Abstract

A total of 0.3%C-Cr-Mo-V steel, a high-strength alloy steel widely used in rocket motor housings, suspension systems in high-performance vehicles, etc., is noted due to its high strength-to-weight ratio. However, its high carbon equivalent (CE > 1%) makes it challenging to weld, as it is prone to brittle martensitic formation, which increases the risk of cracking and embrittlement. The present paper focuses on enhancing the microstructure and mechanical properties of 0.3% C-Cr-Mo-V steel by gas tungsten arc welded (GTAW) joints, utilizing post-weld heat treatment and cooling strategies (PWHTCS). A systematic experimental approach was employed to ensure a defect-free weld through dye penetrant testing (DPT) and X-ray radiography techniques. Subsequently, test specimens were extracted from the welded sections and subjected to PWHT protocols, including hardening, tempering, and rapid quenching using air and oil cooling (AC and OC, respectively) mediums. Results show that OC has enhanced tensile strength and hardness while simultaneously maintaining and improving ductility, ensuring a well-balanced combination of strength and toughness. Fractography analysis revealed ductile fracture in AC samples, whereas OC weldments exhibited a mixed ductile–brittle fracture mode. Thus, the findings demonstrate the critical role of PWHTCS, with OC, as an effective method for achieving enhanced mechanical performance and microstructural stability in high-integrity applications.

1. Introduction

Alloy steels, particularly those containing principal elements such as carbon (C), chromium (Cr), molybdenum (Mo), and vanadium (V), are widely used in demanding applications. This is due to the formation of stable secondary phases, which refine the microstructure and result in improved mechanical performance [1]. One such material, 0.3% C-Cr-Mo-V steel, is an ultra-high-strength low-alloy steel (HSLA) used in pressure vessels, aerospace components, and high-performance vehicle suspension systems [2]. However, welding these steels poses considerable challenges due to the generation of microstructural heterogeneities, residual stresses, and the formation of undesired phases. Additionally, all these factors can adversely affect the mechanical properties of the weld joints [3,4]. Due to the rapid cooling during the welding process, the formation of martensitic structures is frequently witnessed, particularly if its Carbon Equivalent (CE) value exceeds 1% [5]. HSLA is generally welded through Gas Tungsten Arc Welding (GTAW), which is favored for its exceptional ability to regulate heat input, arc stability, and ability to generate defect-free welds [6]. Considering these benefits, the localized temperature cycles during welding lead to microstructural inconsistencies within the base metal (BM), heat-affected zone (HAZ), and fusion zone (FZ) [7]. These variances affect hardness, toughness, and strength, frequently necessitating post-weld heat treatment (PWHT) to homogenize the microstructure and mitigate residual stresses produced during welding [8]. Recent studies have explored PWHT and cooling strategies (PWHTCS), such as AC and OC, to optimize the microstructural features and enhance the mechanical properties of weldments. In this context, Alipooramirabad et al. [9] performed PWHT at 600 °C for 60 min on HSLA and reported that the acicular ferrite/granular bainite formed during welding transformed into polygonal ferrite, leading to the generation of equiaxed grains, which enhanced mechanical performance while slightly reducing tensile residual stresses. Jorge et al. [10] organized a comparative study of HSLA subjected to shielded metal arc (SMAW) and gas metal arc (GMAW) welding processes and investigated the influence of PWHT. They reported that the use of the GMAW process can enhance the performance of HSLA welds with sound quality. The in situ neutron diffraction technique was employed by Alipooramirabad et al. [11], where they studied the effect of residual stress relaxation with three different holding times: 0.5, 1, and 3 h. They reported that with the prolonged holding time (3 h), the amount of strain relaxation increased with the holding time, which was not beneficial to the weldment and deteriorated its mechanical properties. Indeed, PWHT plays a crucial role in welding HSLA, as it improves the microstructural stability, diminishes hardness gradients, and enhances ductility and fracture resistance [12]. The cooling rate following PWHT is crucial in determining phase transitions, grain refinement, and precipitation behavior [13]. Diverse cooling methodologies were explored by numerous researchers, including AC, furnace cooling (FC), and water quenching (WC), which displayed distinct microstructural morphologies that eventually influence the strength–toughness equilibrium of the weld joints [14]. Tiwari et al. [15] studied the influence of PWHT, followed by AC of samples, and observed a transformation of martensitic microstructure formed during welding to the formation of tempered martensite with a heating of 450 °C. However, PWHT influenced the microstructural softening and grain refining. Hardness and tensile strength demonstrate a consistent decline as heat treatment temperature rises to 520 °C; after 580 °C, both ductility and strength diminished considerably. Ramkumar et al. [16] investigated the pre- and PWHT of 0.3%C-CrMoV (ESR) HSLA alloy and inferred that welding in the annealed state, followed by PWHT, achieved weld efficiencies of 100% for tensile strength and 90% for fracture toughness, with tempered martensitic microstructure when compared with the base metal in a hardened and tempered condition. The maximum strength and fracture toughness, along with 100% weld efficiency, were achieved in the welding of heat-treated samples that underwent PWHT in which they were hardened and tempered in the initial state, then welded and again subjected to hardened and tempered conditions. However, welding in a heat-treated state without PWHT conditions led to poor mechanical characteristics in contrast to those that had at least one hardening and tempering process. Radhakrishnan et al. [17] studied the effect of various quenching media and PWHT of multi-pass welded 0.3% C-Cr Mo V HSLA. They reported that annealed weld condition revealed ferrite with carbides in the microstructure, whereas the hardened and tempered condition, followed by rapid AC, revealed bainitic structure along with martensite, ferrite, and carbides. Samples quenched in WC and OC displayed fine-tempered martensite with bainite and martensite in HAZ and in FZ. Furthermore, they observed that OC yielded the maximum strength of 1417 MPa, whereas WC yielded a strength of 1325 MPa. When AC is employed as a quenching medium, it obtains a strength of 1225 MPa due to a lower cooling rate compared to OC and WC.

