The Effect of Welding Parameters on the Morphology and Mechanical Properties of AA6061-T6/CF-PPS Friction Stir Lap Welding Joints

Abstract

1. Introduction

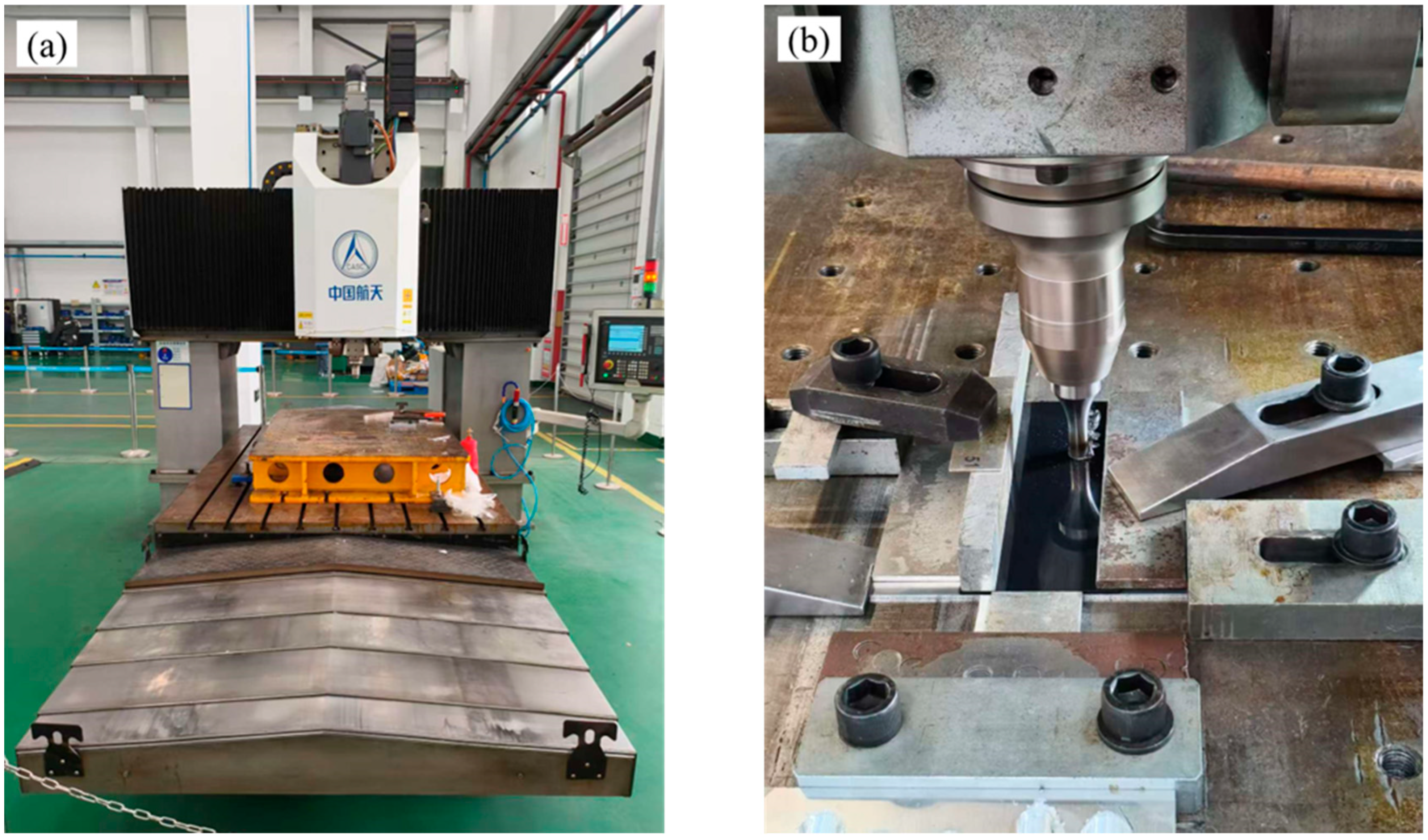

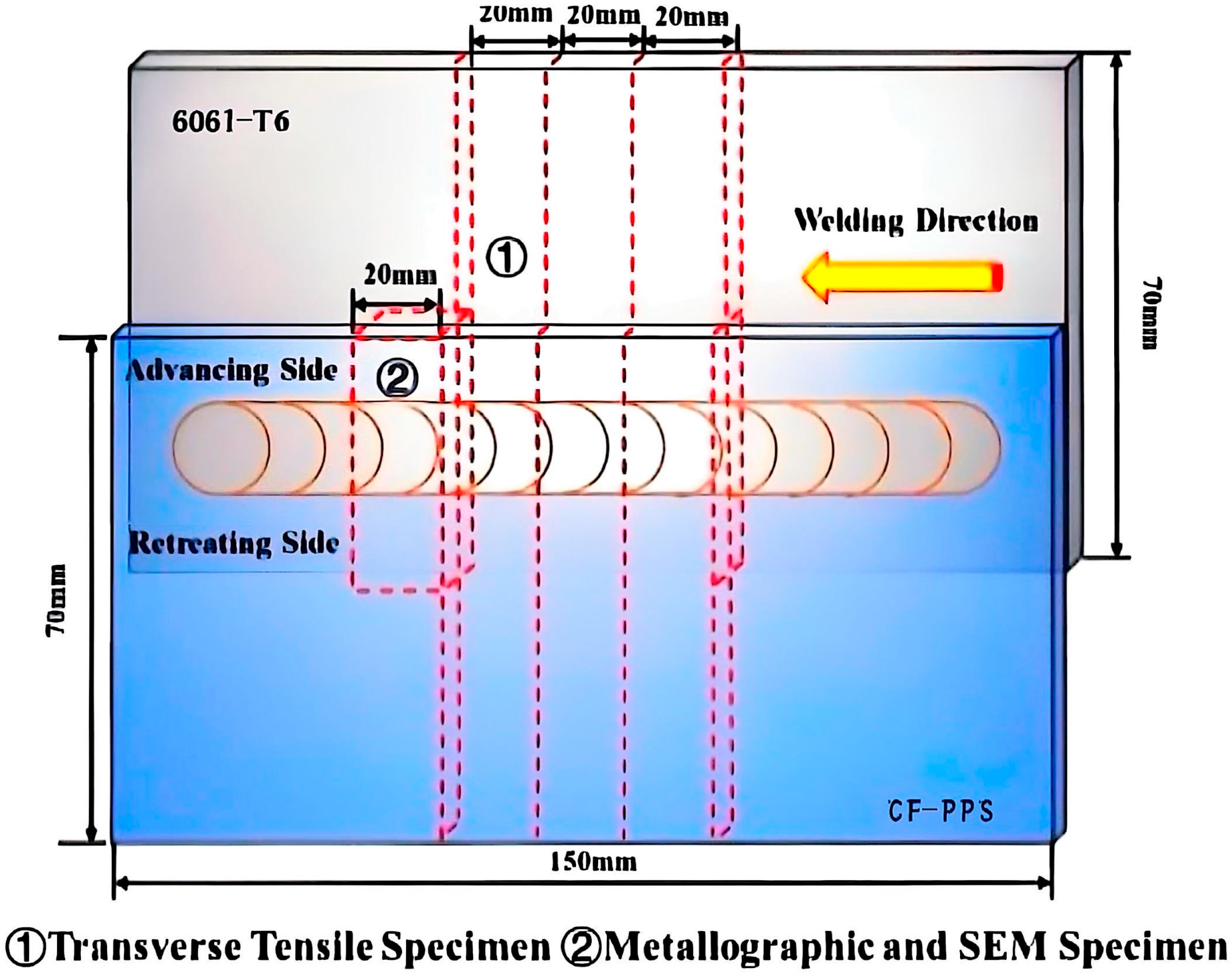

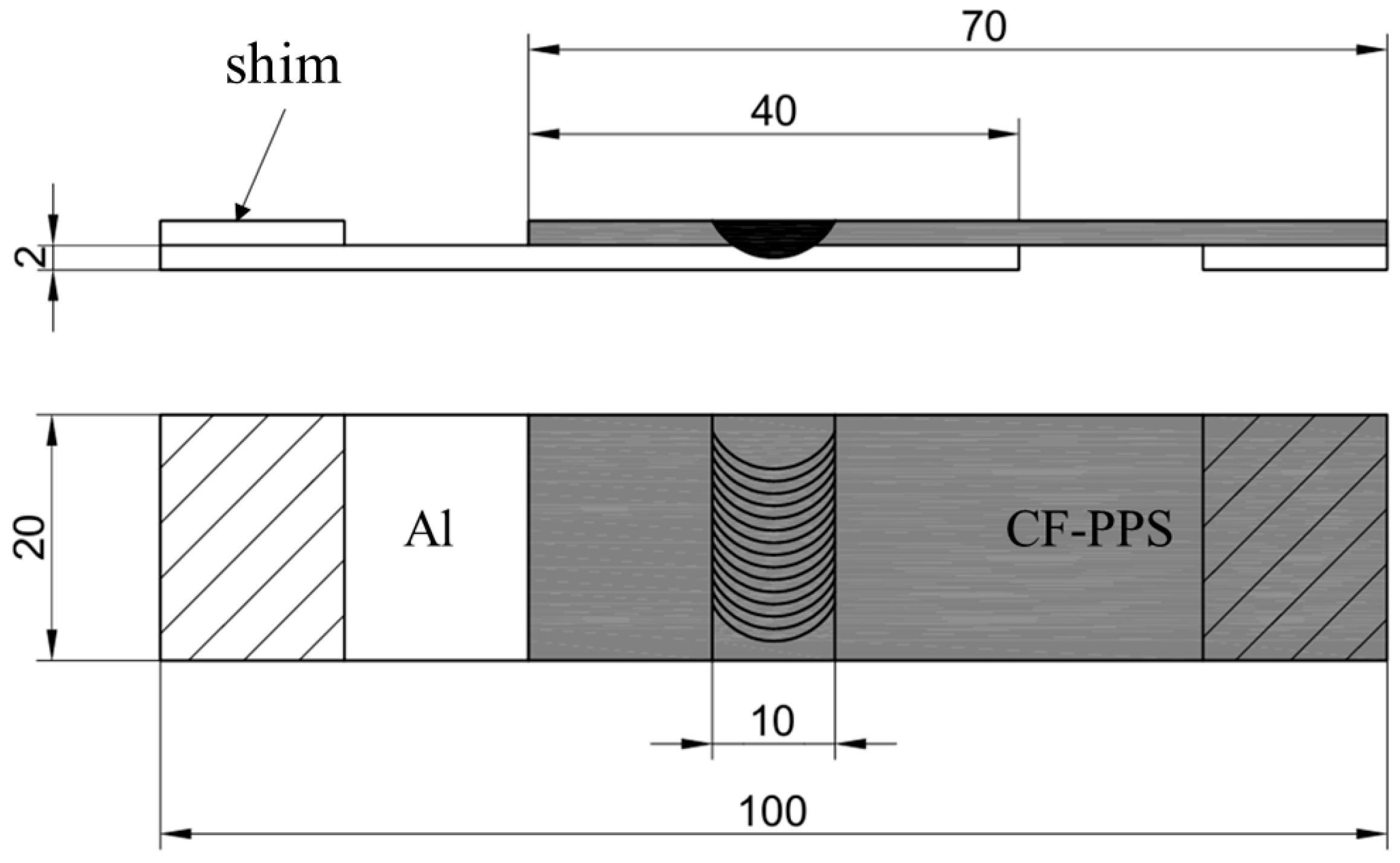

2. Materials and Methods

