Numerical Investigation of Burden Distribution in Oxygen Blast Furnace Ironmaking

Abstract

1. Introduction

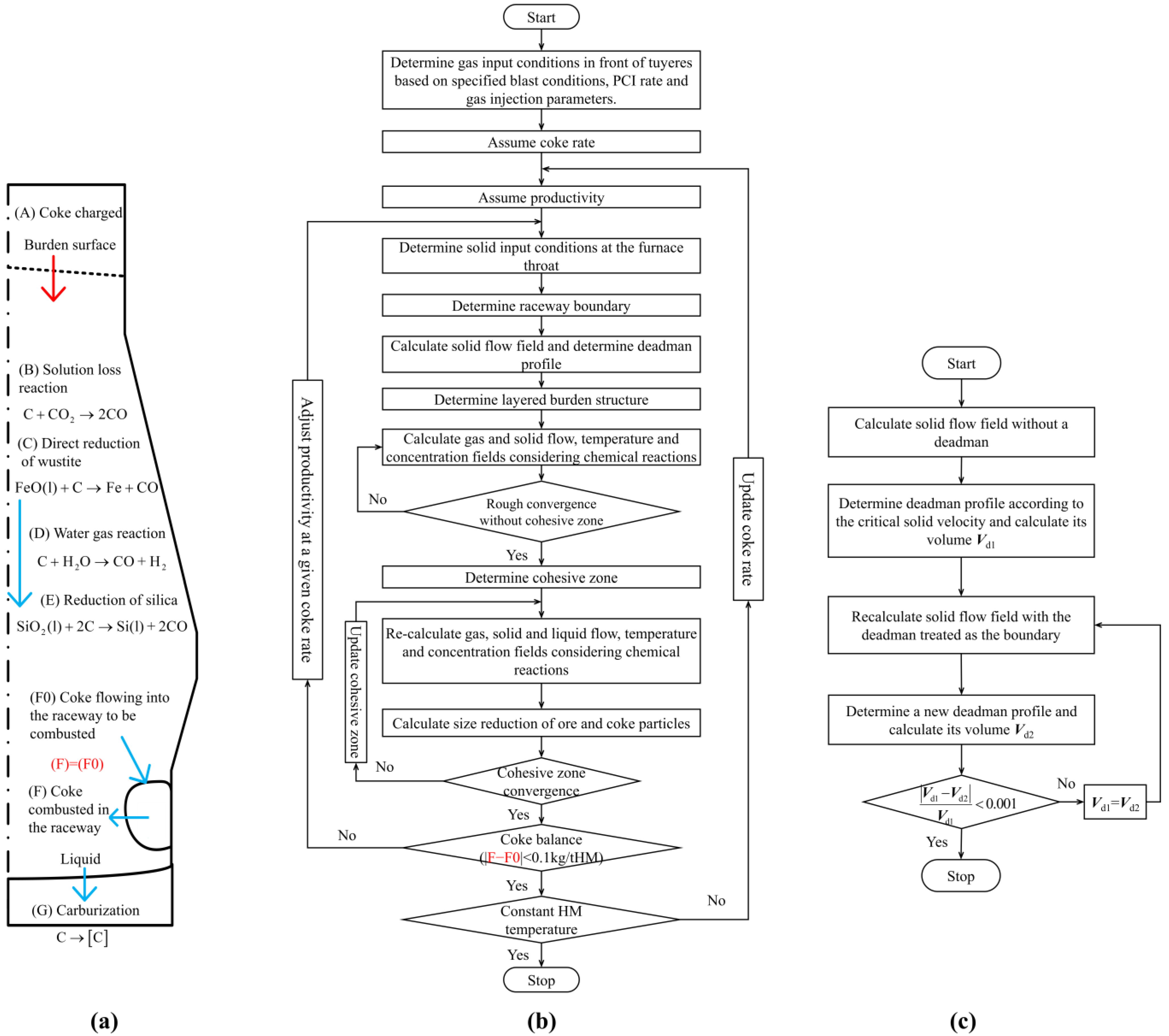

2. Model Description

2.1. Model Framework

2.2. Prediction of Productivity

2.3. Prediction of Fuel Rate

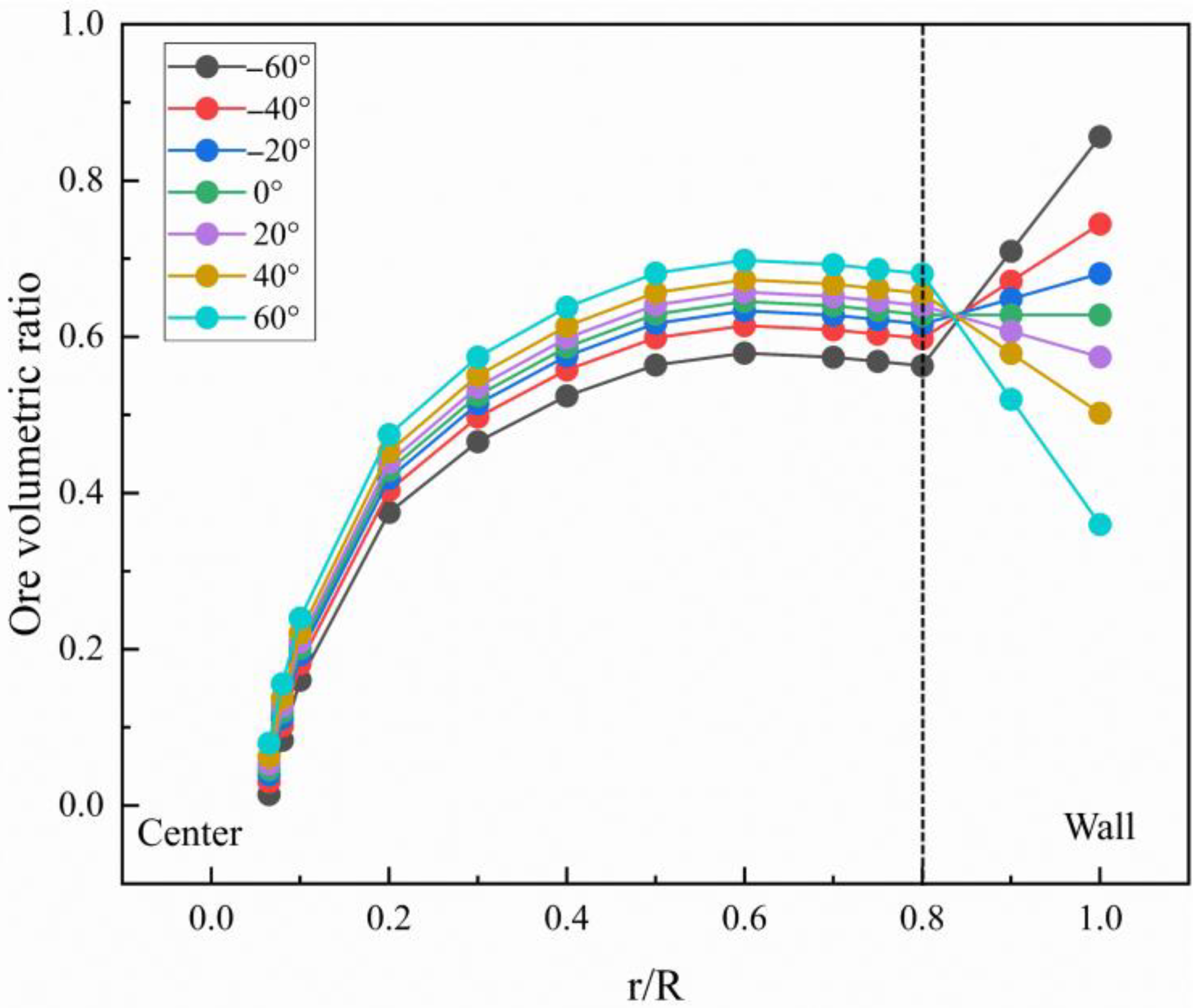

2.4. Layered Burden Structure

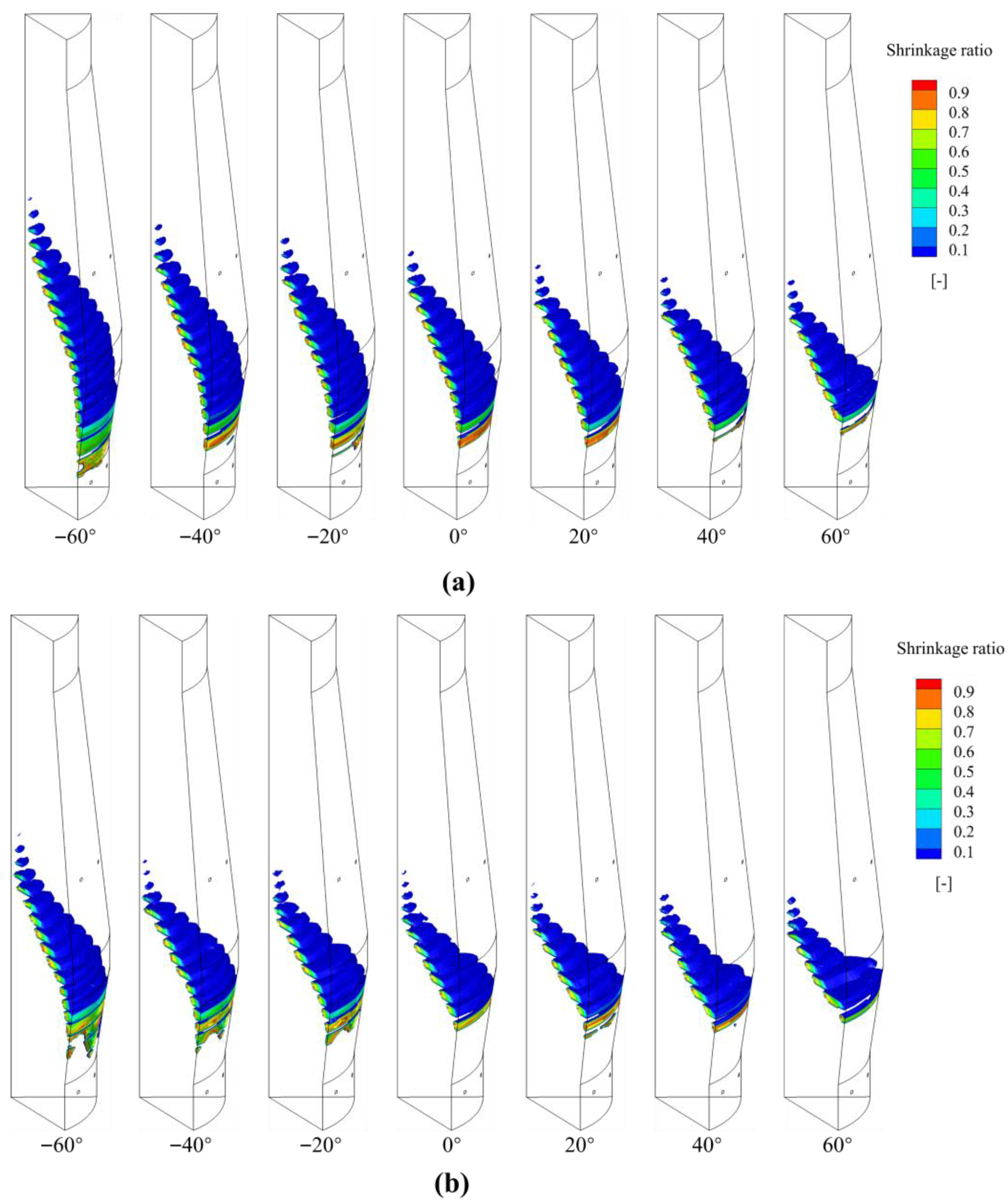

