Austenite Grain Growth Behavior and Dynamic Model of ADB790E Hydropower Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Composition

2.2. Experimental Scheme

- (1)

- The experimental steel is cut into rectangular samples of 5 × 10 × 20 mm (length × width × height) by wire cutting. The surface of the sample is cleaned by an ultrasonic cleaner, and basic treatment is carried out with 400-mesh and 600-mesh sandpaper to eliminate the influence of an oxide layer and stains on the surface of the sample during heat treatment.

- (2)

- Quenching heat treatment. To explore the influence of different heating temperatures on the growth of austenite grains, the samples are heated to 850 °C, 900 °C, 950 °C, 1000 °C, 1050 °C, 1100 °C, 1150 °C, 1200 °C, and 1250 °C, respectively, in a box-type resistance furnace at 5 °C/min. After the furnace temperature rises back to the heating temperature, timing and holding are started, and the samples are taken out immediately after holding for 20 min and put into cold water for quenching; to explore the influence of different holding times on the growth of austenite grains, the experimental steel is put into a box-type resistance furnace and heated to 1150 °C. After the furnace temperature rises back to 1150 °C, timing and holding are started, and the samples are taken out immediately after holding for 20 min, 40 min, and 60 min to complete austenitization. Subsequently, water quenching was applied to preserve the high-temperature austenite microstructure for metallographic examination. The purpose of selecting water quenching was to accurately characterize the prior austenite grain size after isothermal holding. During cooling, austenite undergoes phase transformation; hence, a sufficiently high cooling rate is essential to suppress any phase transformation and retain the austenite grain boundaries at room temperature. Compared to oil quenching or air cooling, water quenching provides a significantly faster cooling rate, which is critical for obtaining clearly discernible prior austenite grain boundaries and ensuring the accuracy of measurement results. Slower cooling methods may initiate phase transformation, thereby obscuring or obliterating the original austenite boundaries.It should be noted that the selected holding times (20–60 min) were not intended to simulate the short interpass intervals during hot rolling but were strictly based on the actual industrial heat treatment cycles—such as normalizing or austenitizing prior to quenching and tempering—applied to heavy-gauge hydroelectric steel plates. The objective of hot rolling is to refine the grain structure through deformation and recrystallization, with interpass times typically on the order of seconds to prevent static recrystallization and grain growth. In contrast, the heat treatment processes simulated in this study aim to achieve complete phase transformation, dissolution of alloying elements, and microstructural homogenization throughout the workpiece, which necessitates significantly longer holding times.

- (3)

- Corrosion of austenite grains. There will be a layer of scale on the surface of the quenched steel, which needs to be treated before the 10 × 20 mm surface of the experimental steel is ground and polished to make metallographic samples. Austenite metallographic etchant is prepared with 1 g picric acid, 50 mL distilled water, and 2.5 g Haier shampoo, and the polished surface of the sample is placed upward. To corrode clear austenite grain boundaries, the sample should be heated in a constant temperature water bath furnace to 60 °C for 4 min of corrosion. During this period, the polished surface is wiped with absorbent cotton or the sample is stirred, and care should be taken not to scratch the surface. After 4 min, the sample is taken out and put into alcohol for soaking and cleaning, then taken out, rinsed with absolute ethanol, and dried on the surface.

- (4)

- Observation and analysis of metallographic microscope. The microstructure of the experimental steel is observed with a Keyence VHX-5000 ultra-depth 3D digital microscope (Keyence Corporation, Osaka, Japan) to clarify the growth of austenite grains, and the average size of austenite grains is calculated by the intercept method. Beck’s model and Sellars’ model were used to establish the austenite grain variable temperature growth model and the austenite grain isothermal growth model, and the influence laws of heating temperature and holding time on the growth of austenite grains are explored.

