Influence of Friction-Stir-Processing Parameters on the Microstructure and Local Mechanical Properties of an Aluminium-6% Magnesium-H18 Alloy

Abstract

1. Introduction

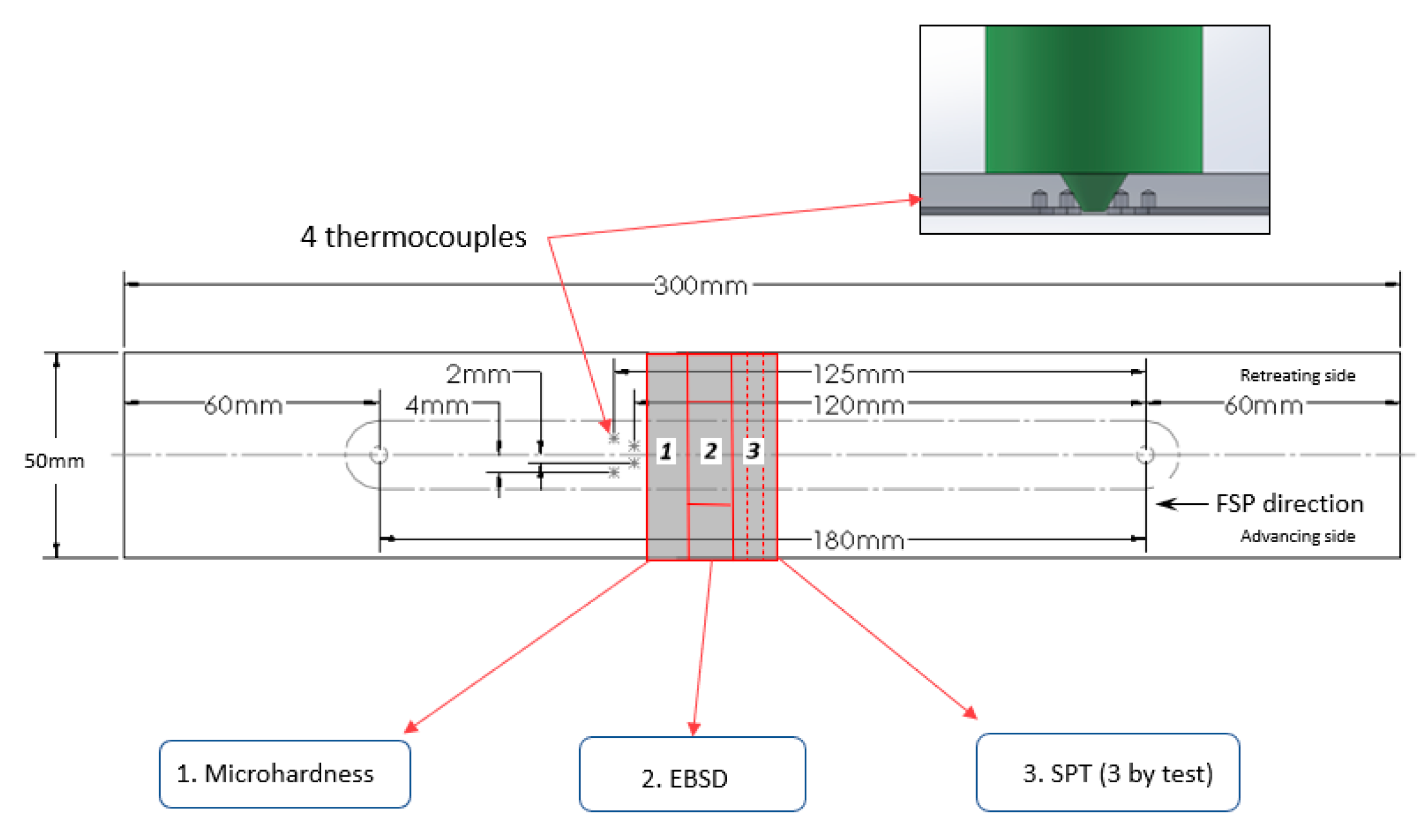

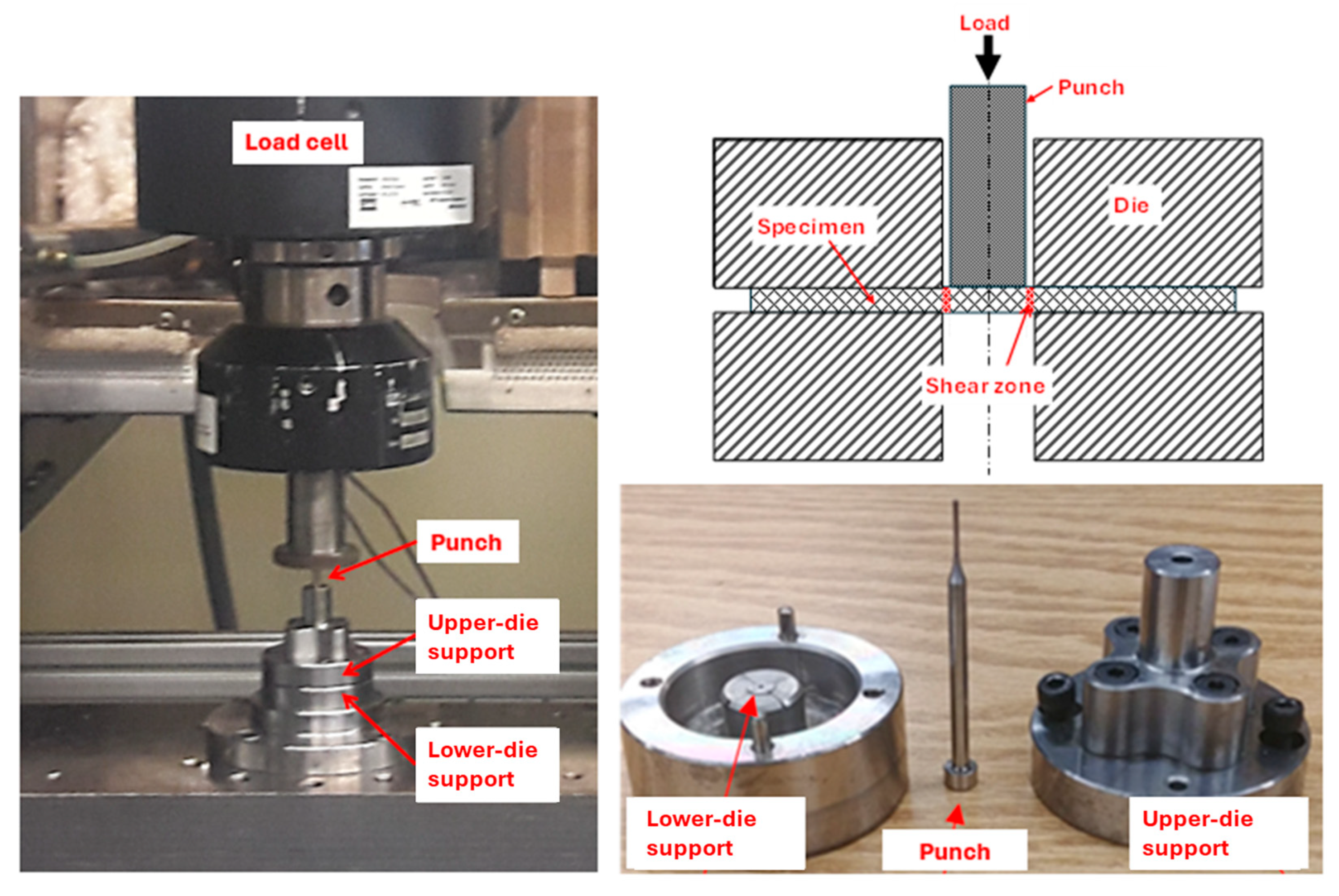

2. Materials and Methods

3. Results and Discussion

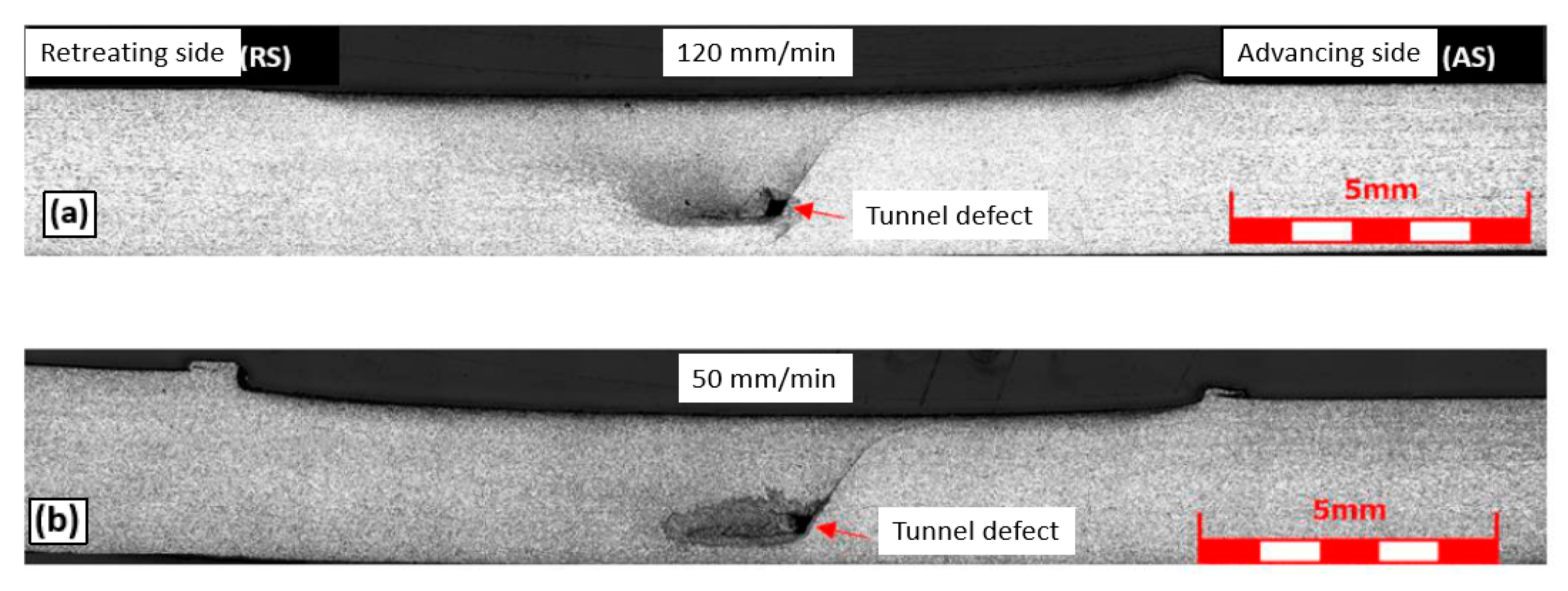

3.1. Macroscopic Examination and Thermal Mapping

3.2. Microhardness of the Processed Regions

3.3. Microstructural Characteristics

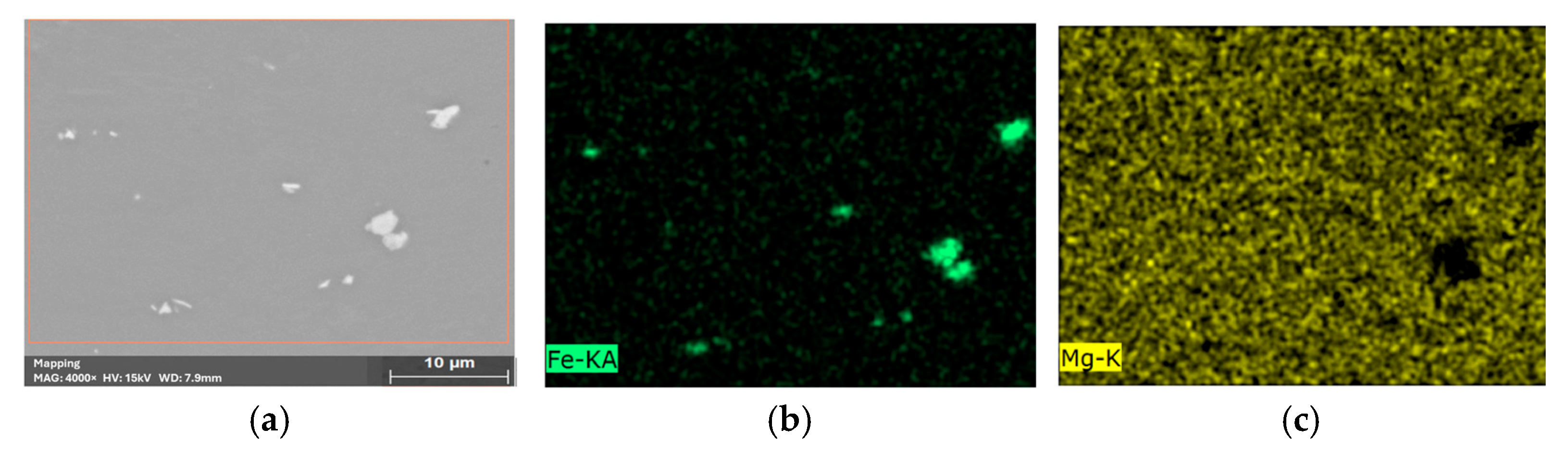

