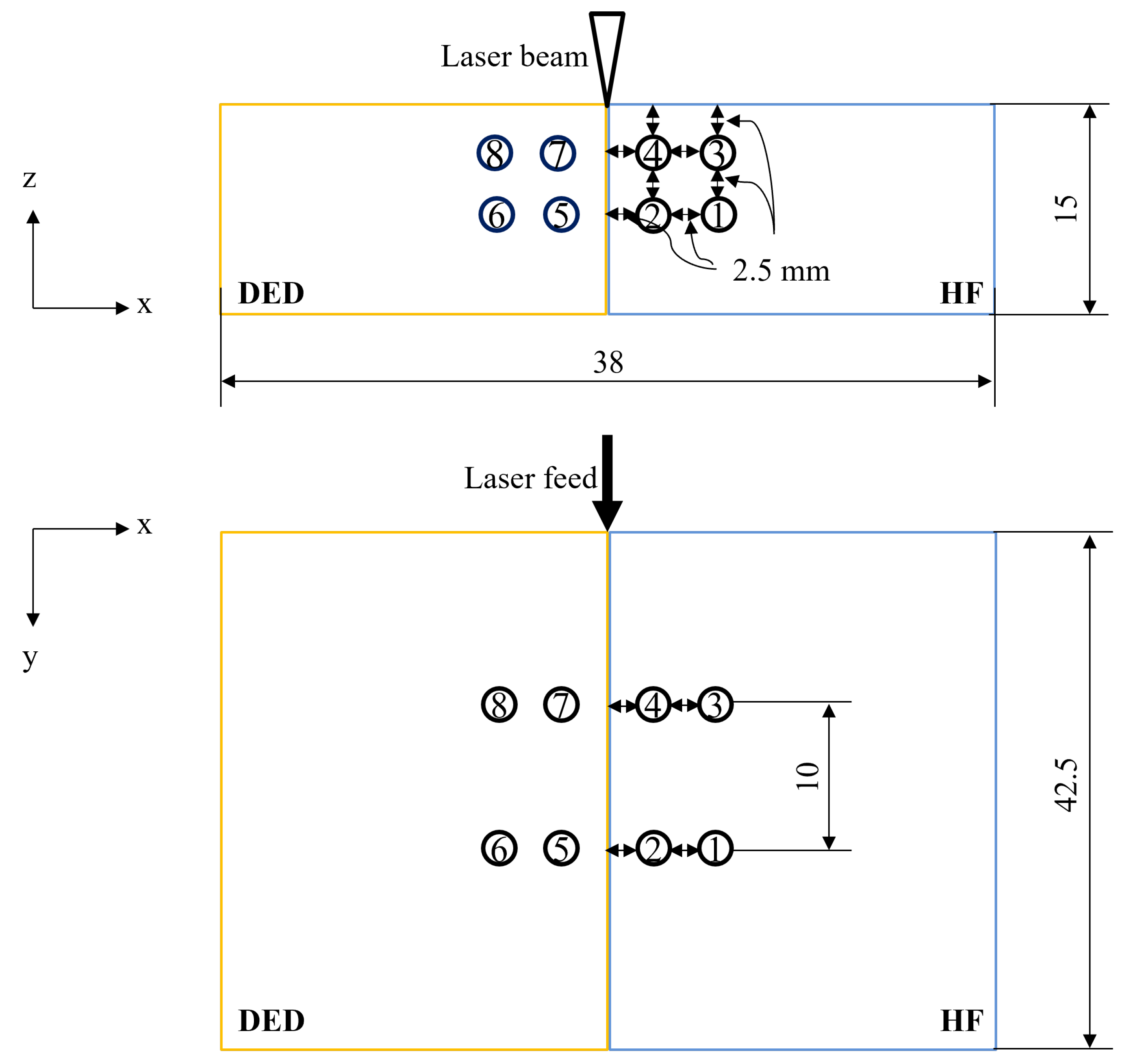

2.5. Experimental Approaches

3. Results

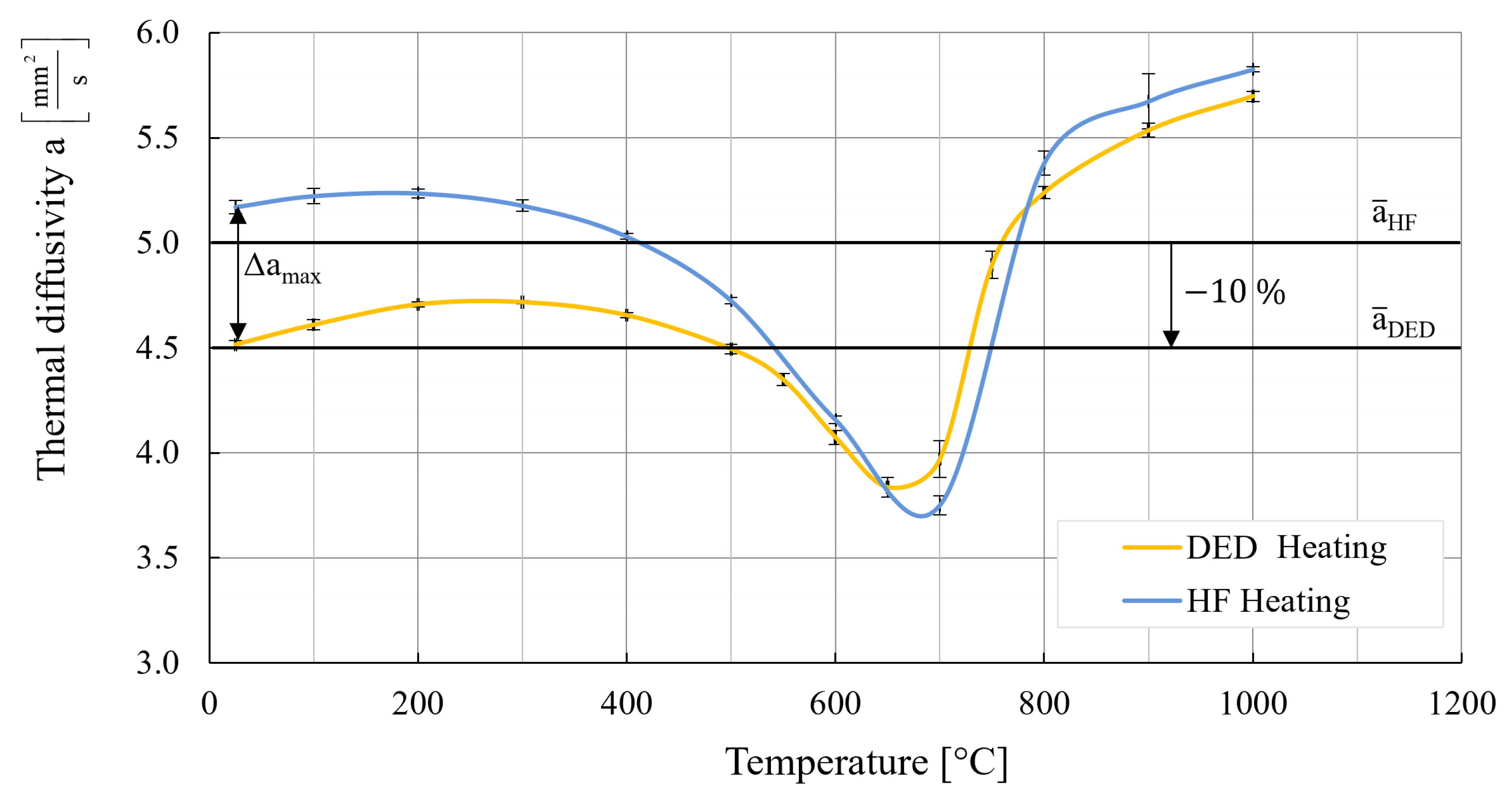

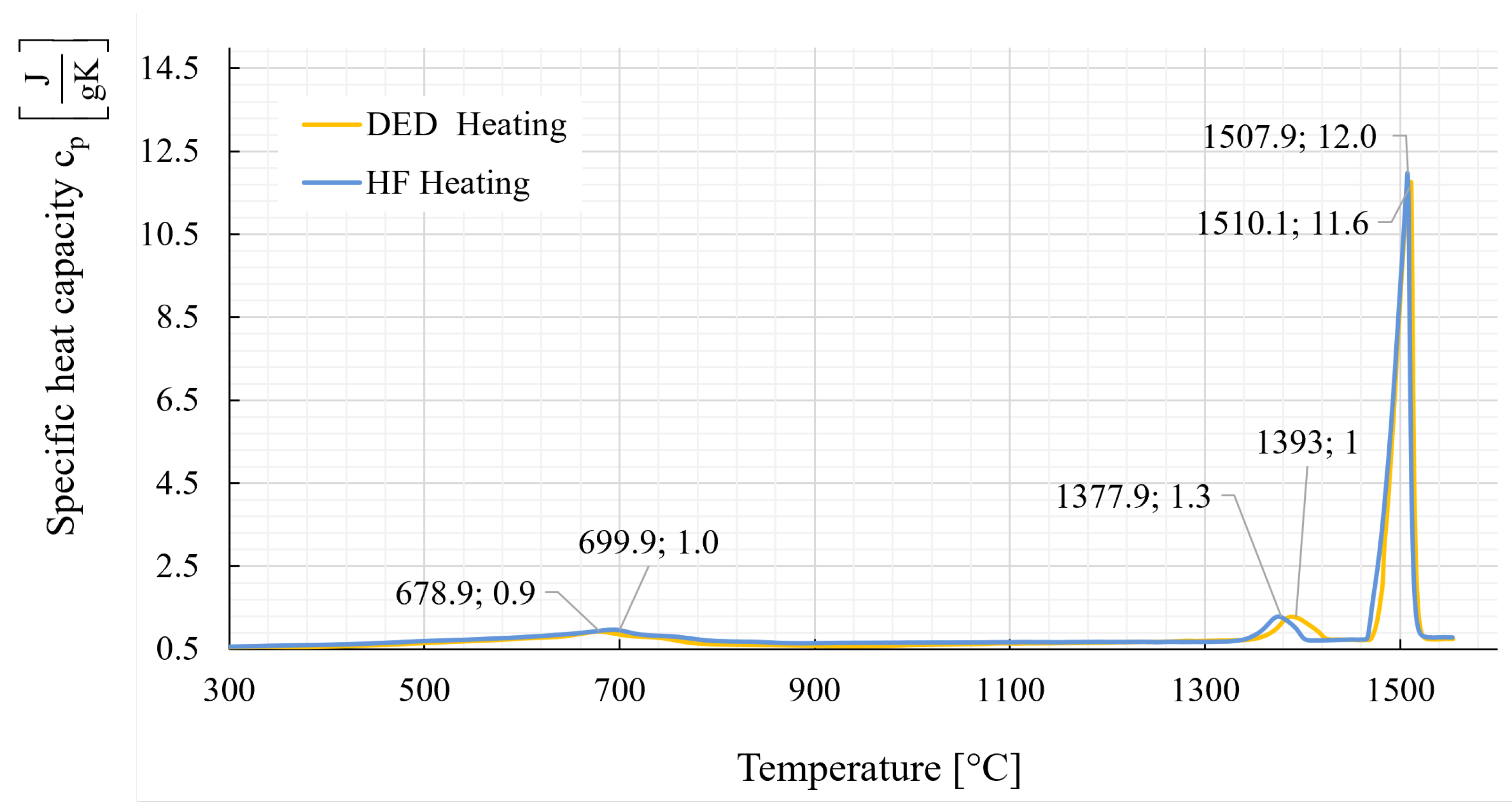

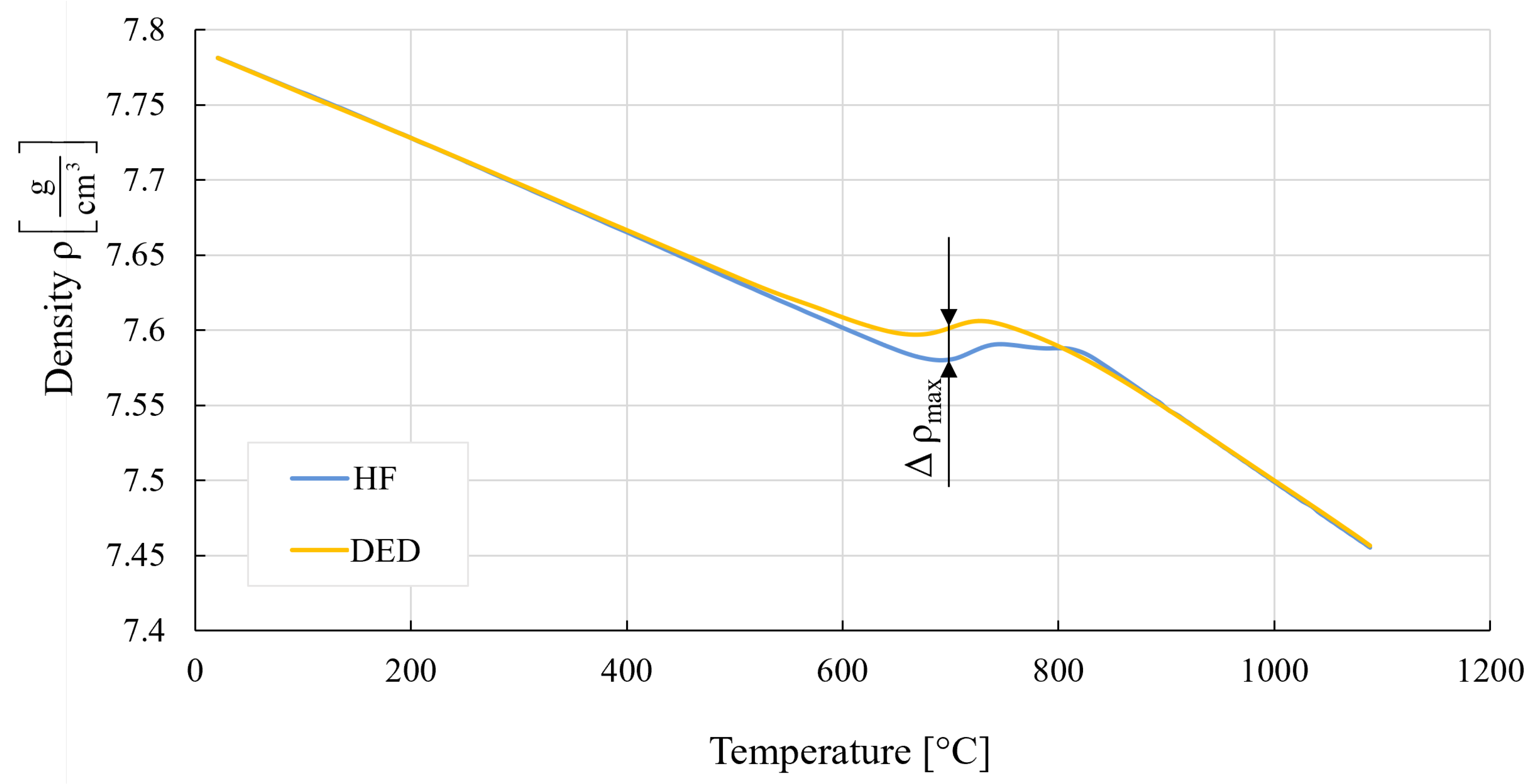

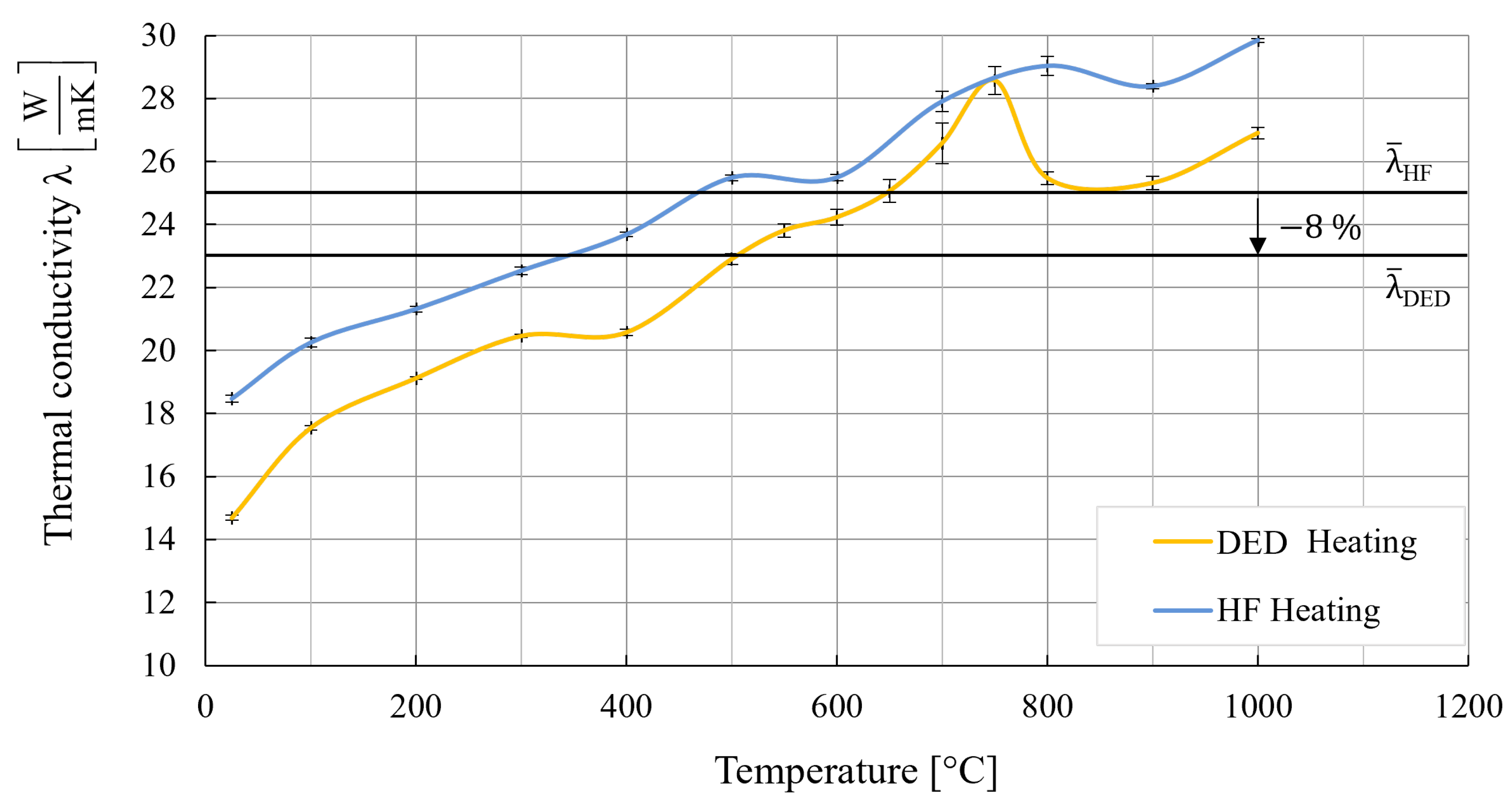

3.1. Material Properties

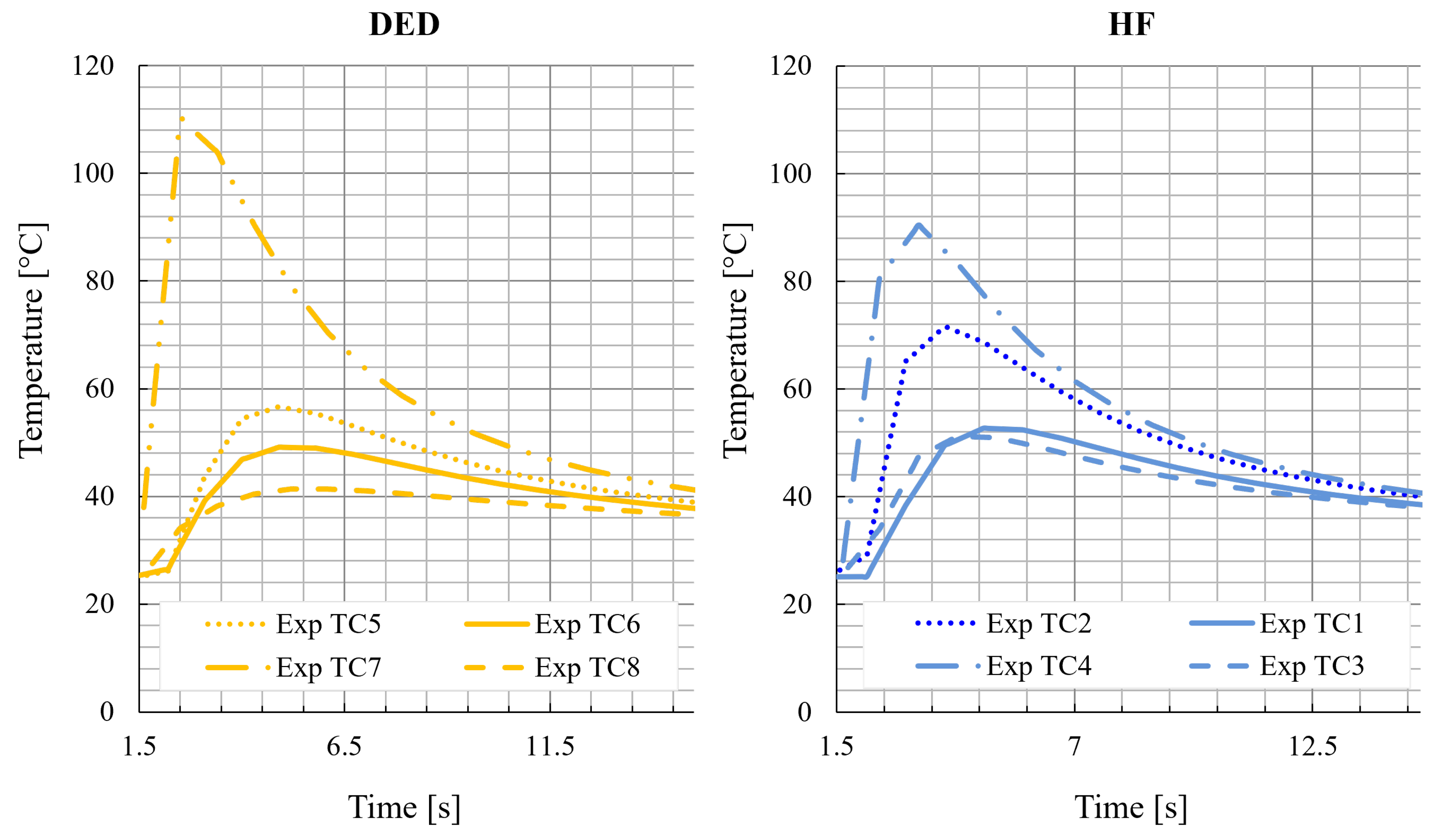

3.2. Temperature Measurements

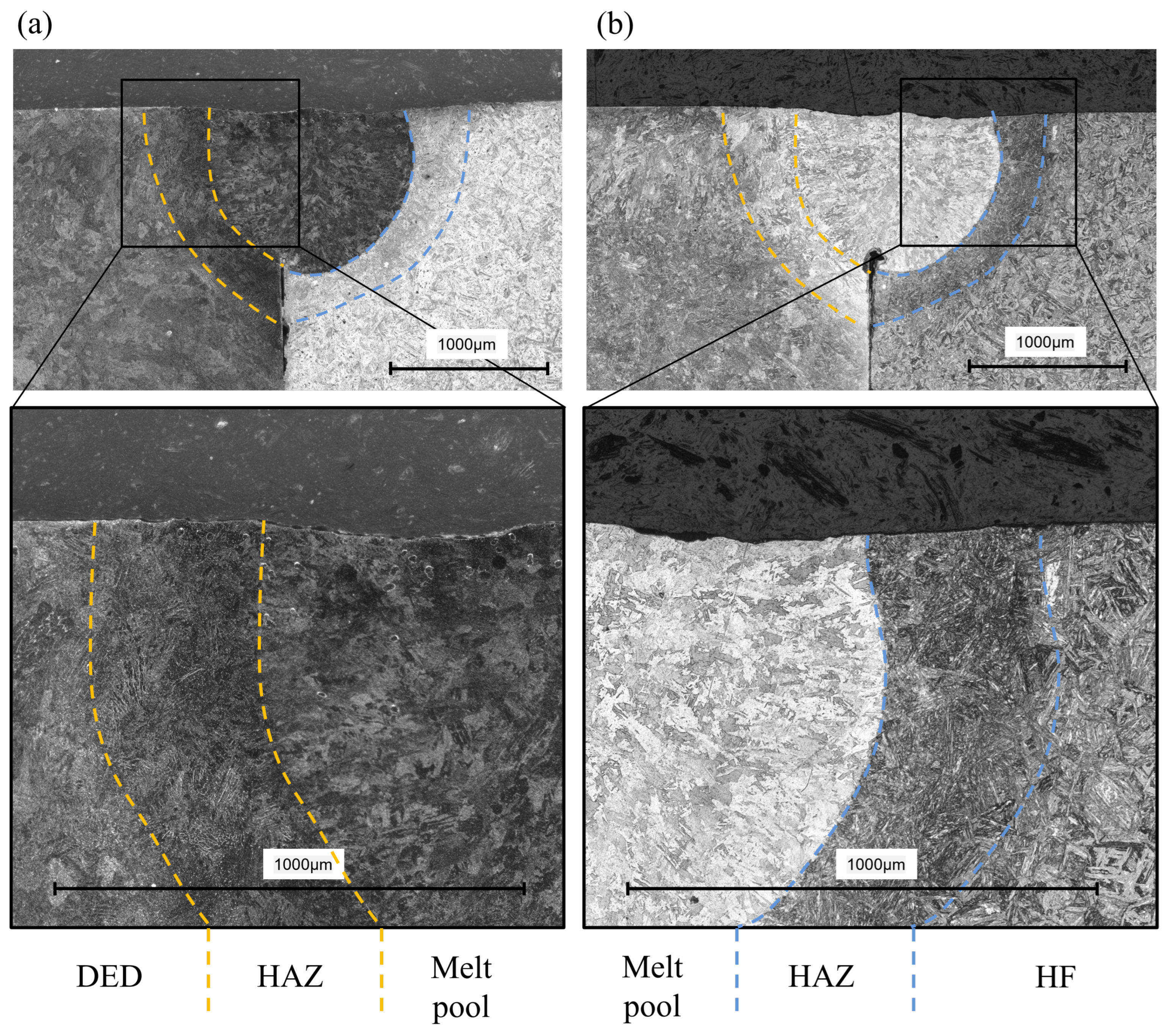

3.3. Microstructural Evolution

4. Discussion

5. Conclusions