3. Results and Discussion

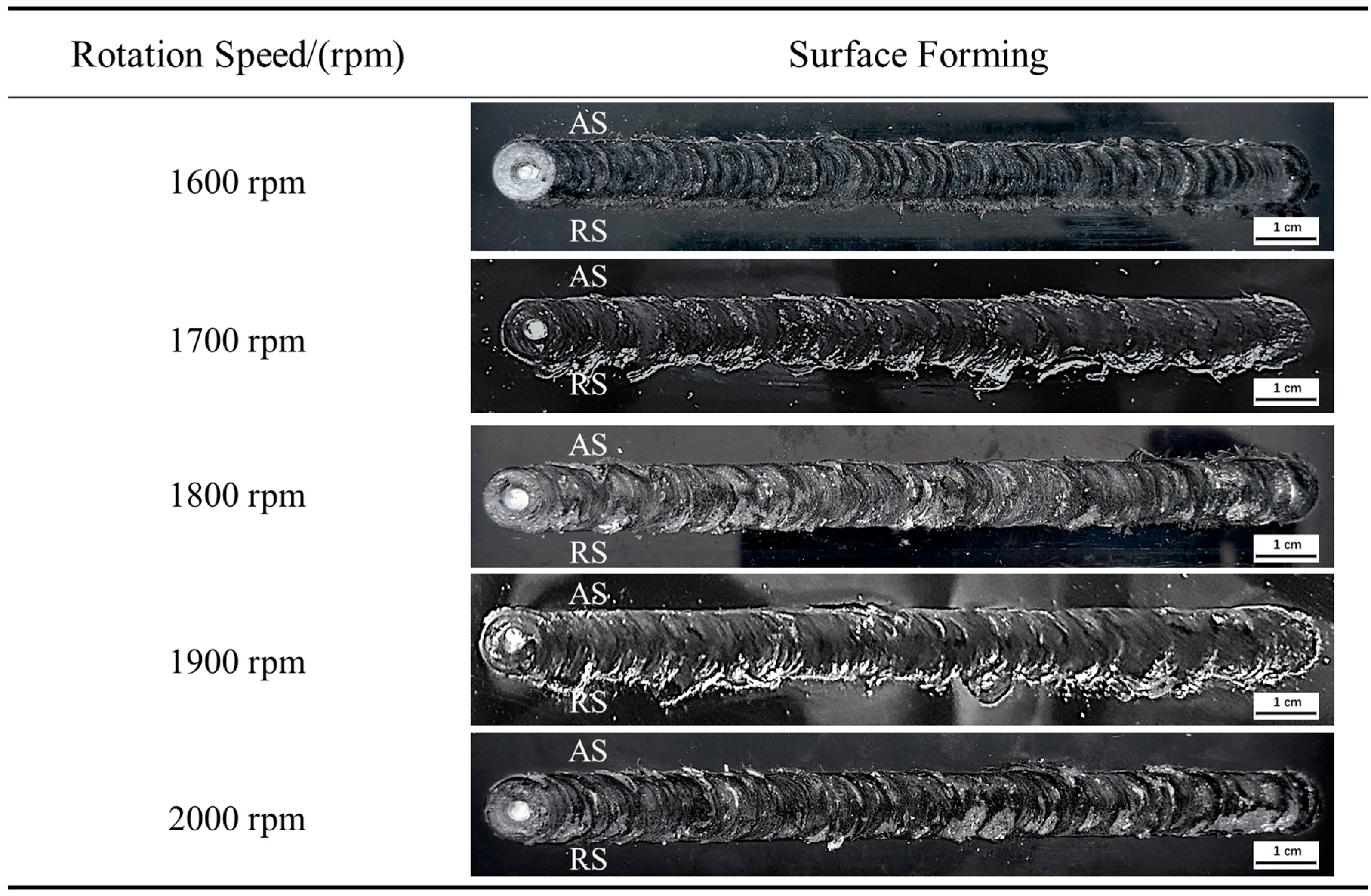

3.1. The Effect of Spindle Rotation Speed on Welding Quality

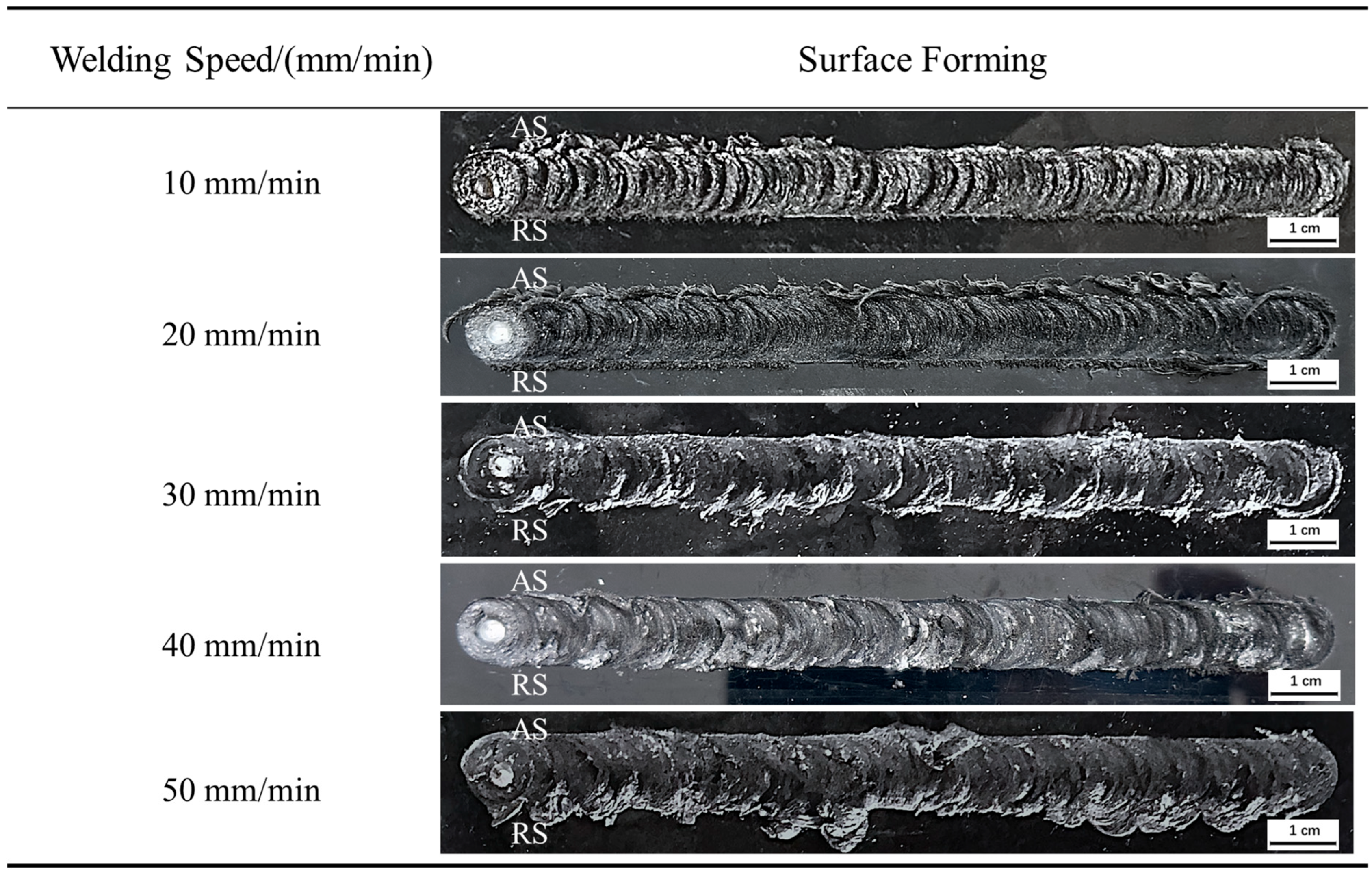

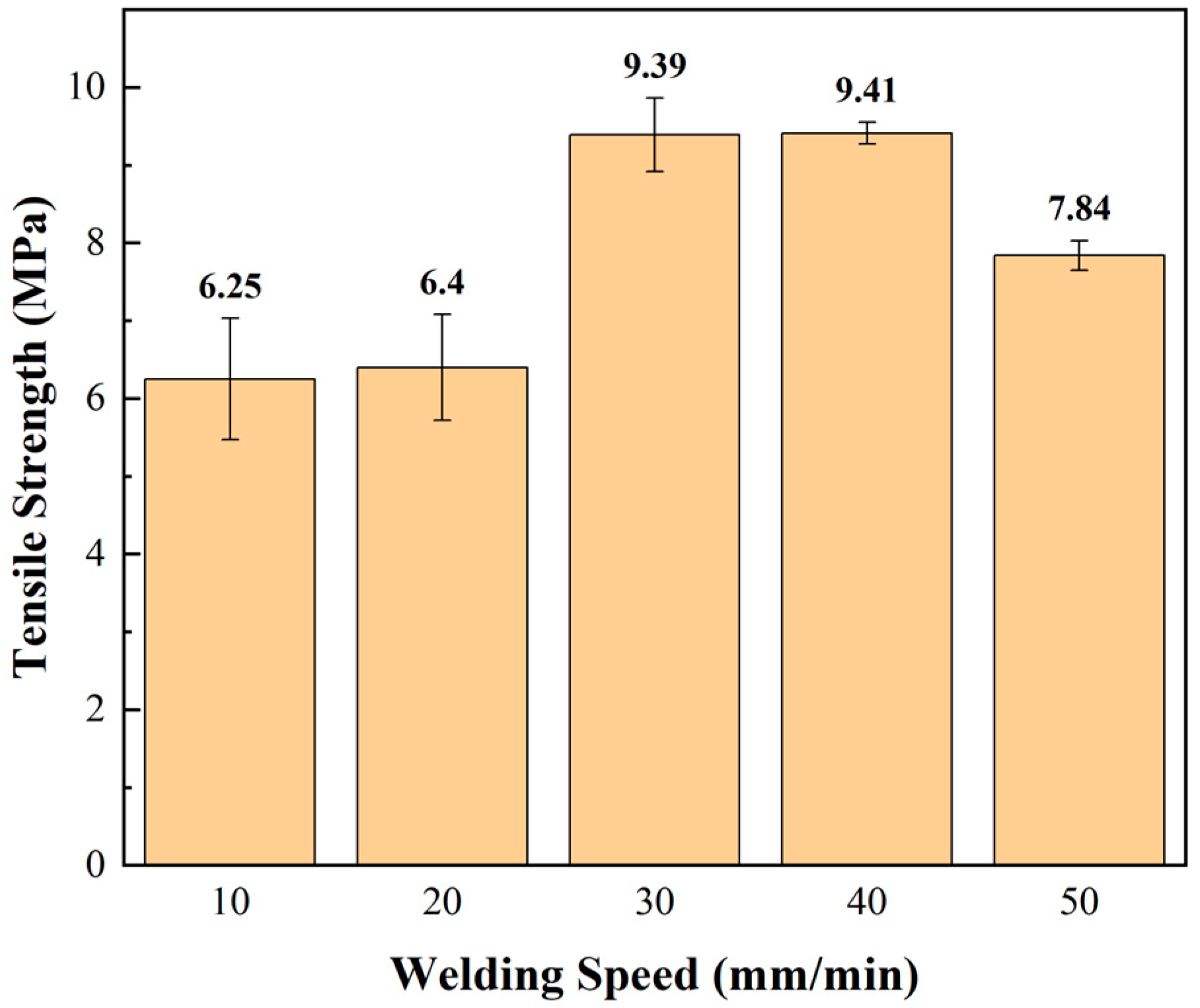

3.2. The Effect of Welding Speed on Welding Quality

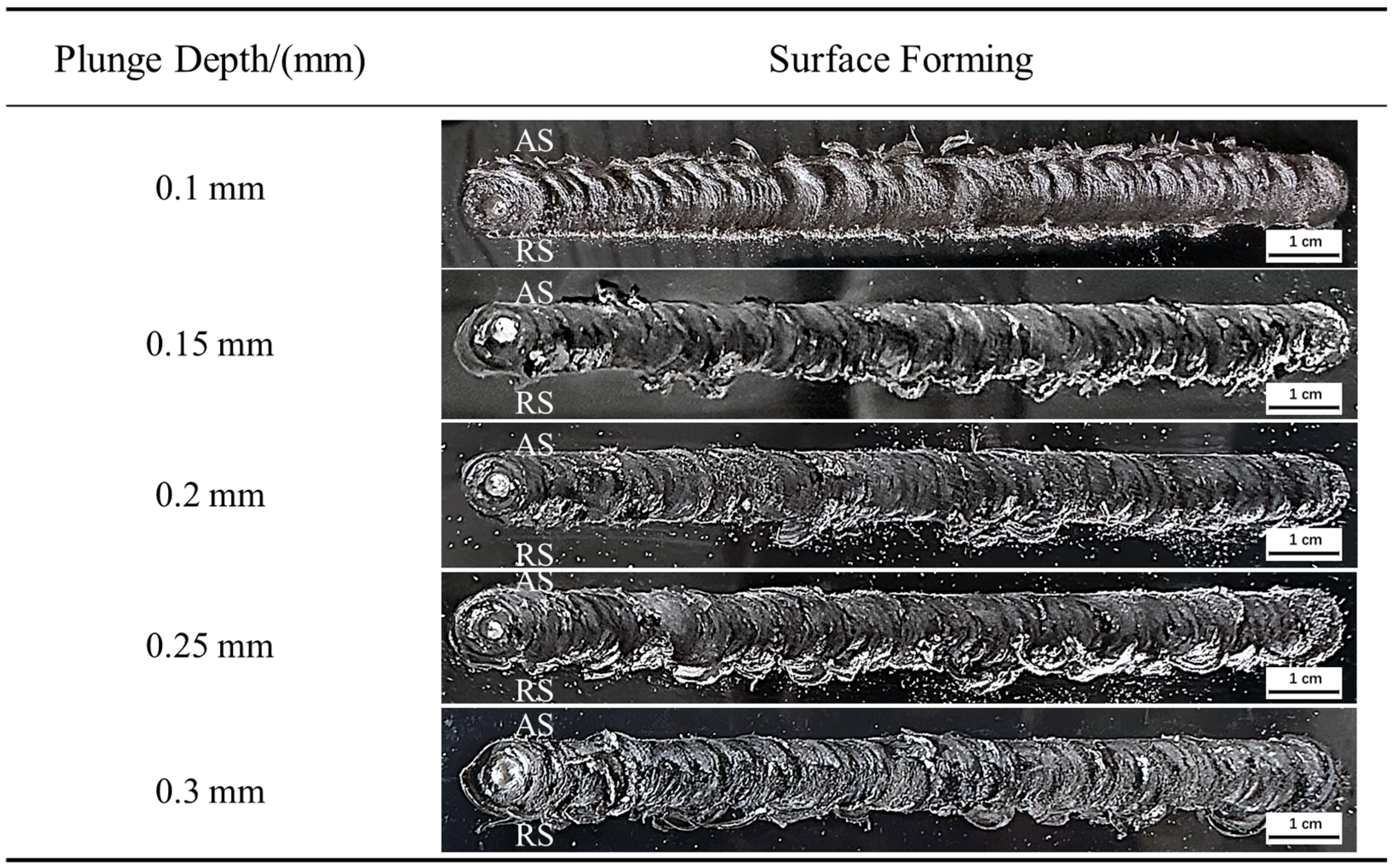