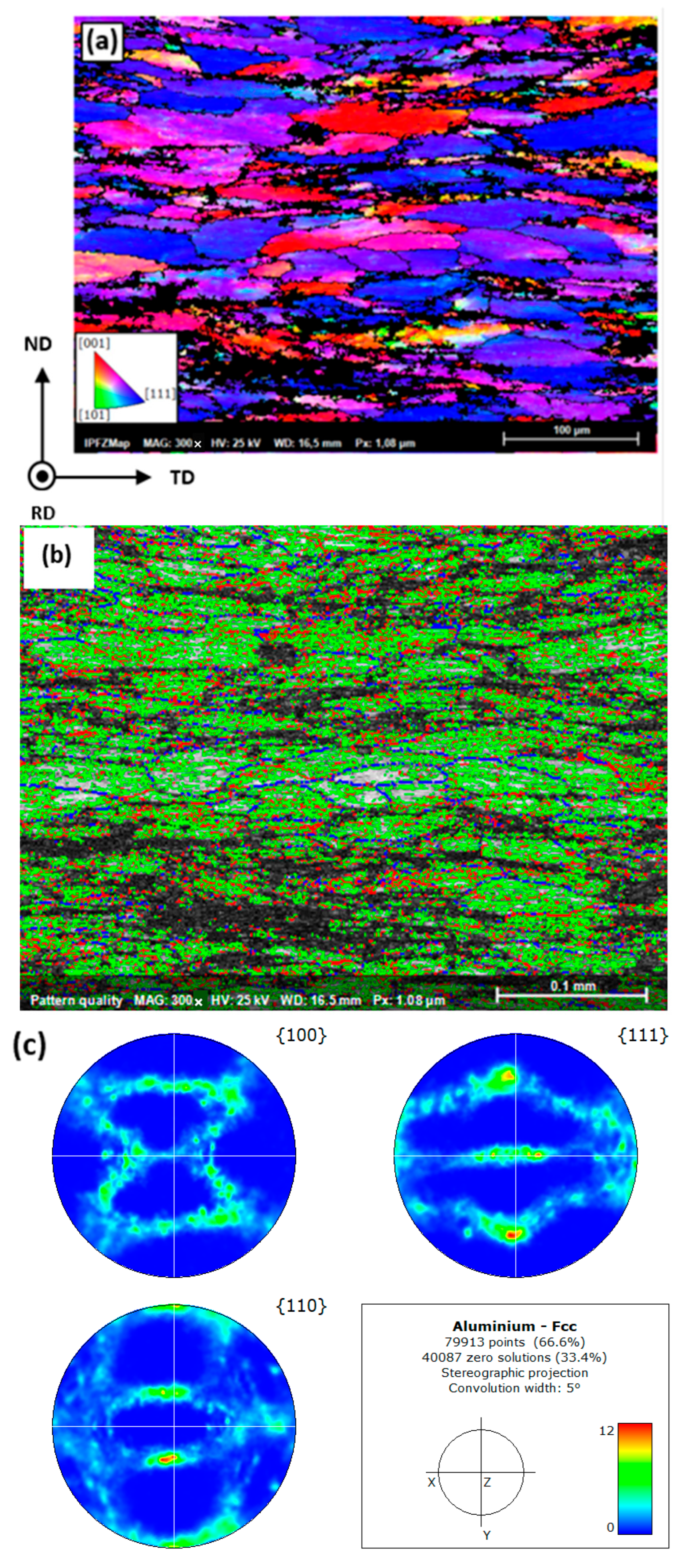

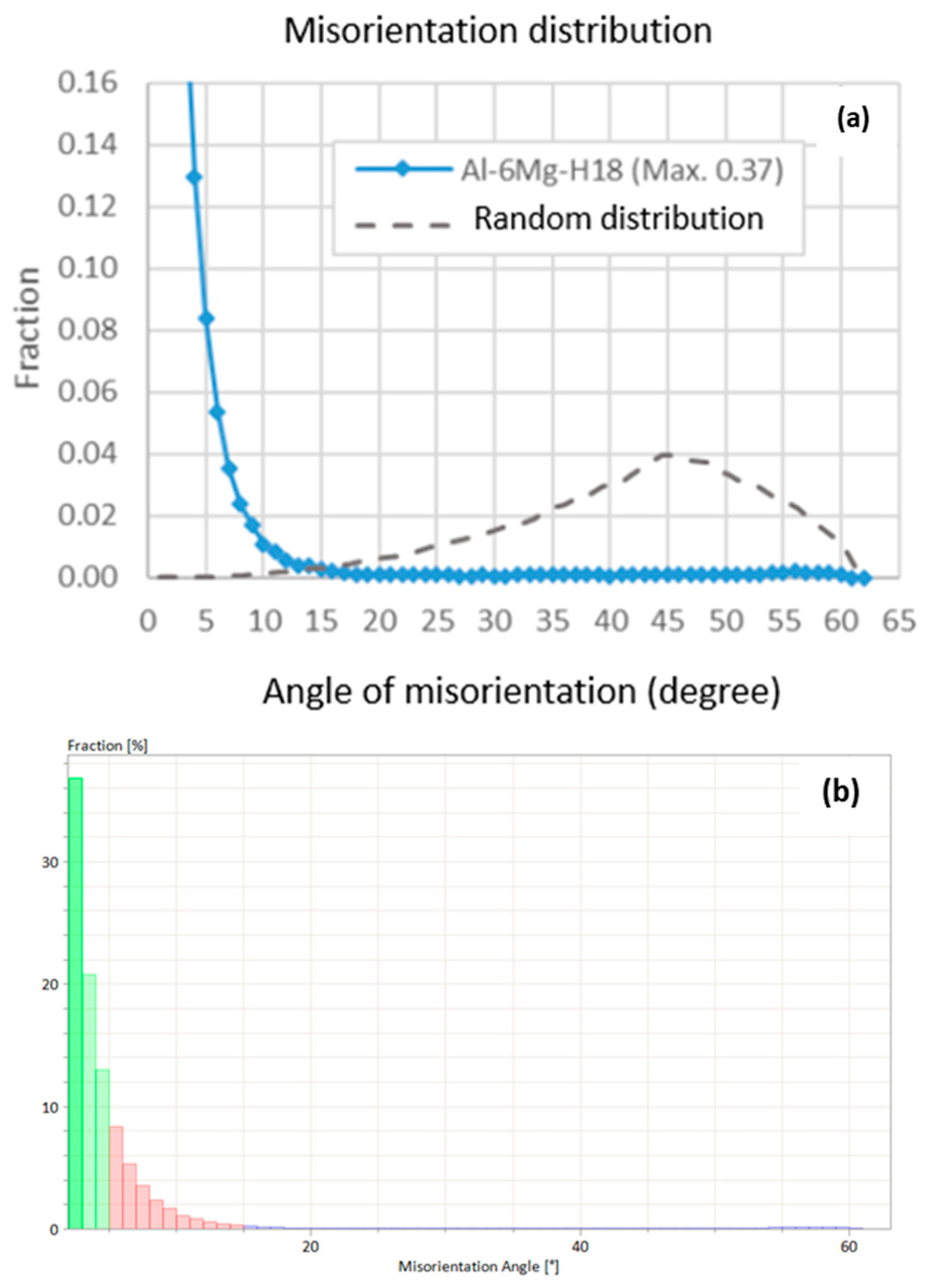

3.3.1. Base Material

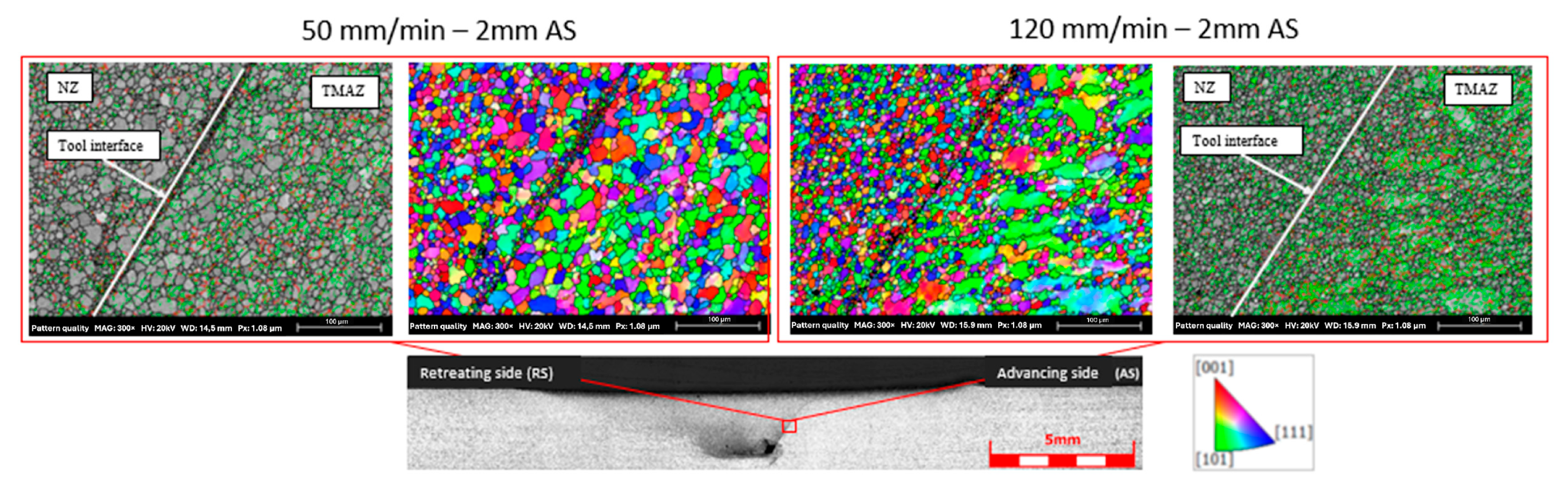

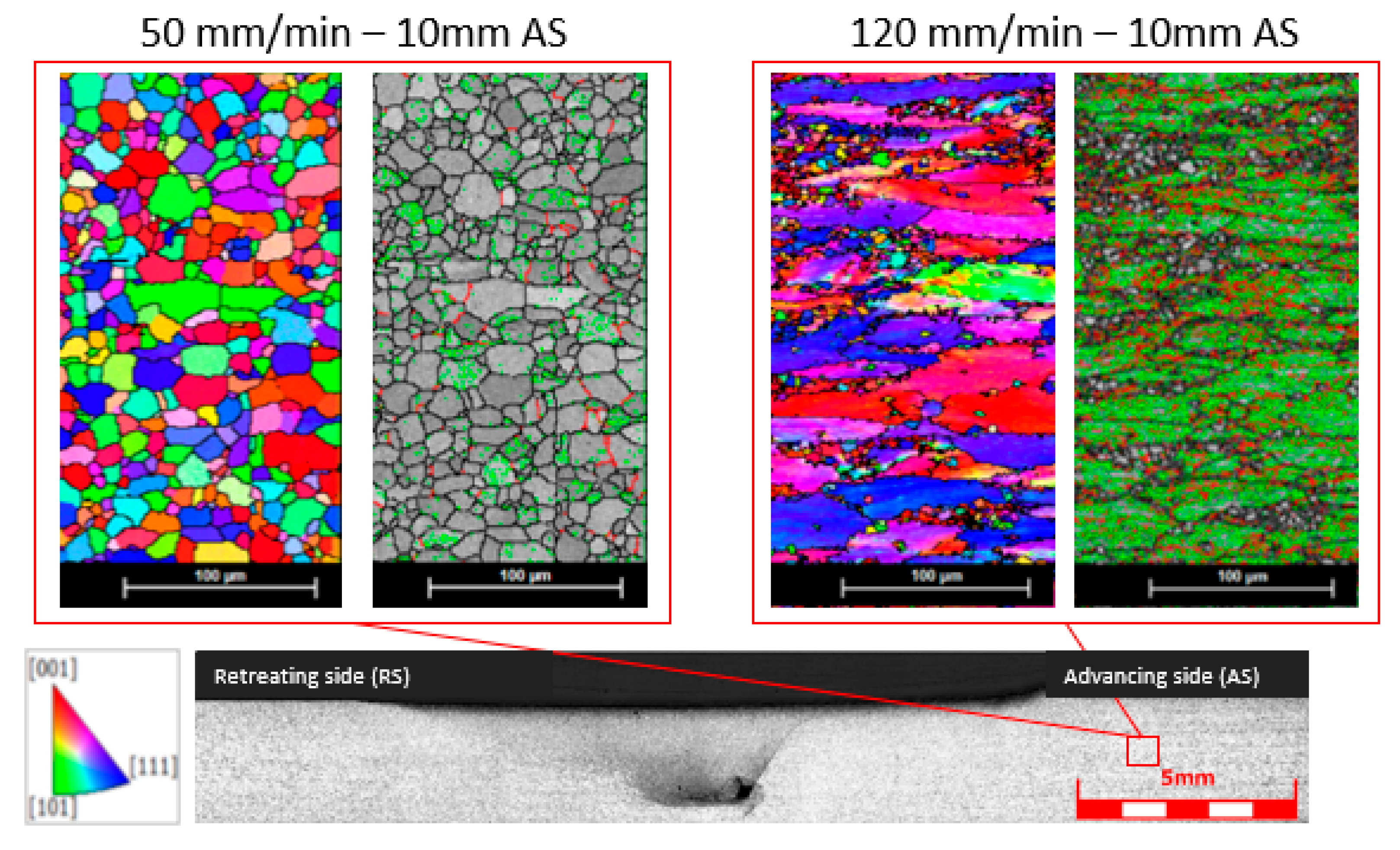

3.3.2. Influence of Travel Speed on the Microstructure

- 1.

- Nugget zones

- 2.

- Thermo-mechanically affected zones (TMAZ)

- Advancing side (AS)

- Retreating side (RS)

- Heat-affected zone

3.4. Mechanical Properties

4. Conclusions

- Travel speed significantly impacts the microstructure of different regions of FSPed material, including the nugget