Despite the significant progress in understanding the impact of PWHT on the mechanical behavior of welded joints, there remains a gap in systematically comparing the effects of various cooling media on 0.3% C-Cr-Mo-V steel. This study aims to investigate the influence of various PWHTCS—air and oil—on enhancing the microstructure and mechanical properties of GTAW-welded 0.3% C-Cr-Mo-V steel. A comprehensive literature review facilitates identifying the range of welding process parameters [8,16]. The process parameters were determined based on the design of experiments (DOE), considering three levels and four variables, including current, root gap, number of passes, and type of PWHTCS to evaluate their interactions and impact on weld integrity. By employing a systematic experimental approach, including microstructural characterization, hardness testing, tensile strength evaluation, and impact toughness measurements. Further, the research work aims to provide insights into the optimal combination of welding parameters and cooling strategies that yield the highest quality weld joints.

2. Materials and Methods

Experiments were conducted using the GTAW process to join 0.3% C-Cr-Mo-V steel (SAE/AISI 4340 (ArcelorMittal, Luxembourg) as per international standards) plates with dimensions 8 mm × 200 mm × 150 mm, having a 60 °V groove angle joint configuration (ASTM Standards) [18,19,20]. A 2.4 mm diameter filler rod made of 0.3% C-Cr-Mo-V steel was used to fill the groove gap in multiple passes. The chemical composition of the base and filler material is listed in Table 1.

Table 1.

Chemical composition of 0.3% C-Cr-Mo-V steel (base and filler material).

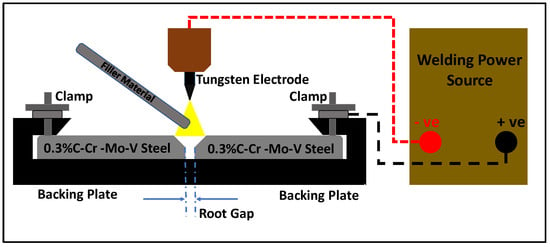

Figure 1 illustrates the experimental setup used, wherein the GTAW process (Pulse TIG-Miller, Miller Electric, Appleton, WI, USA) operates in synergic mode and uses a non-consumable electrode made of a 2% thoriated tungsten electrode with a diameter of 2.4 mm, connected in direct current electrode negative (DCEN) polarity. The synergic mode takes control of other process parameters and sets the values automatically based on the current characteristics or one drop per pulse. The shielding gas used was high-purity argon (Ar), with a gas flow rate ranging from 12 to 15 liters per minute (lpm). The contact tip-to-work distance (CTWD) was carefully controlled at a constant 8 mm to ensure arc stability and weld quality throughout the process.

Figure 1.

Schematic experimental setup.

The primary process variables, including welding current, voltage, travel speed, root gap, and number of passes, were optimized using a DOE approach, with the selected values summarized in Table 2. Due to the plate thickness, an external filler wire with a different number of passes (2 passes, 3 passes, 4 passes) is used to fill the V groove. The interpass temperature was maintained at approximately ≈150 °C to reduce the risk of hydrogen cracking, potential residual stress, preserving the mechanical properties, and thereby the weld quality. Table 2 outlines the experimental conditions through the non-destructive testing (NDT) techniques, such as Dye Penetrant Testing (DPT) and X-ray Diffraction (XRD), to ensure the weld joints are defect-free and verify their integrity [21,22,23,24].

Table 2.

Proposed experimental conditions.

