2. Experimental

Alloy ingots with a composition of Zr58.75Cu21.15Fe4.7Al9.4Nb6 were produced through the process of arc melting. Elemental metals of exceptional purity (≥99.5% by weight) were handled within a titanium-gettered argon environment. To guarantee uniformity in the composition of the alloy, each ingot underwent a minimum of four remelting processes. Subsequently, the alloy was suction-cast into a copper mold, yielding plates measuring 3 mm by 6.5 mm by 40 mm.

A tailor-made ultrasonic apparatus, featuring a KNbO3 piezoelectric transducer with a resonant frequency of 20 kHz and a cylindrical emitter measuring 20 mm in diameter and 500 mm in length, was utilized to administer ultrasonic stimulation. The as-cast plate was affixed to a supporting platform using adhesive, positioned directly beneath the emitter. The emitter was lowered via a precision displacement controller until its end face made tangential contact with the plate surface. Longitudinal ultrasound waves, possessing an amplitude near 15 micrometers, were administered for periods of 15 min and 30 min.

Samples intended for the evaluation of fracture resistance were precisely fabricated from both the processed and unprocessed panels. These specimens were characterized by dimensions with a thickness of 3 mm, a width of 6 mm, and a distance between supports of 24 mm. The six surfaces of the sample were successively ground with 400, 800, 1200 and 2000 grit sandpapers, and then polished to a mirror finish with diamond grinding paste of 5 μm particle size. They were meticulously smoothed and buffed to achieve a reflective surface before assessment. A continuous notch was created by means of wire-electrode discharge machining, featuring a root radius close to 300 micrometers and a notch approximately 0.4 times the specimen width. A cycle of pre-cracking to induce fatigue was applied using a WDW-10E (Shanghai, China) universal testing apparatus under ambient conditions. The cumulative length of the crack, combining both the notch and the pre-existing fatigue-induced crack, was maintained between 0.45 and 0.55 times the width (W).

The fracture toughness of the material was assessed through the application of three-point bend tests utilizing the WDW-10E apparatus at ambient temperature. The thin-foil specimens intended for the transmission electron microscope (TEM, Tecnai G2 F20, FEI, Hillsboro, OR, USA) were crafted from samples that had undergone a mechanical polish (with thicknesses of 30–40 micrometers) by employing the method of twin-jet electropolishing (Buehler, Lake Bluff, IL, USA); the volume ratio of the double spray electrolytic polishing solution is 5:85:5, consisting of perchloric acid, methanol and deionized water.

