Effect of the Heat Affected Zone Hardness Reduction on the Tensile Properties of GMAW Press Hardening Automotive Steel

Abstract

1. Introduction

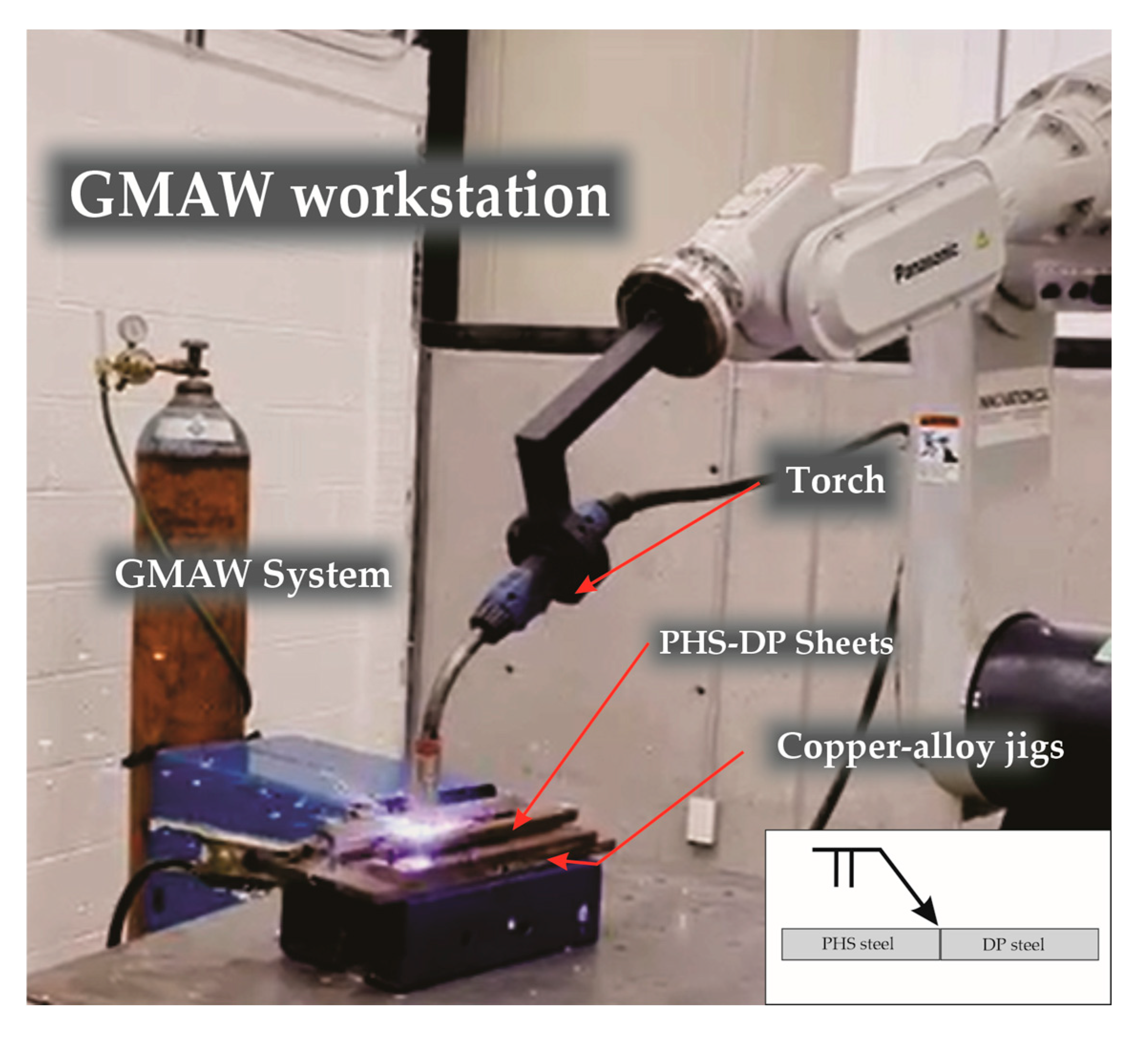

2. Materials and Methods

3. Results and Discussion

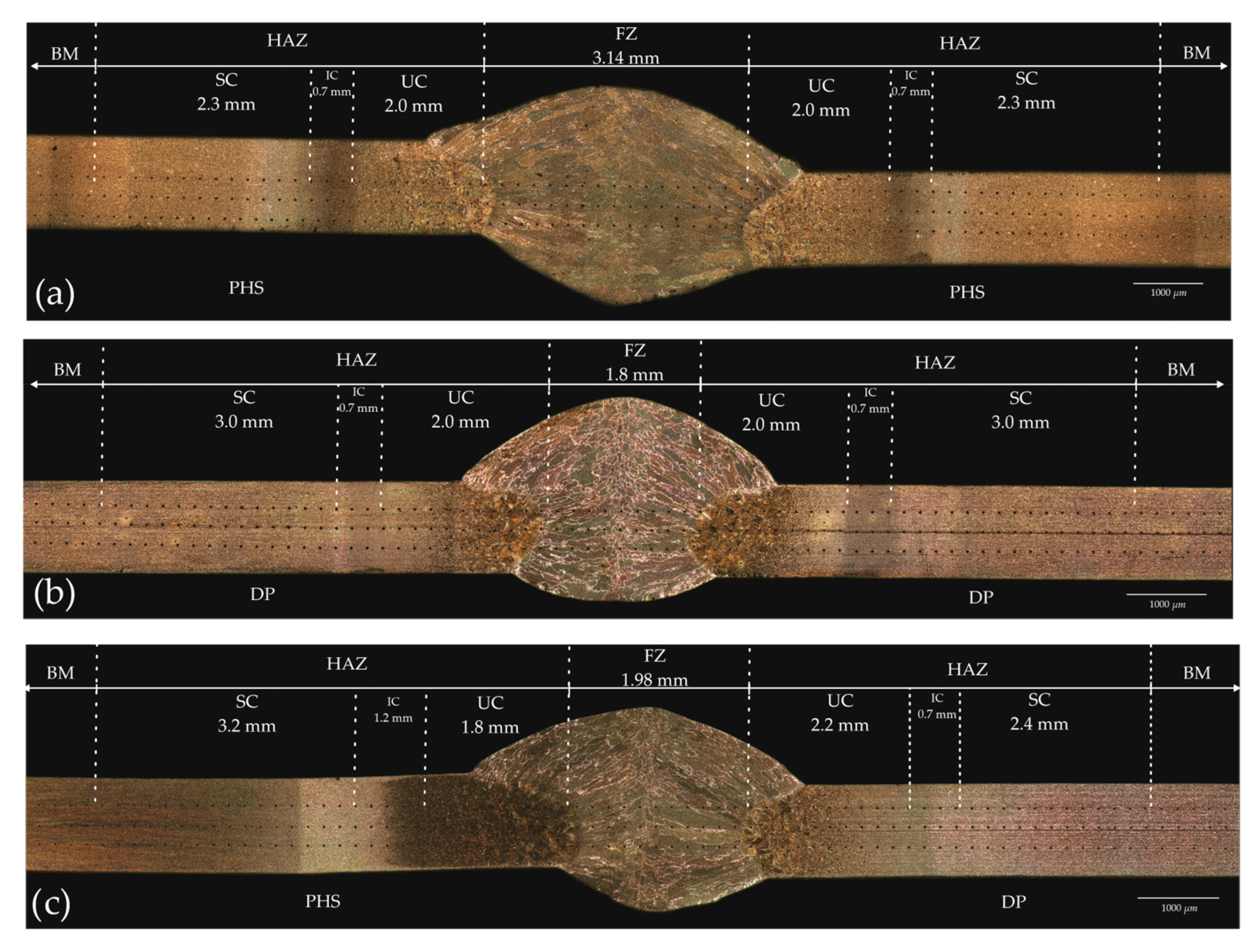

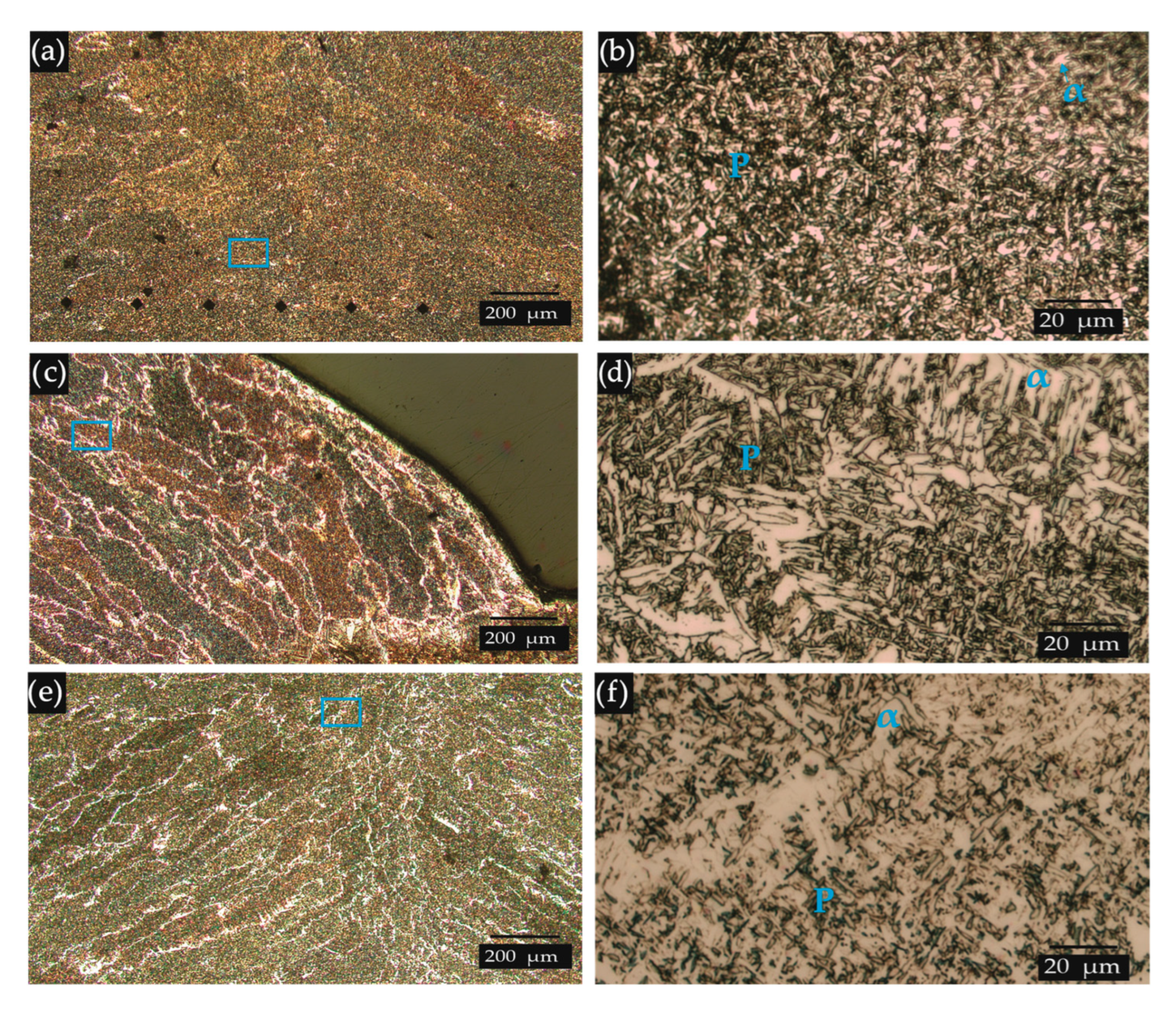