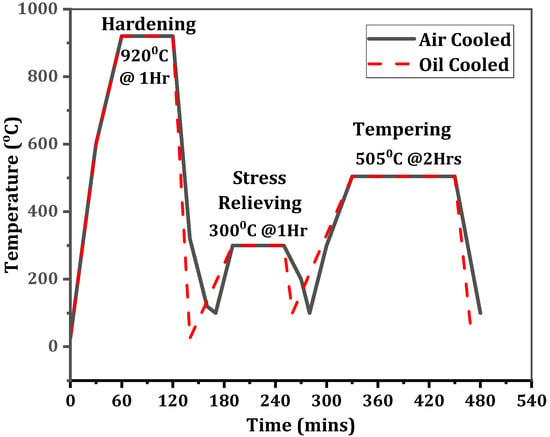

Post experimentation, all defect-free welded samples were subjected to different PWHT procedures, as shown in Figure 2 and Table 3, which involve hardening, tempering, stress relieving, and quenching processes. The processes of hardening and tempering are conducted in an electrical heating furnace with a controlled heating rate of 100 °C per hour. The welded samples underwent PWHT to optimize their mechanical properties. The heat treatment process began with loading at 600 °C to ensure uniform temperature distribution before hardening at 920 °C for 1 h, allowing for complete austenitization and carbide dissolution [2,4]. The samples were then quenched in either oil or air, with a quenching delay of approximately 45 s, which is short enough to ensure minimal temperature drop and maintain the desired martensitic microstructure. Following quenching, stress relieving was carried out at 300 °C for 1 h to alleviate residual stresses without compromising the hardness [2,9]. The next step involved tempering at 505 °C for 2 h, promoting a balanced improvement in strength and toughness. Finally, the samples were quenched in oil and air cooled after tempering to preserve the refined microstructure and ensure optimal mechanical properties of the welded joints by enhancing toughness, improving hardness, and ensuring the integrity of the welds, making them suitable for high-strength structural applications.

Figure 2.

PWHT cycle for different cooling strategies.

Table 3.

Proposed PWHTCS cycle.

Upon completion of PWHTCS, the samples were cut into desired dimensions using a wire-electric discharge machine (EDM) to perform microstructure analysis and mechanical testing. For microstructure analysis, the small specimens were polished up to 1 micron, etched using 2% nital solution, and visualized through an optical microscope. On the other hand, mechanical properties such as hardness, tensile, and impact were measured using a Brinell hardness tester, a universal tensile machine (UTM), and an impact test machine, respectively. Further, the fractography studies were carried out on impact specimens using a scanning electron microscope (SEM) to understand the mode of fracture. The outcomes of both are correlated with process variables viz. PWHTCS, root gap, and number of passes, and are compared.

3. Results and Discussion

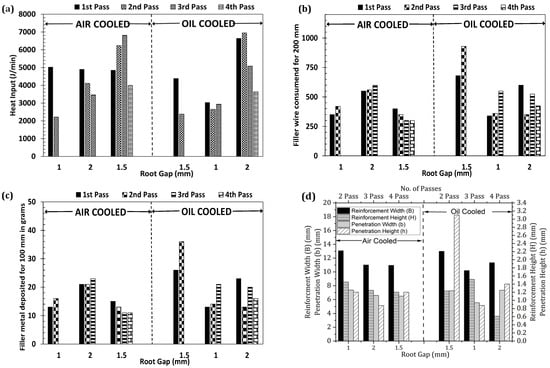

3.1. Correlation of Heat Input, Filler Usage, and Weld Bead Geometry

Figure 3 illustrates the impact of process variables, including root gaps and the number of passes, on heat input, filler metal consumption, deposition, and weld bead geometry. The filler metal consumption, deposition, and weld bead geometry depend on the effective heat utilization and distribution. The heat input can be calculated by multiplying the efficiency of the GTAW process by the current and voltage, then dividing by the travel speed. The heat input is determined for every pass and equivalent root gap, as shown in Figure 3a. It is noted that the combined effect of welding parameters, root gaps, and number of passes has a significant influence on heat input utilization and distribution. Regardless of the welding conditions for the first pass of AC samples, the heat input generated is almost the same (approx. ≈ 5000 J/min). This is due to the initial arc of the first pass interacting with the fresh material, where more heat is required to melt the fresh material. The same phenomenon is applicable to the first pass of OC samples and indicates that as the root gap increases, heat input also increases (see Figure 3a). However, the welding speed plays a crucial role in the arc interaction time; therefore, preheating or partial melting of the material takes place. Therefore, heat generated is concentrated more on the base metal and remaining filler material, leading to less consumption (see Figure 3b) and less deposition (see Figure 3c). Additionally, the filler metal droplet also contributes to the heat supplied to the base metal for full melting, and the joint forms. Further, this is apparent in the shallow weld bead geometry wherein the weld width has increased, and penetration has decreased, as shown in Figure 3d.

Figure 3.

Effect of process variables on (a) Heat input, (b) Filler consumption, (c) Filler deposited, and (d) Weld bead Geometry.

In the case of the second pass, third pass, and fourth pass, the arc encounters the preheated deposited bead of the previous pass, drawing more heat input to melt the fresh filler material rather than the base metal, unlike the first pass. This heat distribution has increased the filler consumption (see Figure 3b) and deposition (see Figure 3c), which, in turn, influences the weld bead geometry (see Figure 3d). Further, the decrease in heat input for the higher passes is due to the influence of process conditions selected through DOE, as shown in Table 2. In addition to heat input, PWHTCS play a crucial role in refining the microstructure and enhancing the mechanical properties of 0.3% C-Cr-Mo-V steel, as elaborated in the following sections.

