Enhanced Mechanical Performance of SLM-Printed Inconel 718 Lattice Structures Through Heat Treatments

Abstract

1. Introduction

2. Materials and Methods

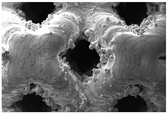

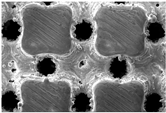

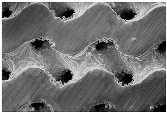

2.1. Lattice Design

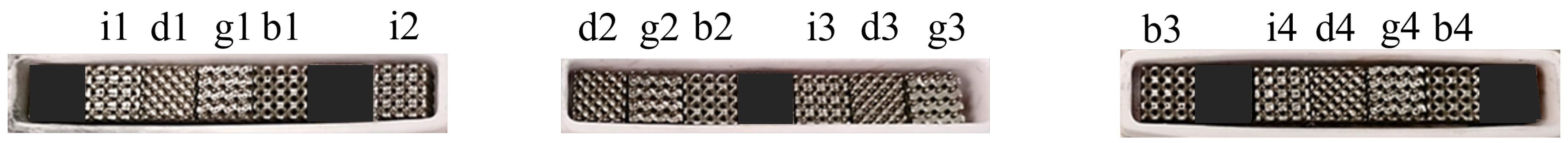

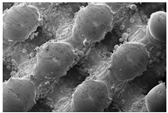

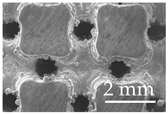

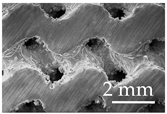

