High-Temperature Mechanical Properties and the Portevin–Le Chatelier Effect for Wire Arc Additively Manufactured Inconel 718 Superalloy

Abstract

1. Introduction

2. Experimental Methodology

2.1. Wire and Arc Additive Manufacturing Process

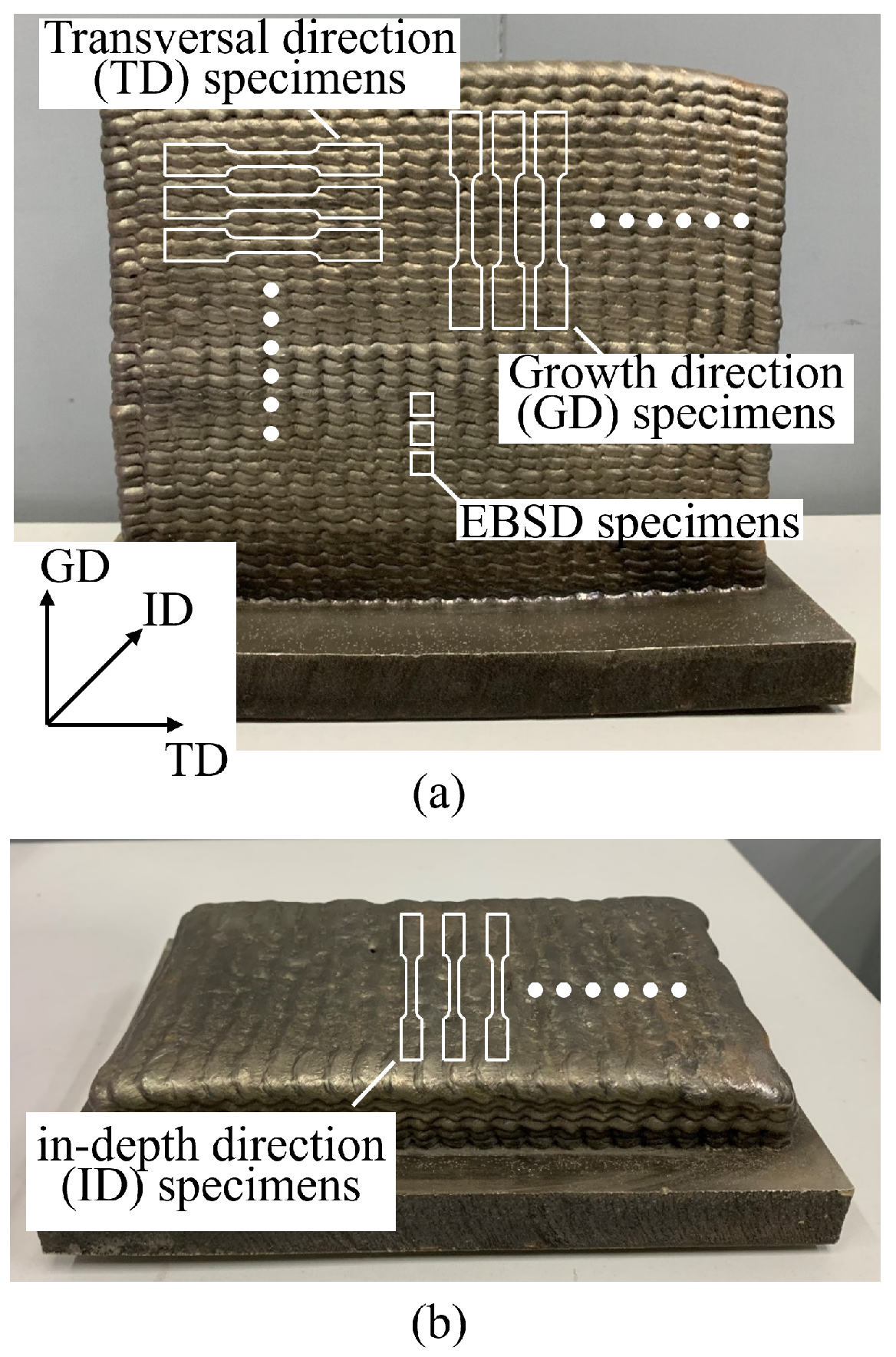

2.2. Methods for Microstructural Characterization and Mechanical Testing

3. Experiment Results

3.1. Microstructure

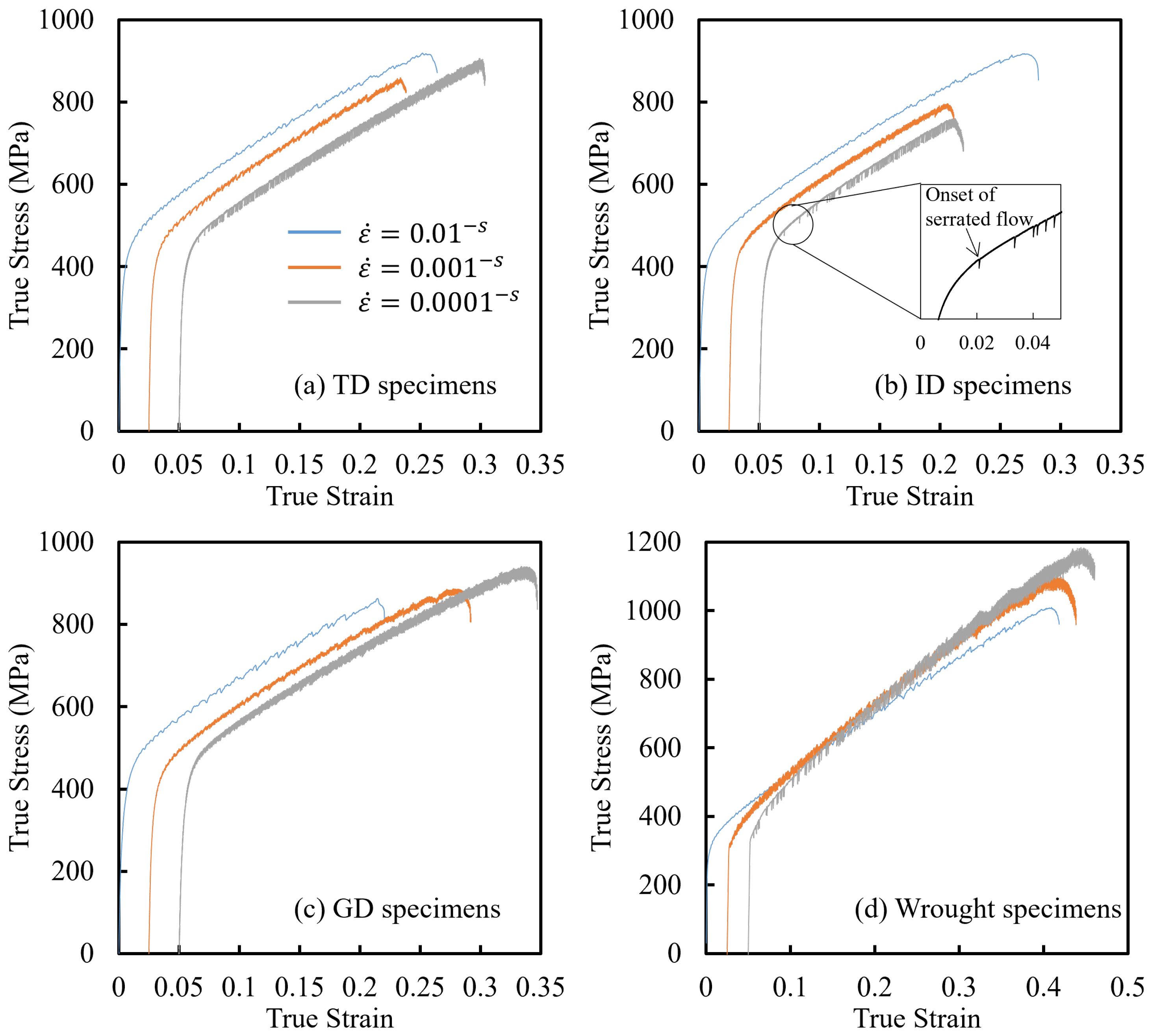

3.2. Mechanical Properties

4. Portevin–Le Chatelier Effect

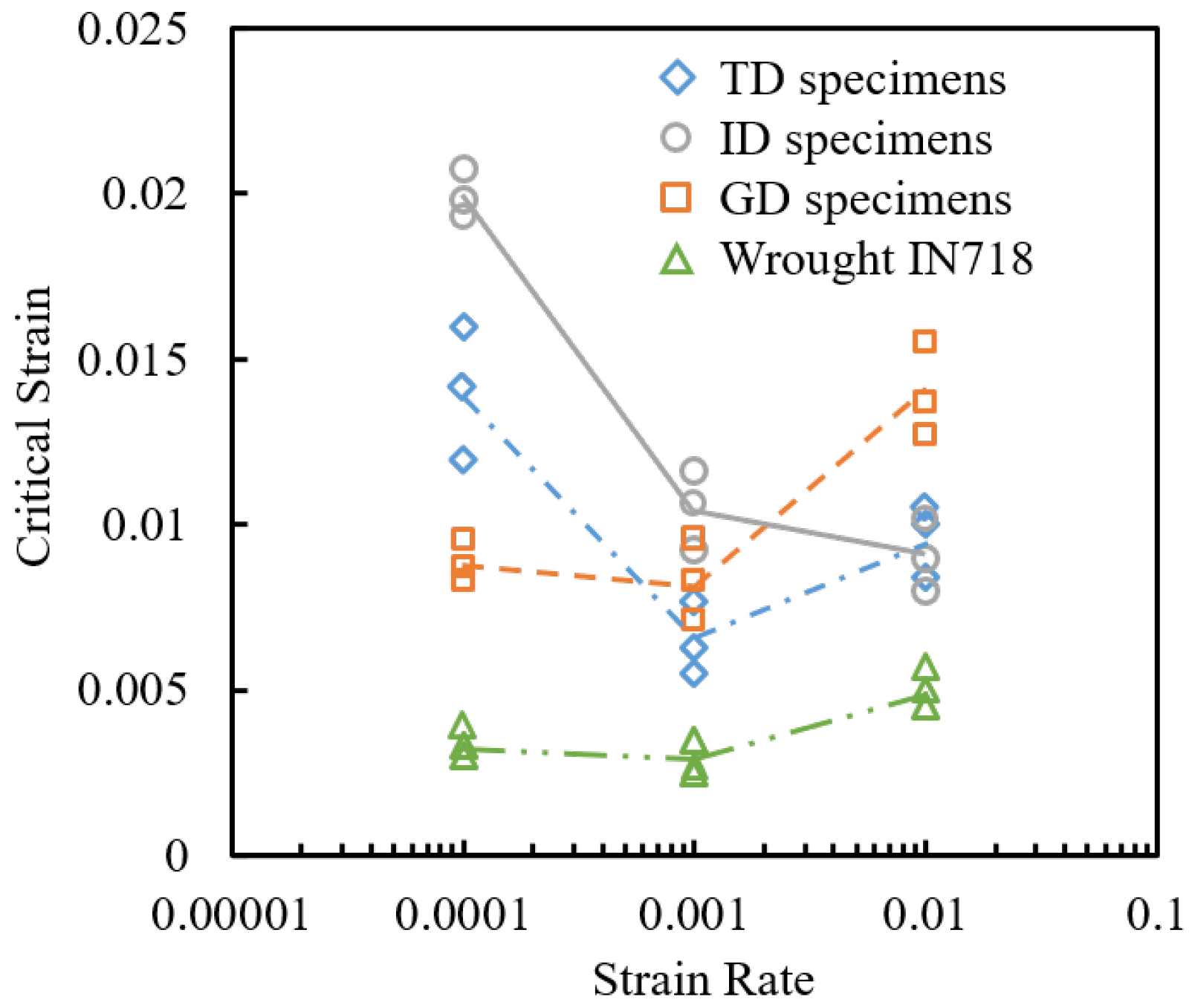

4.1. Critical Strain of PLC Onset

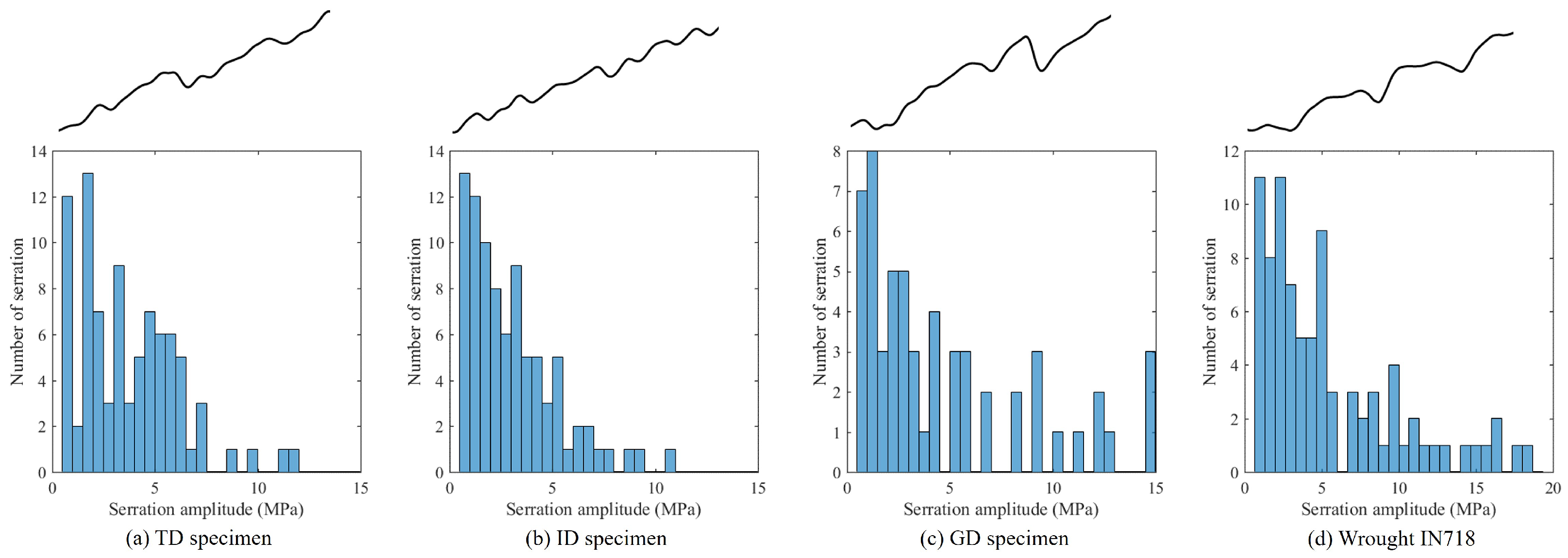

4.2. Statistics of Stress Drops

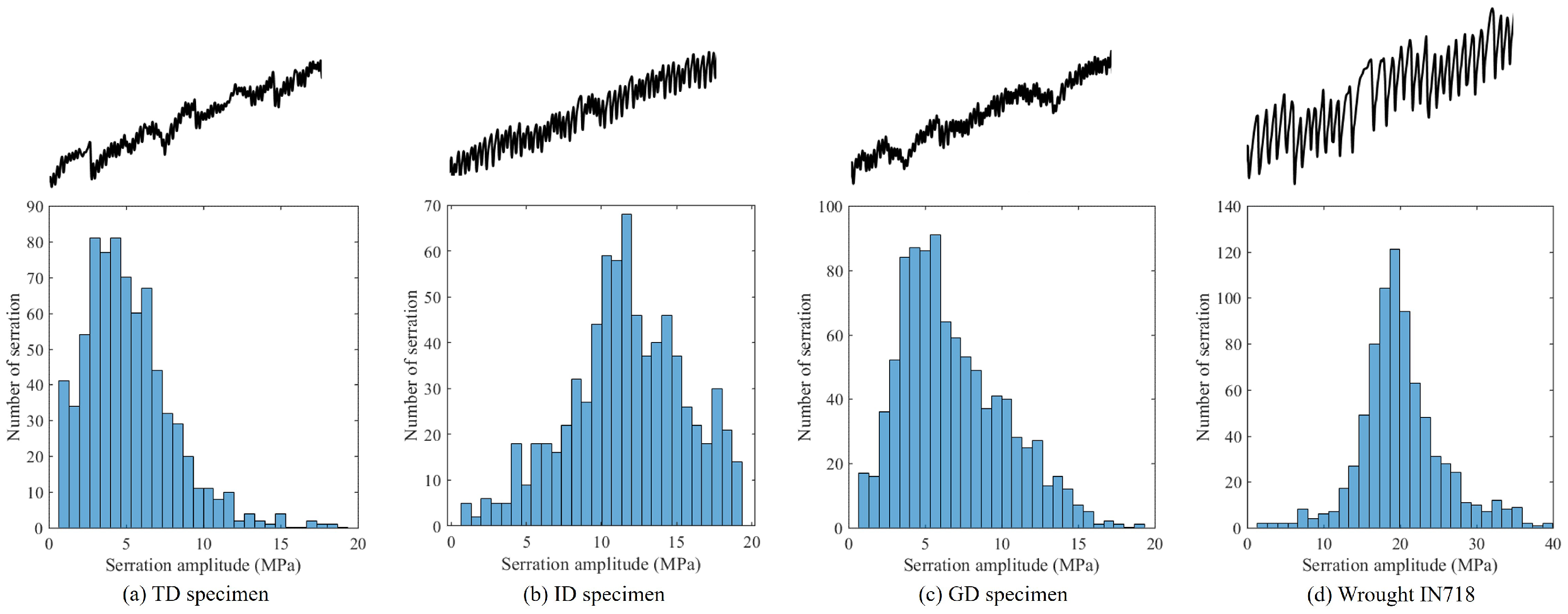