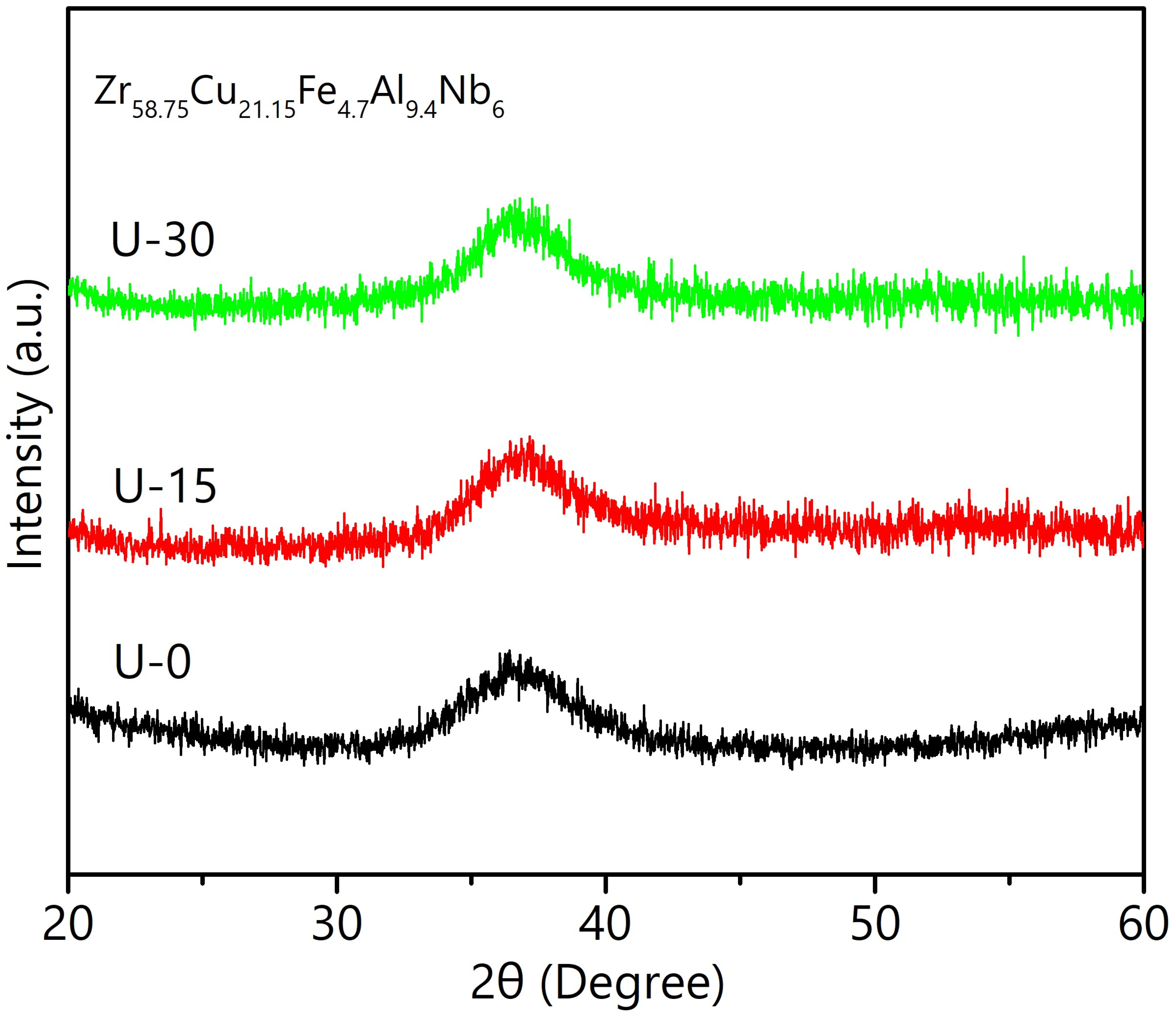

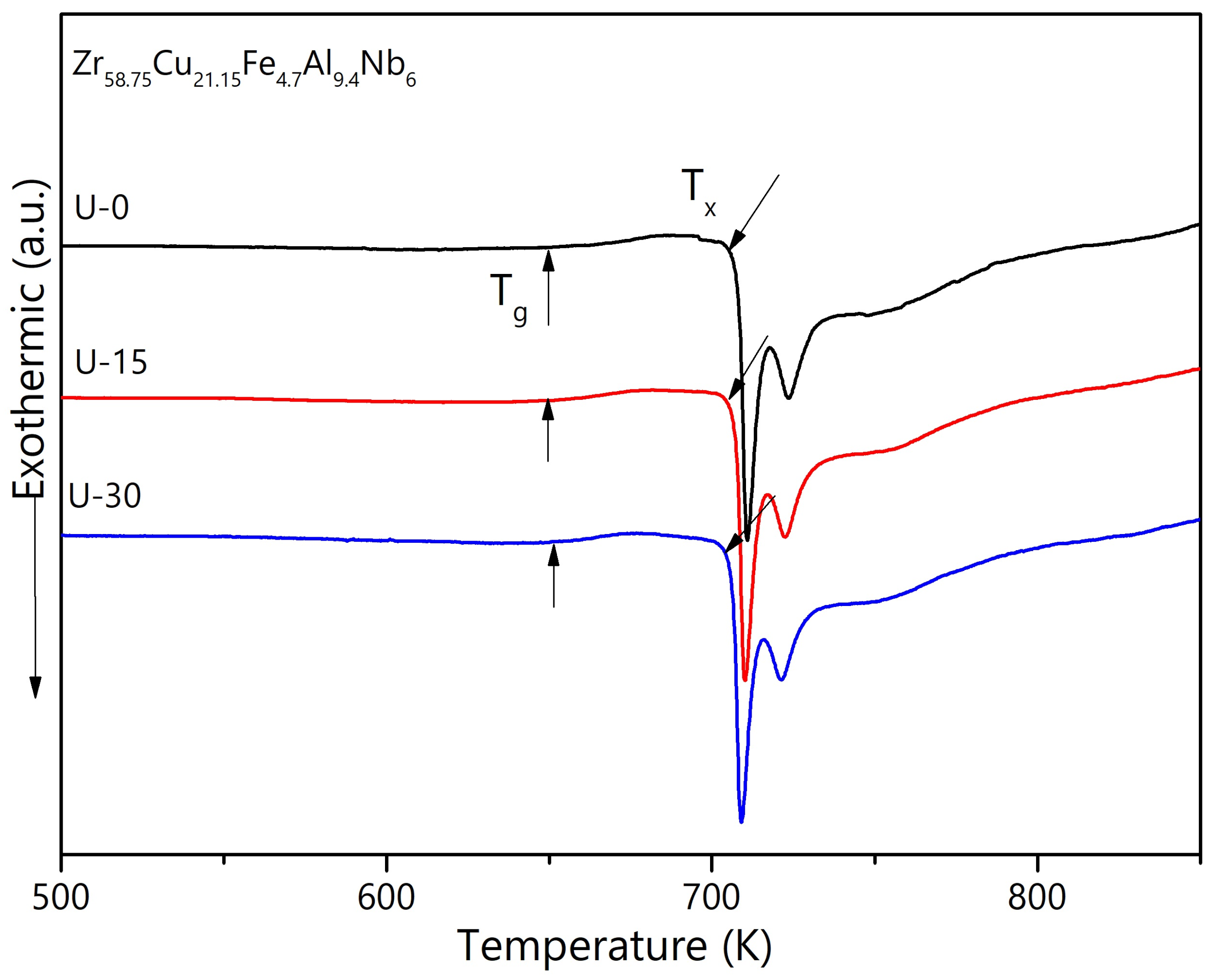

The amorphous nature of the samples was verified by X-ray diffraction (XRD, Bruker D8 ADVANCE diffractometer in Billerica, MA, USA) with Cu Kα radiation. Crystallization kinetics were investigated via differential scanning calorimetry (DSC, Netzsch STA 449C, Sürburg, Germany) under high-purity argon atmosphere, employing a constant heating rate of 5 K/min. Microstructural observations of lateral and fracture surfaces were examined using field-emission scanning electron microscopy (SEM, LEO1430VP, Zeiss, Jena, Germany). For atomic-scale structural analysis, high-resolution transmission electron microscopy (HRTEM, Tecnai G2 F20, FEI, Hillsboro, OR, USA), coupled with an energy-dispersive X-ray spectroscopy (EDX) system for concurrent elemental mapping.

