1. Introduction

Additive manufacturing (AM) generally includes a range of technologies that fabricate products layer by layer from a digital three-dimensional model. Additive manufacturing technologies are more efficient for producing complex parts in small quantities where traditional manufacturing techniques would incur significant lead times and material waste. However, a major issue with additive manufacturing (AM) and electron beam melting (EBM) in particular is the building of structures with overhanging parts. That is because overhanging surfaces require supporting structures when the part is built. Support structures are essential for sustaining overhanging elements in nearly all AM methods. Support structures are generated according to the part’s specifications during the pre-processing phase. In the post-processing phase, support structures are removed using various processes, including chemical, mechanical, and thermal methods, among others [

1,

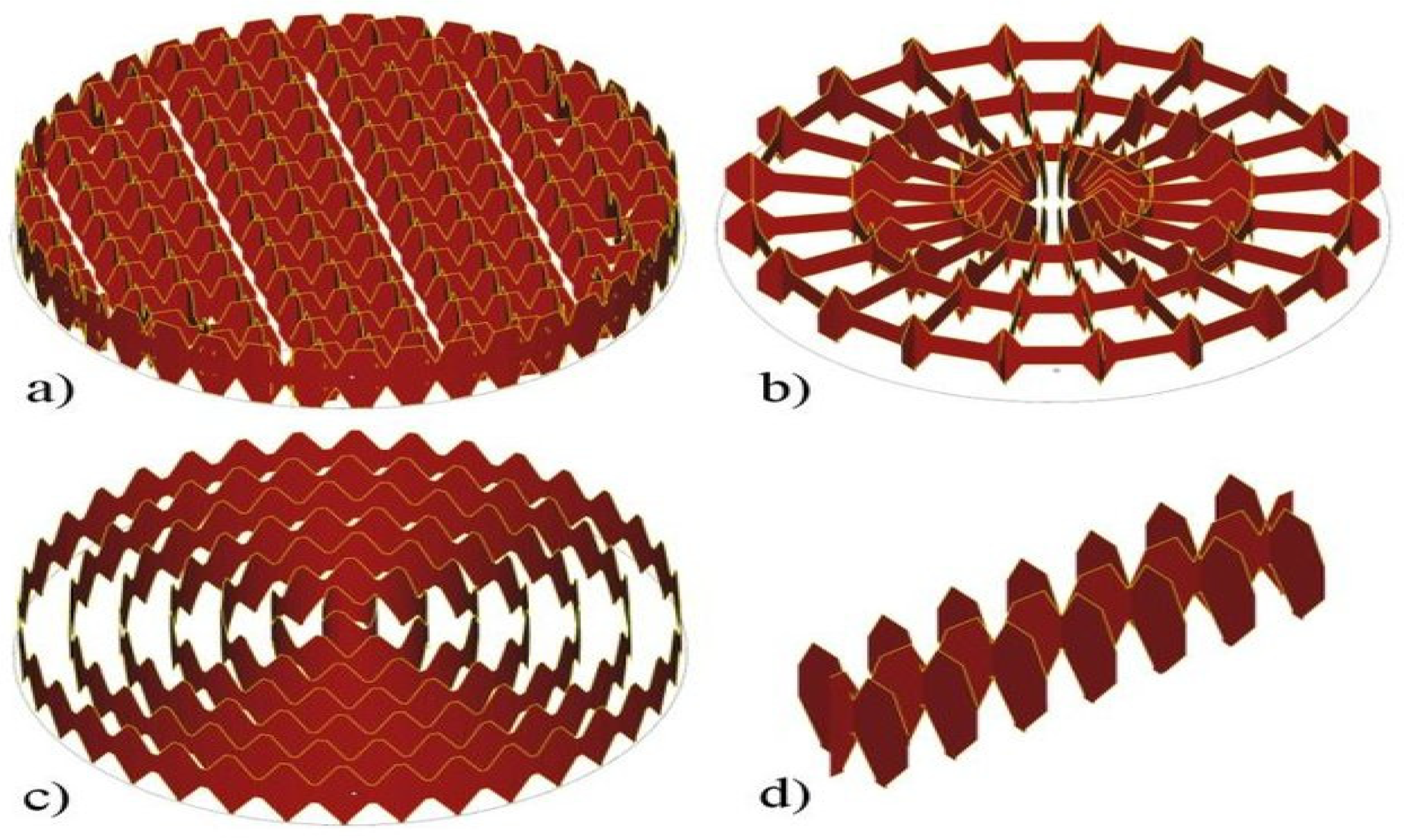

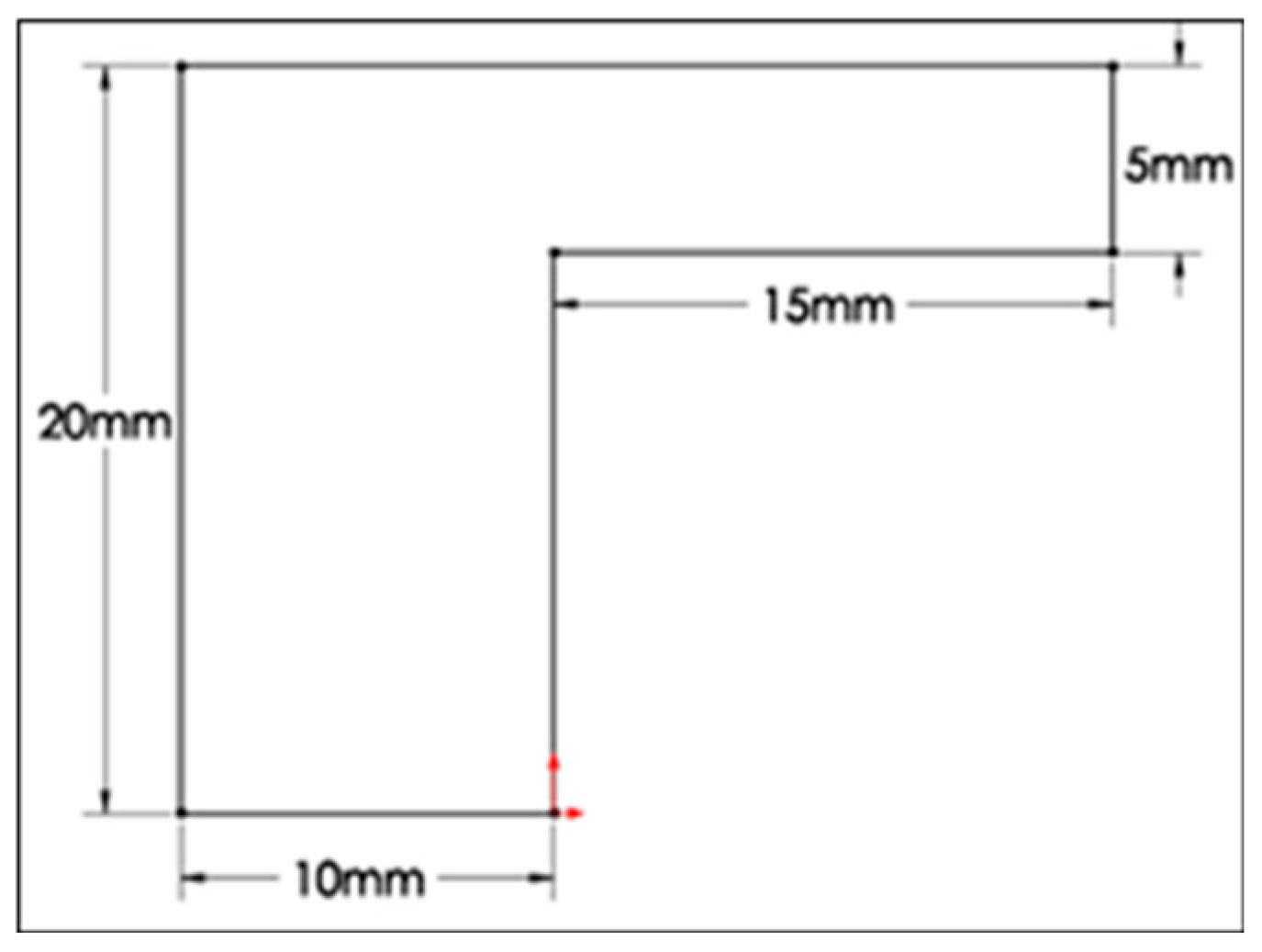

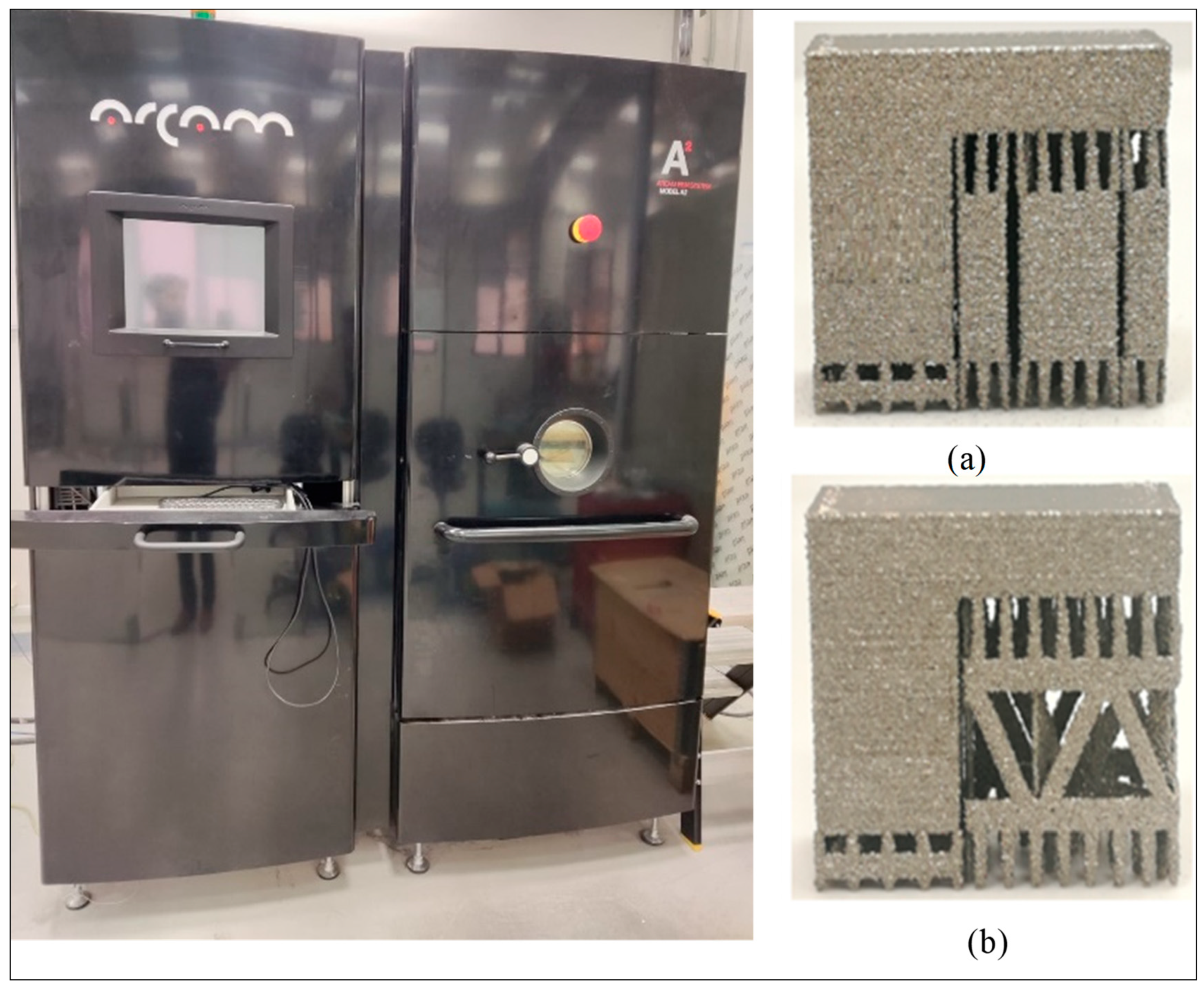

2]. The SG + module in Magics software is utilized for the design and fabrication of support structures. The SG + module provides many forms of support, including points, webs, blocks, and contour, as seen in

Figure 1. The block support structure is ideal for large volumetric parts, point support is suitable for small features, web support is used for circular areas, and line support structures are applied in narrow downward-facing locations. The block contour support structure was utilized to improve the stability of object contours during metal sintering [

1].

Automated support generated by software, particularly block support, often fails to accommodate complicated geometries and generally overestimates support thickness. Furthermore, it is inadequate for retrieving the raw loose powder that becomes ensnared in the support structures throughout the construction process [

3]. Block support structures possess numerous design parameters that can influence the performance of the final parts. Several researchers have paid attention to the design and optimization of the support structure of metal additive manufacturing, for instance. Jiang et al. [

4] developed a support generation technique via print path planning to minimize support material usage in additive manufacturing parts with flat features. In their study, two parts were produced using the proposed technique, resulting in significantly reduced support material usage compared to conventional line and grid support production methods. The results demonstrate the efficacy of this support generation approach in lowering both support usage and surface degradation, hence rendering additive manufacturing a more environmentally friendly and sustainable production technology. Ameen et al. [