3.2. Microstructure Characterization

The evolution of microstructure is a combined effect of heat input from process parameters and every stage of the heat treatment cycle, as shown in Table 2 and Table 3, respectively. These steels are difficult to weld due to the carbon equivalent being 1% [3] and form a mixture of martensitic–bainitic structure due to the presence of 0.3% of C, 1.5% Cr, and 0.9% Mo. In the as-welded condition, the fusion zone consists of a dendritic structure for untempered martensite, and HAZ consists of coarse-grained untempered martensite [16,17]. As the number of passes increases, the martensitic structure is refined to finer grains, enhancing the mechanical properties.

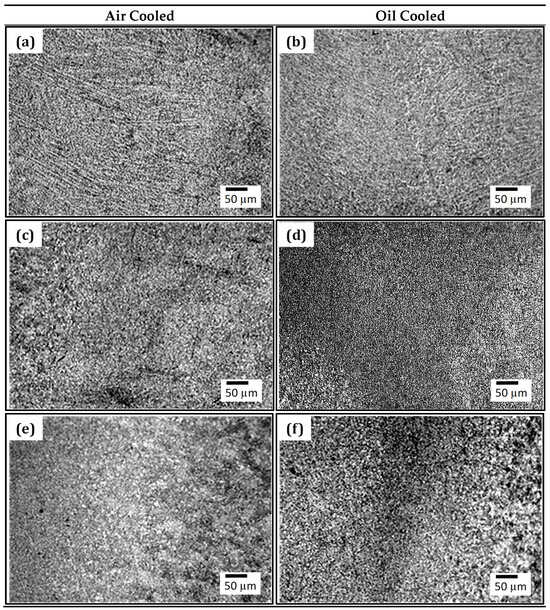

During the first phase heat treatment cycle, known as hardening, the samples were subjected to austenitic temperature (920 °C), wherein the microstructure is transformed into a fully austenitic phase. This was followed by quenching medium (AC), resulting in the formation of a mixture of coarse martensitic and bainitic structures with carbide precipitates [25] in the weldment HAZ and base metal, as shown in Figure 4a, Figure 4c and Figure 4e, respectively.

Figure 4.

Optical microstructure for various cooling mediums; (a,b) Fusion Zone, (c,d) HAZ, and (e,f) Base Metal.

The formation of coarse-grain structure is due to a slow cooling rate, i.e., sufficient time for bainitic phase transformation from austenitic and grain growth. In contrast, the OC medium weldment predominantly consists of martensite (Figure 4b) and a mixture of martensitic and bainitic lath structures in the HAZ and base metal, as described in Figure 4d and Figure 4f, respectively. This is due to the OC, which cools relatively faster than AC, no adequate time to travel through the bainitic phase, resulting in a direct transformation from the austenitic phase to the martensitic phase with few traces of bainite structure [4,6,16].

Moreover, to enhance the mechanical properties, the heat treatment cycle continues with stress relieving and tempering. The stress relieving (300 °C) allows for the relief of the residual stresses without substantially altering the mechanical properties. Further, the last stage of the heat treatment cycle is tempering (505 °C). followed by quenching with AC and OC mediums. This stage is performed to refine the martensite structure and enhance the ductility without altering the hardness.

However, the same microstructure is retained, the only difference is that from untempered martensite changes to refined tempered martensite. Additionally, when compared with WC and AC, the OC provides a favorable microstructure formation that has fine tempered martensite and bainite structures in the fusion zone, and tempered martensite in the HAZ, which aligns well with the literature [3,4,6]. In the subsequent section, the significance of PWHTCS and the correlation of the formed microstructures, which reveal the impact on mechanical properties, will be discussed.

3.3. Mechanical Properties

3.3.1. Testing Hardness

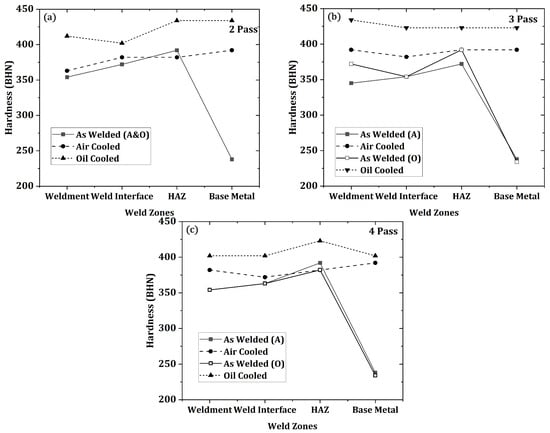

Figure 5 illustrates the hardness profile measured across different weld zones, including the weldment, weld interface, HAZ, and base metal, under various experimental conditions outlined in Table 2. The variation in hardness across these zones is primarily attributed to microstructural transformations influenced by the combined effects of welding heat input and the cooling characteristics following PWHT.

Figure 5.

Hardness profile for different welding conditions and heat treatments; (a) 2 pass, (b) 3 pass, and (c) 4 pass.

