Abstract

The selection of process parameters for an ultra-high-pressure water jet directly affects the adhesion ability of the subsequent coating on the ship’s surface. This study investigates the effect of jet pressure, standoff distance, and nozzle traverse speed on the surface roughness of grade-A marine steel, aiming to optimize the process parameters and improve the quality of surface treatment. Based on single-factor experiments and orthogonal experiments, a three-factor, three-level experimental design was employed, considering jet pressure, standoff distance, and nozzle traverse speed. Scanning electron microscopy (SEM) and a confocal microscope were used to analyze the surface morphology and roughness of grade-A marine steel. The experimental results proved that surface roughness exhibited a nonlinear relationship with jet pressure, initially increasing and then decreasing as pressure rose. Conversely, surface roughness showed negative correlations with both standoff distance and nozzle traverse speed, progressively decreasing with increases in these parameters. Through hierarchical analysis, the effect hierarchy of the three factors on surface roughness was determined as follows: jet pressure > standoff distance > nozzle traverse speed. Parametric optimization revealed that a jet pressure of 150 MPa, a standoff distance of 25 mm, and a nozzle traverse speed of 180 mm/min collectively yielded a peak surface roughness of 62.549 μm. This value aligns with the pre-coating surface preparation standards for grade-A marine steel substrates, ensuring optimal adhesion for subsequent anti-corrosion treatments.

1. Introduction

As an efficient and environmentally friendly surface treatment method, ultra-high-pressure water jet technology has emerged as a widely adopted solution in recent years, demonstrating significant industrial value across critical applications, such as marine corrosion removal, metal surface strengthening, and high-precision material cutting [1,2,3]. By taking advantage of the impact effect of a high-pressure water jet, this technology can not only effectively remove rust layers, oxides, and contaminants from the surface of materials, but it can also significantly change the surface microstructure and mechanical properties of materials, such as surface roughness [4,5]. An increase in surface roughness can effectively enhance the adhesion of subsequent coatings.

International research on ultra-high-pressure water jet technology demonstrates multi-dimensional innovation, with applications expanding beyond conventional manufacturing into emerging sectors, including energy development and environmental remediation. In precision manufacturing, through an orthogonal experimental design, Grigoraș et al. systematically established the nonlinear regulatory mechanism of jet pressure and standoff distance on S235JR steel alloy cutting precision, providing critical parameter optimization benchmarks for high-accuracy metal processing [6]. Addressing electrical steel lamination processing challenges, Szada-Borzyszkowska’s team overcame traditional process limitations by refining nozzle geometry and abrasive mixture formulations, achieving not only enhanced cutting efficiency but also effective suppression of interlayer delamination [7]. Furthermore, Borkowski and colleagues developed a water jet-based granulometric control technique for hard coal micronization, enabling precise and efficient particle size distribution management [8]. In environmental applications, Ahn et al. constructed a quantitative relationship model between pressure, standoff distance, and cleaning efficacy via multifactor response surface methodology, delivering optimization decision support for marine biofouling removal [9]. Regarding material durability, Srivastava’s recent work established a notch corrosion fatigue prediction model for water jet-processed grade-A marine steel. Employing strain energy density gradient analysis, this model reveals the dynamic evolution of stress concentration factors and advances a novel theoretical framework for ship structural integrity assessment [10].

