Low-Temperature Tempering to Tailor Microstructure, Mechanical and Contact Fatigue Performance in the Carburized Layer of an Alloy Steel for Heavy-Duty Gears

Abstract

1. Introduction

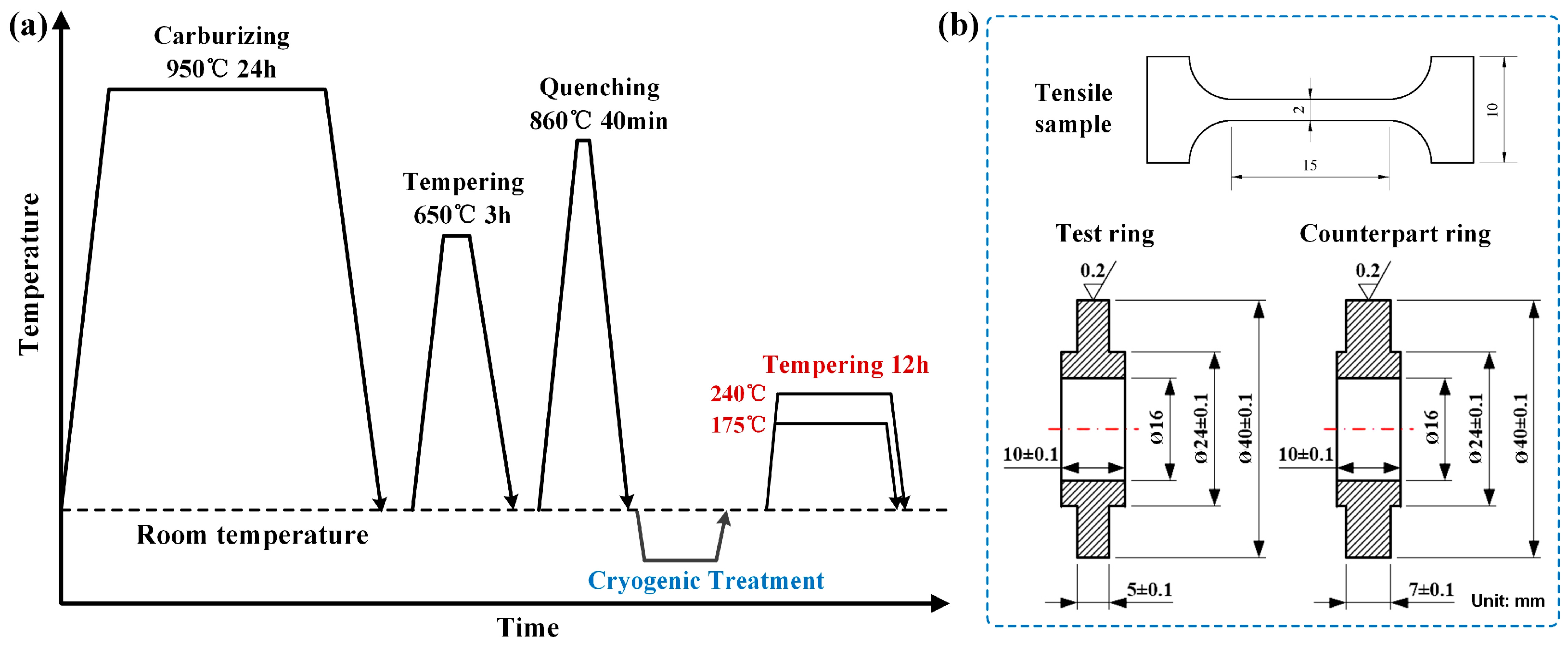

