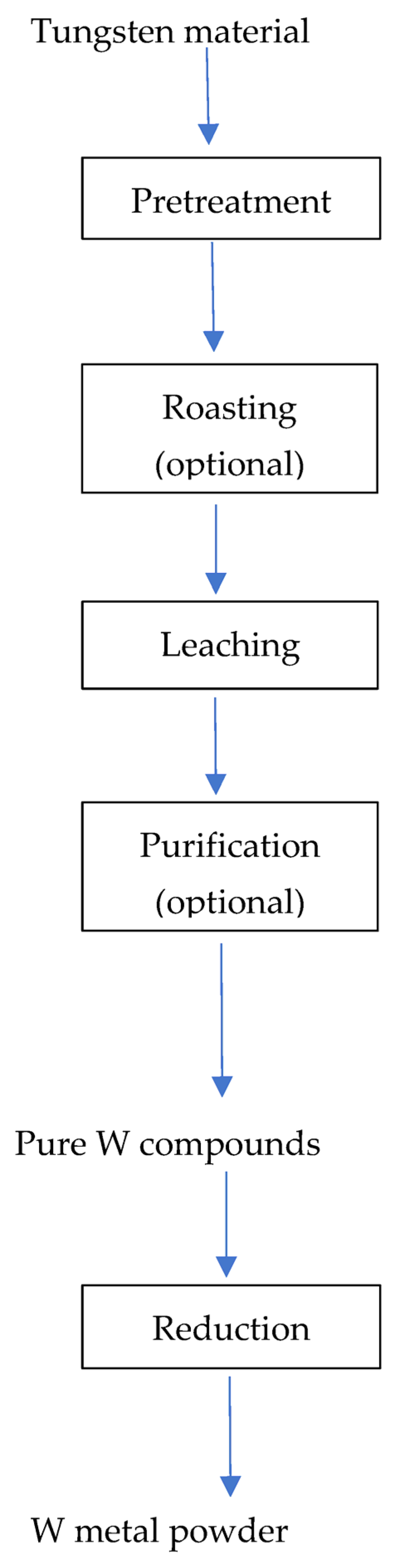

As is well known, hydrometallurgy involves the use of aqueous media and low and/or moderate temperatures. This type of processing consists of unit operations that allow sequential treatment of a starting material, either an ore or a secondary residue, until the metal or a product of that metal that is of practical interest, either to be sold or to be recycled, is obtained. Sometimes, prior to hydrometallurgical processing, the starting material may require some pre-treatment (concentration, thermal treatment, etc.). Once the starting material is prepared for treatment, the first unit operation is the dissolution of the metal of interest, or the leaching process. Sometimes, this first operation is also used to remove impurities, keeping the metal of interest in the solid residue. Then, after a filtration stage, the solution containing the metal of interest is subjected to a series of separation and/or concentration operations to obtain a product, either solid or liquid, which allows the final pure metal or metallic product of interest to be obtained. The advantage of all these unit operations is that they can be scaled up according to the needs of the process, and with little or no modification they can be used for the treatment of both raw and secondary materials.

In the case of tungsten specifically, the most-used unit operation is leaching, followed by ion exchange with resins, adsorption, liquid–liquid extraction (solvent extraction), precipitation, and evaporation/crystallization.

2.1. Unit Operation: Leaching

As stated above, after the preparation or pretreatment of the metal-bearing material, the next stage is the dissolution of the constituents of the starting material; thus, this leaching operation is a solid–liquid mass transfer process. The conditions for this leaching step vary in terms of temperature, pressure, type of leachant, etc. These parameters need to be fixed in line with the requirements of the given process. The final objective of this step is to produce metal ions or metal complexes in solution in the most selective form, or to enable their further selective recovery from the solution. In the case of tungsten, the leaching step is normally conducted in acidic or alkaline media, or even in water. This section describes the most recent advances in the dissolution of tungsten contained in different types of such raw or secondary materials.

