Abstract

This article studies the effects of a laser remelting treatment on the microstructure and properties of Al-Cu-Mn alloy surfaces, as well as the effects of a heat treatment process on the microstructure and mechanical properties of the matrix zone and remelting zone. The results showed that the remelting zone structure was mainly composed of equiaxed dendrites and fine columnar dendrites. The α(Al) phase and θ(Al2Cu) phase were greatly refined after laser remelting. The T(Al12CuMn2) phase was completely dissolved into the α(Al) matrix. The hardness of the remelting zone increased significantly with an increase in the height of the molten pool, and the strengthening mechanism was mainly fine grain strengthening and second phase strengthening. For identical aging treatments, the solution treatment at 530 °C for 4 h yielded the highest hardness. Relative to samples aged without prior solution treatment, hardness increased by 80% in the matrix zone and 59.1% in the remelting zone. When the solid solution process was the same, the time to reach peak hardness was shortened when the aging temperature increased, and the hardness of both the matrix zone and remelting zone reached its peak at 175 °C for 8 h of aging. After aging, the friction coefficient of the alloy decreased due to the increase in the strength of the alloy.

1. Introduction

Al-Cu-Mn series aluminum alloys are widely used in the aerospace, weapon and automotive fields due to their high strength, excellent high-temperature performance, strong weldability, low density, good processing performance and low price [1,2,3]. With the deepening of research on aluminum alloys, their microstructure and properties have been further improved [4,5,6]. At different cooling rates, the size and morphology of the solid microstructure of Al-Cu-Mn alloys have a great influence on their mechanical properties [7,8,9]. In the process of direct cooling casting, the cooling rate in different regions of the ingot is not uniform, resulting in serious interdendritic segregation and coarse intermetallic compounds, as well as segregation, shrinkage, porosity, especially hot cracking, and other defects, which also have serious effects on the machinability of the alloy and its subsequent serviceability [10,11,12,13].

The Al-Cu-Mn system alloy is a heat-treatable, reinforced, high-strength aluminum alloy formed by adding Mn, Ti and other elements to an Al-Cu alloy [14,15,16,17]. The heat treatment processes of Al-Cu-Mn alloys include solution treatment, aging treatment and thermomechanical treatment [18,19,20,21]. Al-Cu-Mn series aluminum alloys are generally composed of α(Al), θ(Al2Cu), T(Al12CuMn2), Al3Ti and other precipitated phases [22,23,24]. When the alloy is solid solution-treated, Cu, Ti, Mn and other solute elements are uniformly generated and a supersaturated solid solution is obtained. While the primary T-phase in the alloy does not undergo phase transformation, most of the θ(Al2Cu) phase is dissolved into the matrix, and a large number of fine secondary T-phase particles in the matrix are diffusely precipitated to strengthen the alloy [25,26,27].

After solution treatment and aging, the strength of the Al-Cu-Mn system increases due to the high-density metastable θ′ and a large amount of precipitated T(Al20Cu2Mn3)-phase particles [28,29,30,31]. When the degree of solid solution is low, the reinforcing phase in the alloy cannot be fully solid solved, resulting in the lower precipitation of the secondary T-phase. The diffuse precipitation phase is also relatively reduced after aging treatment, and the change in alloy strength is negligible. When the solid solution temperature is excessively high, the alloy is prone to overburning, leading to a significant deterioration in alloy performance. Therefore, the selection of reasonable solution process parameters plays an important role in the subsequent strengthening of alloys [32,33,34]. FrancZupanič et al. [35] added beryllium, scandium and zirconium microalloying elements to Al-Mn-Cu alloys and carried out a compression test and accelerated creep test on samples aged at 400 °C, 300 °C and 350 °C, respectively, for 1 h at room temperature. The results show that the new alloys had better hardness, strength and creep resistance than the original Al-Mn-Cu alloy. Prabhu et al. [36] demonstrated the effect of aging time on the conductivity and mechanical properties of AlCu alloy round rods with different diameters. The results showed that the precipitates gradually coarsened with the extension of aging time, but no segregation of precipitates was found in the microstructure under any combination of rod diameter and aging time.

Laser remelting is a surface modification technology that uses a high-energy laser beam to scan the surface of the alloy to be treated [37]. The surface area of the material melts rapidly and cools rapidly, so that a melting layer with a certain thickness is formed on the surface of the alloy. The surface microstructure of the alloy after laser remelting is refined and segregation is reduced. Laser remelting reduces defects, refines structure and can increase the strength of the alloy surface and improve its friction and wear properties. Therefore, laser remelting is often applied to the surface strengthening of cast alloys such as aluminum alloys and magnesium alloys [38]. Liu et al. [39] studied the effects of laser remelting on the microstructure, mechanical properties and wear resistance of AlCoCrFeNi coatings. Their results showed that the remelted AlCoCrFeNi coating retained the same single BCC solid solution structure as a sprayed AlCoCrFeNi coating. Laser remelting basically eliminated the defects in the coating, reduced the porosity of the coating from 4.8% to 0.3%, increased the hardness, fracture toughness and elastic modulus of the coating by 38%, and reduced the wear loss of the remelted AlCoCrFeNi coating to only 22% of that of the sprayed coating. J. Karimi et al. [40] studied the effects of laser remelting on the surface morphology, mechanical properties and sliding wear of alloys. Studies [41,42,43,44,45] compared the effects of laser remelting and heat treatment on the anisotropy of mechanical and tribological properties. Surface quality and high circumferential fatigue strength increased with the number of melting steps. Moreover, compressive and impact strength also increased during multiple melting steps.

In summary, considering China’s rapid development in various fields, a single performance alloy gradually fails to meet the demand for materials in the field of technology, and thus, the hardness, wear resistance and other performance requirements of Al-Cu-Mn alloys must be improved [46,47]. Laser remelting technology can make the matrix alloy rapidly melt and rapidly cool so as to induce alloy microstructure refinement, a strength increase, and a wear-resistant performance increase. Heat treatment can further improve the mechanical and other properties of the alloy by adjusting second phase precipitation. It is of great significance for the application and development of Al-Cu-Mn alloys to prepare laser remelting for the casting of Al-Cu-Mn alloys and study the effect of heat treatment on their microstructure and properties.

In this paper, laser remelting is carried out on the surface of a cast Al-Cu-Mn alloy by means of a fiber-coupled semiconductor laser, and the Al-Cu-Mn alloy after laser remelting is heat-treated by solid solution aging with different processes in order to achieve the purpose of improving alloy strength as well as wear resistance. In this paper, an in-depth study on Al-Cu-Mn alloys after laser remelting is carried out, and the specific research content includes the following aspects:

(1) Laser remelting experiments were carried out on the surface of a cast Al-Cu-Mn alloy to study the effects of laser remelting on the microstructure and properties of the melt pool and to analyze the rapid dissolution and condensation behavior of the Al-Cu-Mn alloy under a laser.

(2) The laser-remelted Al-Cu-Mn alloy was subjected to a solid solution aging heat treatment with different process parameters, and the microstructure and mechanical properties of the laser-remelted Al-Cu-Mn alloy and casting area were compared under different heat treatment processes so as to determine the optimal heat treatment process for the laser-remelted Al-Cu-Mn alloy.

2. Models and Experiments

2.1. Alloy Preparation

The main chemical composition (mass fraction, wt%) of the Al-Cu-Mn alloy used in this experiment is shown in Table 1. Intermediate alloys such as 99.7% industrial pure Al, Al-50Cu, Al-10Mn and Al-Zr were melted in a graphite crucible at a certain ratio. After heating the alloy to 740 °C to fully melt the alloy, the appropriate amount of hexachloroethane was added into the alloy and then stirred thoroughly to eliminate the residual gas and impurities in the alloy. After impurity removal, the alloy was left for 10~15 min. When the alloy temperature was 720 °C it was poured into a preheated casting mold, attempting to make its speed even when pouring. The molding was cooled down at room temperature after pouring.

Table 1.

Chemical composition of Al-Cu-Mn alloy (wt%).

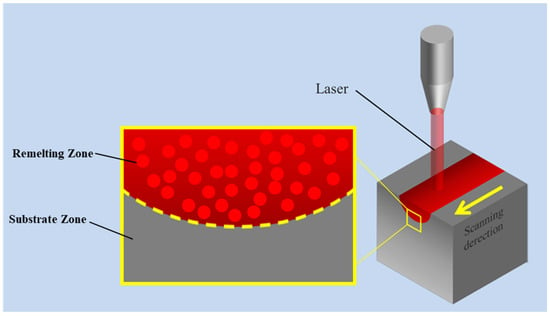

Alloy specimens with dimensions of 50 mm × 10 mm × 10 mm were cut from the casting plate using EDM wire cutting. A model LDF4000-100 fiber-coupled semiconductor laser (Laserline, Mülheim-Kärlich, Germany) with a circular spot size of 4 mm in diameter was used for surface laser remelting on the sample with a scanning speed of 10 mm/s and a laser power of 1100 W. The protective gas was argon. Figure 1 shows the schematic diagram of the laser remelting of the Al-Cu-Mn alloy.

Figure 1.

Schematic diagram of laser remelting Al-Cu-Mn alloy.

2.2. Heat Treatment Process

The heat treatment process optimization test of the Al-Cu-Mn alloy after laser remelting was carried out by a solid solution aging heat treatment process. The plan was the following:

(1) To analyze the effect of solid solution temperature on the microstructure and mechanical properties of laser remelting cast Al-Cu-Mn alloys, 530 °C, 540 °C and 550 °C were selected as solid solution temperatures (the heat treatment furnace was heated to the solution temperature at a rate of 20 °C/min), and the solid solution time was 4 h. The laser remelting-cast Al-Cu-Mn alloy samples were solutioned, and an artificial aging treatment at 175 °C × 8 h was used after water quenching.

