High-Speed Nanoindentation and Local Residual Stress Analysis for Cut Edge Damage in Complex Phase Steels for Automotive Applications

Abstract

1. Introduction

2. Materials and Methods

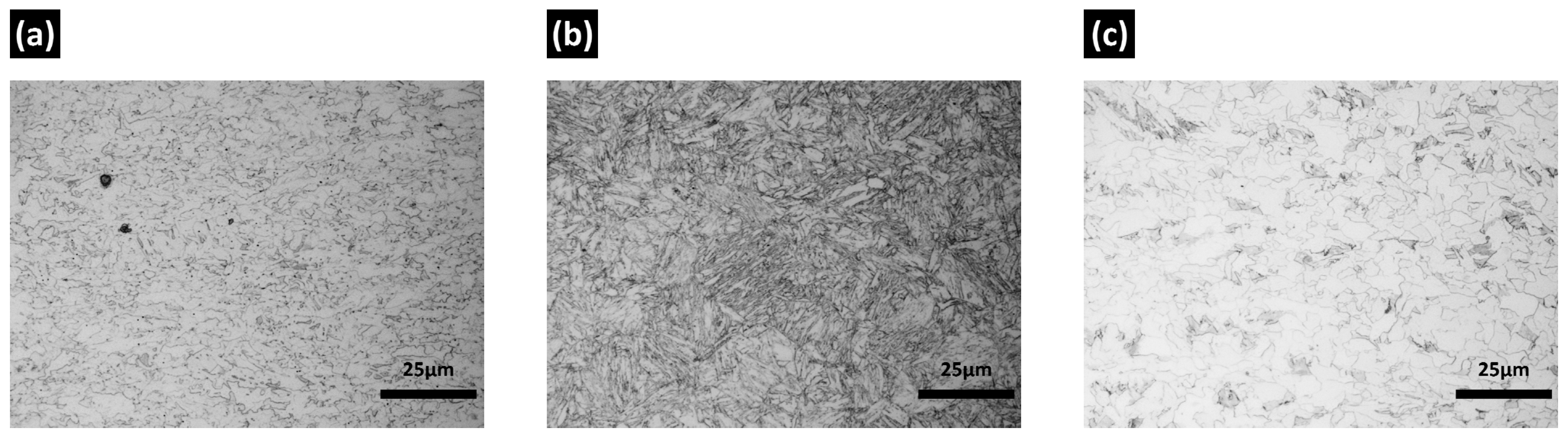

2.1. Materials

2.2. High-Speed Nanoindentation (HSN)

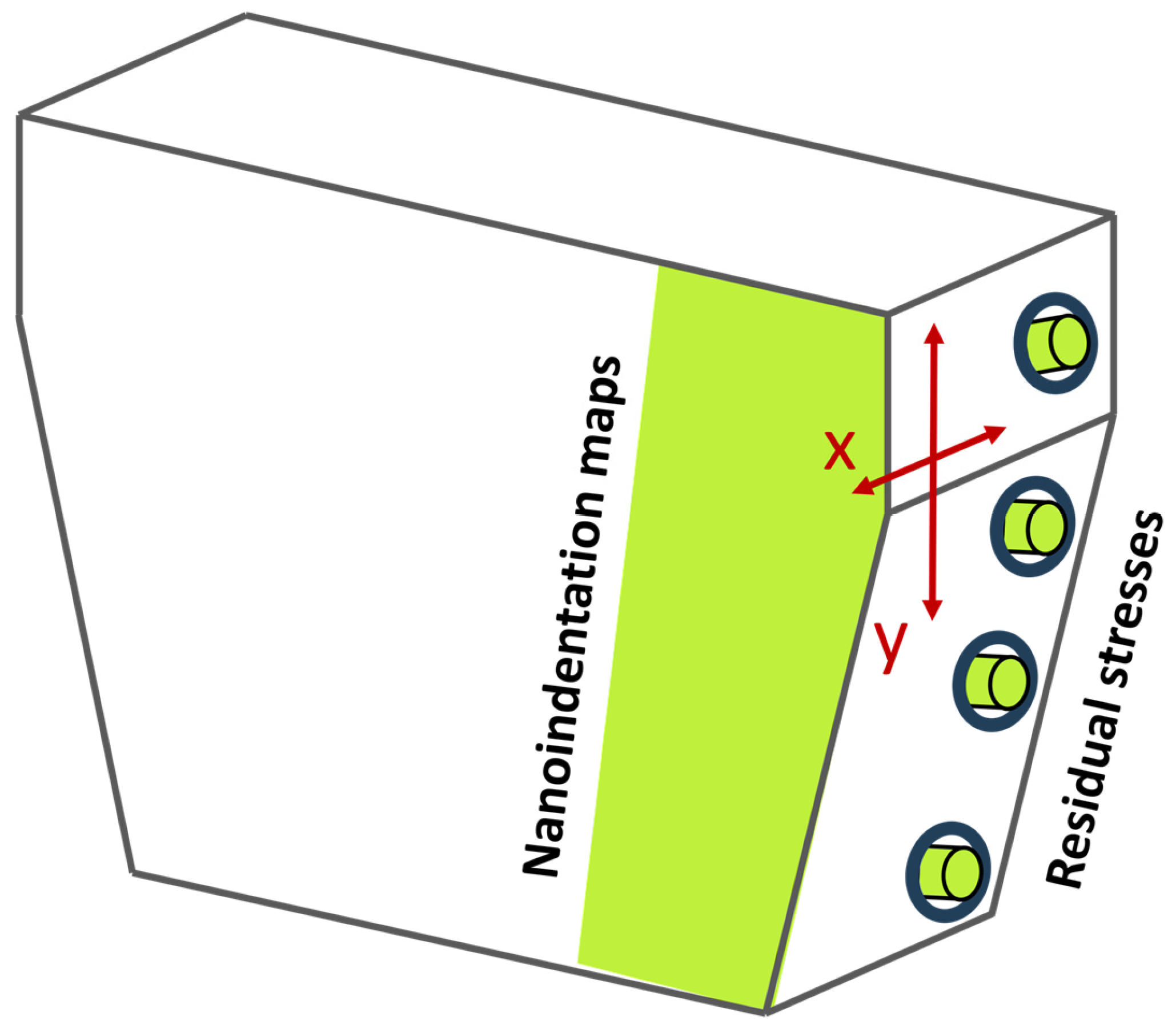

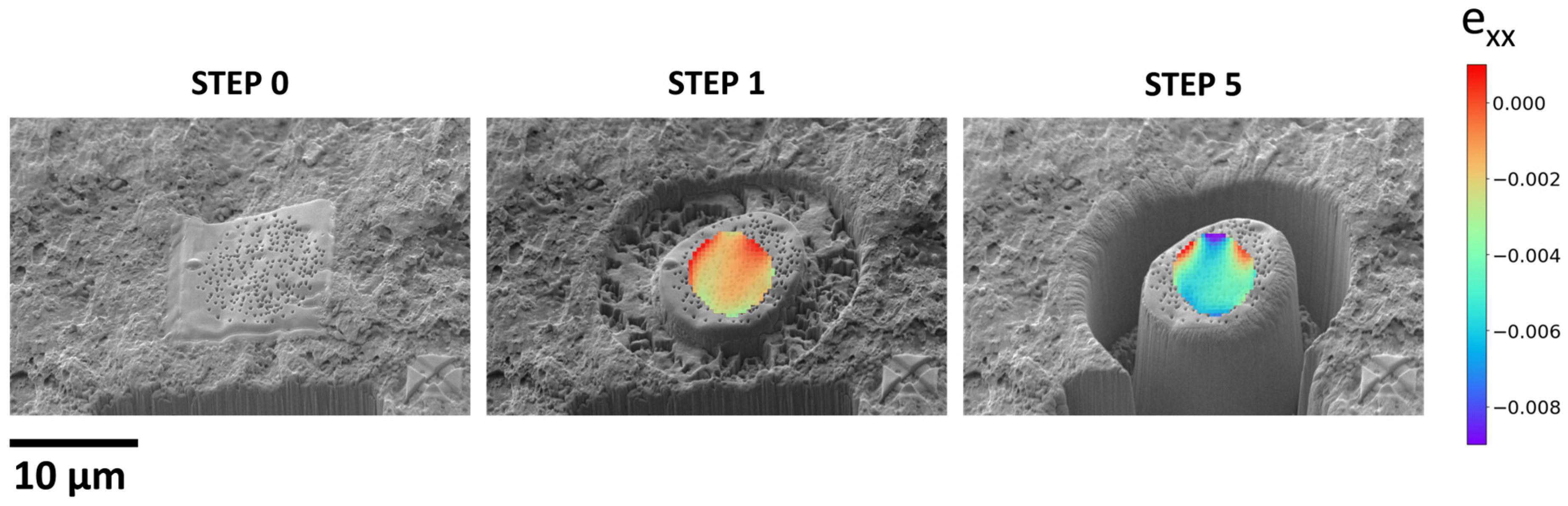

2.3. Residual Stress Measurement

3. Results and Discussion

3.1. Analysis of the Cut Edge Cross-Sections

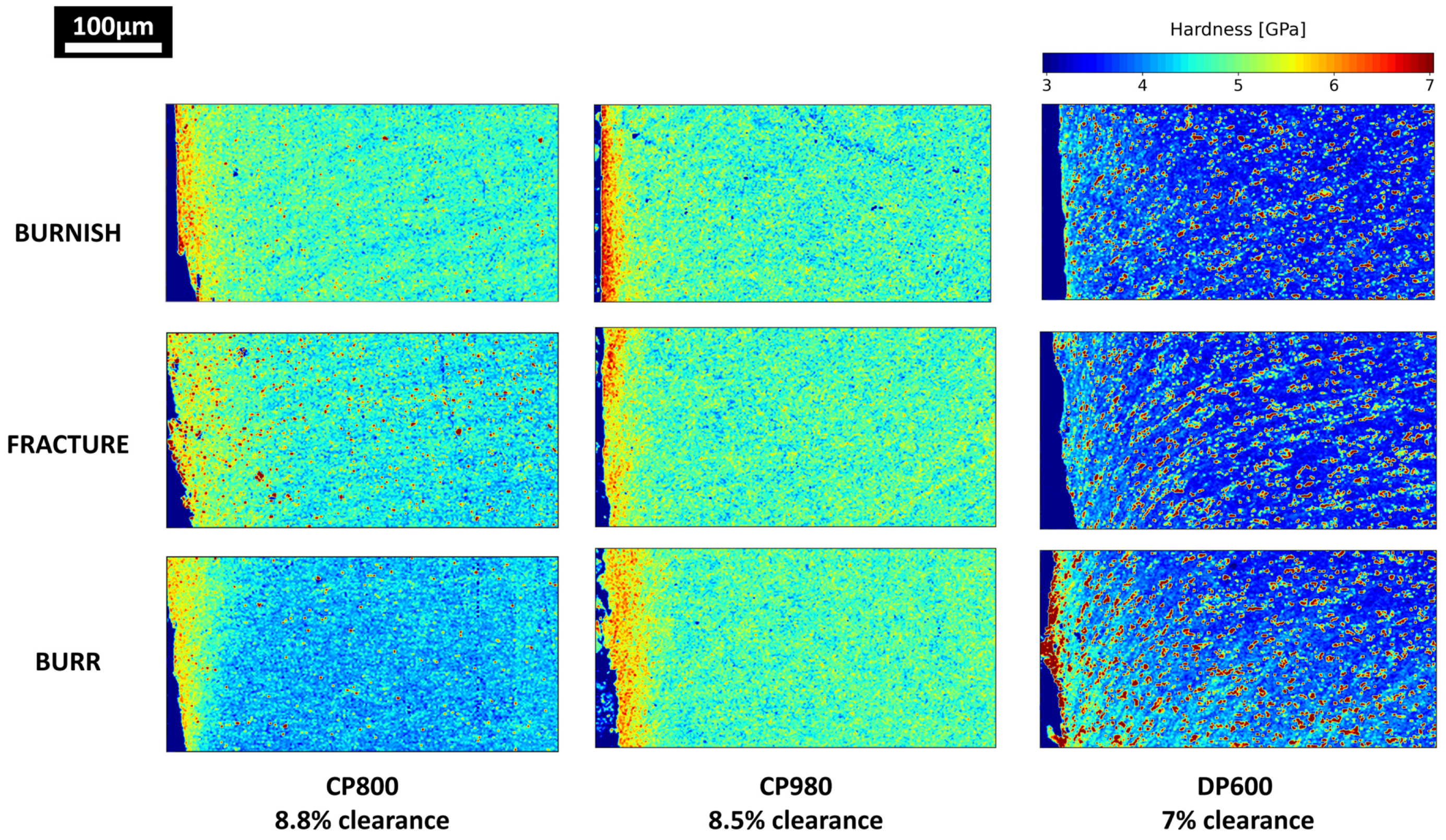

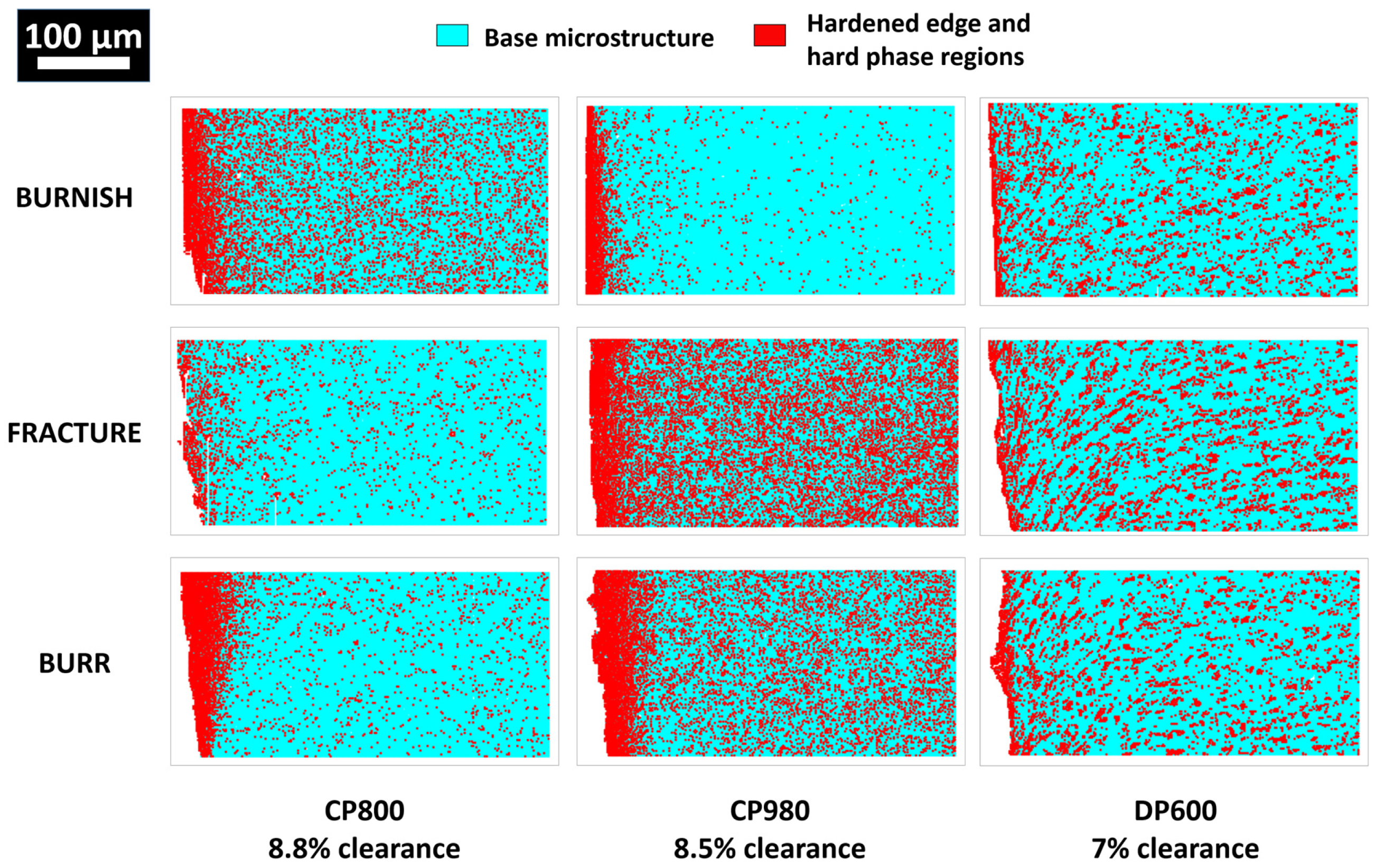

3.2. Effect of the Microstructure: Trimmed CP800, CP980, and DP600 Specimens