Research on ultra-high-pressure water jet technology in China exhibits a strong engineering application-oriented focus, with significant industrial progress achieved in shipbuilding, mining, and railway cleaning applications [11,12,13]. Xue S X. et al. developed a 350 MPa-grade automated wall-climbing derusting system that demonstrates high-efficiency removal of corrosion layers from ship surfaces while maintaining a substrate damage rate below 2% [14]. This validates the precision control capability of water jet technology in surface treatment and lays the groundwork for subsequent surface enhancement research. Wu Y Z. et al. derived the indentation equation of pure water jet impact on a metal surface based on the indentation fracture theory and verified the influence law of jet pressure, standoff distance, and nozzle traverse speed on the surface roughness of 304 stainless steel through numerical simulation and experiments [15]. It was found that the surface roughness shows a trend of first increasing and then decreasing with the increase in jet pressure. The increase in standoff distance and nozzle traverse speed causes the roughness to continue to decrease. Dong X. et al. studied the effect of water jet shot peening on metal surface roughness and pointed out that appropriate process parameters can effectively improve surface quality [16]. The above study provides an important theoretical basis for understanding the microscopic mechanism and surface effects of water jet impact. In our previous study, the process parameters for abrasive blasting cleaning of grade-A shipbuilding steel surfaces were optimized [17]. However, further systematic research is still needed on the variation pattern in the surface roughness of grade-A marine steel in ship rust removal areas and the optimal combination of process parameters.

This paper is based on single-factor experiments and orthogonal experiments; three factors and three levels of jet pressure, standoff distance, and nozzle traverse speed are designed. The surface topography and roughness of grade-A marine steel are analyzed using scanning electron microscopy and a confocal microscope. The hierarchical order of process parameter effects was identified via range analysis in orthogonal experiments. This study systematically investigates the effects of jet pressure, standoff distance, and nozzle traverse speed on surface roughness, aiming to establish a theoretical and technical basis for the application of ultra-high-pressure water jet descaling in green ship rust removal areas.

2. Experimental Principles and Design

2.1. Experimental Factors and Levels

In accordance with the specifications for ultra-high-pressure water jet ship derusting technology, a study on the ultra-high-pressure water jet surface treatment process for ships was conducted. The key process parameters of the ultra-high-pressure water jet involved jet pressure, standoff distance, and nozzle traverse speed. The efficiency of ultra-high-pressure water jet descaling and rust removal was primarily determined by the descaling coverage regulated by jet pressure and standoff distance, while the surface treatment quality was jointly influenced by jet pressure, standoff distance, and nozzle traverse speed. As the cleaning equipment operates vertically, impact angle effects were excluded from consideration. Focusing on the effects of jet pressure, standoff distance, and nozzle traverse speed on surface treatment efficiency and surface treatment quality, this research employed a three-factor three-level orthogonal experimental design. The specific factor levels are detailed in Table 1.

Table 1.

Factor-level table of the experimental design.

Under the experimental parameters of 200 MPa jet pressure and 30 mm standoff distance, both flat and curved grade-A marine steel specimens exhibited significant surface damage [18]. To prevent damage to the grade-A marine steel specimens, both standoff distance reduction and pressure adjustment were required. Therefore, to ensure surface treatment quality and identify optimal water jet parameters, three critical operational variables were investigated: jet pressure (P) at 130 MPa, 150 MPa, and 170 MPa; standoff distance (L) at 25 mm, 35 mm, and 45 mm; and nozzle traverse speed (V) at 120 mm/min, 180 mm/min, and 240 mm/min. The process parameters for the single-factor experiments are detailed in Table 2.

Table 2.

Process parameters of the single-factor experiment.

2.2. Experimental Materials and Equipment

To study the effect of ultra-high-pressure water jet process parameters on surface roughness, 100 mm × 100 mm × 15 mm grade-A marine steel (yield strength: 301 MPa, tensile strength: 466 MPa. Hunan Valin Xiangtan Iron and Steel Co., Ltd., Xiangtan, China) was selected for the experiment. This material has good corrosion resistance and fatigue resistance and is widely used in shipbuilding [10]. The main chemical composition is shown in Table 3 [19].

Table 3.

Chemical composition of grade-A marine steel (mass fraction/%).