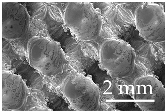

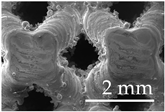

2.2. SLM IN718 Lattice Structures

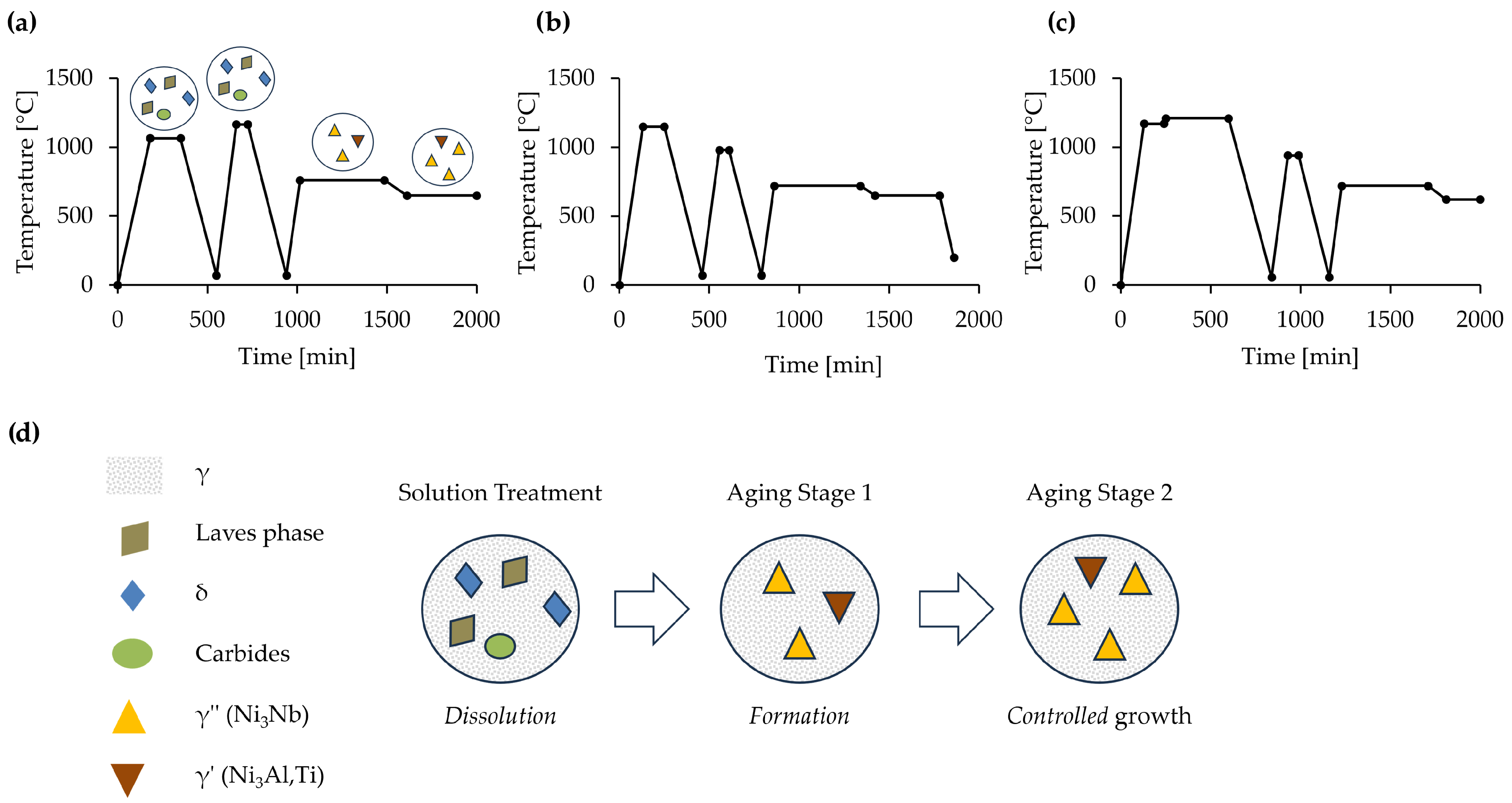

2.3. Heat Treatments

2.4. Mechanical Testing

2.5. X-Ray Diffraction (XRD) Analysis

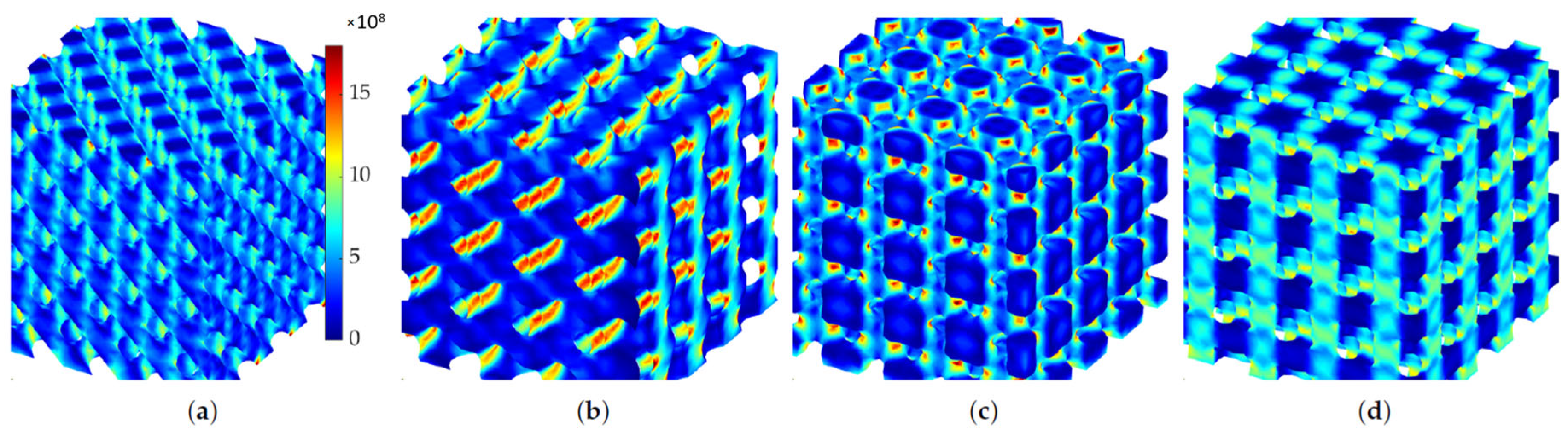

3. Numerical Simulation of 3D-Printed Lattice Structures Using the PDE Toolbox

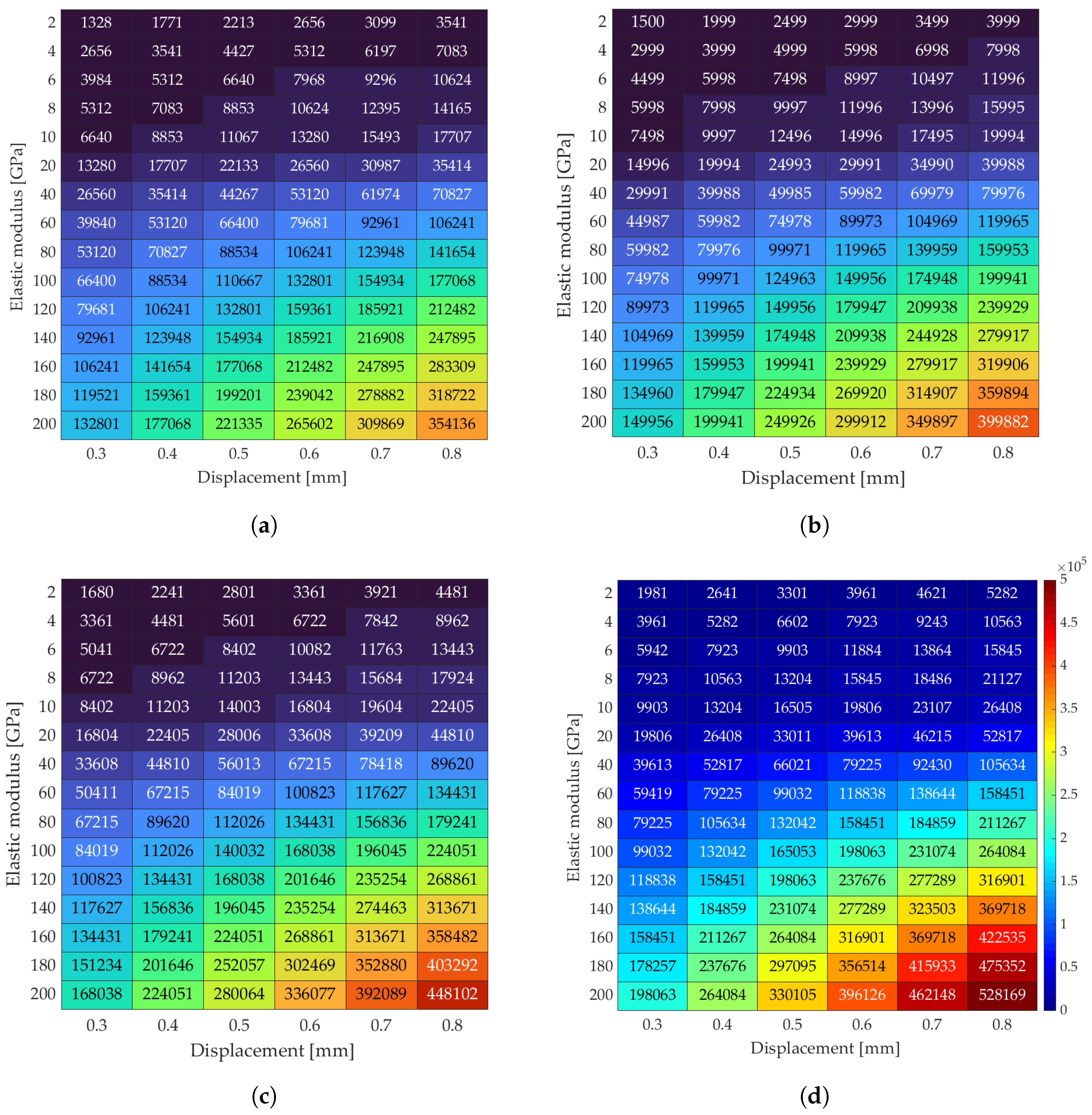

3.1. Estimation of Young’s Modulus

3.2. Simulation and Experimental Validation Results