4. Discussion

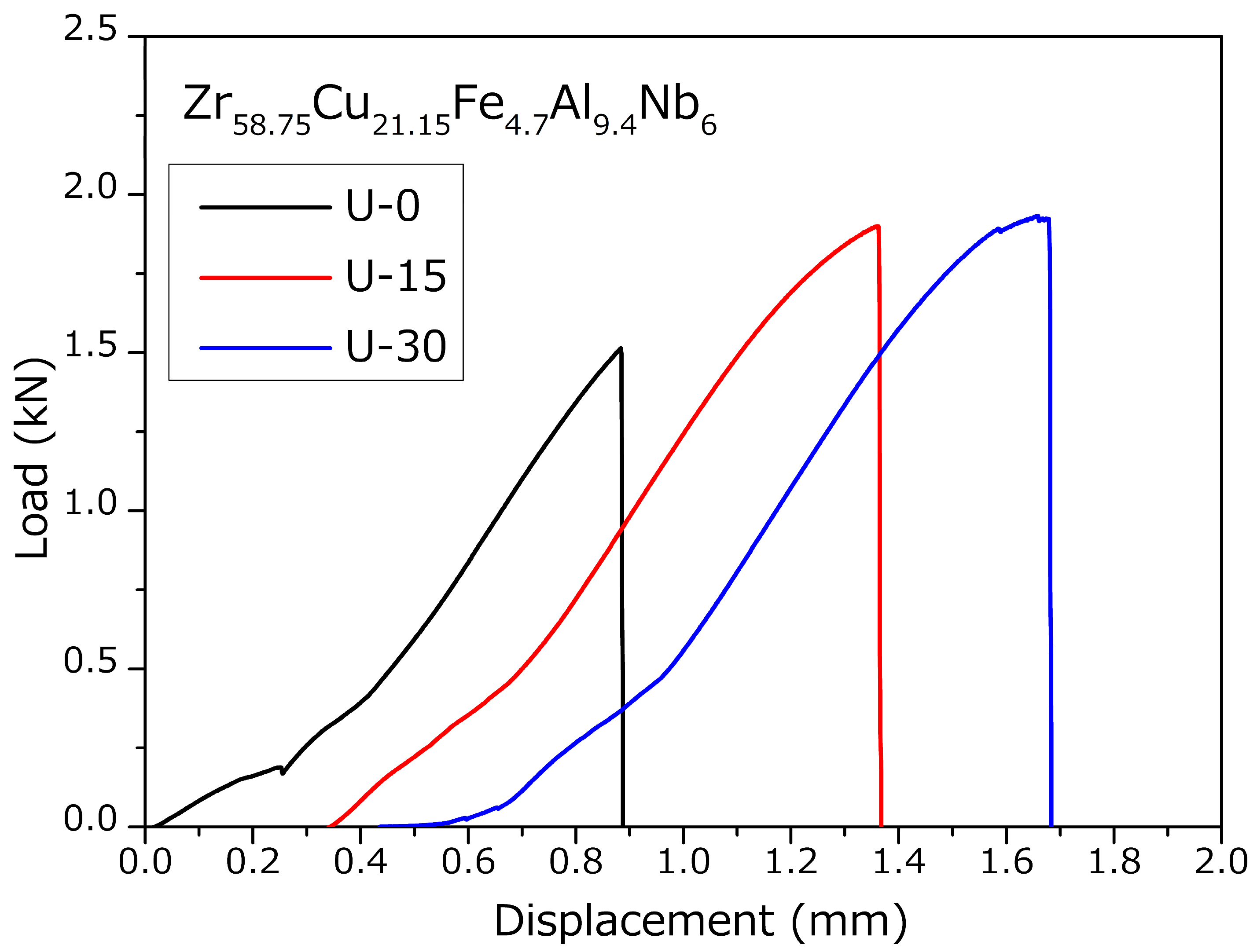

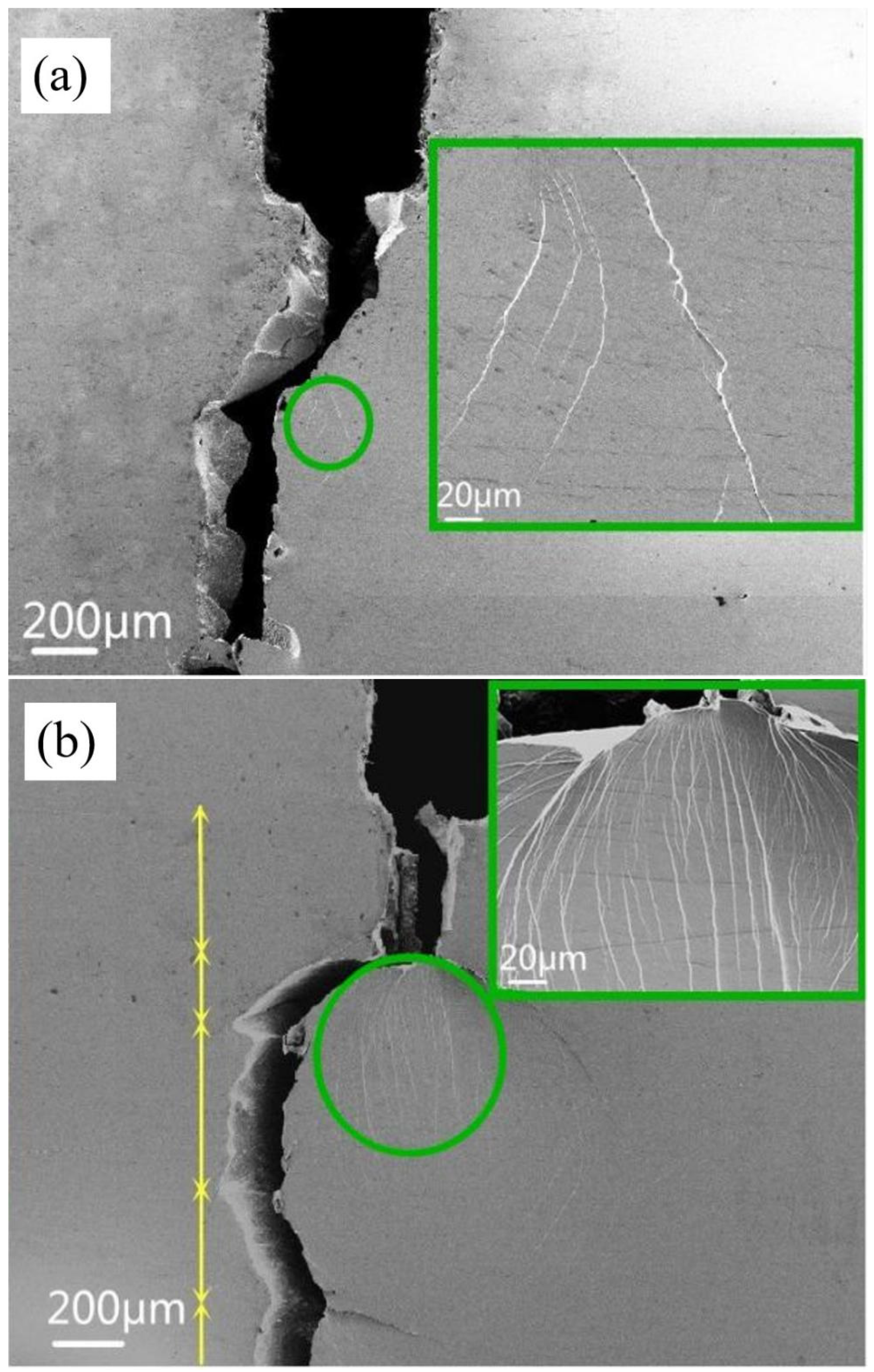

As mentioned above, the ultrasonic-treated samples exhibited enhanced yield stress and a distinct plastic plateau following yielding, indicating improved plasticity compared to the as-cast sample. A thorough examination of the microscopic characteristics in both the U-0 and U-30 specimens, before and after deformation, was performed to clarify the underlying mechanisms that account for the noted enhancements in strength and ductility.

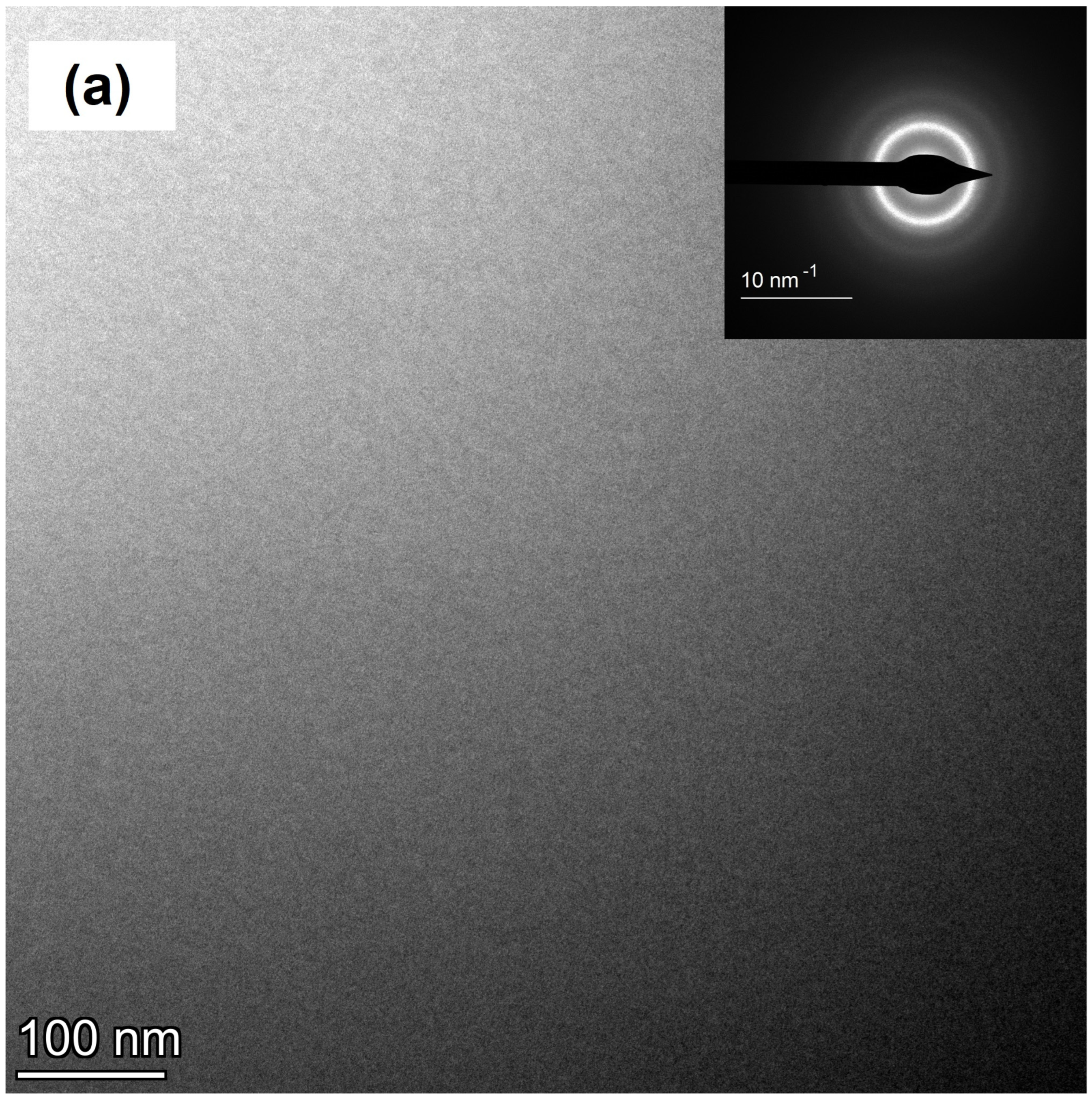

Figure 5a displays a transmission electron microscopy (TEM) image at low magnification for the U-0 sample before it was deformed. The homogenous appearance in this image, coupled with the appearance of a blurred ring in the selected area electron diffraction (SAED) pattern, where the diameter of the SAED pattern was about 1 μm, corroborates the sample’s completely amorphous constitution. Moreover, as shown in

