Multi-Scale Mechanical Anisotropy and Heat Treatment Effects in Additively Manufactured AlSi10Mg

Abstract

1. Introduction

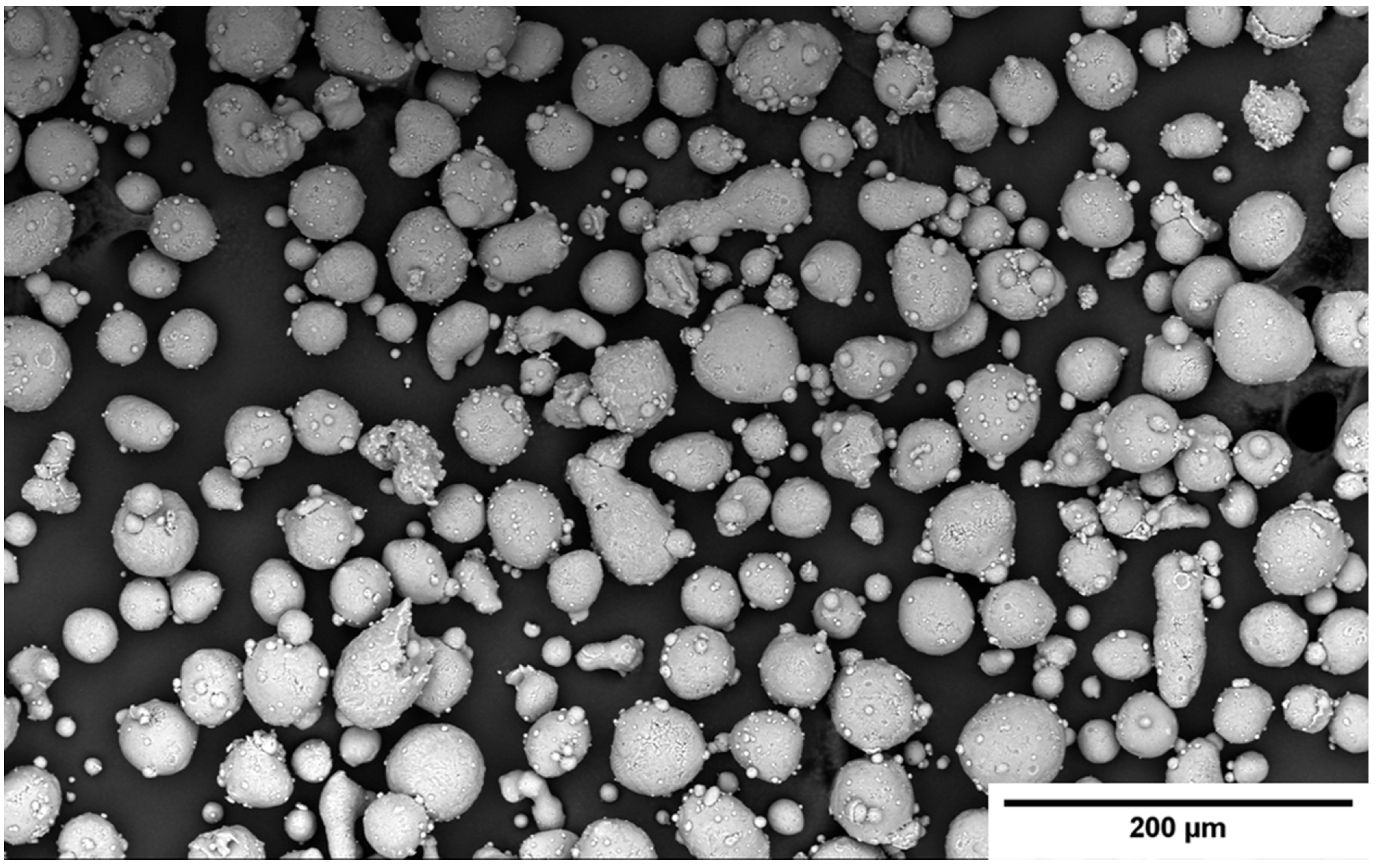

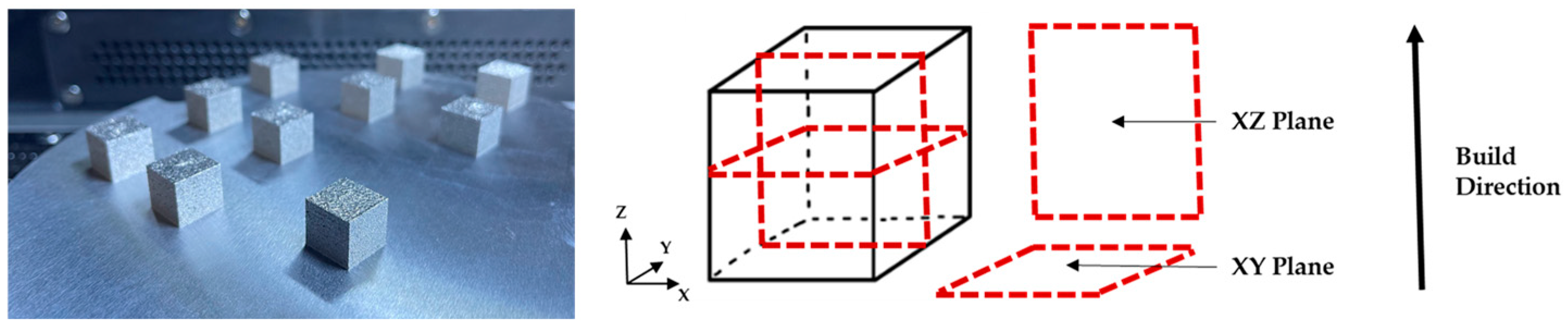

2. Materials and Methods

3. Results

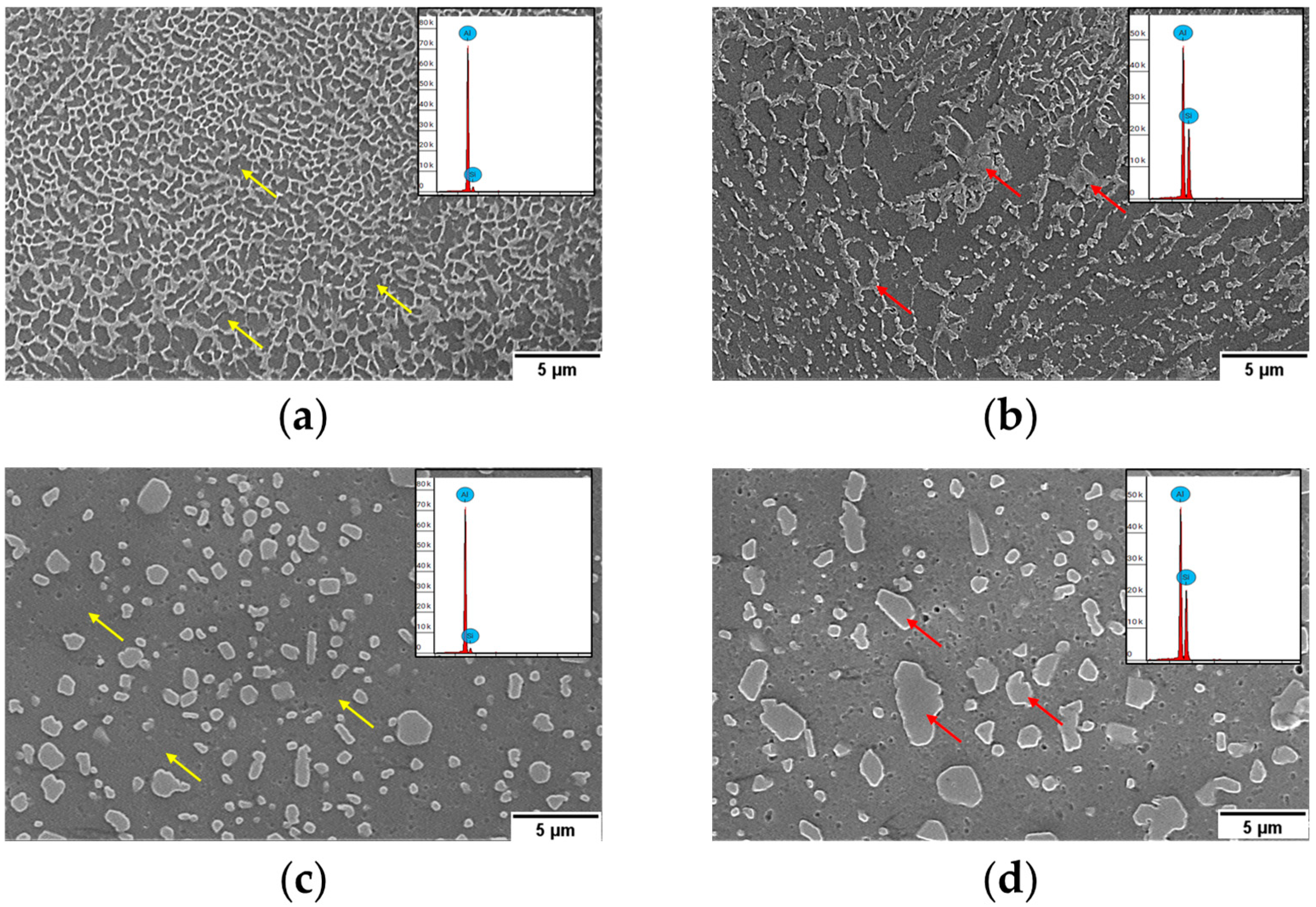

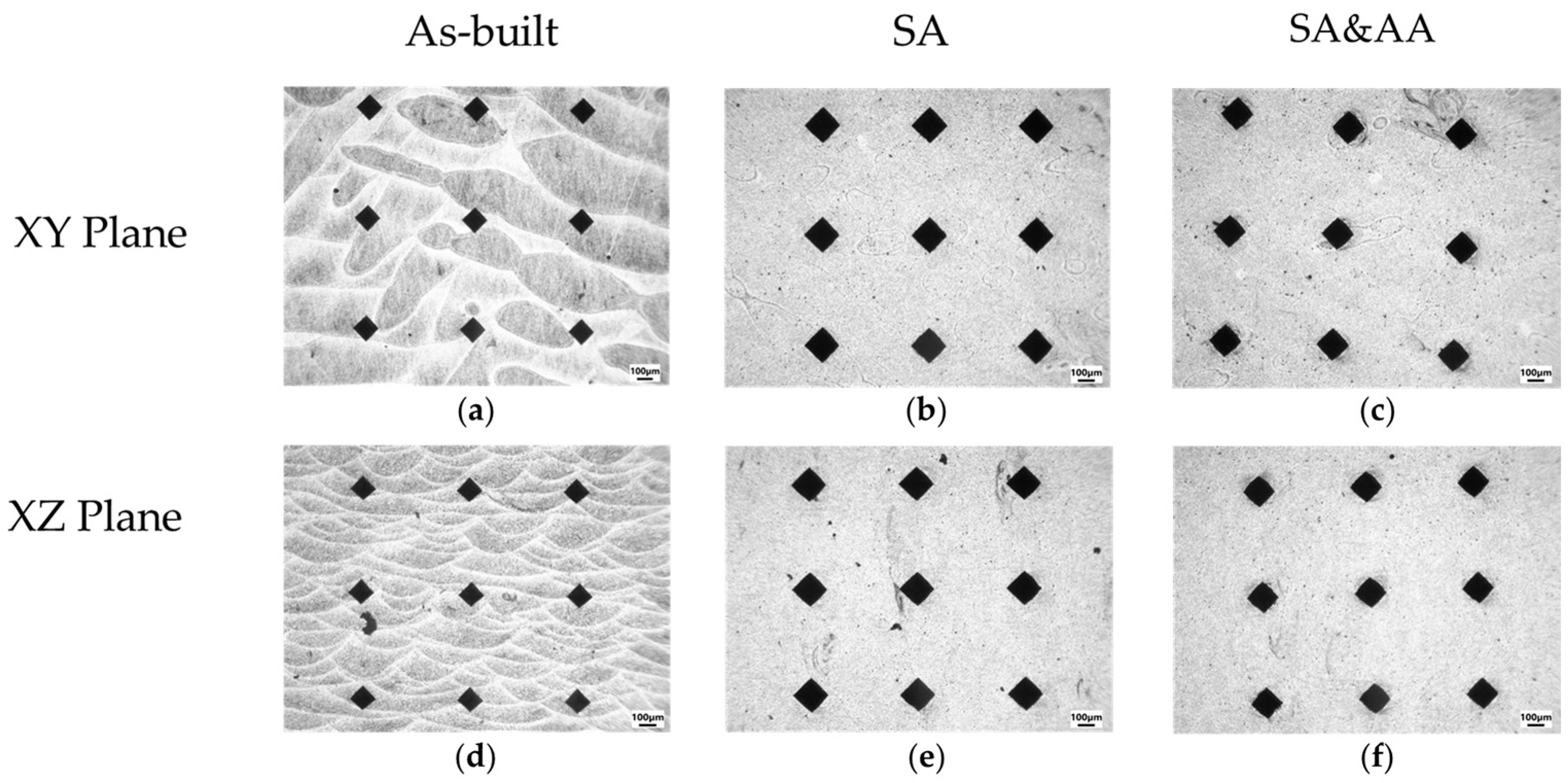

3.1. Microstructure

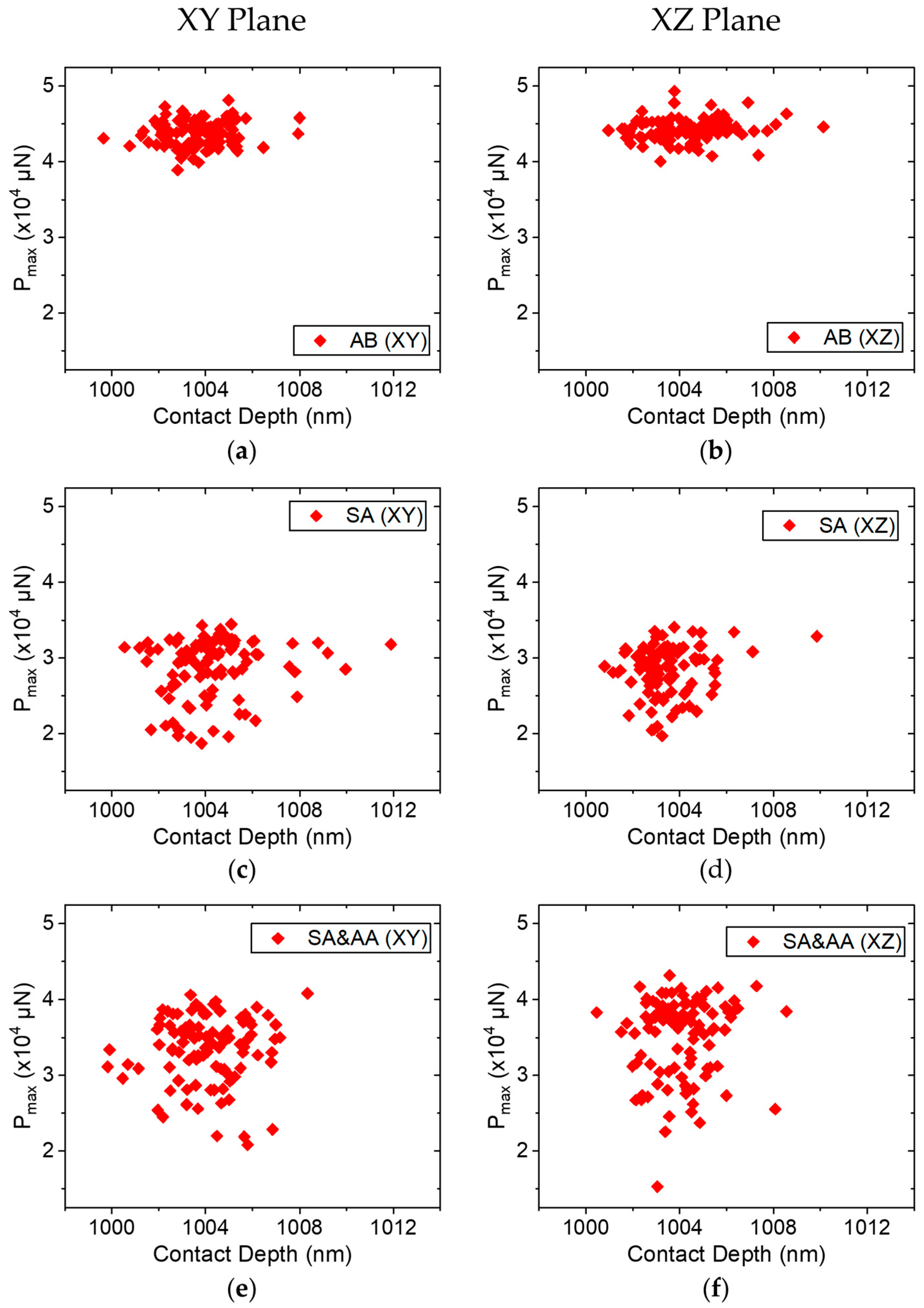

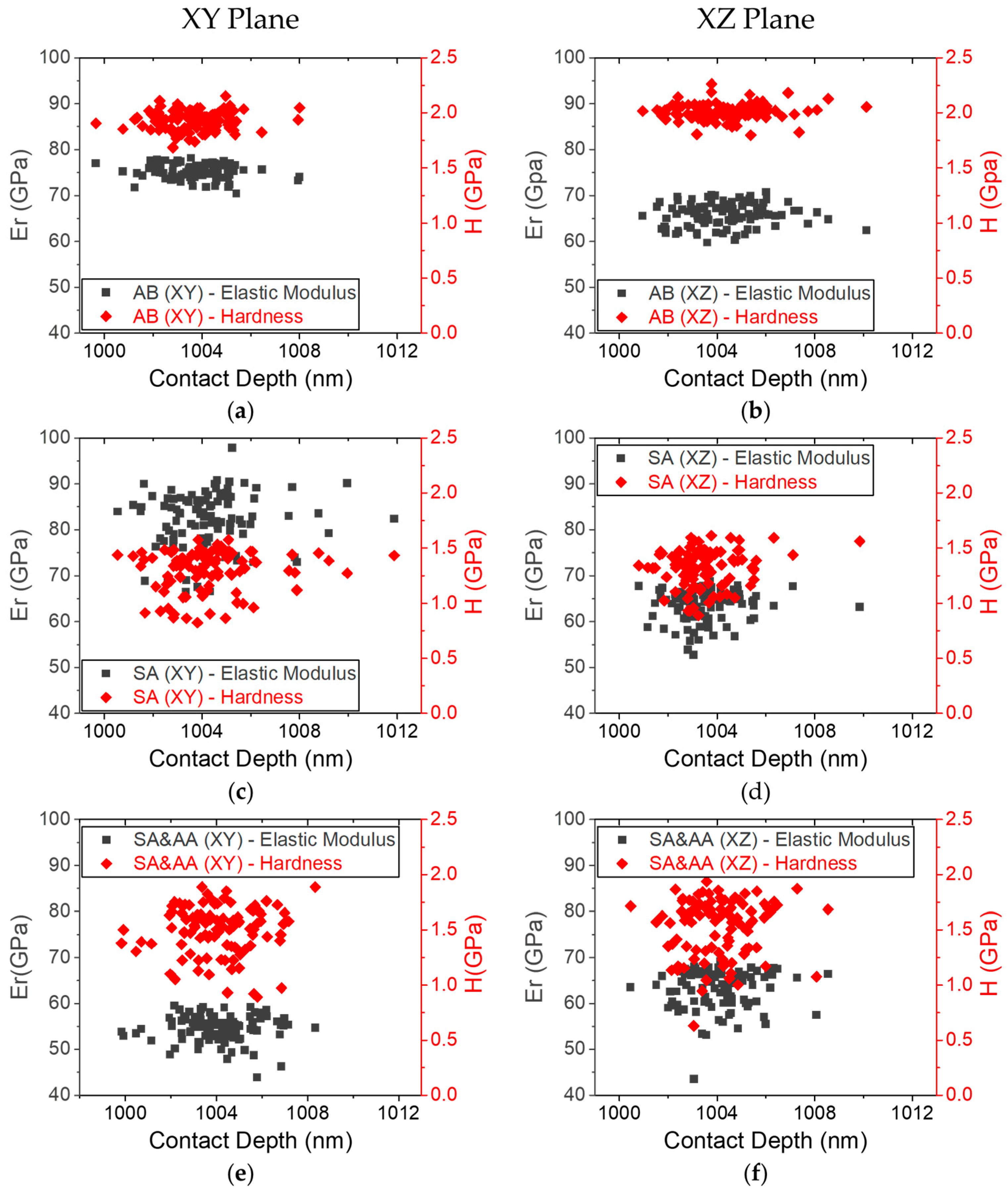

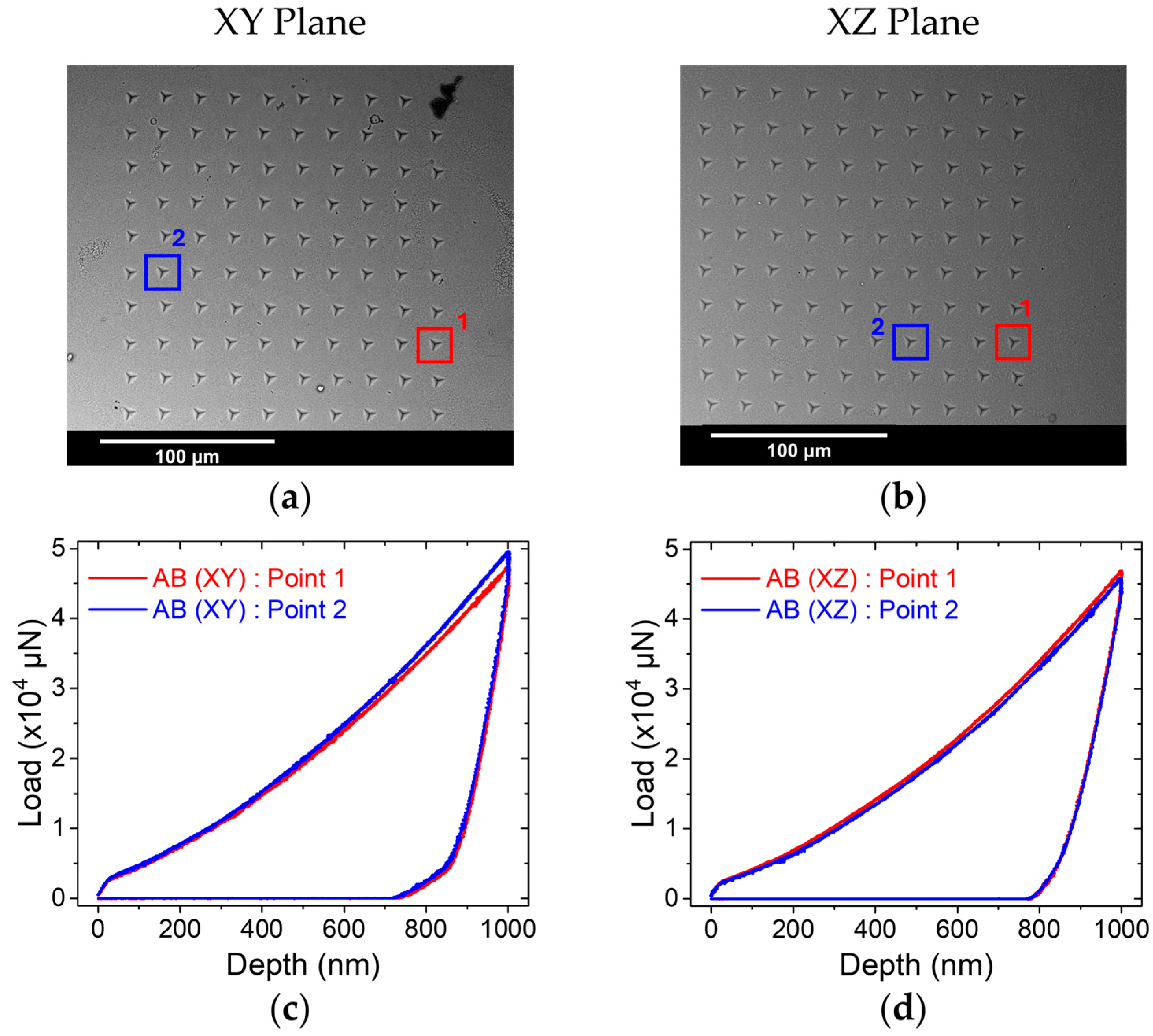

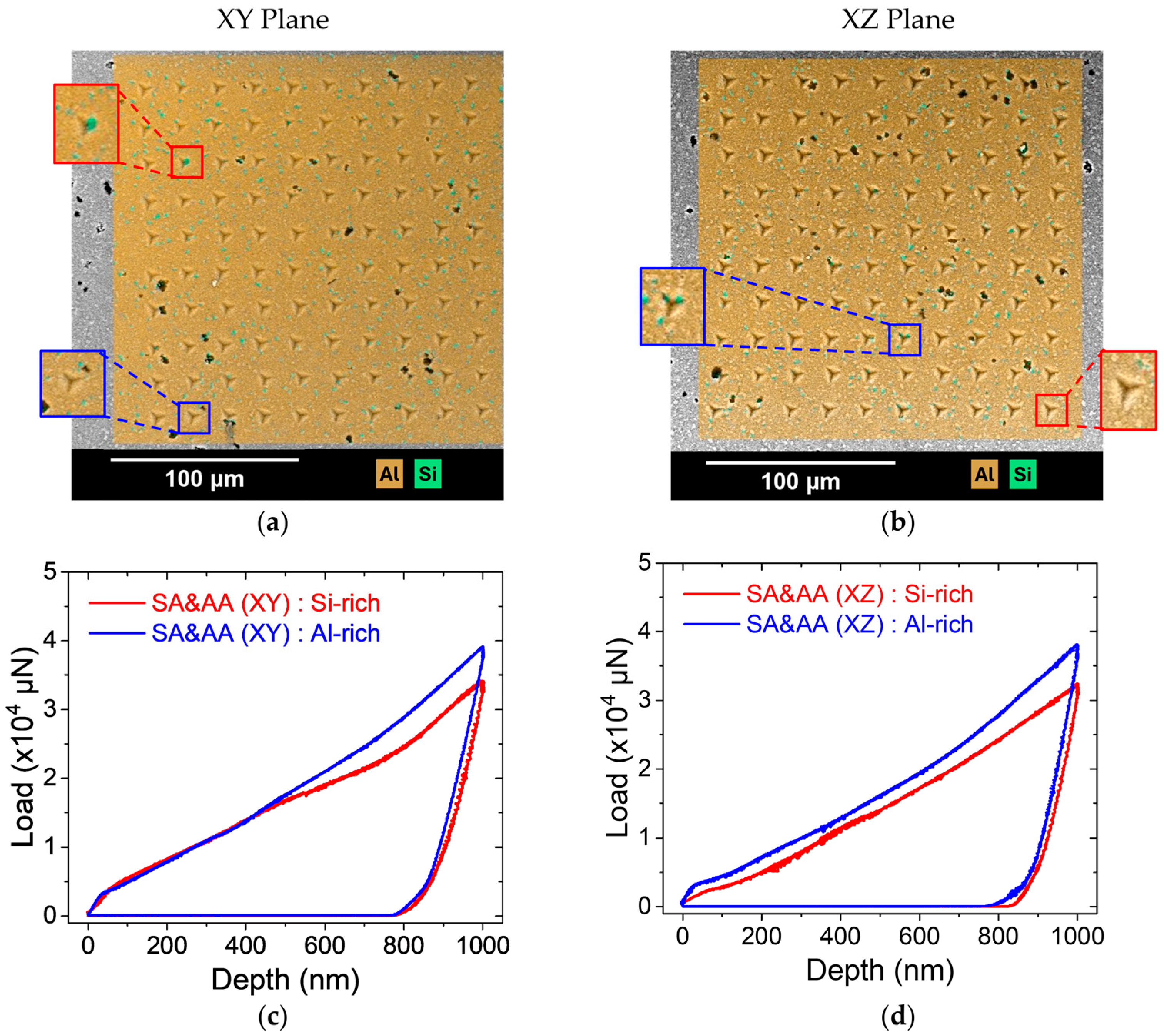

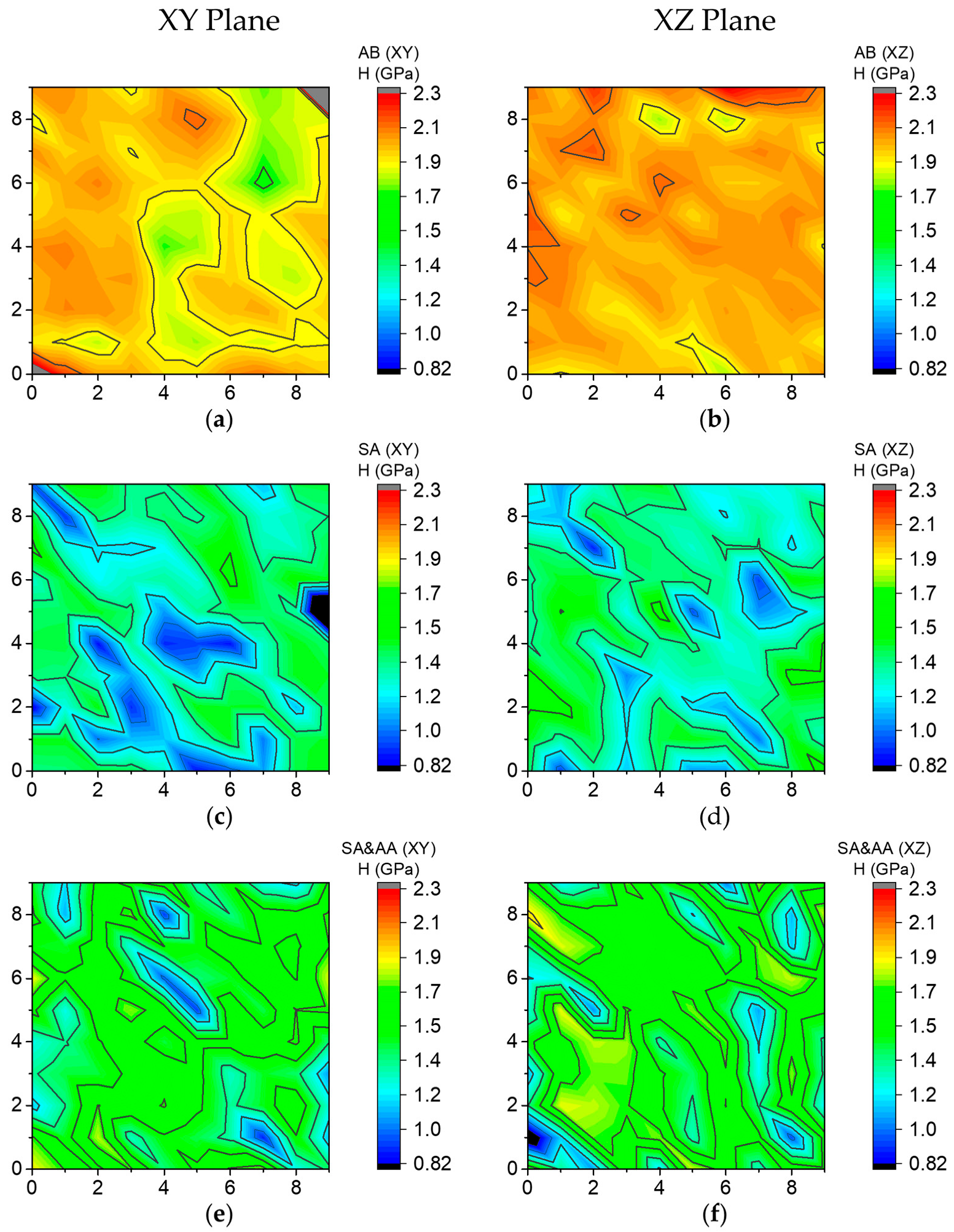

3.2. Micro- and Nanomechanical Properties

4. Discussion

4.1. Anisotropy-Dependent Mechanical Properties

4.2. Effect of Heat Treatment

4.3. Interaction Between Anisotropy and Heat Treatment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Murr, L.E. A Metallographic Review of 3D Printing/Additive