In the as-welded condition, a similar hardness distribution is observed across the weld zones for both AC and OC mediums (Figure 5). The HAZ exhibits the highest hardness, ranging from 370 to 390 BHN, followed by the weld metal at 345 to 365 BHN, while the unaffected parent metal maintains a hardness of 238 BHN. These values align well with the literature [16,17]. This hardness variation is attributed to the presence of 0.3% C, 0.2% V, and 0.8% Mo, which promote air-hardening, leading to the transformation of austenite into martensite. As the number of weld passes increases, the weldment undergoes multiple thermal cycles, refining the microstructure and thereby influencing the hardness distribution across the weld zones (see Figure 5a, Figure 5b, and Figure 5c, respectively).

Additionally, the thermal cycles induced by PWHT, in combination with different cooling strategies (AC and OC), result in a more homogeneous hardness distribution and an overall reduction in hardness across the weld zones (see Figure 5b,c). The PWHT-treated samples cooled in OC exhibit higher and more uniform hardness compared to those AC. This difference is due to the cooling rate, which determines the resulting microstructure—faster cooling (OC) promotes the formation of fine tempered martensite, whereas slower cooling (AC) leads to a coarse bainitic structure with ferrite, as shown in Figure 4. Furthermore, the hardness of the base metal after PWHTCS significantly increases, ranging from 400 to 440 BHN, depending on the cooling medium. This enhancement is attributed to the formation of fine bainite and ferrite in AC samples, while OC samples develop a fine tempered martensitic structure with bainite. Hardness analysis indicates that both the number of weld passes and the quenching medium play a crucial role in determining the final hardness. The observed hardness trend follows the order: WC > OC > AC [8,16,20].

3.3.2. Tensile and Impact Testing

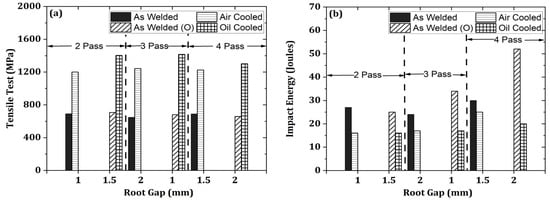

Figure 6 presents the tensile and impact properties of weldments subjected to various PWHTCS. All tensile specimens failed outside the weldment zone, predominantly in the heat-affected zone (HAZ) or at the HAZ–base metal interface. The highest tensile strength is observed in the as-welded condition (before PWHTCS) for both AC and OC weldments, ranging between 650 ± 10 MPa and 690 ± 10 MPa, with an elongation to failure of 11 ± 2% to 18 ± 2%. Table 4 summarizes the recorded ultimate tensile strength (UTS), 0.2% proof strength (PS), elongation (%), and impact toughness under different PWHTCS. The weld joint efficiency, calculated as the ratio of as-welded joint tensile strength to that of the as-received plate, exceeds 90%, consistent with literature findings [16,17]. As discussed in Section 3.3.1, the variation in cooling rates across different weld zones results in microstructural heterogeneity, influencing the tensile failure location [26,27,28]. In case of fracture toughness, the PWHTCS and number of passes has significantly improved the fracture toughness. Figure 6a illustrates that an increase in the number of passes leads to a reduction in tensile strength, indicating enhanced ductility. The inverse relationship between hardness and toughness is evident in Figure 6a,b. As a result, impact toughness improves with increasing passes, with energy absorption capacity rising from 25 ± 2 J to 50 ± 2 J. This variation in impact toughness, despite increased hardness during heat treatment, such as oil quenching or air cooling, occurs because martensite, which forms during quenching, is very hard yet brittle (see Figure 5). While tempering can improve toughness by reducing brittleness, excessive quenching or improper tempering may result in retained austenite or overhardened martensite, which reduces toughness [29,30]. Oil cooling, however, achieves a balance between high hardness and maintaining toughness, as it produces a finer martensitic microstructure compared to air cooling, while also preventing excessive brittleness. Additionally, the number of passes significantly refined microstructure prior to heat treatment, thereby enhancing toughness without sacrificing strength, as shown in Figure 6b. This makes oil quenching, followed by tempering and combined with optimized welding procedures, an effective method for achieving both improved hardness and enhanced toughness in welded components.

Figure 6.

Mechanical Properties for various PWHTCS; (a) Tensile test and (b) Impact test.

Table 4.

Tensile properties and impact toughness for different PWHTCS. Adapted from [8,26].

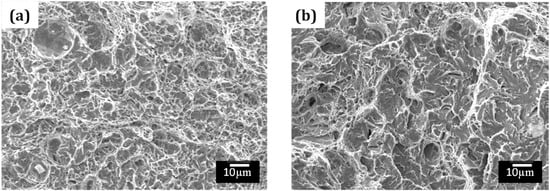

Fractographic analysis of impact-tested specimens (Figure 7) reveals that as-welded samples exhibit a mixed fracture mode, characterized by brittle cleavage facets (martensitic regions) and ductile dimples at ferrite–bainite interfaces (Figure 7a).