2.5. Particle Size Degradation

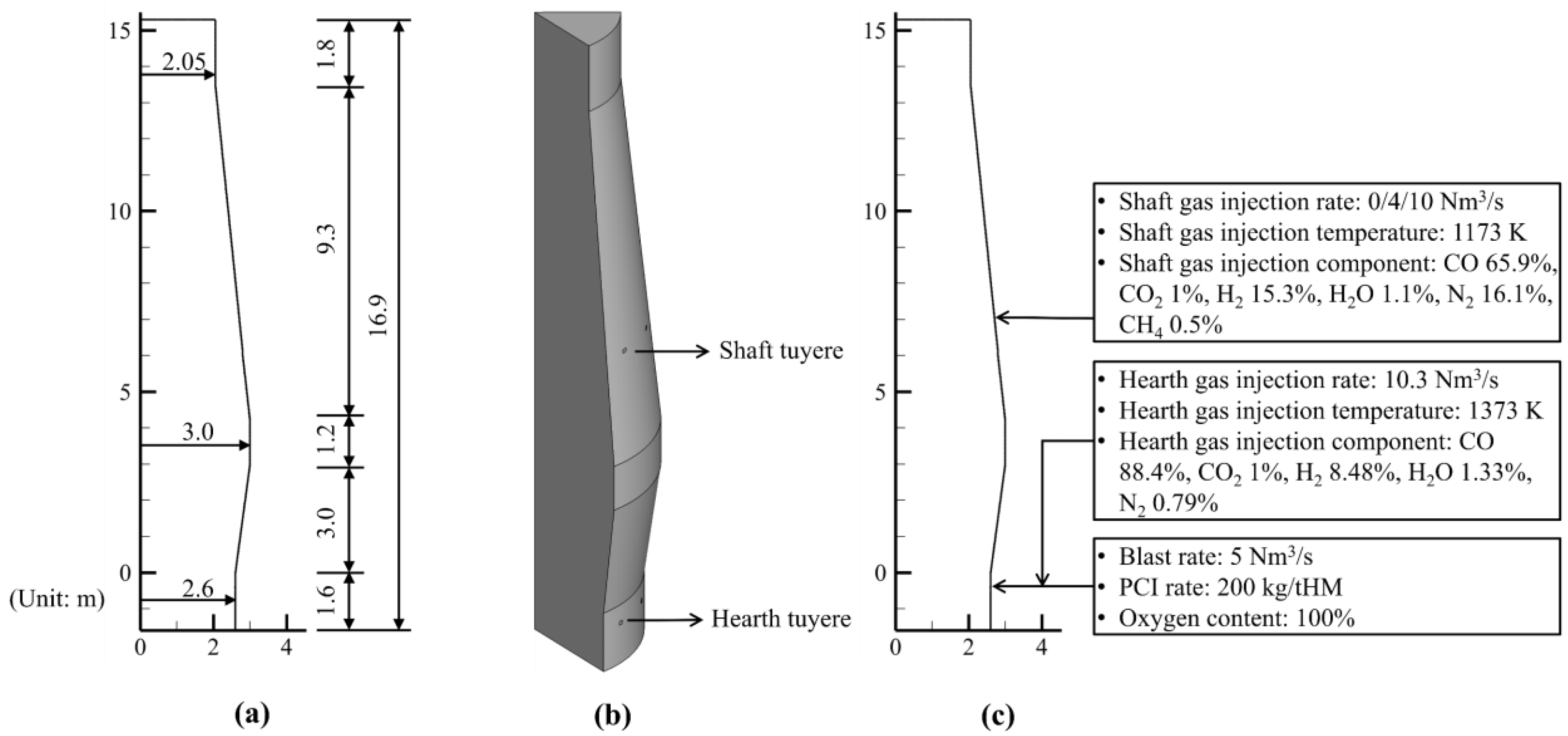

3. Simulation and Boundary Conditions

4. Results and Discussion

4.1. Model Applicability

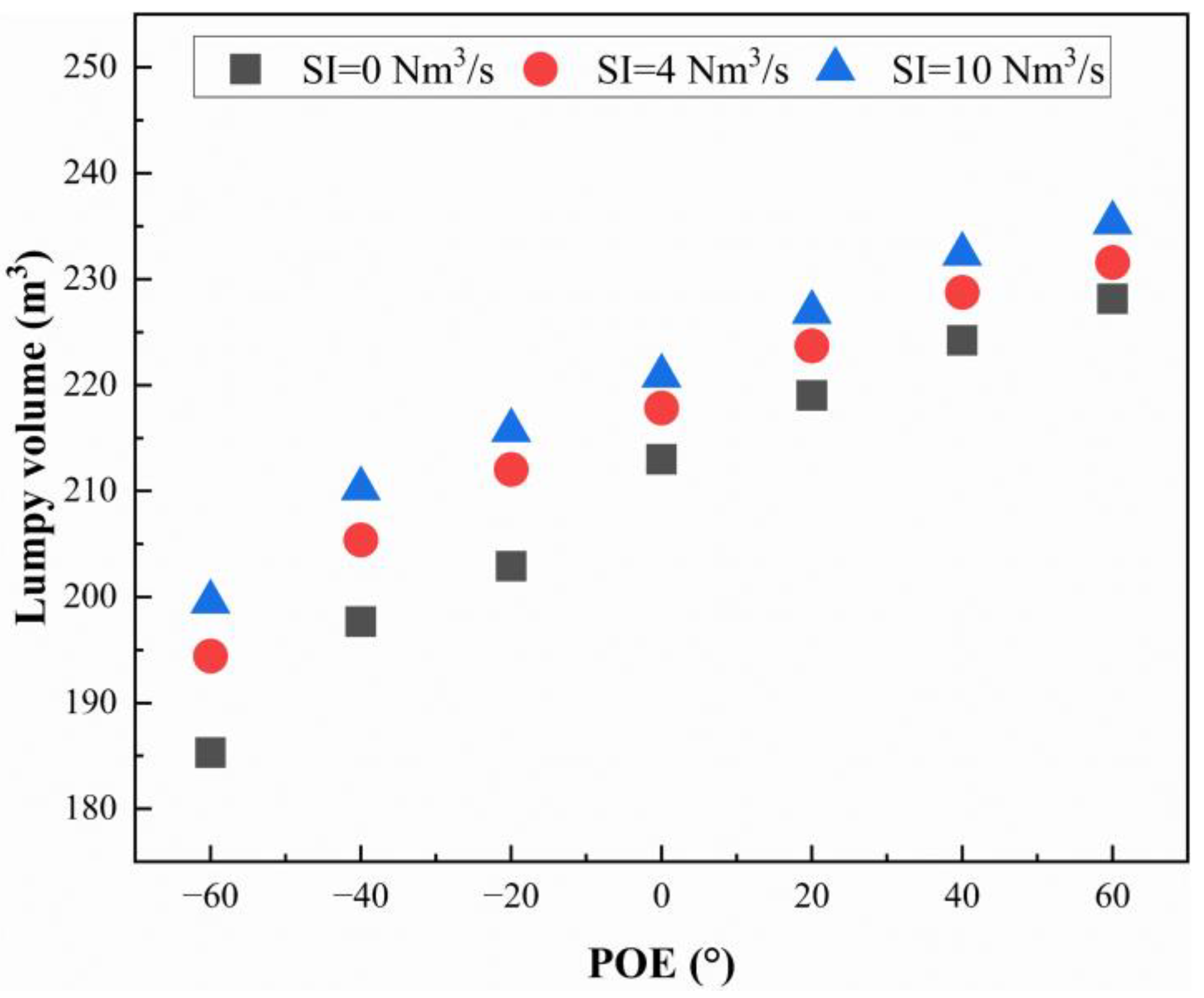

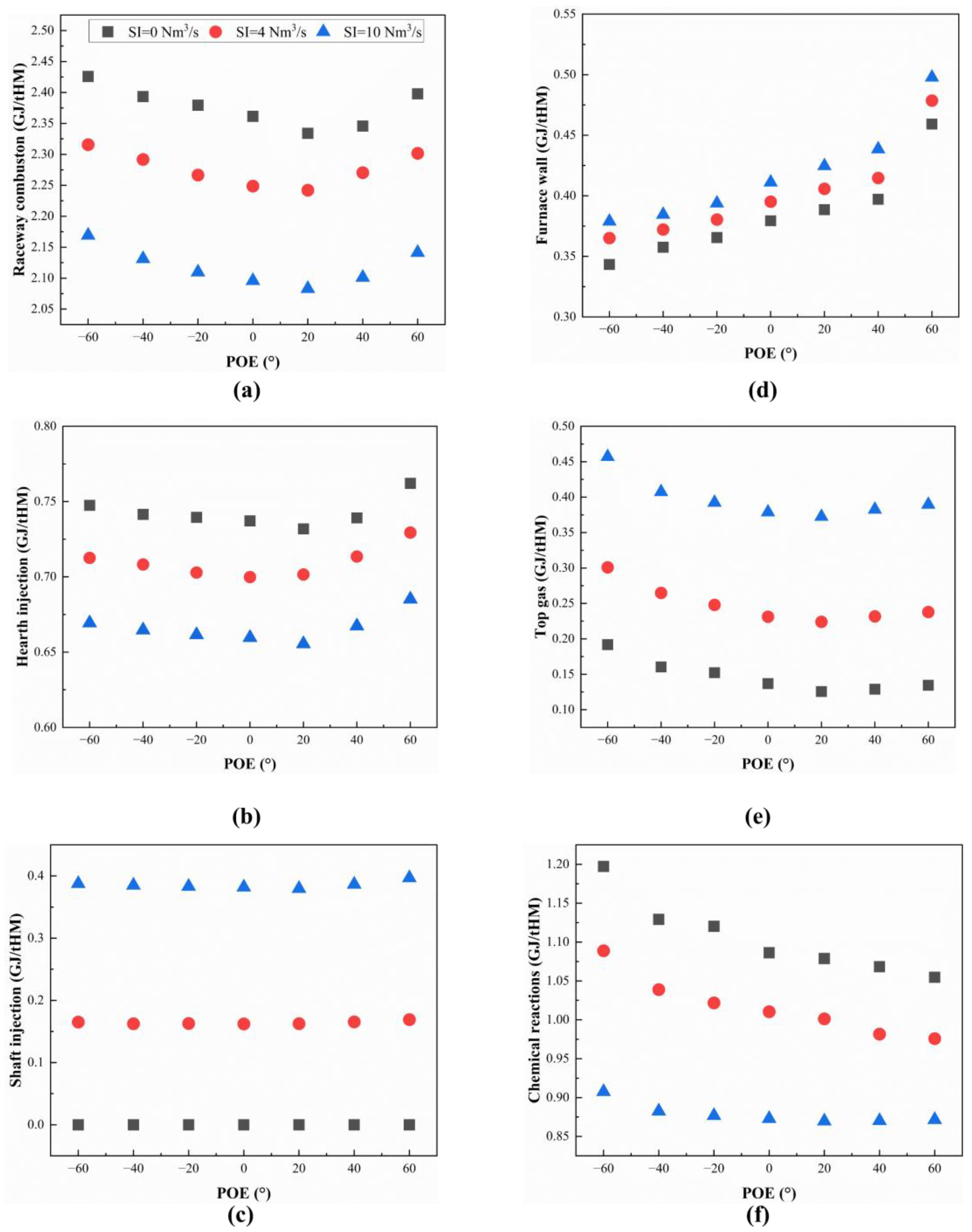

4.2. Effect of POE on BF Global Performance

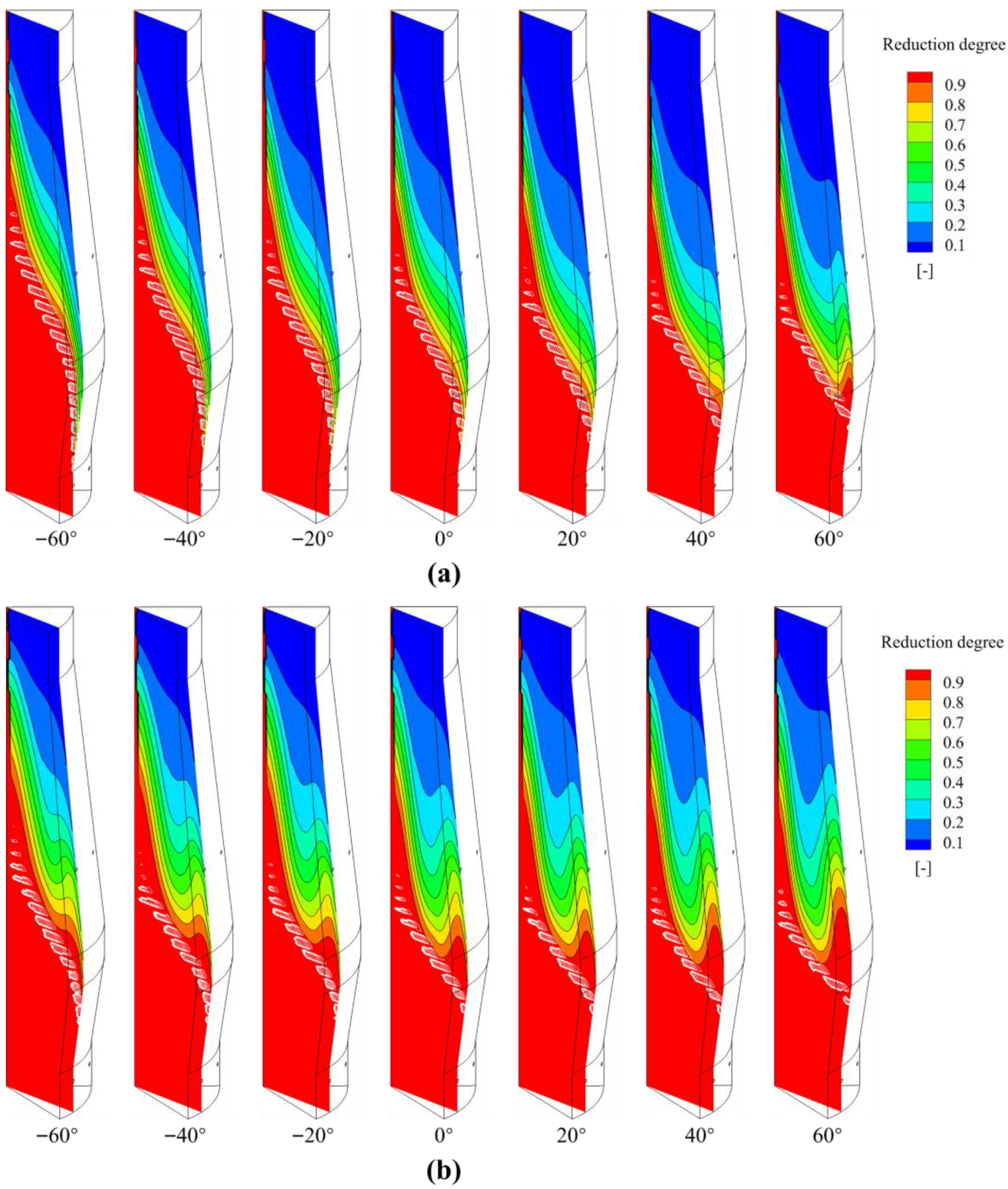