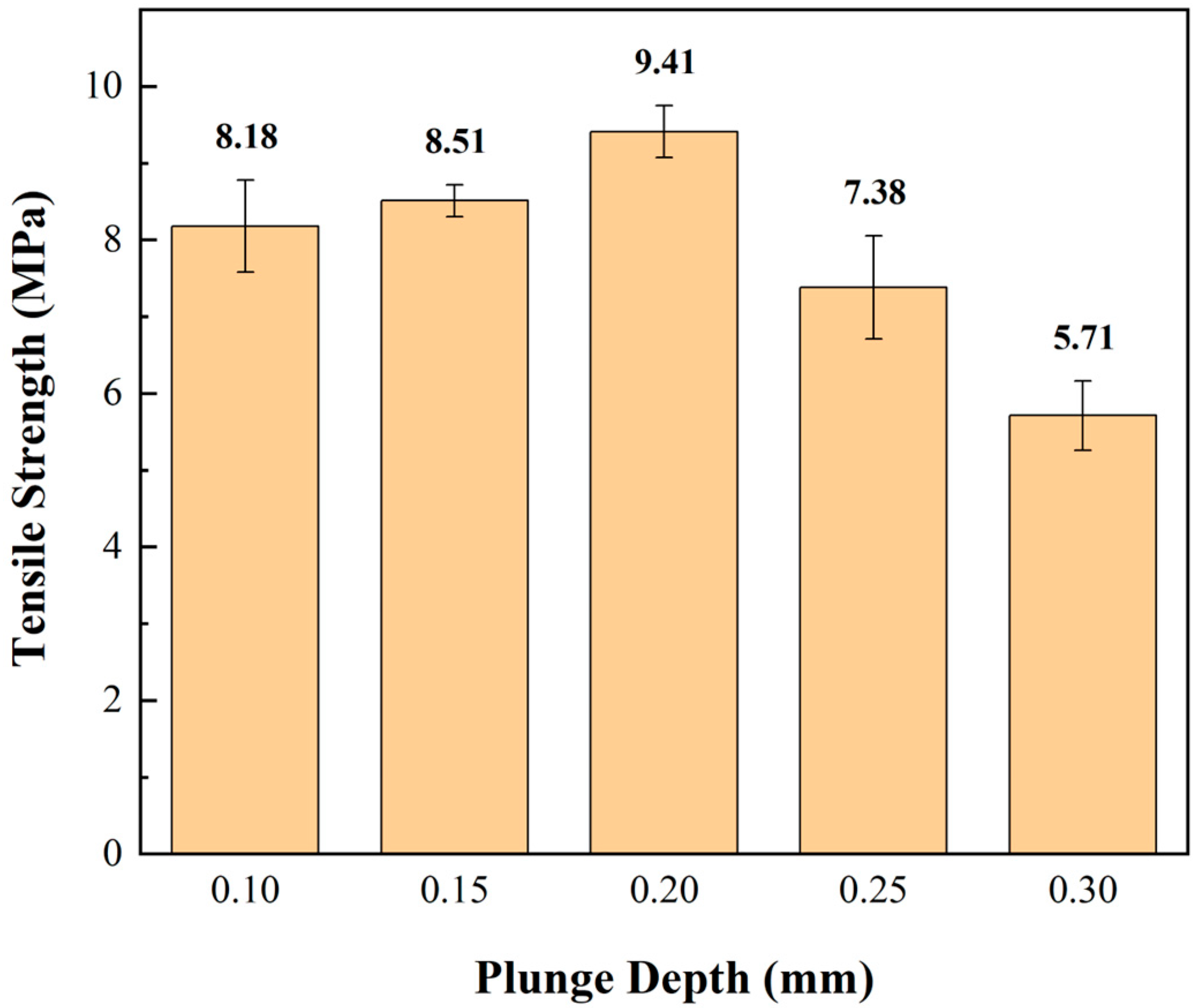

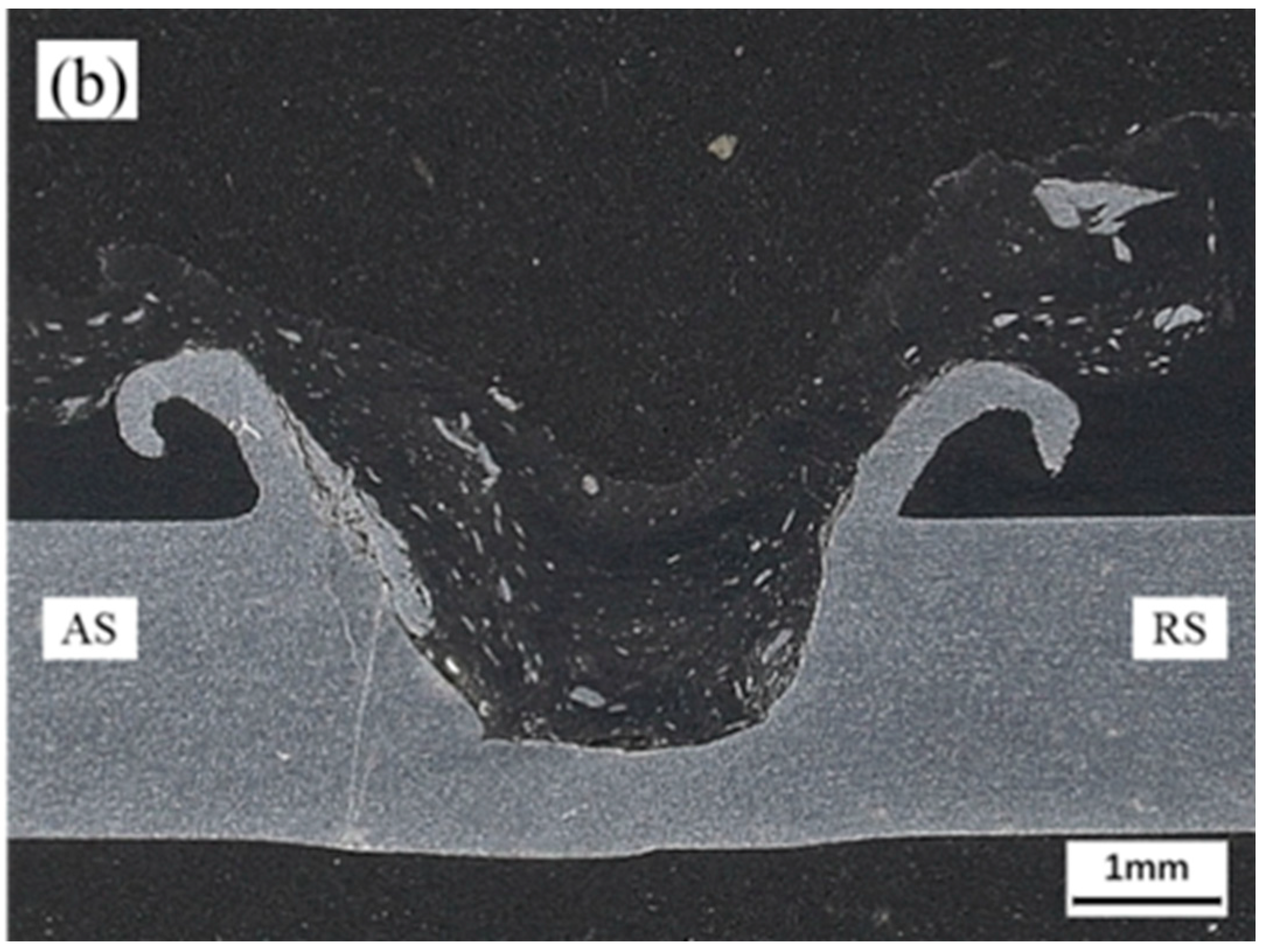

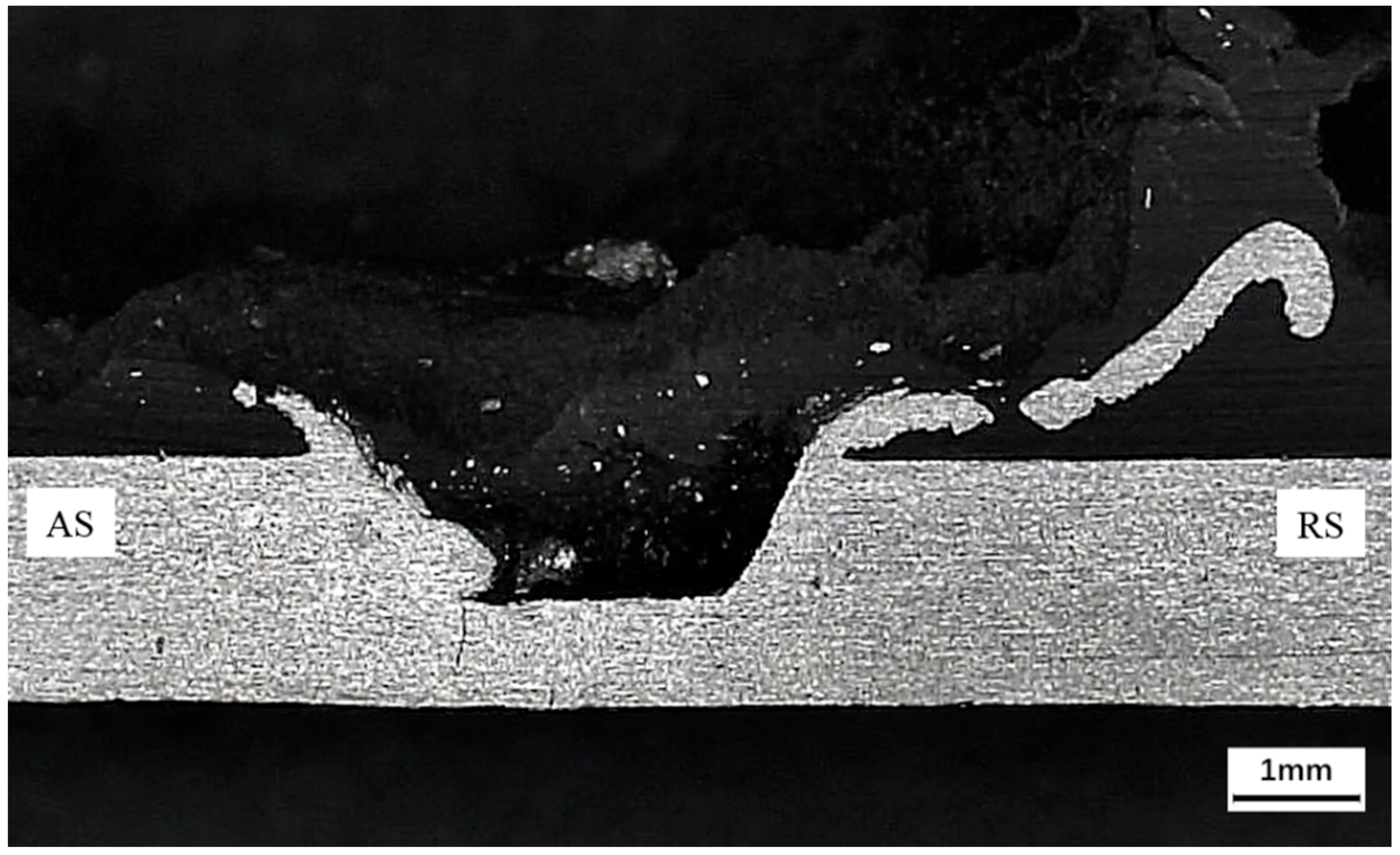

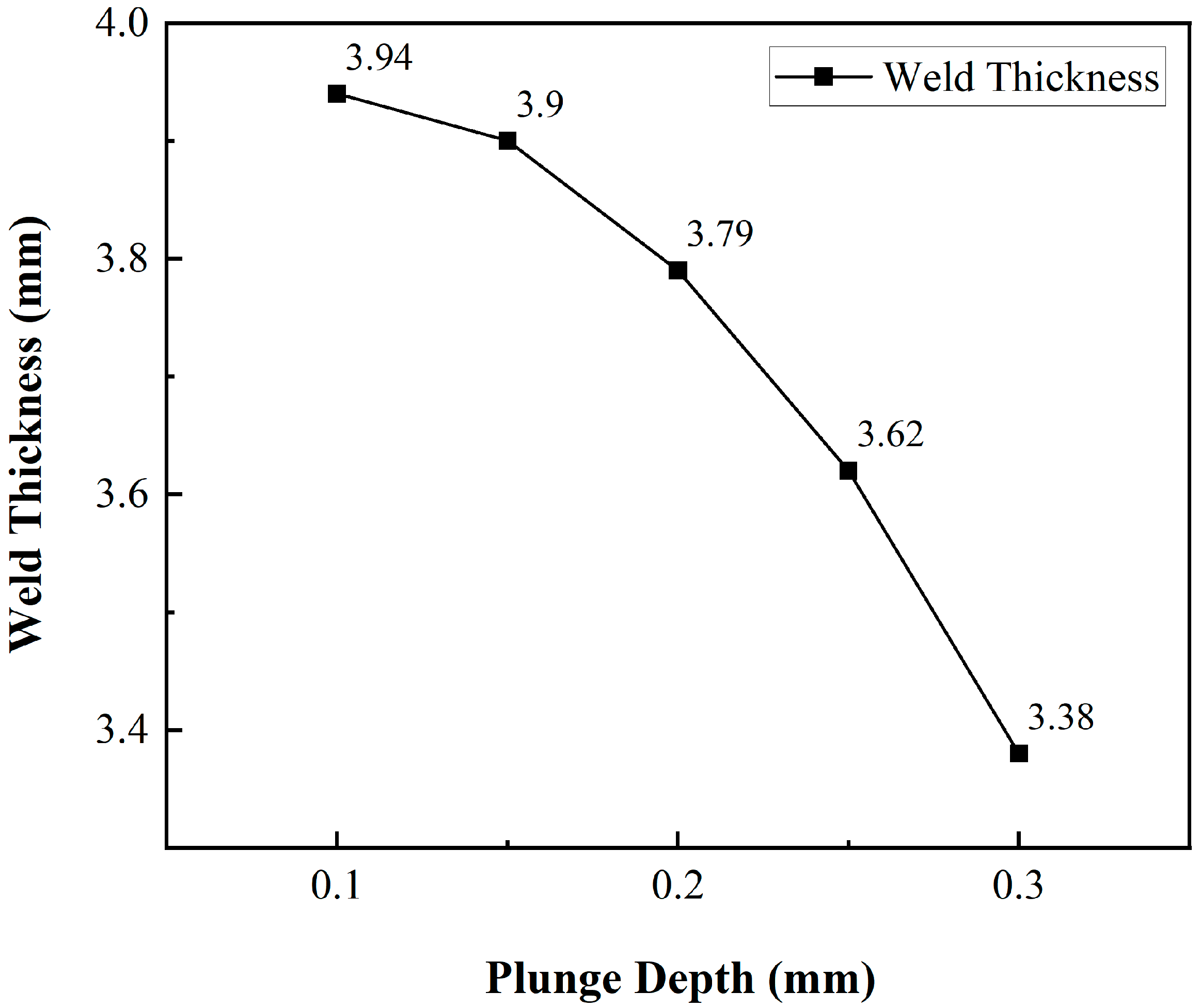

3.3. The Effect of Plunge Depth on Welding Quality

4. Conclusions

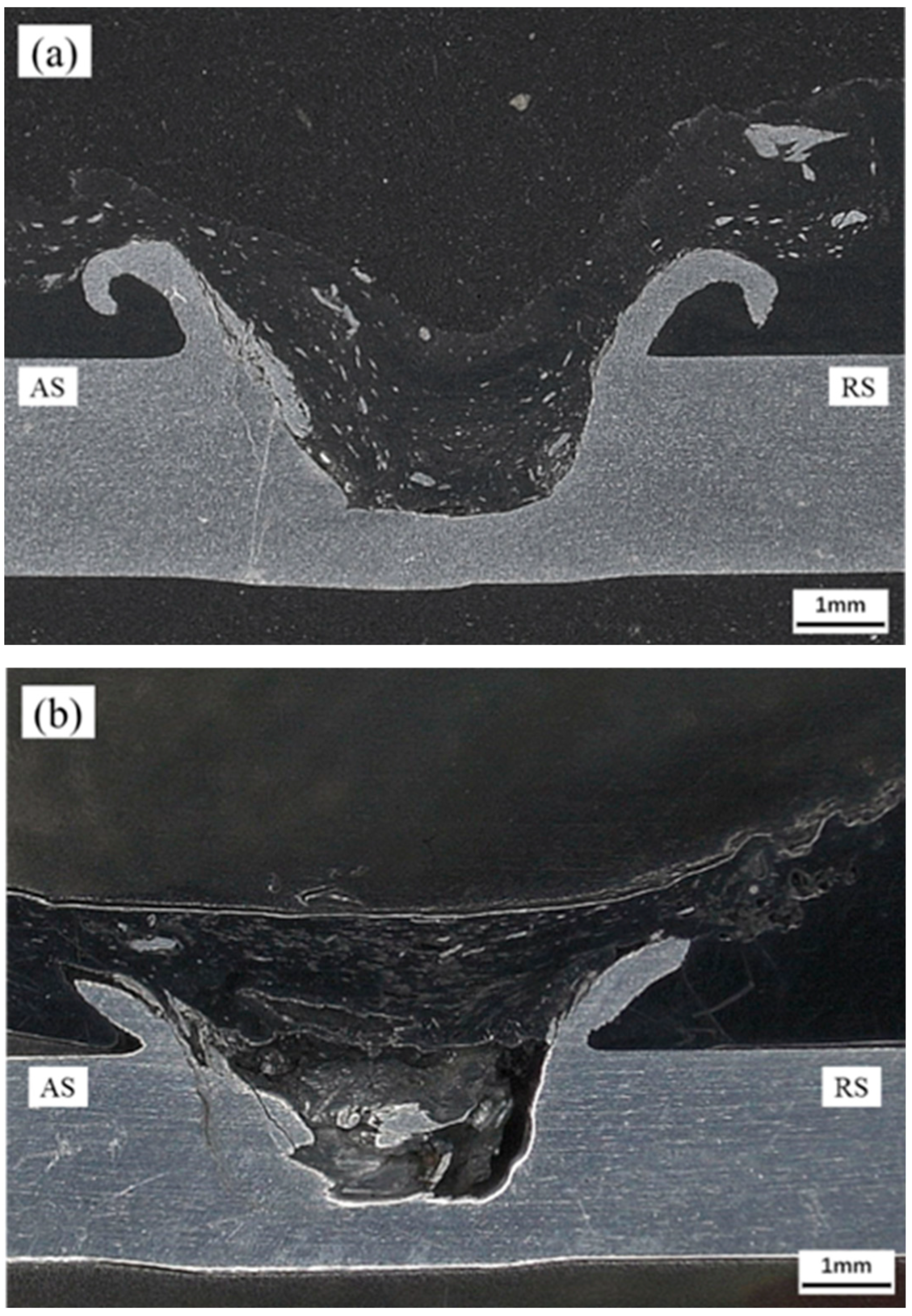

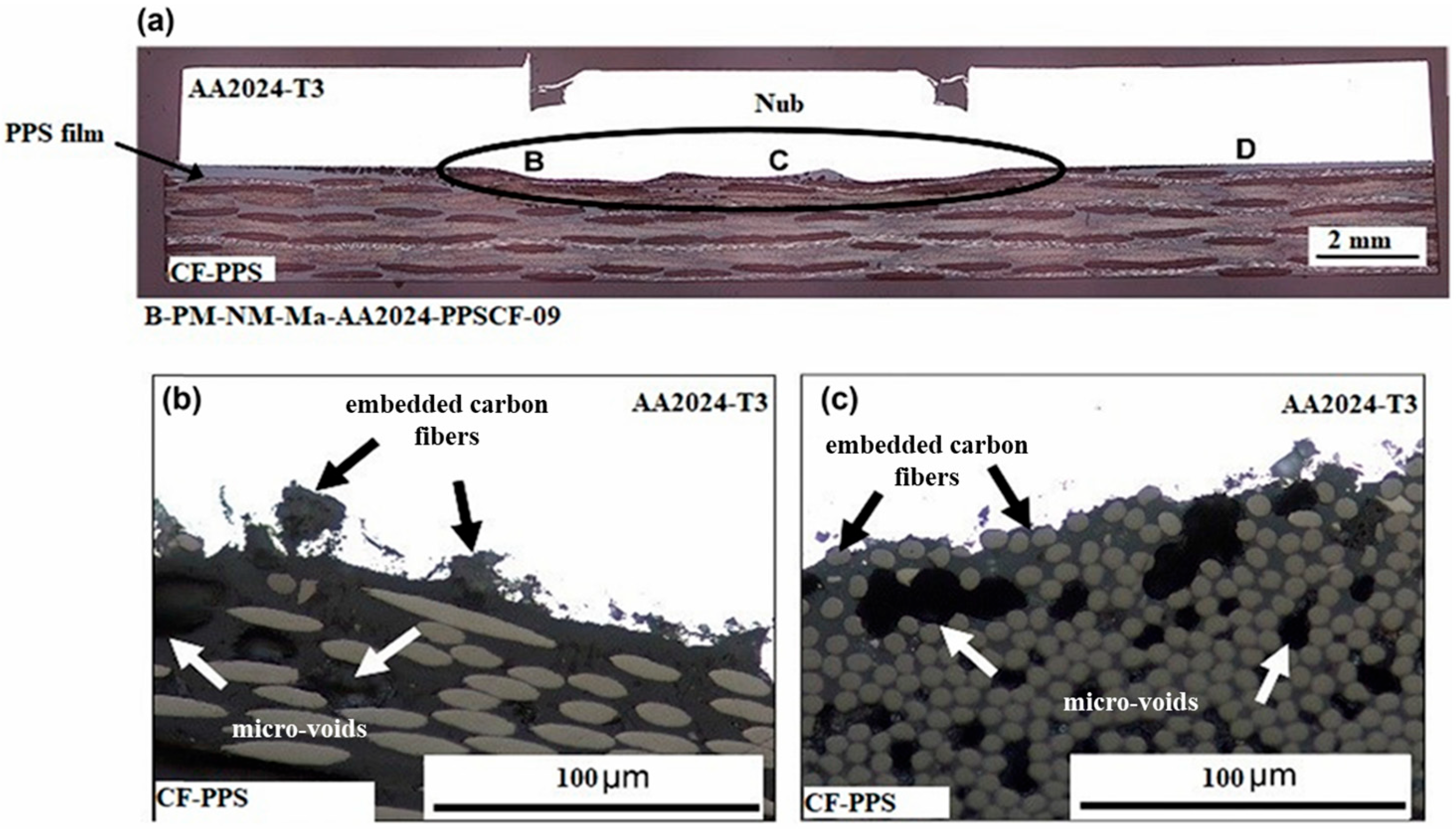

