Solid-State Recycling of AA6063 Aluminum Chips via Accumulative Roll Bonding: A Green Pathway to High-Performance Materials

Abstract

1. Introduction

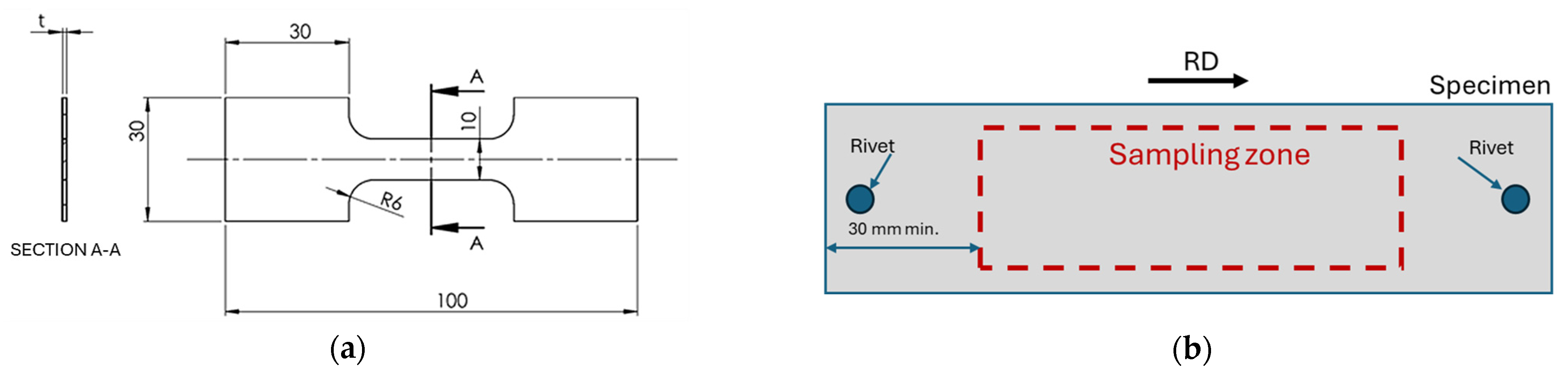

2. Materials and Methods

3. Results and Discussion

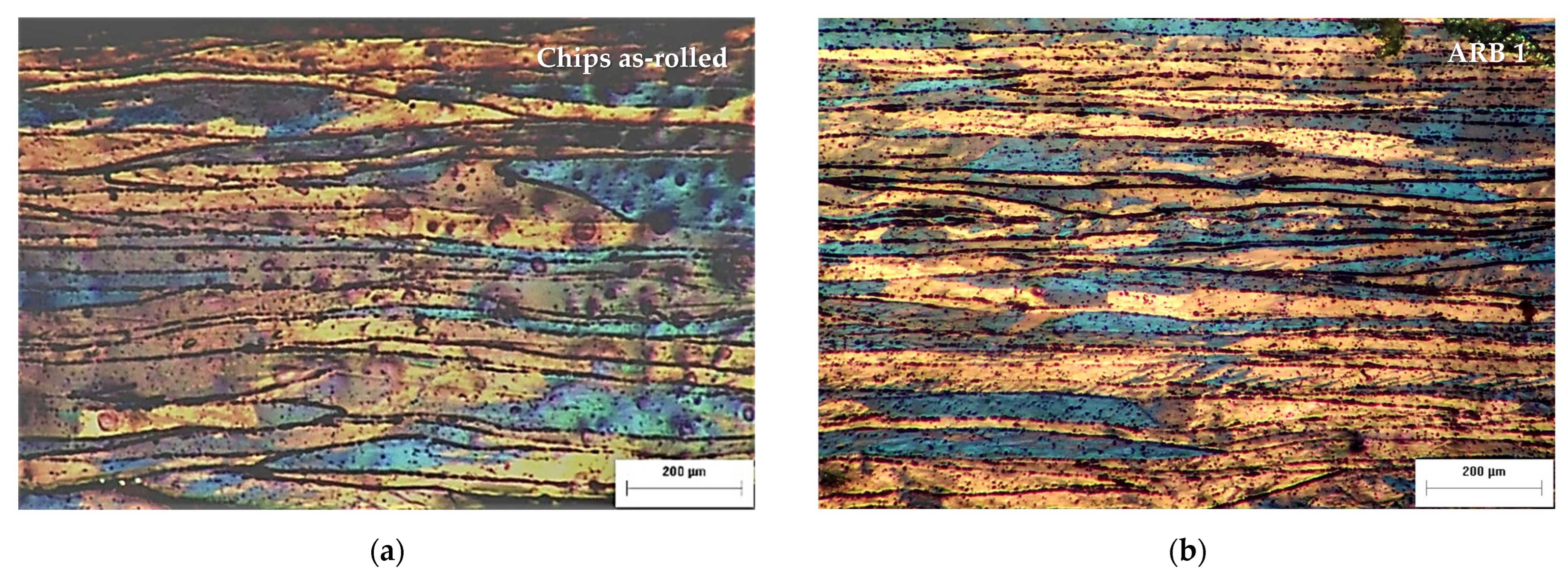

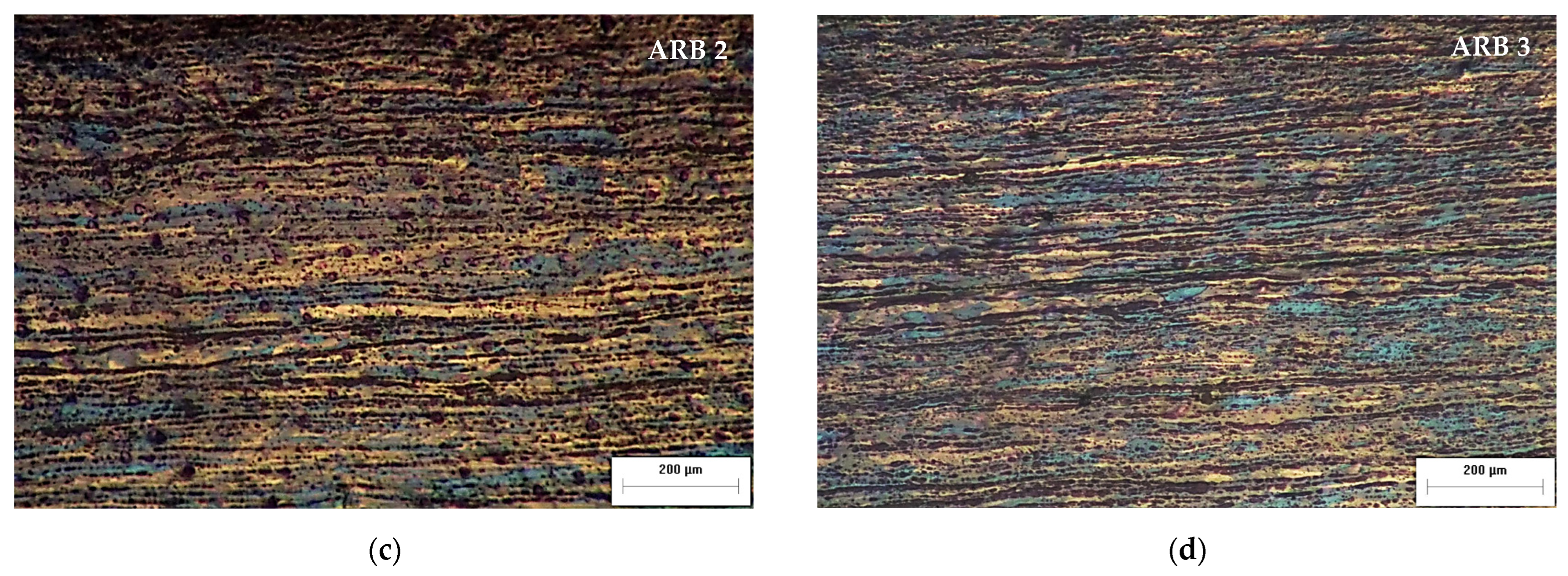

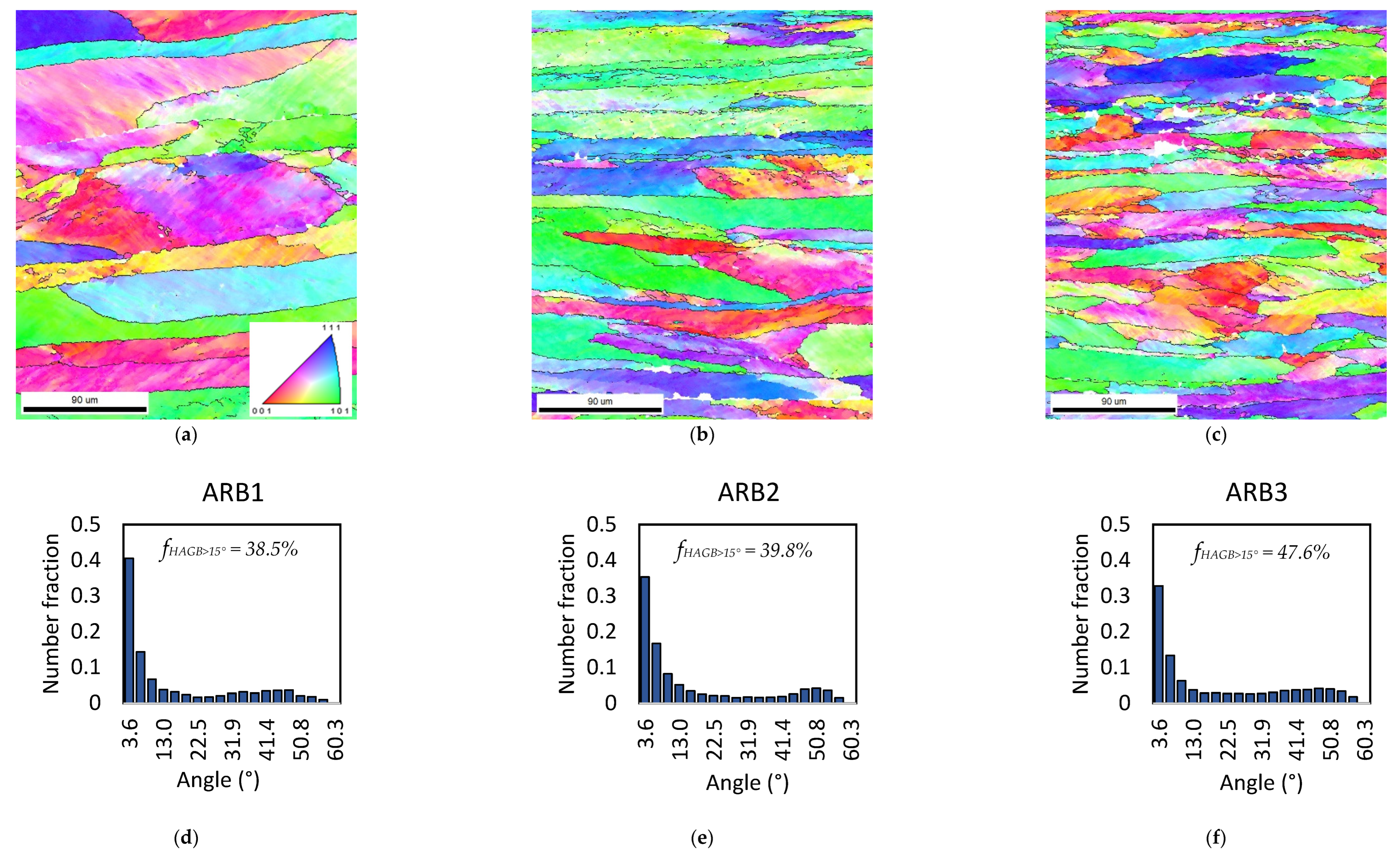

3.1. Microstructures

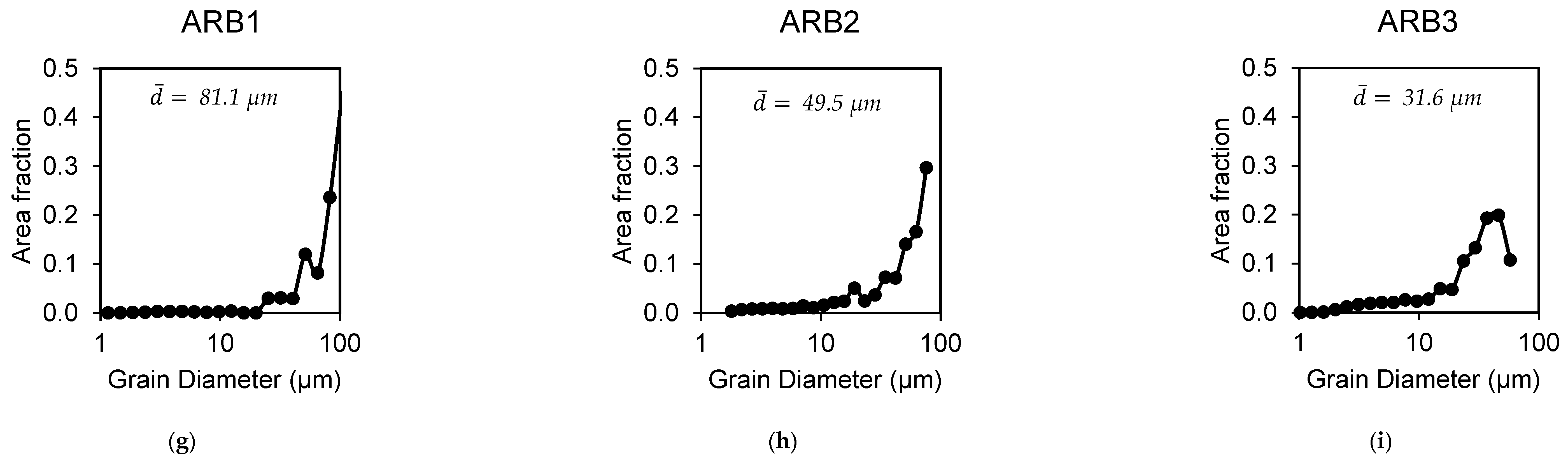

3.2. SEM and EDS Analysis

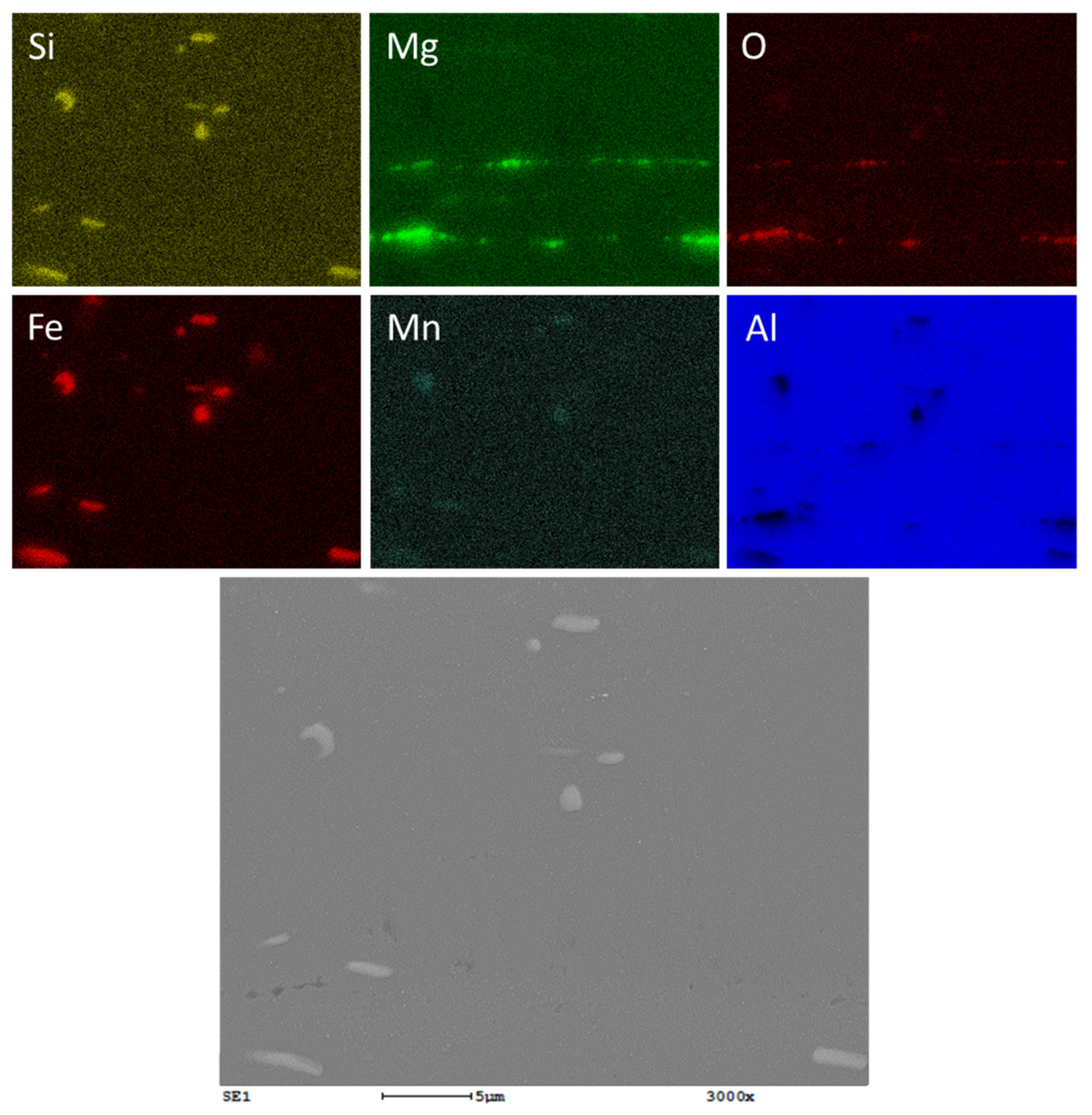

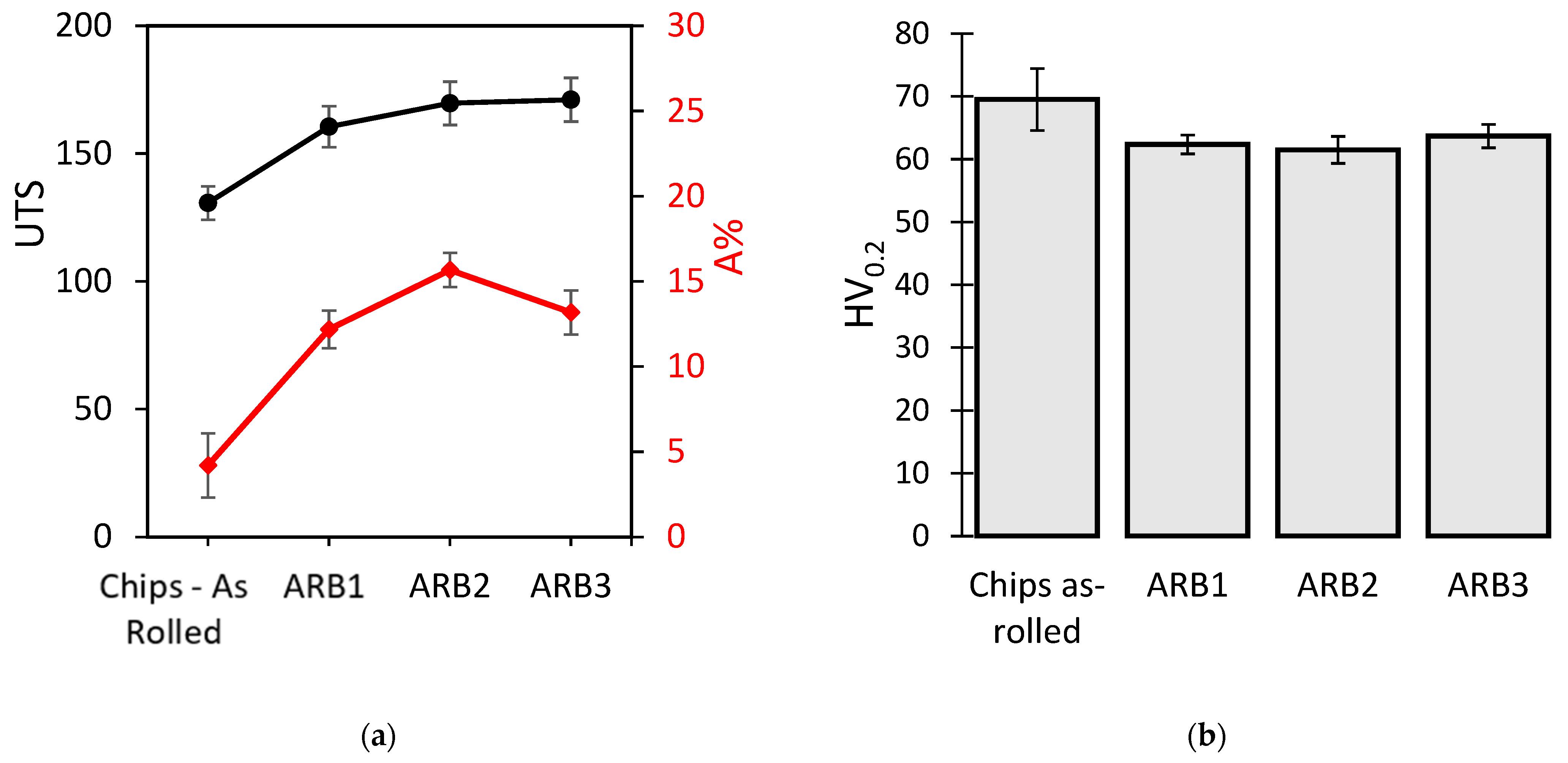