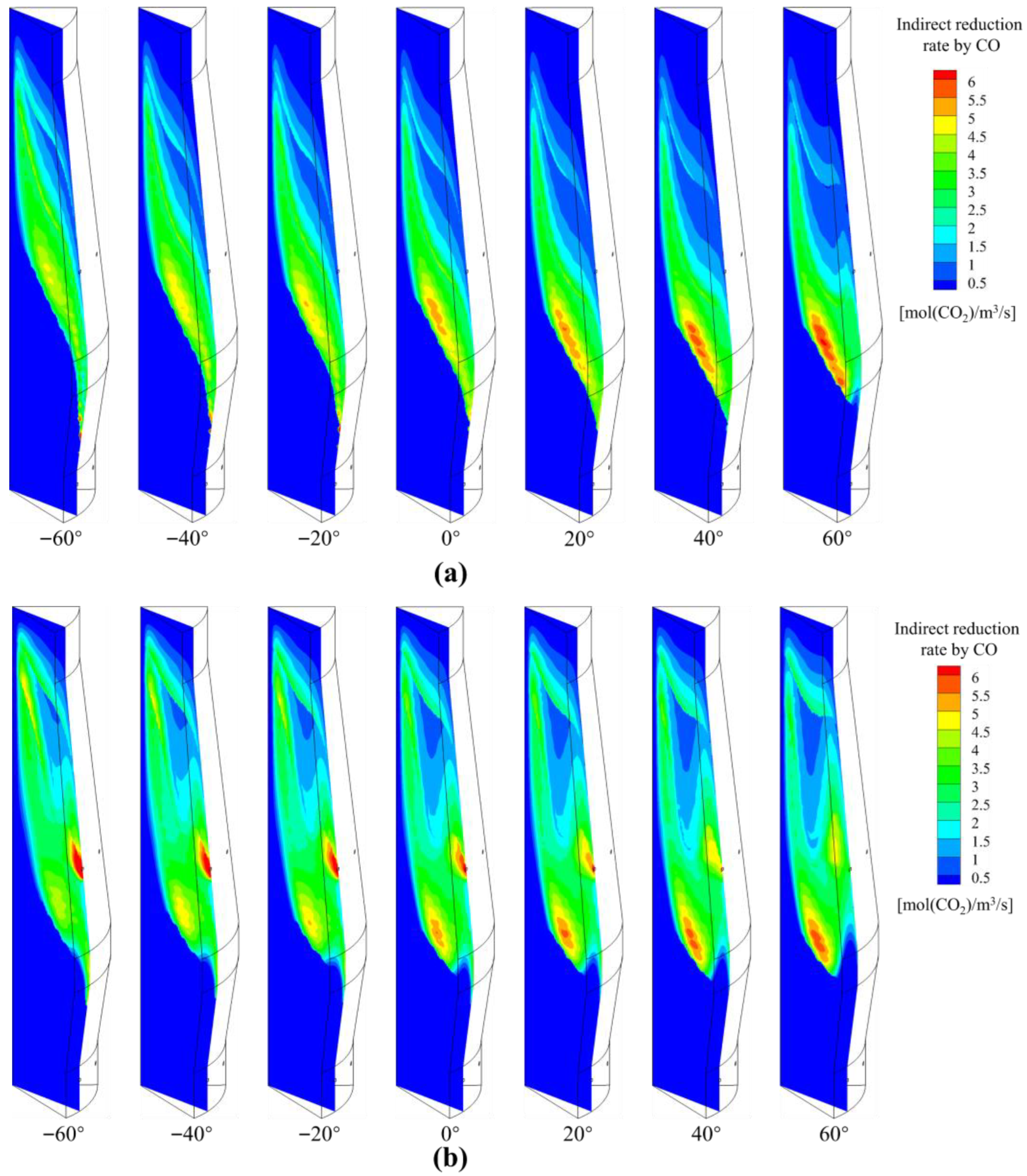

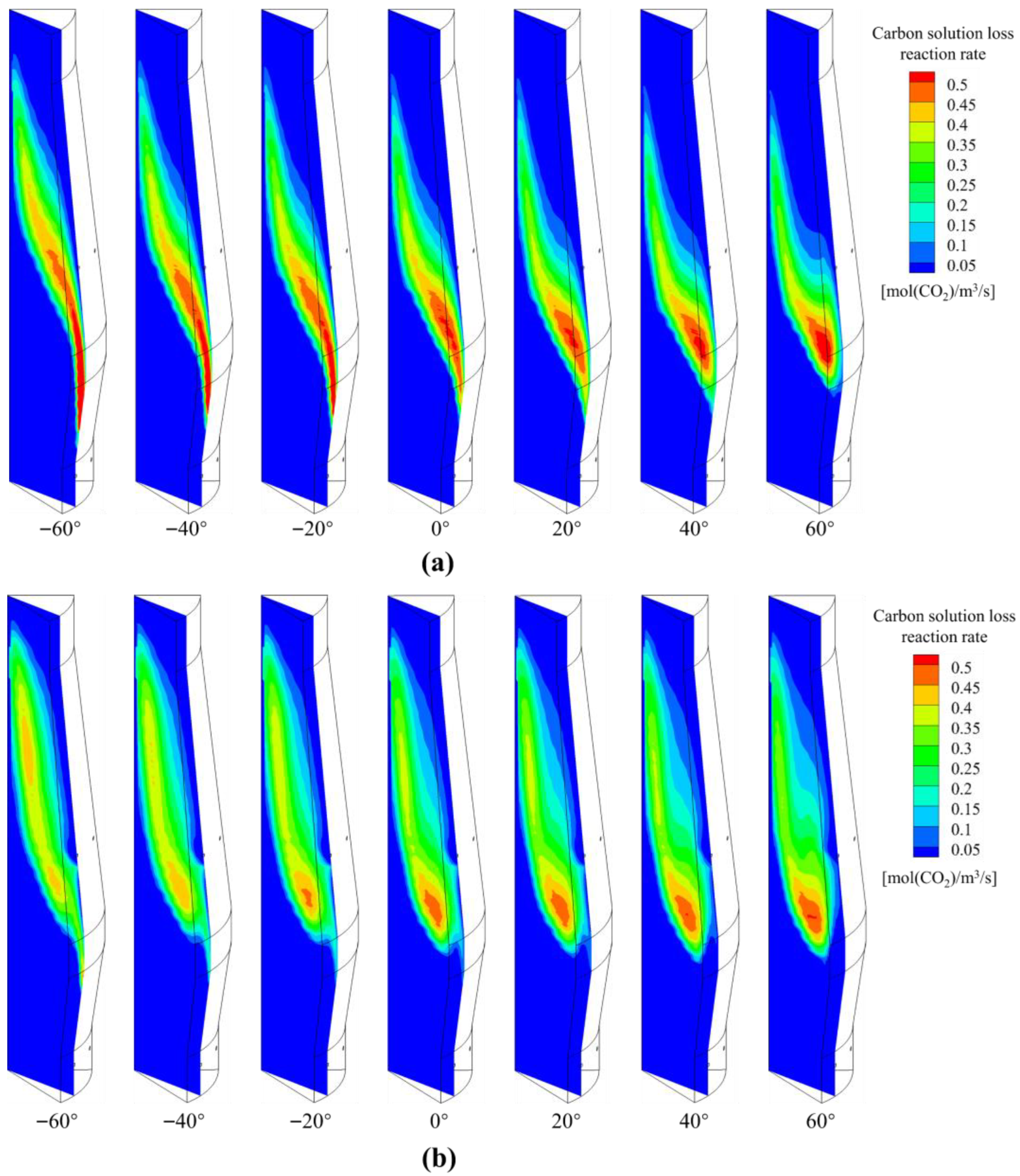

4.3. Effect of POE on BF Inner States

5. Conclusions

- (1)

- As POE increases from −60° to 60°, the fuel rate of the OBF first decreases and then increases. The results indicate that when POE is 20°, the OBF achieves its lowest fuel rate, highest productivity, and maximum top gas utilization factor. These findings suggest that an appropriate peripheral opening promotes overall performance in the OBF.

- (2)

- As POE increases, the carbon consumption of direct reduction initially decreases and then increases, while the carbon consumption from the carbon solution reaction decreases and becomes dominant, resulting in an overall reduction in chemical reaction carbon consumption. In addition, the combustion heat in front of the tuyere first decreases and then increases, causing a corresponding decrease followed by an increase in carbon consumption in tuyeres. The combined effects of combustion and chemical reaction carbon consumption lead to a fuel rate that first decreases and then increases.