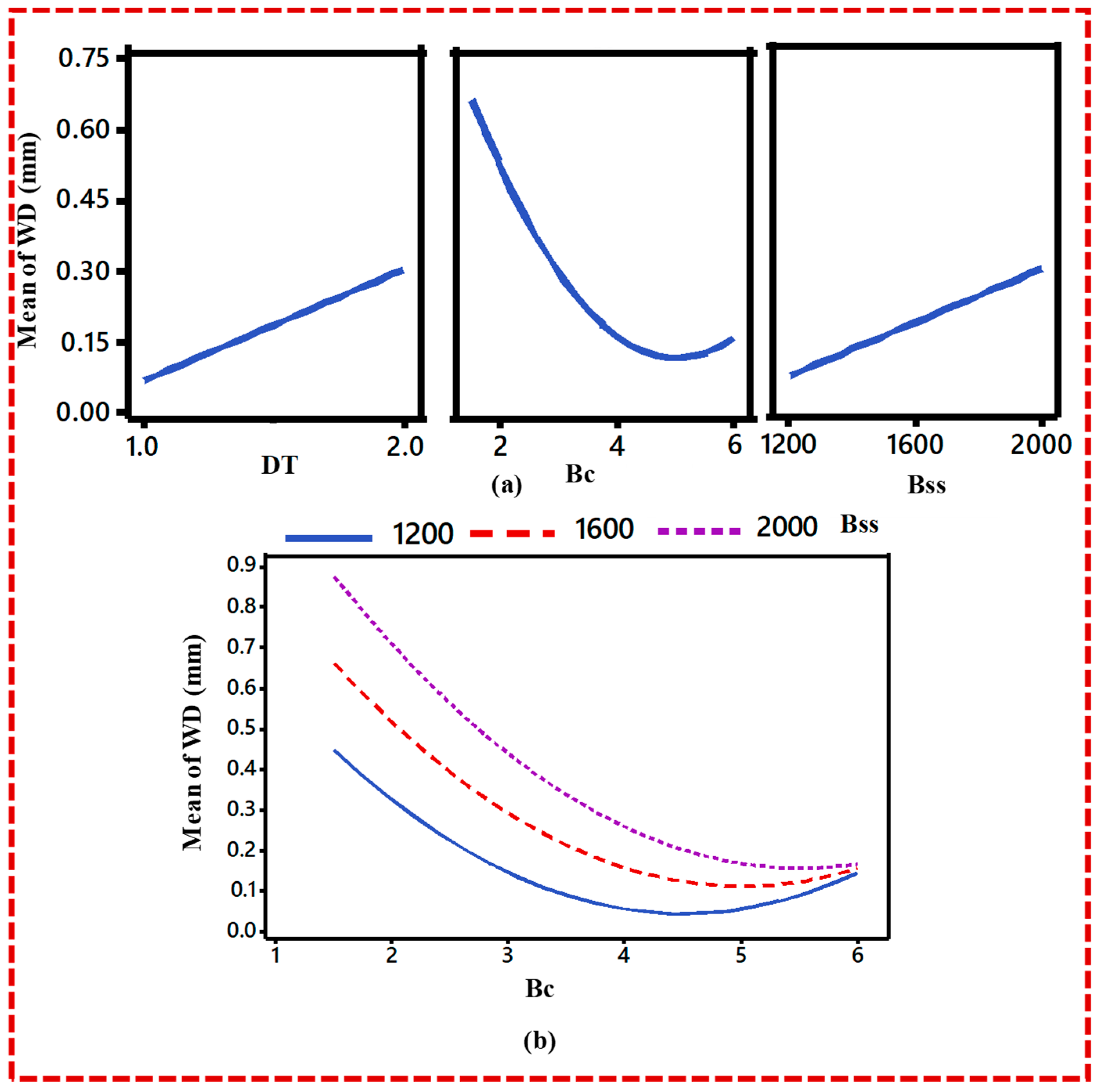

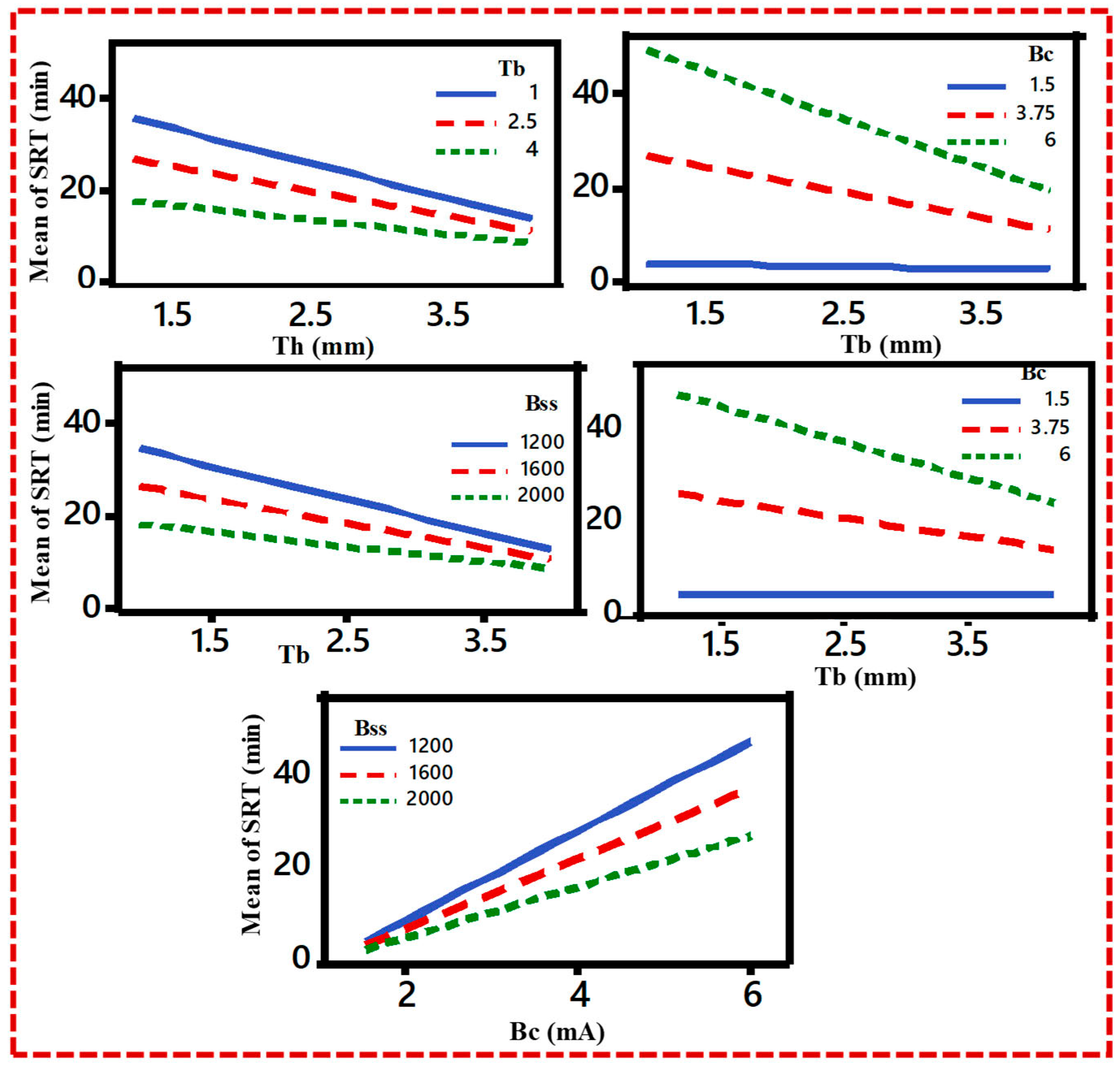

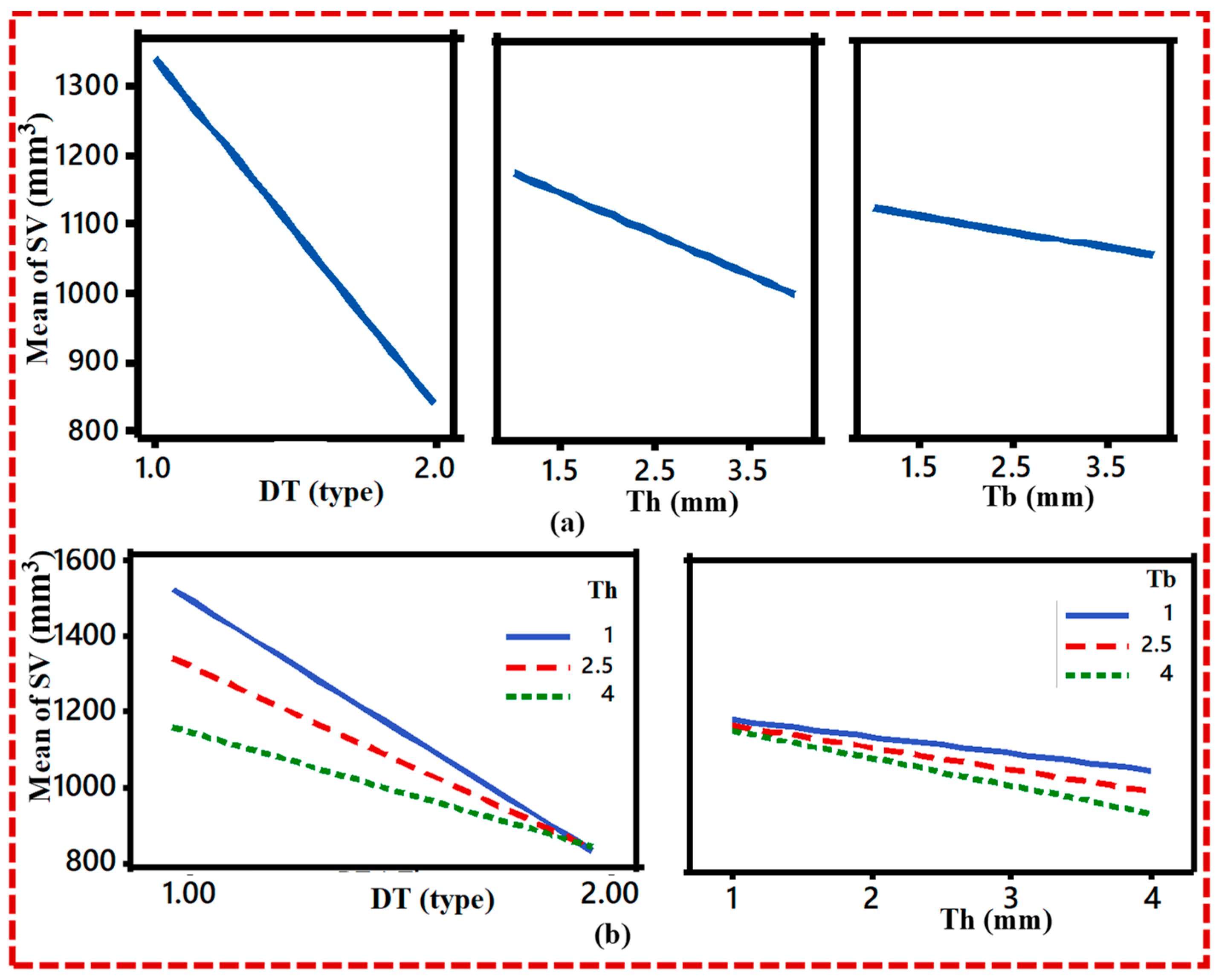

5] examined how different process parameters and support design aspects impacted the cost and quality of the support structures used in printing the EBM Ti6Al4V part. The findings indicate that the design and process parameters of the support significantly impact the support volume and accuracy of overhangs. The most significant deformations linked to overhang manufacturing were shown to be warping and side loss deformations. Shen [