The authors of [

25] carried out a series of investigations into the processing of Akchatau ores, with the aim of improving the treatment of wolframite concentrates. Concentrates (60–62% WO

3) was first reacted with sodium carbonate at 520–550 °C. Temperature was then increased further, to 750–850 °C. This sintering process was conducted to yield sodium tungstate (Na

2WO

4), which was leached at temperatures around 95 °C with water (98.6% leaching effectiveness). Purification of the leachates was carried out via electrodialysis in a two-chamber cell with separation of anode and cathode spaces by a cation exchange membrane, the end product being marketable Na

2WO

4.

Using a secondary source as hydrocracking catalyst (102-HC W/Ni/Al

2O

3, SiO

2) a process to recover tungsten was developed by the authors of [

26]. Firstly, material with a pulp density of 10 was roasted at 798 °C for two hours. Next, the roasted material was leached in alkaline medium (sodium hydroxide) at 70 °C for one hour, resulting in a tungsten recovery rate of 93%. The investigation did not present data about the further processing of this tungsten-bearing solution.

Another secondary material, specifically, spent tungsten-containing catalysts of organic production, formed the object of another investigation [

27]. In this case, the leaching process consisted of two stages. In the first stage, the starting material was leached with water. In the second stage, the material from the first operation was leached with sodium carbonate. During the first step, cesium alum was precipitated. Calcium tungstate (KVGF grade) was the product of the second leaching step. This calcium salt was treated with hydrochloric acid to yield tungstic acid (WO

3 content exceeding 80%).

A procedure which aimed to recover tungsten from scheelite (Chinese origin) using a mixture of H

3AsO

4 and H

2SO

4 solution was developed in [

28]. Under leaching conditions of 70 °C and eight hours, arsenotungstic acid (H

3AsW

12O

40) was formed with a near-quantitative (99.9%) tungsten leaching rate. This acid was purified by application of a solvent-extraction operation, with sec-octanol found to be the extractant presenting the best extraction rates (

Table 1); however, due to the volatility associated with this chemical, dodecanol was selected as the most promising extractant. Tungsten was stripped from the loaded organic phase by water at 70 °C, with 30 min of contact time and an O/A ratio of 1. After five consecutive stages, the accumulated stripping rate was 99.9%. The purified arsenotungstic acid solution was precipitated in ammoniacal medium to yield solid (NH

3)

3AsW

12O

40·xH

2O. This chemical was then subjected to a reductive step using hydrogen to yield tungsten powder, while arsenic was volatilized and condensed. The most curious aspect of this work is the use as a leachant of an arsenic product which is considered toxic by many standards.

In [

29], scheelite tailings (Canadian origin) were subjected to a leaching step in carbonate solutions (2.5 M) at temperatures in the 25–75 °C range [

29]. The best dissolution results (near-99% efficiency) were obtained with a temperature of 75 °C and 15–20 min of reaction time. Further processing of the Na

2WO

4 solution was not described in the published manuscript.

In [

30], in order to recover tungsten, diamond core drilling crowns (Serbian origin) were recycled by aqua regia leaching and further alkali leaching [

30]. After the first step, cobalt, iron and nickel all dissolved, whereas tungstic acid and diamonds remained undissolved. This solid was leached (about 98% efficiency) in ammoniacal medium (20% ammonium hydroxide, three hours at 89 °C, S/L ratio of 1/10), resulting in the dissolution of tungsten as ammonium tungstate while diamonds remained undissolved. Once these diamonds were filtered, the tungsten-bearing solution was evaporated, and ammonium paratungstate ((NH

4)

10H

2W

12O

42·xH

2O) crystallized. This salt was used as a precursor to yield metallic tungsten. Processing of the solution obtained from the first leaching step yielded cobalt powder.

In the next reviewed study, the authors investigated the treatment of wolframite (Chinese origin) in sulfuric–phosphoric acid mixtures under pressure conditions [

31].