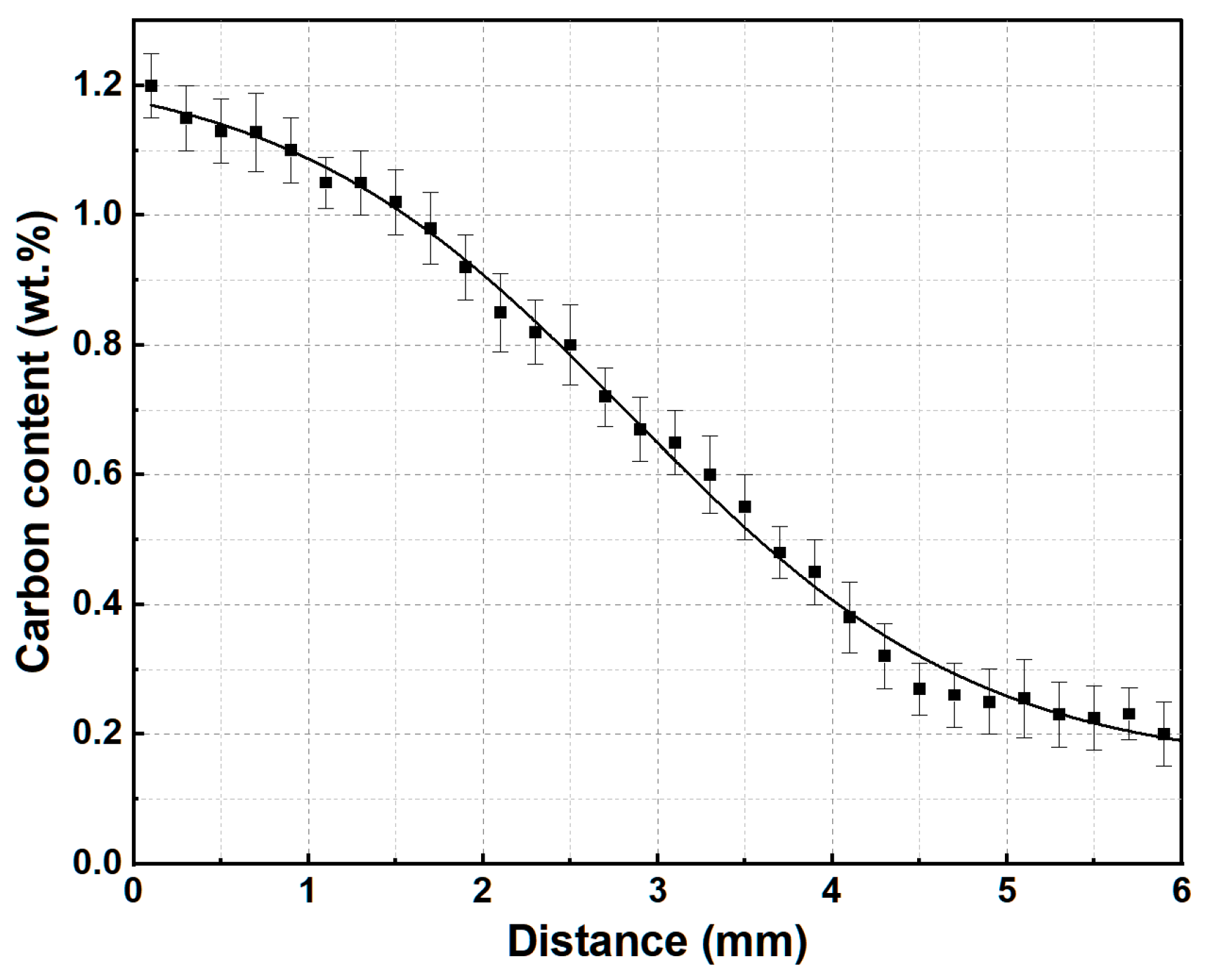

2. Materials and Methods

3. Results and Discussion

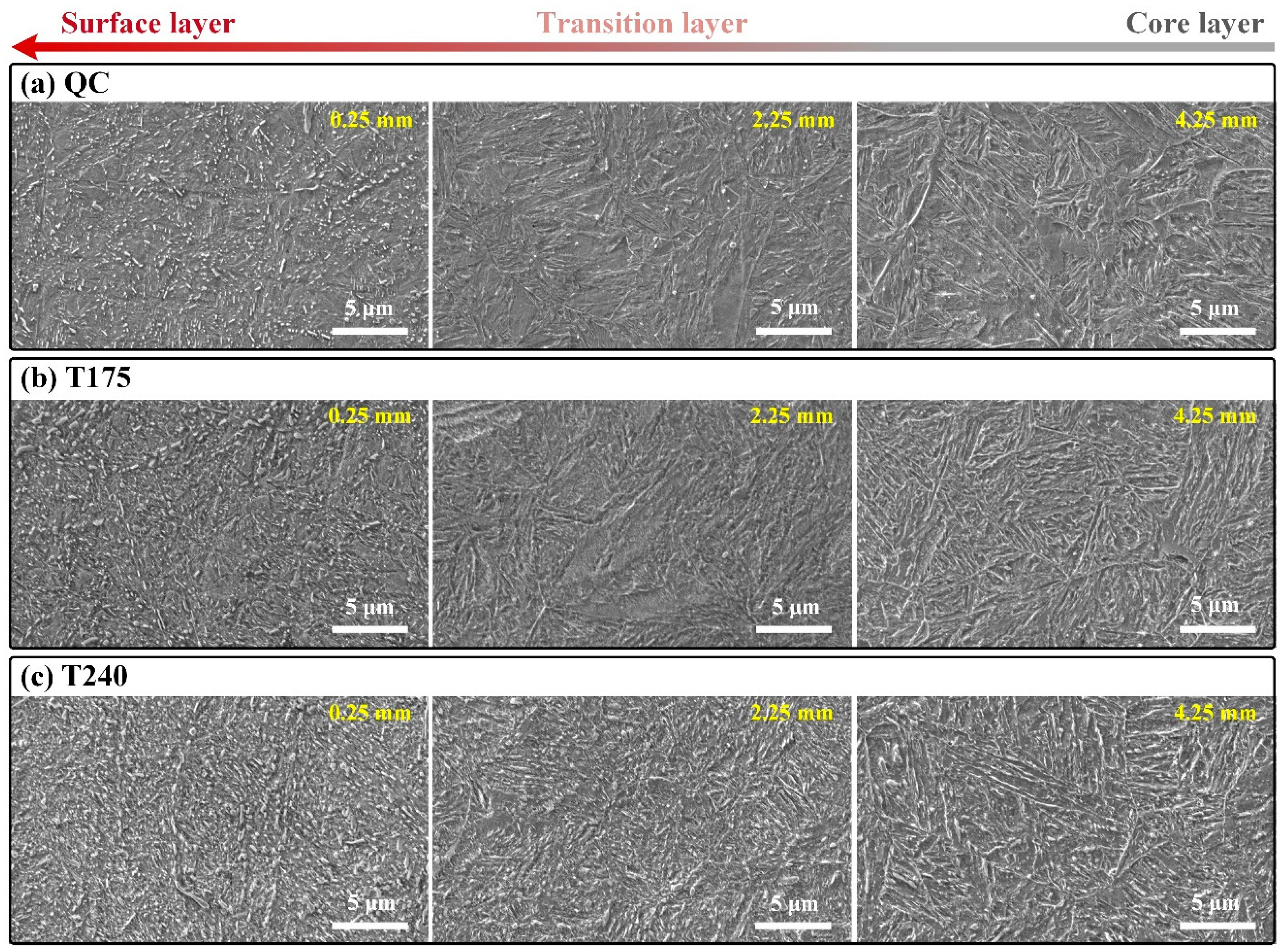

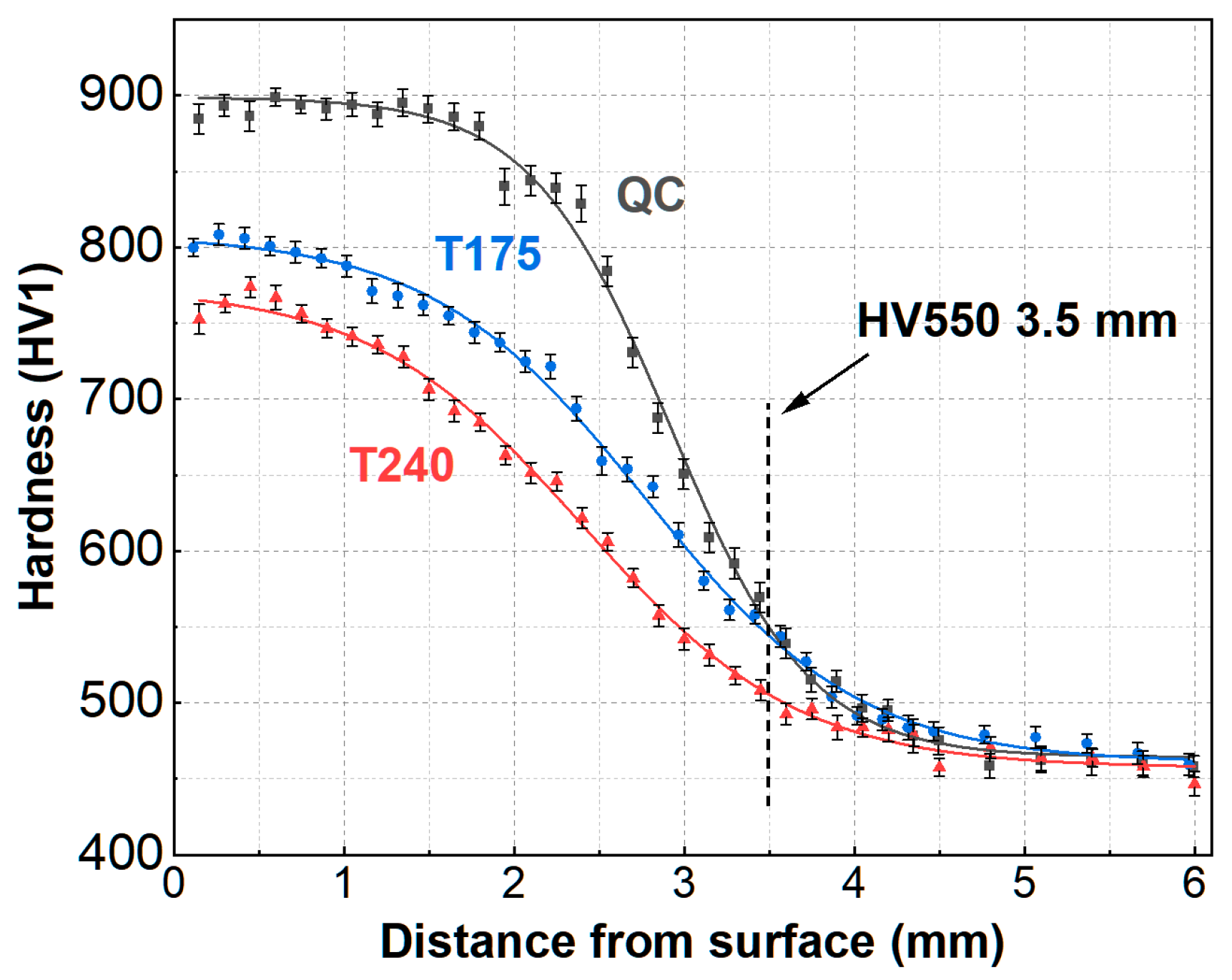

3.1. Microstructure Evolution