6] proposed a method for generating bridge support structures that may reduce material usage by around 15.19% and time by 24.41% compared to traditional vertical support structures. Calig-nano [

7] studied the manufacturability of overhanging structures using improved support parts for aluminum and titanium alloys. They executed an experimental investigation to determine the optimum self-supporting overhanging structures utilizing the Taguchi L36 design methodology. The findings showed that non-assembly mechanisms with overhang surfaces may be built with optimum support. They also recommended that to achieve the optimal balance between accuracy, cost, and production time, it is important to orient the item appropriately in the SLM machine to build it with minimal support structure.

Support structures are a significant issue in additive manufacturing, increasing production time, material usage, effort, processing time, and post-processing costs. Several research attempts have been made to address these issues. For example, Ameen et al. [

8] studied the influence of EBM process parameters (current, scan speed, line offset, and focus offset) on warping deformation. They found that a scan speed of 4530 mm/s, a focus offset of 3 mm, a line offset of 0.3 mm, and a current of 15 mA obtained the lowest deformation at 0.28 mm. Vaidya and Anand [

9] utilized Dijkstra’s shortest-path method [

10] to develop cellular support structures that reduce support volume. They employed a numerical model to demonstrate the capability of the proposed approaches. Their case studies demonstrate a significant reduction in support volume, sintered area, and support contact area as compared to totally solid support, while adequately accounting for support accessibility during post-processing. Järvinen et al. [

11] evaluated the usefulness of two support structure designs, namely, web and tube support, for the LAM of stainless steel in two industrial applications: one for dentistry and another for jewelry use. The results show that the removability of the web support type was much superior to that of the tube support type. In addition, it was found that support structures are crucial to the LAM process, significantly influencing both manufacturability and the final quality of the part. Lindecke et al. [

12] investigated the tensile strength of the connection between support structures and the SLM TiAl6V4 parts for different support structures. The findings indicate that standard block support structures yield an average actual support strength of around 269 MPa, representing a significant decrease from the solid material’s strength of 1286 MPa. Allen and Dutta [

13] delineated a method for ascertaining the orientation necessary for fabricating an item with minimum support systems. The algorithm selects the optimal orientation from a collection of potential orientations. For example, if two orientations necessitate support structures with identical contact surface areas, the orientation with the lower center of mass is selected. It is improbable that the two orientations would possess a support structure with similar contact areas. Wei et al. [

14] proposed a model decomposition strategy utilizing genetic algorithm optimization for identifying overhang regions and support-related overhang regions to enhance the precision of overhang identification and printing accuracy in fused filament fabrication (FFF). The findings indicated that the suggested approach for producing support structures might decrease material consumption by 27%.

Many researchers have suggested various designs and optimizations of support structure design. Poyraz et al. [

15] examined several support structure designs and applied them to a thin-walled IN625 part fabricated by DMLS. To accurately portray extreme situations, they conducted two tests on support structures with an overhanging geometry parallel to the XY plane rather than on inclined surfaces. They employed block supports to facilitate simplicity and enhance comprehension of the impacts seen during studies. The results indicated that hatching factors impact support structures significantly more than tooth factors. Dimopoulos et al. [

16] evaluated the thermal behavior of various support structures and optimized the designs to minimize support volume and residual stress while maintaining high-quality prints during LPBF. They evaluated several support structures, including blocks, lines, contours, and cones, to find the best strategies for reducing support volume and residual stress without sacrificing print quality. The results showed that the block supports had great thermal behavior. Weber et al. [

17] employed tree-like support structures to evaluate the effect of design and laser powder bed fusion (L-PBF) parameters. They identified scanning speed and laser power as the most influential L-PBF parameters. In addition, it was found that the design parameters of stem and branch diameter and the number of branches had the most significant impact on the structural qualities. Strano et al. [

18] introduced an innovative methodology for designing support structures that enhance the orientation of the build section and the configuration of the support cellular structure. Wang et al. [

19] investigated the overhanging structural fabrication capabilities of selective laser melting for 316L stainless steel parts. They determined that in overhanging constructions beyond the crucial inclination angle, the support line should be designed according to the slicing slope, utilizing a tooth profile with a higher contact rate at the base to ensure effective operation. Hussein et al. [

20] investigated the feasibility of using cellular support structures to support selective laser sintering for metallic parts. They validated their technique by conducting some exploratory experiments and conducting more studies based on their early findings [

21]. Investigating two forms of lattice structures, the gyroid and the diamond, for their appropriateness as support structures, the results demonstrate that the structural needs may be satisfied with less material and building time spent. In addition, cellular support systems have demonstrated the capability to sustain metallic parts and mitigate part deformation. White et al. [

22] introduced a computational framework that helps with the design of lattice support structures, using stochastic optimization to maximize heat dissipation for LPBF. The results show that the framework is valid by producing optimum hybrid lattice support structures for a cantilever beam, outperforming the uniformly distributed benchmark design by around 16% while still meeting manufacturing restrictions. Additionally, White et al. [

23] presented a modified simulated annealing technique for developing lattice structures using laser powder bed fusion by optimizing the distribution of a library of diverse unit cell types, resulting in hybrid lattice support structures. The results demonstrate that the technology can meet production restrictions while saving up to 62% in post-processing costs and 61% in material costs compared to a solid support domain. Concerning residual stress and the time needed for support removal, Sulaiman et al. [

24] optimized the parameters of the contour support structure, which include contour offset, teeth height, teeth top length, and teeth base length, for AlSi10Mg SLM parts. The findings demonstrate that contour offset substantially affects the magnitude of residual stress and the duration needed for support removal, whereas all factors are relevant for support volume. For minimal residual stress, the optimal parameters are a contour offset of 0.6 mm, a height of 1.4 mm, a top length of 0.75 mm, and a base length of 1.55 mm of teeth.

Table 1 summarizes the reported studies on the AM technology-based block support structure for metal parts. These studies showed that support structure design in AM is crucial for enhancing the performance of fabricating high-quality parts to satisfy the requirements of sustainable manufacturing.