Figure 7.

Fractured Surface Morphology (impact) at (a) Surface and (b) Core for OC PWHTCS.

Comparing as-welded and PWHTCS samples, a twofold increase in tensile strength is observed after PWHT, regardless of the cooling medium (Figure 6a). The tempering effect enhances toughness while stabilizing hardness. Notably, OC weldments exhibit higher tensile strength than their AC counterparts, attributed to the formation of fine martensite and bainite (Section 3.2). In contrast, AC promotes a bainitic transformation, leading to higher UTS and 0.2% PS, but lower elongation and impact toughness (Figure 6b and Table 4).

The SEM fractography analysis (Figure 7) reveals significant differences between ductile and brittle fracture modes, influenced by the cooling method. Fractographic observations of air-cooled (AC) samples (Figure 7b) reveal deep dimples and micro-voids, indicative of shear ductile fracture, often associated with a cup-and-cone morphology, which suggests significant plastic deformation and energy absorption before failure [2,9,31]. In contrast, oil-cooled (OC) samples (Figure 7c) exhibit a mixed ductile–brittle failure mode, characterized by shallow dimples and cleavage facets, indicating a more complex fracture behavior with both plastic deformation and rapid crack propagation [2,4,31]. The cooling method plays a significant role in the material’s fracture characteristics, with oil cooling producing a more refined martensitic microstructure, providing a balance between tensile strength and impact toughness, while air cooling results in a coarser microstructure, which can lead to higher brittleness. Additionally, as the number of welding passes increases from two to four, the microstructure becomes more refined, enhancing the combination of tensile strength and impact toughness. This improvement is a result of the more uniform distribution of phases and reduced residual stresses, providing better overall mechanical performance in welded components [8,16,26].

The selected heat treatment cycle for 0.3% C-Cr-Mo-V steel, involving oil quenching followed by tempering (OC), demonstrates clear advantages over conventional PWHT methods such as air cooling [2,9]. This approach leads to noticeable improvements in mechanical properties, including higher tensile and yield strength, enhanced impact toughness, and increased hardness. These enhancements are attributed to the formation of a finer martensitic microstructure [2,4], in contrast to the coarse bainitic or tempered structures typically resulting from air cooling [9]. Among the different PWHT cycles, OC produces an optimized microstructure, offering enhanced mechanical performance that is particularly suitable for demanding applications. Furthermore, the insights from this research pave the way for integrating additive manufacturing techniques to further enhance material properties for high-performance applications [32,33].

4. Conclusions

The present study attempts to enhance the microstructure and mechanical properties of GTAW 0.3% C-Cr-Mo-V steel plate through PWHTCS. The findings demonstrate that the cooling rate and the number of passes play a decisive role in determining the microstructure and mechanical properties, including hardness, tensile strength, and impact toughness. The specific conclusions are listed below:

- As-welded specimens exhibited tensile strengths ranging from 650 to 690 MPa, with failure occurring at the HAZ–base metal interface, indicating that the weldment retained high strength. The weld joint efficiency exceeded 90%, aligning with the literature.

- An increase in the number of passes resulted in lower tensile strength but improved ductility and impact toughness, accentuating the inverse relationship between hardness and toughness.

- OC produced a fine martensitic–bainitic microstructure, leading to higher tensile strength than AC, though with slightly reduced ductility. PWHT enhanced impact toughness while maintaining hardness, leading to a more balanced mechanical performance. The OC offered a refined microstructure and an optimal combination of strength and toughness.

- Fractography analysis showed that OC samples had a mixed ductile–brittle failure mode, while AC samples exhibited ductile fracture with deep dimples and micro-voids.

Overall, OC offers an optimal trade-off between strength, hardness, and impact toughness, making it the preferred cooling strategy for applications requiring high-performance weld integrity. Future work may explore further optimization of PWHT parameters to enhance mechanical performance under various service conditions.

Author Contributions

Conceptualization, S.Q.M., M.C. and K.R.; methodology, S.Q.M., V.M. and M.F.K.; validation, S.Q.M., M.C. and K.A.; formal analysis, S.Q.M., K.A. and S.J.; investigation, S.Q.M., M.F.K., S.S.H. and K.R.; resources, S.Q.M., S.S.H., V.M. and K.R.; data curation, S.Q.M., S.S.H. and S.J.; writing—original draft preparation, S.Q.M., M.F.K. and M.C.; writing—review and editing, S.Q.M., M.F.K., K.A. and M.C.; visualization, V.M., S.J. and K.A.; supervision, S.Q.M., M.C. and V.M.; project administration, S.S.H. and S.Q.M.; funding acquisition, S.Q.M., M.F.K., M.C., V.M., K.A. and S.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia [KFU251023].