3. Results

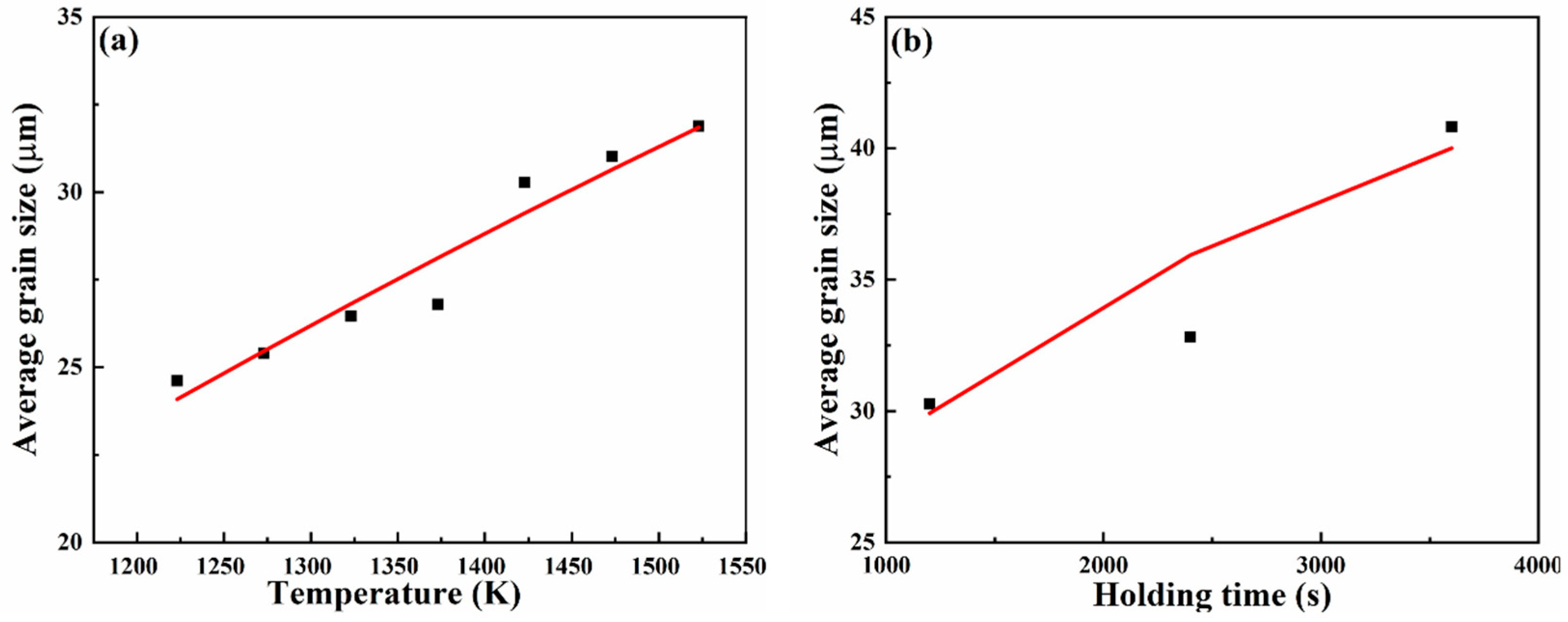

3.1. Influence of Heating Temperature on Austenite Grain Growth Behavior

3.2. Influence of Holding Time on Austenite Grain Growth Behavior