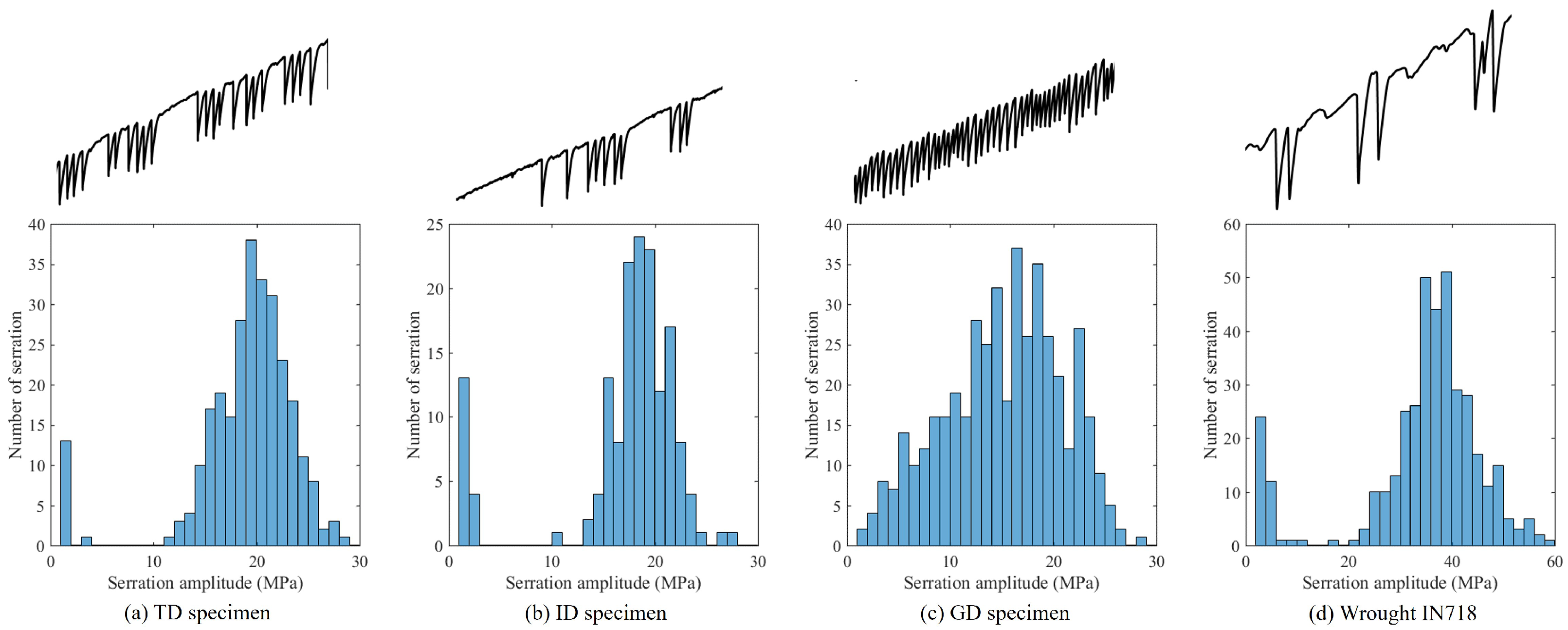

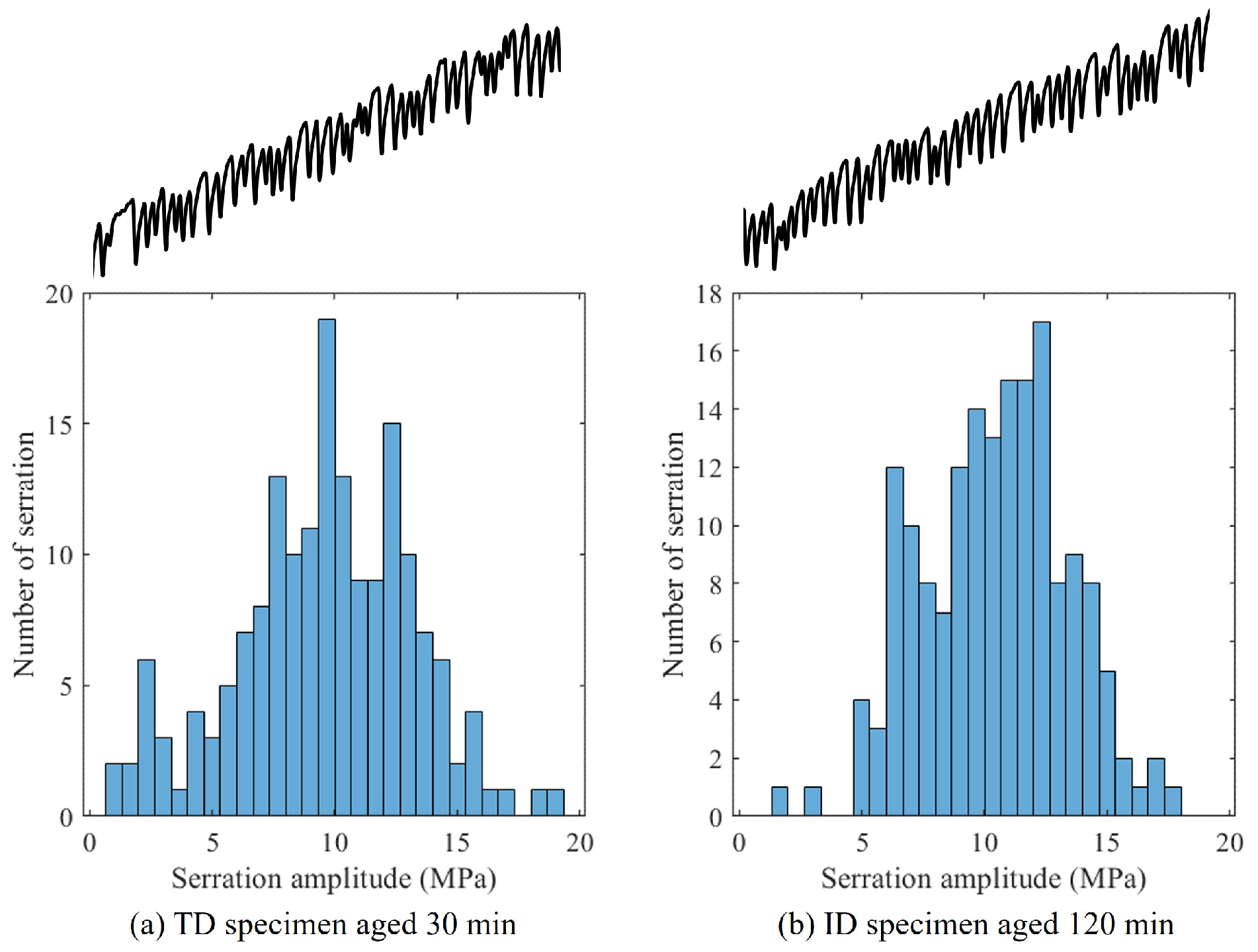

5. Discussion

5.1. Factors Influencing PLC Effect

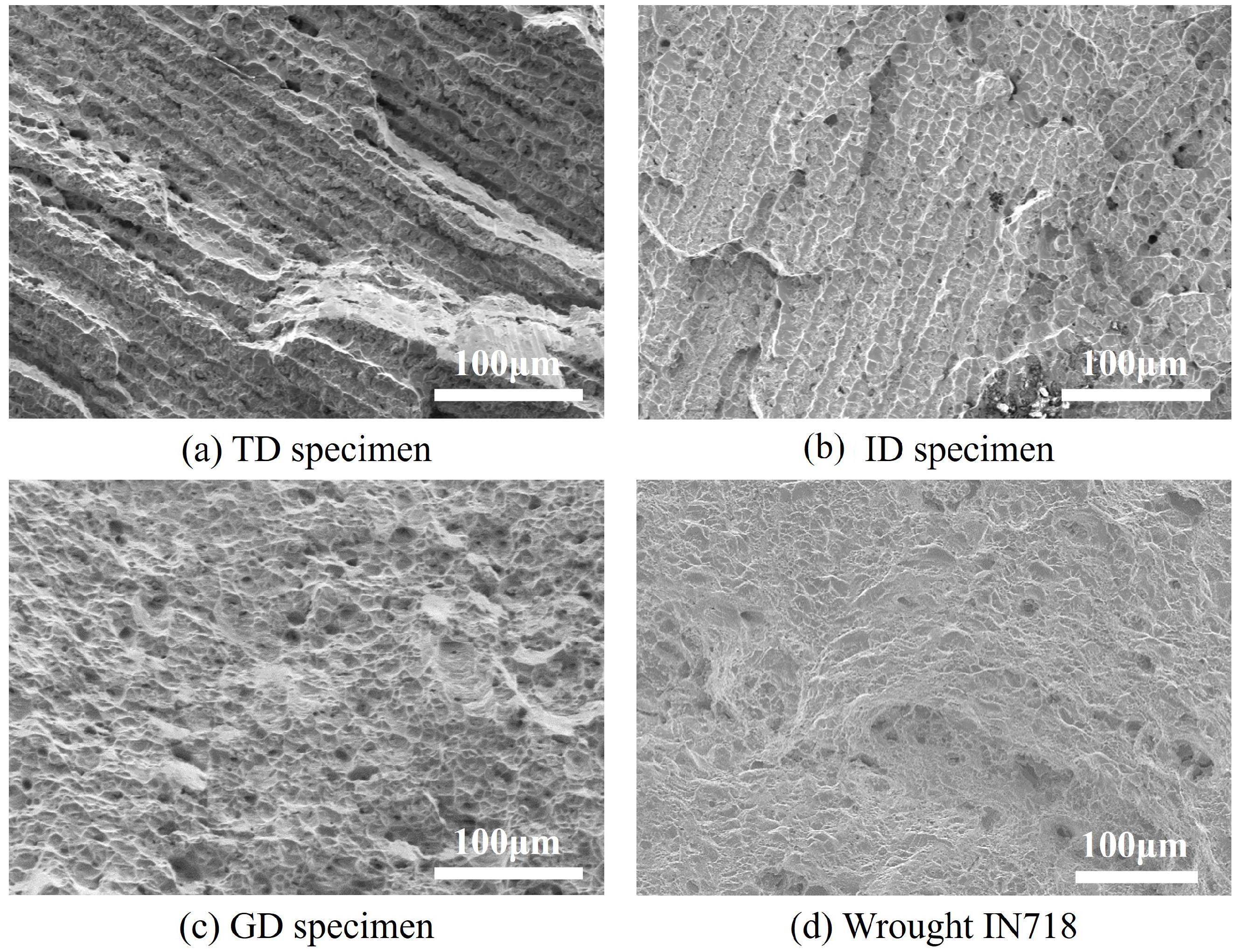

5.2. Fracture Morphology

6. Conclusions

- The EBSD characterization results revealed significant growth anisotropy in the WAAM-fabricated IN718 alloy, characterized by a columnar grain structure.

- The yield strength of the WAAM-fabricated IN718 alloy consistently exceeded that of the wrought IN718 alloy, while the elastic modulus and elongation to failure were generally lower. Additionally, the WAAM-fabricated IN718 alloy exhibited negative strain rate sensitivity.