(2) To analyze the effect of solid solution time on the microstructure and mechanical properties of a laser remelting-cast Al-Cu-Mn alloy, the optimal solid solution temperature was determined from the experiment to be 530 °C. Then, 4 h, 8 h and 12 h were selected as the solid solution times for the laser remelting-cast Al-Cu-Mn alloy specimens, and water quenching was followed by an artificial aging treatment of 175 °C × 8 h.

(3) To analyze the effect of aging temperature and time on the microstructure and mechanical properties of a laser remelting-cast Al-Cu-Mn alloy, the best solid solution process was determined as 4 h at 530 °C. After the solid solution and water quenching of the laser remelting-cast Al-Cu-Mn alloy specimens with the best solid solution process parameters, 165 °C, 175 °C and 185 °C were selected as the aging temperatures, and 2 h, 4 h, 6 h, 8 h, 10 h and 12 h as the aging times for the specimens to undergo artificial aging treatment. The experimental protocol is shown in Table 2.

Table 2.

Aging heat treatment process parameters.

2.3. Microstructure Characterization and Mechanical Testing

The 10 mm × 10 mm sample section taken by wire cutting was polished with 400#, 800#, 1500#, 2000#, 3000# and 5000# water sandpaper, and then was polished with 1.5# and 0.5# polishing solutions, ultrasonically cleaned and finally corroded with Keller’s reagent for 5 s. An optical microscope (Axiovert200MAT, Carl Zeiss AG, Oberkochen, Germany) was used to observe and compare the metallographic structure of the specimens, the changes in grain size and the distribution of the reinforced phases before and after remelting. The microstructure of the specimens was observed using a JSM-7900F thermal field emission scanning electron microscope (SEM) (JEOL, Tokyo, Japan). Energy dispersive X-ray spectroscopy (EDS) was also used to determine the elemental distribution by surface scanning and line scanning, as well as to analyze specific precipitated phases and tissues for specified point elements. Phase analysis was carried out using X-ray diffraction (XRD). X-ray diffraction spectroscopy (XRD) was used to analyze the phase composition of the alloys before and after the laser remelting, as well as to analyze the occurrence of phase transformations and to calibrate the phases using JADE 6.5 software. The hardness of the laser-remelted Al-Cu-Mn alloy was measured using a JMHVS-1000AT microhardness tester (Shanghai Aolong Xingdi Testing Equipment Co., Ltd., Shanghai, China). Ten points were randomly measured on the surface of the remelted area of the alloy. The diagonal lengths of the craters were measured, and the hardness values of the alloys were calculated using the hardness calculation formula and the average value was taken. The surface of the alloy sample needs to be polished before testing. A load of 10N was selected and the holding time was 15 s. An HSR-2M type friction and wear machine (Lanzhou Zhongke Kaihua Technology Development Co., Ltd., Lanzhou, China) was used to carry out friction and wear experiments on the specimen after laser remelting at room temperature. The loading load was 10 N, the wear time was 20 min, the frequency was 2 Hz, the friction distance was 5 mm, and the friction vise selected was a GCr15 bearing steel with a diameter of 4 mm and a hardness of 65HRC.

3. Results and Discussion

3.1. Study on Microstructure and Properties of Laser-Remelted Al-Cu-Mn Alloy

3.1.1. Microstructure and Phase Composition

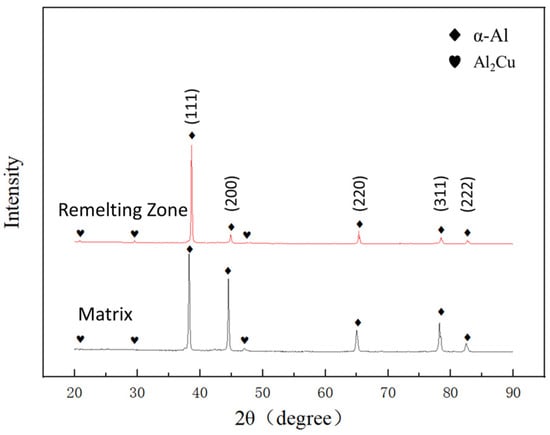

The surface of the Al-Cu-Mn alloy was laser remelted by single-channel scanning. The laser power was 1100W and the scanning speed was 10 mm/s. Figure 2 shows the XRD pattern of the surface and matrix of the Al-Cu-Mn alloy sample after remelting. As shown in this Figure, an α-Al phase and Al2Cu phase can be detected in the samples after laser remelting. By comparing the diffraction peaks of the α-Al phase in the samples before and after remelting, it can be found that the strength of the {111} crystal plane family of the α-Al phase increases significantly after remelting, while the strength of the {200}, {220}, {311} and {222} crystal plane families of the α-Al phase decreases significantly.

Figure 2.

XRD pattern of remelting zone and matrix of Al-Cu-Mn alloy cast by laser remelting.

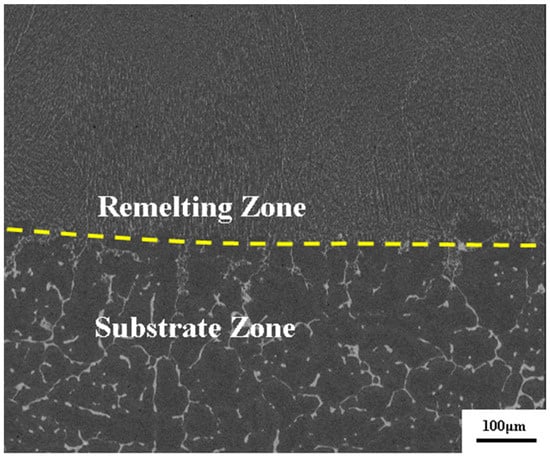

Figure 3 shows the cross section microstructure of the laser remelting Al-Cu-Mn alloy. After laser remelting, Al-Cu-Mn alloy can be clearly divided into three parts: the top is the laser remelting zone, the middle is the heat-affected zone and the bottom is the original casting. It can be seen that the microstructure difference between the matrix and the remelting zone is obvious. Different from the typical as-cast microstructure of Al-Cu-Mn alloy samples, which is composed of coarse grains, the microstructure of the laser-remelted Al-Cu-Mn alloy’s remelting zone is mainly composed of equiaxed dendrites and fine columnar dendrites.

Figure 3.

BSE image of as-cast Al-Cu-Mn alloy by laser remelting.

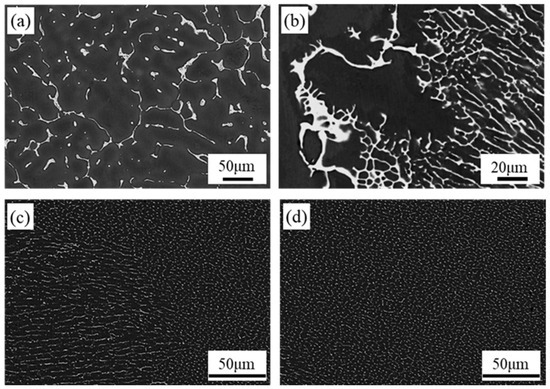

Figure 4 shows the microstructure images of the laser-remelted as-cast Al-Cu-Mn alloy in different regions. Figure 4b,c show that the microstructure at the bottom of the laser-remelted Al-Cu-Mn alloy’s molten pool is a small columnar dendrite with a relatively uniform growth direction. This is due to the fact that the bottom of the molten pool is close to the substrate. The rapid heat dissipation produces a large degree of supercooling, which increases the nucleation rate. The laser-remelted microstructure cools faster, its heat dissipation direction is relatively stable and the grain growth time is short; therefore, a small and uniform grain growth direction is formed.

Figure 4.

BSE images of different areas of Al-Cu-Mn alloy cast by laser remelting: (a) cast Al-Cu-Mn alloy, (b) heat-affected zone (interface between laser remelting and matrix), (c) bottom of molten pool, and (d) top of molten pool.

Figure 4a shows the microstructure of the cast Al-Cu-Mn alloy. It can be seen that the grains of the cast Al-Cu-Mn alloy are relatively coarse, and the second phase is precipitated along the interdendritic region in a continuous network form. This is due to the relatively low heat input of the cast Al-Cu-Mn alloy structure, which makes it difficult to generate a supersaturated solid solution. Additionally, the atoms at the grain boundary are loosely arranged and disordered, and the second phase is easy to precipitate in the interdendritic region. Comparing Figure 4a,d, it can be seen that compared with the as-cast Al-Cu-Mn alloy structure, the microstructure after laser remelting has the distribution of the second phase between the interdendritic and dendritic stem. Also, the farther away from the matrix region, the less the second phase exists between the dendrites, and the second phase structure is intermittently distributed.