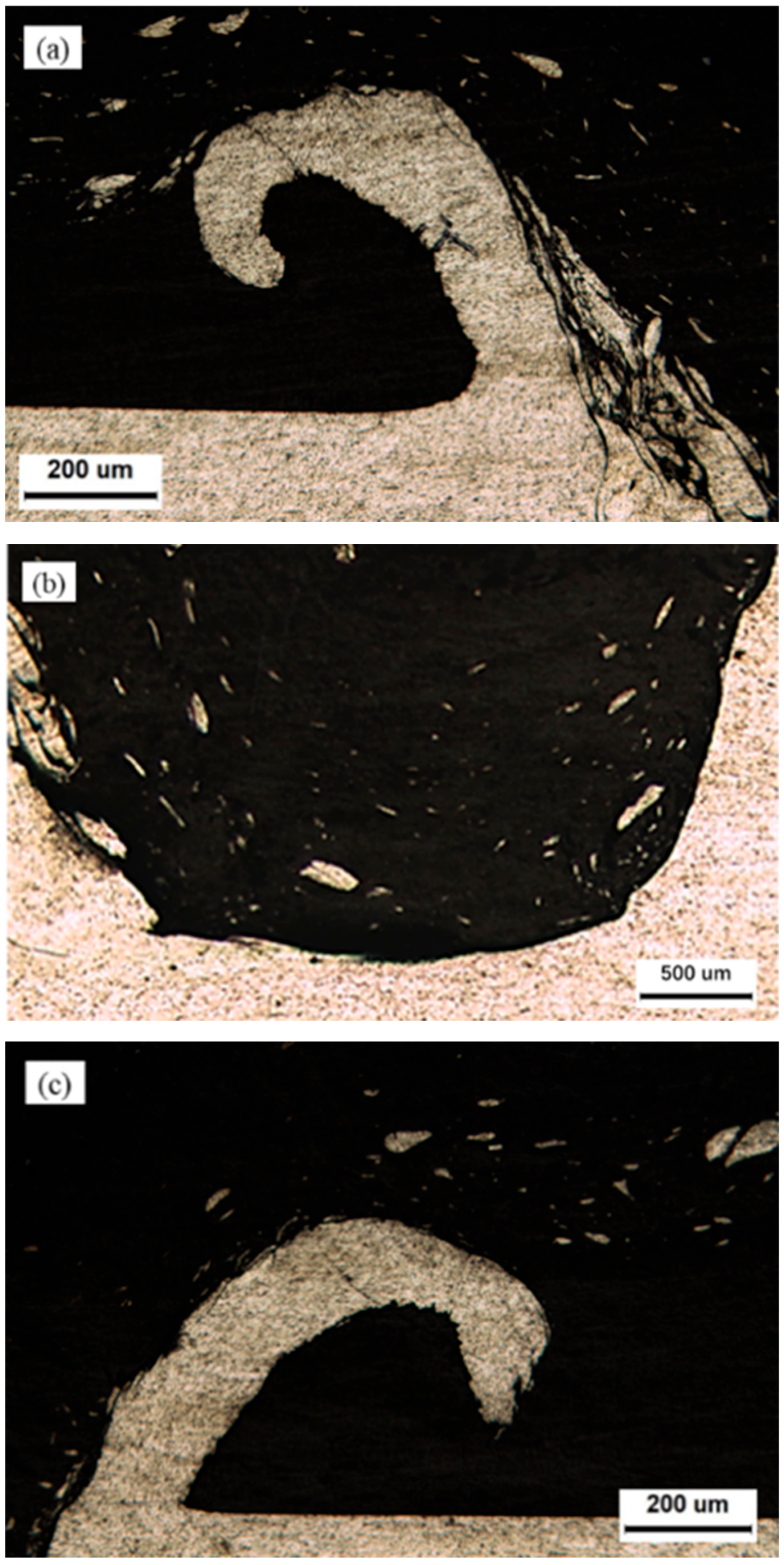

- The macro mechanical interlocking structure is the main connection form that facilitates the successful connection of aluminum alloy and CF-PPS dissimilar materials. The concave shoulder facilitates the outward extension of the aluminum at the edge of the stirring zone, thereby forming a hook that serves to connect the upper and lower plates. The inward curvature of the aluminum anchor serves to augment the connection area between the two plates, thereby enhancing the tensile strength of the weld.

- It has been demonstrated that, under welding parameters of 1800 rpm rotation speed, 40 mm/min welding speed, and 0.2 mm plunge depth, the tensile strength of the joint can reach a maximum value of 9.41 MPa. Concurrently, the microscopic mixture formed by the adhesion between the metal and polymer inside the SZ also increases the tensile strength of the joint.