Figure 1a shows the grade-A marine steel specimen required for the experiment. Figure 1b depicts the experimental platform for studying the impact of the ultra-high-pressure water jet on the grade-A marine steel. The jet power system of the platform is a 280 MPa-20 L/min horizontal triplex plunger ultra-high-pressure pump (Nantong COSCO Shipping Engineering Co., Ltd., Nantong, China), characterized by stable jet flow, simple operation, and easy disassembly and maintenance. The jet delivery device used in this experiment is the rotary nozzle (Shanghai Shuineng Metal Technology & Development Co., Ltd., Shanghai, China) shown in Figure 1c, which features multi-angle jetting, minimal water jet pressure loss, and uniform water flow.

Figure 1.

Materials and equipment. (a) Grade-A marine steel, (b) ultra-high-pressure water jet impact experimental platform, and (c) rotary nozzle.

3. Experimental Results and Analysis

3.1. Analysis of Surface Roughness in Single-Factor Experiments

The surface roughness of materials is intrinsically linked to their microstructural characteristics. Materials with higher surface roughness exhibit numerous micro-peaks and valleys of varying heights, characterized by significant peak-to-valley deviations and small spatial wavelengths. However, elevated roughness often correlates with increased micro-defects, such as cracks, pores, and scratches, which compromise surface integrity and mechanical performance. For the measurement of the mean roughness depth according to ISO 21920-2:2021 (Rz) [20], analysis zones were selected from regions where ultra-high-pressure water jet treatment achieved ISO 8501-1 Sa2.5 cleanliness standards [21]. The three-dimensional surface topography and roughness values of the treated grade-A marine steel were analyzed using a confocal microscope, ensuring quantitative characterization of post-processing surface morphology.

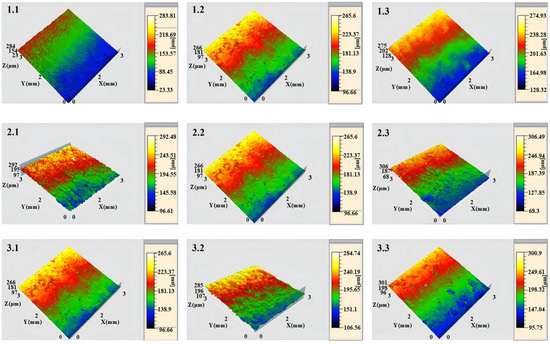

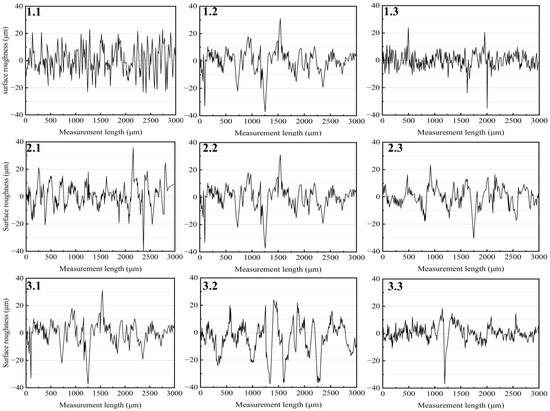

Figure 2 (Specimen number 1.1–3.3 shown in Table 2) presents the surface topography of the grade-A marine steel under different jet parameters in the single-factor experiments. All specimens exhibit undulating surfaces with varying degrees of height fluctuations. Notably, Specimens 1.2, 2.2, and 3.1, representing the same test piece under distinct parameter sets, demonstrate relatively smoother surfaces compared to the others, achieving a balance between controlled roughness and morphological uniformity. Figure 3 (Specimen number 1.1–3.3 shown in Table 2) illustrates the variations in surface roughness at the central position of the specimen under different jet parameters, while Table 4 (Specimen number 1.1–3.3 shown in Table 2) quantifies the corresponding roughness values. Based on the data in Table 4, a bar chart (Figure 4) was generated to visualize the surface roughness distribution of grade-A marine steel after the single-factor experiments.

Figure 2.

Surface topography of the grade-A marine steel specimens.

Figure 3.

Surface roughness profilograms of grade-A marine steel.

Table 4.

Surface roughness values.