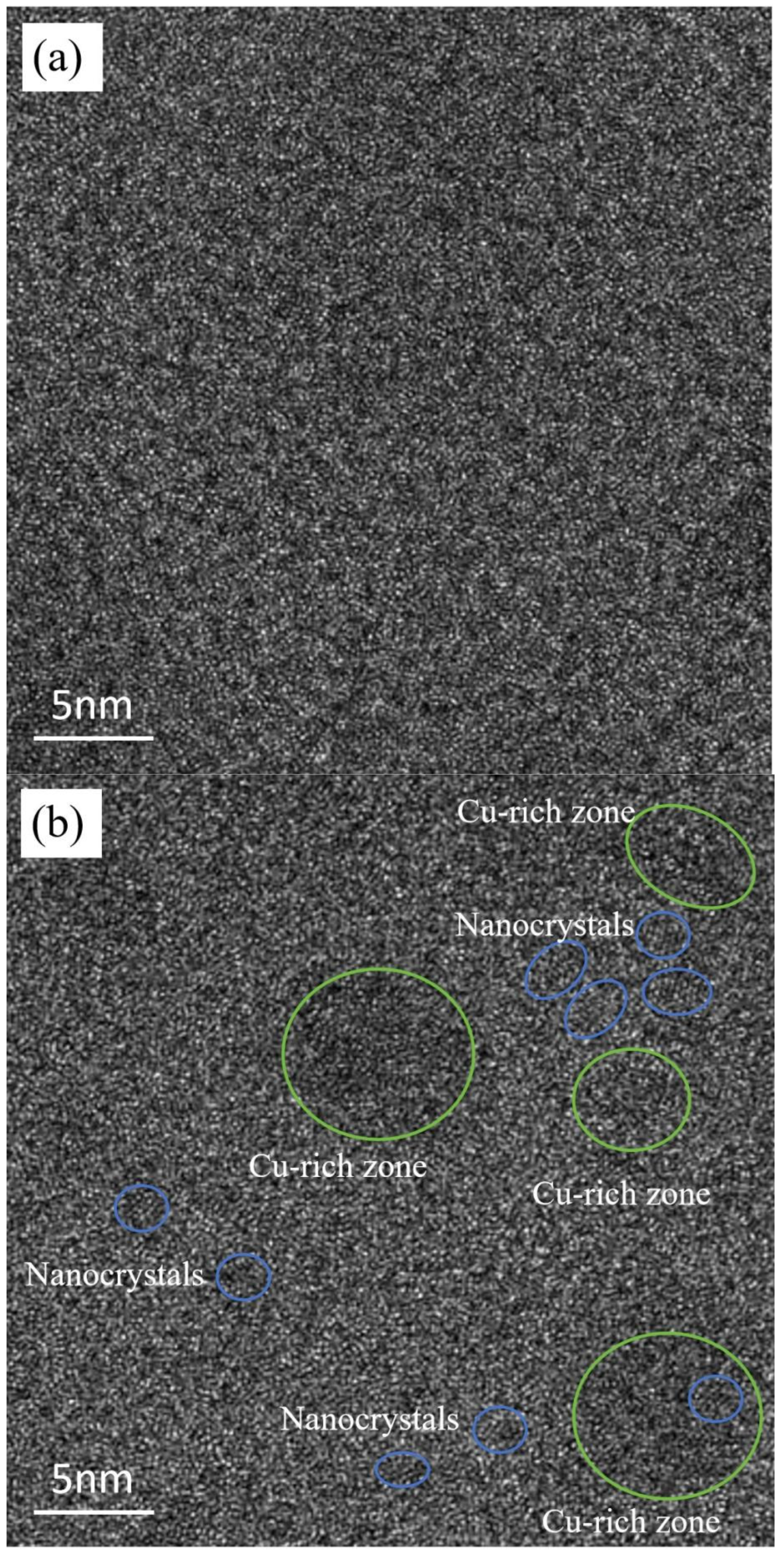

Figure 6a, an examination with high-resolution transmission electron microscopy (HRTEM) substantiates this finding, as it shows the absence of any nanocrystalline structures.