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors would like to express their gratitude to their respective affiliated universities for their support and facilitation in the completion of this collaborative research work.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AC | Air Cooled |

| ASTM | American Standard Testing Method |

| BHN | Brinell Hardness |

| BM | Base Metal |

| CE | Carbon Equivalent |

| DCEN | Direct Current Electrode Negative |

| DOE | Design of Experiments |

| DPT | Dye Penetration Test |

| EDM | Electric Discharge Machining |

| FC | Furnace cooled |

| FZ | Fusion Zone |

| GMAW | Gas Metal Arc Welding |

| GTAW | Gas Tungsten Arc Welding |

| HAZ | Heat Affected Zone |

| HSLA | High-Strength Low-Alloy |

| OC | Oil Cooled |

| PS | Proof Stress |

| PWHT | Post-Weld Heat Treatment |

| PWHTCS | Post-Weld Heat Treatment and Cooling Strategies |

| SEM | Scanning Electron Microscope |

| SMAW | Shielded Metal Arc Welding |

| TIG | Tungsten Inert Gas |

| UTM | Universal Testing Machine |

| UTS | Ultimate Tensile Strength |

| WC | Water Cooled. |

References

- Ju, J.; Fu, H.-G.; Fu, D.-M.; Wei, S.-Z.; Sang, P.; Wu, Z.-W.; Tang, K.-Z.; Lei, Y.-P. Effects of Cr and V Additions on the Microstructure and Properties of High-Vanadium Wear-Resistant Alloy Steel. Ironmak. Steelmak. 2018, 45, 176–186. [Google Scholar] [CrossRef]

- Ramkumar, P.; Kumar, V.A.; Gupta, R.K.; Karthikeyan, M.K.; Prasad, S.N.; Prakash, F.G.; Chakravarthi, K.V.A.; Prasad, Y.M.; Venkitakrishnan, P.V. Melting and Thermomechanical Processing of High Strength 0.3%C–CrMoV (ESR) Steel. Trans. Indian Inst. Met. 2018, 71, 1475–1485. [Google Scholar] [CrossRef]

- Chandra Sekhar, M.; Srinivasa Rao, D.; Ramesh, D. Welding Development in ESR Modified 15CDV6 Material. Int. J. Recent Res. Civ. Mech. Eng. 2014, 1, 12–17. [Google Scholar]

- Ramkumar, P.; Karthikeyan, M.K.; Gupta, R.K.; Anil Kumar, V.; Magadum, C.; Muthupandi, V. Plasma Arc Welding of High Strength 0.3%C–CrMoV (ESR) Steel. Trans. Indian Inst. Met. 2017, 70, 1317–1322. [Google Scholar] [CrossRef]

- Song, K.; Lin, Z.; Fa, Y.; Zhao, X.; Zhu, Z.; Ya, W.; Sun, Z.; Yu, X. Microstructure and Mechanical Properties of High-Strength, Low-Alloy Steel Thin-Wall Fabricated with Wire and Arc Additive Manufacturing. Metals 2023, 13, 764. [Google Scholar] [CrossRef]

- Srinivasan, L.; Kannan, T.D.B.; Sathiya, P.; Biju, S. Effect of Heat Input, Heat Treatment on Microstructure and Mechanical Properties of GTA Welded Aerospace Material 15CDV6. J. Mater. Res. 2017, 32, 1361–1366. [Google Scholar] [CrossRef]

- Franceschi, M.; Bregolin, E.; Miotti-Bettanini, A.; Pasqualini, L.; Campagnolo, S.; Zambon, A.; Pezzato, L.; Dabalà, M. Effect of the Welding Technique and Post-Welding Heat Treatments on the Microstructure and Mechanical Properties of a High Silicon Nanostructured Carbide-Free Bainitic Steel. J. Mater. Res. Technol. 2024, 31, 718–732. [Google Scholar] [CrossRef]

- Radhakrishnan, K.; Hameed, S.S.; Muralidharan, V.; Moinuddin, S.Q. Optimizing Process Parameters and a Comparative Study of Post-Weld Heat Treatments on the Microstructure and Mechanical Properties of 0.3%C-Cr-Mo-V Steel. Int. J. Interact. Des. Manuf. 2024, 19, 365–374. [Google Scholar] [CrossRef]

- Alipooramirabad, H.; Paradowska, A.; Nafisi, S.; Reid, M.; Ghomashchi, R. Post-Weld Heat Treatment of API 5L X70 High Strength Low Alloy Steel Welds. Materials 2020, 13, 5801. [Google Scholar] [CrossRef]

- Jorge, J.C.F.; Monteiro, J.L.D.; Gomes, A.J.d.C.; Bott, I.d.S.; de Souza, L.F.G.; Mendes, M.C.; Araújo, L.S. Influence of Welding Procedure and PWHT on HSLA Steel Weld Metals. J. Mater. Res. Technol. 2019, 8, 561–571. [Google Scholar] [CrossRef]

- Alipooramirabad, H.; Paradowska, A.; Reid, M.; Ghomashchi, R. Effect of Holding Time on Strain Relaxation in High-Strength Low-Alloy Steel Welds: An In-Situ Neutron Diffraction Approach. J. Manuf. Process. 2022, 73, 326–339. [Google Scholar] [CrossRef]