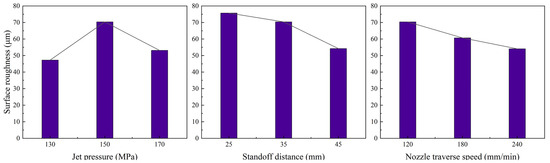

Figure 4.

Surface roughness graph of grade-A marine steel.

As can be seen in Figure 2 and Figure 4, the surface roughness shows a trend of increasing first and then decreasing with the increase in jet pressure. When the pressure reaches 150 MPa, the surface roughness reaches the maximum value of 70.381 μm. Based on Figure 3, the roughness profile exhibits a peak fluctuation amplitude at 150 MPa, signifying heightened irregularity in the surface morphology at this pressure level. Combined with the analysis of its surface topography, it can be seen that when the jet pressure begins to increase, the impact force of the jet on the material surface gradually increases. At the lower pressure stage, the energy of the jet is not sufficient to effectively remove the rust layer, but only to create more surface irregularities. As the jet pressure increases further and the jet energy reaches a certain level, more efficient material removal and surface leveling of the rust layer can be achieved. The ultra-high-pressure jet can impact the material surface to make it more flat, gradually reducing the height difference between the peaks and valleys of the surface, making the microscopic texture of the material surface more regular, and forming a more uniform microscopic morphology of the surface, thereby reducing the surface roughness. With the increase in the standoff distance, the surface roughness gradually decreases, and when the standoff distance is 25 mm, the surface roughness reaches the experimental maximum of 75.717 μm. Based on Figure 3, the roughness profile exhibits high-frequency oscillations at a 25 mm standoff distance, whereas the curve stabilizes to a planar morphology at 45 mm. Combined with the analysis of its surface topography, it can be seen that when the standoff distance increases, the energy distribution range of the jet impact widens, and the energy acting on the material surface per unit area relatively decreases, making the impact on the material surface more uniform and smooth, and the surface roughness value decreases accordingly. The energy distribution of the jet impact on the material surface will diffuse to a certain extent because of factors such as air resistance. As can be seen from the figure, at a smaller standoff distance, the jet energy is more concentrated and is prone to cause local deep erosion on the material surface, resulting in an increase in surface roughness. When the standoff distance increases, the energy distribution range of the jet impact widens, and the energy acting on the material surface per unit area relatively decreases, making the erosion on the material surface more uniform and smooth, and the surface roughness value decreases accordingly. When the nozzle traverse speed increases, the surface roughness also shows a decreasing trend. Based on Figure 3, the roughness profile displays pronounced undulations under a nozzle traverse speed of 120 mm/min. At the same time, it can be seen that the surface roughness value and its variation range of the material treated with the water jet at different lateral movement speeds are smaller than those treated with the water jet at different jet pressures and standoff distances. The experiment found that the surface roughness initially increased and then decreased with increasing jet pressure, while it showed a gradually decreasing trend with increasing standoff distance and nozzle traverse speed. These findings are consistent with the pattern observed by Wu et al. [15] in their study on 304 stainless steel.