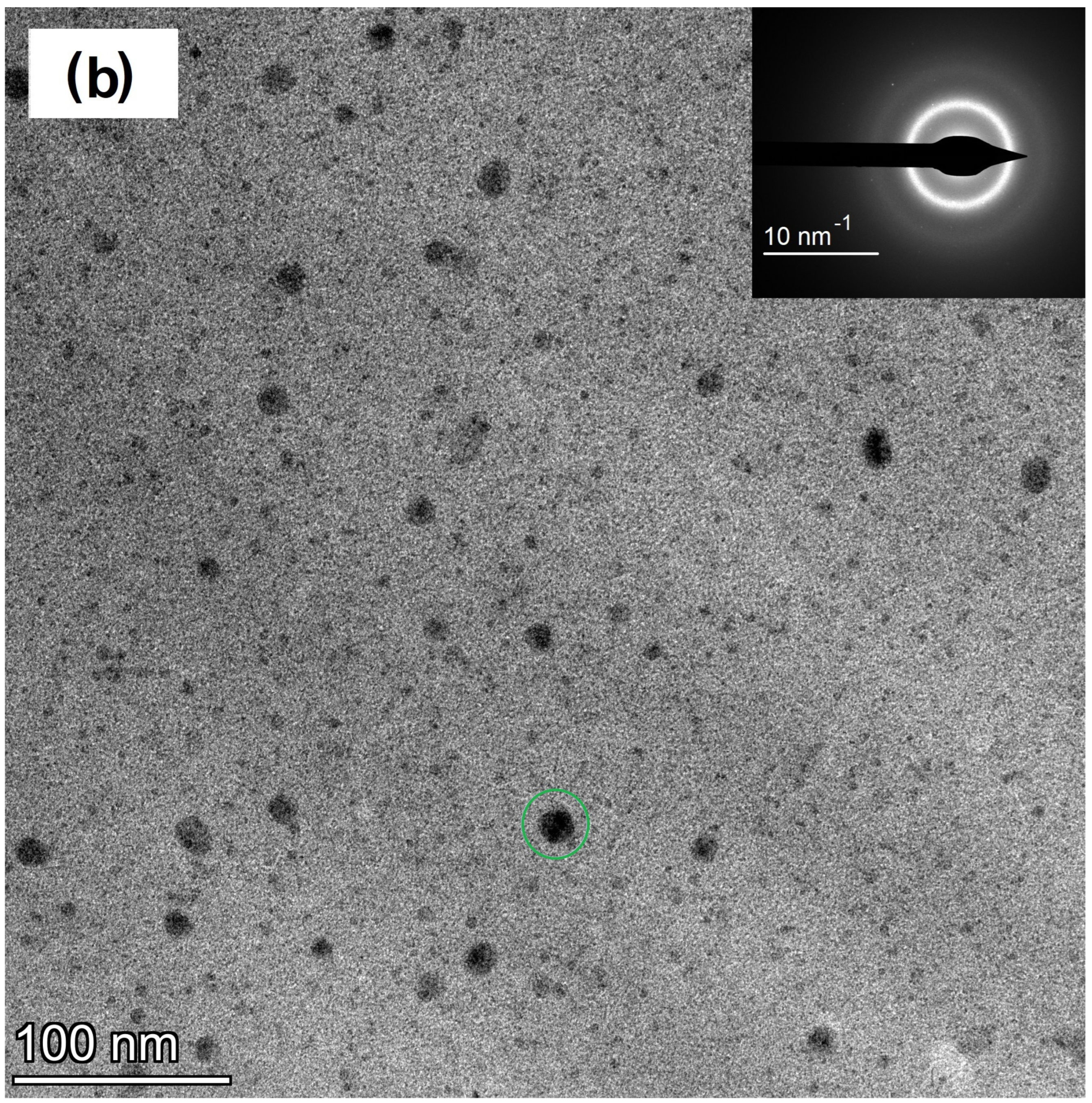

Conversely, the U-30 specimen exhibits considerable alterations in its structure following exposure to ultrasonic processing. As shown in

Figure 5b, small dark contrast features (~20 nm) appear within the amorphous matrix. The SAED pattern displays a diffuse halo and a small number of diffraction spots because the features occupy a minor volume fraction (less than 10%); HRTEM (

Figure 6b) confirms that they are nanocrystals, as evidenced by the presence of lattice fringes in the inset. These findings suggest partial crystallization induced by ultrasonic excitation.

It is probable that the appearance of these nanocrystals can be ascribed to the inherent metastability of bulk metallic glasses (BMGs), which are prone to crystallizing when subjected to external factors like thermal exposure [

23,

24,

25] or mechanical stress [

5,

13]. Ultrasound generates strong forced vibration, enhancing atomic mobility and diffusivity through mechanisms such as acoustic cavitation and streaming [

26]. Recently, similar ultrasonic-induced crystallization phenomena have been reported in Pd-based BMGs by Ichitsubo et al. [

18,

19].

Therefore, it is reasonable to deduce that ultrasonic excitation promotes atomic rearrangement, allowing atoms to occupy lower-energy configurations. This enhanced mobility facilitates structural relaxation and eventual crystallization. Under such conditions, atomic jumps deviate from conventional diffusion behavior. The cumulative effect of such anomalous displacements perturbs the thermodynamic energy landscape, ultimately driving the nucleation of crystalline phases through localized energy minimization. According to Fan et al. [

24], strength improvements occur when the crystalline volume fraction remains below ~30%, as also supported by other studies [

23,

25]. This study reveals that nanocrystals, which are more minute than typical shear bands (approximately 10 nanometers), are dispersed haphazardly throughout the material, obstructing the extension of shear bands and preserving the amorphous structure. Such an enhancement at the microscopic level contributes to a rise in both the resistance to breaking and yield strength.

Moreover, ultrasonic excitation likely promotes structural relaxation, driving atoms into more stable positions. This process increases packing density in formerly loose-packed regions, reducing local structural weaknesses and contributing to overall strength and ductility. When the size of the nano-particles is much smaller than that of the shear band and the nano-particles are separated by a glassy matrix, the deformation of the shear band is dominated by the glassy matrix, and the nanocrystals may inhibit the deformation of the shear bands [

23]. Thus, it can be inferred that a small amount of precipitated nanocrystals leads to an increase in fracture stress and yield stress. The causes of the increase in fracture stress and yield stress may be as follows: Firstly, the high-strength nanocrystals serve as robust obstacles like nails that effectively restrict the propagation of shear bands and arrest crack advancement through microstructural pinning effects. In this work, 2–5 nm nanocrystals precipitated on the glassy matrix during the ultrasound excitation for U-30 (

Figure 6b), and their size was much smaller than that of the shear band. The volume fraction of the crystalline part of U-30 was less than 10%, and the amorphous matrix was mainly retained. In this stress-concentrated configuration, these localized high-stress nanocrystals distributed along shear bands acted as effective obstacles, which not only obstructed further propagation of the primary shear bands but also delayed crack initiation and growth. Secondly, owing to the pronounced stress gradient at crystalline–amorphous interfaces, primary shear bands preferentially nucleate through stress-activated free volume coalescence, subsequently undergoing directional propagation governed by interfacial shear stress anisotropy. These secondary shear bands form hierarchical branching networks with wing-like primary counterparts, creating a three-dimensional stress redistribution architecture that enables (1) strain accommodation through coordinated shear band intersection and bifurcation; (2) energy dissipation via interface-mediated dislocation–STZ (shear transformation zone) interactions; and (3) crack blunting by shear band network rearrangement. This multiscale deformation synergy effectively delays strain localization while maintaining structural integrity under loading. Consequently, the partial crystallization, in tandem, improves both strength and the capacity of plastic deformation [

27,

28,

29].