Machine learning (ML) is an effective method for constructing industrial models, especially for monitoring and predicting manufacturing process performance. ML is a field of artificial intelligence that develops models or systems that can learn from data and make predictions or take actions. Artificial neural networks (ANN) and adaptive neuro-fuzzy inference systems (ANFISs) are part of a family of machine learning (ML) algorithms and have achieved more accurate outcomes compared with traditional methods in developing models [

25,

26,

27,

28,

29]. Several researchers have adapted artificial intelligence techniques such as ANNs and ANFISs to enhance multi-objective optimization and guarantee reliable results in manufacturing processes, primarily because these processes are highly complex and nonlinear [

30,

31,

32]. For example, Abbas et al. [

33] integrated the Edgeworth–Pareto approach with ANNs to optimize the optimization of milling parameters, reducing the time spent on machining and improving surface integrity. Based on the effective results of the ANFIS method, Alqahtani et al. [

30] used this method to enhance the quality of micromachining performance. In the milling of titanium alloys with difficult-to-machine surfaces, energy efficiency and tool wear may be predicted and optimized using the hybrid technique proposed by Xi et al. [

34], which combines radial basis function with ANN and MOPSO models. The data clearly show the efficacy of the proposed strategy. Deb and Jain [

35] developed a multi-objective NSGA-II approach, designated NSGA-III, which exhibits improved efficacy in addressing problems with more than two objectives. The implementation of NSGA-III demonstrated its superiority in generating efficient optimal solutions across several objectives. Nasr and Anwar [