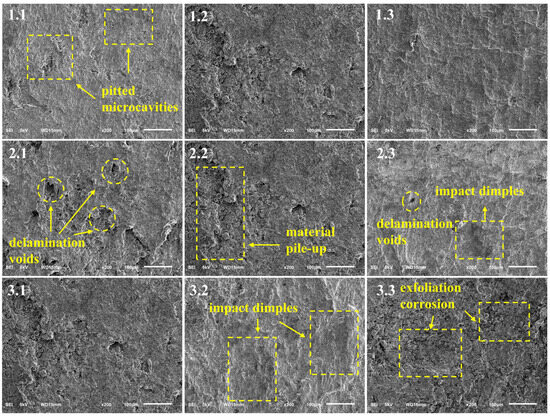

3.2. Analysis of Microstructural Morphology in Single-Factor Experiments

The microstructural characteristics and surface features of the specimens reflect the impact strengthening mechanism of ultra-high-pressure water jet impingement. Figure 5 and Figure 6 (Specimen number 1.1–3.3 shown in Table 2) present SEM images of the grade-A marine steel at 200× and 500× magnifications. As observed, Specimen 1.1 (130 MPa) exhibited pitted microcavities with poor surface integrity and incomplete rust removal. In Specimen 1.2 (150 MPa), delamination voids significantly increased in density, depth, and size, accompanied by localized material pile-up and a sharp rise in surface roughness, indicating effective rust layer stripping at moderate pressure. Conversely, Specimen 1.3 (170 MPa) showed reduced delamination voids, increased pitted microcavities, and lower roughness. From the standoff distance perspective, Specimen 2.1 (25 mm) demonstrated dense delamination voids and exfoliation corrosion pits due to high energy density, achieving efficient rust removal. Specimen 2.2 (35 mm, same as 1.3) displayed intermediate effects, while Specimen 2.3 (45 mm) suffered from dispersed impact energy, resulting in fewer delamination voids and impact dimples. Regarding nozzle traverse speed, Specimen 3.1 (120 mm/min, same as 1.3) showed incomplete rust removal. In Specimen 3.2 (180 mm/min), pit density decreased, surface flatness improved, and roughness dropped to Rz = 60 μm. However, Specimen 3.3 (240 mm/min) exhibited insufficient dwell time, leaving residual rust layers. Based on the comprehensive analysis, the optimal parameters are determined as follows: a water jet pressure of 150 MPa effectively removes rust layers while avoiding substrate damage; a standoff distance of 25 mm balances impact force with flow field uniformity, minimizing material accumulation; and a nozzle traverse speed of 180 mm/min optimizes surface roughness control while maintaining substrate integrity.

Figure 5.

Surface SEM image of grade-A marine steel (200×).

Figure 6.

Surface SEM image of grade-A marine steel (500×).

4. Orthogonal Experimental Range Analysis

4.1. Results of Orthogonal Experiments

To better reflect the interaction among various factors and ensure the reliability of the results, orthogonal experiments were used to examine the surface roughness values under different combinations of the process parameters and to determine the optimal combination of the process parameters. According to the factors and the number of levels in Table 1, the L9 (34) orthogonal analysis table was selected. The experimental workload is reduced, bias is mitigated, and result reliability is enhanced. The orthogonal experimental results are shown in Table 5.

Table 5.

Process parameters and results of orthogonal experiments on surface roughness.

4.2. Range Analysis

Range analysis is a widely used method in orthogonal experimental data processing, enabling intuitive determination of the hierarchical influence relationships between various factors and their levels. The specific calculation formulas are as follows:

where Kjm—The sum of experimental results for the m-th factor at each level in the j-th column;

Tjm—The mean value of experimental results for the m-th factor at each level in the j-th column;

n—The number of occurrences for each factor level;

Rj—The difference between the maximum and minimum mean values of the experimental results across all levels of the factor in the j-th column.

In range analysis, Tjm represents the average value of Kjm, where a higher Tjm indicates a stronger influence on the experimental outcomes. Rj, defined as the difference between the maximum and minimum Tjm, quantifies the magnitude of each factor’s effect—a larger Rj corresponds to a more significant impact. The hierarchical order of influencing factors can be determined by comparing Rj values. To investigate the effects of jet pressure, standoff distance, and nozzle traverse speed on surface roughness in ultra-high-pressure water jet processing, range analysis was applied to the orthogonal experimental results in Table 5. The derived range analysis results for surface roughness are summarized in Table 6, revealing the relative significance of each process parameter.

Table 6.

Range analysis of surface roughness.