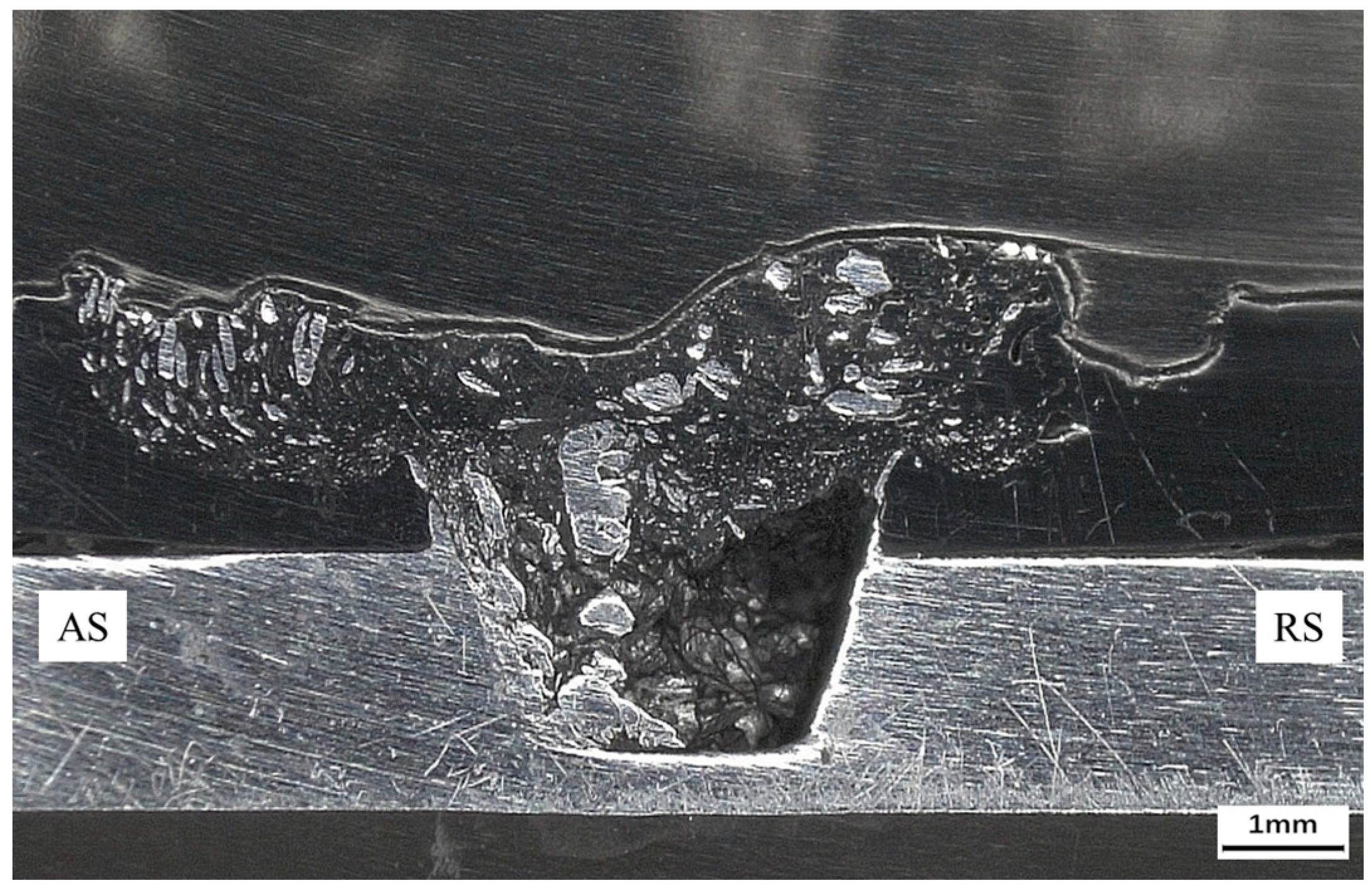

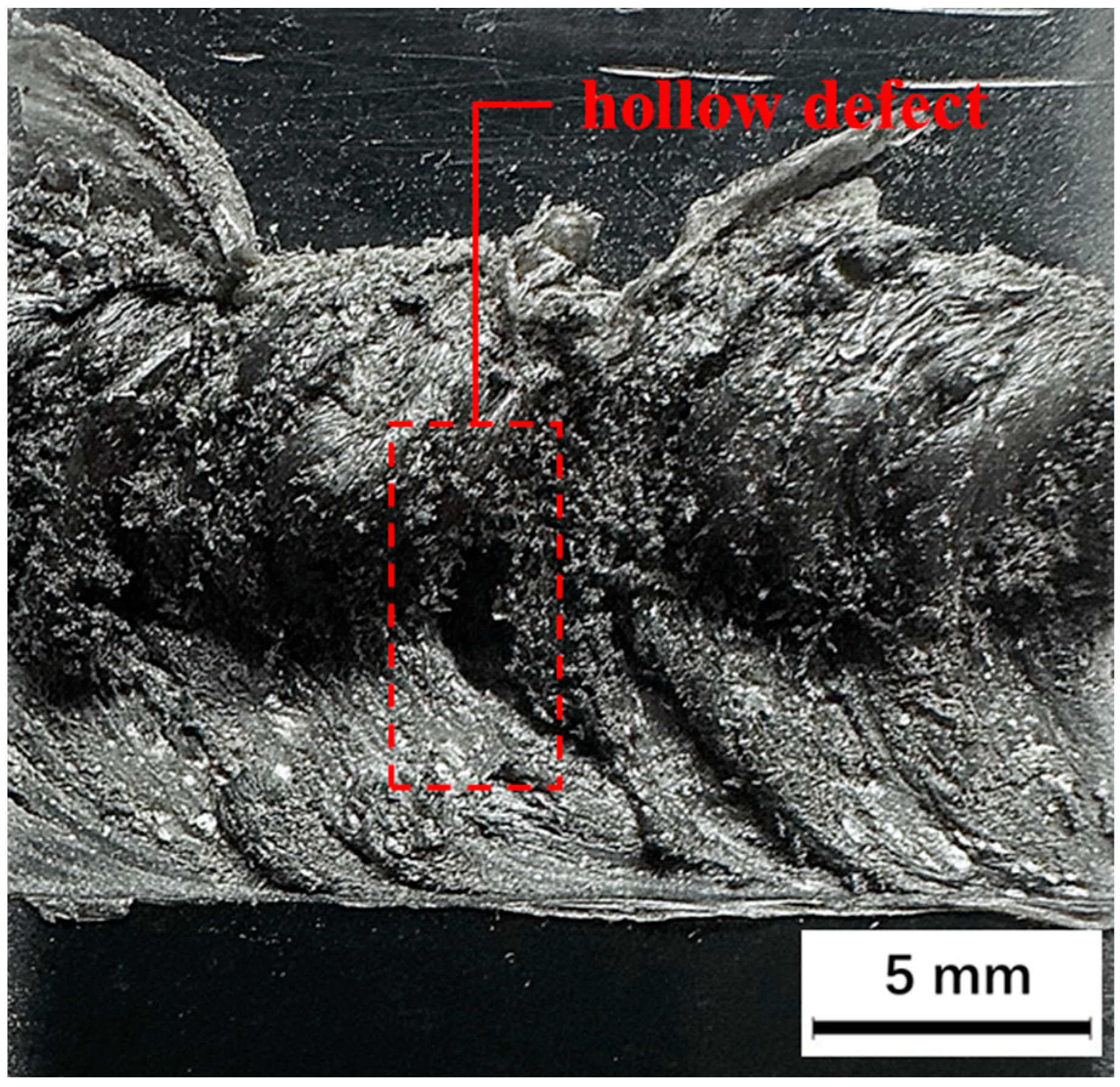

- At low rotation speeds (1600 rpm) and low welding speeds (10 mm/min), an effective mechanical interlocking structure cannot be formed at the center of the weld, which weakens the connection strength. The low rotation speed fails to provide sufficient frictional heat input, resulting in incomplete plasticization of the aluminum below, failure to form aluminum anchors on both sides of the SZ, and the formation of hollow at the bottom. The low welding speed leads to excessive heat generation by friction, resulting in thermal decomposition of a portion of the resin matrix in CF-PPS, which subsequently forms a gas phase. This gas phase expands within the base material, creating cavities, while the aluminum anchors generated on the AS undergo significant damage.