- (3)

- Shaft injection significantly enhances the thermal condition within the furnace, while the reducing gases injected further improve the reducing atmosphere in the upper part of the furnace. Together, these factors promote indirect reduction in the upper furnace, leading to a notable reduction in the fuel rate. Additionally, the impact of shaft injection on CZ is less pronounced than that of POE. Regardless of the shaft injection rate, POE = 20° remains the optimal peripheral opening and achieves the lowest fuel rate. Therefore, the selection of POE is independent of shaft injection rate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| aFeO | The activity of molten wustite |

| Ac | Effective surface area of coke for reaction, m2 |

| BF | Blast furnace |

| cp | Specific heat, J·kg−1·K−1 |

| CSiO2 | Concentration of SiO2, mol·m−3 |

| CZ | Cohesive zone |

| d | Diameter of solid phase, m |

| do | Ore particle size, m |

| do,0 | Initial ore particle size before degradation, m |

| D | Diffusion coefficient, m2·s−1 |

| Ds5 | Intra-particle diffusion coefficient of H2 in reduced iron phase, m2·s−1 |

| Ef | Effectiveness factors of solution loss reaction by CO |

| E’f | Effectiveness factors of water gas reaction |

| Egl | Volumetric enthalpy flux between gas and liquid, W·m−3 |

| fo | Reduction degree of iron ore |

| F | Interaction force per unit volume, kg·m−2·s−2 |

| g | Gravitational acceleration, m·s−2 |

| hij | Heat transfer coefficient between i and j phase, W·m−2·K−1 |

| H | Enthalpy, J·kg−1 |

| ΔH | Reaction heat, J·mol−1 |

| HM | Hot metal |

| k | Thermal conductivity, W·m−1·K−1 |

| k1 | Rate constant of indirect reduction of iron ore by CO, m·s−1 |

| k2 | Rate constant of direction reduction of molten wustite, mol·m2·s−1 |

| K3 | Rate constant of solution loss reaction by CO, m3·kg−1·s−1 |

| K5 | Rate constant of indirect reduction of iron ore by H2, m·s−1 |

| K6 | Rate constant of water gas reaction, m3·kg−1·s−1 |

| K8 | Rate constant of silica reduction reaction in slag, m·s−1 |

| Kf | Gas-film mass transfer coefficient, m·s−1 |

| Kf5 | Gas-film mass transfer coefficient in indirect reduction of iron ore by H2, m·s−1 |

| Kf6 | Gas-film mass transfer coefficient water gas reaction, m·s−1 |

| K1 | Equilibrium constant of indirect reduction of iron ore by CO |

| K5 | Equilibrium constant of indirect reduction of iron ore by H2 |

| Mi | Molar mass of the ith species in the gas phase |

| Msm | Molar mass of FeO, or flux in solid phase, kg·mol−1 |

| Ncoke | Number of coke in unit volume of bed, m−3 |

| Nore | Number of iron oxide in unit volume of bed, m−3 |

| p | Pressure, Pa |

| Pe | Peclet number |

| Pr | Prandtl number |

| R | Gas constant, 8.314 J·mol−1·K−1 |

| Reaction rate for the kth reaction, mol·m3·s−1 | |

| RDI | Reduction degradation index, % |

| Re | Reynolds number |

| S | Source term |

| Sc | Schmidt number |

| Normalized shrinkage ratio | |

| ts | Timeline, s |

| T | Temperature, K |

| TFT | Theoretical flame temperature, K |

| u | Velocity, m·s−1 |

| yi | Mole fraction of the ith species in the gas phase |

| Molar fraction of CO and H2 | |

| Molar fraction of CO and H2 in equilibrium state for indirect reaction | |

| Molar fraction of CO2 and H2O(g) | |

| Greek Symbols | |

| α | Specific surface area, m2·m−3 |

| Γ | Diffusion coefficient |

| ε | Volume fraction |

| η | Fractional acquisition of reaction heat |

| Ι | Identity tensor |

| μ | Viscosity, kg·m−1·s−1 |

| ξore, ξcoke | Local ore, coke volume fraction |

| ρ | Density, kg·m−3 |

| ρbulk | Bulk density of burden at BF throat, kg·m−3 |

| τ | Stress tensor, Pa |

| General variable | |

| ω | Mass fraction |

| Subscripts | |

| e | Effective |

| g | Gas |

| i | Identifier (g, s or l) |

| i,m | mth species in i phase |

| j | Identifier (g, s or l) |

| k | kth reaction |

| l | Liquid |

| l,d | Dynamic liquid |

| s | Solid |

| sm | FeO or flux in solid phase |

| Superscripts | |

| e | Effective |

| g | Gas |

| l | Liquid |

| s | Solid |

| T | Transpose |

References

- Ariyama, T.; Murai, R.; Ishii, J.; Sato, M. Reduction of CO2 emissions from integrated steel works and its subjects for a future study. ISIJ Int. 2005, 45, 1371–1378. [Google Scholar] [CrossRef]

- Ujisawa, Y.; Nakano, K.; Matsukura, Y.; Sunahara, K.; Komatsu, S.; Yamamoto, T. Subjects for achievement of blast furnace operation with low reducing agent rate. ISIJ Int. 2005, 45, 1379–1385. [Google Scholar] [CrossRef]

- Ariyama, T.; Sato, M. Optimization of ironmaking process for reducing CO2 emissions in the integrated steel works. ISIJ Int. 2006, 46, 1736–1744. [Google Scholar] [CrossRef]

- Takeda, K.; Anyashiki, T.; Sato, T.; Oyama, N.; Watakabe, S.; Sato, M. Recent Developments and Mid and Long Term CO2 Mitigation Projects in Ironmaking. Steel Res. Int. 2011, 82, 512–520. [Google Scholar] [CrossRef]

- Rahmatmand, B.; Tahmasebi, A.; Lomas, H.; Honeyands, T.; Koshy, P.; Hockings, K.; Jayasekara, A. A technical review on coke rate and quality in low-carbon blast furnace ironmaking. Fuel 2023, 336, 127077. [Google Scholar] [CrossRef]

- Li, X.; Tian, W.; Li, H.; Quan, K.; Zhang, X.; Lu, X.; Bai, H. Effect of applying full oxygen blast furnace on the transformation of energy mix and reduction of CO2 emissions for an integral steel plant. Energy 2025, 315, 134390. [Google Scholar] [CrossRef]

- Qin, L.; Zhao, B.; Zhou, B.; Chen, W.; Han, J. Numerical simulation of biosyngas injection in air-blown and full-oxygen blast furnaces with lower carbon emissions. Appl. Therm. Eng. 2025, 279, 127798. [Google Scholar] [CrossRef]

- Zhang, W.; Dai, J.; Li, C.; Yu, X.; Xue, Z.; Saxén, H. A review on explorations of the oxygen blast furnace process. Steel Res. Int. 2021, 92, 2000326. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, J.; Wang, Z.; Zong, Y.; Guo, P.; Jiang, D.; Zhang, S. Advancements in oxygen blast furnace technology and its application in the smelting of vanadium-titanium magnetite: A comprehensive review. Miner. Eng. 2024, 212, 108732. [Google Scholar] [CrossRef]

- Tseitlin, M.A.; Lazutkin, S.E.; Styopin, G.M. A folw-chart for iron making on the basis of 100% usage of process oxygen and hot reducing gases injection. ISIJ Int. 1994, 34, 570–573. [Google Scholar] [CrossRef]

- Fang, M.; Xie, Y.; Shao, Y.; Xu, X.; Xia, Y.; Mou, M.; Hu, X.; Wang, T.; Liu, Z. Development of carbon capture absorbents for top gas recycling-oxygen blast furnace in the steel industry. Sep. Purif. Technol. 2025, 355, 129616. [Google Scholar] [CrossRef]

- Wang, H.; Chu, M.; Guo, T.; Zhao, W.; Feng, C.; Liu, Z.; Tang, J. Mathematical simulation on blast furnace operation of coke oven gas injection in combination with top gas recycling. Steel Res. Int. 2016, 87, 539–549. [Google Scholar] [CrossRef]

- Zhou, H.; Tian, X.; Yao, S.; Kou, M.; Wu, S.; Shen, Y. Numerical Analysis of Blast Furnace with Injection of COREX Export Gas After Removal of CO2. ISIJ Int. 2021, 61, 174–181. [Google Scholar] [CrossRef]