As shown in Table 6, the range analysis of surface roughness revealed the hierarchy of parameter effects as Rjet pressure > Rstandoff distance > Rnozzle traverse speed, demonstrating that the significance of the ultra-high-pressure water jet parameters on grade-A marine steel follows jet pressure > standoff distance > nozzle traverse speed. Analysis of jet pressure levels, T12 > T13 > T11, indicated that surface roughness peaked at 150 MPa, exhibiting an initial increase followed by a decrease with rising pressure. For standoff distance, T21 > T22 > T23, the highest roughness occurred at 25 mm, decreasing monotonically to 54.081 μm at 45 mm. Nozzle traverse speed analysis, T31 > T32 > T33, showed a nonlinear roughness trend, with initial elevation and subsequent reduction. These findings, derived from range analysis, align with results from the single-factor experiments, validating the reliability of the experimental methodology and confirming that a jet pressure of 150 MPa, a standoff distance of 25 mm, and a nozzle traverse speed of 180 mm/min optimize roughness control while adhering to IMO PSPC standards for surface integrity.

Linear regression is a statistical analysis method used to investigate the linear relationship between a dependent variable and multiple independent variables. In this study, a multiple linear regression approach was employed to develop a predictive model for surface roughness based on key process parameters. The general form of the regression equation is expressed as:

where Rz represents the surface roughness of the material (μm), P denotes the jet pressure (MPa), l stands for the standoff distance (mm), and v indicates the nozzle traverse speed (mm/min).

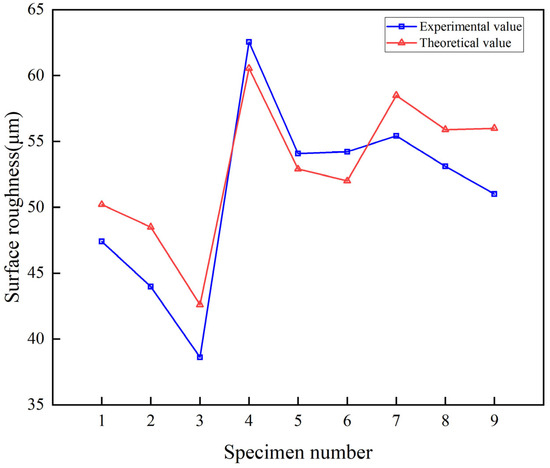

This equation indicates that surface roughness exhibits a positive correlation with jet pressure, where roughness increases with rising pressure. However, the single-factor experiments revealed a nonlinear trend: while roughness initially increases and then decreases with pressure elevation, it remains higher at pressures above 150 MPa compared to the 130 MPa treated specimens. Conversely, standoff distance and nozzle traverse speed show negative correlations with roughness, where larger parameter values reduce roughness—a finding consistent with the conclusions derived from range analysis. Theoretical predictions from the linear regression model were compared against the orthogonal experimental results using numerical computation software, as graphically validated in Figure 7.

Figure 7.

Comparison between experimental and theoretical values.

Under theoretical predictions, Sample No. 4 exhibited the highest surface roughness, aligning closely with the experimental measurements and validating the model’s accuracy. By applying Equation (3), surface roughness under varying process parameters can be reliably predicted, with a maximum deviation of 5 μm between the theoretical and experimental values.

5. Conclusions

The effects of ultra-high-pressure water jet process parameters on the surface roughness of grade-A marine steel were studied via single-factor and orthogonal experiments. By combining microstructural morphology characterization with range analysis, the optimal parameter combination was identified, leading to the following conclusions:

- Surface roughness exhibited a nonlinear relationship with jet pressure, initially increasing and then decreasing as pressure rose. Conversely, surface roughness showed negative correlations with both standoff distance and nozzle traverse speed, progressively decreasing with increases in these parameters.

- The range analysis of surface roughness revealed the following hierarchy of effect magnitudes: Rjet pressure > Rstandoff distance > Rnozzle traverse speed. This indicated that the primary to secondary order of influencing factors on surface roughness in orthogonal experiments is as follows: jet pressure, standoff distance, and nozzle traverse speed.