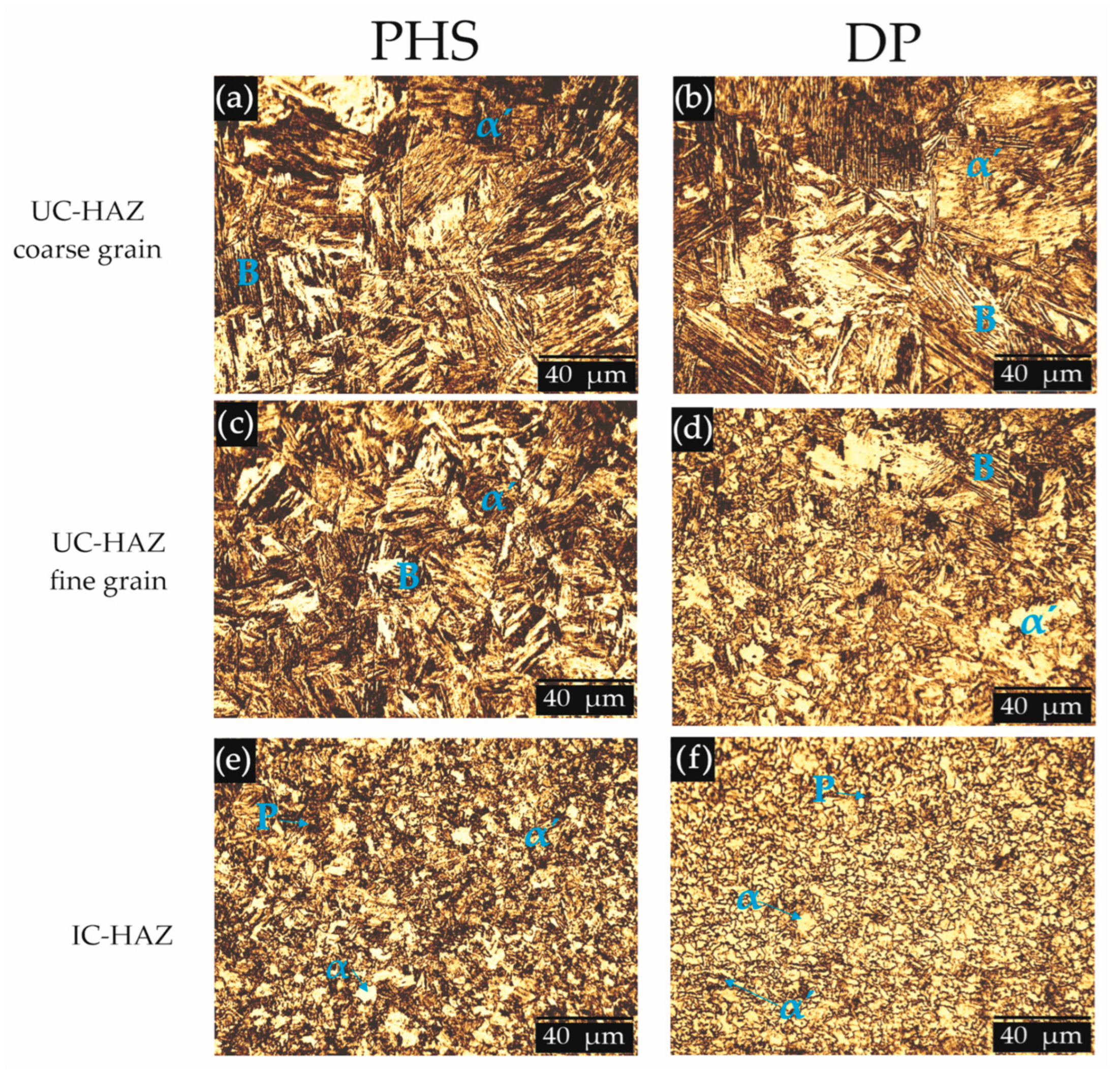

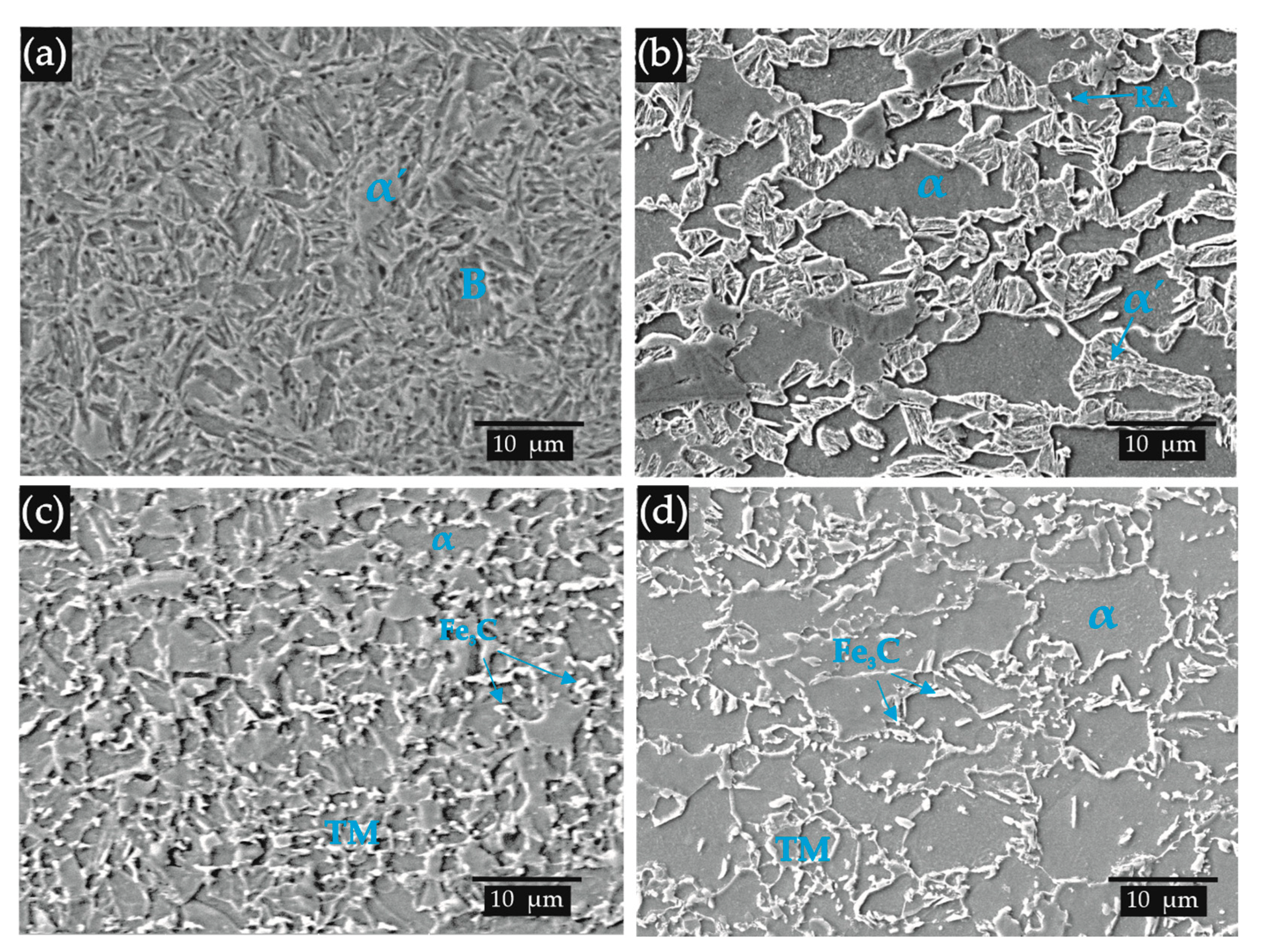

3.1. Microstructure and Hardness

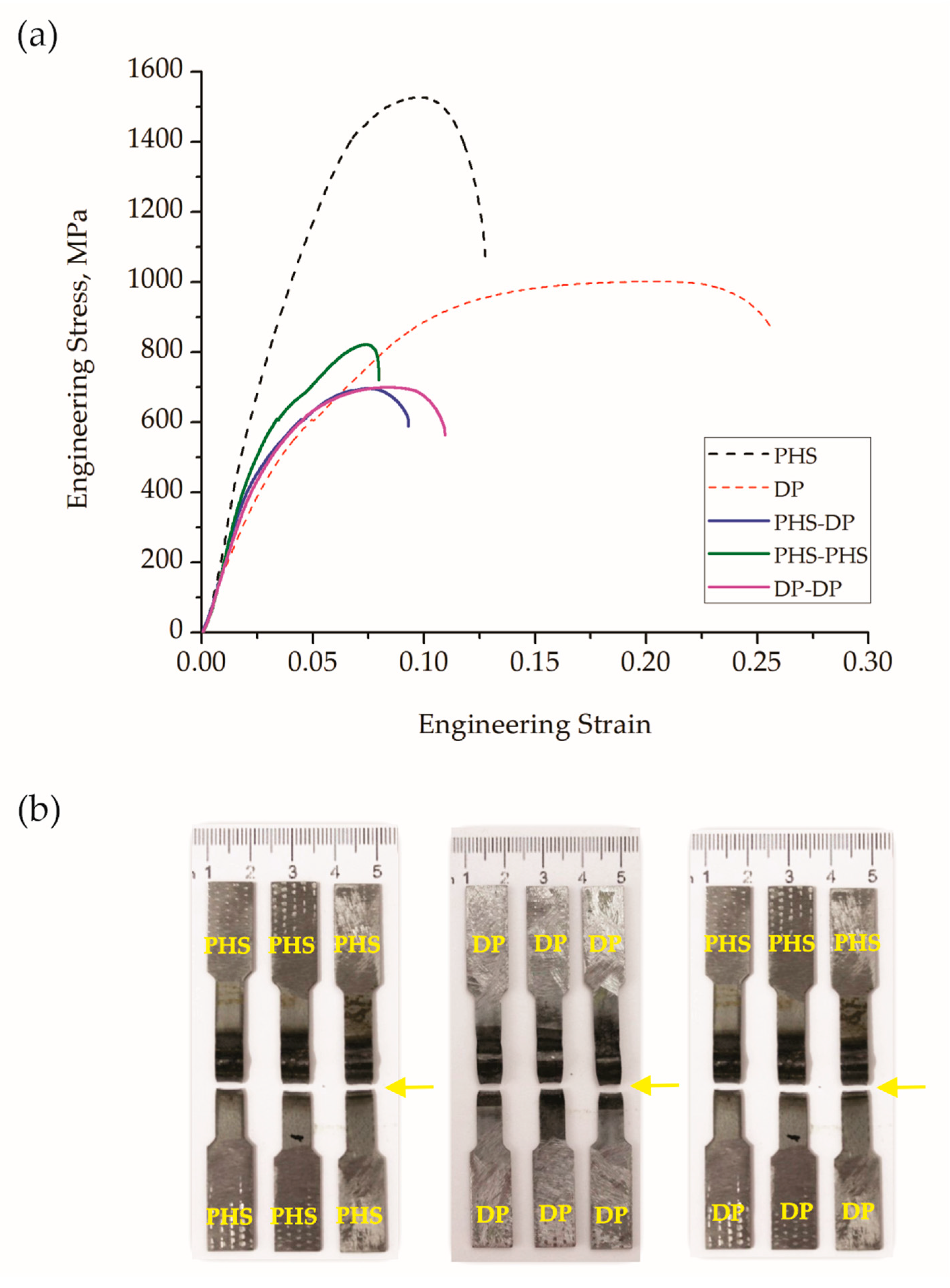

3.2. Uniaxial Tensile Behavior

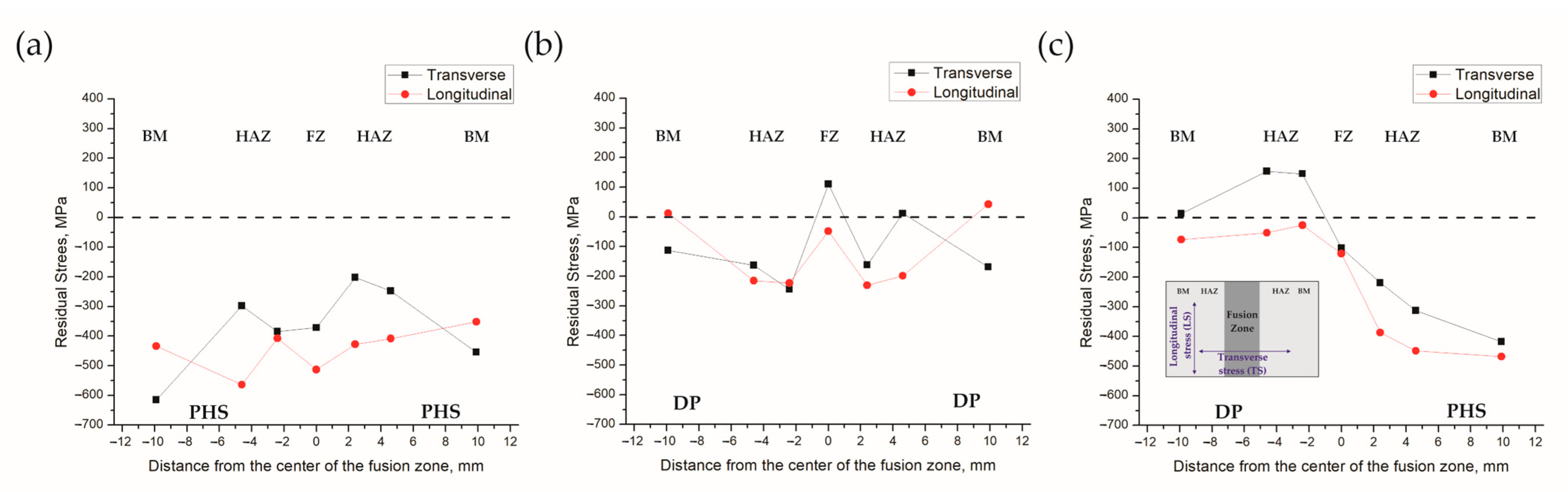

3.3. Residual Stress Analysis

4. Conclusions

- A drastic hardness reduction of 262 HV was measured at the SC-HAZ of the PHS