3.3. Effect of Sandblasting on Hardness Distribution at the Cut Edge

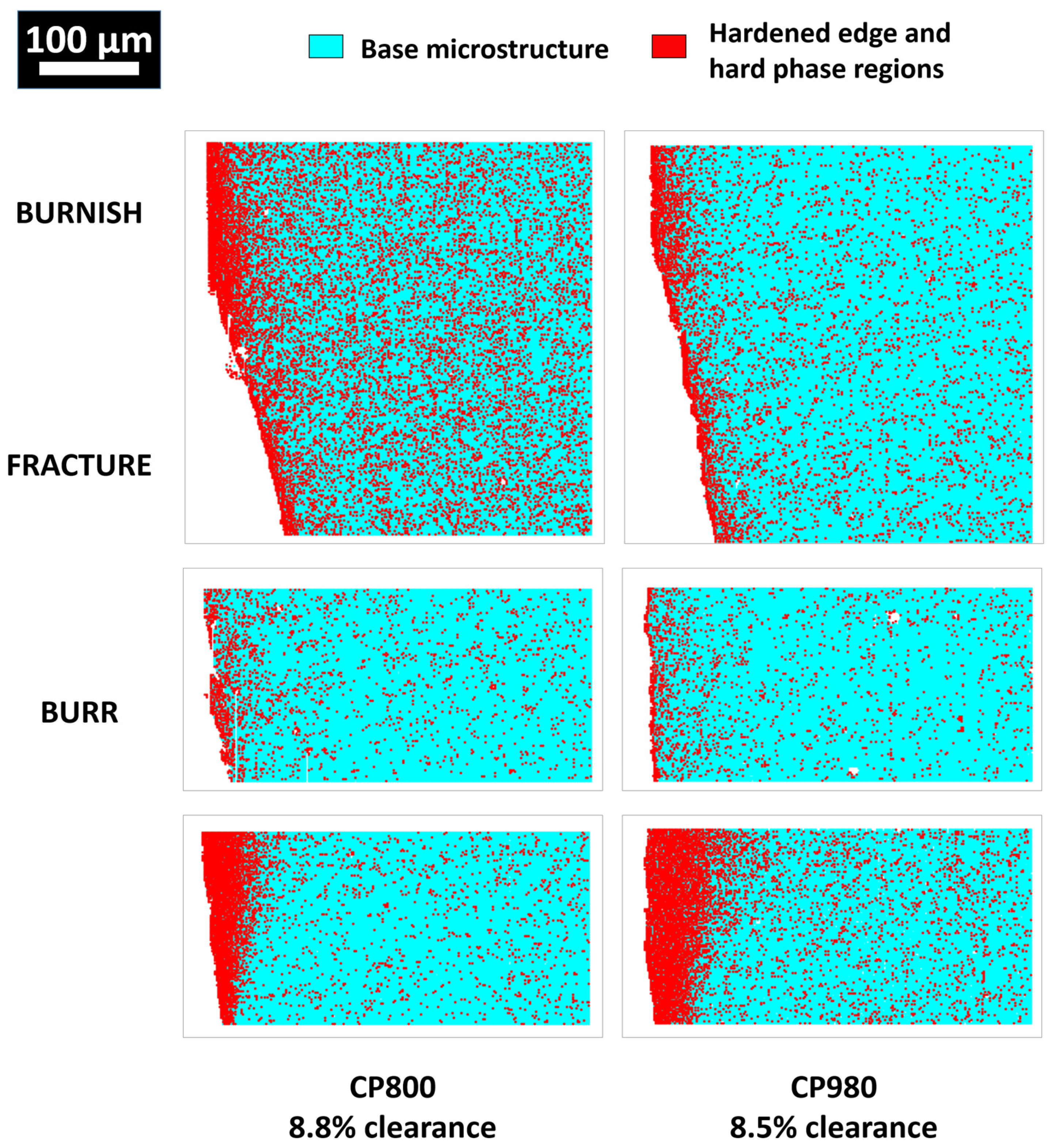

3.4. Effect of Cutting Clearance on the Hardness Distribution at the Cut Edge

3.5. Effect of Cutting Clearance on the Residual Stresses of CP980 Trimmed Specimens

3.6. Integrated Interpretation of the Results

4. Conclusions

- Hardness increases significantly near the shear edge due to cutting-induced plastic deformation. In DP600, lower hardening and more visible deformation lines were observed, while CP800 and CP980 showed higher hardening with less apparent plastic flow.