Table 2 shows that an increase in the temperature increased the percentage of the leaching efficiency. It was proposed that tungsten was dissolved as an H

3PW

12O

40 species; however, no further data was provided about the processing of the as-obtained solutions.

Several issues relating to the leaching of scheelite concentrates with sulfur–phosphorus mixed acid have led to the development of a new procedure involving the inhibition effects of a calcium sulfate-blocking membrane, the selective extraction of tungsten by ion exchange, and the removal of phosphorus by the magnesium ammonium salt procedure [

32]. Scheelite concentrate (Chinese origin) was leached in a H

2SO

4-H

3PO

4 mixture at 80 °C and six hours of reaction, with addition of calcium sulfate improving the crystallization environment of gypsum dihydrate. The leachate containing about 90 g/L WO

3 was treated by ion exchange resin technology using D301 resin (weak base resin). In the process, PW

12O

403− groups in the leachate were interchanged with HSO

4− from the resin. Once tungsten was loaded onto the resin, the desorption step consisted of its reaction with 4–6 M ammonia at 60 °C. After desorption, PW

12O

403− was depolymerized by ammonia into phosphate ions and WO

42−, and ammonium paratungstate was finally crystallized after evaporation of the solution. Phosphorus was removed in the form of magnesium ammonium phosphate after a magnesium salt was used.

Because armor-piercing shells utilize W-Ni-Fe alloys, the recycling of scrap material from these shells is of interest. The authors of the next reviewed investigation dissolved such scrap in a mixture of hydrochloric acid and hydrogen peroxide [

33]. The leaching of the scrap was found to be largely dependent on a series of variables, with the best operational leaching parameters being determined as follows: 2 mol/L HCl, 2 mol/L H

2O

2, temperature of −5 °C, one hour of reaction time. The process allowed tungsten powder to be yielded.

In the next reviewed work [

34], tungsten was recovered from scheelite ores (Spanish origin) via microwave-assisted alkaline fusion. The process converted scheelite into tungstate salts ([Na

2WO

4, K

2WO

4 and/or K

3Na(WO

4)

2). The use of a low-melting eutectic alkali (NaOH/KOH) system decreased the reaction temperature to 150–200 °C, while the use of microwave technology reduced reaction times to 10–30 min. Leaching of the fused material was carried out with water at temperatures of 60–80 °C and 30 min. The investigation did not mention the subsequent processing of the dissolution. This type of process can be used for high-low grade ores and tailings.

Using synthetic scheelite, a dissolution process using the mixture H

2SO

4/H

2O

2 was developed to recover tungsten in [

35]. The leaching conditions were as follows: 1 M H

2SO

4, 1.5 M H

2O

2, 60 °C, two hours of reaction time. The dissolution process yielded gypsum and H

4W

4O

12(O

2)

2 in solution. Then, after a filtration step, the solution was thermally decomposed (90 °C and four hours), yielding tungsten in the form of tungstic acid.

In [

36], de-nitration processing was carried out using a catalyst of the V

2O

5-WO

3/TiO

2 type so that the spent catalyst could then be used as tungsten source [

36]. In this investigation, the spent material was leached in Na

2S medium to yield species containing WO

4-XS

X2− groups (X = 1 or 2). Because these groups cannot be used to produce calcium tungstate, an oxidizing step (30 °C) was necessary to transform these compounds to WO

42− containing species. This oxidation was performed using ozone (flow rate 2 g/L). After this step, impurities (titanium and silicon) present in the solution were precipitated by shifting the pH of the solution from 10.2 to 9 using HCl. The other experimental conditions for this step were 95 °C and four hours of reaction time. Finally, calcium (CaCl

2) precipitation was used to recover tungsten from the solution. In this operation, the pH of the solution was shifted again to pH 10.9, while a temperature of 85 °C and a 30 min reaction time were used to precipitate calcium tungstate with a near-95% efficiency. The chemical composition of this calcium tungstate fulfilled the GB5192-85 requirements for impurity content of II-class synthetic scheelite.