- The critical strain values for the PLC effect in the WAAM-fabricated IN718 alloy were generally lower than those observed in wrought IN718 alloy. Furthermore, the critical strain values of the WAAM samples varied with strain rate in different directions.

- As the strain rate decreases, both WAAM and deformed IN718 alloys exhibit a transition from type A to type B and then to type C PLC serrations. Considering the behavior of serration vibrations and the trend of critical strain values, the strain rate corresponding to the same PLC behavior is highest for the in-depth (ID) specimen, lowest for the growth direction (GD) specimen, and intermediate for the transverse direction (TD) specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahobia, G.S.; Paulose, N.; Mannan, S.L.; Sudhakar, R.G.; Chattopadhyay, K.; Srinivas, N.S.; Singh, V. Effect of hot corrosion on low cycle fatigue behavior of superalloy IN718. Int. J. Fatigue 2014, 59, 272–281. [Google Scholar] [CrossRef]

- Zhang, S.H.; Zhang, H.Y.; Cheng, M. Tensile deformation and fracture characteristics of delta-processed Inconel 718 alloy at elevated temperature. Mater. Sci. Eng. A 2011, 528, 6253–6258. [Google Scholar] [CrossRef]

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Song, R.H.; Qin, H.L.; Li, D.F.; Bi, Z.N.; Busso, E.P.; Yu, H.Y.; Liu, X.L.; Du, J.H.; Zhang, J. An Experimental and Numerical Study of Quenching-Induced Residual Stresses Under the Effect of Dynamic Strain Aging in an IN718 Superalloy Disc. J. Eng. Mater. Technol. 2022, 144, 011002. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. Int. Sch. Res. Not. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Dye, D.; Hunziker, O.; Reed, R.C. Numerical analysis of the weldability of superalloys. Acta Mater. 2001, 49, 683–697. [Google Scholar] [CrossRef]

- Benz, M.G. Preparation of clean superalloys. Mater. Eng. 1999, 15, 31–48. [Google Scholar]

- Jinhui, D.; Xudong, L.; Qun, D.; Ying, L. Effect of solution treatment on the microstructure and mechanical properties of IN718 alloy. Rare Met. Mater. Eng. 2017, 46, 2359–2365. [Google Scholar] [CrossRef]