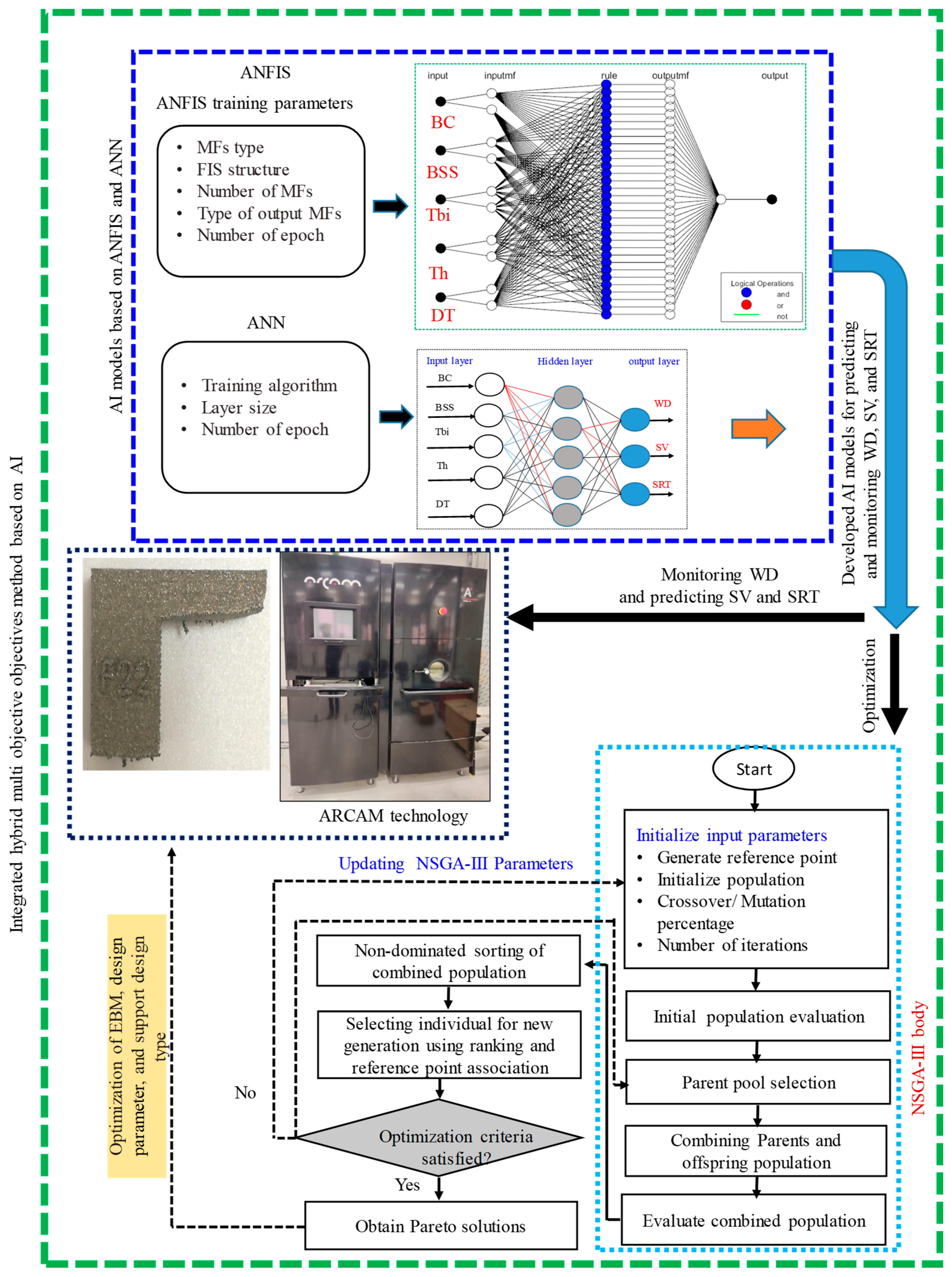

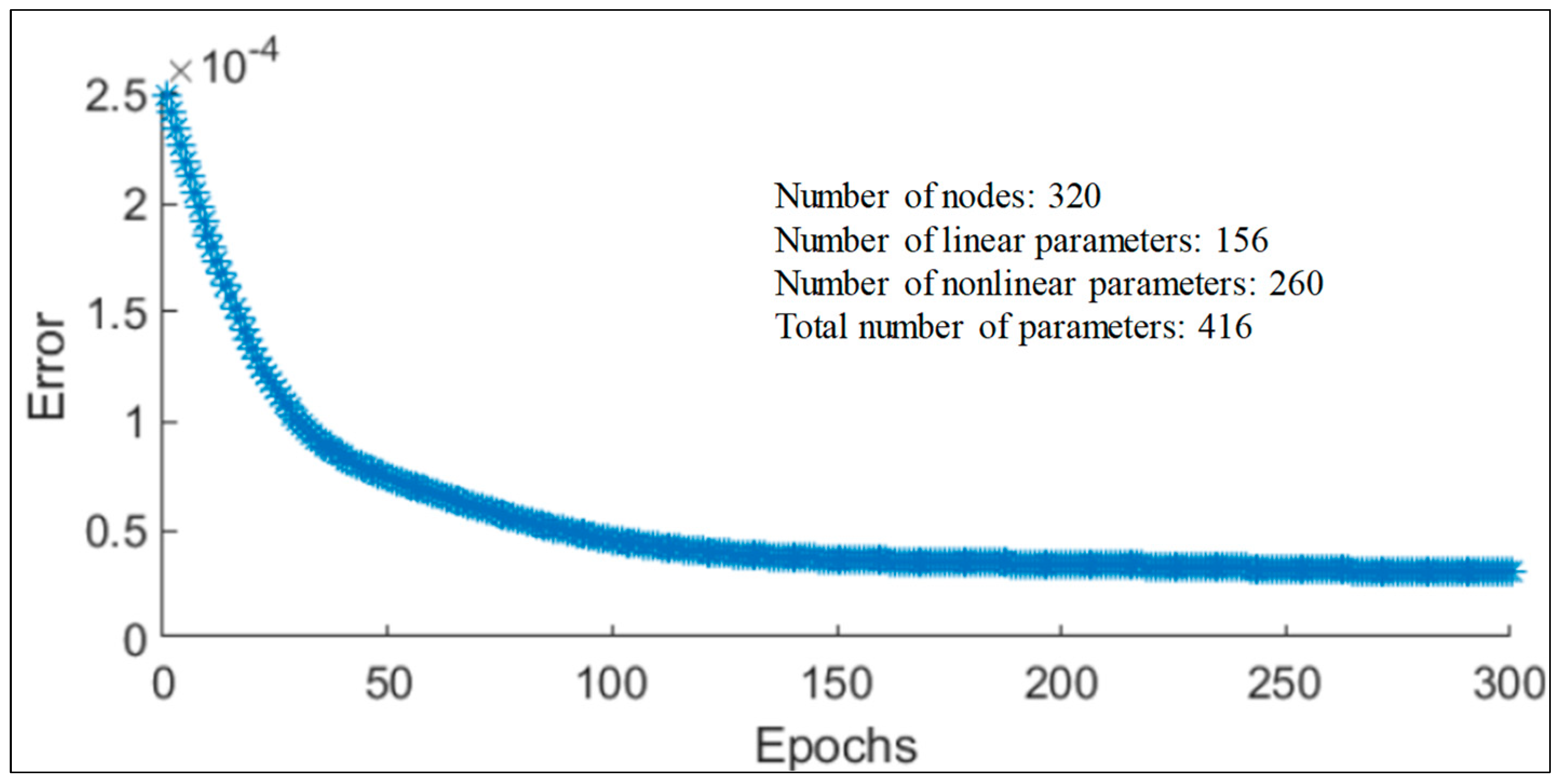

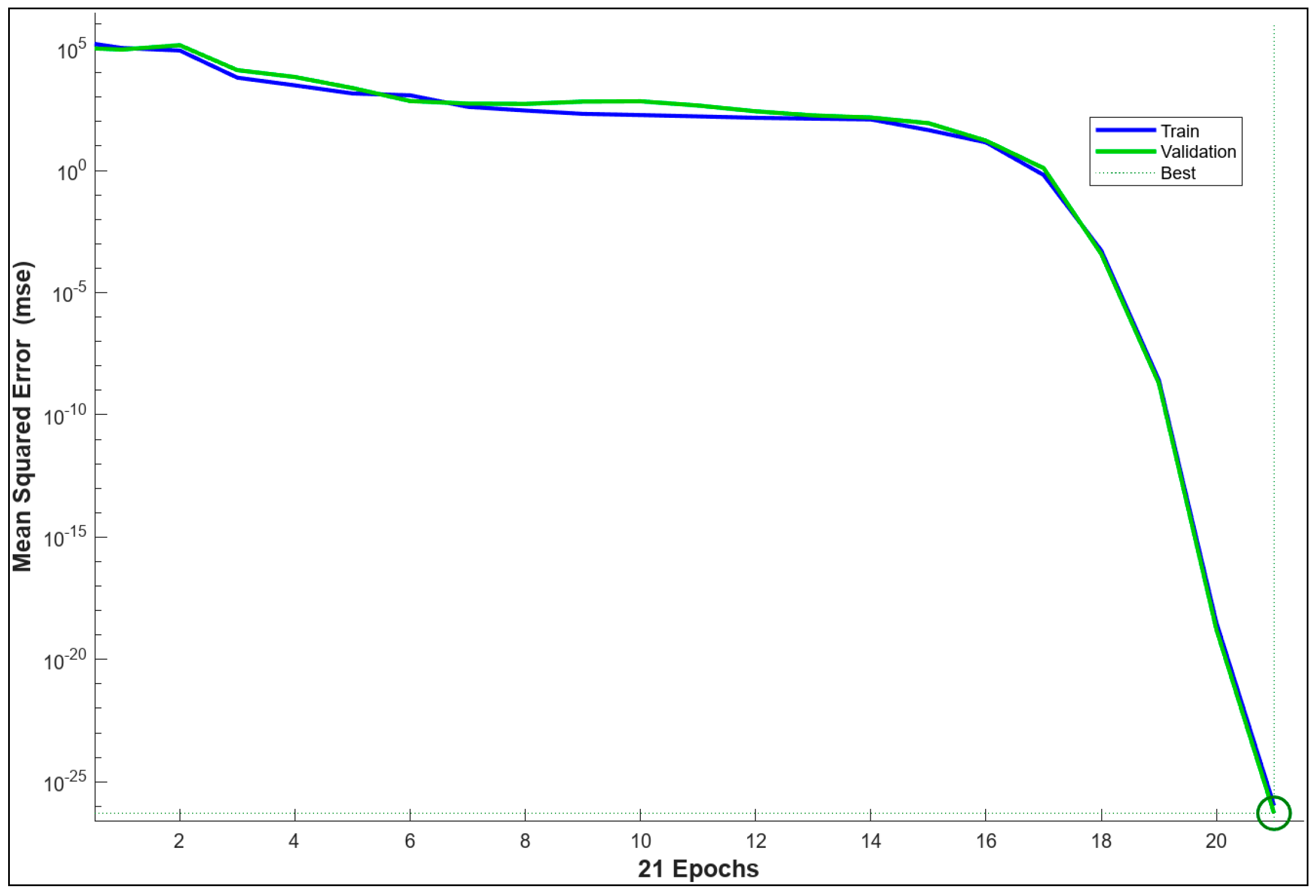

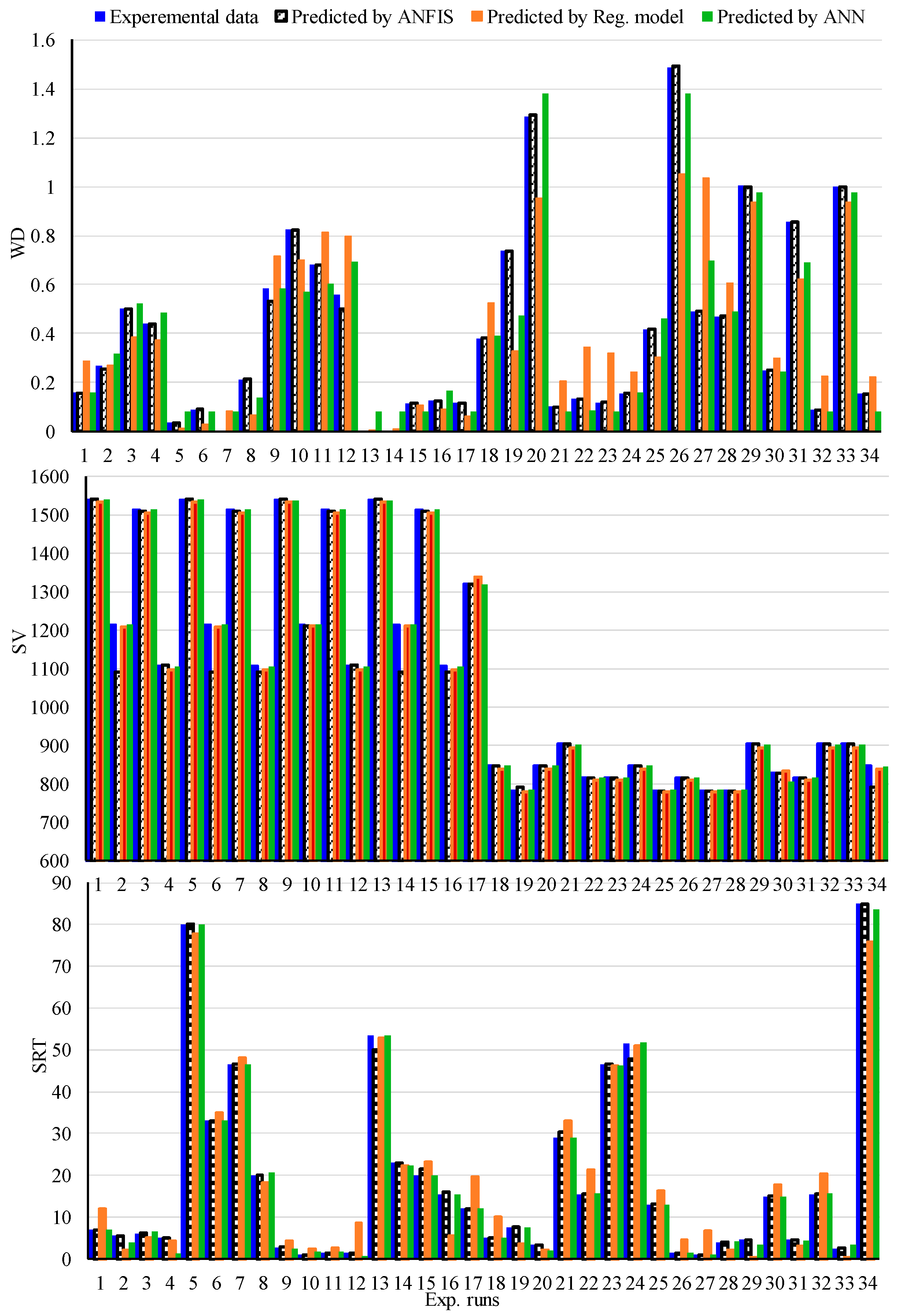

36] developed an intelligent method, utilizing improved NSGA-III with AI-based ANFIS to enhance the performance of the post-processing EBM parts. Their research demonstrates significant promise for employing developed predictive models, utilizing artificial intelligence and the combined ANFIS models in an improved NSGA-III method to improve the precision of the intricate turning process.