- AM and CM materials can be successfully joined by welding, resulting in a geometrically symmetric weld bead.

- The mean thermal diffusivity of the DED samples is approximately 10% lower, and the mean thermal conductivity is approximately 8% lower than those of the HF specimens.

- The reason according to the literature for the lower thermal conductivity is a higher dislocation density, alloying elements that are not dissolved in a solid solution, and a lower rest austenite content that reduces the phononic contribution.

- The transition between the weld seam and the HF base material is clearly visible on the DED supart when using Kalling II and on the HF subpart using Adler. However, the HAZ on the DED side is not distinguishable from the base material because its microstructure is similar to that of the weld zone.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| CM | Conventional Manufacturing |

| DED | Direct Energy Deposition of Metals |

| EDM | Electric Discharge Machining |

| HAZ | Heat-Affected Zone |

| HF | Hot Forged |

References

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Microstructure and mechanical properties of AISI 316L produced by directed energy deposition-based additive manufacturing: A review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Liu, M.; Kumar, A.; Bukkapatnam, S.; Kuttolamadom, M. A review of the anomalies in directed energy deposition (DED) processes & potential solutions-Part quality & defects. Procedia Manuf. 2021, 53, 507–518. [Google Scholar]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Dey, I.; Floeder, R.; Kunze, K.; Roth, C.; Wegener, K. Mechanical properties and microstructure analysis of laser welded hybrid parts made of additively and conventionally manufactured 1.4313 soft martensitic steel. Mater. Des. 2025, 253, 113858. [Google Scholar] [CrossRef]

- Akbari, M.; Kovacevic, R. Joining of elements fabricated by a robotized laser/wire directed energy deposition process by using an autogenous laser welding. Int. J. Adv. Manuf. Technol. 2019, 100, 2971–2980. [Google Scholar] [CrossRef]

- Matilainen, V.P.; Pekkarinen, J.; Salminen, A. Weldability of additive manufactured stainless steel. Phys. Procedia 2016, 83, 808–817. [Google Scholar] [CrossRef]

- Wits, W.W.; Becker, J.J. Laser beam welding of titanium additive manufactured parts. Procedia CIRP 2015, 28, 70–75. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Y.; Li, F.; Huang, W.; Jing, G.; Wang, Z.; Zeng, X. Weldability, microstructure and mechanical properties of laser-welded selective laser melted 304 stainless steel joints. J. Mater. Sci. Technol. 2019, 35, 1817–1824. [Google Scholar] [CrossRef]

- Parchegani, S.; Piili, H.; Ganvir, A.; Salminen, A. Laser welding of additively manufactured parts—A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2023; Volume 1296, p. 012030. [Google Scholar]