3.3. Comparison of Austenite Grain Growth Models

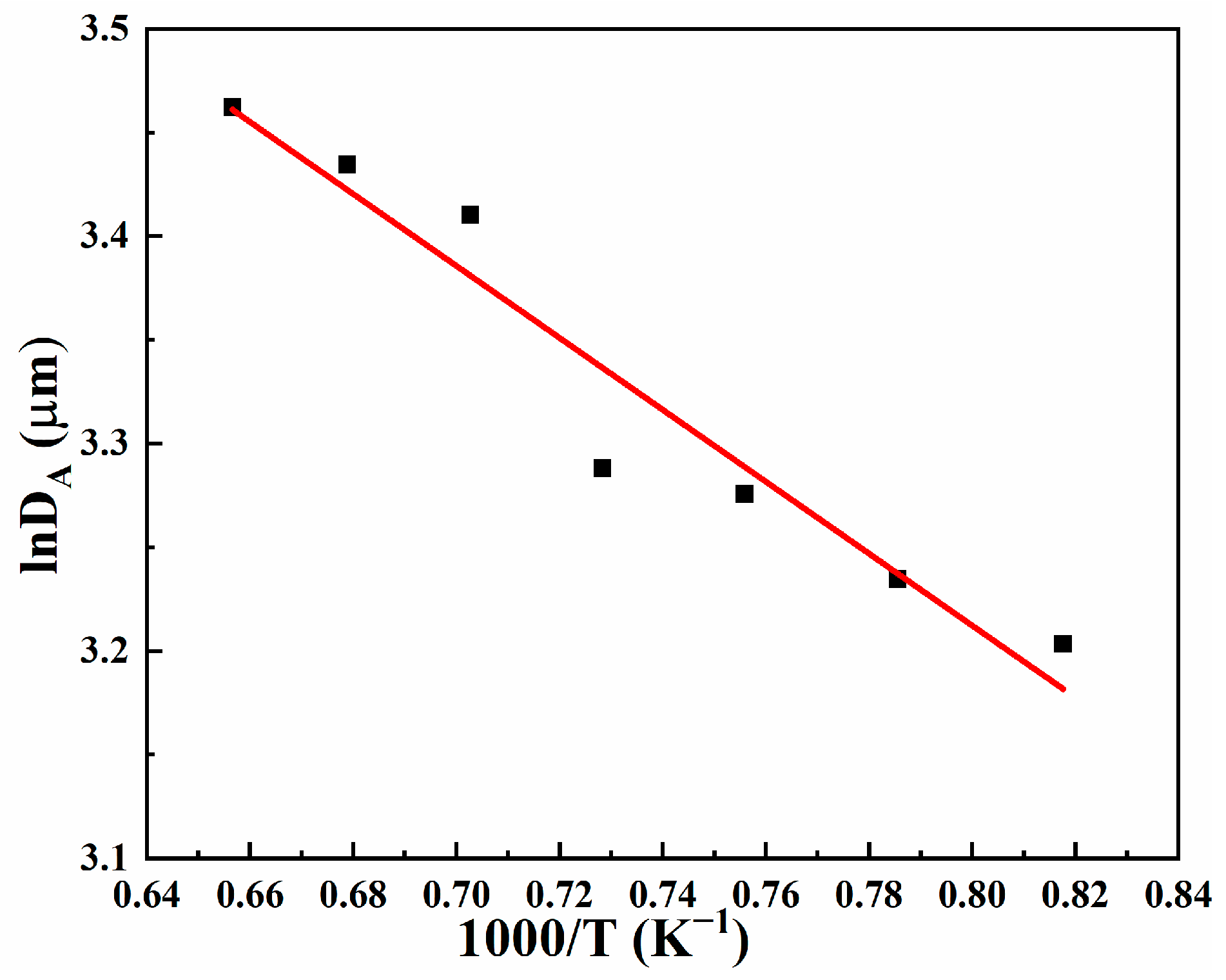

3.3.1. Beck’s Model for Austenite Grain Growth

- Variable-temperature growth model

- 2.