4. Experimental Results for Heat Treatments and Microstructural Characterization

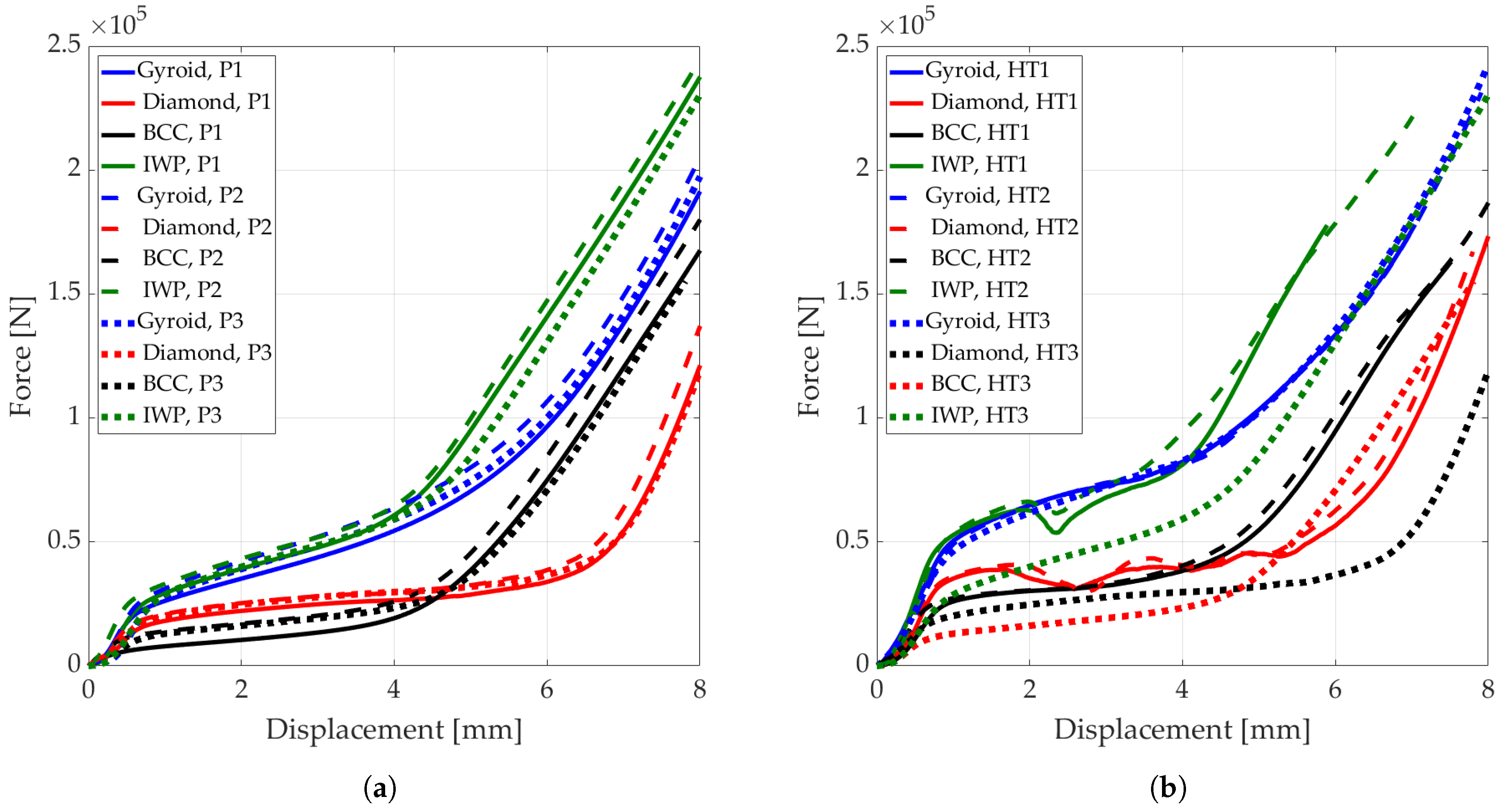

4.1. Compression Test

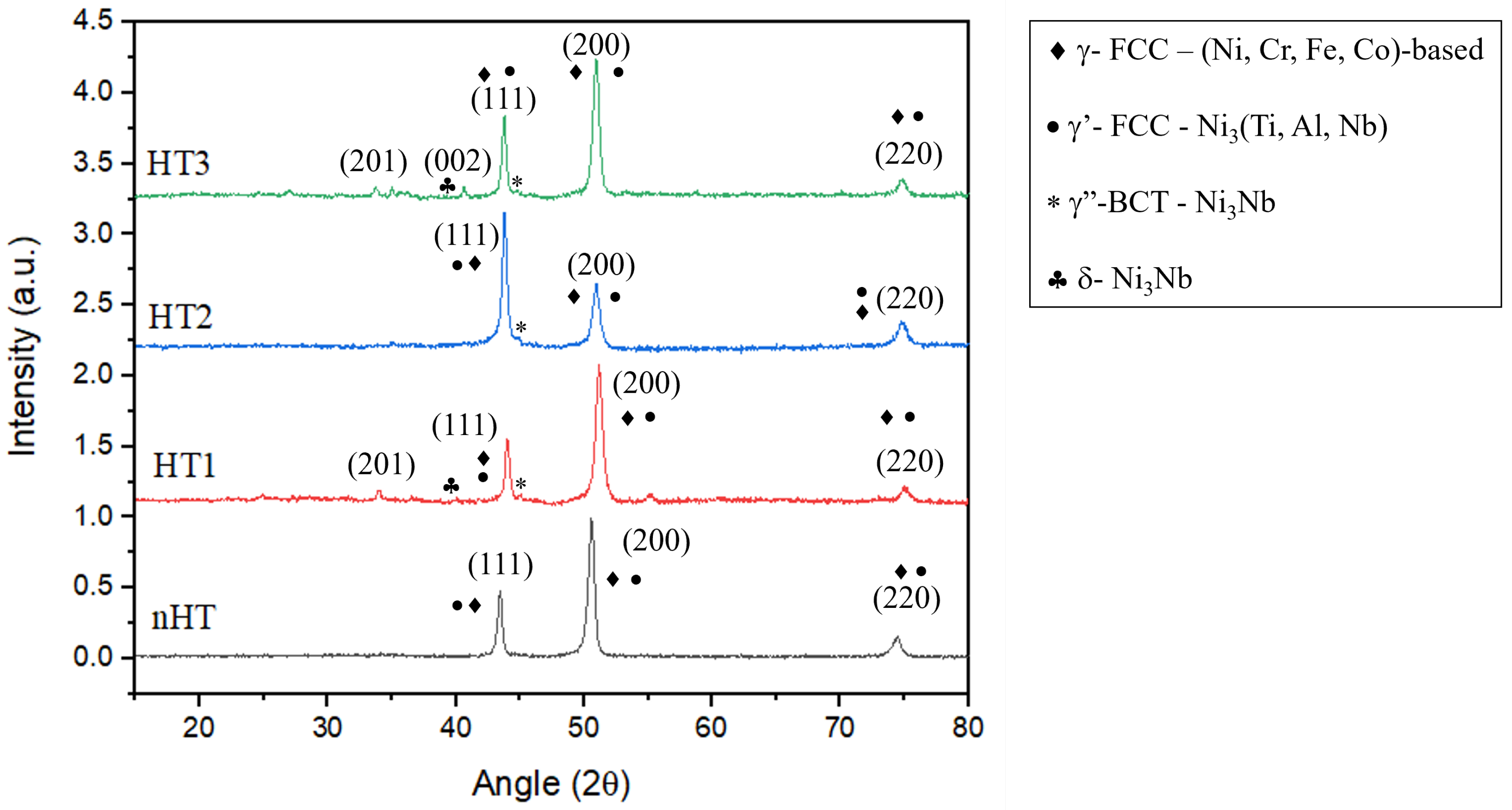

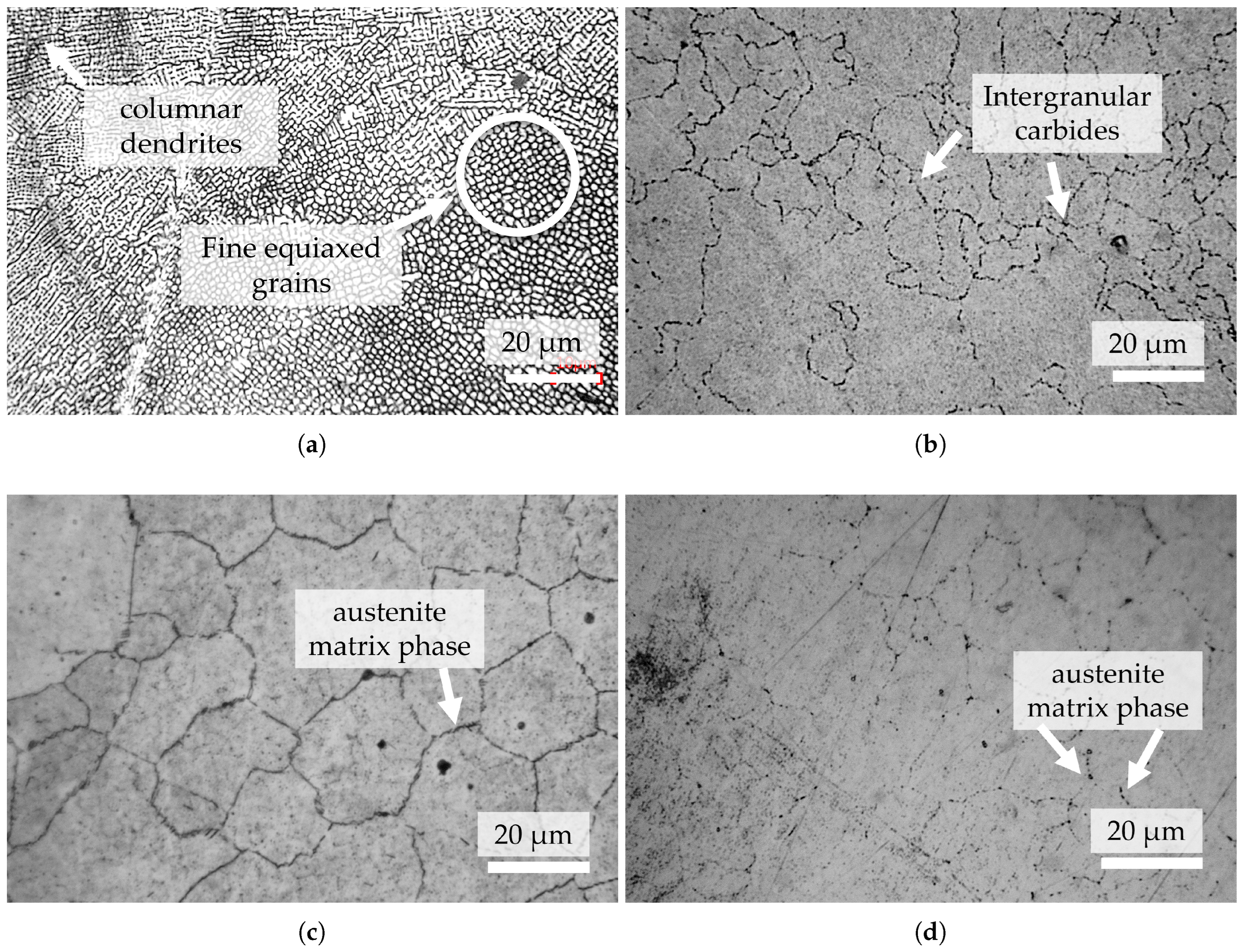

4.2. Microstructural Analysis

5. Conclusions

- Tailored heat treatments significantly enhanced mechanical performance, with the HT3 protocol increasing yield strength by approximately 25% and energy absorption capacity by 30% compared to HT1 and HT2. These improvements were attributed to a refined microstructure, characterized by uniform / phase distribution and the elimination of intergranular carbides.

- Lattice geometry and printing parameters directly influenced compressive behavior, with adjustments in laser power, scan speed, hatch spacing, and layer thickness resulting in variations of up to 20% in stiffness across different parameter sets. The parameter set 2 ( W, mm/s) demonstrated superior structural integrity, as evidenced by reduced porosity and improved powder fusion observed in SEM analyses.

- Numerical simulations accurately predicted the linear elastic response of the diamond, gyroid, and IWP geometries, showing deviations of less than 5% from experimental force–displacement curves for displacements up to 0.8 mm. For the BCC geometry, nonlinear effects emerged beyond 0.3 mm, leading to increased discrepancies between the simulation and experimental data.