3.3. Mechanical Properties

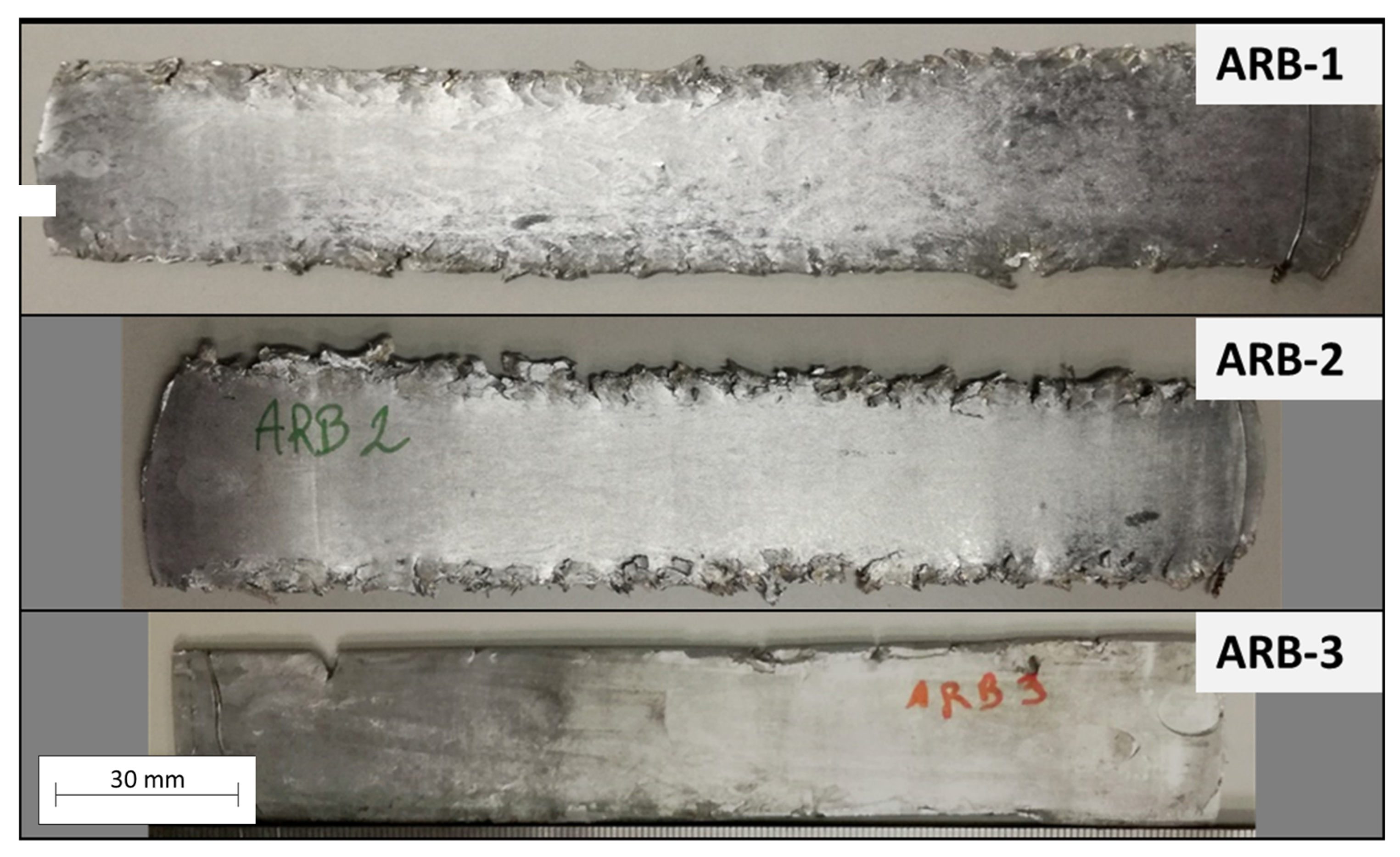

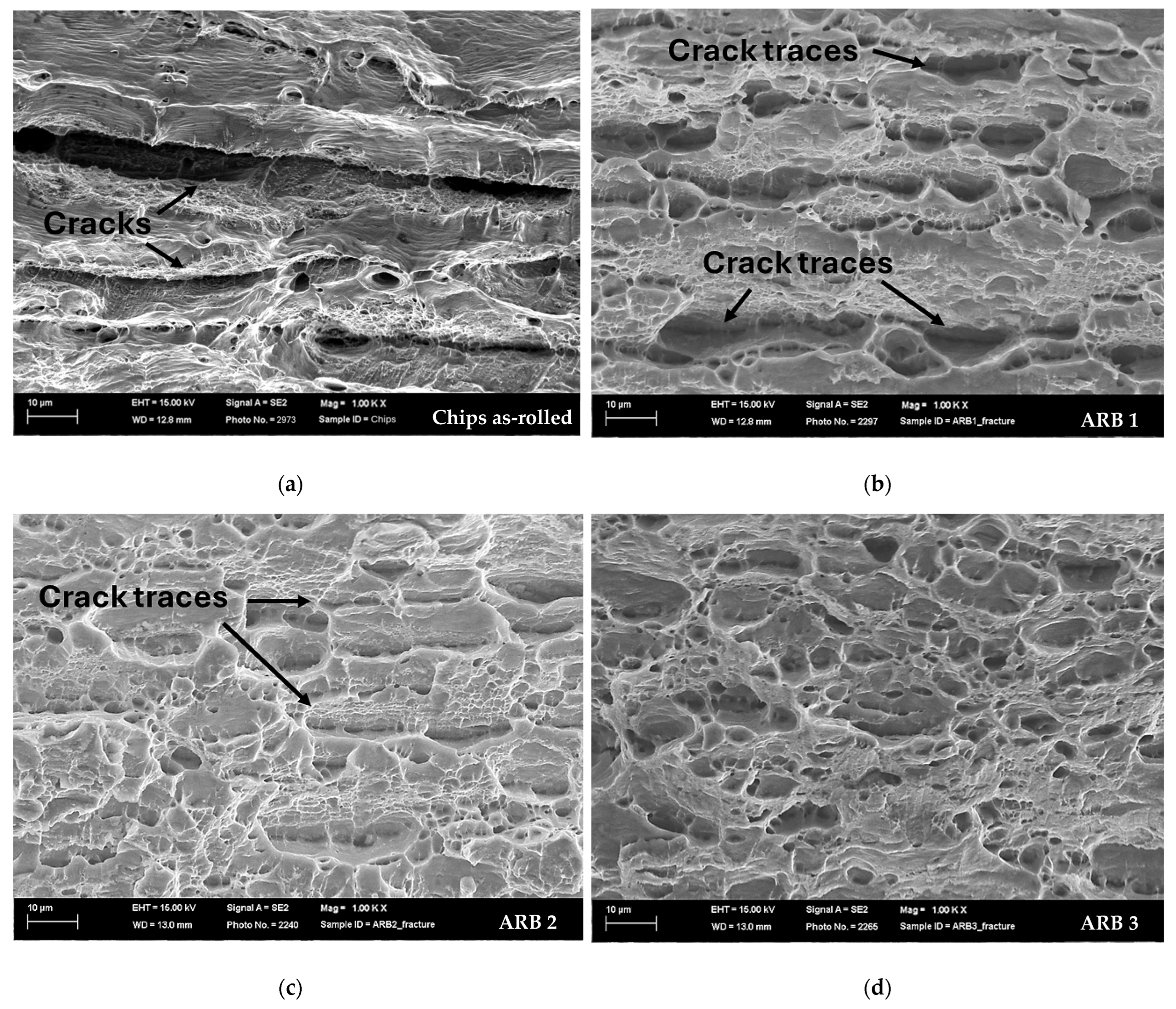

3.4. Fracture Surfaces

4. Conclusions

- Direct hot rolling of compacted chips without heat treatment resulted in poor bonding and suboptimal mechanical properties;

- The ARB process significantly improved chip consolidation; after two cycles, the material reached a UTS of 170 MPa and an elongation at break of 15.7%;

- Microstructural observations revealed progressive grain refinement; EBSD analysis showed an increase in high-angle