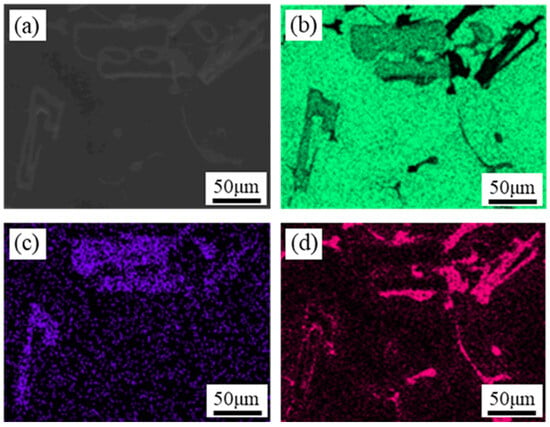

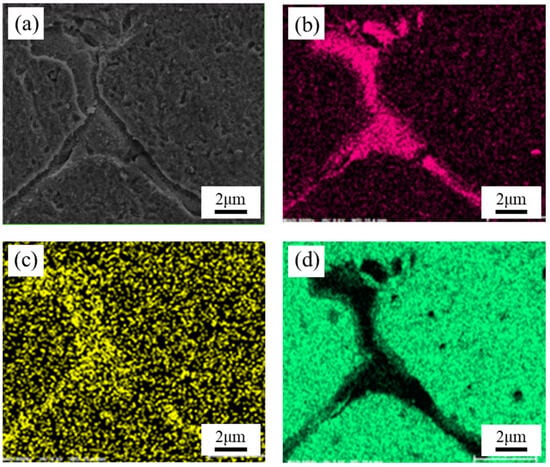

In the as-cast Al-Cu-Mn alloy, the distribution position and brightness of the Al, Cu and Mn elements in the second phase region are highly similar (Figure 5b–d), indicating a uniform elemental distribution. From the elemental distribution, it can be seen that there are two kinds of precipitation phases, one composed of three elements, the Al, Cu and Mn elements, and one composed of two elements, the Al element and Cu element. The as-cast Al-Cu-Mn alloy is mainly composed of α(Al) and θ(Al2Cu) phases and a small amount of T phase. θ is mainly generated by the binary eutectic reaction L → α(Al) + θ(Al2Cu), while the T phase is precipitated by the L → α(Al) + θ(Al2Cu) + T ternary eutectic reaction.

Figure 5.

SEM images and EDS analysis of microstructure of cast Al-Cu-Mn alloy: (a) SEM image of microstructure, (b) Al element distribution, (c) Mn element distribution, (d) Cu element distribution.

Combined with the distribution of the Al, Cu and Mn elements in Figure 3 and Figure 5, it can be seen that the gray phase in Figure 3 is α(Al), representing the matrix phase. A large number of bright white granular phases are wrapped in the gray matrix phase and represent the dendritic distribution of continuous/semi-continuous structures in the interdendritic region are observed in the casting area, which is θ(Al2Cu). The deeper white-gray phase is the T phase.

Figure 6 shows the SEM image of the microstructure of laser remelting casting Al-Cu-Mn alloy and its mechanical analysis by EDS analysis at different times. By comparing the element distribution of the matrix zone and the remelting zone in Figure 5 and Figure 6, it can be clearly observed that the Cu element is partially segregated after the laser remelting treatment to form a smaller-sized second phase, and the distribution is more uniform than the matrix zone; meanwhile, the α(Al) phase and θ(Al2Cu) phase are greatly refined. The T phase in the matrix is completely dissolved into the α(Al) matrix, and the Mn element in the remelting zone is evenly distributed without segregation. This is because under the action of the laser, the cast Al-Cu-Mn alloy is rapidly heated, melted and solidified, the alloy in the remelting zone is completely renucleated and grown and the second phase cannot be fully grown due to this rapid solidification speed. At the bottom of the remelting zone, a small amount of undissolved second phase remains due to the rapid heat dissipation of the alloy, while the second phases in the middle and top of the remelting zone renucleate and grow into finer new phases due to the rapid melting and solidification of laser remelting.

Figure 6.

SEM images and EDS analysis of microstructure of laser-remelted cast Al-Cu-Mn alloy: (a) SEM image of microstructure, (b) Al element distribution, (c) Mn element distribution, (d) Cu element distribution.

3.1.2. Effect of Laser Remelting on Hardness of Cast Al-Cu-Mn Alloy

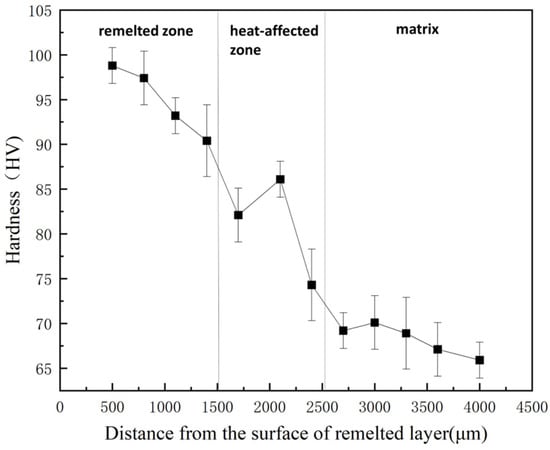

Figure 7 shows the Vickers hardness test diagram of the Al-Cu-Mn alloy’s longitudinal cross section matrix, heat-affected zone and remelting zone. It can be found that for the laser-remelted Al-Cu-Mn alloy, the Vickers hardness of the remelting zone was about 95 HV, while that of the matrix was only 68 HV. The heat-affected zone is between the remelted zone and the matrix, and the hardness increases significantly with the increase in the height of the molten pool. Laser remelting can significantly refine the microstructure of the remelting zone on the surface of the Al-Cu-Mn alloy, and also greatly improve the surface hardness of the remelting zone.

Figure 7.

Hardness distribution of longitudinal section of laser surface-remelted Al-Cu-Mn alloy.

The microstructure of the remelting zone on the surface of the cast Al-Cu-Mn alloy can be well refined by laser remelting, and the second phase in the remelting zone is also significantly refined so as to achieve a significant increase in surface hardness. Therefore, the improvement in the surface hardness of the laser-remelted Al-Cu-Mn alloy is mainly caused by two strengthening mechanisms: fine grain strengthening and second phase strengthening. These two strengthening mechanisms are discussed below:

- (1)

- Fine grain strengthening

The surface grains of the Al-Cu-Mn alloy are obviously refined after laser remelting. The microstructure size of each region after laser remelting can be measured by the intercept method, as shown in Figure 3. The heat-affected zone is the junction of the matrix and the remelting zone. Although the laser beam generation temperature does not reach its melting point, the alloy in the remelting zone begins to recrystallize. This thermodynamic behavior is similar to high-temperature annealing. The hardness of the aluminum alloy is mainly related to the alloy material and alloy grain size. According to the Hall–Petch formula, the following is derived:

In this formula, HV is microhardness; H0 represents material-related constants; KH is a constant related to the material; and d is the grain size.

The material-related constants HV and H0 are unchanged before and after the laser remelting of aluminum alloys. Therefore, in the Hall–Petch relationship, the grain size becomes a key factor determining microhardness. After laser remelting, the θ eutectic phase in the remelting zone is the most prominent, followed by the heat-affected zone, and the θ eutectic phase in the matrix region is the least prominent. According to the critical nucleus radius formula, and are the shear modulus and bulk modulus.

In this formula, Tm is the intersection temperature (K); σ is the free energy per unit area (J/mm2); Lm is the latent heat of melting (J/mm3); rk is the critical nucleus radius (mm); and ∆T is undercooling (K).

It can be seen that the relationship between the critical nucleation radius and subcooling degree is inversely proportional. Due to the rapid heating and rapid cooling of the surface of the cast Al-Cu-Mn alloy by laser remelting, resulting in increased metal subcooling during solidification, the critical nucleation radius decreases. Therefore, the number of crystal nuclei generated per unit volume of the alloy increases and grain refinement is obvious. It should be pointed out that the influence of the second phase hardness is not considered here.

- (2)

- Second phase strengthening

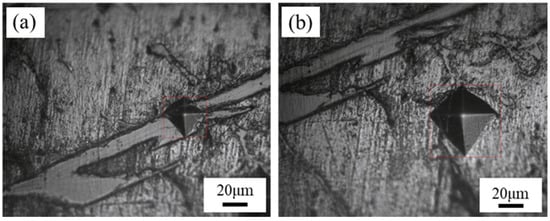

In Figure 8a,b, the hardness maps of the T phase and matrix α phase in the cast Al-Cu-Mn alloy are shown, respectively. It can be seen that the hardness of the T phase is significantly higher than that of the matrix α phase. The Al-Cu-Mn alloy is a high-temperature aluminum alloy, and second phase strengthening is its main strengthening method. Compared with the non-remelted Al-Cu-Mn alloy, the second phase precipitated by laser remelting is significantly finer and the amount of second phase precipitated is increased; therefore, the hardness of the laser remelting area is higher than that of the matrix.

Figure 8.

Microhardness test points of cast Al-Cu-Mn alloy: (a) T phase, (b) matrix α phase.

3.1.3. Effect of Laser Surface Remelting on Wear Resistance

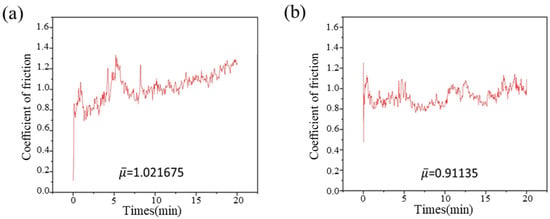

It can be seen from Figure 9 that the friction coefficient of the laser-remelted Al-Cu-Mn alloy increases rapidly at the beginning and then decreases greatly, and finally tends to be stable after fluctuation. This is because at the beginning of the friction and wear experiment, the steel ball sliding needs to overcome static friction. Since the maximum static friction force is higher than the sliding friction force, the maximum static friction force is reached at the moment of the onset of frictional wear. After that, the friction force generated by the sliding of the steel ball decreases, so the coefficient of friction of the material decreases immediately after a rapid increase in the beginning.