- Based on the analysis of surface roughness and microtopography, parametric optimization revealed that a jet pressure of 150 MPa, a standoff distance of 25 mm, and a nozzle traverse speed of 180 mm/min collectively yielded a peak surface roughness of 62.549 μm. This conforms to the surface roughness profile requirements specified in ISO 8503-2 [22] for pre-painting surfaces in shipbuilding.

- While this study focuses on surface roughness as the key indicator for coating adhesion, future research perspectives should include investigating the impact of water jet processing under optimized parameters on the surface hardness and other mechanical properties of grade-A marine steel.

Author Contributions

Conceptualization, W.S. (Wuyang Shan) and Y.C.; methodology, Y.C., W.S. (Weidong Shi), Q.Z. and Y.Y.; software, Q.Z.; investigation, W.S. (Wuyang Shan); resources, Z.W. and Y.Y.; writing—original draft preparation, W.S. (Wuyang Shan); writing—review and editing, Y.C., W.S. (Weidong Shi) and R.Z.; visualization, W.S. (Weidong Shi) and R.Z.; project administration, Z.W.; funding acquisition, Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

We are grateful to the projects supported by the Natural Science Foundation of Jiangsu Province (BK20220609), the National High-Tech Ship Research Project (MC-202031-Z07), and the Nantong University Scientific Research and Technical Service Project (24ZH616).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Author Zhengang Wang was employed by the company Nantong COSCO Shipping Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Xu, Z.G.; Chen, Z.T.; Huang, L.F. Research on the Outline of Strengthening Technology of Surface Deformation. Equip. Manuf. Technol. 2007, 4, 69–71+75. [Google Scholar]

- Chen, Y.G.; Liu, H.; Chen, H.J. Design and optimization of ultra-high pressure watermachine ships derusting. Guangdong Shipbuild. 2022, 41, 60–62+59. [Google Scholar]

- Wang, X.Y.; Yu, J.; Zhou, Y.T.; Yang, L. Research on the design of a ship rust removal robot based on high-pressure abrasive water jet. South. Agric. Mach. 2022, 53, 16–19. [Google Scholar]

- Sun, H.; Hu, M.; Jiang, G.; Cao, G.; Ge, J.; Zhang, S.; Zhao, Q.; Wang, C.; Zhang, Y.; Ouyang, Q. Micro-nano twins appearing in ultrafine-grained Ti–6Al–4 V alloy induced by high-pressure water jet technology. Mater. Res. Express 2022, 9, 106514. [Google Scholar] [CrossRef]

- Dong, X.; Guo, R.Z.; Somg, S.W.; Zhuo, C.Y. Water Jet Shot Peening Strengthening Surface Roughness. Adv. Mater. Res. 2013, 670, 174–179. [Google Scholar] [CrossRef]

- Grigoraș, C.C.; Chiriță, B.; Brabie, G.; Zichil, V.; Herghelegiu, E.; Tâmpu, C.; Ciubotariu, V.A. High-pressure water jet cutting of S235JR steel alloy. Influence of process parameters on dimensional accuracy. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1182, 012027. [Google Scholar] [CrossRef]

- Szada-Borzyszkowska, M.E.; Kacalak, W.; Bohdal, Ł.; Szada-Borzyszkowski, W. Analysis and Basics of Improving the Process of Cutting Electrical Sheet Bundles with a High-Pressure Abrasive Water Jet. Materials 2024, 17, 1666. [Google Scholar] [CrossRef] [PubMed]

- Borkowski, P.J.; Szada-Borzyszkowski, W. Micronization of Hard Coal with the Use of a High-Pressure Water Jet. Energies 2021, 14, 4745. [Google Scholar] [CrossRef]

- Ahn, J.; Yan, K.; Bazher, S.A.; Oh, J.; Seo, D.; Cho, S.G.; Kim, H. Evaluation of Influencing Factors in Cleaning Performance for Bio-Fouling Removal Based on High-Pressure Water Jets. J. Mar. Sci. Eng. 2024, 12, 1086. [Google Scholar] [CrossRef]