- Yuan, G.J.; Chen, H.; Li, D.F.; Gong, C.Y.; Zhang, X.C.; Tu, S.T. The effect of δ phase on the microplasticity evolution of a heat-treated nickel base superalloy. Mech. Mater. 2020, 148, 103520. [Google Scholar] [CrossRef]

- Zhang, F.; Cao, W.; Zhang, C.; Chen, S.; Zhu, J.; Lv, D. Simulation of Co-precipitation Kinetics of γ′ and γ′′ in Superalloy 718. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications, Pittsburgh, PA, USA, 3–6 June 2018; Springer: Cham, Switzerland, 2018; pp. 147–161. [Google Scholar]

- Qin, H.; Bi, Z.; Yu, H.; Feng, G.; Zhang, R.; Guo, X.; Chi, H.; Du, J.; Zhang, J. Assessment of the stress-oriented precipitation hardening designed by interior residual stress during ageing in IN718 superalloy. Mater. Sci. Eng. A 2018, 728, 183–195. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Raghavan, N.; Dehoff, R.; Pannala, S.; Simunovic, S.; Kirka, M.; Turner, J.; Carlson, N.; Babu, S.S. Numerical modeling of heat-transfer and the influence of process parameters on tailoring the grain morphology of IN718 in electron beam additive manufacturing. Acta Mater. 2016, 112, 303–314. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Ajith, J.; Fahmidha, A.F.Y.; Jagadeesha, T.; Sathish, T.; Stalin, B. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys—A review. Mater. Today Proc. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Xu, X.; Ganguly, S.; Ding, J.; Seow, C.E.; Williams, S. Enhancing mechanical properties of wire+ arc additively manufactured INCONEL 718 superalloy through in-process thermomechanical processing. Mater. Des. 2018, 160, 1042–1051. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Srivastava, S.; Garg, R.K.; Sharma, V.S.; Sachdeva, A. Measurement and Mitigation of Residual Stress in Wire-Arc Additive Manufacturing: A Review of Macro-Scale Continuum Modelling Approach. Arch. Comput. Methods Eng. 2020, 28, 1–25. [Google Scholar] [CrossRef]

- Lan, B.; Wang, Y.; Liu, Y.; Hooper, P.; Hopper, C.; Zhang, G.; Zhang, X.; Jiang, J. The influence of microstructural anisotropy on the hot deformation of wire arc additive manufactured (WAAM) Inconel 718. Mater. Sci. Eng. A 2021, 823, 141733. [Google Scholar] [CrossRef]

- Xu, X.; Ding, J.; Ganguly, S.; Williams, S. Investigation of process factors affecting mechanical properties of INCONEL 718 superalloy in wire+ arc additive manufacture process. J. Mater. Process. Technol. 2019, 265, 201–209. [Google Scholar] [CrossRef]

- Bhujangrao, T.; Veiga, F.; Suárez, A.; Iriondo, E.; Mata, F.G. High-Temperature Mechanical Properties of IN718 Alloy: Comparison of Additive Manufactured and Wrought Samples. Crystals 2020, 10, 689. [Google Scholar] [CrossRef]

- Chen, Z.; Soh, G.S. Microstructure and mechanical properties of Wire Arc Additive Manufactured (WAAM) Inconel 718 parts via post heat treatments. Mater. Today Proc. 2022, 70, 567–573. [Google Scholar] [CrossRef]

- Seow, C.E.; Coules, H.E.; Wu, G.; Khan, R.H.; Xu, X.; Williams, S. Wire+ Arc Additively Manufactured Inconel 718: Effect of post-deposition heat treatments on microstructure and tensile properties. Mater. Des. 2019, 183, 108157. [Google Scholar] [CrossRef]

- Kindermann, R.M.; Roy, M.J.; Morana, R.; Francis, J.A. Effects of microstructural heterogeneity and structural defects on the mechanical behaviour of wire+ arc additively manufactured Inconel 718 components. Mater. Sci. Eng. A 2022, 839, 142826. [Google Scholar] [CrossRef]

- Alonso, U.; Veiga, F.; Suárez, A.; Del Val, A.G. Characterization of Inconel 718 superalloy fabricated by wire Arc Additive Manufacturing: Effect on mechanical properties and machinability. J. Mater. Res. Technol. 2021, 14, 2665–2676. [Google Scholar] [CrossRef]

- Sun, L.; Jiang, F.; Huang, R.; Yuan, D.; Guo, C.; Wang, J. Anisotropic mechanical properties and deformation behavior of low-carbon high-strength steel component fabricated by wire and arc additive manufacturing. Mater. Sci. Eng. A 2020, 787, 139514. [Google Scholar] [CrossRef]

- Hassel, T.; Carstensen, T. Properties and anisotropy behaviour of a nickel base alloy material produced by robot-based wire and arc additive manufacturing. Weld. World 2020, 64, 1921–1931. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Kortabarria, A.; Madariaga, A.; Esnaola, J.A.; Fernandez, E.; Cappellini, C.; Ulutan, D.; Özel, T. On the machining induced residual stresses in IN718 nickel-based alloy: Experiments and predictions with finite element simulation. Simul. Model. Pract. Theory 2014, 41, 87–103. [Google Scholar] [CrossRef]

- Hönnige, J.; Seow, C.E.; Ganguly, S.; Xu, X.; Cabeza, S.; Coules, H.; Williams, S. Study of residual stress and microstructural evolution in as-deposited and inter-pass rolled Wire plus Arc Additively Manufactured Inconel 718 alloy after ageing treatment. Mater. Sci. Eng. A 2020, 801, 140368. [Google Scholar] [CrossRef]

- Shen, C.; Reid, M.; Liss, K.D.; Pan, Z.; Ma, Y.; Cuiuri, D.; Van Duin, S.; Li, H. Neutron diffraction residual stress determinations in Fe3Al based iron aluminide components fabricated using wire-arc additive manufacturing (WAAM). Addit. Manuf. 2019, 29, 100774. [Google Scholar] [CrossRef]

- Wang, Z.; Denlinger, E.; Michaleris, P.; Stoica, A.D.; Ma, D.; Beese, A.M. Residual stress mapping in Inconel 625 fabricated through additive manufacturing: Method for neutron diffraction measurements to validate thermomechanical model predictions. Mater. Des. 2017, 113, 169–177. [Google Scholar] [CrossRef]