- In CP800, sandblasting induces a thin additional hardened layer at the cut edge surface, superimposed on the cutting-induced hardening. While the hardness gradient across the edge remains similar to that of the untreated specimen, the surface hardness increases. The smoother profile and surface strengthening could contribute to improved fatigue resistance.

- In CP980, a clearance of 8.5% produces a broader and more localized hardened zone, with hardness extending up to 100 µm from the edge. This is attributed to increased shear deformation and dislocation accumulation prior to fracture. In contrast, a 17% clearance leads to a narrower hardened zone (∼20 µm), as the material fractures more abruptly with less localized plastic deformation.

- FIB-DIC analysis of CP980 reveals that the residual stress distribution across the cut edge is strongly influenced by the cutting clearance. At 8.5%, high tensile stresses are observed in the transition and fracture zones, while compressive stresses dominate in the burnish zone. At 17% clearance, tensile stresses shift towards the burr, and the transition zone shows reduced or compressive values, indicating stress relaxation. These trends correlate with the observed hardening patterns and help explain the shift in fatigue nucleation sites reported in the literature.

- The use of low cutting clearance improves both the extent of strain hardening and the distribution of residual stresses, reducing tensile residual stresses at the burr, which is the most critical region for fatigue initiation. Sandblasting can be used as a complementary surface treatment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bull, M. Mass reduction and performance of PEV and PHEV vehicles. In Proceedings of the 22nd International Technical Conference on the Enhanced Safety of Vehicles (ESV), Washington, DC, USA, 13–16 June 2011. [Google Scholar]

- Klose, F.B.; Kwiaton, N.; Lesch, C. Advanced High Strength Steels (AHSS) for Automotive Applications—Tailored Properties by Smart Microstructural Adjustments. Steel Res. Int. 2017, 88, 1700210. [Google Scholar] [CrossRef]

- Hilditch, T.B.; De Souza, T.; Hodgson, P.D. Properties and automotive applications of advanced high-strength steels (AHSS). In Welding and Joining of Advanced High Strength Steels (AHSS); Elsevier Ltd.: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Yokota, H.; Matsuno, T.; Goto, K.; Watanabe, I.; Ando, R.; Yamashita, N. Analysis of preliminary local hardening close to the ferrite–martensite interface in dual-phase steel by a combination of finite element simulation and nanoindentation test. Int. J. Mech. Sci. 2020, 180, 105663. [Google Scholar] [CrossRef]