- Wu, W.; Zhu, R.; Wei, G.; Dong, K.; Jiang, J. Modeling on the blast furnace with CO2-enriched hot blast. J. Clean. Prod. 2021, 319, 128690. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, L.; Xu, R.; Zhao, P.; Yu, Y.; Guo, P.; Li, T.; Wang, Y.; Zhu, J. Effects of Hydrogen-Rich Gas Composition on Energy Consumption and the Raceway State of Oxygen Blast Furnace. Metall. Mater. Trans. B 2025, 56, 499–514. [Google Scholar] [CrossRef]

- Ohno, Y.; Hotta, H.; Matsuura, M.; Mitsufuji, H.; Saito, H. Development of oxygen blast furnace process with preheating gas injection into upper shaft. Tetsu Hagané 1989, 75, 1278–1285. [Google Scholar] [CrossRef] [PubMed]

- Jiao, L.; Nie, H.; Kuang, S.; Li, J.; Yu, A. Numerical simulation and analysis of oxygen blast furnace under different injection conditions. Fuel 2024, 369, 131726. [Google Scholar] [CrossRef]

- Ichida, M.; Nishihara, K.; Tamura, K.; Sugata, M.; Ono, H. Influence of ore to coke ratio distribution on descending and melting behavior of burden in the blast furnace. Tetsu Hagané 1991, 77, 1617–1624. [Google Scholar] [CrossRef][Green Version]

- Tian, J.; Tanaka, A.; Gao, D.; Liu, Z.; Hou, Q.; Chen, X. Characterization of the Blast Furnace Burden Surface: Experimental Measurement and Roughness Statistics. ISIJ Int. 2023, 63, 1217–1225. [Google Scholar] [CrossRef]

- Saxén, H.; Nikus, M.; Hinnelä, J. Burden distribution estimation in the blast furnace from stockrod and probe signals. Steel Res. 1998, 69, 406–412. [Google Scholar] [CrossRef]

- Chakrabarty, A.; Ohri, R.; Chaudhari, U.; Sahoo, T.; Nag, S.; Gupta, I.P. Influence of above burden probes in blast furnace on centre coke charging and subsequent operational stability. J. Sustain. Metall. 2023, 9, 1790–1802. [Google Scholar] [CrossRef]

- Wei, J.; Chen, X.; Kelly, J.; Cui, Y. Blast furnace stockline measurement using radar. Ironmak. Steelmak. 2015, 42, 533–541. [Google Scholar] [CrossRef]

- Zhu, Q.; Lü, C.-L.; Yin, Y.-x.; Chen, X.-z. Burden distribution calculation of bell-less top of blast furnace based on multi-radar data. J. Iron Steel Res. Int. 2013, 20, 33–37. [Google Scholar] [CrossRef]

- Kajiwara, Y.; Jimbo, T.; Joko, T.; Aminaga, Y.-i.; Inada, T. Investigation of bell-less charging based on full scale model experiments. Trans. Iron Steel Inst. Jpn. 1984, 24, 799–807. [Google Scholar] [CrossRef]

- Jimenez, J.; Mochón, J.; Formoso, A.; de Ayala, J.S. Burden distribution analysis by digital image processing in a scale model of a blast furnace shaft. ISIJ Int. 2000, 40, 114–120. [Google Scholar] [CrossRef]

- Hattori, M.; Iino, B.; Shimomura, A.; Tsukiji, H.; Ariyama, T. Development of burden distribution simulation model for bell-less top in a large blast furnace and its application. ISIJ Int. 1993, 33, 1070–1077. [Google Scholar] [CrossRef]

- Yang, Y.; Yin, Y.; Wunsch, D.; Zhang, S.; Chen, X.; Li, X.; Cheng, S.; Wu, M.; Liu, K.-Z. Development of blast furnace burden distribution process modeling and control. ISIJ Int. 2017, 57, 1350–1363. [Google Scholar] [CrossRef]

- Chen, J.; Zuo, H.; Xue, Q.; Wang, J. A review of burden distribution models of blast furnace. Powder Technol. 2022, 398, 117055. [Google Scholar] [CrossRef]

- Chen, J.-S.; Zuo, H.-B.; Wang, J.-X.; Xue, Q.-G.; Wang, J.-S. Mathematical model of burden distribution in bell-less top blast furnace. J. Iron Steel Res. Int. 2023, 30, 216–226. [Google Scholar] [CrossRef]

- Yu, Y.; Saxén, H. Particle flow and behavior at bell-less charging of the blast furnace. Steel Res. Int. 2013, 84, 1018–1033. [Google Scholar] [CrossRef]

- Yu, Y.; Saxén, H. Flow of pellet and coke particles in and from a fixed chute. Ind. Eng. Chem. Res. 2012, 51, 7383–7397. [Google Scholar] [CrossRef]

- Yu, Y.; Saxén, H. Effect of DEM parameters on the simulated inter-particle percolation of pellets into coke during burden descent in the blast furnace. ISIJ Int. 2012, 52, 788–796. [Google Scholar] [CrossRef]

- Mitra, T.; Saxén, H. Investigation of coke collapse in the blast furnace using mathematical modeling and small scale experiments. ISIJ Int. 2016, 56, 1570–1579. [Google Scholar] [CrossRef]

- Mitra, T.; Saxén, H. Discrete element simulation of charging and mixed layer formation in the ironmaking blast furnace. Comput. Part. Mech. 2016, 3, 541–555. [Google Scholar] [CrossRef]

- Zhao, Z.; Saxén, H.; Liu, Y.; She, X.; Xue, Q. Numerical study on the influence of pellet proportion on burden distribution in blast furnace. Ironmak. Steelmak. 2023, 50, 613–620. [Google Scholar] [CrossRef]

- Chakrabarty, A.; Raju, A.B.; Pani, S.; Ghosh, U.; Nag, S.; Pal, P.; Singh, U. Effect of Selective Pellet Loading on Burden Distribution and Blast Furnace Operations. ISIJ Int. 2023, 63, 271–281. [Google Scholar] [CrossRef]

- Arroyo, J.; Pérez, L.; Cuervo-Piñera, V. CFD modeling and validation of blast furnace gas/natural gas mixture combustion in an experimental industrial furnace. Processes 2023, 11, 332. [Google Scholar] [CrossRef]

- Zhuo, Y.; Shen, Y. Transient 3D CFD study of pulverised coal combustion and coke combustion in a blast furnace: Effect of blast conditions. Fuel 2023, 340, 127468. [Google Scholar] [CrossRef]

- Okosun, T.; Nielson, S.; Zhou, C. Blast furnace hydrogen injection: Investigating impacts and feasibility with computational fluid dynamics. JOM 2022, 74, 1521–1532. [Google Scholar] [CrossRef]

- Xu, D.; Wang, S.; Shen, Y. Numerical investigation of the reacting flows of three adjunct raceways in an industrial-scale blast furnace. Fuel 2023, 354, 129339. [Google Scholar] [CrossRef]

- Li, Z.; Kuang, S.; Liu, S.; Gan, J.; Yu, A.; Li, Y.; Mao, X. Numerical investigation of burden distribution in ironmaking blast furnace. Powder Technol. 2019, 353, 385–397. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, X.; Shen, Y. Transient CFD study of wet burden charging on dynamic in-furnace phenomena in an ironmaking blast furnace: Impacts and remedies. Powder Technol. 2022, 408, 117708. [Google Scholar] [CrossRef]