Manufacturing of Metal and Alloy Products and Components. Metallogr. Microstruct. Anal. 2018, 7, 103–132. [Google Scholar] [CrossRef]

- Egon, A.; Bell, C.; Shad, R.; Egon, A.; Bell, C.; Shad, R. Additive Manufacturing for Complex Geometries. Preprints 2024. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Pratap, R.; Suman, R.; Rab, S. Advanced Industrial and Engineering Polymer Research Role of additive manufacturing applications towards environmental sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. ISBN 9780128140628. [Google Scholar] [CrossRef]

- Sarzyński, B.; Śnieżek, L.; Grzelak, K. Metal Additive Manufacturing (MAM) Applications in Production of Vehicle Parts and Components—A Review. Metals 2024, 14, 195. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Tejo-Otero, A.; Fenollosa-Artés, F. Development of am technologies for metals in the sector of medical implants. Metals 2020, 10, 686. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, J.; Zhang, B.; An, K.; Wang, Y.; Liu, D.; Lu, W.; Zhu, L.; Liu, C. Recent advance in laser powder bed fusion of Ti–6Al–4V alloys: Microstructure, mechanical properties and machinability. Virtual Phys. Prototyp. 2025, 20, e2446952. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Jamhari, F.I.; Foudzi, F.M.; Buhairi, M.A.; Sulong, A.B.; Mohd Radzuan, N.A.; Muhamad, N.; Mohamed, I.F.; Jamadon, N.H.; Tan, K.S. Influence of heat treatment parameters on microstructure and mechanical performance of titanium alloy in LPBF: A brief review. J. Mater. Res. Technol. 2023, 24, 4091–4110. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Donik, Č.; Kraner, J.; Kocijan, A.; Paulin, I.; Godec, M. Evolution of the ε and γ phases in biodegradable Fe–Mn alloys produced using laser powder-bed fusion. Sci. Rep. 2021, 11, 19506. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D.; Li, A.; Yi, D.; Li, T. A Review on Traditional Processes and Laser Powder Bed Fusion of Aluminum Alloy Microstructures, Mechanical Properties, Costs, and Applications. Materials 2024, 17, 2553. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, G.; Jayaganthan, R. Improved Corrosion Resistance Behaviour of AlSi10Mg Alloy due to Selective Laser Melting. Coatings 2023, 13, 225. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Paul, M.J.; Liu, Q.; Best, J.P.; Li, X.; Kruzic, J.J.; Ramamurty, U.; Gludovatz, B. Fracture resistance of AlSi10Mg fabricate d by laser powder b e d fusion. Acta Mater. 2021, 211, 116869. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Shakil, S.I.; Hadadzadeh, A.; Shalchi Amirkhiz, B.; Pirgazi, H.; Mohammadi, M.; Haghshenas, M. Additive manufactured versus cast AlSi10Mg alloy: Microstructure and micromechanics. Results Mater. 2021, 10, 100178. [Google Scholar] [CrossRef]

- Marola, S.; Bosia, S.; Veltro, A.; Fiore, G.; Manfredi, D.; Lombardi, M.; Amato, G.; Baricco, M.; Battezzati, L. Residual stresses in additively manufactured AlSi10Mg: Raman spectroscopy and X-ray diffraction analysis. Mater. Des. 2021, 202, 109550. [Google Scholar] [CrossRef]

- Chen, S.; Tan, Q.; Gao, W.; Wu, G.; Fan, J.; Feng, Z.; Huang, T.; Godfrey, A.W.; Zhang, M.; Huang, X. Effect of heat treatment on the anisotropy in mechanical properties of selective laser melted AlSi10Mg. Mater. Sci. Eng. A 2022, 858, 144130. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. On the formation of single tracks and layers in selective laser melting: Microstructure and Nano-mechanical propertiesf. J. Mater. Process. Technol. 2016, 230, 88–98. [Google Scholar] [CrossRef]

- Everitt, N.M.; Aboulkhair, N.T.; Maskery, I.; Tuck, C.J.; Ashcroft, I. Nanoindentation Shows Uniform Local Mechanical Properties Across Melt Pools and Layers Produced by Selective Laser Melting of AlSi 10Mg Alloy. Adv. Mater. Lett. 2016, 7, 13–16. [Google Scholar] [CrossRef][Green Version]

- Gargalis, L.; Karavias, L.; Graff, J.S.; Diplas, S.; Koumoulos, E.P.; Karaxi, E.K. A Comparative Investigation of Duplex and Super Duplex Stainless Steels Processed through Laser Powder Bed Fusion. Metals 2023, 13, 1897. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, H.; Liao, H.; Cheng, Y.; Hu, Z.; Zeng, X. Effect of heat treatments on fatigue property of selective laser melting AlSi10Mg. Int. J. Fatigue 2018, 116, 513–522. [Google Scholar] [CrossRef]