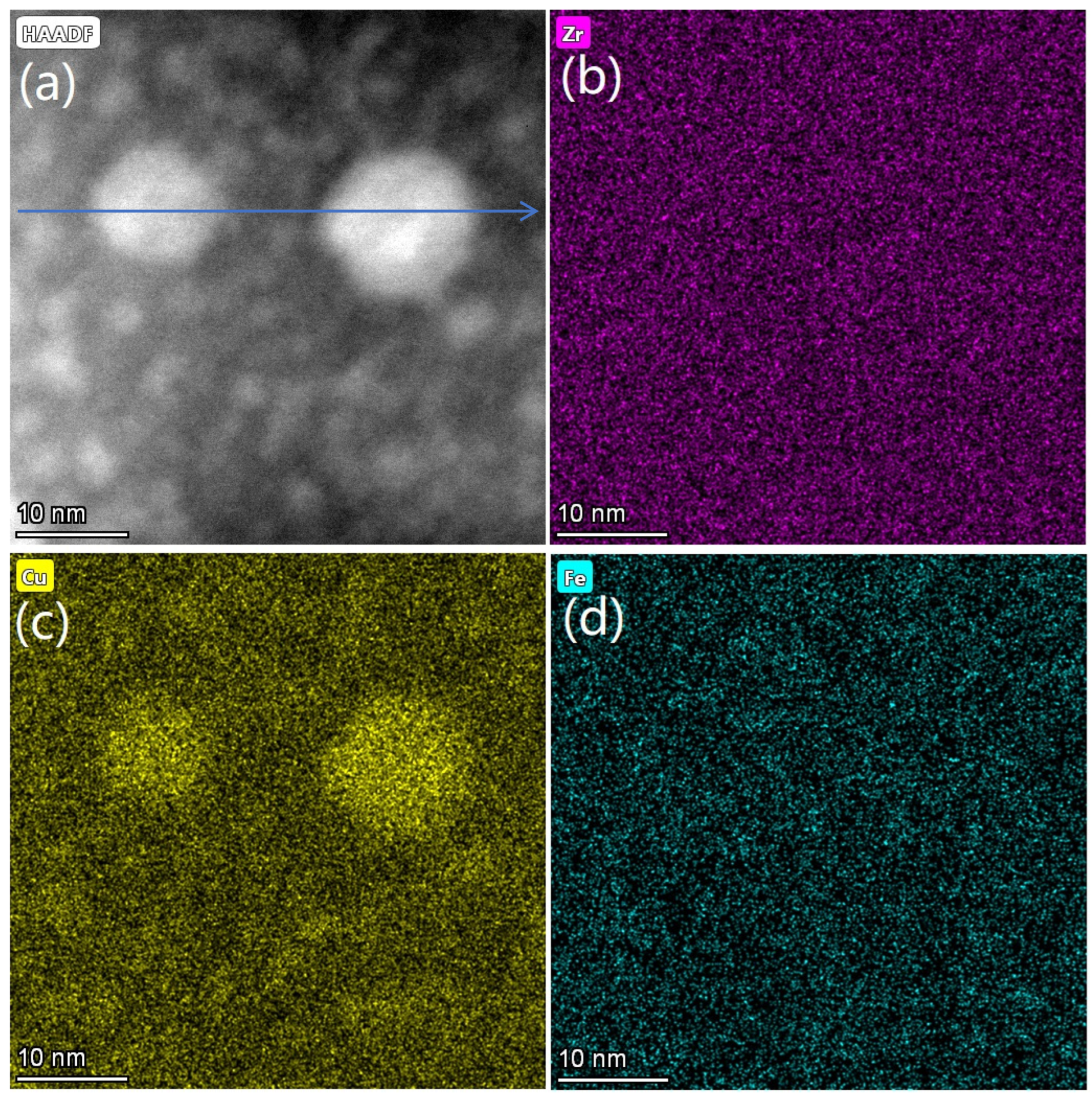

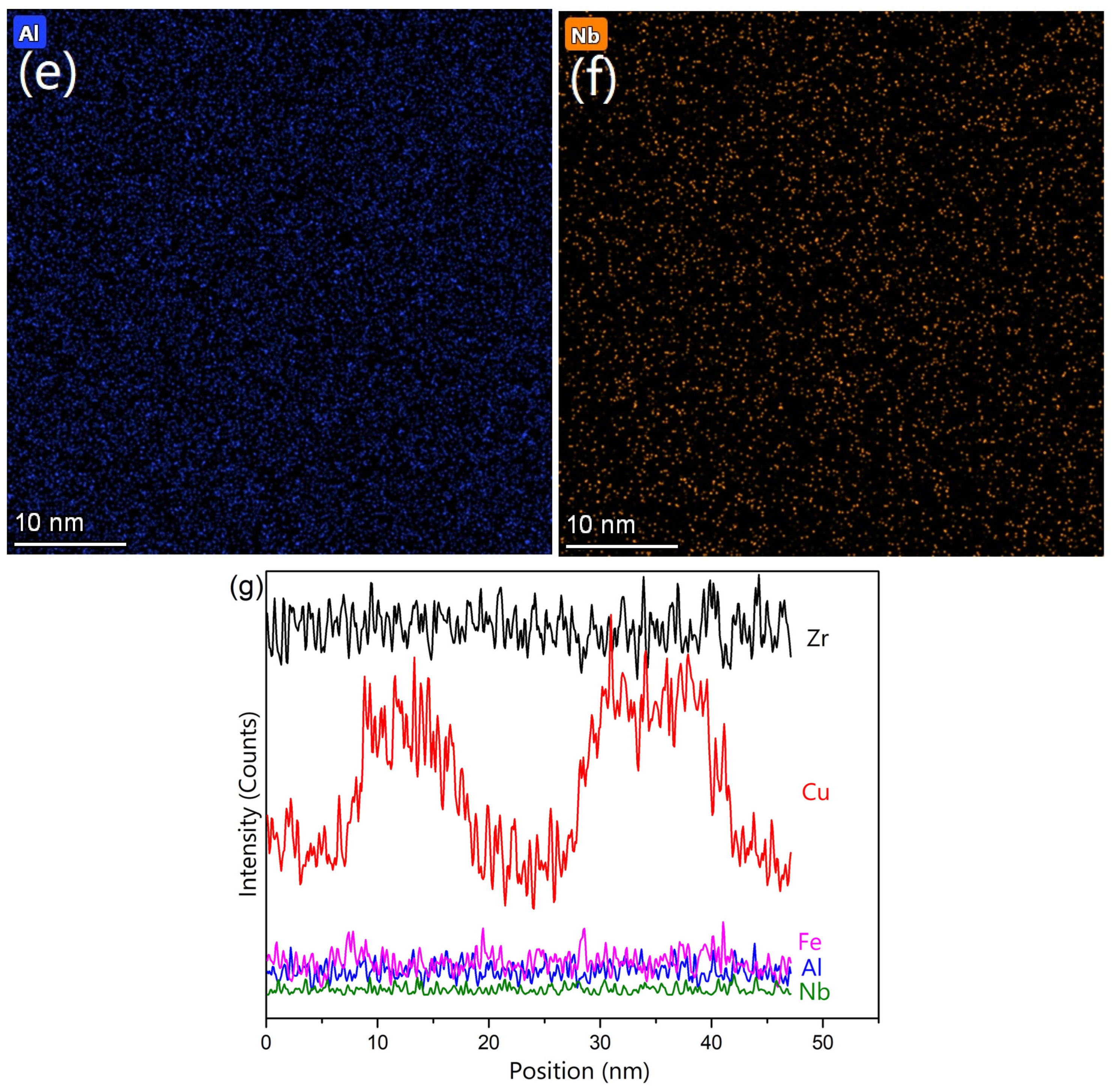

To deepen the insight into the impact of ultrasound, the elemental composition distribution of specimen U-30 was examined.

Figure 7a shows a scanning TEM (STEM) image with visible spherical precipitates, consistent with the dark contrast features observed in

Figure 5b. Elemental mapping (

Figure 7b–f) reveals that these precipitates are Cu-rich, indicative of local chemical inhomogeneity. The elemental line scanning image of

Figure 7g shows the distribution of Zr, Cu, Al, Fe and Nb elements along the blue arrow in

Figure 7a, which indicates that the concentration of the Cu element reaches a peak in the Cu-rich area and then becomes relatively stable in the Cu-poor area.

Viewed through the lens of thermodynamics, the emergence of distinct phases can be attributed to the endothermic nature of mixing for Cu-Fe (13 kJ/mol) and Cu-Nb (3 kJ/mol) pairs [

30], which promotes segregation. Conversely, the Fe-Nb pair, displaying an exothermic mixing response with an enthalpy of −16 kJ/mol, favors the creation of regions rich in Fe and Nb. Although Fe and Nb are present in low concentrations and not clearly resolved in EDS, Cu is abundant and has a diffusion coefficient significantly higher than that of Zr [

30], making it more prone to mobilization during deformation. The suppression of Cu mobility by larger Zr and Al atoms likely results in the formation of Cu-rich zones [

31]. Interestingly, phase separation is absent in the untreated U-0 sample, suggesting that ultrasonic excitation plays a critical role in triggering this phenomenon. This aligns with prior findings regarding phase separation in amorphous alloys triggered by stress or heat, as documented in earlier works [

32]. Ultrasonic stress and prolonged localized heating may synergistically promote the development of heterogeneous microstructures in U-30.