- Microstructural analyses confirmed the critical role of heat treatment tuning, with HT2 and HT3 treatments reducing defect density by approximately 40% compared to untreated or sub-optimally treated samples, thereby enhancing mechanical reliability under compressive loading.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, C.; Hao, L.; Hussein, A.; Raymont, D. Evaluations of cellular lattice structures manufactured using selective laser melting. Int. J. Mach. Tools Manuf. 2012, 62, 32–38. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Sun, S.; Shidid, D.; Brandt, M. 5—Mechanical properties of Ti6Al4V and AlSi12Mg lattice structures manufactured by Selective Laser Melting (SLM). In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Cambridge, UK, 2017; pp. 119–161. [Google Scholar] [CrossRef]

- Feng, Q.; Tang, Q.; Liu, Z.; Liu, Y.; Setchi, R. An investigation of the mechanical properties of metallic lattice structures fabricated using selective laser melting. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2018, 232, 1719–1730. [Google Scholar] [CrossRef]

- Sing, S.L.; Wiria, F.E.; Yeong, W.Y. Selective laser melting of lattice structures: A statistical approach to manufacturability and mechanical behavior. Robot. Comput.-Integr. Manuf. 2018, 49, 170–180. [Google Scholar] [CrossRef]

- Yang, P.; Su, H.; Guo, Y.; Zhou, H.; Xia, L.; Shen, Z.; Wang, M.; Zhang, Z.; Guo, M. Influence of cooling rate during the heat treatment process on the precipitates and ductility behavior of inconel 718 superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2024, 902, 146603. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, L.; Lu, W.; Wei, D.; Meng, T.; Gao, S. Microstructure and elevated temperature mechanical properties of IN718 alloy fabricated by laser metal deposition. Mater. Sci. Eng. A 2020, 771, 138580. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, T.; Liu, L.; Li, Y.; Han, C.; Tan, H.; Zhou, W.; Yang, Y.; Wang, D. Thermomechanical Behavior and Experimental Study of Additive Manufactured Superalloy/Titanium Alloy Horizontal Multi-Material Structures. Metals 2025, 15, 454. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Lancea, C.; Kruk, A.; Cempura, G.; Gruszczyński, A.; Chicos, L.A.; Pop, M.A. Mechanical Properties and Microstructure of Inconel 718 Lattice Structures Produced by Selective Laser Melting Process. Materials 2024, 17, 622. [Google Scholar] [CrossRef]

- Banait, S.; Jin, X.; Campos, M.; Pérez-Prado, M. Precipitation-induced transition in the mechanical behavior of 3D printed Inconel 718 bcc lattices. Scr. Mater. 2021, 203, 114075. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Zhou, X.; Wang, D.; Zhang, M.; Gao, Y.; Wang, L.; Zhang, P. Evaluating Lattice Mechanical Properties for Lightweight Heat-Resistant Load-Bearing Structure Design. Materials 2020, 13, 4786. [Google Scholar] [CrossRef]

- Thuneman, T.; Raja, K.S.; Charit, I. Room Temperature Corrosion Behavior of Selective Laser Melting (SLM)-Processed Ni-Fe Superalloy (Inconel 718) in 3.5% NaCl Solution at Different pH Conditions: Role of Microstructures. Crystals 2024, 14, 89. [Google Scholar] [CrossRef]

- Bai, L.; Gong, C.; Chen, X.; Sun, Y.; Xin, L.; Pu, H.; Peng, Y.; Luo, J. Mechanical properties and energy absorption capabilities of functionally graded lattice structures: Experiments and simulations. Int. J. Mech. Sci. 2020, 182, 105735. [Google Scholar] [CrossRef]

- Ozdemir, Z.; Hernandez-Nava, E.; Tyas, A.; Warren, J.A.; Fay, S.D.; Goodall, R.; Todd, I.; Askes, H. Energy absorption in lattice structures in dynamics: Experiments. Int. J. Impact Eng. 2016, 89, 49–61. [Google Scholar] [CrossRef]

- Choi, K.H.; Shin, G.Y.; Lee, K.Y.; Shim, D.S. Directed Energy Deposition on Structurally Low-density Substrate and its Effects on Microstructural and Interfacial Bonding Characteristics. Int. J. Precis. Eng.-Manuf.-Green Technol. 2024. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Xiao, Z.; Song, C.; Weng, C. Effect of heat treatment on the microstructure and mechanical properties of Ti6Al4V gradient structures manufactured by selective laser melting. Mater. Sci. Eng. A 2018, 736, 288–297. [Google Scholar] [CrossRef]

- Li, D.; Qin, R.; Xu, J.; Chen, B.; Niu, X. Effect of heat treatment on AlSi10Mg lattice structure manufactured by selective laser melting: Microstructure evolution and compression properties. Mater. Charact. 2022, 187, 111882. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Z.; Lu, W.; Meng, F.; Zhao, T. Heat treatment for selective laser melting of Inconel 718 alloy with simultaneously enhanced tensile strength and fatigue properties. J. Alloys Compd. 2022, 913, 165171. [Google Scholar] [CrossRef]

- Huang, L.; Cao, Y.; Zhang, J.; Gao, X.; Li, G.; Wang, Y. Effect of heat treatment on the microstructure evolution and mechanical behaviour of a selective laser melted Inconel 718 alloy. J. Alloys Compd. 2021, 865, 158613. [Google Scholar] [CrossRef]