Figure 9.

Friction coefficient of laser-remelted Al-Cu-Mn alloy: (a) base alloy, (b) laser remelting zone.

Because the surface of the alloy after laser remelting is relatively rough, the maximum static friction force is larger than that of the matrix, and the initial value of the friction coefficient is higher. In the later stage of the experiment, the friction coefficient of the substrate is significantly higher than that of the laser remelting area. This is because under the same positive pressure, the deeper pressure of the friction pair on the surface of the substrate leads to an increase in the contact area between the friction pair and the surface of the substrate, thus increasing the sliding friction force. Due to the existence of micro-convex surfaces on the laser remelting surface, the micro-convex surfaces contacted by the friction pair during the wear process are constantly changing, and these micro-convex surfaces are deformed under the force of the friction pair, resulting in a large fluctuation in the friction coefficient. Because the hardness of the laser remelting zone is higher than that of the matrix zone, the average friction coefficient of the remelting zone is lower than that of the matrix zone.

3.2. Effect of Solution Temperature on Microstructure and Properties of Alloy

3.2.1. Microstructure and Phase Composition After Solution Treatment

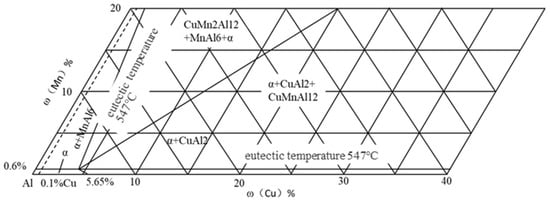

The distribution of the Al-Cu-Mn alloy solid phase zone near the aluminum corner is shown in Figure 10. During the solution treatment of the cast Al-Cu-Mn alloy, the binary eutectic structure of α(Al) + θ(Al2Cu) and the ternary eutectic structure of α(Al) + θ(Al2Cu) + T(Al12CuMn2) are dissolved into the α(Al) matrix, and an α(Al) supersaturated solid solution is formed after quenching, which plays the role of solid solution strengthening. Because the content of Cu and Mn elements in the α(Al) matrix is supersaturated, the T(Al12CuMn2) phase containing the Mn element will continuously precipitate during the artificial aging process, creating a point-like diffuse distribution in α(Al) matrix. Because the ternary eutectic temperature of Al-Cu-Mn is 547 °C and the binary eutectic temperature of Al-Cu is 548 °C, for the Al-Cu-Mn alloy, if the solid solution temperature is low, the diffusion ability of elements in the alloy is poor, and the coarse second phase particles in the alloy cannot be fully dissolved, resulting in a decrease in the supersaturation of the solid solution in the alloy; thus, the strength and hardness of the alloy are also reduced. When the solution treatment temperature exceeds the eutectic temperature, the eutectic structure melts, forming voids and remelted material, and the mechanical properties of the alloy decrease.

Figure 10.

Distribution of solid phase region of Al-Cu-Mn alloy close to aluminum corner.

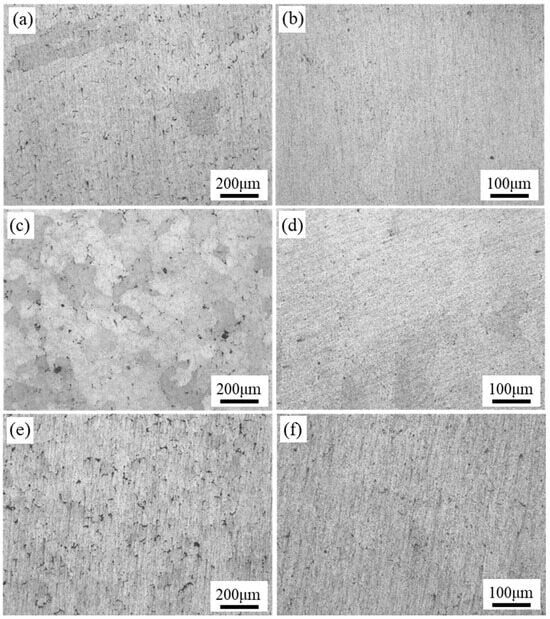

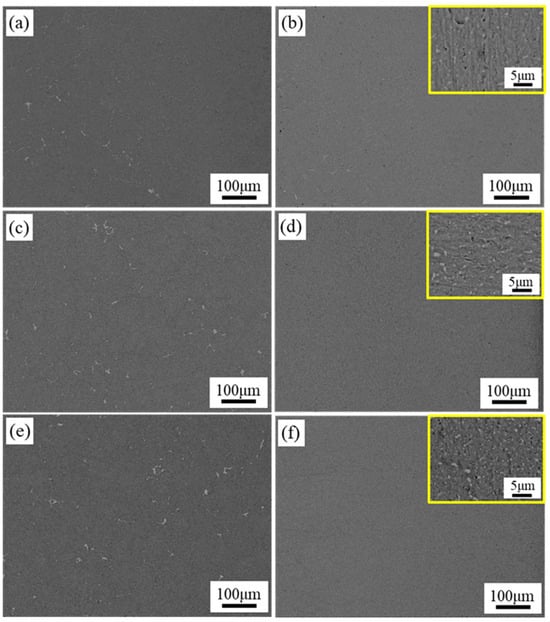

In the process of solution treatment, the more fully the second phase particles in the alloy are dissolved in the α(Al) matrix, the more uniform the composition of the alloy, and the higher the mechanical properties of the alloy after subsequent artificial aging. With the increase in solution temperature, the elements in the alloy are easier to diffuse, and the second phase particles are dissolved faster and more completely in the matrix. Figure 11 shows the OM images of the microstructure of the cast Al-Cu-Mn alloy at different solution temperatures. Figure 11a,c,e are the images of the laser-remelted Al-Cu-Mn alloy casting area after solid solution at 530 °C, 540 °C and 550 °C for 4 h and aging at 175 °C for 8 h. It can be seen that after solid solution at different temperatures, there are many large-sized undissolved phases distributed on the grain boundaries in the matrix alloy.

Figure 11.

OM image of microstructure of laser-remelted Al-Cu-Mn alloy at different solution temperatures (after aging at 175 °C for 8 h): (a,c,e) 530 °C, 540 °C and 550 °C images of casting area; (b,d,f) 530 °C, 540 °C and 550 °C images of remelting area.

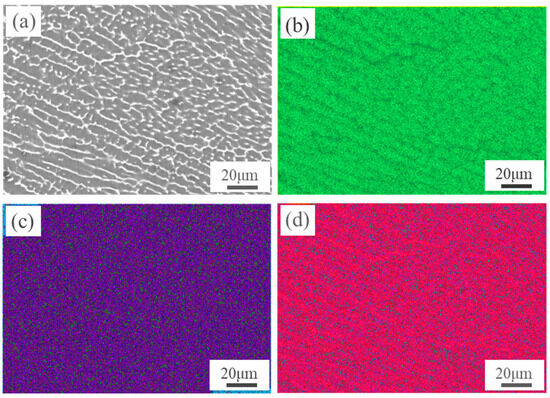

As shown in Figure 12, the SEM microscopic images of the undissolved phases on the grain boundaries after heat treatment and the EDS energy spectrum surface scan distribution corresponding to the Al, Cu, and Mn elements show that these undissolved phases are primarily T(Al12CuMn2) phases, while the θ(Al2Cu) in the matrix is completely dissolved into the matrix. Comparing the microstructures in Figure 11a,c,e, it can be found that when the solid solution temperature is 530 °C, the undissolved phase at the grain boundary is lesser, the supersaturation of the matrix is higher and the alloy composition is uniform. When the solution temperature is 540 °C, the primary eutectic precipitated phase at some grain boundaries melts to form a triangular remelted zone, and a typical overburning phenomenon occurs, which aggravates the uneven distribution of the solid solution elements in the matrix and reduces the mechanical properties of the alloy. When the solution temperature is 550 °C, the triangular remelted zone is more obvious, and the microstructure has obvious defects, which will lead to a significant decrease in the mechanical properties of the alloy.

Figure 12.

SEM images and EDS analysis of microstructure of cast Al-Cu-Mn alloy at a high solution temperature (530 °C): (a) SEM image of microstructure, (b) Al element distribution, (c) Mn element distribution, (d) Cu element distribution.

When the temperature rises to 540 °C, a small portion of the remelting zone begins to appear in the alloy. However, because the main precipitated phase in the remelting zone before the solution treatment is the θ(Al2Cu) phase, the low-melting-point eutectic precipitated phase is less than that in the casting zone, and the precipitated phase is finer, so when the remelting zone is formed, the area is smaller. However, when the solution temperature is 550 °C, a large number of remelting zones are formed.

The solution treatment promotes the formation of a supersaturated solid solution in the theta(Al2Cu) phase while also eliminating the residual stresses formed in the alloy during the laser remelting process.