- Isothermal growth model

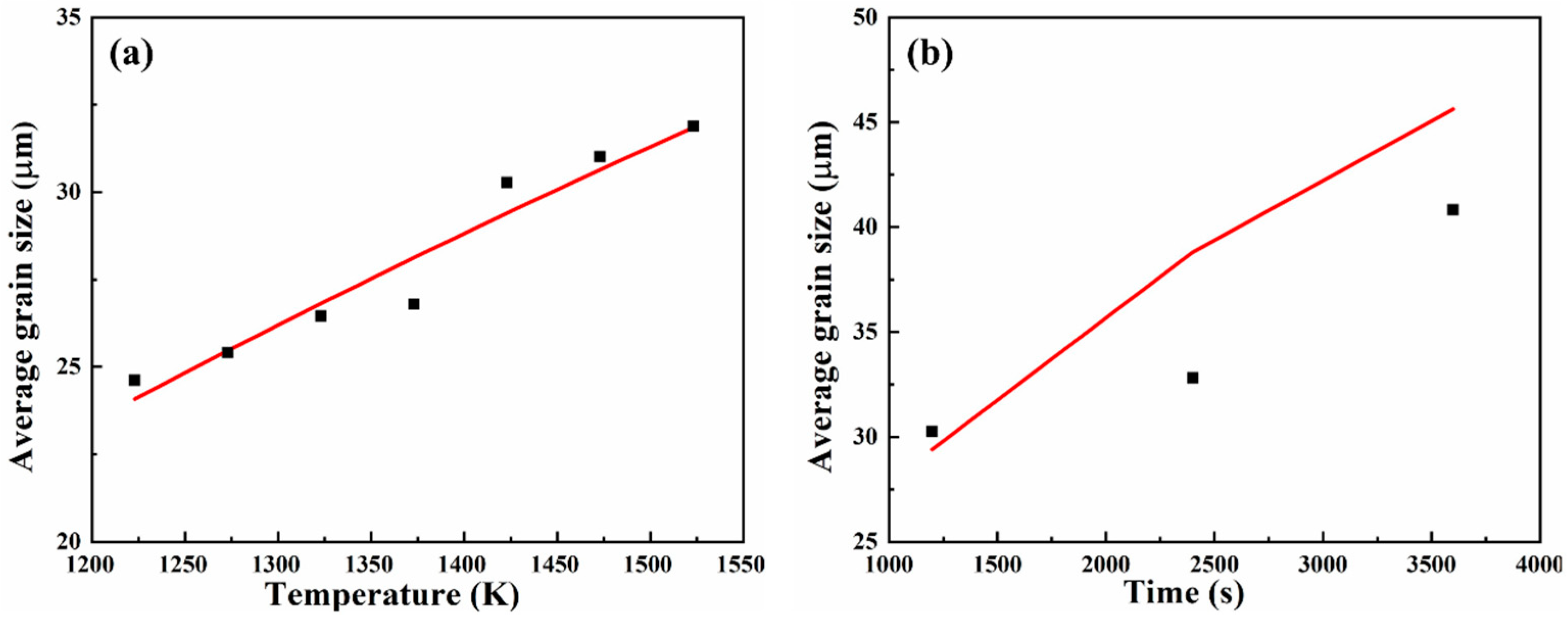

3.3.2. Sellars’ Model for Austenite Grain Growth

3.4. Model Verification

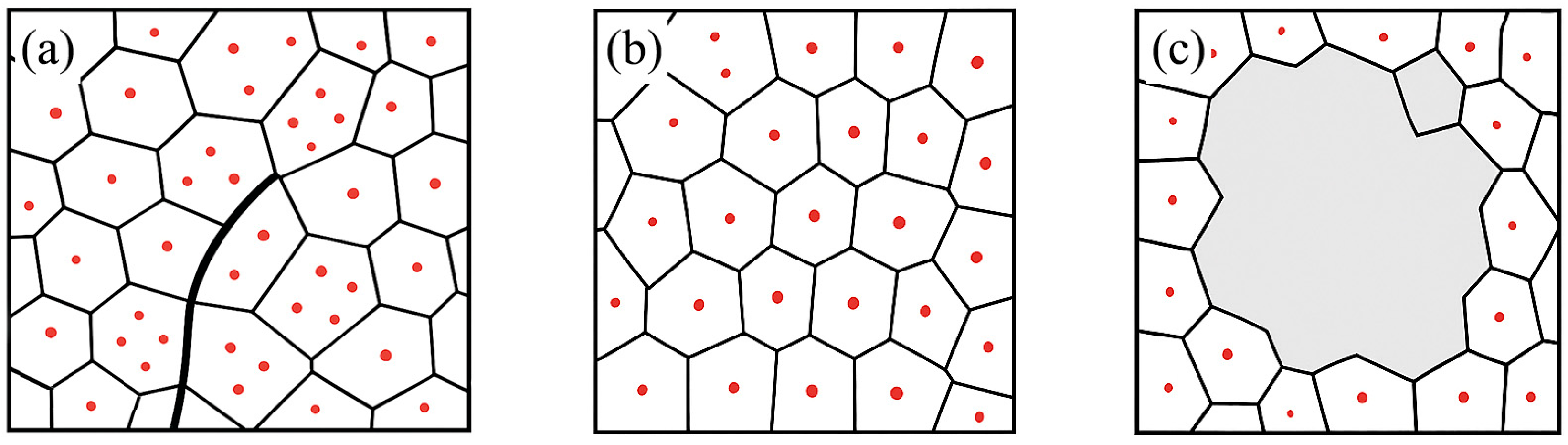

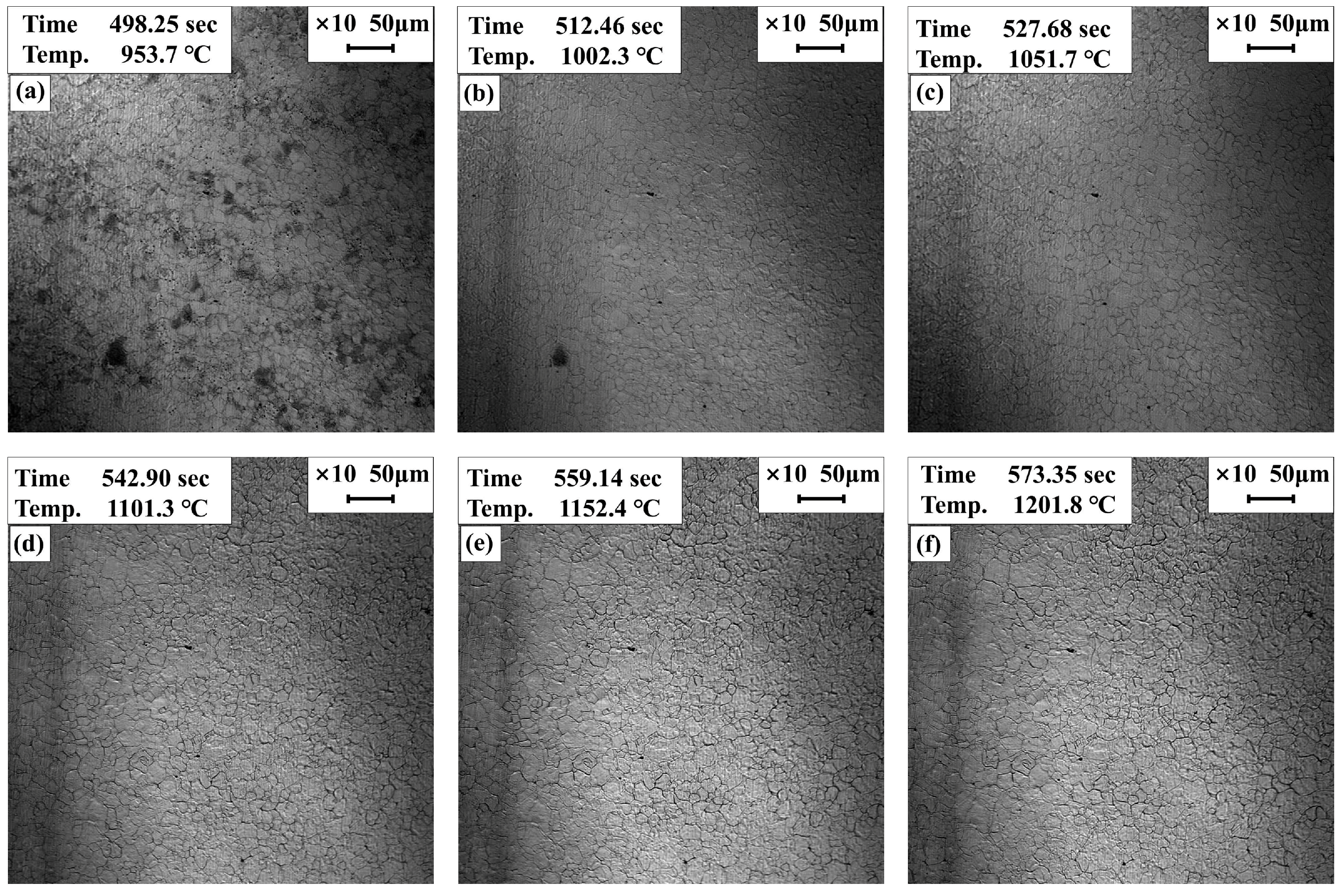

3.4.1. In Situ Observation Experiment with High-Temperature Confocal Laser Scanning Microscope

- Sample preparation. Since ordinary metallographic samples cannot meet the requirements of high-temperature in situ observation, special requirements are put forward for sample preparation. The sample is processed into Φ7 × 2.5 mm by wire cutting, and one side of the Φ7 mm experimental steel is ground with 400~1000-mesh sandpaper, then polished to a mirror surface with a polishing machine. But no etching is carried out. Chemical etching is not required for HT-CLSM research.

- High-temperature laser confocal experiment. The ground and polished experimental steel is put into an alumina ceramic crucible, the crucible is placed on a fixed plate connected with a thermocouple and put into the furnace of the high-temperature laser confocal microscope, and the furnace cover is closed. To prevent oxidation of the sample at high temperature which leads to experimental failure, vacuum pumping (3 min) and argon filling (3 min) are carried out, and the program can be input to heat the steel after 3 cycles. The setting logic of the temperature program should cover the research requirements and avoid equipment damage. The heating rate is 200 °C/min, the holding temperature is 1550 °C, the holding time is 5 min, and the cooling rate is 0.5 °C/s. The heating rate was set at 200 °C/min primarily to minimize selective surface evaporation of low-melting-point or high-vapor-pressure elements from the steel sample during extended exposure to high temperatures and high vacuum. Even with an inert gas atmosphere, prolonged experiments cannot fully prevent the release of trace impurity gases from internal furnace components such as the chamber walls and sample stage at elevated temperatures. Minute amounts of oxygen or water vapor are sufficient to cause slight surface oxidation, forming an oxide film that severely interferes with surface energy measurements and obscures genuine grain boundaries, thereby compromising in situ observations. Consequently, an excessively slow heating rate was not feasible in this study.