- Vikram, R.J.; Singh, A.; Suwas, S. Effect of heat treatment on the modification of microstructure of selective laser melted (SLM) IN718 and its consequences on mechanical behavior. J. Mater. Res. 2020, 35, 1949–1962. [Google Scholar] [CrossRef]

- Zhao, J.R.; Hung, F.Y.; Lui, T.S. Microstructure and tensile fracture behavior of three-stage heat treated inconel 718 alloy produced via laser powder bed fusion process. J. Mater. Res. Technol. 2020, 9, 3357–3367. [Google Scholar] [CrossRef]

- Sui, S.; Tan, H.; Chen, J.; Zhong, C.; Li, Z.; Fan, W.; Gasser, A.; Huang, W. The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing. Acta Mater. 2019, 164, 413–427. [Google Scholar] [CrossRef]

- Xi, N.; Fang, X.; Duan, Y.; Zhang, Q.; Huang, K. Wire arc additive manufacturing of Inconel 718: Constitutive modelling and its microstructure basis. J. Manuf. Process. 2022, 75, 1134–1143. [Google Scholar] [CrossRef]

- Song, R.H.; Qin, H.L.; Bi, Z.N.; Zhang, J.; Chi, H.; Busso, E.P.; Li, D.F. Experimental and numerical investigations of dynamic strain ageing behaviour in solid solution treated Inconel 718 superalloy. Eng. Comput. 2020, 38, 19–35. [Google Scholar] [CrossRef]

- Ren, S.C.; Morgeneyer, T.F.; Mazière, M.; Forest, S.; Rousselier, G. Effect of Lüders and Portevin-Le Chatelier localization bands on plasticity and fracture of notched steel specimens studied by DIC and FE simulations. Int. J. Plast. 2020, 136, 102880. [Google Scholar] [CrossRef]

- Marais, A.; Maziére, M.; Forest, S.; Parrot, A.; Le Delliou, P. Identification of a strain-aging model accounting for Lüders behavior in a C-Mn steel. Philos. Mag. 2012, 92, 3589–3617. [Google Scholar] [CrossRef]

- McCormigk, P.G. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Chihab, K.; Fressengeas, C. Time distribution of stress drops, critical strain and crossover in the dynamics of jerky flow. Mater. Sci. Eng. A 2003, 356, 102–107. [Google Scholar] [CrossRef]

- Lebyodkin, M.; Dunin-Barkowskii, L.; Brechet, Y.; Estrin, Y.; Kubin, L.P. Spatio-temporal dynamics of the Portevin–Le Chatelier effect: Experiment and modelling. Acta Mater. 2000, 48, 2529–2541. [Google Scholar] [CrossRef]

- Lebedkina, T.A.; Lebyodkin, M.A. Effect of deformation geometry on the intermittent plastic flow associated with the Portevin–Le Chatelier effect. Acta Mater. 2008, 56, 5567–5574. [Google Scholar] [CrossRef]

- Cheng, X.M.; Morris, J.G. The anisotropy of the portevin-le chatelier effect in aluminum alloys. Scr. Mater. 2000, 43, 651–658. [Google Scholar] [CrossRef]

- Mizera, J.; Kurzydlowski, K.J. On the anisotropy of the Portevin–Le Chatelier plastic instabilities in Al–Li–Cu–Zr alloy. Scr. Mater. 2001, 45, 801–806. [Google Scholar] [CrossRef]

- Cruzado, A.; Lucarini, S.; LLorca, J.; Segurado, J. Crystal plasticity simulation of the effect of grain size on the fatigue behavior of polycrystalline Inconel 718. Int. J. Fatigue 2018, 113, 236–245. [Google Scholar] [CrossRef]

- Laskowski, R.; Wang, K.; Ahluwalia, R.; Bai, K.; Vastola, G.; Zhang, Y.W. Phase field model for multiphase alloys under arbitrary thermal history: An application to IN718 super-alloy. J. Alloys Compd. 2021, 861, 158630. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Some aspects of the precipitation of metastable intermetallic phases in Inconel 718. Metall. Trans. A 1992, 23, 2015–2028. [Google Scholar] [CrossRef]

- Venkadesan, S.; Phaniraj, C.; Sivaprasad, P.V.; Rodriguez, P. Activation energy for serrated flow in a 15Cr-5Ni Ti-modified austenitic stainless steel. Acta Metall. Mater. 1992, 40, 569–580. [Google Scholar] [CrossRef]

- Zhou, H.; Fang, J.; Chen, Y.; Yang, L.; Zhang, H.; Lu, Y.; He, Y. Internal friction studies on dynamic strain aging in P91 ferritic steel. Mater. Sci. Eng. A 2016, 676, 361–365. [Google Scholar] [CrossRef]

- Fu, S.; Cheng, T.; Zhang, Q.; Hu, Q.; Cao, P. Two mechanisms for the normal and inverse behaviors of the critical strain for the Portevin–Le Chatelier effect. Acta Mater. 2012, 60, 6650–6656. [Google Scholar] [CrossRef]

- Mazière, M.; Dierke, H. Investigations on the Portevin Le Chatelier critical strain in an aluminum alloy. Comput. Mater. Sci. 2012, 52, 68–72. [Google Scholar] [CrossRef]

- Lebyodkin, M.A.; Estrin, Y. Multifractal analysis of the Portevin–Le Chatelier effect: General approach and application to AlMg and AlMg/Al2O3 alloys. Acta Mater. 2005, 53, 3403–3413. [Google Scholar] [CrossRef]

- Maj, P.; Zdunek, J.; Gizynski, M.; Mizera, J.; Kurzydlowski, K.J. Statistical analysis of the Portevin–Le Chatelier effect in Inconel 718 at high temperature. Mater. Sci. Eng. A 2014, 619, 158–164. [Google Scholar] [CrossRef]

- Hähner, P. On the critical conditions of the Portevin-Le Chatelier effect. Acta Mater. 1997, 45, 3695–3707. [Google Scholar] [CrossRef]

- Abbadi, M.; Hähner, P.; Zeghloul, A. On the characteristics of Portevin–Le Chatelier bands in aluminum alloy 5182 under stress-controlled and strain-controlled tensile testing. Mater. Sci. Eng. A 2002, 337, 194–201. [Google Scholar] [CrossRef]

- Rodriguez, P.; Venkadesan, S. Serrated plastic flow revisited. In Solid State Phenomena; Trans Tech Publications Ltd.: Pfäffikon, Switzerland, 1995; Volume 42, pp. 257–266. [Google Scholar]