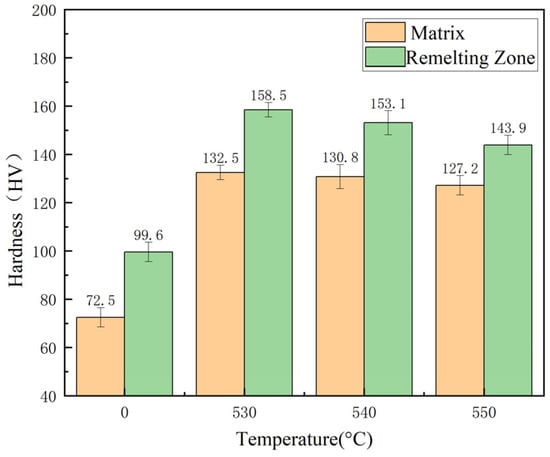

3.2.2. Mechanical Property Analysis at Different Temperatures

The average hardness of the matrix and remelting zone of the laser-remelted Al-Cu-Mn alloy at different solid solution temperatures (530 °C, 540 °C, 550 °C) is shown in Figure 13. It can be seen from this Figure that with the increase in solution temperature, the hardness of the sample increases first and then decreases. When the solution temperature is 530 °C, the hardness is the highest. The hardness of the matrix zone of the sample without solution aging treatment is 72.5 HV, and the hardness of the remelting zone is 99.6 HV, which is increased by 37.4%. After solution treatment at 530 °C for 4 h and aging at 175 °C for 8 h, the hardness of the matrix region is 132.7 HV, which is increased by 80%. After solution treatment at 530 °C for 4 h and aging at 175 °C for 8 h, the hardness of the remelting zone is 158.5 HV, which is increased by 59.1%. This is due to the formation of solid solution strengthening after solid solution aging and dispersion strengthening after aging. The combined effect results in a substantial increase in the hardness of the alloy. When the solution temperature rises to 540 °C and 550 °C, the hardness of the matrix zone and the remelting zone of the alloy sample decreases to varying degrees, and the higher the temperature, the lower the hardness. When the temperature rises to 540 °C, overburning occurs at some grain boundaries of the alloy. When the temperature rises to 550 °C, the overburning phenomenon is obvious, which is the main reason for the decrease in alloy hardness.

Figure 13.

Effect of solution temperature on hardness of laser-remelted Al-Cu-Mn alloy matrix and remelting zone.

3.3. Effect of Solution Time on Microstructure and Properties of Alloy

3.3.1. Microstructure

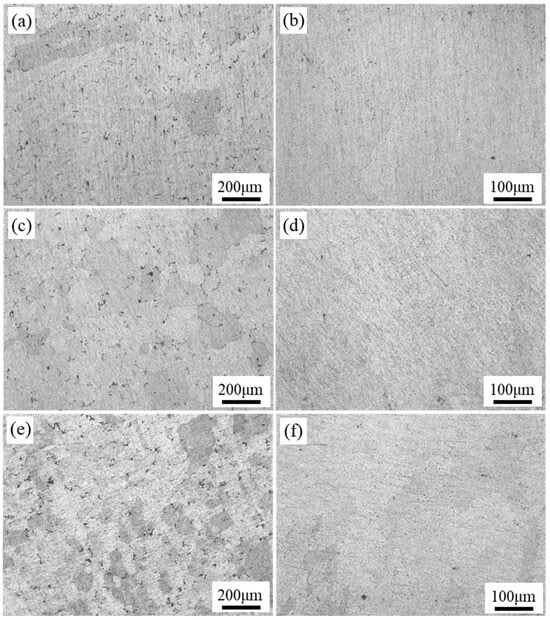

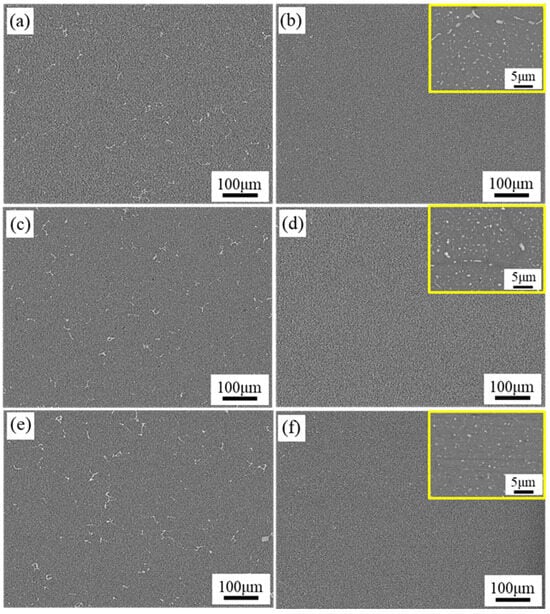

When the solid solution temperature of the Al-Cu-Mn alloy is constant, the solid solution time should be long enough to obtain a good solid solution effect. While ensuring a good solution effect, the solution time should be shortened as much as possible to improve work efficiency and reduce energy consumption. On the other hand, when the solution time is too long, the grain growth of the Al-Cu-Mn alloy is not conducive to its mechanical properties. The optimal solution temperature of the laser-remelted Al-Cu-Mn alloy was determined to be 530 °C, as shown in Figure 13. Therefore, 530 °C was selected as the solid solution temperature, and the samples were aged at 175 °C for 8 h after holding for 4 h, 8 h and 12 h, respectively. The microstructure of the alloy is shown in Figure 14. Figure 14a,c,e are the OM images of the casting area after holding for 4 h, 8 h and 12 h, respectively. It can be seen that as the holding time increases, the eutectic precipitated phase in the alloy has a higher degree of solid solution in the matrix. When the holding time is extended to 12 h, a small amount of overburning occurs in the matrix region. Figure 14b,d,f are the images of the remelting zone with holding times of 4 h, 8 h and 12 h, respectively. The microstructure change rule is similar to that of the matrix. With the increase in holding time, most of the primary θ(Al2Cu) phase in the remelting zone is dissolved into the α-Al matrix, and a small amount of overburning also occurs when the holding time is 12 h.

Figure 14.

OM images of microstructure of laser-remelted Al-Cu-Mn alloy with different solid solution times (after aging at 175 °C for 8 h): (a,c,e) 4 h, 8 h and 12 h casting area images; (b,d,f) 4 h, 8 h and 12 h remelting area images.

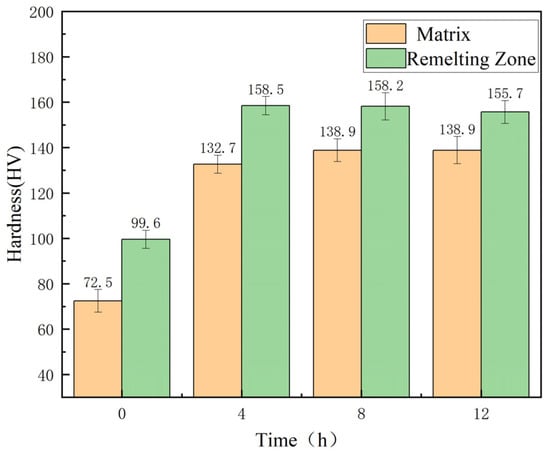

3.3.2. Mechanical Property Analysis at Different Times

The average hardness of the matrix and remelting zone of the laser-remelted Al-Cu-Mn alloy under different solid solution times (4 h, 8 h, 12 h) is shown in Figure 15. It can be seen from this Figure that with the extension of holding time, the hardness of the matrix zone increases first and then remains unchanged for a certain period of time. The hardness of the remelting zone reaches its maximum when the holding time is 4 h, and then the hardness decreases slightly with the increase in holding time. Therefore, holding for 4 h is selected as the best solution time for laser remelting Al-Cu-Mn alloys.

Figure 15.

Effect of time on matrix hardness and remelting zone of laser-remelted Al-Cu-Mn alloys at solution temperature of 530 °C.

3.4. Effect of Aging on Microstructure and Properties of Alloy

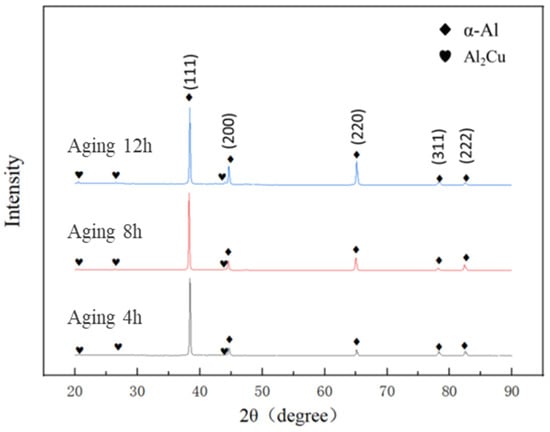

3.4.1. Microstructure and Phase Composition After Aging

Figure 16 shows the XRD patterns of the laser-remelted Al-Cu-Mn alloy’s remelting zone after solution treatment held at 175 °C for different times. As shown in this Figure, the α-Al phase and Al2Cu phase can be detected in the samples after solution aging treatment. By comparing the diffraction peaks of the α-Al phase in the samples at different holding times, it can be found that with the increase in holding time, the {111} of the α-Al phase does not change significantly, and the strength of the {200} and {220} crystal planes increases significantly, while that of the {311} and {222} crystal planes of the α-Al phase decreases significantly with the increase in holding time.

Figure 16.

XRD of remelted zone of Al-Cu-Mn alloy with solid solution temperature of 530 °C at different holding times.