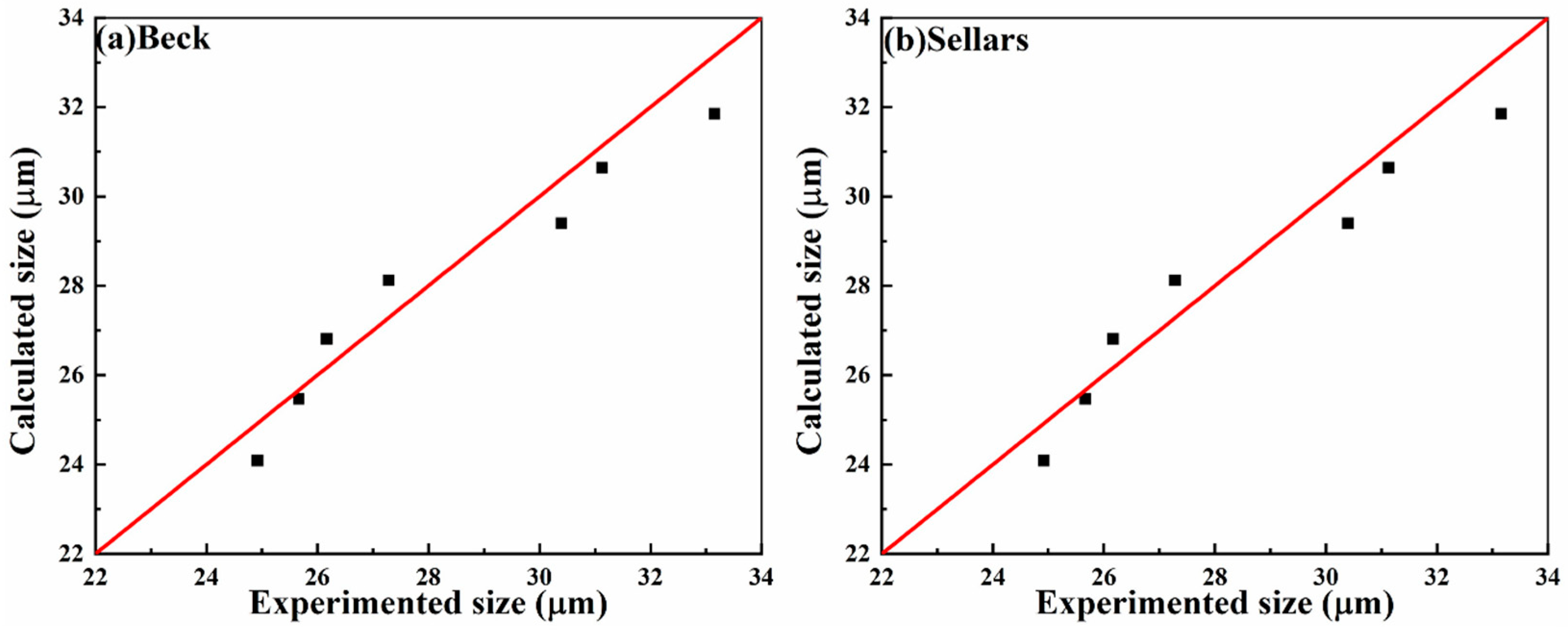

3.4.2. Model Verification

4. Conclusions

- When the holding time is constant, the average austenite grain size of ADB790E hydropower steel increases with the increase in heating temperature. It can be known from the experimental results that the growth rate of grain size below 1150 °C is less than that above 1150 °C. The grain coarsening temperature should be avoided when formulating hot working processes.

- When the heating temperature is constant, the average austenite grain size of ADB790E hydropower steel increases with the prolongation of holding time. The growth rate of grain size above 40 min of holding is much greater than that below 40 min of holding.

- Based on experimental data, Beck’s and Sellars’ models for ADB790E hydroelectric steel were established. The fitted variable-temperature elongation model is: DA = 99.47 exp(14,421/RT), with a regression accuracy of 0.9255; the isothermal elongation model is: DA = 4.83 t0.2552, with a regression accuracy of 0.9306; Sellars’ model is: D2.5 − D02.5 = 4.9 × 103 × t × exp(−36,052/RT), with a regression accuracy of 0.933.

- The calculated apparent activation energy for grain growth in this study was lower than the values commonly reported for simple C-Mn steels. This discrepancy does not stem from experimental error but rather originates from the strong pinning effect of second-phase particles (e.g., TiN) and solute drag effects inherent to ADB790E steel. Furthermore, compared to other steel grades, the abnormal austenite grain growth observed in ADB790E exhibited a limited final grain size. This can be primarily attributed to the unique initial microstructure of ADB790E, characterized by a finer original grain size and a highly dispersed distribution of precipitates. The increased dispersion of carbides and nitrides provides a higher density of pinning sites per unit volume. Consequently, even if local pinning failure occurs and abnormal growth initiates, the ultimate grain size remains significantly constrained.

- Using a high-temperature laser confocal microscope to directly observe the changes in austenite grain size during heating, the experimental grain size values measured by the intercept method were found to be consistent with the predicted values from both models. However, Sellars’ model had a higher correlation coefficient. Therefore, during hot processing, the grain refinement temperature can be set based on the Sellars’ model’s predicted values, while the grain refinement holding time can be set based on the Beck’s model’s predicted values.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pan, Z.D.; Wang, E.M.; Wu, H.B. Precipitation behavior and strengthening–toughening mechanism of Nb micro-alloyed direct-quenched and tempered 1000 MPa grade high-strength hydropower steel. Metals 2024, 14, 794. [Google Scholar] [CrossRef]

- Fang, Q.; Xia, Y.Q.; Zhu, Y.S.; Cheng, T.H. Application and development of hydraulic steel structure safety information management system in pumped storage hydropower. E3S Web Conf. 2024, 573, 03009. [Google Scholar] [CrossRef]

- Feng, L.L.; Zhang, D.; Wu, K.M.; Qiao, W.W. Study on microstructure and properties of 1000MPa grade steel plate for hydropower station. J. Phys. Conf. Ser. 2020, 1637, 012072. [Google Scholar] [CrossRef]