- Clement, C.D.; Masson, J.; Kabir, A.S. Effects of Heat Treatment on Microstructure and Mechanical Properties of AlSi10Mg Fabricated by Selective Laser Melting Process. J. Manuf. Mater. Process. 2022, 6, 52. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Anisotropic Mechanical Behavior of AlSi10Mg Parts Produced by Selective Laser Melting. JOM 2017, 69, 516–522. [Google Scholar] [CrossRef]

- Wu, Z.; Wu, S.; Gao, X.; Lin, Y.; Xue, Y.; Withers, P.J. The role of internal defects on anisotropic tensile failure of L-PBF AlSi10Mg alloys. Sci. Rep. 2023, 13, 14681. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding melt pool characteristics in laser powder bed fusion: An overview of single- and multi-track melt pools for process optimization. Adv. Powder Mater. 2023, 2, 137. [Google Scholar] [CrossRef]

- Zhang, H.; Chan, C.; Li, Y.; Chu, F.; Wu, X.; Cao, Z.; Li, L.; Yi, Y.; Wang, X.; Cao, S. Anisotropic microstructure and tensile property of laser powder bed fusion fabricated Al-Mn-Mg-Sc-Zr alloy built at different layer thickness. J. Mater. Res. Technol. 2024, 33, 845–860. [Google Scholar] [CrossRef]

- Yu, S.J.; Wang, P.; Li, H.C.; Setchi, R.; Wu, M.W.; Liu, Z.Y.; Chen, Z.W.; Waqar, S.; Zhang, L.C. Heterogeneous microstructure and mechanical behaviour of Al-8.3Fe-1.3V-1.8Si alloy produced by laser powder bed fusion. Virtual Phys. Prototyp. 2023, 18, e2155197. [Google Scholar] [CrossRef]

- Maeshima, T.; Oh-ishi, K.; Kadoura, H. Microstructural evolution and hardening phenomenon caused by aging of AlSi10Mg alloy by laser powder bed fusion. Heliyon 2024, 10, e28006. [Google Scholar] [CrossRef] [PubMed]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- ASTM E384-22; Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Fiocchi, J.; Tuissi, A.; Biffi, C.A. Heat treatment of aluminium alloys produced by laser powder bed fusion: A review. Mater. Des. 2021, 204, 109651. [Google Scholar] [CrossRef]

- Ramesh, R.; Gairola, S.; Jayaganthan, R.; Kamaraj, M. Effects of post-processing on the microstructural evolution and mechanical behaviour of an additively manufactured AlSi10Mg alloy. J. Mater. Res. Technol. 2025, 34, 2802–2813. [Google Scholar] [CrossRef]

- Zou, Q.; Dong, Z.; Zhang, Z.; Qiao, C.; Jie, J.; An, X.; Han, N. Electromagnetic construction and mechanical properties of in-situ Si reinforced Al matrix functionally graded material with Si-rich◎Si-poor coating structure. Compos. Part B Eng. 2021, 226, 109341. [Google Scholar] [CrossRef]

- Liu, Y.J.; Liu, Z.; Jiang, Y.; Wang, G.W.; Yang, Y.; Zhang, L.C. Gradient in microstructure and mechanical property of selective laser melted AlSi10Mg. J. Alloys Compd. 2018, 735, 1414–1421. [Google Scholar] [CrossRef]

- Limbasiya, N.; Jain, A.; Soni, H.; Wankhede, V.; Krolczyk, G.; Sahlot, P. A comprehensive review on the effect of process parameters and post-process treatments on microstructure and mechanical properties of selective laser melting of AlSi10Mg. J. Mater. Res. Technol. 2022, 21, 1141–1176. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Dong, Z.; Xu, M.; Guo, H.; Fei, X.; Liu, Y.; Gong, B.; Ju, G. Microstructural evolution and characterization of AlSi10Mg alloy manufactured by selective laser melting. J. Mater. Res. Technol. 2022, 17, 2343–2354. [Google Scholar] [CrossRef]

- Snopiński, P.; Barlak, M.; Nowakowska-Langier, K. Ar+ Ion Irradiation Response of LPBF AlSi10Mg Alloy in As-Built and KOBO-Processed Conditions. Symmetry 2024, 16, 1158. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; Peng, H.; Attardo, R.; Ostiguy, P.; Neidig, J.; Billo, R.; Hoelzle, D.; Shankar, M.R. Comparing microstructure and hardness of direct metal laser sintered AlSi10Mg alloy between different planes. J. Manuf. Process. 2019, 37, 274–280. [Google Scholar] [CrossRef]

- Ghio, E.; Cerri, E. Work Hardening of Heat-Treated AlSi10Mg Alloy Manufactured by Selective Laser Melting: Effects of Layer Thickness and Hatch Spacing. Materials 2021, 14, 4901. [Google Scholar] [CrossRef] [PubMed]

- Cabrini, M.; Calignano, F.; Fino, P.; Lorenzi, S.; Lorusso, M.; Manfredi, D.; Testa, C.; Pastore, T. Corrosion Behavior of Heat-Treated AlSi10Mg Manufactured by Laser Powder Bed Fusion. Materials 2018, 11, 1051. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Z.H.; Liu, S.L.; Li, S.F.; Shi, Y.; Yang, Y.F.; Misra, R.D.K. Role of melt pool boundary condition in determining the mechanical properties of selective laser melting AlSi10Mg alloy. Mater. Sci. Eng. A 2019, 740–741, 148–156. [Google Scholar] [CrossRef]

- Randall, N.X.; Vandamme, M.; Ulm, F.-J. Nanoindentation analysis as a two-dimensional tool for mapping the mechanical properties of complex surfaces. J. Mater. Res. 2009, 24, 679–690. [Google Scholar] [CrossRef]

- Kurdi, A.; Tabbakh, T.; Basak, A.K. Microstructural and Nanoindentation Investigation on the Laser Powder Bed Fusion Stainless Steel 316L. Materials 2023, 16, 5933. [Google Scholar] [CrossRef]