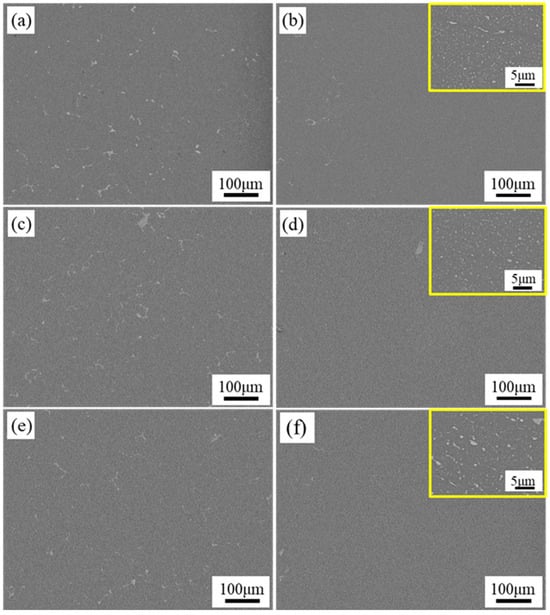

Figure 17 shows the microstructure images of the casting zone and the remelting zone of laser-remelted Al-Cu-Mn alloys aged at 165 °C for different times. Figure 17a,c,e show images of the casting area of the laser-remelted Al-Cu-Mn alloy with a holding time of 4 h, 8 h and 12 h. With the extension of holding time, the supersaturated solid solution in the alloy gradually precipitates, and the undissolved precipitated T phase still exists at the grain boundary. By observing the changes in the precipitated phases in the casting zone, it can be found that with the increase in holding time, the precipitated phases at the grain boundary of the casting zone increase significantly and gradually become continuous. From Figure 17b,d,f, it can be seen that the Al2Cu precipitates in the remelting zone gradually increase with the increase in aging time, and desolvation generally occurs in the grain boundaries. These precipitated phases are fine and uniform, a large number of dispersions are distributed in the remelting zone, and they have a tendency to grow with time.

Figure 17.

BSE image of microstructure of laser-remelted Al-Cu-Mn alloy aged at 165 °C for different holding times: (a,c,e) 4 h, 8 h and 12 h casting area images; (b,d,f) 4 h, 8 h and 12 h remelting zone images.

Figure 18 shows the microstructure images of the casting zone and the remelting zone of laser-remelted Al-Cu-Mn alloys aged at 175 °C for different times. Figure 18a,c,e show the images of the casting area of the laser-remelted Al-Cu-Mn alloy with holding times of 4 h, 8 h and 12 h. Similar to the microstructure evolution at 165 °C aging, with the extension of holding time, the supersaturated solid solution in the alloy gradually precipitates, and the undissolved precipitated T phase in the solution treatment still exists at the grain boundary. The precipitated phase at the grain boundary of the casting zone is obviously increased and gradually becomes continuous. It can be seen from Figure 18b,d,f that the precipitated phases in the remelting zone increase with aging time, and the precipitated phases in the alloy gradually increase. The microstructure of these precipitated phases is fine and uniform, and a large number of precipitated phases are dispersed in the remelting zone. The precipitation at the 175 °C aging grain boundary is more continuous.

Figure 18.

BSE image of microstructure of laser-remelted Al-Cu-Mn alloy aged at 175 °C for different holding times: (a,c,e) 4 h, 8 h and 12 h casting area images; (b,d,f) 4 h, 8 h and 12 h remelting zone images.

Figure 19 shows microstructure images of the casting zone and remelting zone of the Al-Cu-Mn alloy that was laser remelted and aged at 185 °C for different times. Compared with Figure 17 and Figure 18, no obvious difference was found in the aging microstructure at 185 °C, and the precipitated phases in the alloy gradually increased with the prolongation of the holding time. It can be seen from Figure 19f that when the holding time is 12 h, the precipitated phase in the alloy coarsens, which is an obvious overaging phenomenon.

Figure 19.

BSE image of microstructure of laser-remelted Al-Cu-Mn alloy at 185 °C for different holding times: (a,c,e) 4 h, 8 h and 12 h casting area images; (b,d,f) 4 h, 8 h and 12 h remelting zone images.

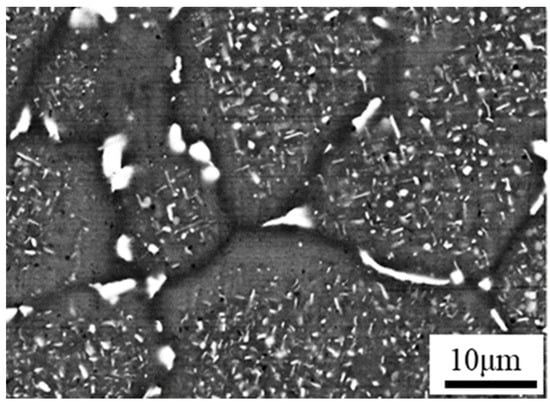

Figure 20 shows the BSE images of the substrate of the laser-remelted Al-Cu-Mn alloy held at 175 °C for 8 h. It can be found that when the alloy is held at 175 °C for 8 h, a large number of needle-like and granular precipitates are dispersed in the grain boundary, and the precipitates at the grain boundary gradually become continuous. The needle-like precipitates in the grain boundary are distributed regularly, mainly precipitated in two mutually perpendicular directions. This is because the unsaturated solid solution in the alloy is unstable. After holding at a certain temperature for a period of time, the solid solution in the alloy decomposes. When holding at 175 °C for 8 h, the intragranular and grain boundaries are generally dissolved. The precipitated phase in the matrix of the Al-Cu-Mn alloy is mainly the θ′ phase. The θ″ phase exists when the aging time is short, whereas the θ phase exists when the aging time is long. At the same time, the secondary T phase is dispersed in the matrix. These dispersed precipitates can effectively improve the mechanical properties of the alloy.

Figure 20.

BSE image of substrate of laser-remelted Al-Cu-Mn alloy at 175 °C for 8 h.

3.4.2. Mechanical Property Analysis

- (1)

- Hardness analysis

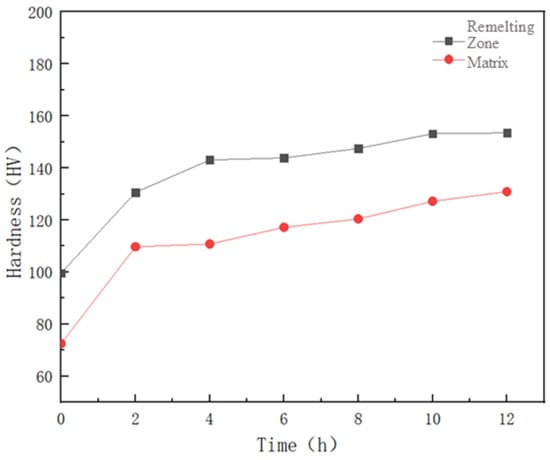

Figure 21 is the average hardness of laser-remelted Al-Cu-Mn alloys at 165 °C for different aging times. It can be found that the hardness of the alloy is greatly improved when the aging time is 2 h. After 2 h, the hardness gradually increases with the aging time, and there is no obvious peak value within 12 h. This is due to the relatively low temperature of 165 °C, where the supersaturated solid solution in the alloy is not completely desolved. In order to reach the peak aging stage of the alloy, the aging time should be longer. The hardness of both the remelting zone and the matrix is obviously improved. During the aging process, the hardness of the remelting zone shows the same growth trend as that of the matrix and is greater than that of the matrix.

Figure 21.

Effect of different aging times at 165 °C on hardness of laser-remelted Al-Cu-Mn alloy.

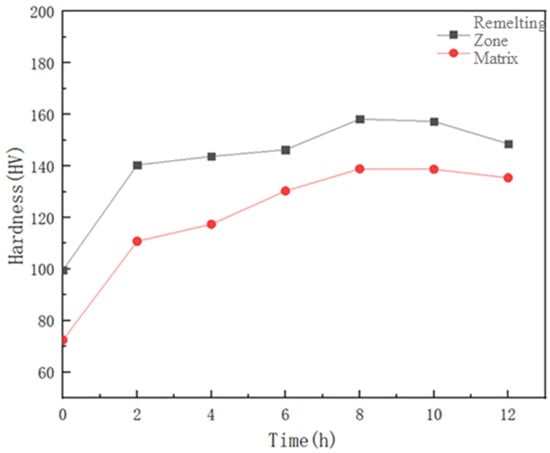

Figure 22 shows the average hardness of laser-remelted Al-Cu-Mn alloys with different aging times at 175 °C. It can be found that the hardness of the alloy increases significantly when aging for 2 h. After 2 h, the increase in hardness decreases with the extension of aging time and reaches a peak when the aging time is 8 h. After that, as the holding time continues to increase, the hardness gradually decreases, but the hardness is not lower than that before solid solution aging.

Figure 22.

Hardness distribution of remelting zone and matrix after aging at 175 °C over time.

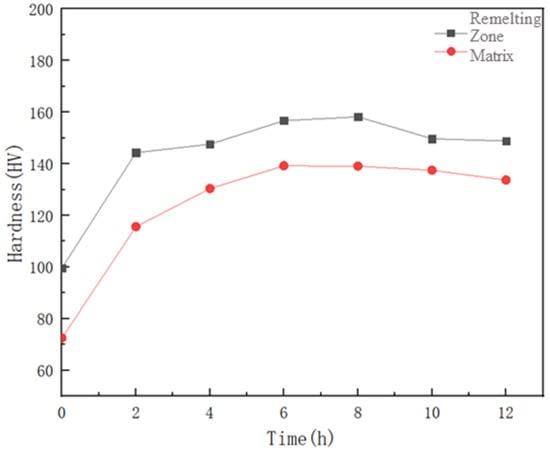

Figure 23 shows the average hardness of laser-remelted Al-Cu-Mn alloys with different aging times at 185 °C. It can be found that the alloy still has the largest growth rate in the first two hours, indicating that in the first two hours of aging, the supersaturated solid solution in the alloy has a large amount of desolvation, and the θ′′ phase is formed in the alloy, resulting in a significant increase in the hardness of the alloy. Compared with aging at 175 °C, the peak hardness of the matrix aged at 185 °C is significantly earlier, and the peak hardness of the remelting zone does not change significantly. At the same time, it can be found that the peak hardness of the alloy aged at 185 °C is slightly lower than that aged at 175 °C.