- Lebyodkin, M.A.; Lebedkina, T.A. Multifractality and randomness in the unstable plastic flow near the lower strain-rate boundary of instability. Phys. Rev. E 2008, 77, 026111. [Google Scholar] [CrossRef]

- Han, G.M.; Tian, C.G.; Chu, Z.K.; Cui, C.Y.; Hu, Z.Q.; Sun, X.F. Activation energy calculations for the Portevin–Le Chatelier effect in nimonic 263 superalloy. Metall. Mater. Trans. A 2015, 46, 4629–4635. [Google Scholar] [CrossRef]

- Max, B.; Viguier, B.; Andrieu, E.; Cloue, J.M. A re-examination of the Portevin-Le Chatelier effect in alloy 718 in connection with oxidation-assisted intergranular cracking. Metall. Mater. Trans. A 2014, 45, 5431–5441. [Google Scholar] [CrossRef]

- Rezende, M.C.; Araújo, L.S.; Gabriel, S.B.; Dille, J.; de Almeida, L.H. Observations on dynamic strain aging manifestation in inconel 718 superalloy. In Materials Science Forum; Trans Tech Publications Ltd.: Pfäffikon, Switzerland, 2018; Volume 930, pp. 390–394. [Google Scholar]

- Chen, J.Z.; Liang, Z.H.E.N.; Fan, L.W.; Yang, S.J.; Dai, S.L.; Shao, W.Z. Portevin-Le Chatelier effect in Al-Zn-Mg-Cu-Zr aluminum alloy. Trans. Nonferrous Met. Soc. China 2009, 19, 1071–1075. [Google Scholar] [CrossRef]

- Chen, W.; Chaturvedi, M.C. On the mechanism of serrated deformation in aged Inconel 718. Mater. Sci. Eng. A 1997, 229, 163–168. [Google Scholar] [CrossRef]

- Thevenet, D.; Mliha-Touati, M.; Zeghloul, A. The effect of precipitation on the Portevin-Le Chatelier effect in an Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 1999, 266, 175–182. [Google Scholar] [CrossRef]

- Hale, C.L.; Rollings, W.S.; Weaver, M.L. Activation energy calculations for discontinuous yielding in Inconel 718SPF. Mater. Sci. Eng. A 2001, 300, 153–164. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Q.; Wu, X.; Fan, J. Spatiotemporal aspects of the Portevin–Le Chatelier effect in annealed and solution-treated aluminum alloys. Scr. Mater. 2006, 54, 2041–2045. [Google Scholar] [CrossRef]

- Charnock, W. The influence of grain size on the nature of portevin-lechatelier yielding. Philos. Mag. J. Theor. Exp. Appl. Phys. 1968, 18, 89–99. [Google Scholar] [CrossRef]

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Brechet, Y.; Estrin, Y. On the influence of precipitation on the Portevin-Le Chatelier effect. Acta Metall. Mater. 1995, 43, 955–963. [Google Scholar] [CrossRef]

- Chen, J.; Madi, Y.; Morgeneyer, T.F.; Besson, J. Plastic flow and ductile rupture of a 2198 Al–Cu–Li aluminum alloy. Comput. Mater. Sci. 2011, 50, 1365–1371. [Google Scholar] [CrossRef]

- Pink, E.; Król, J. Precipitation and serrated flow in AlZn10. Acta Metall. Mater. 1995, 43, 2351–2357. [Google Scholar] [CrossRef]

- Zhu, K.Y.; Dai, S.; Zou, S.H.; Yu, Y.J.; Deng, Z.C. Experimental study and crystal plasticity modeling of additive manufacturing IN718 superalloy considering negative strain rate sensitivity behavior. Eur. J. Mech. A Solids 2024, 106, 105304. [Google Scholar] [CrossRef]

| Ni | Cr | Fe | Nb | Mo | Ti | Al | C | |

|---|---|---|---|---|---|---|---|---|

| WAAM IN718 wire | Balance | 18.56 | 17.80 | 5.01 | 2.87 | 0.97 | 0.60 | 0.04 |

| Wrought IN718 | Balance | 18.05 | 18.00 | 5.42 | 2.90 | 0.91 | 0.48 | 0.023 |

| WAAM IN718 | Wrought IN718 | ||||||

|---|---|---|---|---|---|---|---|

| Strain Rate () | |||||||

| Young’s Modulus (GPa) | TD | ||||||

| ID | |||||||

| GD | |||||||

| Yield Strength (MPa) | TD | ||||||

| ID | |||||||

| GD | |||||||

| UTS (MPa) | TD | ||||||

| ID | |||||||

| GD | |||||||

| Elongation (%) | TD | ||||||

| ID | |||||||

| GD | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, R.-H.; Zhang, X.; Yang, Y.-J.; Zhou, Q.-W.; Zhang, L.; Qin, H.-L.; Li, D.-F.; Shi, R.-P. High-Temperature Mechanical Properties and the Portevin–Le Chatelier Effect for Wire Arc Additively Manufactured Inconel 718 Superalloy. Metals 2025, 15, 949. https://doi.org/10.3390/met15090949

Song R-H, Zhang X, Yang Y-J, Zhou Q-W, Zhang L, Qin H-L, Li D-F, Shi R-P. High-Temperature Mechanical Properties and the Portevin–Le Chatelier Effect for Wire Arc Additively Manufactured Inconel 718 Superalloy. Metals. 2025; 15(9):949. https://doi.org/10.3390/met15090949

Chicago/Turabian StyleSong, Run-Hua, Xin Zhang, Ya-Jin Yang, Qing-Wen Zhou, Liang Zhang, Hai-Long Qin, Dong-Feng Li, and Rong-Pei Shi. 2025. "High-Temperature Mechanical Properties and the Portevin–Le Chatelier Effect for Wire Arc Additively Manufactured Inconel 718 Superalloy" Metals 15, no. 9: 949. https://doi.org/10.3390/met15090949

APA StyleSong, R.-H., Zhang, X., Yang, Y.-J., Zhou, Q.-W., Zhang, L., Qin, H.-L., Li, D.-F., & Shi, R.-P. (2025). High-Temperature Mechanical Properties and the Portevin–Le Chatelier Effect for Wire Arc Additively Manufactured Inconel 718 Superalloy. Metals, 15(9), 949. https://doi.org/10.3390/met15090949