- Srivastava, V.; Mankari, K.; Basu, B.; Prabhu, N. Notch corrosion fatigue behaviour and simplified strain energy density-based notch fatigue life assessment of Grade-A shipbuilding steel. Theor. Appl. Fract. Mech. 2024, 132, 104453. [Google Scholar] [CrossRef]

- Cao, S.R.; Ge, Z.L.; Zhang, D.; Zhou, Z.; Lu, Y.; Zhao, H. An experimental study of ultra-high pressure water jet-induced fracture mechanisms and pore size evolution in reservoir rocks. Int. J. Rock Mech. Min. Sci. 2022, 150, 104995. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Zeng, J.J.; Jing, L.J.; Xu, C.; Xiong, F. Numerical study on the rock breaking mechanism of high-pressure water jet-assisted TBM digging technique based on 2D-DEM modelling. Front. Earth Sci. 2023, 2022, 1047484. [Google Scholar] [CrossRef]

- Xu, X.; Meng, Z.; Lv, H. Exploration on Application of High Pressure Water Jet Cleaning Technology. In Proceedings of the 4th International Conference on Advances in Materials, Machinery, Electronics (AMME 2021), Wuhan, China, 23–24 October 2021; Wuhan Zhicheng Times Cultural Development Co., Ltd.: Wuhan, China; Shandong Xiehe University: Jinan, China; Jinan Vocational College: Jinan, China, 2021; pp. 25–28. [Google Scholar]

- Xue, S.X. Studies on the Removal Rust Forming By UHP Waterjetting Auto-Robot and insUnit Technology; Zhejiang University: Hangzhou, China, 2005. [Google Scholar]

- Wu, Y.Z.; Hu, J.C.; Fu, Y.R.; Wen, X.T.; Zhang, T.Y.; Wang, X.C. Surface Characteristic of 304 Steel after Ultra-high Pressure Jet Peening Based on Indentation Theory. Surf. Technol. 2023, 52, 406–416. [Google Scholar]

- Dong, X.; Wang, R.H.; Duan, X. Water jet shot peening experimental study. J. Coal 2014, 33, 568–573. [Google Scholar]

- Zhang, Q.B.; Cao, Y.P.; Shi, W.D.; Zhou, R.; Cheng, S.M.; Wang, Z.G. Experimental Study on the Optimization of Rust Removal Effect on Surface Erosion of Grade A Marine Steel by Ultra-High-Pressure Water Jet. Metals 2024, 14, 1335. [Google Scholar] [CrossRef]

- Cheng, S.M.; Cao, Y.P.; Lu, H.; Hua, G.R.; Wang, Z.G.; Chen, Z.; Ding, H.H. Experimental Study on Surface Erosion of Grade-A Marine Steel by Ultra-high Pressure Water Jet. Surf. Tech. 2022, 51, 229–238. [Google Scholar]

- Cao, Y.P.; Cheng, S.M.; Shi, W.D.; Yang, Y.F.; Wang, G.W. Experimental Study on Surface Erosion of Grade A Marine Steel by Ultrahigh-Pressure Water Jet. Water 2022, 14, 1953. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- ISO 8501-1:2007; Preparation of Steel Substrates Before Application of Paints and Related Products—Visual Assessment of Surface Cleanliness—Part 1: Rust Grades and Preparation Grades of Uncoated Steel Substrates and of Steel Substrates After Overall Removal of Previous Coatings. ISO: Geneva, Switzerland, 2007.

- ISO 8503-2:2012; Preparation of Steel Substrates Before Application of Paints and Related Products—Surface Roughness Characteristics of Blast-Cleaned Steel Substrates—Part 2: Method for the Grading of Surface Profile of Abrasive Blast-Cleaned Steel—Comparator Procedure. ISO: Geneva, Switzerland, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).