Figure 23.

Hardness distribution over time for remelting zone and matrix after aging at 185 °C.

Combined with the above aging–hardening curves at different temperatures, it can be seen that with the increase in aging temperature, the time for the hardness to reach a peak value is shorter, and the time for the remelting zone and the matrix to reach a peak value is similar. Comparing the hardness of the alloy at different temperature peaks, it can be found that the hardness of both the matrix and remelting zone is highest at 175 °C for 8 h.

- (2)

- Friction and wear behavior analysis

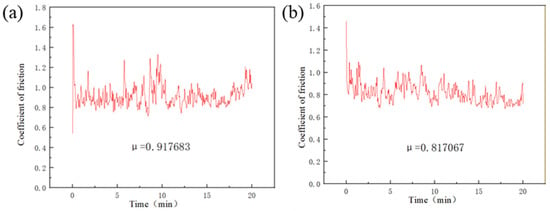

Reciprocating friction and wear experiments were carried out on the laser-remelted Al-Cu-Mn alloy after aging at 175 °C for 8 h. Figure 24 shows the change curve of the friction coefficient during the reciprocating friction and wear experiments on the surface of the alloy sample. It can be found that the friction coefficient still decreases greatly in the initial stage because the steel ball needs to overcome the rapid increase in static friction force, and then tends to be stable in its fluctuations. It can be seen from this Figure that after aging treatment, due to the increase in alloy hardness, the friction coefficient of both the alloy matrix and the surface of the remelting zone is lower than that before aging. The wear mechanism of the aged alloy does not change, but due to the increased hardness of the aged alloy, the amount of abrasive debris is reduced compared to that of the unaged base alloy, resulting in a lower coefficient of friction on the surface of both the alloy matrix and the remelted zone than that before aging.

Figure 24.

(a) Friction coefficient of laser-remelted Al-Cu-Mn alloy aged at 175 °C for 8 h: base alloy; (b) laser remelting zone.

4. Conclusions

In this paper, laser remelting was carried out on the surface of a cast Al-Cu-Mn alloy by a fiber-coupled semiconductor laser. The microstructure and mechanical properties of different regions of the laser-remelted Al-Cu-Mn alloy were studied. The effects of different solid solution aging processes on the microstructure and mechanical properties of the Al-Cu-Mn alloy after laser remelting were studied. The results are as follows:

(1) The microstructure of the laser-remelted Al-Cu-Mn alloy is mainly composed of equiaxed dendrites and fine columnar dendrites. The α(Al) phase and θ(Al2Cu) phase are greatly refined after laser remelting. The T phase in the matrix is completely dissolved into the α(Al) matrix, and the Mn element in the remelting zone is evenly distributed without segregation.

(2) An increase in hardness is mainly caused by two strengthening mechanisms: fine grain strengthening and second phase strengthening. The Vickers hardness of the remelted zone is about 95 HV, while that of the matrix is only 68 HV. The heat-affected zone is between the remelting zone and the matrix, and the hardness increases significantly with the increase in the height of the molten pool.

(3) With the same aging process, the hardness is highest at 530 °C in the solid solution for 4 h. The hardness in the matrix zone is 132.7 HV, which is 80% higher than that in the matrix zone without solid solution aging, and the hardness in the remelting zone is 158.5 HV, which is 59.1% higher than that in the remelting zone without solid solution aging. The solid solution process is the same. With the increase in aging temperature, the time for the hardness to reach its peak is shorter. The time for the remelting zone and the matrix to reach their peaks is similar. The hardness of the matrix and the remelting zone is highest after aging at 175 °C for 8 h.

Author Contributions

J.H.: Writing—original draft, validation and investigation. H.L.: Writing—review and editing, investigation and resources. Q.D.: Writing—review and editing, methodology and formal analysis. Z.Z.: Supervision, funding acquisition and formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 52275389). This work is financially supported by the Shanxi Natural Science Fund for Distinguished Young Scholars (202403021223005), as well as the special fund for Science and Technology Innovation Teams of Shanxi Province.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Luo, Z.; Zhang, X.; Liu, Z.; Zhou, H.; Wang, M.; Xie, G. Mechanical properties and interfacial characteristics of 6061 Al alloy plates fabricated by hot-roll bonding. Int. J. Miner. Metall. Mater. 2024, 31, 1890–1899. [Google Scholar] [CrossRef]

- Yu, J.; Geng, Y.; Chen, Y.; Wang, X.; Zhang, Z.; Tang, H.; Xu, J.; Ju, H.; Wang, D. High-strength and thermally stable TiB2 -modified Al–Mn–Mg–Er–Zr alloy fabricated via selective laser melting. Int. J. Miner. Metall. Mater. 2024, 31, 2221–2232. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Zhang, M.; Gong, W.; Lai, R.; Li, Y. Preheating-assisted solid-state friction stir repair of Al–Mg–Si alloy plate at different rotational speeds. Int. J. Miner. Metall. Mater. 2024, 31, 725–736. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, H.; Zhang, M.-X.; Addad, A.; Kong, Y.; Lezaack, M.B.; Gan, W.; Chen, Z.; Ji, G. Break through the strength-ductility trade-off dilemma in aluminum matrix composites via precipitation-assisted interface tailoring. Acta Mater. 2023, 242, 17. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z.; Wu, Q.; Yang, Z.; Zhou, K.; Fan, X.; Li, J.; Wang, J. Modulation of Multiple Precipitates for High Strength and Ductility in Al-Cu-Mn Alloy. Materials 2021, 14, 7383. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.-R.; Wang, J.; Shi, W.-N.; Liu, X.-B.; Zhang, X.-F.; Zhou, H.-F. Manipulating Precipitation Through Thermomechanical Treatment to Control Corrosion Behavior of an Al-Cu-Mg Alloy. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 1547–1558. [Google Scholar] [CrossRef]

- Safary, E.; Taghiabadi, R.; Ghoncheh, M.H. Mechanical properties of Al-15Mg2Si composites prepared under different solidification cooling rates. Int. J. Miner. Metall. Mater. 2022, 29, 1249–1260. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, M.; Yang, B.; Zhao, E.; Liu, F.; Guan, R. Microstructural evolution and mechanical property of Al–Mg–Mn alloys with various solidification cooling rates. Mater. Charact. 2022, 184, 10. [Google Scholar] [CrossRef]

- Ji, S.; Cui, X.; Ma, L.; Liu, H.; Zuo, Y.; Zhang, Z. Achieving High-Quality Aluminum to Copper Dissimilar Metals Joint via Friction Stir Double-Riveting Welding. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 552–572. [Google Scholar] [CrossRef]

- Yang, L.; Yang, J.; Han, F.; Zhang, Z.; Li, Q.; Dong, Z.; Wang, L.; Ofori-Opoku, N.; Provatas, N. Hot cracking susceptibility prediction from quantitative multi-phase field simulations with grain boundary effects. Acta Mater. 2023, 250, 12. [Google Scholar] [CrossRef]

- Yang, S.; Yang, S.; Liu, W.; Li, J.; Gao, J.; Wang, Y. Microstructure, segregation and precipitate evolution in directionally solidified GH4742 superalloy. Int. J. Miner. Metall. Mater. 2023, 30, 939–948. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Yu, W. Effect of Cr/Mn segregation on pearlite-martensite banded structure of high carbon bearing steel. Int. J. Miner. Metall. Mater. 2021, 28, 665–675. [Google Scholar] [CrossRef]

- Li, J.; Chen, R.; Ma, Y.; Ke, W. Hot Tearing of Sand Cast Mg-5 wt.% Y-4 wt.% RE(WE54) Alloy. Acta Metall. Sin. (Engl. Lett.) 2013, 26, 728–734. [Google Scholar] [CrossRef]

- He, T.; Liu, H.J.; Shi, X.J.; Huo, Y.M.; Min, L.; Pan, T.T. Effect of Si and Mn on Microstructure and Mechanical Properties of Vacuum Suction Casting Al–4.5Cu Alloy. Strength Mater. 2018, 50, 665–673. [Google Scholar] [CrossRef]

- Ravikumar, V.V.; Kumaran, S. Improved strength and ductility of high alloy containing Al–12Zn–3Mg–2.5Cu alloy by combining non-isothermal step rolling and cold rolling. Int. J. Miner. Metall. Mater. 2017, 24, 179–185. [Google Scholar] [CrossRef]

- Deng, Z.-H.; Yin, H.-Q.; Jiang, X.; Zhang, C.; Zhang, G.-F.; Xu, B.; Yang, G.-Q.; Zhang, T.; Wu, M.; Qu, X.-H. Machine-learning-assisted prediction of the mechanical properties of Cu—Al alloy. Int. J. Miner. Metall. Mater. 2020, 27, 362–373. [Google Scholar] [CrossRef]

- Ganjehfard, K.; Taghiabadi, R.; Noghani, M.T.; Ghoncheh, M.H. Tensile properties and hot tearing susceptibility of cast Al-Cu alloys containing excess Fe and Si. Int. J. Miner. Metall. Mater. 2021, 28, 718–728. [Google Scholar] [CrossRef]