A recent trend in manufacturing process optimization emphasizes hybrid optimization techniques that integrate artificial intelligence modeling methods (e.g., ANN, ANFIS) with metaheuristic algorithms (e.g., PSO, GA, MOPSO, NSGA–II, and NSGA–III) to identify optimal process parameters for improved performance. In the realm of additive manufacturing, several contributions have emerged in the literature on the EBM technique. A few contributions concerning the EBM technique have appeared in the literature in the additive manufacturing area. Saleem [

37] proposed in her thesis that the Support Vector Machine (SVM) and ANN methods can be used to predict the EBM parameters. Regarding the other AM technology, several researchers proposed machine learning models to predict the AM process performance [

38,

39,

40,

41]. For example, Khalad et al. [

42] explored a data-driven machine learning approach for optimizing process parameters of the laser powder bed fusion (L-PBF) process. As a result, they found that gradient boosting with particle swarm optimization was the most effective way of predicting L-PBF performance. To predict the best process parameters for pressureless sintering and photopolymerization-based 3D printing, Singh et al. [

43] proposed the use of ANNs and regression models. The results showed that the ANN model demonstrated superior predictive performance. To enhance the quality of fabricated 316L stainless steel parts, Hodroj et al. [

44] used machine learning techniques based on ANN, SVM, and AdaBoost to predict SLM part density and optimize SLM parameters. These parameters include scan speed, laser power, hatch spacing, and layer thickness. According to the findings, the AdaBoost model outperformed others in terms of density prediction accuracy. Consequently, there is growing interest in developing intelligent models based on ML to address complex issues while providing dependable outcomes. ML models based on artificial intelligence are being constructed to achieve precise outcomes when modeling highly complex nonlinear processes.

Table 1.

Summary of studies conducted on metallic support structure that relies on AM technology.

| Ref. | Materials/3D Printing Technology | Study Objectives | Type of Support/Design Support Parameters/BM Parameters | Type Study | Machine Learning Models |

|---|

| [45] | EBM | Developing a model to simulate the deformation of overhang parts during 3D printing of EBM parts. | Design type/design parameters | Explore study | No |

| [5] | Ti6Al4V/EBM | Investigating how the process parameters and support design impacted the support volume and overhangs. | Design parameters/EBM parameters | Single approach at the time | No |

| [8] | Ti6Al4V/EBM | Studying the influence of building settings and EBM parameters on warping deformation. | EBM parameters | Statistical analysis | No |

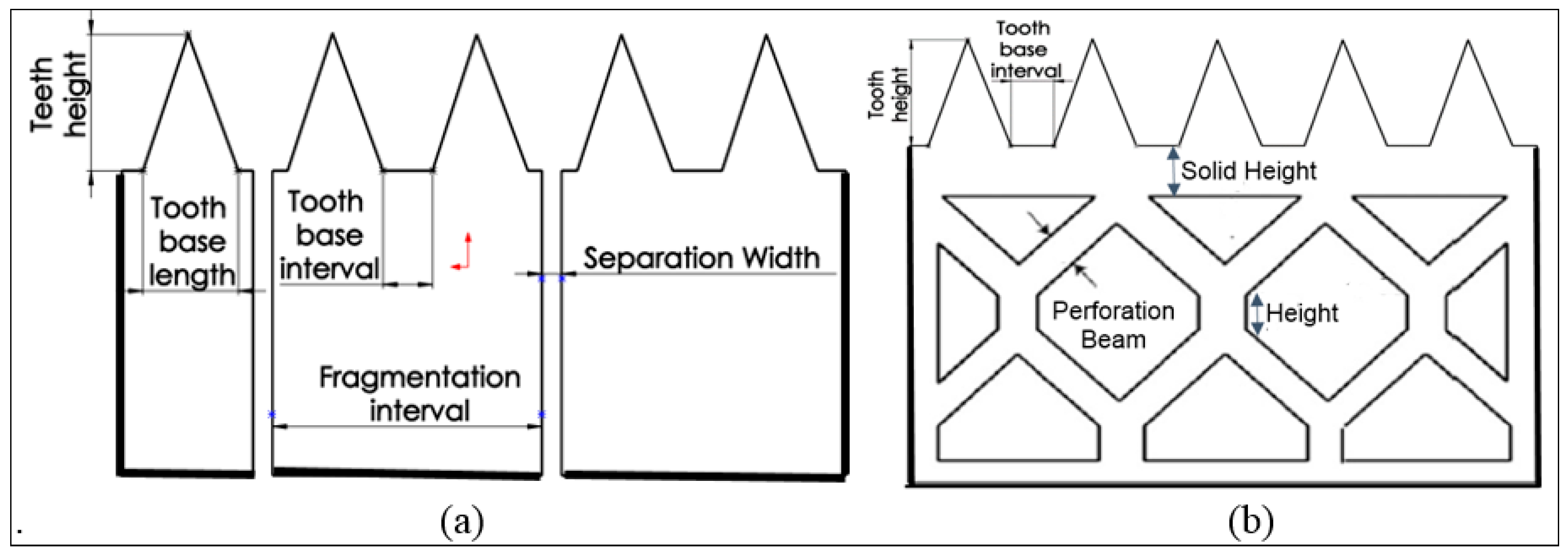

| [46] | Ti6Al4V/EBM | Studying the effect of design and process parameters of the perforated block support structures. | Perforated block structure parameters and EBM parameters | Statistical analysis/RSM with GA | No |

| [47] | Ti6Al4V/EBM | Designing support structures for metal AM that are easy to remove and consume less support material. | fragmented support structures and EBM parameters | Statistical analysis/RSM with MOGA-II | No |

| [48] | Inconel 718/LPBF | Investigating the influence of support geometries on the mechanical characteristics of Inconel 718 overhang parts. | Different support geometries | Single approach at the time | No |

| [17] | LPBF | They evaluated the support structure type and its design parameters. | Support structure type design parameters | Statistical analysis based on Taguchi design | No |

| [24] | AlSi10Mg/SLM | Optimizing the contour support structure parameters on residual stress and the time required for support removal. | Support structure parameters | Optimization | No |

| [12] | TiAl6V4/SLM | Examining the properties of various support structures. | Support structure parameters | NA | No |

| [15] | IN625/DMLS | The initial series of tests investigating the influence of Block supports dimensions. | Different support structure design | NA | No |

| [49] | L-BPF | Optimizing the tree-like support structure parameters. | Different support structure parameters | Optimization based on the Advanced Meta-model | No |