grain boundaries and reduced grain elongation with each ARB cycle, indicating recrystallization and improved homogeneity;

- SEM and EDS analyses confirmed the breakup and redistribution of oxides and intermetallic phases, contributing to enhanced mechanical behavior and cleaner fracture surfaces;

- Although the ARB process is effective, it still faces industrial challenges, including manual preparation steps, the absence of lubricants, and roll sticking. However, its compatibility with conventional rolling equipment makes it a promising solution for upcycling aluminum scrap into high-performance products.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rudnick, R.L.; Gao, S. Composition of the Continental Crust. In Treatise on Geochemistry; Holland, H.D., Turekian, K.K., Eds.; Elsevier-Pergamon: Oxford, UK; London, UK, 2003; Volume 3, pp. 1–64. [Google Scholar]

- Das, S.K.; Yin, W. The worldwide aluminum economy: The current state of the industry. JOM 2007, 59, 57–63. [Google Scholar] [CrossRef]

- Raabe, D.; Ponge, D.; Uggowitzer, P.J.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making sustainable aluminum by recycling scrap: The science of “dirty” alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Al Mahmood, A.; Kader, A.; Islam, M.B.; Hossain, R. Sustainable transformation of waste Aluminium into high-performance composites: A review. Int. J. Light. Mater. Manuf. 2025, 8, 194–204. [Google Scholar] [CrossRef]

- Al-Alimi, S.; Yusuf, N.K.; Ghaleb, A.M.; Lajis, M.A.; Shamsudin, S.; Zhou, W.; Altharan, Y.M.; Abdulwahab, H.S.; Saif, Y.; Didane, D.H.; et al. Recycling aluminium for sustainable development: A review of different processing technologies in green manufacturing. Results Eng. 2024, 23, 102566. [Google Scholar] [CrossRef]

- Altharan, Y.M.; Shamsudin, S.; Al-Alimi, S.; Saif, Y.; Zhou, W. A review on solid-state recycling of aluminum machining chips and their morphology effect on recycled part quality. Heliyon 2024, 10, e34433. [Google Scholar] [CrossRef] [PubMed]

- Shamsudin, S.; Lajis, M.; Zhong, Z. Solid-state recycling of light metals: A review. Adv. Mech. Eng. 2016, 8, 1687814016661921. [Google Scholar] [CrossRef]