- Li, J.; Kuang, S.; Zou, R.; Yu, A. Numerical investigation of burden distribution in hydrogen blast furnace. Metall. Mater. Trans. B 2022, 53, 4124–4137. [Google Scholar] [CrossRef]

- Nie, H.; Li, Z.; Kuang, S.; Yan, L.; Zhong, W.; Yu, A.; Mao, X.; Xu, H. Numerical investigation of oxygen-enriched operations in blast furnace ironmaking. Fuel 2021, 296, 120662. [Google Scholar] [CrossRef]

- Li, Z.; Kuang, S.; Yu, A.; Gao, J.; Qi, Y.; Yan, D.; Li, Y.; Mao, X. Numerical investigation of novel oxygen blast furnace ironmaking processes. Metall. Mater. Trans. B 2018, 49, 1995–2010. [Google Scholar] [CrossRef]

- Zhang, Z.; Meng, J.; Guo, L.; Guo, Z. Numerical study of the reduction process in an oxygen blast furnace. Metall. Mater. Trans. B 2016, 47, 467–484. [Google Scholar] [CrossRef]

- Jiao, L.; Kuang, S.; Yu, A.; Li, Y.; Mao, X.; Xu, H. Three-dimensional modeling of an ironmaking blast furnace with a layered cohesive zone. Metall. Mater. Trans. B 2020, 51, 258–275. [Google Scholar] [CrossRef]

- Jiao, L. Development and Applications of a Comprehensive Three-Dimensional (3D) Blast Furnace Process Model. Ph.D. Thesis, Monash University, Melbourne, VIC, Australia, 2020. [Google Scholar]

- Ergun, S. Pressure drop in blast furnace and in cupola. Ind. Eng. Chem. 1953, 45, 477–485. [Google Scholar] [CrossRef]

- Wang, G.; Chew, S.; Yu, A.; Zulli, P. Modeling the discontinuous liquid flow in a blast furnace. Metall. Mater. Trans. B 1997, 28, 333–343. [Google Scholar] [CrossRef]

- Omori, Y. Blast Furnace Phenomena and Modelling; Elsevier Applied Science: London, UK; New York, NY, USA, 1987. [Google Scholar]

- Austin, P.R.; Nogami, H.; Yagi, J.-i. A mathematical model of four phase motion and heat transfer in the blast furnace. ISIJ Int. 1997, 37, 458–467. [Google Scholar] [CrossRef]

- Austin, P.R.; Nogami, H.; Yagi, J.-i. A mathematical model for blast furnace reaction analysis based on the four fluid model. ISIJ Int. 1997, 37, 748–755. [Google Scholar] [CrossRef]

- Muchi, I. Mathematical model of blast furnace. Trans. Iron Steel Inst. Jpn. 1967, 7, 223–237. [Google Scholar] [CrossRef]

- Yang, K.; Choi, S.; Chung, J.; Yagi, J.-i. Numerical modeling of reaction and flow characteristics in a blast furnace with consideration of layered burden. ISIJ Int. 2010, 50, 972–980. [Google Scholar] [CrossRef]

- Fu, D.; Chen, Y.; Zhao, Y.; D’Alessio, J.; Ferron, K.J.; Zhou, C.Q. CFD modeling of multiphase reacting flow in blast furnace shaft with layered burden. Appl. Therm. Eng. 2014, 66, 298–308. [Google Scholar] [CrossRef]

- Zhou, P.; Li, H.-l.; Shi, P.-y.; Zhou, C.Q. Simulation of the transfer process in the blast furnace shaft with layered burden. Appl. Therm. Eng. 2016, 95, 296–302. [Google Scholar] [CrossRef]

- Dong, X.; Yu, A.; Chew, S.J.; Zulli, P. Modeling of blast furnace with layered cohesive zone. Metall. Mater. Trans. B 2010, 41, 330–349. [Google Scholar] [CrossRef]

- Jiao, L.; Kuang, S.; Liu, L.; Yu, A.; Li, Y.; Mao, X.; Xu, H. CFD modeling and analysis of particle size reduction and its effect on blast furnace ironmaking. Metall. Mater. Trans. B 2021, 52, 138–155. [Google Scholar] [CrossRef]

| Items | Descriptions |

|---|---|

| Mass conservation | |

| Momentum conservation | |

| Gas | |

| Solid | |

| Liquid | |

| Heat and species conservations | |

| , | |

| Phase volume fraction | |

| State equation | |

| Timeline equation |

| Items | Formulations |

|---|---|

| Interaction forces | |

| Gas–solid [49] | |

| Liquid–gas [50] | |

| Liquid–solid [50] | |

| Gas diffusion coefficients [51] | |

| Conductivity | |

| Gas [51] | |

| Solid [51] | |

| Liquid [52] | |

| Heat transfer coefficients | |

| Gas–solid [53] | |

| Gas–liquid [52] | |

| Solid–liquid [53] | |

| Items | Formulations |

|---|---|

| [54] | |

| [51] | |

| [54] | |

| [53] | |

| [51] | |

| [51] | |

| [51] | |

| [51] |

| Variables | Values |

|---|---|

| Gas phase | |

| Inlet oxygen content, % | 100 |

| Inlet oxygen temperature, K | 298 |

| Inlet oxygen flow rate, Nm3/s | 5.0 |

| Top pressure, kPa | 188 |

| Solid phase | |

| Ore components, mass fraction, % | Fe2O3 74.55; FeO 7.67; CaO 7.86; MgO 1.40; SiO2 6.61; Al2O3 1.00; MnO 0.34; P2O5 0.57 |

| Average ore particle size, mm | 15.52 |

| Coke components, mass fraction, % | C 86.31; S 0.44; H 0.44; N 0.44; Ash 12.37 |

| Average coke particle size, mm | 42.10 |

| Flux components, mass fraction, % | CaO 1.87; MgO 1.82; SiO2 52.38; Al2O3 14.64; CaCO3 14.64; MgCO3 14.65 |

| Ore voidage | 0.403 (100dore)0.14 |

| Coke voidage | 0.153log dcoke + 0.742 |

| Ore batch weight, t | 11.1 |

| RDI value of iron ore | 20 |

| Burden temperature, K | 298 |

| Powder phase | |

| Pulverized coal, kg/tHM | 200 |

| Coal components, mass fraction, % | C 78.30; H 3.64; O 5.50; N 1.07; S 0.46; H2O 3.84; Ash 9.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, L.; Shu, X.; Yu, A. Numerical Investigation of Burden Distribution in Oxygen Blast Furnace Ironmaking. Metals 2025, 15, 1048. https://doi.org/10.3390/met15091048

Jiao L, Shu X, Yu A. Numerical Investigation of Burden Distribution in Oxygen Blast Furnace Ironmaking. Metals. 2025; 15(9):1048. https://doi.org/10.3390/met15091048

Chicago/Turabian StyleJiao, Lulu, Xinyang Shu, and Aibing Yu. 2025. "Numerical Investigation of Burden Distribution in Oxygen Blast Furnace Ironmaking" Metals 15, no. 9: 1048. https://doi.org/10.3390/met15091048

APA StyleJiao, L., Shu, X., & Yu, A. (2025). Numerical Investigation of Burden Distribution in Oxygen Blast Furnace Ironmaking. Metals, 15(9), 1048. https://doi.org/10.3390/met15091048