steel, which contrasts with the drop in hardness of 118 HV at the SC-HAZ of the DP steel. Correspondingly, the prior martensite content in the PHS steel had a marked influence on post-weld softening, as the higher the amount of martensite, the higher the volume of martensite tempering at the SC-HAZ of the PHS steel.

- The tensile behavior of the weldments resulted in a clear reduction of strength and ductility as compared to their corresponding BM. While the UTS was drastically reduced with respect to the PHS steel (i.e., 46%), the associated elongation was severely diminished in the DP steel (i.e., 58%). The strength of the dissimilar welding pair, PHS-DP steel (699 MPa), was similar to the DP-DP weldment, whereas the elongation was comparable to that of the PHS-PHS weldment (7.9%).

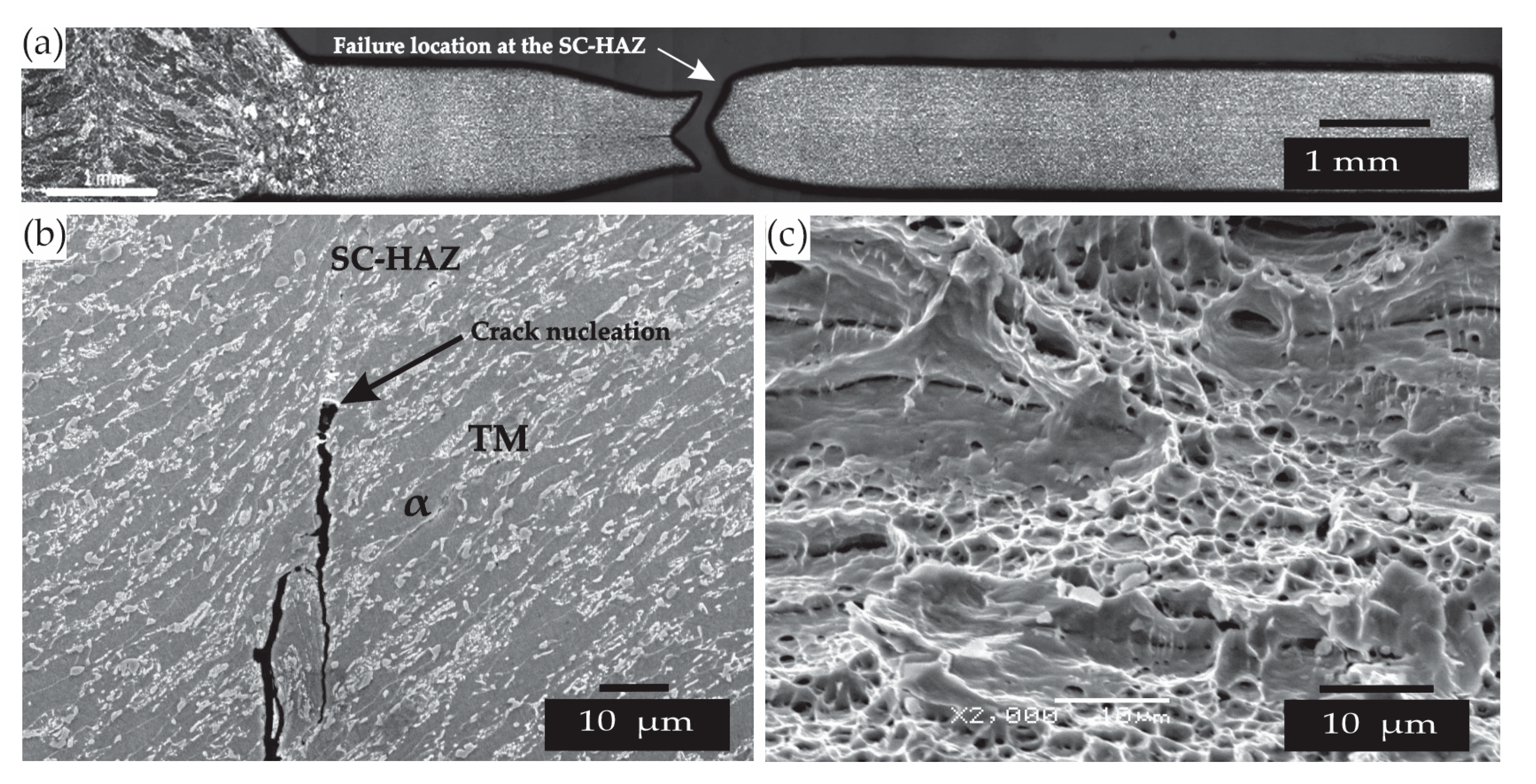

- All failure locations systematically occurred at the SC-HAZ in similar steel joints, whereas for dissimilar pair PHS-DP, the failure was consistently found at the SC-HAZ of the DP steel side.