- Tekkaya, A.; Schikorra, M.; Becker, D.; Biermann, D.; Hammer, N.; Pantke, K. Hot profile extrusion of AA-6060 aluminum chips. J. Mech. Work. Technol. 2009, 209, 3343–3350. [Google Scholar] [CrossRef]

- Gronostajski, J.; Marciniak, H.; Matuszak, A. New methods of aluminium and aluminium-alloy chips recycling. J. Mech. Work. Technol. 2000, 106, 34–39. [Google Scholar] [CrossRef]

- Mani, B.; Paydar, M. Application of forward extrusion-equal channel angular pressing (FE-ECAP) in fabrication of aluminum metal matrix composites. J. Alloys Compd. 2010, 492, 116–121. [Google Scholar] [CrossRef]

- Bocchi, S.; Zambelli, M.; D’urso, G.; Giardini, C. Efficiency and Microstructural Forecasts in Friction Stir Extrusion Compared to Traditional Hot Extrusion of AA6061. J. Manuf. Mater. Process. 2024, 8, 172. [Google Scholar] [CrossRef]

- Baffari, D.; Buffa, G.; Campanella, D.; Fratini, L. Design of continuous Friction Stir Extrusion machines for metal chip recycling: Issues and difficulties. Procedia Manuf. 2018, 15, 280–286. [Google Scholar] [CrossRef]

- Altharan, Y.M.; Shamsudin, S.; Al-Alimi, S.; Jubair, M.A. Development of Zirconia Reinforced AA7075/AA7050 Aluminum Chip-Based Composite Processed Using Hot Press Forging Method. Int. J. Technol. 2023, 14, 5. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; El Mohtadi, R.; Loi, G.; Aymerich, F.; Ben Khalifa, N.; Carta, M. Feasibility Study of Solid-State Recycling through Direct Hot Rolling of AA5754 Aluminum Chips for Automotive Applications. Mater. Sci. Forum 2024, 1130, 3–12. [Google Scholar] [CrossRef]

- Carta, M.; Ben Khalifa, N.; Buonadonna, P.; El Mohtadi, R.; Bertolino, F.; El Mehtedi, M. Innovative Solid-State Recycling of Aluminum Alloy AA6063 Chips Through Direct Hot Rolling Process. Metals 2024, 14, 1442. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Carta, M.; Buonadonna, P. A Novel Direct Hot Rolling Process for Sustainable Recycling of AA3105 Alu-minum Chips Using a Protective Envelopment. Manuf. Lett. 2025, 45, 70–74. [Google Scholar] [CrossRef]

- Chino, Y.; Hoshika, T.; Lee, J.-S.; Mabuchi, M. Mechanical properties of AZ31 Mg alloy recycled by severe deformation. J. Mater. Res. 2006, 21, 754–760. [Google Scholar] [CrossRef]

- Hu, M.-L.; Ji, Z.-S.; Chen, X.-Y.; Wang, Q.-D.; Ding, W.-J. Solid-state recycling of AZ91D magnesium alloy chips. Trans. Nonferrous Met. Soc. China 2012, 22, s68–s73. [Google Scholar] [CrossRef]

- Zhang, T.; Ji, Z.; Wu, S. Effect of extrusion ratio on mechanical and corrosion properties of AZ31B alloys prepared by a solid recycling process. Mater. Des. 2011, 32, 2742–2748. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Lai, D.; Almehtedi, R.; Carta, M.; Buonadonna, P.; Aymerich, F. Bonding of similar AA3105 aluminum alloy by Accumulative Roll Bonding process. ESAFORM 2021. [Google Scholar] [CrossRef]

- Ghalehbandi, S.M.; Malaki, M.; Gupta, M. Accumulative Roll Bonding—A Review. Appl. Sci. 2019, 9, 3627. [Google Scholar] [CrossRef]

- Carta, M.; Ben Khalifa, N.; Buonadonna, P.; Mele, A.; El Mehtedi, M. Life cycle assessment (LCA) of a novel solid-state recycling process for aluminum alloy AA6063 chips via direct hot rolling. Mater. Res. Proc. 2024, 41, 2881–2890. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; Carta, M.; El Mohtadi, R.; Mele, A.; Morea, D. Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach. Sustainability 2023, 15, 11434. [Google Scholar] [CrossRef]

- ASTM E8/E8M-2016a; Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- UNI EN 895:1997; Prove Distruttive sui Giunti Saldati di Materiali Metallici—Prova di Trazione sui Campioni di Grosso Spessore (Destructive Tests on Welded Joints in Metallic Materials—Transverse Tensile Test). UNI: Milan, Italy, 1997.

- Babu, V.; Shanmugavel, B.P.; Padmanabhan, K.A. Effects of processing temperature and number of passes on the microstructure and mechanical properties of AA 6063 processed by cyclic expansion extrusion. Arch. Civ. Mech. Eng. 2021, 21, 38. [Google Scholar] [CrossRef]

- Alvandi, H.; Farmanesh, K. Microstructural and Mechanical Properties of Nano/Ultra-fine Structured 7075 Aluminum Alloy by Accumulative Roll-Bonding Process. Procedia Mater. Sci. 2015, 11, 17–23. [Google Scholar] [CrossRef]

- Kuijpers, N.; Vermolen, F.; Vuik, C.; Koenis, P.; Nilsen, K.; van der Zwaag, S. The dependence of the β-AlFeSi to α-Al(FeMn)Si transformation kinetics in Al–Mg–Si alloys on the alloying elements. Mater. Sci. Eng. A 2005, 394, 9–19. [Google Scholar] [CrossRef]