- Schneider, J.; Lund, B.; Fullen, M. Effect of heat treatment variations on the mechanical properties of Inconel 718 selective laser melted specimens. Addit. Manuf. 2018, 21, 248–254. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, S.; Liu, H.; Liang, Y.; Yi, F.; Lin, J. Microstructure evolution and mechanical properties of additively manufactured Ni-based GH4099 superalloy via hot isostatic pressing and heat treatment. Mater. Sci. Eng. A 2024, 903, 146696. [Google Scholar] [CrossRef]

- Ma, K.; Wang, J. Microstructural Characteristics and Mechanical Properties of an Additively Manufactured Nickel-Based Superalloy. Crystals 2022, 12, 1358. [Google Scholar] [CrossRef]

- Yu, S.; Sun, J.; Bai, J. Investigation of functionally graded TPMS structures fabricated by additive manufacturing. Mater. Des. 2019, 182, 108021. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Baskaran, J.; Muthukannan, D.; Shukla, R.; Konda Gokuldoss, P. Manufacturability and deformation studies on a novel metallic lattice structure fabricated by Selective Laser Melting. Vacuum 2024, 222, 113065. [Google Scholar] [CrossRef]

- Estrada-Díaz, J.A.; Elías-Zúñiga, A.; Martínez-Romero, O.; Olvera-Trejo, D. Enhanced Mathematical Model for Producing Highly Dense Metallic Components through Selective Laser Melting. Materials 2021, 14, 1571. [Google Scholar] [CrossRef]

- Estrada-Díaz, J.A.; Elías-Zúñiga, A.; Martínez-Romero, O.; Palacios-Pineda, L.M.; Guzmán-Nogales, R.; Cedeño-Viveros, L.D.; Olvera-Trejo, D. A novel mathematical model for predicting a sustainable selective laser melting and controlled densification. Int. J. Sustain. Eng. 2024, 17, 239–249. [Google Scholar] [CrossRef]

- Rosete, D.X. Validation of the Process Parameter for Enhancing Densification and Thermal Conductivity of the IN718 superalloy manufactured by Selective Laser Melting. Master’s Thesis, Tecnologico de Monterrey, Monterrey, Mexico, 2022. [Google Scholar]

- Estrada-Díaz, J.A.; Elías-Zúñiga, A.; Martínez-Romero, O.; Rodríguez-Salinas, J.; Olvera-Trejo, D. A Mathematical Dimensional Model for Predicting Bulk Density of Inconel 718 Parts Produced by Selective Laser Melting. Materials 2021, 14, 512. [Google Scholar] [CrossRef]

- Ghiaasiaan, R.; Poudel, A.; Ahmad, N.; Muhammad, M.; Gradl, P.R.; Shao, S.; Shamsaei, N. Room Temperature Mechanical Properties of Additively Manufactured Ni-base Superalloys: A Comparative Study. Procedia Struct. Integr. 2022, 38, 109–115. [Google Scholar] [CrossRef]

- ISO 13314; Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals. International Organization for Standardization (ISO): Geneva, Switzerland, 2011.

- Song, J.; Zhang, L.; Wu, W.; He, B.; Ni, X.; Xu, J.; Zhu, G.; Yang, Q.; Wang, T.; Lu, L. Understanding processing parameters affecting residual stress in selective laser melting of Inconel 718 through numerical modeling. J. Mater. Res. 2019, 34, 1395–1404. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Estrada-Diaz, J.A.; Martinez-Romero, O.; Olvera-Trejo, D.; Elias-Zuniga, A. Elucidating the Fractal Nature of Powder Bed in Selective Laser Melting of Metallic Components. Fractals 2022, 30. [Google Scholar] [CrossRef]

- Majari, P.; Olvera-Trejo, D.; Estrada-Díaz, J.A.; Elías-Zúñiga, A.; Martinez-Romero, O.; Ramírez-Herrera, C.A.; Perales-Martínez, I.A. Enhanced Lightweight Structures Through Brachistochrone-Inspired Lattice Design. Polymers 2025, 17, 654. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, Y.; Li, Z.; Davies, C.; Maharaj, C.; Dear, J.; Hooper, P. Acoustic resonance testing of additive manufactured lattice structures. Addit. Manuf. 2018, 24, 566–576. [Google Scholar] [CrossRef]

- Mahshid, R.; Hansen, H.N.; Højbjerre, K.L. Strength analysis and modeling of cellular lattice structures manufactured using selective laser melting for tooling applications. Mater. Des. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2016, 84, 1391–1411. [Google Scholar] [CrossRef]

- Ghorbanpour, S.; Deshmukh, K.; Sahu, S.; Riemslag, T.; Reinton, E.; Borisov, E.; Popovich, A.; Bertolo, V.; Jiang, Q.; Sanchez, M.; et al. Additive manufacturing of functionally graded inconel 718: Effect of heat treatment and building orientation on microstructure and fatigue behaviour. J. Mater. Process. Technol. 2022, 306, 117573. [Google Scholar] [CrossRef]