zone (NZ), thermo-mechanically affected zone (TMAZ), and heat-affected zone (HAZ). Travel speed influences heat input, material flow, and, consequently, grain size.

- In the nugget zone (NZ), and as a consequence of the material stirring and the heat input, the FSP leads to grain refinement at both travel speeds. However, at the lower travel speed of 50 mm/min, the action of the higher heat input induces a slight increase in the grain size compared to 120 mm/min. EBSD analysis showed that continuous dynamic recrystallization occurs in both the upper (UNZ) and the lower nugget zones (LNZ). However, the grain size in the LNZ is slightly lower than that in the UNZ.

- At the lower travel speed (50 mm/min), the combination of significant hardening and higher temperatures compared to the 120 mm/min travel speed results in recrystallization. In contrast, elongated grains were widely observed at the higher travel speed of 120 mm/min. SPT conducted in different locations revealed similarities in the center of the FSP for both travel speeds. However, at 2 mm from the nugget zone, differences were observed between the AS and the RS, which are related to the presence of non-recrystallized original grains.

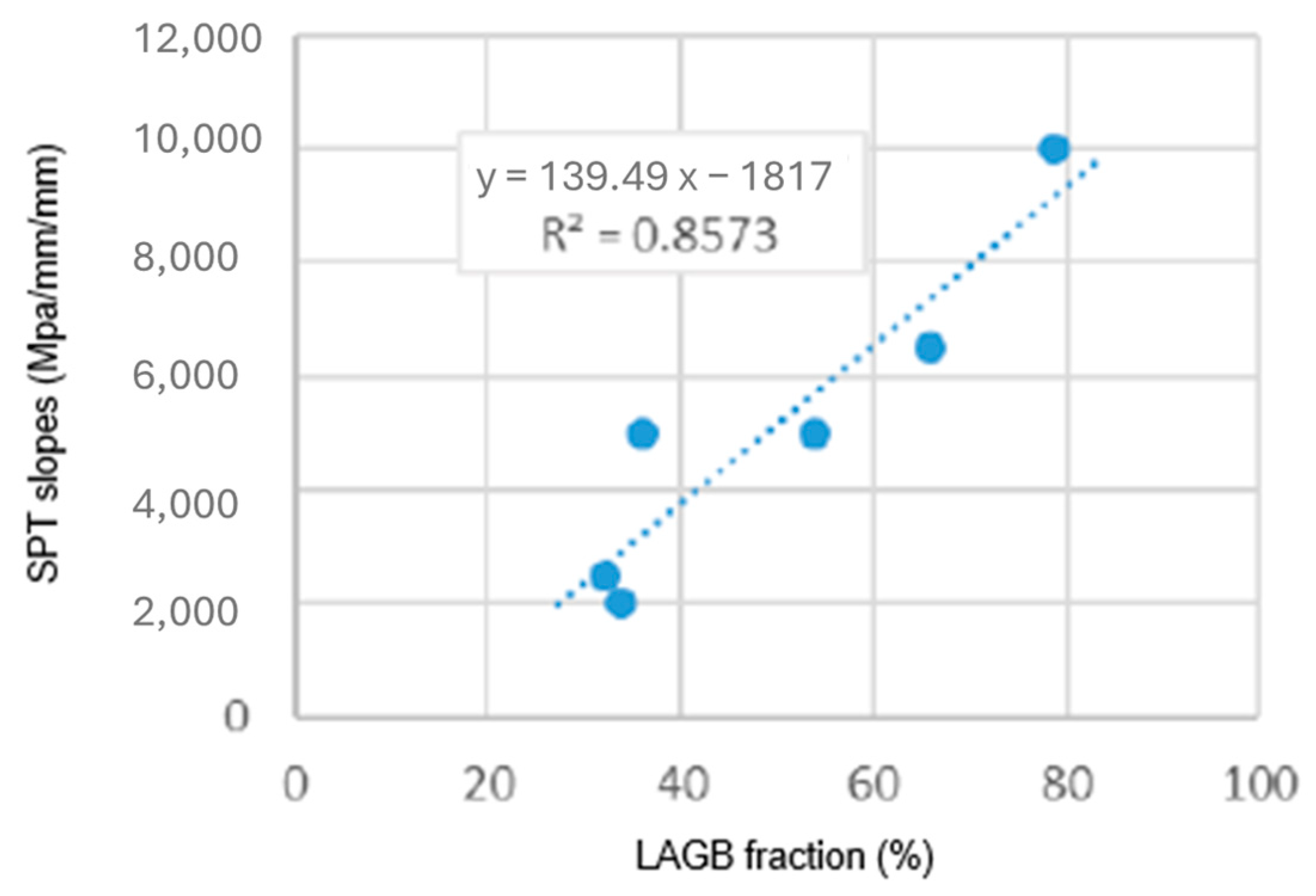

- A linear correlation between the SPT slope and LAGB fraction can be assumed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, W.; Liu, C.Y.; Huang, H.F.; Zhang, L.; Zhang, B.; Shi, L. High strength and ductility of Al–Si–Mg alloys fabricated by deformation and heat treatment. Mater. Charact. 2021, 178, 111278. [Google Scholar] [CrossRef]