- Que, Z.; Mendis, C.L. Heterogeneous nucleation and phase transformation of Fe-rich intermetallic compounds in Al–Mg–Si alloys. J. Alloys Compd. 2020, 836, 155515. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, J.; Xia, T.; Xie, Y.; Chan, S.L.I.; Wang, J.; Zhang, D. Effects of Oxide Fragments on Microstructure and Mechanical Properties of AA6061 Aluminum Alloy Tube Fabricated by Thermomechanical Consolidation of Machining Chips. Materials 2023, 16, 1384. [Google Scholar] [CrossRef]

- Laurent-Brocq, M.; Lilensten, L.; Pinot, C.; Schulze, A.; Duchaussoy, A.; Bourgon, J.; Leroy, E.; Tekkaya, A.E. Solid state recycling of aluminium chips: Multi-technique characterization and analysis of oxidation. Materialia 2023, 31, 101864. [Google Scholar] [CrossRef]

- Duchateau, T.; Lilensten, L.; Zhang, X.; Gebhard, J.; Tekkaya, A.E.; Laurent-Brocq, M. Effect of annealing on oxidation during solid-state recycling of aluminium chips. J. Alloys Compd. 2024, 1010, 178178. [Google Scholar] [CrossRef]

- ASM Specialty Handbook: Aluminum and Aluminum Alloys; Davis, J.R., Ed.; ASM International: Almere, The Netherlands, 1993; ISBN 978-0-87170-496-2. [Google Scholar]

- Arigela, V.; Palukuri, N.; Singh, D.; Kolli, S.; Jayaganthan, R.; Chekhonin, P.; Scharnweber, J.; Skrotzki, W. Evolution of microstructure and mechanical properties in 2014 and 6063 similar and dissimilar aluminium alloy laminates produced by accumulative roll bonding. J. Alloys Compd. 2019, 790, 917–927. [Google Scholar] [CrossRef]

- Jafarian, H.; Miyamoto, H. Tailoring Microstructure and Mechanical Properties of Nano/Ultrafine Grained AA6063 Alloy Processed by Accumulative Roll Bonding Process. Iran. J. Mater. Sci. Eng. 2020, 17, 1–10. [Google Scholar] [CrossRef]

- Jafarian, H.; Anijdan, S.M.; Miyamoto, H. Observation of low temperature superplasticity in an ultrafine grained AA6063 alloy. Mater. Sci. Eng. A 2020, 795, 140015. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.585 | 0.231 | 0.027 | 0.030 | 0.489 | 0.007 | 0.007 | 0.033 | 0.018 | Bal. |

| Number of Passes | h0 | h1 | h2 | h3 | h4 | h5 | h6 | h7 | ARB1 | ARB2 | ARB3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chips [mm] | 10.5 | 6.5 | 4.4 | 3.2 | 2.4 | 2.0 | 1.8 | 1.5 | 1.5 | 1.5 | 1.5 |

| True Strain per pass | - | 0.480 | 0.390 | 0.318 | 0.288 | 0.182 | 0.105 | 0.182 | 0.693 | 0.693 | 0.693 |

| Cumulative strain | - | 0.480 | 0.870 | 1.188 | 1.476 | 1.658 | 1.764 | 1.946 | 2.639 | 3.332 | 4.025 |

| Chips As-Rolled | ARB 1 | ARB 2 | ARB 3 | Typical AA6063 Wrought Alloy (O) [34] | Typical AA6063 Wrought Alloy (T4) [34] | Typical AA6063 Wrought Alloy (T6) [34] | |

|---|---|---|---|---|---|---|---|

| Proof Stress [MPa] | 75 ± 4 | 69 ± 3 | 62 ± 5 | 83 ± 4 | 50 | 90 | 215 |

| UTS [MPa] | 131 ± 7 | 161 ± 8 | 170 ± 9 | 171 ± 9 | 90 | 170 | 240 |

| A% [%] | 4.2 ± 1.9 | 12.2 ± 1.1 | 15.7 ± 1.0 | 13.2 ± 1.3 | - | 22 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carta, M.; Ben Khalifa, N.; Buonadonna, P.; Aymerich, F.; El Mehtedi, M. Solid-State Recycling of AA6063 Aluminum Chips via Accumulative Roll Bonding: A Green Pathway to High-Performance Materials. Metals 2025, 15, 1042. https://doi.org/10.3390/met15091042

Carta M, Ben Khalifa N, Buonadonna P, Aymerich F, El Mehtedi M. Solid-State Recycling of AA6063 Aluminum Chips via Accumulative Roll Bonding: A Green Pathway to High-Performance Materials. Metals. 2025; 15(9):1042. https://doi.org/10.3390/met15091042

Chicago/Turabian StyleCarta, Mauro, Noomane Ben Khalifa, Pasquale Buonadonna, Francesco Aymerich, and Mohamad El Mehtedi. 2025. "Solid-State Recycling of AA6063 Aluminum Chips via Accumulative Roll Bonding: A Green Pathway to High-Performance Materials" Metals 15, no. 9: 1042. https://doi.org/10.3390/met15091042

APA StyleCarta, M., Ben Khalifa, N., Buonadonna, P., Aymerich, F., & El Mehtedi, M. (2025). Solid-State Recycling of AA6063 Aluminum Chips via Accumulative Roll Bonding: A Green Pathway to High-Performance Materials. Metals, 15(9), 1042. https://doi.org/10.3390/met15091042