- Zheng, C.; Tsuzaki, K.; Raabe, D.; Ponge, D.; Peranio, N.; Bechtold, M.; Tasan, C.; Schemmann, L.; Roters, F.; Yan, D.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Frómeta, D.; Tedesco, M.; Calvo, J.; Lara, A.; Molas, S.; Casellas, D. Assessing edge cracking resistance in AHSS automotive parts by the Essential Work of Fracture methodology. J. Phys. Conf. Ser. 2017, 896, 012102. [Google Scholar] [CrossRef]

- Hedström, P.; Borgenstam, A.; Larsson, J.; Sieurin, H.; Heshmati, N. Correlation between microstructure and fatigue properties of hot-rolled thick-plate complex-phase steel. Mater. Sci. Eng. A 2023, 885, 145624. [Google Scholar] [CrossRef]

- Yang, X.; Sun, H.; Wu, Y.; Wei, K.; Xiao, Z. Effects of pre-strain and annealing on the fatigue properties of complex phase steel CP800. Int. J. Fatigue 2020, 131, 105364. [Google Scholar] [CrossRef]

- Bleck, W.; Ramazani, A.; Li, X.; Prahl, U. Quantification of complex-phase steel microstructure by using combined EBSD and EPMA measurements. Mater. Charact. 2018, 142, 179–186. [Google Scholar] [CrossRef]

- Richter, S.; Bleck, W.; Lin, M.; Hangen, U.; Chang, Y.; Haase, C. Revealing the relation between microstructural heterogeneities and local mechanical properties of complex-phase steel by correlative electron microscopy and nanoindentation characterization. Mater. Des. 2021, 203, 109620. [Google Scholar] [CrossRef]

- Bardelcik, A.; Butler, Q. Strain partitioning characterization of advanced high strength steels using in-situ tensile tests with Micro digital image correlation—Methodology and analysis. Mater. Charact. 2024, 218, 114451. [Google Scholar] [CrossRef]

- Shih, H.-C.; Chiriac, C.; Shi, M.F. The effects of AHSS shear edge conditions on edge fracture. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2010; Volume 1, pp. 599–608. [Google Scholar] [CrossRef]

- Thomas, D.J. Characterization of steel cut-edge properties for improved life predictions for preventing automotive structural failure. In Handbook of Materials Failure Analysis with Case Studies from the Aerospace and Automotive Industries; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 341–363. [Google Scholar]

- Pathak, N.; Butcher, C.; Worswick, M.J.; Bellhouse, E.; Gao, J. Damage Evolution in complex-phase and dual-phase steels during edge stretching. Materials 2017, 10, 346. [Google Scholar] [CrossRef]

- Heibel, S.; Dettinger, T.; Nester, W.; Clausmeyer, T.; Tekkaya, A.E. Damage mechanisms and mechanical properties of high-strength multiphase steels. Materials 2018, 11, 761. [Google Scholar] [CrossRef] [PubMed]

- Abe, Y.; Yonekawa, R.; Sedoguchi, K.; Mori, K.-I. Shearing of ultra-high strength steel sheets with step punch. Procedia Manuf. 2018, 15, 597–604. [Google Scholar] [CrossRef]

- Qiao, L.; Yu, H.; Zhang, C.; Yan, Y. Novel bake hardening mechanism for bainite-strengthened complex phase steel. J. Mater. Sci. Technol. 2023, 143, 117–128. [Google Scholar] [CrossRef]

- Fafard, M.; Rachik, M.; Ben Ismail, A.; Hug, E.; Mazeran, P.-E. Material characterization of blanked parts in the vicinity of the cut edge using nanoindentation technique and inverse analysis. Int. J. Mech. Sci. 2009, 51, 899–906. [Google Scholar]

- Wo, P.C.; Ruimi, A.; Zhang, F.; Field, D.P. Morphology and distribution of martensite in dual phase (DP980) steel and its relation to the multiscale mechanical behavior. Mater. Sci. Eng. A 2016, 659, 93–103. [Google Scholar] [CrossRef]

- Yokoi, T.; Zhang, K.; Hamada, S.; Zhang, J.; Noguchi, H.; Koyama, M. Effect of shear-affected zone on fatigue crack propagation mode. Int. J. Fatigue 2018, 116, 36–47. [Google Scholar] [CrossRef]