- Hong, G.T.; Huo, S.B.; Zhu, X.C.; Zhao, Y.; Li, C.S.; Chen, L.Q. Investigation of microstructures and mechanical properties of 800 MPa grade hydroelectric steel. Henan Metall. 2014, 22, 9–11. (In Chinese) [Google Scholar] [CrossRef]

- Jia, T.; Wang, S.; Xiao, N.Y.; Li, M.Y. Quantitative investigation on strengthening and toughening mechanism of 1000 MPa grade hydropower steel. J. Mater. Eng. Perform. 2023, 32, 2193–2204. [Google Scholar] [CrossRef]

- Beires, P.; Vasconcelos, M.; Moreira, C.; Lopes, J. Stability of autonomous power systems with reversible hydropower plants: A study case for large scale renewables integration. Electr. Power Syst. Res. 2018, 158, 1–14. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Mei, Y.; Hu, M.S.; Jiang, W.L. Study on pressure pipe steel in large sized hydropower station. Weld. Technol. 2007, 36, 43–46. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Y.W.; Jin, G.Y.; Gao, J.J.; Liu, Y.J. Stable fatigue crack propagation of 16MnR steel. J. Beijing Inst. Technol. 2020, 29, 603–612. [Google Scholar] [CrossRef]

- Han, L.Z.; Ye, T. The development status and prospect of the production technology of domestic hydropower steel plate. J. Nanyang Norm. Univ. 2017, 16, 26–30. (In Chinese) [Google Scholar] [CrossRef]

- He, B.H.; Sun, J.J.; Tu, Q.A. Effects of heat treatment on mechanical properties and corrosion performance of 12MnNiVR oil tank steel. Int. J. Electrochem. Sci. 2015, 10, 10631–10638. [Google Scholar] [CrossRef]

- Zhang, Z.M.; Yu, W.; Cai, Q.W. Control basis for cooling rate of plates during roller quenching in high-pressure zone. Adv. Mater. Res. 2012, 538, 2090–2094. [Google Scholar] [CrossRef]

- Hirota, M. A novel application concept of high–temperature superconducting cable for seabed coils in ship magnetic deperming. J. Mater. Res. 2024, 39, 2934–2946. [Google Scholar] [CrossRef]

- Fuchs, N.; Bernhard, C. In-situ-Untersuchung von Austenitkornwachstumsprozessen in Stählen mittels Hochtemperatur-Laser-Scanning-Konfokal-Mikroskop. Berg-Huettenmaenn. Monatsh. 2019, 164, 200–204. [Google Scholar] [CrossRef]

- Sarkar, S.; Moreau, A.; Militzer, M.; Poole, W. Evolution of austenite recrystallization and grain growth using laser ultrasonics. Metall. Mater. Trans. A 2008, 39, 897–907. [Google Scholar] [CrossRef]

- Chamanfar, A.; Chentouf, S.M.; Jahazi, M.; Lapierre-Boire, L. Austenite grain growth and hot deformation behavior in a medium carbon low alloy steel. J. Mater. Res. Technol. 2020, 9, 12102–12114. [Google Scholar] [CrossRef]

- An, X.X.; Tian, Y.; Wang, H.J.; Shen, Y.F.; Wang, Z.D. Suppression of austenite grain coarsening by using Nb–Ti microalloying in high temperature carburizing of a gear steel. Adv. Eng. Mater. 2019, 21, 1900132. [Google Scholar] [CrossRef]

- Yue, C.X.; Zhang, L.W.; Liao, S.L.; Gao, H.J. Kinetic analysis of the austenite grain growth in GCr15 steel. J. Mater. Eng. Perform. 2010, 19, 112–115. [Google Scholar] [CrossRef]

- Xiao, J.; Tian, G.; Wang, D.; Cao, K.; Zhao, A.M. Effect of aging at different temperatures on microstructure evolution of 347H heat-resistant steel-welded joints. Metals 2025, 15, 518. [Google Scholar] [CrossRef]

- An, J.Z.; Cai, Z.Z.; Cheng, B.; Zhu, M.Y. Nb–Ti composite precipitation behaviour and its effect on the growth of austenite grains in peritectic steel. Ironmak. Steelmak. 2023, 50, 410–417. [Google Scholar] [CrossRef]

- Chen, J.H.; Liu, Z.B.; Wang, X.H.; Jiang, F.C.; Zhang, Y.Q.; Yang, Z.Y.; Liang, J.X.; Zhao, W.Y. Study on the dissolution of intermetallic compounds and austenite grain growth behavior in Cr-Ni-Mo-Ti-Al ultra-high strength stainless steel. Mater. Res. Express 2025, 12, 076510. [Google Scholar] [CrossRef]