- Brunner-Schwer, C.; Simón-Muzás, J.; Biegler, M.; Hilgenberg, K.; Rethmeier, M. Laser welding of L-PBF AM components out of Inconel 718. Procedia CIRP 2022, 111, 92–96. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Tavlovich, B.; Shirizly, A.; Katz, R. EBW and LBW of additive manufactured Ti6Al4V products. Weld J. 2018, 97, 179S–190S. [Google Scholar]

- Zapf, H.; Höfemann, M.; Emmelmann, C. Laser welding of additively manufactured medium manganese steel alloy with conventionally manufactured dual-phase steel. Procedia CIRP 2020, 94, 655–660. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Technol. 2013, 68, 209–216. [Google Scholar] [CrossRef]

- Oerlikon. Inspection Report of 1.4313 Powder; Technical Report; Oerlikon Metco (US) Inc.: Westbury, NY, USA, 2018. [Google Scholar]

- Freital. Inspection Report of 1.4313 Bar Steel Forged; Technical Report; BGH Edelstahl Freital GmbH: Freital, Germany, 1996. [Google Scholar]

- Bergman, T.L. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Kreith, F.; Bohn, M. Principles of Heat Transfer; West Publishing Company: St. Paul, MN, USA, 1993. [Google Scholar]

- Oettel, H.; Schumann, H. Metallografie: Mit einer Einführung in die Keramografie; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Folkhard, E.; Folkhard, E. Welding Metallurgy of Austenitic Stainless Steels; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Wilzer, J.; Küpferle, J.; Weber, S.; Theisen, W. Temperature-dependent thermal conductivities of non-alloyed and high-alloyed heat-treatable steels in the temperature range between 20 and 500 °C. J. Mater. Sci. 2014, 49, 4833–4843. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wavelength | 1.064 μm |

| Laser Power | 1000 W |

| Feed | 320 mm/min |

| Hatch distance | 1.05 mm |

| Spot diameter | 2.1 mm |

| Layer height | 1.7 mm |

| Powder feed rate | 5 g/min |

| Shielding gas | 15 L/min |

| Carrier gas | 4 L/min |

| Line energy | 187.5 J/mm |

| Cr | Ni | Mn | Mo | Si | O | N | C | S | P | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Powder | 13.07 | 4.01 | 0.53 | 0.49 | <0.7 | 0.028 | 0.02 | 0.31 | 0.003 | 0.003 | Bal |

| Hot forged | 12.7 | 3.65 | 0.85 | 0.48 | 0.34 | - | - | 0.024 | 0.008 | 0.020 | Bal |

| Parameter | Value |

|---|---|

| Wavelength | |

| Laser Power | 1000 W |

| Feed | 1500 mm/min |

| Spot diameter | mm |

| DED | [°C] | R [°C/s] | HF | [°C] | R [°C/s] |

|---|---|---|---|---|---|

| TC5 | 56.6 | 12 | TC2 | 71.6 | 18 |

| TC6 | 49.2 | 10 | TC1 | 52.7 | 11 |

| TC7 | 110.2 | 44 | TC4 | 90.5 | 27 |

| TC8 | 41.3 | 8 | TC3 | 51.3 | 12 |

| 64.33 (−3%) | 18.4 (+8%) | 66.51 | 16.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dey, I.; Mayer, T.; Egli, B.; Klingler, D.; Wegener, K. Thermal Characterisation of Hybrid Laser Welds Made of Conventionally and Additively Soft Martensitic Steel 1.4313. Metals 2025, 15, 950. https://doi.org/10.3390/met15090950

Dey I, Mayer T, Egli B, Klingler D, Wegener K. Thermal Characterisation of Hybrid Laser Welds Made of Conventionally and Additively Soft Martensitic Steel 1.4313. Metals. 2025; 15(9):950. https://doi.org/10.3390/met15090950

Chicago/Turabian StyleDey, Indira, Thomas Mayer, Bianca Egli, Damian Klingler, and Konrad Wegener. 2025. "Thermal Characterisation of Hybrid Laser Welds Made of Conventionally and Additively Soft Martensitic Steel 1.4313" Metals 15, no. 9: 950. https://doi.org/10.3390/met15090950

APA StyleDey, I., Mayer, T., Egli, B., Klingler, D., & Wegener, K. (2025). Thermal Characterisation of Hybrid Laser Welds Made of Conventionally and Additively Soft Martensitic Steel 1.4313. Metals, 15(9), 950. https://doi.org/10.3390/met15090950