- When the rotation speed and welding speed, the two main parameters affecting the heat input of the welding process are appropriately selected and kept constant. A smaller plunge depth can form an effective mechanical interlocking structure. Excessive plunge depth will thin the weld and reduce the joint strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Lin, Y.; Qian, W.; Lei, L.; Liu, Y.; Zhang, J.; Liu, J.; Kong, W.; Hu, Y.; Shi, Y.; Wu, Z.; et al. Structural integrity issues of composite materials and structures in future transportation equipment. Compos. Struct. 2025, 358, 118943. [Google Scholar] [CrossRef]

- Asmael, M.; Safaei, B.; Kalaf, O.; Zeeshan, Q.; Aldakheel, F.; Nasir, T.; Yang, Z. Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review. Nanotechnol. Rev. 2022, 11, 1408–1436. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Zhou, L.; Zhao, H.; Han, X.; Tan, C.; Song, X. Achievement of high-strength Al/CFRP hybrid joint via high-speed friction stir lap joining and laser texturing pretreatment parameters variation. Thin-Walled Struct. 2024, 199, 111762. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Y.; Wang, W.; Tian, Y.; Zhang, X.; Huang, H.; Zheng, D. Enhancing interfacial bonding in friction stir lap welding of light metal and carbon fiber reinforced polymer composite. J. Manuf. Process. 2022, 83, 729–741. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.; Dong, Y.; Sarker, P.; Uddin, M.; Littlefair, G.; Dixit, A.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys—A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Li, J.; Dong, H.; Tang, Z.; Li, P.; Wu, B.; Ma, Y.; Huang, L.; Zhang, L.; Li, C.; Xiong, J. Influence of surface pretreatment on the bonding mechanism and mechanical properties of AA5052/CFRP friction stir spot welded joint. J. Manuf. Process. 2023, 105, 112–123. [Google Scholar] [CrossRef]

- MirHashemi, S.; Amadeh, A.; Khodabakhshi, F. Effects of SiC nanoparticles on the dissimilar friction stir weldability of low-density polyethylene (LDPE) and AA7075 aluminum alloy. J. Mater. Res. Technol. 2021, 13, 449–462. [Google Scholar] [CrossRef]

- Ingen, V.; Wijngaarden, V.; Iii, S. Development of the gulfstream G650 induction welded thermoplastic elevators and rudder. In Proceedings of the Sampe Seattle 2010, Seattle, WA, USA, 17–20 May 2010; Available online: https://www.researchgate.net/publication/332403057 (accessed on 13 April 2019).

- Lyu, Y.; Wu, J.; Zhang, H.; Brádaigh, C.M.Ó.; Yang, D. Effects of thermal process conditions on crystallinity and mechanical properties in material extrusion additive manufacturing of discontinuous carbon fibre reinforced polyphenylene sulphide composites. J. Compos. Mater. 2023, 57, 3775–3787. [Google Scholar] [CrossRef]

- Eixeres, B.; Sanchez-Caballero, S.; Peydro, M.; Parres, F.; Selles, M. Influence of injection molding process conditions on the mechanical properties of CF-PPS/PTFE composites. Alex. Eng. J. 2025, 123, 381–391. [Google Scholar] [CrossRef]

- André, N.M.; dos Santos, J.F.; Amancio-Filho, S.T. Evaluation of Joint Formation and Mechanical Performance of the AA7075-T6/CFRP Spot Joints Produced by Frictional Heat. Materials 2019, 12, 891. [Google Scholar] [CrossRef]

- Schäfer, H.; Blaga, L.; Stöver, E.; Klusemann, B. Refill friction stir spot welding of thermoplastic composites: Case study on Carbon-fiber-reinforced polyphenylene sulfide. Thin-Walled Struct. 2023, 191, 111037. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.-S.; Zhang, Y.; Yuan, T.; Hodúlová, E.; Šimeková, B.; Bober, M.; Senkara, J.; Li, Z.-X. Influence of the rotation speed on the interface microstructure and joining quality of aluminum alloy 6061/CF-PPS joints produced by refill friction stir spot welding. Weld. World 2022, 66, 923–933. [Google Scholar] [CrossRef]

- Sandeep, R.; Nagarajan, B.M.; Kumar, M.P.; Jose, B.; Manoharan, M.; Natarajan, A. Influence of welding environment on joint characteristics of friction stir lap welded AA7475-PPS polymer hybrid joints. Mater. Lett. 2023, 349, 134781. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Li, J.; Si, X.; Fan, Q. Improving mechanical properties of composite/metal friction stir lap welding joints via a taper-screwed pin with triple facets. J. Mech. Work. Technol. 2019, 268, 80–86. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Elyasi, M. The influence of process parameters in friction stir welding of Al-Mg alloy and polycarbonate. J. Manuf. Process. 2018, 35, 88–98. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Fard, R.K.; Khodabakhshi, F. Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld. World 2018, 62, 117–130. [Google Scholar] [CrossRef]

- GB/T 7124-2008; Adhesives—Determination of Tensile Lap-Shear Strength of Rigid-to-Rigid Bonded Assemblies. Standardization Administration of China: Beijing, China, 2008.

- Haghshenas, M.; Khodabakhshi, F. Dissimilar friction-stir welding of aluminum and polymer: A review. Int. J. Adv. Manuf. Technol. 2019, 104, 333–358. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F.; Simchi, A. Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: Thermo-mechanical modelling and experimental feasibility study. Sci. Technol. Weld. Join. 2018, 23, 35–49. [Google Scholar] [CrossRef]

- André, N.M.; Alessio, R.P.; dos Santos, J.F.; Amancio-Filho, S.T. Microscale Damage Evolution and Failure Behavior of Metal–Composite Friction Spot Joints: Modelling and Experimental Analyses. Metals 2022, 12, 2080. [Google Scholar] [CrossRef]

- André, N.M.; Goushegir, S.M.; dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Friction Spot Joining of aluminum alloy 2024-T3 and carbon-fiber-reinforced poly(phenylene sulfide) laminate with additional PPS film interlayer: Microstructure, mechanical strength and failure mechanisms. Compos. Part B Eng. 2016, 94, 197–208. [Google Scholar] [CrossRef]

- Ren, S.; Ma, Y.; Saeki, S.; Iwamoto, Y.; Chen, C.; Ma, N. Fracture mechanism and strength evaluation of Al5052/CFRP joint produced by coaxial one-side resistance spot welding. Compos. Struct. 2020, 252, 112766. [Google Scholar] [CrossRef]

- Ren, S.; Shen, Y.; Chen, H.; Zheng, W.; Ma, Y.; Feng, D.; Yang, J. Investigation on the joining process and strength of laser circle welding between Al5052 and CFRP dissimilar materials. J. Manuf. Process. 2024, 120, 426–434. [Google Scholar] [CrossRef]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Friction Spot Joining of aluminum AA2024/carbon-fiber reinforced poly(phenylene sulfide) composite single lap joints: Microstructure and mechanical performance. Mater. Des. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Esteves, J.V.; Goushegir, S.M.; dos Santos, J.F.; Canto, L.B.; Hage, E., Jr.; Amancio-Filho, S.T. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly(phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater. Des. 2015, 66, 437–445. [Google Scholar] [CrossRef]

| Chemical Composition (wt%) | |||||||

|---|---|---|---|---|---|---|---|

| Mg | Fe | Si | Cu | Zn | Mn | Cr | Al |

| 0.8–1.2 | 0.7 | 0.4–0.8 | 0.15–0.4 | 0.25 | 0.15 | 0.04–0.35 | Base |

| Mechanical Properties | ||

|---|---|---|

| Yield Strength (MPa) | Tensile Strength (MPa) | Extension Rate (%) |

| 240 | 310 | 8 |

| Density (g/cm3) | Melting Temperature (°C) | Tensile Strength (MPa) | In-Plane Strength (MPa) | Extension Rate (%) |

|---|---|---|---|---|

| 1.35 | 295 | 170 | 119 | 1.2 |

| FSLW Experimental Program | Rotation Speed | Welding Speed | Plunge Depth | Inclination Angle |

|---|---|---|---|---|

| The effect of rotation speed | 1600 rpm | 40 mm/min | 0.2 mm | 2° |

| 1700 rpm | ||||

| 1800 rpm | ||||

| 1900 rpm | ||||

| 2000 rpm | ||||

| The effect of welding speed | 1800 rpm | 10 mm/min | 0.2 mm | 2° |

| 20 mm/min | ||||

| 30 mm/min | ||||

| 40 mm/min | ||||

| 50 mm/min | ||||

| The effect of plunge depth | 1800 rpm | 40 mm/min | 0.1 mm | 2° |

| 0.15 mm | ||||

| 0.2 mm | ||||

| 0.25 mm | ||||

| 0.3 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Lin, Y.; Feng, Q.; Wang, Y.; Wang, J.; Niu, S.; Lou, M. The Effect of Welding Parameters on the Morphology and Mechanical Properties of AA6061-T6/CF-PPS Friction Stir Lap Welding Joints. Metals 2025, 15, 1049. https://doi.org/10.3390/met15091049

Xu W, Lin Y, Feng Q, Wang Y, Wang J, Niu S, Lou M. The Effect of Welding Parameters on the Morphology and Mechanical Properties of AA6061-T6/CF-PPS Friction Stir Lap Welding Joints. Metals. 2025; 15(9):1049. https://doi.org/10.3390/met15091049

Chicago/Turabian StyleXu, Wenhao, Yongyong Lin, Qiaobo Feng, Yangjun Wang, Jie Wang, Sizhe Niu, and Ming Lou. 2025. "The Effect of Welding Parameters on the Morphology and Mechanical Properties of AA6061-T6/CF-PPS Friction Stir Lap Welding Joints" Metals 15, no. 9: 1049. https://doi.org/10.3390/met15091049

APA StyleXu, W., Lin, Y., Feng, Q., Wang, Y., Wang, J., Niu, S., & Lou, M. (2025). The Effect of Welding Parameters on the Morphology and Mechanical Properties of AA6061-T6/CF-PPS Friction Stir Lap Welding Joints. Metals, 15(9), 1049. https://doi.org/10.3390/met15091049