- Wang, J.T.; Liu, A.X.; Zhang, Y.K.; Xie, L.; He, M.T.; Luo, K.Y. Influence of Process Parameters on Wear Resistance of Surfaces Modified by Friction Stirring Processing in 7075 Aluminum Alloy. Met. Mater. Int. 2025, 31, 625–635. [Google Scholar] [CrossRef]

- Rohim, M.N.M.; Abdullah, M.E.; Mohammed, M.M.; Kubit, A.; Aghajani Derazkola, H. Friction Stir Processed AA5754-Al2O3 Nanocomposite: A Study on Tribological Characteristics. J. Compos. Sci. 2024, 8, 216. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Arun Kumar Shettigar, A.; Mervin, A.; Herbert, M.A.; Manjunath Patel, G.C.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, Z.; Wang, G.; Sun, X.; Zhang, Y. Enhancing metallurgical and mechanical properties of friction stir lap welding of aluminum alloys by microstructure reconstruction. Sci. Rep. 2024, 14, 31987. [Google Scholar] [CrossRef]

- Dhairiyasamy, R.; Gabiriel, D.; Kandasamy, M.; Rajendran, S. Investigation of Microstructural and Mechanical Characteristics of Friction Stir Welded Aluminum Alloy 7075-t6. Trans. Indian Inst. Met. 2024, 77, 3789–3797. [Google Scholar] [CrossRef]

- Kolagotla, R.K.; Krishna, B.V.; Bhargavi, P.; Janaki, D.V.; Babu, B.R.; Babu, M.V.; Satyanarayana, M.V.; Naresh, G. Toward Achieving Grain Refinement in Al2014 Alloy Through Multi-pass FSP: Microstructure and Mechanical Behavior. J. Inst. Eng. India Ser. D 2024, 1–10. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Javidani, M.; Mofarrehi, M.; Farzaneh, A.; Chen, X.-G. Submerged Dissimilar Friction Stir Welding of AA6061 and AA7075 Aluminum Alloys: Microstructure Characterization and Mechanical Property. Metals 2021, 11, 1592. [Google Scholar] [CrossRef]

- Chang, I.; Du, X.H.; Huang, J.C. Achieving ultrafine grain size in Mg–Al–Zn alloy by friction stir processing. Scr. Mater. 2007, 57, 209–212. [Google Scholar]

- Zheng, Z.; Li, Q.; Chen, X.; Gao, A.; Zhang, N. Application Status and Prospects of Friction Stir Processing in Wrought Magnesium Alloys: A Review. Trans. Indian Inst. Met. 2024, 77, 1891–1906. [Google Scholar] [CrossRef]

- Xu, N.; Qiu, Z.; Gu, B.; Liu, Z.; Zhu, S.; Song, Q.; Wang, D.; Shen, J. Enhanced mechanical properties of thermo-mechanically affected zone of friction-stir welded AZ61 magnesium alloy joint. Mater. Res. Technol. 2024, 30, 3594–3601. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mohammadzadeh, R.; Jafarian, H.R.; Pruncu, C.I.; Simar, A. Role of geometrically necessary dislocations on mechanical properties of friction stir welded single-phase copper with medium stacking fault energy. J. Mater. Res. Technol. 2022, 16, 194–200. [Google Scholar] [CrossRef]

- Chen, M.; Chang, Z.; Li, H.; Tao, H.; Jiang, B.; Li, Z.; Zhang, H. The microstructure evolution and mechanical properties of multi-layer friction stir additive manufacturing for T2 copper. Mater. Today Commun. 2024, 42, 111213. [Google Scholar] [CrossRef]

- Kalashnikova, T.; Cheremnov, A.; Eliseev, A.; Gurianov, D.; Knyazhev, E.; Moskvichev, E.; Beloborodov, V.; Chumaevskii, A.; Zykova, A.; Kalashnikov, K. Structural Changes in Block-Shaped WEBAM’ed Ti6Al4V Samples after Friction Stir Processing. Lubricants 2022, 10, 349. [Google Scholar] [CrossRef]

- Regev, M.; Almoznino, B.; Spigarelli, S. A Study of the Metallurgical and Mechanical Properties of Friction-Stir-Welded Pure Titanium. Metals 2023, 13, 524. [Google Scholar] [CrossRef]

- Zykova, A.; Vorontsov, A.; Chumaevskii, A.; Gurianov, D.; Savchenko, N.; Gusarova, A.; Kolubaev, E.; Tarasov, S. In Situ Intermetallics-Reinforced Composite Prepared Using Multi-Pass Friction Stir Processing of Copper Powder on a Ti6Al4V Alloy. Materials 2022, 15, 2428. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.S.; Kokawa, H.; Hirano, S.; Pilchak, A.L.; Semiatin, S.L. Microstructural Characterization of Friction-Stir Processed Ti-6Al-4V. Metals 2020, 10, 976. [Google Scholar] [CrossRef]

- Kim, J.Y.; Jung, W.S.; Lee, W.S.; Byeon, J.W. Surface modification of cast Inconel 740 superalloy by heat-assisted friction stir processing. Met. Mater. Int. 2016, 22, 694–699. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Vairis, A.; Badheka, V. Recent Development in Friction Stir Processing as a Solid-State Grain Refinement Technique: Microstructural Evolution and Property Enhancement. Crit. Rev. Solid State Mater. Sci. 2019, 44, 378–426. [Google Scholar] [CrossRef]

- Guduru, R.K.; Darling, K.A.; Kishore, R.; Scattergood, R.O.; Koch, C.C.; Murty, K.L. Evaluation of mechanical properties using shear–punch testing. Mater. Sci. Eng. A 2005, 395, 307–314. [Google Scholar] [CrossRef]