These Cu-rich zones act as soft zones [

33], reaching critical shear stress earlier than the surrounding harder glass matrix. According to the concept of shear transformation zones (STZs), soft regions initiate deformation, while adjacent hard regions constrain it, resulting in STZ branching and the multiplication of shear bands. This behavior contributes to increased crack resistance and improved plasticity, as observed in the U-30 sample. Thus, deformation-induced phase separation provides an additional explanation for the enhanced mechanical performance (especially fracture toughness) and plastic platform observed in U-30.

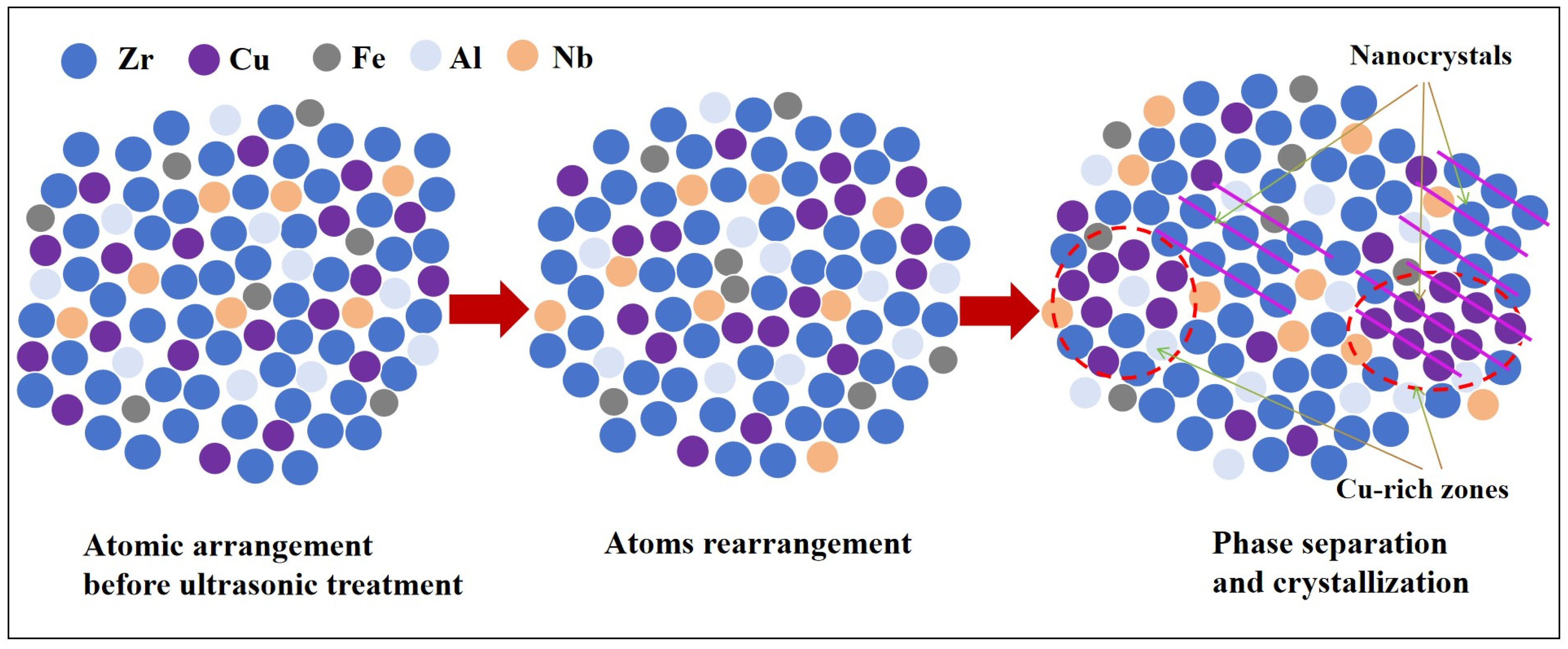

In summary, ultrasonic treatment can induce structural changes in bulk metallic glass. The internal microstructure variation mechanism of bulk metallic glasses under ultrasonic treatment is shown in

Figure 8. The amorphous structure is in an unstable form. Ultrasonic treatment induces multiscale structural modifications in bulk metallic glasses through thermomechanical coupling effects, and the amorphous structure undergoes phase separation or crystallization. In the first place, under the action of ultrasonic treatment, the atoms in the bulk metallic glass are rearranged. High-frequency ultrasonic vibrations generate localized stress concentrations, activating cooperative shear transformations that facilitate atomic reconfiguration through free volume redistribution. This process triggers structural relaxation with a reduced activation energy barrier under the continuous action of ultrasonic treatment, and atoms in certain regions of bulk metallic glasses may crystallize, forming nanocrystals. The ultrasonic-induced stress gradient drives preferential nucleation of nanocrystalline phases at stress-concentrated regions. These nanocrystals form semi-coherent interfaces with the amorphous matrix. Simultaneously, phase separation occurs in some regions of the bulk metallic glass under the continuous action of ultrasonic treatment. There are two different kinds of phase separation. One form of phase separation is amorphous–amorphous phase separation. The compositional fluctuations promote the formation of copper-rich amorphous regions in zirconium-based amorphous materials. Another form of phase separation is crystal–amorphous phase separation. Localized crystallization occurs in phase-separated regions through stress-assisted diffusion. This improvement in both strength and ductility is attributed to the formation of nanoscale crystalline phases and ultrasound-induced phase separation within the amorphous matrix, which collectively promote shear band multiplication and inhibit crack propagation.

Author Contributions

Conceptualization, X.H.; methodology, X.C., T.W., Y.L. and R.B.; formal analysis, X.C., Z.Z., T.W., Y.L., R.B. and M.W.; investigation, Z.Z. and M.W.; data curation, X.C.; writing—original draft, X.C. and T.W.; writing—review and editing, T.W. and X.H.; visualization, Z.Z.; supervision, X.H.; funding acquisition, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (No. U23A20621, U22A20105, No. 52461031) and the Natural Science Foundation of Xinjiang Uygur Autonomous Region of China (No. 2024D01C13).

Data Availability Statement

The original contributions presented in this study are included in the rticle. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Xiaoming Chen and Mingming Wang were employed by the company Water Machinery and Remanufacturing Technology Engineering Laboratory of Zhejiang Province, Hangzhou River Mechanical and Electrical Equipment Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wang, W. The Elastic Properties, Elastic Models and Elastic Perspectives of Metallic Glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Wang, R.; Zhao, D.; Pan, M.; Wang, W. Super plastic bulk metallic glasses at room temperature. Science 2007, 315, 1385–1388. [Google Scholar] [CrossRef]

- Lu, Z.; Jiao, W.; Wang, W.; Bai, H. Flow Unit Perspective on Room Temperature Homogeneous Plastic Deformation in Metallic Glasses. Phys. Rev. Lett. 2014, 113, 045501. [Google Scholar] [CrossRef]

- Gao, M.; Dong, J.; Huan, Y.; Wang, Y.; Wang, W. Macroscopic tensile plasticity by scalarizating stress distribution in bulk metallic glass. Sci. Rep. 2016, 6, 21929. [Google Scholar] [CrossRef]