- Compressive residual stresses resulted along the weldments of all specimens. The more negative stresses observed at the PHS steel have been attributed to the presence of preponderant martensite. It is believed that the negative stresses measured at the FZ were promoted by the weld restraint (sheet anchoring during the welding procedure) in spite of the presence of soft ferrite and pearlite phases.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmitt, J.-H.; Iung, T. New developments of advanced high-strength steels for automotive applications. Comptes Rendus Phys. 2018, 19, 641–656. [Google Scholar] [CrossRef]

- Matlock, D.; Speer, J.G.; De Moor, E.; Gibbs, P.J. Recent developments in advanced high strength sheet steels for automotive applications: An overview. JESTECH 2012, 15, 1–12. [Google Scholar]

- Bonnen, J.; Mandapati, R.; Kang, H.; Khosrovaneh, A.K.; Amaya, M.; Citrin, K.; Shih, H.-C. Durability of Advanced High Strength Steel Gas Metal Arc Welds. SAE Int. J. Mater. Manuf. 2009, 2, 155–171. [Google Scholar] [CrossRef]

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Mendiguren, J.; Herrero-Dorca, N.; Saenz de Argandoña, E.; Galdos, L. Press hardening of alternative materials: Conventional high- strength steels. Int. J. Mater. Form. 2018, 11, 663–670. [Google Scholar] [CrossRef]

- Wei, X.; Chai, Z.; Lu, Q.; Hu, J.; Liu, Z.; Lai, Q.; Wang, J.; Xu, W. Cr-alloyed novel press-hardening steel with superior combination of strength and ductility. Mater. Sci. Eng. A 2021, 819, 141461. [Google Scholar] [CrossRef]

- Fan, D.; Kim, H.; De Cooman, B. A Review of the Physical Metallurgy related to the Hot Press Forming of Advanced High Strength Steel. Steel Res. Int. 2010, 80, 241–248. [Google Scholar] [CrossRef]

- WorldAutoSteel AHSS Application Guidelines. Press Hardened Steels. Available online: https://ahssinsights.org/metallurgy/steel-grades/phs-grades/ (accessed on 16 October 2024).

- Cheng, Z.; Gao, M.; Liu, J.; Wang, S.; Wu, G.; Gao, J.; Wu, H.; Mao, X. Multi-Scale Microstructural Tailoring and Associated Properties of Press-Hardened Steels: A Review. Materials 2023, 16, 3799. [Google Scholar] [CrossRef]

- Hannula, J.; Porter, D.A.; Kaijalainen, A.; Kömi, J. Evaluation of Mechanical Properties and Microstructures of Molybdenum and Niobium Microalloyed Thermomechanically Rolled High-Strength Press Hardening Steel. JOM 2019, 71, 2405–2412. [Google Scholar] [CrossRef]

- Votava, F.; Jirková, H.; Kučerová, L.; Jeníček, Š. Study of Transition Areas in Press-Hardened Steels in a Combined Tool for Hot and Cold Forming. Materials 2023, 16, 442. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; De Cooman, B.C. Application of Quenching and Partitioning (Q&P) Processing to Press Hardening Steel. Metall. Mater. Trans. A 2014, 45, 4022–4037. [Google Scholar] [CrossRef]

- Kim, D.-Y.; Lee, T.H.; Kim, C.; Kang, M.; Park, J. Gas metal arc welding with undermatched filler wire for hot-press-formed steel of 2.0 GPa strength: Influence of filler wire strength and bead geometry. Mater. Today Commun. 2023, 34, 105244. [Google Scholar] [CrossRef]

- Yaakob, K.I.; Ishak, M.; Idris, S.R.A.; Aiman, M.H.; Quazi, M.M. Characterization of heat-treated gas metal arc-welded boron steel sheets. Int. J. Adv. Manuf. Technol. 2018, 94, 827–834. [Google Scholar] [CrossRef]

- Hwang, I.; Yun, H.; Kim, D.; Kang, M.; Kim, Y.-M. Gas metal arc weldability of 1.5 GPa grade martensitic steels. Met. Mater. Int. 2018, 24, 149–156. [Google Scholar] [CrossRef]

- de Lima, E.H.; de Almeida, D.T.; Souza, D.; Bianchi, K.E.; Mohrbacher, H. Evaluation of Fatigue Performance of Press Hardening Steel Joints Welded by GMAW-CSC and PAW Processes. Metals 2022, 12, 2131. [Google Scholar] [CrossRef]

- Shome, M.; Tumuluru, M. (Eds.) Introduction to welding and joining of advanced high-strength steels (AHSS). In Welding and Joining of Advanced High Strength Steels (AHSS); Woodhead Publishing: Cambridge, UK, 2015; pp. 1–8. [Google Scholar]

- Duchet, M.; Haouas, J.; Gibeau, E.; Pechenot, F.; Honecker, C.; Munier, R.; Weber, B. Improvement of the fatigue strength of welds for lightweight chassis application made of Advanced High Strength Steels. Procedia Struct. Integr. 2019, 19, 585–594. [Google Scholar] [CrossRef]

- Führ, T.; Almeida, D.; Bertol, D.; de Souza, J.; Lopes, A. Mechanical performance of heavy gauge press hardened steel modified with Nb and Mo additions on GMAW welded joints. Tecnol. Metal. Mater. Min. 2021, 18, e2123. [Google Scholar] [CrossRef]

- Pfeifer, T.; Węglowski, M.S. Characteristic of MAG welded joints of 22MnB5 steel grade for automotive industry. Adv. Manuf. Sci. Technol. 2014, 38, 71–80. [Google Scholar]

- Varol, F.; Ferik, E.; Ozsarac, U.; Aslanlar, S. Influence of current intensity and heat input in Metal Inert Gas-brazed joints of TRIP 800 thin zinc coated steel plates. Mater. Des. 2013, 52, 1099–1105. [Google Scholar] [CrossRef]