- Fall, A.; Monajatia, H.; Khodabandehb, A.; Fesharakib, M.H.; Champliaud, H.; Jahazi, M. Local mechanical properties, microstructure, and microtexture in friction stir welded Ti-6Al-4V alloy. Mater. Sci. Eng. A 2005, 749, 166–175. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Scharifi, E.; Weidig, U.; Steinhoff, K.; Niendorf, T. Effect of Tool Temperature on Mechanical Properties and Microstructure of Thermo-Mechanically Processed AA6082 and AA7075 Aluminum Alloys. HTM J. Heat Treatm. Mat. 2020, 75, 177–191. [Google Scholar] [CrossRef]

- Sahraoui, T.; Hadji, M.; Bacha, N.; Badji, R. Superplastic Deformation Behavior of 7075 Aluminum Alloy. J. Mater. Eng. Perform. 2003, 12, 398–401. [Google Scholar] [CrossRef]

- Kumar, N.; Jayaganthan, R.; Brokmeier, H.-G. Effect of deformation temperature on precipitation, microstructural evolution, mechanical and corrosion behavior of 6082 Al alloy. Trans. Non-Ferr. Met. Soc. China 2017, 27, 475–492. [Google Scholar] [CrossRef]

- Monajati, H.; Zoghlami, M.; Tongne, A.; Jahazi, M. Assessing Microstructure-Local Mechanical Properties in Friction Stir Welded 6082-T6 Aluminum Alloy. Metals 2020, 10, 1244. [Google Scholar] [CrossRef]

- ASTM E8/E8M-06a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2006.

- Nakamura, T.; Obikawa, T.; Nishizaki, I.; Enomoto, M.; Zhenglong, F. Friction Stir Welding of Non-Heat-Treatable High-Strength Alloy 5083-O. Metals 2018, 8, 208. [Google Scholar] [CrossRef]

- Fujii, H.; Cui, L.; Maeda, M.; Nogi, K. Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminum alloys. Mater. Sci. Eng. A 2006, 419, 25–31. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, H.; Wu, X.; Meng, Q. Microstructure and Mechanical Property Evolution of Robotic Friction Stir-Welded Al–Li Alloys. Crystals 2023, 13, 582. [Google Scholar] [CrossRef]

- Kalinenko, A.; Dolzhenko, P.; Malopheyev, S.; Yuzbekova, D.; Shishov, I.; Mishin, V.; Mironov, S.; Kaibyshev, R. Grain Structure Evolution in 6013 Aluminum Alloy during High Heat-Input Friction-Stir Welding. Materials 2023, 16, 5973. [Google Scholar] [CrossRef]

- Polmear, I.J.; Sargant, K.R. Enhanced age-hardening in aluminium-magnesium alloys. Nature 1963, 200, 669–670. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, H.; Zou, J.; Li, B.; Cui, J. Effects of pre-treatment combining with aging on the microstructures and mechanical properties of Al-Mg-Ag alloys. Mater. Sci. Eng. A 2019, 740–741, 82–91. [Google Scholar] [CrossRef]

- Poznak, A.; Freiberg, D.; Sanders, P. Chapter 10—Automotive Wrought Aluminium Alloys. In Fundamentals of Aluminium Metallurgy; Dans, R.N.L., Ed.; Woodhead Publishing: Cambridge, UK, 2018; pp. 333–386. [Google Scholar] [CrossRef]

- Mackenzie, J.K. Second paper on statistics associated with the random disorientation of cubes. Biometrika 1958, 45, 229–240. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. An experimental study of the recrystallization mechanism during hot deformation of aluminium. Mater. Sci. Eng. A 2000, 283, 274–288. [Google Scholar] [CrossRef]

- Song, W.; Wu, Z.; He, S.; Liu, J.; Yang, G.; Liu, Y.; Jin, H.; He, Y.; Heng, Z. Effects of Friction Stir Processing on the Microstructure and Mechanical Properties of an Ultralight Mg-Li Alloy. Crystals 2024, 14, 64. [Google Scholar] [CrossRef]

- Fonda, R.W.; Bingert, J.F.; Colligan, K.J. Development of grain structure during friction stir welding. Scr. Mater. 2004, 51, 243–248. [Google Scholar] [CrossRef]

- Jones, M.J.; Heurtier, P.; Desrayaud, C.; Montheillet, F.; Allehaux, D.; Driver, J.H. Correlation between microstructure and microhardness in a friction stir welded 2024 aluminium alloy. Scr. Mater. 2005, 52, 693–697. [Google Scholar] [CrossRef]

- Nourani, M.; Milani, A.S.; Yannacopoulos, S. On experimental optimization of friction stir welding of aluminum 6061: Understanding processing-microstructure-property relations. Int. J. Adv. Manuf. Technol. 2015, 79, 1425–1441. [Google Scholar] [CrossRef]

- Bin, W.; Bo-Bo, L.; Jia-Xiang, Z.; Quan, F.; Liang, W.; Deng, W. EBSD study on microstructure and texture of friction stir welded AA5052-O and AA6061-T6 dissimilar joint. Mater. Des. 2015, 87, 593–599. [Google Scholar]

- Xiea, G.M.; Cuia, H.B.; Luoa, Z.A.; Misrab, R.D.K.; Wang, G.D. Asymmetric distribution of microstructure and impact toughness in stir zone during friction stir processed a high strength pipeline steel. Mater. Sci. Eng. A 2017, 704, 401–404. [Google Scholar] [CrossRef]

- Kalinenko, A.; Dolzhenko, P.; Malopheyev, S.; Shishov, I.; Mishin, V.; Mironov, S.; Kaibyshev, R. Microstructural Evolution and Material Flow during Friction Stir Welding of 6013 Aluminum Alloy Studied by the Stop-Action Technique. Metals 2023, 13, 1342. [Google Scholar] [CrossRef]

- Lucas, G.E. The development of small specimen mechanical test techniques. J. Nucl. Mater. 1983, 117, 327–339. [Google Scholar] [CrossRef]