- Liu, C.-Y.; Yu, P.-F.; Wang, X.-Y.; Ma, M.-Z.; Liu, R.-P. Preparation of high-strength Al-Mg-Si-Cu-Fe alloy via heat treatment and rolling. Int. J. Miner. Metall. Mater. 2014, 21, 702–710. [Google Scholar] [CrossRef]

- Wang, X.-F.; Guo, M.-X.; Ma, C.-Q.; Chen, J.-B.; Zhang, J.-S.; Zhuang, L.-Z. Effect of particle size distribution on the microstructure, texture, and mechanical properties of Al–Mg–Si–Cu alloy. Int. J. Miner. Metall. Mater. 2018, 25, 957–966. [Google Scholar] [CrossRef]

- Peng, D.; Shen, J.; Tang, Q.; Wu, C.-P.; Zhou, Y.-B. Effects of aging treatment and heat input on the microstructures and mechanical properties of TIG-welded 6061-T6 alloy joints. Int. J. Miner. Metall. Mater. 2013, 20, 259–265. [Google Scholar] [CrossRef]

- Liu, J.; Huang, H.; Xie, J. Effects of aging treatment on the microstructure and superelasticity of columnar-grained Cu 71 Al 18 Mn 11 shape memory alloy. Int. J. Miner. Metall. Mater. 2016, 23, 1157–1166. [Google Scholar] [CrossRef]

- Tang, L.; Wei, P.; Hu, Z.; Pang, Q. Microstructure and mechanical properties stability of pre-hardening treatment in Al–Cu alloys for pre-hardening forming process. Int. J. Miner. Metall. Mater. 2024, 31, 539–551. [Google Scholar] [CrossRef]

- He, C.; Shen, Y.; Xue, W.; Fan, Z.; Zhou, Y. Nanosized κ-Carbide and B2 Boosting Strength Without Sacrificing Ductility in a Low-Density Fe-32Mn-11Al Steel. Nanomaterials 2025, 15, 19. [Google Scholar] [CrossRef] [PubMed]

- Kan, L.; Ye, Q.; Shen, Y.; Wang, Z.; Zhao, T. Co-precipitation of nanosized Cu and carbides improving mechanical properties of 1 GPa grade HSLA steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 859, 15. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Milligan, B.; Bahl, S.; Ma, D.; Shyam, A.; Dunand, D. Progression of creep deformation from grain boundaries to grain interior in Al-Cu-Mn-Zr alloys. Acta Mater. 2023, 250, 13. [Google Scholar] [CrossRef]

- Ding, Z.; Hu, Q.; Yang, F.; Yu, L.; Yang, T.; Zhang, N.; Lu, W.; Yang, J.; Qiao, J.; Li, J. Unveiling the Growth Mechanism of Faceted Primary Al 2 Cu with Complex Morphologies During Solidification. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 124–132. [Google Scholar] [CrossRef]

- Nie, X.; Chen, Z.; Qi, Y.; Zhang, H.; Zhu, H. Spreading Behavior and Hot Cracking Mechanism of Single Tracks in High Strength Al-Cu-Mg-Mn Alloy Fabricated by Laser Powder Bed Fusion. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 1454–1464. [Google Scholar] [CrossRef]

- Yuan, L.; Guo, M.; Wang, Y.; Wang, Y.; Zhuang, L. Synergistic effect of gradient Zn content and multiscale particles on the mechanical properties of Al–Zn–Mg–Cu alloys with coupling distribution of coarse–fine grains. Int. J. Miner. Metall. Mater. 2024, 31, 1392–1405. [Google Scholar] [CrossRef]

- Ghasemi, A.; Eivani, A.R.; Abbasi, S.M.; Jafarian, H.R.; Ghosh, M.; Anijdan, S.H.M. Al-Co-Cr-Fe-Ni-Ti high entropy alloys: A review of microstructural and mechanical properties at elevated temperatures. J. Alloys Compd. 2025, 1010, 17. [Google Scholar] [CrossRef]

- Dong, J.; Jiang, J.; Wang, Y.; Huang, M.; Cui, J.; Song, T. Effect of Solution and Aging Treatment on Microstructure and Mechanical Properties of Al-14Si-5Cu-1.1Mg-2.3Ni-0.3La Alloy. Acta Metall. Sin. (Engl. Lett.) 2025, 38, 449–464. [Google Scholar] [CrossRef]

- Kong, X.; Wang, Y.; Xu, H.; Fan, H.; Zheng, Y.; Xie, B. NbB2 Modified Al-Cu Alloys Fabricated by Freeze-Ablation Casting under High Cooling Rate Solidification. Acta Metall. Sin. (Engl. Lett.) 2024, 37, 921–938. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, T.-F.; Xiao, M.; Shen, Y.-F. Effect of process parameters on the microstructure and properties of laser-clad FeNiCoCrTi0.5 high-entropy alloy coating. Int. J. Miner. Metall. Mater. 2020, 27, 630–639. [Google Scholar] [CrossRef]

- Geng, Y.; Tang, H.; Xu, J.; Hou, Y.; Wang, Y.; He, Z.; Zhang, Z.; Ju, H.; Yu, L. Influence of process parameters and aging treatment on the microstructure and mechanical properties of AlSi8Mg3 alloy fabricated by selective laser melting. Int. J. Miner. Metall. Mater. 2022, 29, 1770–1779. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Letyagin, N.V.; Belov, N.A.; Fortuna, A.S.; Nguen, X.D. The role of Sn trace addition in the precipitation behavior and strengthening of the wrought Al-Cu-Mn-based alloy. J. Mater. Sci. 2023, 58, 8210–8229. [Google Scholar] [CrossRef]

- Zupani, F.; Gspan, C.; Burja, J.; Boncina, T. Quasicrystalline and L12 precipitates in a microalloyed Al-Mn-Cu alloy. Mater. Today Commun. 2020, 22, 6. [Google Scholar] [CrossRef]

- Prabhu, T.R. Effects of ageing time on the mechanical and conductivity properties for various round bar diameters of AA 2219 Al alloy. Eng. Sci. Technol. Int. J. 2017, 20, 133–142. [Google Scholar] [CrossRef]

- Du, L.; Ding, H.; Xie, Y.; Ji, L.; Chen, W.; Xu, Y. Effect of Laser Energy Density on Microstructures and Properties of Additively Manufactured AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. Acta Metall. Sin. (Engl. Lett.) 2025, 38, 233–244. [Google Scholar] [CrossRef]

- Zhao, E.; Yang, H.; Peng, Y.; Wang, L.; Song, B.; Zhu, C.; Liu, H. Microstructure and Wear Behavior of Laser-Remelted High-Manganese Steel. J. Mater. Eng. Perform. 2023, 32, 11422–11431. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, T.-S.; Fu, B.-G.; Li, G.-L.; Yang, L.-J. Effect of Laser Remelting on Microstructure and Properties of AlCoCrFeNi High-Entropy Alloy Coating. J. Mater. Eng. Perform. 2021, 30, 5728–5735. [Google Scholar] [CrossRef]

- Karimi, J.; Antonov, M.; Kollo, L.; Prashanth, K. Role of laser remelting and heat treatment in mechanical and tribological properties of selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2022, 897, 13. [Google Scholar] [CrossRef]

- Yao, L.; He, Y.; Wang, Z.; Peng, B.; Li, G.; Liu, Y. Effect of Heat Treatment on the Wear Properties of Selective Laser Melted Ti-6Al-4V Alloy Under Different Loads. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 517–525. [Google Scholar] [CrossRef]

- Wang, P.; Yu, S.; Shergill, J.; Chaubey, A.; Eckert, J.; Prashanth, K.G.; Scudino, S. Selective Laser Melting of Al-7Si-0.5 Mg-0.5Cu: Effect of Heat Treatment on Microstructure Evolution, Mechanical Properties and Wear Resistance. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 389–396. [Google Scholar] [CrossRef]

- Yue, C.; Zheng, B.; Su, M.; Wang, Y.; Zuo, X.; Wang, Y.; Yuan, X. Effect of Y and Ce Micro-alloying on Microstructure and Hot Tearing of As-Cast Al-Cu-Mg Alloy. Acta Metall. Sin. (Engl. Lett.) 2024, 37, 939–952. [Google Scholar] [CrossRef]

- Shambu, V.; Sahu, D.K.; Padmaganesan, H.T.; Nayan, N.; Prasad, M. Restoration of exceptional mechanical properties of Al-Cu-Li (AA 2198) alloy post- friction stir processing by recovery of T1 precipitates through controlled temper conditions. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2024, 912, 10. [Google Scholar] [CrossRef]

- Hu, J.; Sun, T.; Cao, F.; Shen, Y.; Yang, Z.; Guo, C. Enhanced Strength-Ductility Synergy in Submerged Friction Stir Processing ER2319 Alloy Manufactured by Wire-Arc Additive Manufacturing via Creating Ultrafine Microstructure. Acta Metall. Sin. (Engl. Lett.) 2024, 37, 793–807. [Google Scholar] [CrossRef]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Stavropoulos, P. Additive manufacturing simulations: An approach based on space partitioning and dynamic 3D mesh adaptation. Addit. Manuf. Lett. 2024, 11, 100256. [Google Scholar] [CrossRef]

- Yasa, E. Application of Laser Re-melting on selective laser melting parts. Adv. Prod. Eng. Manag. 2011, 6, 259–270. Available online: https://lirias.kuleuven.be/handle/123456789/332611 (accessed on 18 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).