- Harati, E.; Onochie, U. Effect of Post-Weld Heat Treatment on Mechanical and Microstructural Properties of High Strength Steel Weld Metal. Weld. Int. 2024, 38, 422–429. [Google Scholar] [CrossRef]

- Zhang, L.; Pittner, A.; Michael, T.; Rhode, M.; Kannengiesser, T. Effect of Cooling Rate on Microstructure and Properties of Microalloyed HSLA Steel Weld Metals. Sci. Technol. Weld. Join. 2015, 20, 371–377. [Google Scholar] [CrossRef]

- Tomerlin, D.; Marić, D.; Kozak, D.; Samardžić, I. Post-Weld Heat Treatment of S690QL1 Steel Welded Joints: Influence on Microstructure, Mechanical Properties and Residual Stress. Metals 2023, 13, 999. [Google Scholar] [CrossRef]

- Tiwari, R.; Yadav, V.K.; Singh, I.V. Microstructural Evolution and Mechanical Property Analysis of Weldox-700 Steel: Effect of Welding and Post-Weld Heat Treatments. J. Mater. Eng. Perform. 2024, 33, 1–20. [Google Scholar] [CrossRef]

- Ramkumar, P.; Gupta, R.K.; Anil Kumar, V.; Muthupandi, V. Effect of Pre- and Post-Weld Heat Treatment on Microstructure Development and Mechanical Properties of 0.3%C-CrMoV (ESR) High-Strength Low-Alloy Steel. J. Mater. Eng. Perform. 2021, 30, 7835–7850. [Google Scholar] [CrossRef]

- Radhakrishnan, K.; Muralidharan, V. The Effect of Quenching Mediums on Heat Treatment Properties of Multi-Pass Welding of 0.3%C-Cr Mo V Steel. Adv. Des. Therm. Syst. 2021, 463–474. [Google Scholar] [CrossRef]

- ASTM A370-10; Standard Test Methods and Definition for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM E10-18; Standard Test Method for Brinell Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E8/E8M-22; Standard Test Method for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM E23-18; Standard Test Method for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E165; Test Method for Liquid Penetrant Examination. ASTM International: West Conshohocken, PA, USA, 2023.

- AIR 9112/A; Condition for Checking and Receiving Steel Parts and Assemblies Made by Melting Welding. DGA, Global Specs: Gurgaon, India, 1967.

- IQI EN462-1/ISO19232; Image Quality Indicators. ISO: Geneva, Switzerland, 2013.

- Mishra, S.K.; Das, S.; Ranganathan, S. Precipitation in High Strength Low Alloy (HSLA) Steel: A TEM Study. Mater. Sci. Eng. A 2002, 323, 285–292. [Google Scholar] [CrossRef]

- Radhakrishnan, K.; Muralidharan, V. A Study on the Welding and Heat Treatment of 0.3%C-Cr-Mo-V Steel. In Advances in Design and Thermal Systems; Springer: Singapore, 2021; pp. 463–474. [Google Scholar] [CrossRef]

- Suresh, M.R. 0.3 C–CrMoV (ESR) Steel: A New Ultrahigh Strength Steel. Trans. Indian Inst. Met. 2011, 64, 483–492. [Google Scholar] [CrossRef]

- Kumar, G.D.C.; Kumar, V.A.; Gupta, R.K.; Murty, S.V.S.N.; Kashyap, B.P. Effect of Strain Rate and Temperature on the Tensile Flow Behavior and Microstructure Evolution in Fe-0.3 Pct C-CrMoV Grade Steel. Metall. Mater. Trans. A 2019, 50, 161–178. [Google Scholar] [CrossRef]

- Dudko, V.; Yuzbekova, D.; Gaidar, S.; Vetrova, S.; Kaibyshev, R. Tempering Behavior of Novel Low-Alloy High-Strength Steel. Metals 2022, 12, 2177. [Google Scholar] [CrossRef]

- Jiang, W.; Wu, D.; Zhang, Q.; Li, M.; Liu, W. Effect of Tempering Time on the Microstructure and Properties of Martensitic Stainless Steel. Metals 2024, 14, 322. [Google Scholar] [CrossRef]

- Sun, Q.; Li, X.; Li, K.; Cai, Z.; Han, C.; Li, S.; Gao, D.; Pan, J. Effects of Long-Term Service on Microstructure and Impact Toughness of the Weld Metal and Heat-Affected Zone in CrMoV Steel Joints. Metals 2022, 12, 278. [Google Scholar] [CrossRef]

- Aguilar, F.; Huynh, T.; Kljestan, N.; Knezevic, M.; Sohn, Y. Microstructure and Mechanical Characterization of AISI 4340 Steel Additively Manufactured by Laser Powder Bed Fusion. Metals 2025, 15, 412. [Google Scholar] [CrossRef]

- Jelis, E.; Hespos, M.R.; Ravindra, N.M. Process Evaluation of AISI 4340 Steel Manufactured by Laser Powder Bed Fusion. J. Mater. Eng. Perform. 2018, 27, 63–71. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).