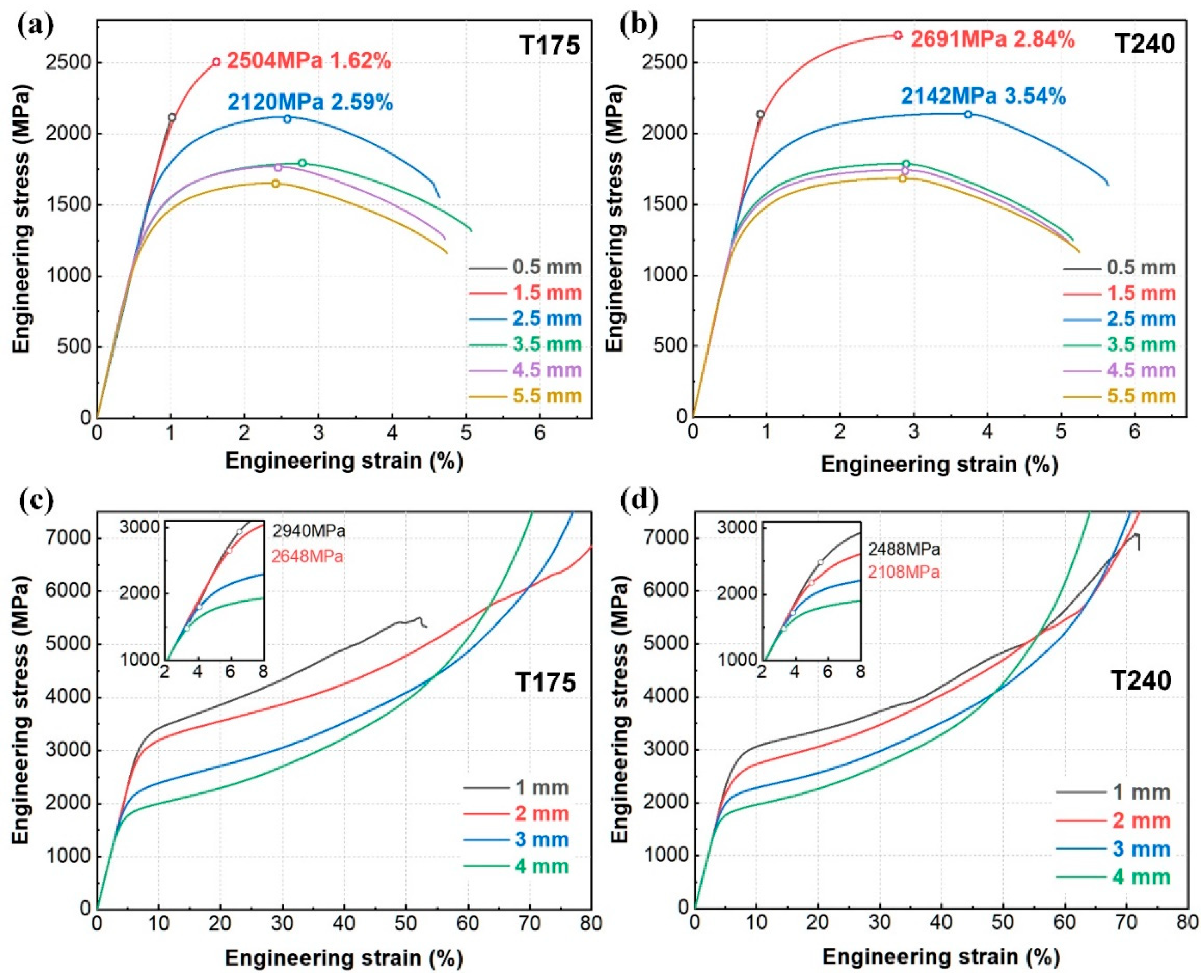

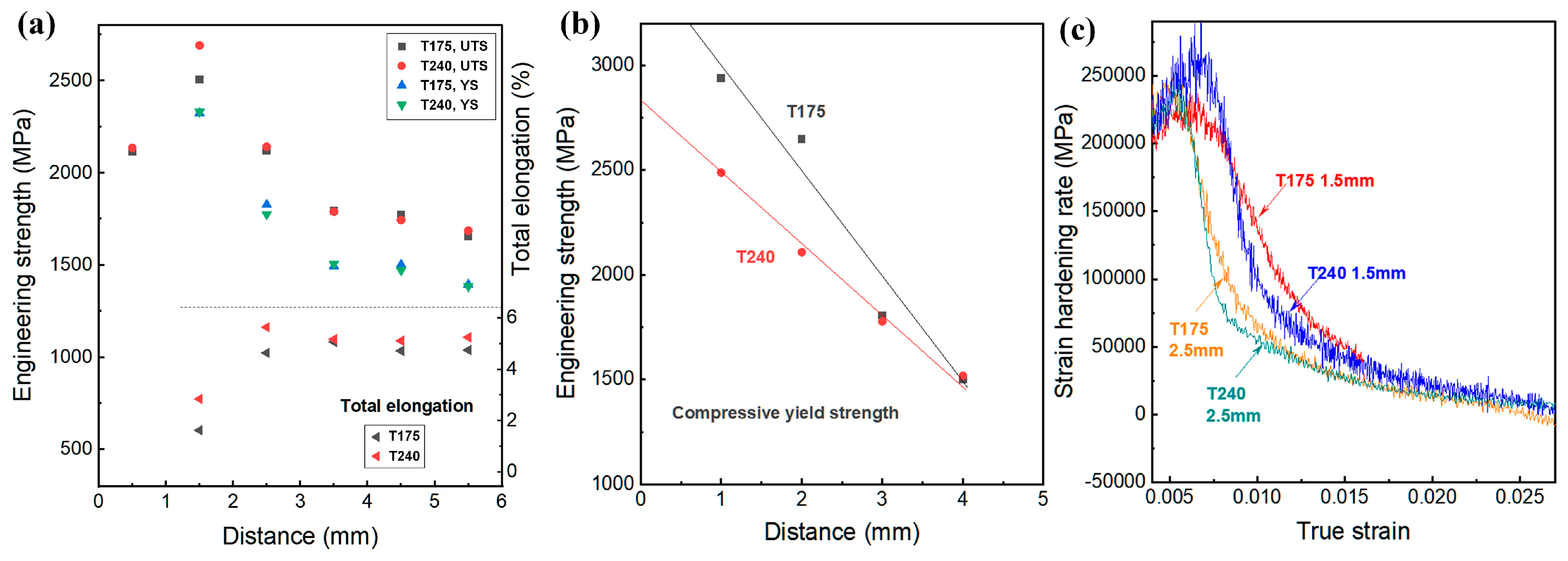

3.2. Mechanical Properties

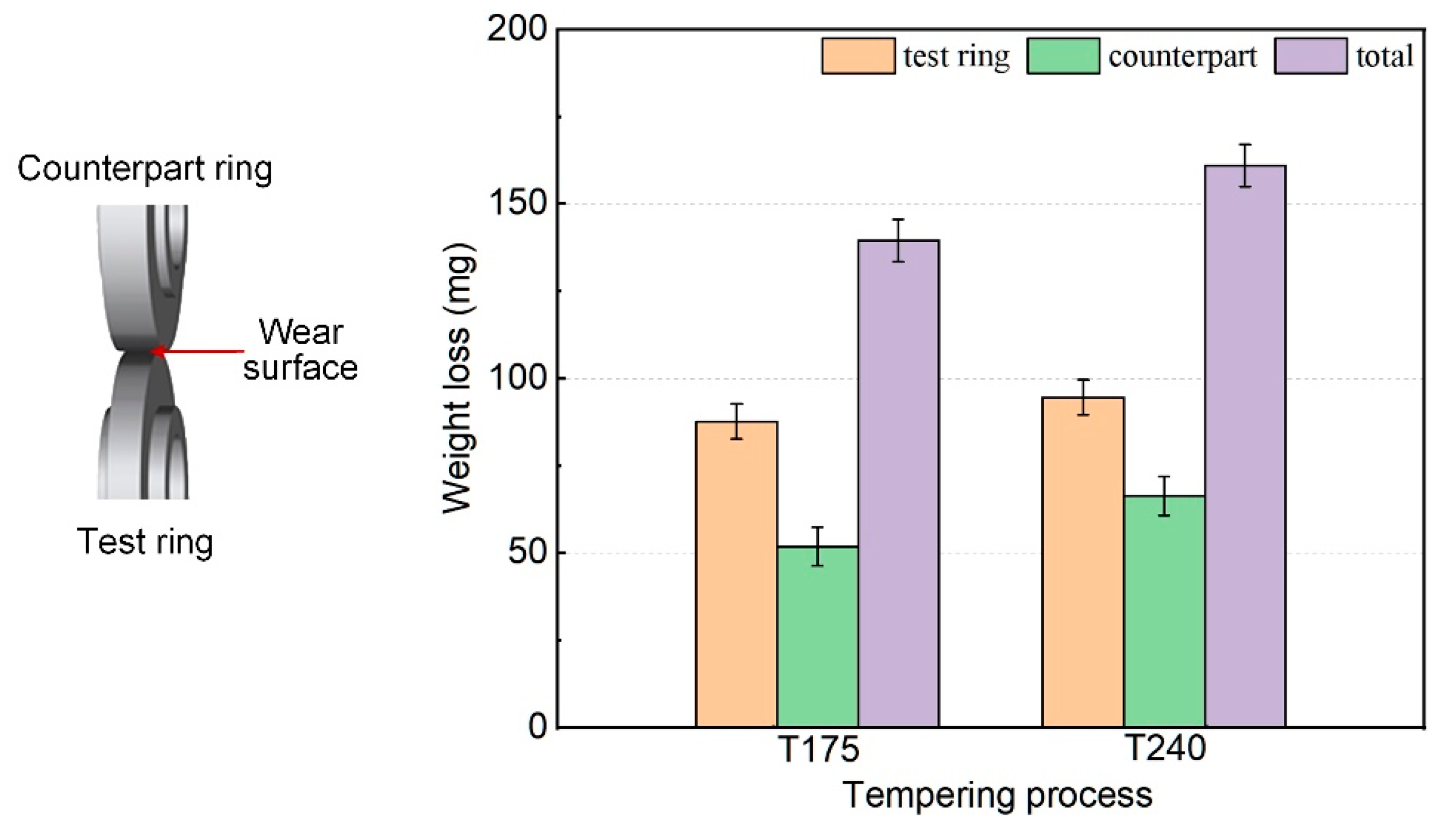

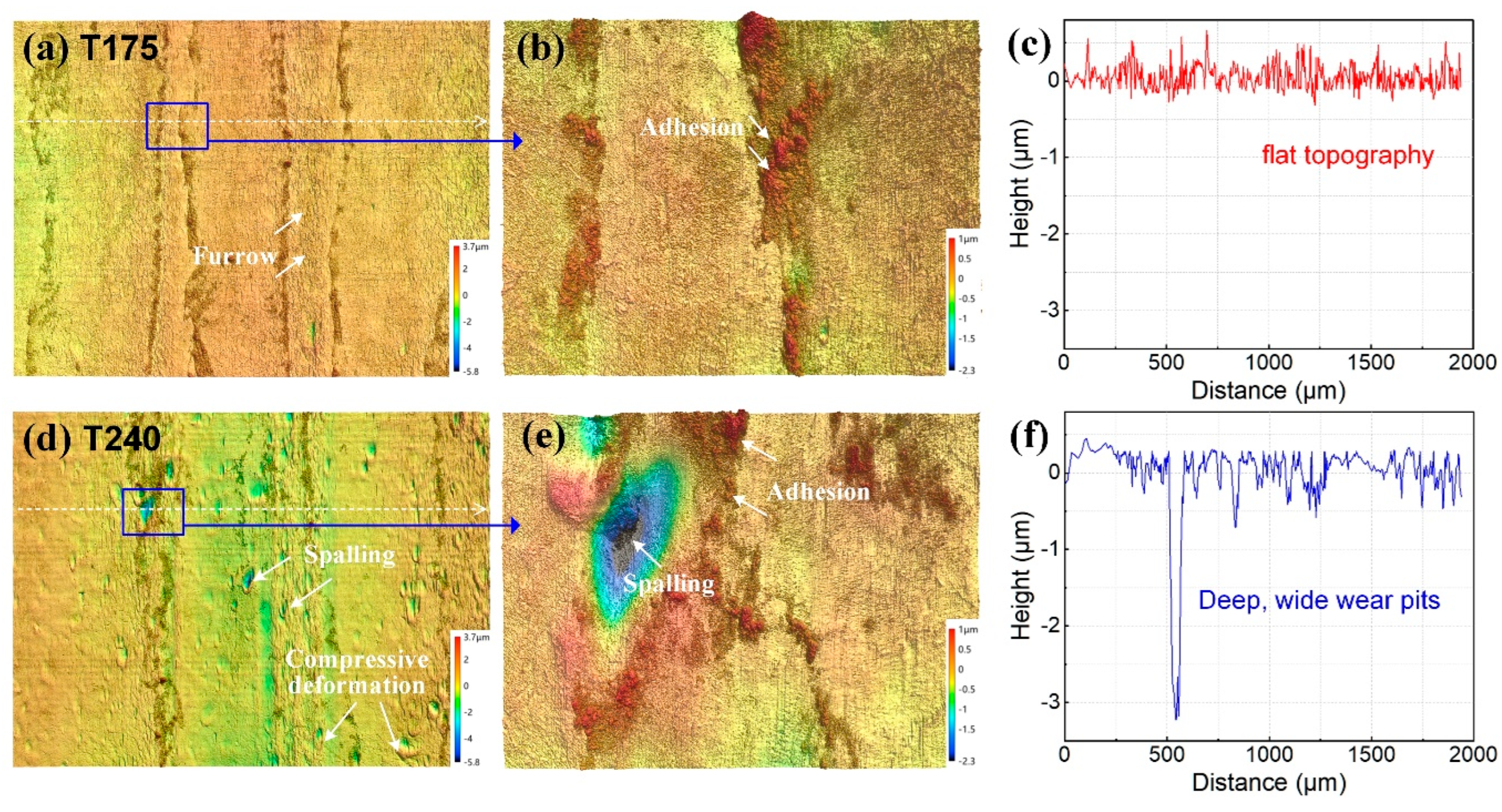

3.3. Fatigue Wear Behavior

3.4. Mechanism of Strengthening and Anti-Wear

4. Conclusions

- (1)

- Carburizing–quenching with cryogenic treatment produces high-carbon martensite at the surface, gradually transitioning to lath martensite toward the core. Low-temperature tempering promotes fine carbide precipitation in martensite, while elevated temperatures cause carbide coarsening. Specimens tempered at 175 °C achieve 800 HV surface hardness and 2940 MPa near-surface compressive yield strength.