- Njock Bayock, F.; Kah, P.; Mvola, B.; Layus, P. Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels. Metals 2019, 9, 883. [Google Scholar] [CrossRef]

- Netto, A.; Njock Bayock, F.M.; Kah, P. Optimization of GMAW Process Parameters in Ultra-High-Strength Steel Based on Prediction. Metals 2023, 13, 1447. [Google Scholar] [CrossRef]

- Májlinger, K.; Kalácska, E.; Russo Spena, P. Gas metal arc welding of dissimilar AHSS sheets. Mater. Des. 2016, 109, 615–621. [Google Scholar] [CrossRef]

- Ahiale, G.K.; Oh, Y.-J. Microstructure and fatigue performance of butt-welded joints in advanced high-strength steels. Mater. Sci. Eng. A 2014, 597, 342–348. [Google Scholar] [CrossRef]

- Svoboda, H.G.; Nadale, H.C. Fatigue Life of GMAW and PAW Welding Joints of Boron Microalloyed Steels. Procedia Mater. Sci. 2015, 9, 419–427. [Google Scholar] [CrossRef]

- Perka, A.K.; John, M.; Kuruveri, U.B.; Menezes, P.L. Advanced High-Strength Steels for Automotive Applications: Arc and Laser Welding Process, Properties, and Challenges. Metals 2022, 12, 1051. [Google Scholar] [CrossRef]

- Hamada, A.; Ali, M.; Ghosh, S.; Jaskari, M.; Keskitalo, M.; Järvenpää, A. Mechanical performance and formability of laser-welded dissimilar butt joints between medium-Mn stainless steel and high-strength carbon steel. Mater. Sci. Eng. A 2022, 831, 142200. [Google Scholar] [CrossRef]

- Baltazar-Hernández, V.H.; López-Baltazar, E.A.; Alvarado-Hernández, F.; Gómez-Jiménez, S.; Ruiz-Mondragón, J.J.; Biro, E.; Zhou, N. Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach. Metals 2022, 12, 880. [Google Scholar] [CrossRef]

- Sharma, R.S.; Molian, P. Yb:YAG laser welding of TRIP780 steel with dual phase and mild steels for use in tailor welded blanks. Mater. Des. 2009, 30, 4146–4155. [Google Scholar] [CrossRef]

- Kang, H.; Khosrovaneh, A.; Link, T.; Bonnen, J.; Amaya, M.; Shih, H.-C. The Effect of Welding Dimensional Variability on the Fatigue Life of Gas Metal Arc Welded Joints. SAE Int. J. Mater. Manuf. 2011, 4, 298–313. [Google Scholar] [CrossRef]

- Möller, F.; Kügler, H.; Goecke, S.-F. Laser-GMA-Hybrid Welding of high strength multi-material joints. In Proceedings of the Lasers in Manufacturing Conference, Center München, Germany, 22–25 June 2015. [Google Scholar]

- Di, H.S.; Sun, Q.; Nie, X.K.; Wang, X.N.; Chen, X.M. Mirostructure and properties of laser welded joints of dual phase and press-hardened steels. Procedia Eng. 2017, 207, 1665–1670. [Google Scholar] [CrossRef]

- Chen, X.; Jin, Z.; Liang, J.; Wang, Y.; Yang, D.; Yi, H.; Xie, G. A comparative study of the galvanized DP980 steel and 2 GPa PHS welded joint via laser beam welding and cold metal transfer welding. Mater. Lett. 2024, 369, 136726. [Google Scholar] [CrossRef]

- Kong, F.; Kovacevic, R. Measurement of surface residual stresses and testing mechanical properties of high-strength steel butt joints obtained by hybrid laser/gas metal arc welding. J. Strain Anal. Eng. Des. 2013, 48, 437–445. [Google Scholar] [CrossRef]

- Colombo, T.C.A.; Rego, R.R.; Otubo, J.; de Faria, A.R. Mechanical reliability of TWIP steel spot weldings. J. Mater. Process. Technol. 2019, 266, 662–674. [Google Scholar] [CrossRef]

- Kang, H.T.; Lee, Y.-L.; Sun, X.J. Effects of residual stress and heat treatment on fatigue strength of weldments. Mater. Sci. Eng. A 2008, 497, 37–43. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Enloe, C.M.; Chuang, A.C.; Coryell, J.J.; Ghassemi-Armaki, H. Mechanisms of paint bake response in resistance spot-welded first and third generation AHSS. Materialia 2021, 15, 100975. [Google Scholar] [CrossRef]

- Ren, S.; Ma, N.; Tsutsumi, S.; Watanabe, G.; He, H.; Cao, C.; Huang, L. Post-weld cold working for fatigue strength improvement of resistance spot welded joint of advanced high-strength steel. J. Mater. Process. Technol. 2022, 299, 117364. [Google Scholar] [CrossRef]

- Mujica, L.; Weber, S.; Pinto, H.; Thomy, C.; Vollertsen, F. Microstructure and mechanical properties of laser-welded joints of TWIP and TRIP steels. Mater. Sci. Eng. A 2010, 527, 2071–2078. [Google Scholar] [CrossRef]

- Kasuya, T.; Yurioka, N. Determination of Necessary Preheat Temperature to Avoid Cold Cracking under Varying Ambient Temperature. ISIJ Int. 1995, 35, 1183–1189. [Google Scholar] [CrossRef]

- AWS A5.18/A5.18M:2023; Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding. American Welding Society: Doral, FL, USA, 2023.

- ASTM E3-95; Standard Practice for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA, USA, 1995.