The recovery process for tungsten–rhenium alloy waste generates calcium tungstate containing rhenium. In light of this, a process to recover these two valuable metals was investigated in [

37]. Separation of both metals (dissolution of rhenium and precipitation of tungsten) was carried out under the following conditions: 2.7 M HCl, liquid–solid ratio of 26:1, temperature of 80 °C, processing time of 5 h. Under these conditions, the rhenium leaching efficiency was about 99%, with negligible tungsten dissolution. While the Re-bearing solution was treated by ion exchange resin processing, the precipitated tungstic acid was calcined at 900 °C for 0.5–5 h to produce WO

3. Longer reaction times produced larger oxide particles, with particle size increasing from 195.53 nm (0.5 h) to 540.10 nm (5 h).

Tungsten fine mud is secondary waste which contains quartz and potassium feldspar as well as a small amount of tungsten. In [

38], such waste was treated in a caustic soda environment in order to recover tungsten contained within it [

38]. Experimentation showed that with a temperature of 160 °C, a caustic soda concentration of 100 g/L, a treatment time of 2 h, and a liquid–solid ratio of 2.5:1 mL/g, the leaching efficiency of WO

3 was about 95%. The caustic concentration in the leaching solution needed to be fixed at 100 g/L. Continuous cycling of the caustic leaching solution allowed the tungsten concentration to increase from 15.9 to almost 120 g/L. Further processing of the leach solution was not reported in the work.

In [

39], the previous use of NaHSO

4·H

2O in scheelite processing was extended to the treatment of wolframite. Wolframite was roasted in the presence of this salt. Rates of conversions of the mineral into WO

3 were found to approach 99% under following conditions: temperature of 650 °C, time of two hours, and use of three times the stoichiometric amount of the salt. The leaching of the roasted product to remove manganese and iron impurities resulted in a concentrate with 93% WO

3. The solid was leached with ammonia (4 mol/L) at 80 °C for two hours. The leachate was then evaporated and crystallized to yield ammonium paratungstate.

Because heap leaching has low operational and capital costs, it was used in [

40] for processing of a scheelite ore utilizing a mixture of hydrochloric and oxalic acid as leachant. Scheelite was placed on the heap in the form of pellets. The presence of hydrochloric acid helped to leach the ore, reducing oxalic acid consumption during the further leaching of tungsten.

Though it is difficult to compare leaching results, due to variations in the tungsten-bearing materials treated and the experimental conditions used in the leaching experiments, a summary of some of the results derived from this review may be offered (

Table 3). It can be seen from the table that, with some exceptions, the efficiency of the leaching process is higher than 95%, with efficiency sometimes being dependent on the temperature [

31] or the type of material [

34]. In the case of [

37], tungsten precipitated and was recovered from residue.

There is little to criticize in those investigations in which the leaching step was applied for the recovery of tungsten from tungsten-bearing materials. Probably the only comment required is that processes were only investigated at the laboratory scale. Implementation on a larger scale is required is the advantages or disadvantages of each process are to be fully appreciated. The results of the reviewed studies show little room for improvement, with all the proposals following the same structure of leaching in acidic or alkaline media followed by a precipitation/crystallization step. Only in the case of selected tungsten-bearing materials, and prior to the leaching step, was a thermal pretreatment proposed in order to facilitate this leaching step. With respect to the end products obtained using these treatments, there are also few if any surprises, and little space for improvements, with tungstic acid, APT or tungsten salts being the most common chemicals obtained from the various processes, and only a couple of investigations managing to obtain W-metal powder as a final product. It is also true that, along with the other tungsten products, they pave the way to obtain this metal powder. We may say that what is really new in all this research is the application of known procedures to “new” tungsten-containing materials.