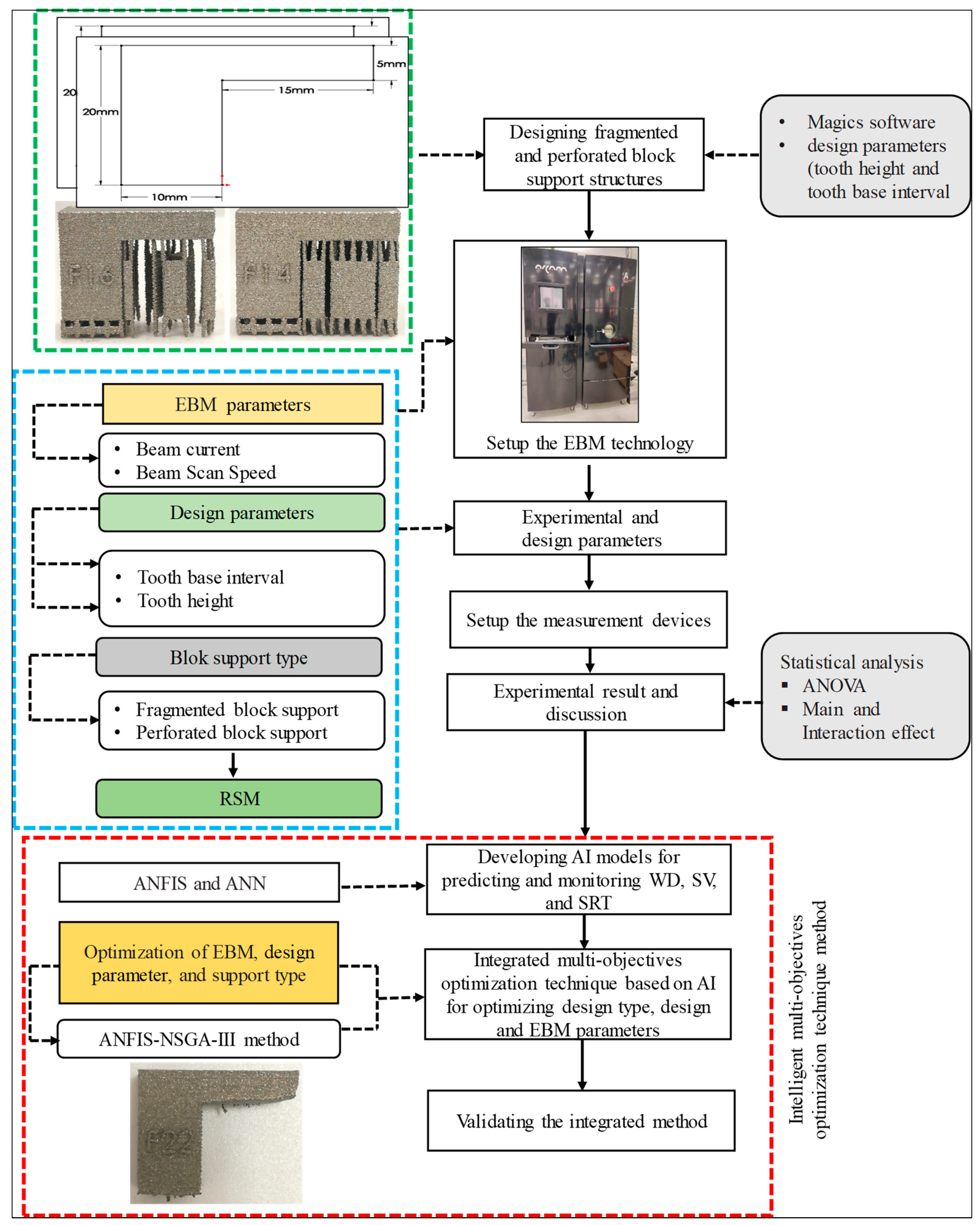

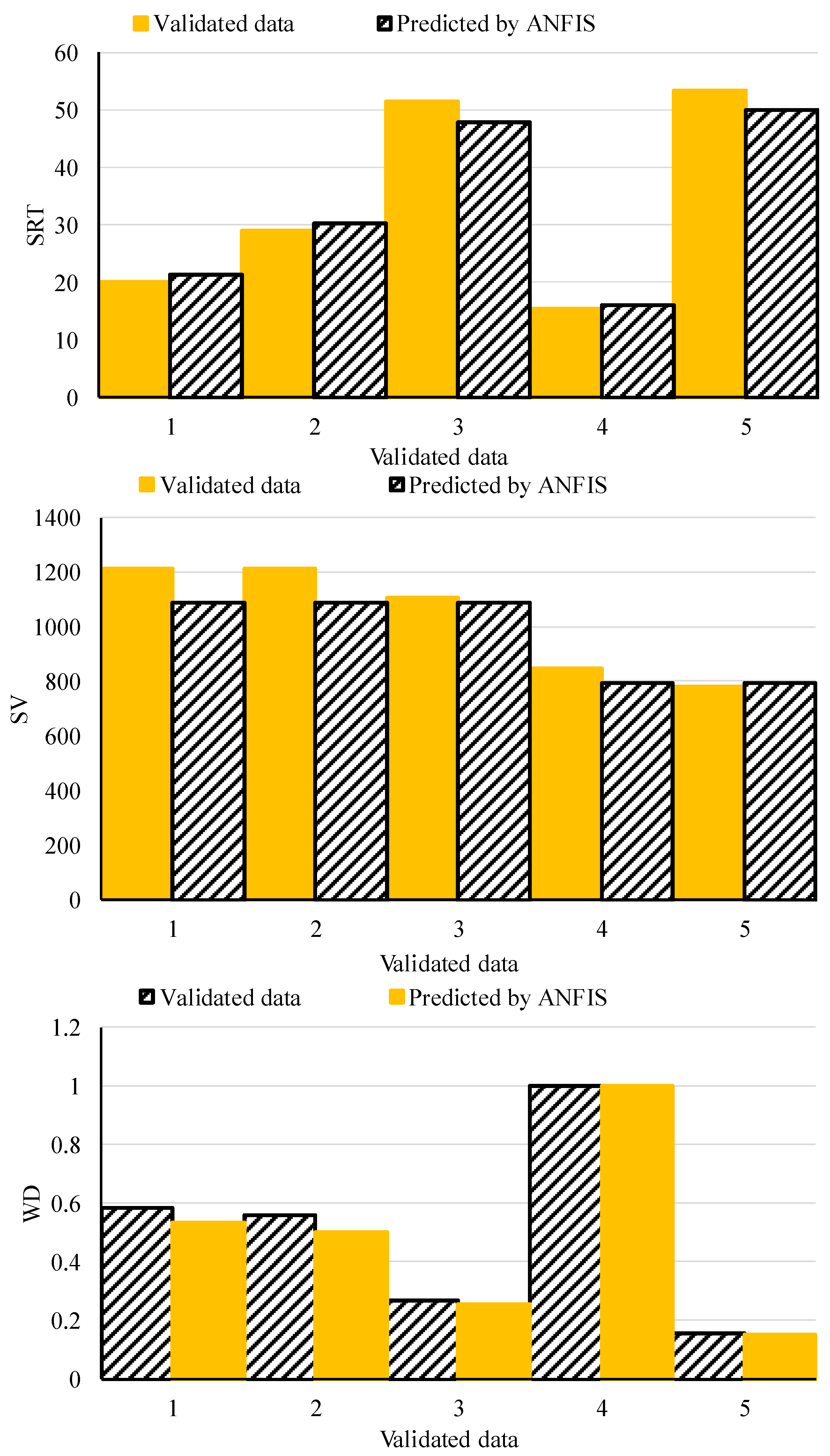

It is evident from the literature review that support structure design and their parameters, as well as AM technologies parameters, are the major challenges enhancing the performance of the fabricated parts. It also found that integrating intelligent models that combine the three phases involved in fabricating the parts—design block structure type, block structure design parameters, and AM technologies processing parameters—remains an obstacle in the domain of additive manufacturing technologies. Recently, machine learning (ML) models have been particularly effective and represent a new trend in manufacturing that seeks to reduce costs and conserve time, emerging as a practical approach. Furthermore, no information is provided regarding the monitoring, prediction, and optimization of the performance of the block support structure, which is one of the major challenges when processing 3D-printed parts (see

Table 1) using MLs. Wadea et al. [

46,

47] explored the influence of support structure design with EBM parameters on the support block structure’s performance. However, their research did not consider the integration of three phases (design block structure type, block structure design parameters, and AM technologies’ processing parameters). Additionally, no study has been conducted to predict and optimize the performance of the support structures of AM technologies for AM in general, and EBM in particular, using an integrated hybrid ANFIS-ANN with the NSGA-III method. This would combine block structure type, block structure design parameters, and EBM parameters to fulfill the smart manufacturing requirements. This study focuses on machine learning models, utilizing AI-ANFIS, AI-ANN, and the improved NSGA-III technique to monitor, predict, and enhance the quality of produced parts, reduce material wastage, and reduce the post-processing time of fabricated EBM Ti6Al4V parts. To achieve this, an RSM-based regression model was first used to study the influence of block support structure type, design parameters, and EBM parameters. Secondly, statistical analysis was developed to provide a detailed analysis of the influence of the design block structure type and its interaction with design parameters and EBM parameters on warping deformation, support volume, and support volume time, which is not covered in the previous study by Wadee [

5,

46,

47]. Thirdly, AI-ANFIS and AI-ANN models are designed to monitor and predict the performance of the support structure. Finally, machine learning models based on the AI-ANFIS technique with the high-performance NSGA-III optimization method were developed to obtain an optimal support structure type while enhancing the quality of produced parts (less warping deformation), reducing material wastage (less support volume), and reducing the post-processing time of fabricated EBM Ti6Al4V parts (less support volume type). This research intends to develop a machine learning system to enhance EBM’s quality and economic performance by integrating the design and processing stages.