- Li, Y.; Guan, Y.; Liu, Y.; Zhai, J.; Hu, K.; Lin, J. Effect of processing parameters on the microstructure and tensile properties of a dualphase MgeLi alloy during friction stir processing. J. Mater. Res. Technol. 2022, 17, 2714–2724. [Google Scholar] [CrossRef]

| Al | Mg | Ti | Fe | Si | Zn | Mn | B | Cu |

| Bal. | 6.09 | 0.075 | 0.071 | 0.058 | 0.033 | 0.027 | 0.0012 | 0.0006 |

| UTS (MPa) | YS 0.2% | A% |

| 372.5 ± 0.22 | 307.5 ± 3.53 | 8.55 ± 0.1 |

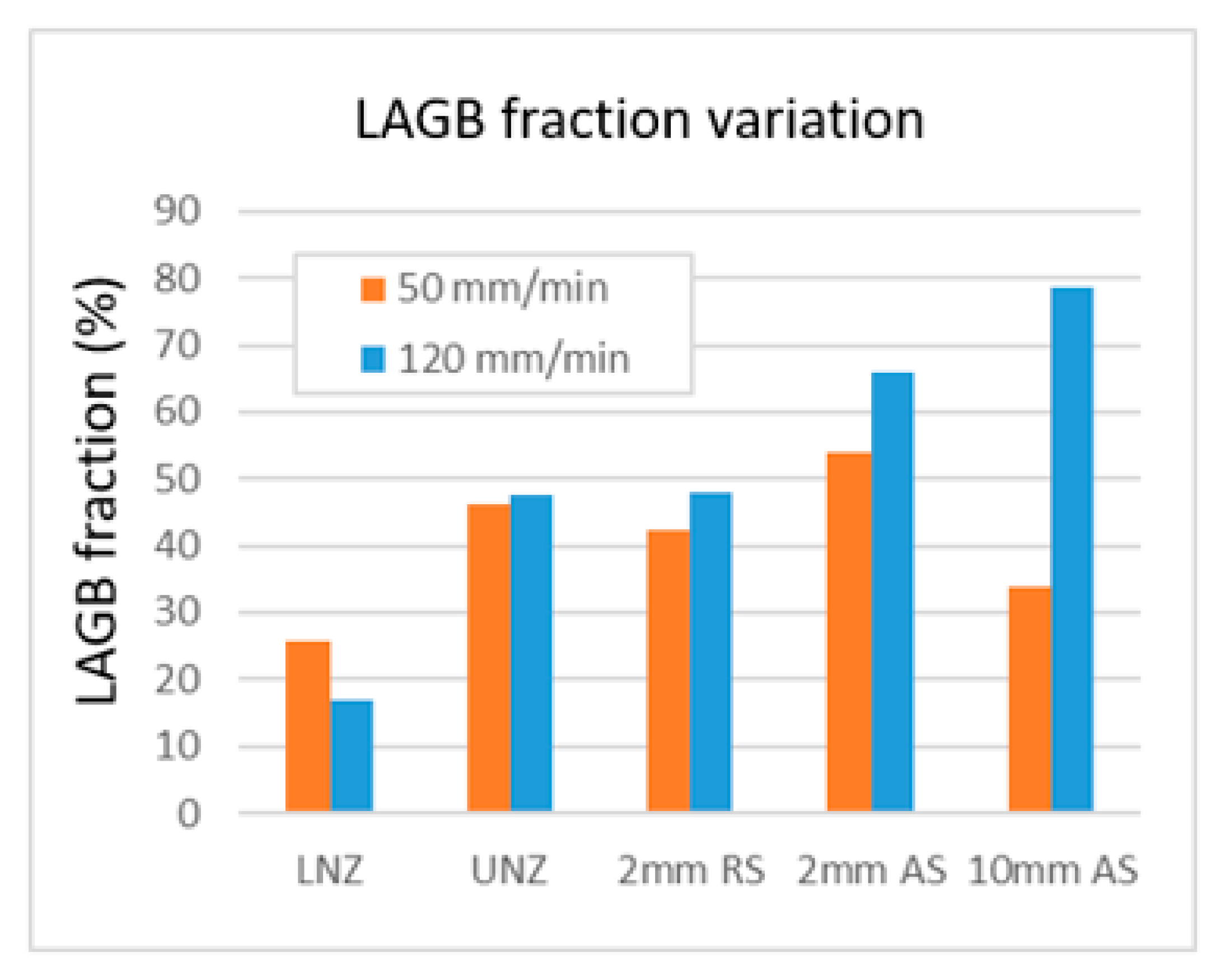

| Travel Speeds | Zones | LAGB Fraction (%) | Grain Size (μm) |

|---|---|---|---|

| 50 mm/min | UNZ | 46.3 | 8.9 |

| LNZ | 25.7 | 5.9 | |

| 120 mm/min | UNZ | 47.6 | 7.8 |

| LNZ | 16.8 | 4.1 |

| Travel Speed | Zone | LAGB Fraction (%) | Grain Size (μm) |

|---|---|---|---|

| 50 mm/min | TMAZ | 54 | 17.5 |

| 120 mm/min | TMAZ | 65.9 | 19.9 |

| Travel Speed | Zone | LAGB Fraction (%) | Grain Size (μm) |

|---|---|---|---|

| 50 mm/min | TMAZ | 42.2 | 11.8 |

| 120 mm/min | TMAZ | 48.1 | 11.8 |

| Travel Speed | Zone | LAGB Fraction (%) | Grain Size (μm) |

|---|---|---|---|

| 50 mm/min | HAZ | 33.7 | 16.6 |

| 120 mm/min | HAZ | 78.6 | 25.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chentouf, S.M.; Grandmont, P.; Saadati, M.; Amimer, N.; Jahazi, M. Influence of Friction-Stir-Processing Parameters on the Microstructure and Local Mechanical Properties of an Aluminium-6% Magnesium-H18 Alloy. Metals 2025, 15, 709. https://doi.org/10.3390/met15070709

Chentouf SM, Grandmont P, Saadati M, Amimer N, Jahazi M. Influence of Friction-Stir-Processing Parameters on the Microstructure and Local Mechanical Properties of an Aluminium-6% Magnesium-H18 Alloy. Metals. 2025; 15(7):709. https://doi.org/10.3390/met15070709

Chicago/Turabian StyleChentouf, Samir Mourad, Philippe Grandmont, Mohammad Saadati, Nora Amimer, and Mohammad Jahazi. 2025. "Influence of Friction-Stir-Processing Parameters on the Microstructure and Local Mechanical Properties of an Aluminium-6% Magnesium-H18 Alloy" Metals 15, no. 7: 709. https://doi.org/10.3390/met15070709

APA StyleChentouf, S. M., Grandmont, P., Saadati, M., Amimer, N., & Jahazi, M. (2025). Influence of Friction-Stir-Processing Parameters on the Microstructure and Local Mechanical Properties of an Aluminium-6% Magnesium-H18 Alloy. Metals, 15(7), 709. https://doi.org/10.3390/met15070709