- (2)

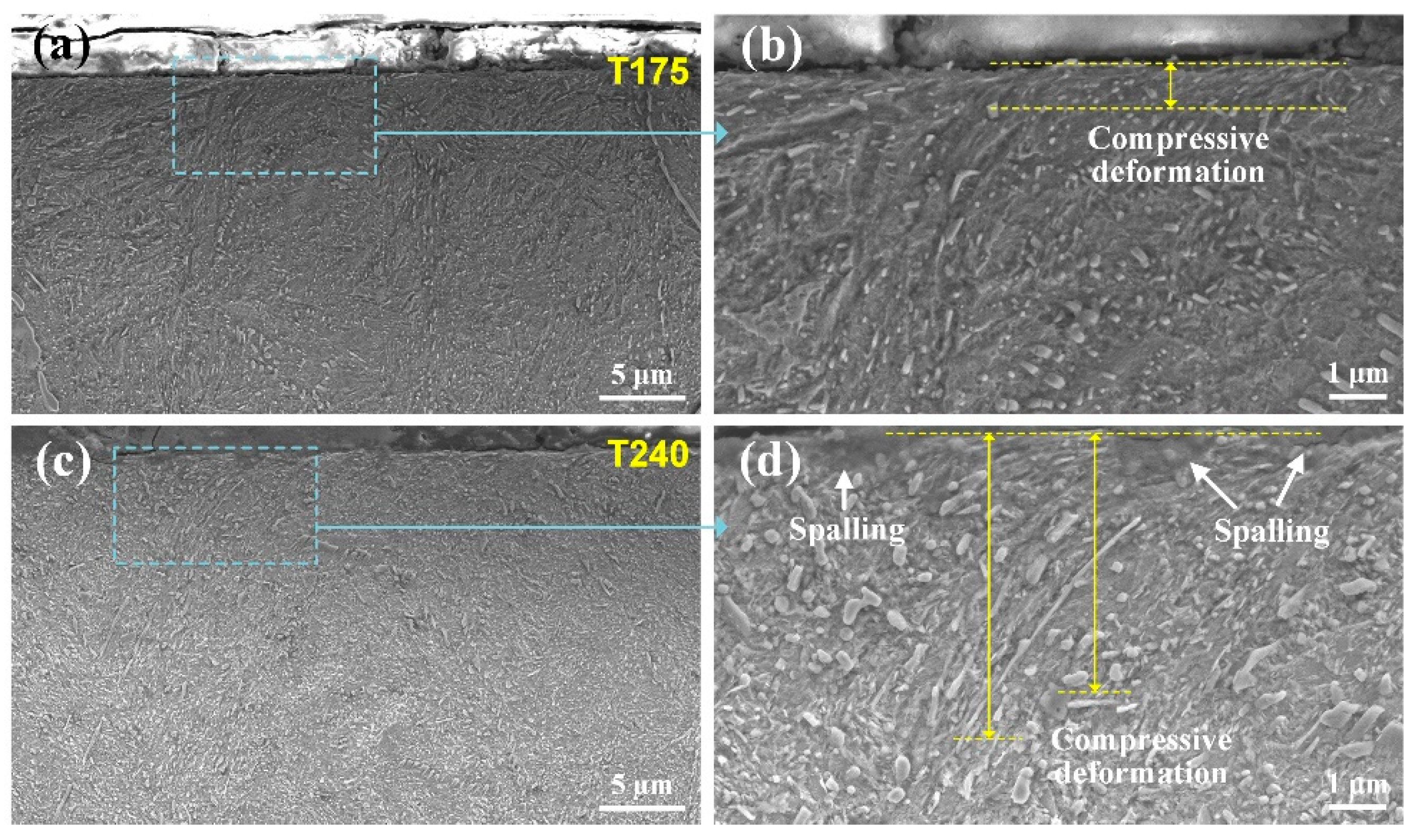

- The 175 °C-tempered specimens exhibit 13% lower wear mass loss than 240 °C treated counterparts, demonstrating superior wear resistance characterized by flat surfaces with uniform stress distribution and submicron plastic deformation zones (<1 μm depth). Conversely, 240 °C tempering generates spalling pits and pronounced plastic deformation exceeding 5 μm depth.

- (3)

- Cryogenic treatment facilitates further transformation of retained austenite to martensite. Post-tempering strengthening mechanisms include solid-solution strengthening, dislocation strengthening, and partial precipitation strengthening. Under contact fatigue stresses, coherent carbides precipitated at lower tempering temperatures impede dislocation motion via shearing mechanisms, suppressing plastic deformation and fatigue crack initiation to enhance wear resistance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, J.; Wei, P.; Zhu, C.; Zhang, P.; Liu, H. Development and application of high strength gears. Int. J. Adv. Manuf. Technol. 2024, 132, 3123–3148. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, C.; Zhang, B.; Ma, H.; Zhao, M. Effect of carburizing process on high cycle fatigue behavior of 18CrNiMo7-6 steel. J. Mater. Res. Technol. 2022, 16, 1136–1149. [Google Scholar] [CrossRef]

- Shi, L.; Cui, X.; Li, J.; Jin, G.; Liu, J.; Tian, H. Improving the wear resistance of heavy-duty gear steels by cyclic carburizing. Tribol. Int. 2022, 171, 107576. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Krauss, G. Steels: Heat Treatment and Processing Principles; ASM International: Almere, The Netherlands, 1990. [Google Scholar]

- Caron, R.N.; Krauss, G. The tempering of Fe-C lath martensite. Metall. Trans. 1972, 3, 2381–2389. [Google Scholar] [CrossRef]