- Fedorenko, A.; Fedulov, B.; Kuzminova, Y.; Evlashin, S.; Staroverov, O.; Tretyakov, M.; Lomakin, E.; Akhatov, I. Anisotropy of Mechanical Properties and Residual Stress in Additively Manufactured 316L Specimens. Materials 2021, 14, 7176. [Google Scholar] [CrossRef]

- Hitzler, L.; Janousch, C.; Schanz, J.; Merkel, M.; Heine, B.; Mack, F.; Hall, W.; Öchsner, A. Direction and location dependency of selective laser melted AlSi10Mg specimens. J. Mater. Process. Technol. 2017, 243, 48–61. [Google Scholar] [CrossRef]

- Shi, S.; Zhao, Y.; Lin, X.; Deng, H.; Zhao, L.; He, G. Significance of α-Al cellular matrix in tensile behavior and work-hardening of additive manufactured AlSi10Mg alloy. Virtual Phys. Prototyp. 2025, 20, e2449189. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Alghamdi, F.; Haghshenas, M. Microstructural and small-scale characterization of additive manufactured AlSi10Mg alloy. SN Appl. Sci. 2019, 1, 255. [Google Scholar] [CrossRef]

- Maeshima, T.; Oh-ishi, K. Solute clustering and supersaturated solid solution of AlSi10Mg alloy fabricated by selective laser melting. Heliyon 2019, 5, e01186. [Google Scholar] [CrossRef]

- Snopiński, P.; Hilšer, O. Mechanism of Grain Refinement in 3D-Printed AlSi10Mg Alloy Subjected to Severe Plastic Deformation. Materials 2024, 17, 4098. [Google Scholar] [CrossRef]

- Zhang, X.X.; Knoop, D.; Andrä, H.; Harjo, S.; Kawasaki, T.; Lutz, A.; Lahres, M. Multiscale constitutive modeling of additively manufactured Al-Si-Mg alloys based on measured phase stresses and dislocation density. Int. J. Plast. 2021, 140, 102972. [Google Scholar] [CrossRef]

- Zhang, D.L.; Zheng, L. The quench sensitivity of cast Al-7 Wt Pet Si-0.4 Wt pct Mg alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1996, 27, 3983–3991. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. Contribution of Mg2Si precipitates to the strength of direct metal laser sintered AlSi10Mg. Mater. Sci. Eng. A 2019, 739, 295–300. [Google Scholar] [CrossRef]

- Wang, Z.; Zhuo, L.; Yin, E.; Zhao, Z. Materials Science & Engineering A Microstructure evolution and properties of nanoparticulate SiC modified AlSi10Mg alloys. Mater. Sci. Eng. A 2021, 808, 140864. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selectively laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Columnar to equiaxed transition during direct metal laser sintering of AlSi10Mg alloy: Effect of building direction. Addit. Manuf. 2018, 23, 121–131. [Google Scholar] [CrossRef]

- Li, X.; Yi, D.; Wu, X.; Zhang, J.; Yang, X.; Zhao, Z.; Feng, Y.; Wang, J.; Bai, P.; Liu, B.; et al. Effect of construction angles on microstructure and mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J. Alloys Compd. 2021, 881, 160459. [Google Scholar] [CrossRef]

- Liu, M.; Takata, N.; Suzuki, A.; Kobashi, M. Effect of heat treatment on gradient microstructure of AlSi10Mg lattice structure manufactured by laser powder bed fusion. Materials 2020, 13, 2487. [Google Scholar] [CrossRef]

- Geng, Y.; Wang, Q.; Wang, Y.; Zang, Q.; Mi, S.; Xu, J.; Xiao, Y.; Wu, Y.; Luan, J. Microstructural evolution and strengthening mechanism of high-strength AlSi8.1Mg1.4 alloy produced by selective laser melting. Mater. Des. 2022, 218, 674. [Google Scholar] [CrossRef]

| AlSi10Mg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al | Cu | Fe | Mg | Mn | Ni | Pb | Si | Sn | Ti | Zn |

| Balance | <0.01 | 0.14 | 0.37 | <0.01 | <0.01 | <0.01 | 9.8 | <0.01 | 0.01 | 0.01 |

| AlSi10Mg | XY Plane | XZ Plane |

|---|---|---|

| AB | 127.68 ± 3.54 HV0.5 | 125.02 ± 2.10 HV0.5 |

| SA | 68.07 ± 1.25 HV0.5 | 69.23 ± 1.30 HV0.5 |

| SA&AA | 83.25 ± 1.48 HV0.5 | 83.72 ± 1.51 HV0.5 |

| Condition | Plane | Hardness (GPa) | Elastic Modulus (GPa) |

|---|---|---|---|

| AB | XY | 1.94 ± 0.09 | 75.4 ± 1.6 |

| XZ | 2.01 ± 0.08 | 65.9 ± 2.5 | |

| SA | XY | 1.42 ± 0.22 | 83.2 ± 6.0 |

| XZ | 1.35 ± 0.16 | 64.6 ± 3.3 | |

| SA&AA | XY | 1.55 ± 0.21 | 55.2 ± 2.7 |

| XZ | 1.61 ± 0.24 | 64.4 ± 3.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argyrou, A.; Gargalis, L.; Karavias, L.; Karaxi, E.K.; Koumoulos, E.P. Multi-Scale Mechanical Anisotropy and Heat Treatment Effects in Additively Manufactured AlSi10Mg. Metals 2025, 15, 890. https://doi.org/10.3390/met15080890

Argyrou A, Gargalis L, Karavias L, Karaxi EK, Koumoulos EP. Multi-Scale Mechanical Anisotropy and Heat Treatment Effects in Additively Manufactured AlSi10Mg. Metals. 2025; 15(8):890. https://doi.org/10.3390/met15080890

Chicago/Turabian StyleArgyrou, Aikaterini, Leonidas Gargalis, Leonidas Karavias, Evangelia K. Karaxi, and Elias P. Koumoulos. 2025. "Multi-Scale Mechanical Anisotropy and Heat Treatment Effects in Additively Manufactured AlSi10Mg" Metals 15, no. 8: 890. https://doi.org/10.3390/met15080890

APA StyleArgyrou, A., Gargalis, L., Karavias, L., Karaxi, E. K., & Koumoulos, E. P. (2025). Multi-Scale Mechanical Anisotropy and Heat Treatment Effects in Additively Manufactured AlSi10Mg. Metals, 15(8), 890. https://doi.org/10.3390/met15080890