- ASTM E8/E8M-09; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- Nayak, S.S.; Baltazar Hernandez, V.H.; Zhou, Y. Effect of Chemistry on Nonisothermal Tempering and Softening of Dual-Phase Steels. Metall. Mater. Trans. A 2011, 42, 3242–3248. [Google Scholar] [CrossRef]

- Baltazar Hernandez, V.H.; Nayak, S.S.; Zhou, Y. Tempering of Martensite in Dual-Phase Steels and Its Effects on Softening Behavior. Metall. Mater. Trans. A 2011, 42, 3115–3129. [Google Scholar] [CrossRef]

- Khan, M.S.; Soleimani, M.; Midawi, A.R.H.; Aderibigbe, I.; Zhou, Y.N.; Biro, E. A review on heat affected zone softening of dual-phase steels during laser welding. J. Manuf. Process. 2023, 102, 663–684. [Google Scholar] [CrossRef]

- Elmesalamy, A.; Francis, J.A.; Li, L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int. J. Press. Vessel. Pip. 2014, 113, 49–59. [Google Scholar] [CrossRef]

- Bate, S.; Green, D.; Buttle, D. A Review of Residual Stress Distributions in Welded Joints for the Defect Assessment of Offshore Structures; HSE Books: London, UK, 1998. [Google Scholar]

- Hu, X.; Jiang, H.-Y.; Luo, Y.; Jin, Q.; Peng, W.; Yi, C.-M. A Study on Microstructure, Residual Stresses and Stress Corrosion Cracking of Repair Welding on 304 Stainless Steel: Part II-Effects of Reinforcement Height. Materials 2020, 13, 2434. [Google Scholar] [CrossRef]

- Balakrishnan, J.; Vasileiou, A.N.; Francis, J.A.; Smith, M.C.; Roy, M.J.; Callaghan, M.D.; Irvine, N.M. Residual stress distributions in arc, laser and electron-beam welds in 30 mm thick SA508 steel: A cross-process comparison. Int. J. Press. Vessel. Pip. 2018, 162, 59–70. [Google Scholar] [CrossRef]

- Francis, J.A.; Bhadeshia, H.K.D.H.; Withers, P.J. Welding residual stresses in ferritic power plant steels. Mater. Sci. Technol. 2007, 23, 1009–1020. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. TRIP-Assisted Steels? ISIJ Int. 2002, 42, 1059–1060. [Google Scholar] [CrossRef]

- Jones, W.K.C.; Alberry, P.J. Paper 78 The role of phase transformations in the development of residual stresses during the welding of some fast reactor steels. Ferritic Steels Fast React. Steam Gener. 1978, 2, 471–475. [Google Scholar] [CrossRef]

- Nichols, R.W. Residual Stresses in Welded Construction and Their Effects, Proceedings of the An International Conference, London, UK, 15–17 November 1977; Welding Institute: Cambridge, UK, 1978. [Google Scholar]

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Wu, X.I.N.; Wang, Z.; Yu, Z.; Liu, S.; Bunn, J.; Kolbus, L.; Feng, Z. Control of Weld Residual Stress in a Thin Steel Plate through Low Transformation Temperature Welding Consumables. Weld. J. 2020, 99, 124–134. [Google Scholar] [CrossRef]

- Liu, C.; Yan, Y.; Cheng, X.; Wang, C.; Zhao, Y. Residual stress in a restrained specimen processed by post-weld ultrasonic impact treatment. Sci. Technol. Weld. Join. 2019, 24, 193–199. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P | Cr | Mo | Ni | Cu | Al | B | CEy |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DP | 0.15 | 0.314 | 1.41 | 0.014 | 0.03 | 0.014 | 0.01 | 0.03 | 0.05 | - | 0.41 |

| PHS | 0.257 | 0.206 | 0.939 | 0.036 | 0.022 | 0.037 | 0.160 | 0.044 | 0.042 | 0.0010 | 0.44 |

| ER70S-6 * | 0.06–0.15 | 0.8–1.15 | 1.40–1.85 | 0.025 | 0.15 | 0.15 | 0.15 | 0.5 | - | - | - |

| Current (A) | Voltage (V) | Shield Gas | Gas Flow (L/min) | Travel Speed (m/min) |

|---|---|---|---|---|

| 75 | 16.5 | 75% Ar + 25% CO2 | 18 | 0.6 |

| Sample | YS (MPa) | UTS (MPa) | Uniform Elongation (%) |

|---|---|---|---|

| BM | |||

| PHS | 902 ± 28 | 1520 ± 20 | 9.1 ± 0.7 |

| DP | 445 ± 39 | 986 ± 14 | 26 ± 2.0 |

| Steel Weld Combination | |||

| PHS-PHS | 467 ± 37 | 824 ± 19 | 7.9 ± 1.1 |

| DP-DP | 413 ± 45 | 703 ± 13 | 10.8 ± 0.3 |

| PHS-DP | 453 ± 20 | 699 ± 16 | 7.9 ± 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina-Castillo, A.E.; López-Baltazar, E.A.; Alvarado-Hernández, F.; Gómez-Jiménez, S.; Espinosa-Lumbreras, J.R.; Ruiz Mondragón, J.J.; Baltazar-Hernández, V.H. Effect of the Heat Affected Zone Hardness Reduction on the Tensile Properties of GMAW Press Hardening Automotive Steel. Metals 2025, 15, 791. https://doi.org/10.3390/met15070791

Molina-Castillo AE, López-Baltazar EA, Alvarado-Hernández F, Gómez-Jiménez S, Espinosa-Lumbreras JR, Ruiz Mondragón JJ, Baltazar-Hernández VH. Effect of the Heat Affected Zone Hardness Reduction on the Tensile Properties of GMAW Press Hardening Automotive Steel. Metals. 2025; 15(7):791. https://doi.org/10.3390/met15070791

Chicago/Turabian StyleMolina-Castillo, Alfredo E., Enrique A. López-Baltazar, Francisco Alvarado-Hernández, Salvador Gómez-Jiménez, J. Roberto Espinosa-Lumbreras, José Jorge Ruiz Mondragón, and Víctor H. Baltazar-Hernández. 2025. "Effect of the Heat Affected Zone Hardness Reduction on the Tensile Properties of GMAW Press Hardening Automotive Steel" Metals 15, no. 7: 791. https://doi.org/10.3390/met15070791

APA StyleMolina-Castillo, A. E., López-Baltazar, E. A., Alvarado-Hernández, F., Gómez-Jiménez, S., Espinosa-Lumbreras, J. R., Ruiz Mondragón, J. J., & Baltazar-Hernández, V. H. (2025). Effect of the Heat Affected Zone Hardness Reduction on the Tensile Properties of GMAW Press Hardening Automotive Steel. Metals, 15(7), 791. https://doi.org/10.3390/met15070791