- Krauss, G. Tempering of Lath Martensite in Low and Medium Carbon Steels: Assessment and Challenges. Steel Res. Int. 2017, 88, 1700038. [Google Scholar] [CrossRef]

- Wang, J.; El-Fallah, G.M.A.M.; Chang, X.; Peng, Y.; Tao, Q. Achieving 2.7 GPa tensile strength in ultrastrong high-carbon steel through prolonged low-temperature tempering. Mater. Charact. 2024, 215, 114241. [Google Scholar] [CrossRef]

- Song, W.; von Appen, J.; Choi, P.; Dronskowski, R.; Raabe, D.; Bleck, W. Atomic-scale investigation of ε and θ precipitates in bainite in 100Cr6 bearing steel by atom probe tomography and ab initio calculations. Acta Mater. 2013, 61, 7582–7590. [Google Scholar] [CrossRef]

- Wang, Y.L.; Shen, Y.F.; Jia, N.; Wang, J.J.; Zhao, S.X. Acicular martensite induced superior strength-ductility combination in a 20Cr2Ni2MoV steel. Mater. Sci. Eng. A 2022, 848, 143400. [Google Scholar] [CrossRef]

- Zhang, J.; Dai, Z.; Zeng, L.; Zuo, X.; Wan, J.; Rong, Y.; Chen, N.; Lu, J.; Chen, H. Revealing carbide precipitation effects and their mechanisms during quenching-partitioning-tempering of a high carbon steel: Experiments and Modeling. Acta Mater. 2021, 217, 117176. [Google Scholar] [CrossRef]

- Li, H.Y.; Lu, X.W.; Li, W.J.; Jin, X.J. Microstructure and Mechanical Properties of an Ultrahigh-Strength 40SiMnNiCr Steel during the One-Step Quenching and Partitioning Process. Metall. Mater. Trans. A 2010, 41, 1284–1300. [Google Scholar] [CrossRef]

- Zhirafar, S.; Rezaeian, A.; Pugh, M. Effect of cryogenic treatment on the mechanical properties of 4340 steel. J. Mater. Process. Technol. 2007, 186, 298–303. [Google Scholar] [CrossRef]

- Sun, J.-J.; Liu, Y.-N.; Zhu, Y.-T.; Lian, F.-L.; Liu, H.-J.; Jiang, T.; Guo, S.-W.; Liu, W.-Q.; Ren, X.-B. Super-strong dislocation-structured high-carbon martensite steel. Sci. Rep. 2017, 7, 6596. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Quan, J.; Salvador, H.; Edwards, J.; Lin, J.; Kozmel, T.; Mathaudhu, S. Ausforming and tempering of a novel ultra-high strength steel. Mater. Sci. Eng. A 2022, 838, 142750. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, J.; Jiang, T.; Sun, Y.; Guo, S.; Liu, Y. A low-alloy high-carbon martensite steel with 2.6 GPa tensile strength and good ductility. Acta Mater. 2018, 158, 247–256. [Google Scholar] [CrossRef]

- Perez, M.; Sidoroff, C.; Vincent, A.; Esnouf, C. Microstructural evolution of martensitic 100Cr6 bearing steel during tempering: From thermoelectric power measurements to the prediction of dimensional changes. Acta Mater. 2009, 57, 3170–3181. [Google Scholar] [CrossRef]

- Preciado, M.; Bravo, P.M.; Alegre, J.M. Effect of low temperature tempering prior cryogenic treatment on carburized steels. J. Mater. Process. Technol. 2006, 176, 41–44. [Google Scholar] [CrossRef]

- Barrow, A.T.W.; Kang, J.H.; Rivera-Díaz-del-Castillo, P.E.J. The ϵ→η→θ transition in 100Cr6 and its effect on mechanical properties. Acta Mater. 2012, 60, 2805–2815. [Google Scholar] [CrossRef]

- Hunkel, M.; Dong, J.; Epp, J.; Kaiser, D.; Dietrich, S.; Schulze, V.; Rajaei, A.; Hallstedt, B.; Broeckmann, C. Comparative Study of the Tempering Behavior of Different Martensitic Steels by Means of In-Situ Diffractometry and Dilatometry. Materials 2020, 13, 5058. [Google Scholar] [CrossRef]

- Tao, Q.; Wang, J.; Galindo-Nava, E.I. Effect of low-temperature tempering on confined precipitation and mechanical properties of carburised steels. Mater. Sci. Eng. A 2021, 822, 141688. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, J.; Pan, Z.; Tao, Q. Effect of Carbon Partition and Precipitation on Wear Resistance of Carburized Layer in Heavy-Duty Gear. Materials 2021, 14, 6958. [Google Scholar] [CrossRef]

- Hertz, H. The Contact of Elastic Solids. J. Reine Angew. Math. 1881, 92, 156–171. [Google Scholar]

- Cavaliere, P.; Zavarise, G.; Perillo, M. Modeling of the carburizing and nitriding processes. Comput. Mater. Sci. 2009, 46, 26–35. [Google Scholar] [CrossRef]

- Goldstein, J.I.; Moren, A.E. Diffusion modeling of the carburization process. Metall. Trans. A 1978, 9, 1515–1525. [Google Scholar] [CrossRef]

- Nova, I.; Machuta, J. Monitoring of the Diffusion Processes during Carburizing Automotive Steel Parts. Manuf. Technol. J. 2016, 16, 225–230. [Google Scholar] [CrossRef]

- Oila, A.; Bull, S.J. Phase transformations associated with micropitting in rolling/sliding contacts. J. Mater. Sci. 2005, 40, 4767–4774. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. A model for the microstructure behaviour and strength evolution in lath martensite. Acta Mater. 2015, 98, 81–93. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. Understanding the factors controlling the hardness in martensitic steels. Scr. Mater. 2016, 110, 96–100. [Google Scholar] [CrossRef]