- Gou, F.H.; Li, J.R.; Zhang, P.F.; Wang, H.L.; Yang, G. Austenite grain growth behavior of 60Mn3Al3Ni2CrVNb quenched and tempered low density steel. Trans. Mater. Heat Treat. 2021, 42, 76–83. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, H.M.; Chen, R.; Jia, H.B.; Li, Y.; Jiang, Z.Y. Effect of solid-solution second-phase particles on the austenite grain growth behavior in Nb-Ti high- strength IF steel. Strength Mater. 2020, 52, 539–547. [Google Scholar] [CrossRef]

- Dong, D.Q.; Chen, F.; Cui, Z.S. Modeling of austenite grain growth during austenitization in a low alloy steel. J. Mater. Eng. Perform. 2016, 25, 152–164. [Google Scholar] [CrossRef]

- Gao, Q.Z.; Qu, H.; Zhang, H.L.; Huo, Q. Austenite grain growth in alumina-forming austenitic steel. J. Mater. Res. 2016, 31, 1732–1740. [Google Scholar] [CrossRef]

- Huo, L.T.; Ma, T.; Gao, W.M.; Li, Y.G.; Zhang, H.C.; Gao, J. Study on the austenite grain growth behavior of Fe-Mn-Al-C low-density steel containing niobium. Metals 2025, 15, 576. [Google Scholar] [CrossRef]

- Wang, L.B.; Wan, X.L.; Hu, C.Y.; Xu, G.; Li, G.Q. High-temperature confocal laser scanning microscopy analysis of phase transformation of steels: A review. J. Iron Steel Res. Int. 2025, 32, 353–363. [Google Scholar] [CrossRef]

- Chen, Y.F.; Xie, J.P.; Wang, A.Q.; Mao, Z.P.; Gao, P.K.; Chang, Q.H. In-situ observation and analysis of the evolution of copper aluminum composite interface. Metals 2023, 13, 1558. [Google Scholar] [CrossRef]

- Gamsjäger, E.; Lin, M.; Tichauer, W.A.; Militzer, M. In-situ austenite grain growth measurements in an X80 line pipe steel. Mater. Charact. 2025, 224, 114998. [Google Scholar] [CrossRef]

- Beck, P.A.; Kremer, J.C.; Demer, L. Grain growth in high purity aluminum. Phys. Rev. 1947, 71, 555. [Google Scholar] [CrossRef]

- Meng, F.Y.; Wang, J.J.; Guo, J.; Fu, K.J.; Zhao, M.; Wang, Z.J.; Xu, Z. Growth behavior and kinetics of austenite grain in low-carbon high-strength steel with copper. Mater. Res. Express 2021, 8, 096504. [Google Scholar] [CrossRef]

- Gorbachev, I.I.; Korzunova, E.I.; Popov, V.V.; Khabibulin, D.M.; Urtsev, N.V. Simulation of Austenite Grain Growth in Low-Alloyed Steels upon Austenitization. Phys. Met. Metallogr. 2023, 124, 290–295. [Google Scholar] [CrossRef]

- Gil, F.J.; Planell, J.A. Behaviour of normal grain growth kinetics in single phase titanium and titanium alloys. Mater. Sci. Eng. A 2000, 283, 17–24. [Google Scholar] [CrossRef]

| Chemical Composition | Content (%) | Chemical Composition | Content (%) |

|---|---|---|---|

| C | 0.0745 | Cr | 0.4736 |

| Si | 0.0493 | Cu | 0.2628 |

| Mn | 1.2865 | Mo | 0.3709 |

| P | 0.00783 | Als | 0.0359 |

| S | 0.00161 | N | 0.003 |

| Nb | 0.0042 | B | 0.00076 |

| V | 0.043 | Ceq | 0.49319 |

| Ti | 0.01 | Pcm | 0.49319 |

| Ni | 0.6722 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, H.; Yu, Z.; Jiang, Z. Austenite Grain Growth Behavior and Dynamic Model of ADB790E Hydropower Steel. Metals 2025, 15, 1028. https://doi.org/10.3390/met15091028

Liu Y, Zhang H, Yu Z, Jiang Z. Austenite Grain Growth Behavior and Dynamic Model of ADB790E Hydropower Steel. Metals. 2025; 15(9):1028. https://doi.org/10.3390/met15091028

Chicago/Turabian StyleLiu, Yuxuan, Hongmei Zhang, Zhongxiang Yu, and Zhengyi Jiang. 2025. "Austenite Grain Growth Behavior and Dynamic Model of ADB790E Hydropower Steel" Metals 15, no. 9: 1028. https://doi.org/10.3390/met15091028

APA StyleLiu, Y., Zhang, H., Yu, Z., & Jiang, Z. (2025). Austenite Grain Growth Behavior and Dynamic Model of ADB790E Hydropower Steel. Metals, 15(9), 1028. https://doi.org/10.3390/met15091028