- Wang, T.; Si, J.; Wu, Y.; Lv, K.; Liu, Y. Two-step work-hardening and its gigantic toughening effect in Zr-based bulk metallic glasses. Scr. Mater. 2018, 150, 106–109. [Google Scholar] [CrossRef]

- Xi, X.; Zhao, D.; Pan, M.; Wang, W.; Wu, Y.; Lewandowski, J.J. Fracture of Brittle Metallic Glasses: Brittleness or Plasticity. Phys. Rev. Lett. 2005, 94, 125510. [Google Scholar] [CrossRef]

- Hess, P.A.; Poon, S.J.; Shiflet, G.J.; Reinhold, H.D. Indentation fracture toughness of amorphous steel. J. Mater. Res. 2005, 20, 783–786. [Google Scholar] [CrossRef]

- Peker, A.; Johnson, W.J. A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 1993, 63, 2342–2344. [Google Scholar] [CrossRef]

- Conner, R.D.; Rosakis, A.J.; Johnson, W.L.; Owen, D.M. Fracture toughness determination for a beryllium-bearing bulk metallic glass. Nat. Mater. 1997, 37, 1373–1378. [Google Scholar] [CrossRef]

- Demetriou, M.D.; Launey, M.E.; Garrett, G.; Schramm, J.P.; Hofmann, D.C.; Johnson, W.L.; Ritchie, R.O. A damage-tolerant glass. Nat. Mater. 2011, 10, 123–128. [Google Scholar] [CrossRef]

- Luo, P.; Wen, P.; Bai, H.Y.; Ruta, B.; Wang, W. Relaxation decoupling in metallic glasses at low temperatures. Phys. Rev. Lett. 2017, 118, 225901. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wang, L.; Wang, Q.; Liu, Y.; Hui, X. Pronounced plasticity caused by phase separation and β-relaxation synergistically in Zr–Cu–Al–Mo bulk metallic glasses. Sci. Rep. 2017, 7, 1238. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wu, Y.; Si, J.; Liu, Y.; Hui, X. Plasticizing and work hardening in phase separated Cu-Zr-Al-Nb bulk metallic glasses by deformation induced nanocrystallization. Mater. Des. 2018, 142, 74–82. [Google Scholar] [CrossRef]

- Ketov, S.V.; Sun, Y.; Nachum, S.; Lu, Z.; Checchi, A.; Beraldin, A.R.; Bai, H.; Wang, W.; Louzguine-Luzgin, D.V.; Carpenter, M.A.; et al. Rejuvenation of metallic glasses by non-affine thermal strain. Nature 2015, 524, 200–203. [Google Scholar] [CrossRef]

- Song, W.; Lu, X. Improving plasticity of the Zr46Cu46Al8 bulk metallic glass via thermal rejuvenation. Sci. Bull. 2018, 63, 840–844. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Z.; Hu, Y.; Xing, J.; Lu, T.; Wei, B. Effect of ion irradiation on mechanical behaviors of Ti40Zr25Be30Cr5 bulk metallic glass. Mater. Res. 2012, 15, 713–717. [Google Scholar] [CrossRef]

- Cao, Y.; Xie, X.; Antonaglia, J.; Winiarski, B.; Wang, G.; Shin, Y.C.; Withers, P.J.; Dahmen, K.A.; Liaw, P.K. Laser shock peening on Zr-based bulk metallic glass and its effect on plasticity: Experiment and modeling. Sci. Rep. 2015, 5, 10789. [Google Scholar] [CrossRef]

- Ichitsubo, T.; Matsubara, E.; Kai, S.; Hirao, M. Ultrasound-induced crystallization around the glass transition temperature for Pd40Ni40P20 metallic glass. Acta Mater. 2004, 52, 423–429. [Google Scholar] [CrossRef]

- Ichitsubo, T.; Matsubara, E.; Yamamoto, T.; Chen, H.; Nishiyama, N.; Saida, J.; Anazawa, K. Microstructure of fragile metallic glasses inferred from ultrasound-accelerated crystallization in Pd-based metallic glasses. Phys. Rev. Lett. 2005, 95, 245501. [Google Scholar] [CrossRef]

- Ma, C.; Qin, H.; Ren, Z.; O’Keeffe, S.C.; Stevick, J.; Doll, G.L.; Dong, Y.; Winiarski, B.; Ye, C. Increasing fracture strength in bulk metallic glasses using ultrasonic nanocrystal surface modification. J. Alloys Compd. 2017, 718, 246–253. [Google Scholar] [CrossRef]

- Zhu, Z.; Gu, L.; Xie, G.; Zhang, W.; Inoue, A.; Zhang, H.; Hu, Z. Relation between icosahedral short-range ordering and plastic deformation in Zr–Nb–Cu–Ni–Al bulk metallic glasses. Acta Mater. 2011, 59, 2814–2822. [Google Scholar] [CrossRef]

- Salivar, G.C.; Goree, J.G. The applicability of ASTM standard test specimens to fracture and fatigue crack growth of discontinuous-fiber composites. J. Test. Eval. 1998, 26, 336–345. [Google Scholar] [CrossRef]

- Qin, F.; Wang, X.; Inoue, A. Effect of annealing on microstructure and mechanical property of a Ti–Zr–Cu–Pd bulk metallic glass. Intermetallics 2007, 15, 1337–1342. [Google Scholar] [CrossRef]

- Fan, C.; Louzguine, D.V.; Li, C.; Inoue, A. Nanocrystalline composites with high strength obtained in Zr–Ti–Ni–Cu–Al bulk amorphous alloys. Appl. Phys. Lett. 1999, 75, 340–342. [Google Scholar] [CrossRef]

- Xing, L.; Bertrand, C.; Dallas, J.-P.; Cornet, M. Nanocrystal evolution in bulk amorphous Zr57Cu20Al10Ni8Ti5 alloy and its mechanical properties. Mater. Sci. Eng. A 1998, 241, 216–225. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, B.; Liu, H.; Hu, L.; Wei, B. Three orthogonal ultrasounds fabricate uniform ternary Al-Sn-Cu immiscible alloy. Sci. Rep. 2019, 6, 36718. [Google Scholar] [CrossRef]

- Greer, A.L.; Cheng, Y.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Qu, R.; Liu, Z.; Wang, G.; Zhang, Z. Progressive shear band propagation in metallic glasses under compression. Acta Mater. 2015, 91, 19–33. [Google Scholar] [CrossRef]

- Nieh, T.G.; Yang, Y.; Lu, J.; Liu, C. Effect of surface modifications on shear banding and plasticity in metallic glasses: An overview. Prog. Nat. Sci. Mater. Int. 2012, 22, 355–363. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, H.; Todd, I. Phase-separation-enhanced plasticity in a Cu47.2Zr46.5Al5.5Nb0.8 bulk metallic glass. Scr. Mater. 2014, 72–73, 47–50. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, T.; Hou, Q.; Hao, Q.; Qiao, J. Deformation-induced microstructural heterogeneity and rejuvenation in a Zr-based bulk metallic glass. J. Non-Cryst. Solids 2021, 574, 121148. [Google Scholar] [CrossRef]

- Nomoto, K.; Ceguerra, A.V.; Gammer, C.; Li, B.; Bilal, H.; Hohenwarter, A.; Gludovatz, B.; Eckert, J.; Ringer, S.P.; Kruzic, J.J. Medium-range order dictates local hardness in bulk metallic glasses. Mater. Today 2021, 44, 48–57. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).