- Davies, R.G.; Magee, C.L. Microcracking in ferrous martensites. Metall. Trans. 1972, 3, 307–313. [Google Scholar] [CrossRef]

- Brobst, R.P.; Krauss, G. The effect of austenite grain size on microcracking in martensite of an Fe-1.22C alloy. Metall. Trans. 1974, 5, 457–462. [Google Scholar] [CrossRef]

- Badinier, G.; Sinclair, C.W.; Sauvage, X.; Wang, X.; Bylik, V.; Gouné, M.; Danoix, F. Microstructural heterogeneity and its relationship to the strength of martensite. Mater. Sci. Eng. A 2015, 638, 329–339. [Google Scholar] [CrossRef]

- Liang, J.; Lu, H.; Zhang, L.; Li, F.; Cao, R.; Liu, K.; Pan, H.; Teng, H.; Li, X.; Guo, A.; et al. A 2000 MPa grade Nb bearing hot stamping steel with ultra-high yield strength. Mater. Sci. Eng. A 2021, 801, 140419. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Wang, S.B.; Chang, X.F.; Key, J. New insight into high-temperature creep deformation and fracture of T92 steel involving precipitates, dislocations and nanovoids. Mater. Charact. 2017, 127, 1–11. [Google Scholar] [CrossRef]

- Suh, N.P. The delamination theory of wear. Wear 1973, 25, 111–124. [Google Scholar] [CrossRef]

- Farokhzadeh, K.; Edrisy, A. Fatigue improvement in low temperature plasma nitrided Ti–6Al–4V alloy. Mater. Sci. Eng. A 2015, 620, 435–444. [Google Scholar] [CrossRef]

- Rajinikanth, V.; Soni, M.K.; Mahato, B.; Rao, M.A. Microstructural investigation of rolling contact fatigue (RCF) on a failed planetary gear of a windmill gearbox. Eng. Fail. Anal. 2021, 121, 105167. [Google Scholar] [CrossRef]

- Takayasu, S.; Umezawa, O.; Yari, K.; Hashimoto, K.; Fuchigami, T. Spectroscopy analyses of tribofilm and surface microcracks in carburized SCM420 steel under high-pressure rolling contact fatigue. Wear 2021, 477, 203807. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Chintha, A.R.; Lenka, S. Critical Assessment 34: Are χ (Hägg), η and ϵ carbides transition-phases relative to cementite in steels? Mater. Sci. Technol. 2019, 35, 1301–1305. [Google Scholar] [CrossRef]

- Gerold, V.; Haberkorn, H. On the Critical Resolved Shear Stress of Solid Solutions Containing Coherent Precipitates. Phys. Status Solidi B 1966, 16, 675–684. [Google Scholar] [CrossRef]

- Kamikawa, N.; Sato, K.; Miyamoto, G.; Murayama, M.; Sekido, N.; Tsuzaki, K.; Furuhara, T. Stress–strain behavior of ferrite and bainite with nano-precipitation in low carbon steels. Acta Mater. 2015, 83, 383–396. [Google Scholar] [CrossRef]

| Samples | YS/MPa | UTS/MPa | UE/% | TE/% |

|---|---|---|---|---|

| T175-0.5 mm | - | 2116 ± 30 | - | - |

| T175-1.5 mm | 2324 ± 20 | 2505 ± 20 | 1.62 ± 0.1 | 1.62 ± 0.1 |

| T175-2.5 mm | 1828 ± 20 | 2120 ± 20 | 2.59 ± 0.1 | 4.63 ± 0.1 |

| T175-3.5 mm | 1494 ± 20 | 1793 ± 25 | 2.69 ± 0.1 | 5.06 ± 0.15 |

| T175-4.5 mm | 1502 ± 20 | 1773 ± 25 | 2.40 ± 0.1 | 4.71 ± 0.15 |

| T175-5.5 mm | 1394 ± 15 | 1655 ± 25 | 2.33 ± 0.1 | 4.74 ± 0.15 |

| T240-0.5 mm | - | 2136 ± 30 | - | - |

| T240-1.5 mm | 2331 ± 20 | 2691 ± 20 | 2.84 ± 0.1 | 2.84 ± 0.1 |

| T240-2.5 mm | 1774 ± 20 | 2142 ± 20 | 3.54 ± 0.1 | 5.63 ± 0.15 |

| T240-3.5 mm | 1506 ± 20 | 1790 ± 25 | 2.84 ± 0.1 | 5.16 ± 0.15 |

| T240-4.5 mm | 1471 ± 20 | 1744 ± 25 | 2.82 ± 0.1 | 5.10 ± 0.15 |

| T240-5.5 mm | 1385 ± 15 | 1686 ± 25 | 2.77 ± 0.1 | 5.24 ± 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wang, J.; Cheng, G.; Tao, Q. Low-Temperature Tempering to Tailor Microstructure, Mechanical and Contact Fatigue Performance in the Carburized Layer of an Alloy Steel for Heavy-Duty Gears. Metals 2025, 15, 934. https://doi.org/10.3390/met15090934

Li Q, Wang J, Cheng G, Tao Q. Low-Temperature Tempering to Tailor Microstructure, Mechanical and Contact Fatigue Performance in the Carburized Layer of an Alloy Steel for Heavy-Duty Gears. Metals. 2025; 15(9):934. https://doi.org/10.3390/met15090934

Chicago/Turabian StyleLi, Qingliang, Jian Wang, Gang Cheng, and Qing Tao. 2025. "Low-Temperature Tempering to Tailor Microstructure, Mechanical and Contact Fatigue Performance in the Carburized Layer of an Alloy Steel for Heavy-Duty Gears" Metals 15, no. 9: 934. https://doi.org/10.3390/met15090934

APA StyleLi, Q., Wang, J., Cheng, G., & Tao, Q. (2025). Low-Temperature Tempering to Tailor Microstructure, Mechanical and Contact Fatigue Performance in the Carburized Layer of an Alloy Steel for Heavy-Duty Gears. Metals, 15(9), 934. https://doi.org/10.3390/met15090934