- Xu, K.; Cao, J.; Zheng, Z.; Zhao, R.; Xu, G.; Wang, H.; Wang, J.; Hur, B.; Yue, X. Deformation Behavior of Inconel 625 Alloy with TPMS Structure. Materials 2025, 18, 396. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.; Aremu, A.; Tuck, C.; Ashcroft, I. Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 2017, 16, 24–29. [Google Scholar] [CrossRef]

- Cheloni, J.P.M.; Zluhan, B.; Silveira, M.E.; Fonseca, E.B.; Valim, D.B.; Lopes, E.S. Mechanical behavior and failure mode of body-centered cubic, gyroid, diamond, and Voronoi functionally graded additively manufactured biomedical lattice structures. J. Mech. Behav. Biomed. Mater. 2025, 163, 106796. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, X.; Xu, Y.; Shi, Y. Friction Performance Analysis of WC-Reinforced IN718 Composite Material Based on SLM Process. Metals 2024, 14, 1361. [Google Scholar] [CrossRef]

- Başcı, Ü.G.; Avcu, E.; Kıraç, M.; Sever, A.; Gökalp, İ.; Yavuz, H.İ.; Oktay, S.; Abakay, E.; Yıldıran Avcu, Y.; Yamanoğlu, R. Microstructural, Mechanical, and Tribological Properties of Selective Laser Melted Inconel 718 Alloy: The Influences of Heat Treatment. Crystals 2025, 15, 18. [Google Scholar] [CrossRef]

- Liu, X.; Wang, T.; Li, N.; Wei, L.; Jiang, S. Effects of heat treatments on the microstructure and mechanical properties of Inconel 718 alloy fabricated by electron beam freeform fabrication. Mater. Sci. Eng. A 2024, 908, 146800. [Google Scholar] [CrossRef]

| Lattice | Equation | V [mm3] | A [mm2] | V/A [mm] |

|---|---|---|---|---|

| Diamond | 872 | 2644 | 0.33 | |

| Gyroid | 872 | 2213 | 0.39 | |

| BCC | 821 | 2364 | 0.35 | |

| IWP | 923 | 2595 | 0.35 | |

| Cube | 1728 | 864 | 2.00 |

| Parameter 1 | Parameter 2 | Parameter 3 | |

|---|---|---|---|

| Laser power, (P) [W] | 300 | 300 | 200 |

| Scan speed, (v) [mm/s] | 900 | 1000 | 525 |

| Hatch spacing, (h) [mm] | 0.12 | 0.12 | 0.12 |

| Energy density, (E) [J/mm3] | 46.3 | 41.7 | 52.9 |

| Heat Treatment | Lattice Structure | Yield Strength (MPa) | Energy Absorption (MJ/m³) |

|---|---|---|---|

| HT1 | BCC | 550 | 30 |

| HT2 | Diamond | 600 | 35 |

| HT3 | IWP | 650 | 40 |

| HT2 | Gyroid | 700 | 45 |

| Parameter | I-WP | Gyroid | Diamond | BCC |

|---|---|---|---|---|

| P = 300 W, v = 900 mm/s |  |  |  |  |

| P = 300 W, v = 1000 mm/s |  |  |  |  |

| P = 200 W, v = 525 mm/s |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briones-Montemayor, M.J.; Guzmán-Nogales, R.; Majari, P.; Estrada-Díaz, J.A.; Elías-Zúñiga, A.; Olvera-Trejo, D.; Martínez-Romero, O.; Perales-Martínez, I.A. Enhanced Mechanical Performance of SLM-Printed Inconel 718 Lattice Structures Through Heat Treatments. Metals 2025, 15, 686. https://doi.org/10.3390/met15070686

Briones-Montemayor MJ, Guzmán-Nogales R, Majari P, Estrada-Díaz JA, Elías-Zúñiga A, Olvera-Trejo D, Martínez-Romero O, Perales-Martínez IA. Enhanced Mechanical Performance of SLM-Printed Inconel 718 Lattice Structures Through Heat Treatments. Metals. 2025; 15(7):686. https://doi.org/10.3390/met15070686

Chicago/Turabian StyleBriones-Montemayor, María J., Rigoberto Guzmán-Nogales, Parisa Majari, Jorge A. Estrada-Díaz, Alex Elías-Zúñiga, Daniel Olvera-Trejo, Oscar Martínez-Romero, and Imperio A. Perales-Martínez. 2025. "Enhanced Mechanical Performance of SLM-Printed Inconel 718 Lattice Structures Through Heat Treatments" Metals 15, no. 7: 686. https://doi.org/10.3390/met15070686

APA StyleBriones-Montemayor, M. J., Guzmán-Nogales, R., Majari, P., Estrada-Díaz, J. A., Elías-Zúñiga, A., Olvera-Trejo, D., Martínez-Romero, O., & Perales-Martínez, I. A. (2025). Enhanced Mechanical Performance of SLM-Printed Inconel 718 Lattice Structures Through Heat Treatments. Metals, 15(7), 686. https://doi.org/10.3390/met15070686