- Hoffmann, H.; Dittmann, F.; Feistle, M.; Golle, R.; Paetzold, I.; Haefele, P.; Volk, W. Influence of shear cutting parameters on the fatigue behavior of a dual-phase steel. J. Phys. Conf. Ser. 2017, 896, 012107. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, D.; Ahadi, A.; Agmell, M.; Stahl, J.-E.; Liu, Y. Investigation on residual stress evolution in nickel-based alloy affected by multiple cutting operations. J. Manuf. Process. 2021, 68, 818–833. [Google Scholar] [CrossRef]

- Tamai, Y.; Urabe, T.; Shiozaki, T. Effect of residual stresses on fatigue strength of high strength steel sheets with punched holes. Int. J. Fatigue 2015, 80, 324–331. [Google Scholar] [CrossRef]

- Casellas, D.; Sandin, O.; Hammarberg, S.; Frómeta, D.; Parareda, S.; Jonsén, P. Prediction of sheared edge characteristics of advanced high strength steel. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1238, 012034. [Google Scholar] [CrossRef]

- Kan, Y.; Pisarev, V.S.; Somov, P.A.; Eleonsky, S.I.; Ozherelkov, D.Y.; Statnik, E.S.; Salimon, A.I. FIB-DIC Residual Stress Evaluation in Shot Peened VT6 Alloy Validated by X-ray Diffraction and Laser Speckle Interferometry. Nanomaterials 2022, 12, 1235. [Google Scholar] [CrossRef]

- Bemporad, E.; Massimi, F.; Sebastiani, M.; Merlati, G. Residual micro-stress distributions in heat-pressed ceramic on zirconia and porcelain-fused to metal systems: Analysis by FIB–DIC ring-core method and correlation with fracture toughness. Dent. Mater. 2015, 31, 1396–1405. [Google Scholar] [CrossRef]

- Sui, T.; Nowell, D.; Korsunsky, A.; Salvati, E.; O’Connor, S. A study of overload effect on fatigue crack propagation using EBSD, FIB–DIC and FEM methods. Eng. Fract. Mech. 2016, 167, 210–223. [Google Scholar] [CrossRef]

- Sebastiani, M.; Wheeler, J.M.; Rossi, E. High-speed nanoindentation mapping: A review of recent advances and applications. Curr. Opin. Solid State Mater. Sci. 2023, 27, 101107. [Google Scholar] [CrossRef]

- Stauffer, D.D.; Maloy, S.A.; Lienert, T.J.; Chen, Y.; Hintsala, E.D.; Eftink, B.P.; Sau, M.; Mara, N.A. High-Throughput Nanoindentation Mapping of Additively Manufactured T91 Steel. JOM 2022, 74, 1469–1476. [Google Scholar] [CrossRef]

- Roa, J.; Llanes, L.; Wheeler, J.; Jiménez-Piqué, E.; Rodriguez-Suarez, T.; Gordon, S.; Besharatloo, H. Micromechanical mapping of polycrystalline cubic boron nitride composites by means of high-speed nanoindentation: Assessment of microstructural assemblage effects. J. Eur. Ceram. Soc. 2023, 43, 2968–2975. [Google Scholar] [CrossRef]

- Besharatloo, H.; Wheeler, J.M. Influence of indentation size and spacing on statistical phase analysis via high-speed nanoindentation mapping of metal alloys. J. Mater. Res. 2021, 36, 2198–2212. [Google Scholar] [CrossRef]

- Munier, R.; Olsson, E.; Parareda, S.; Gustafsson, D. High cycle fatigue life estimation of punched and trimmed specimens considering residual stresses and surface roughness. Int. J. Fatigue 2024, 186, 108384. [Google Scholar] [CrossRef]

- Benítez, R.; Jiménez-Piqué, E.; Mateo, A.; Biserova-Tahchieva, A.; Llorca-Isern, N.; Ortiz-Membrado, L.; Rius-Ayra, O. Surface modification of superduplex stainless steel with C and N: Microstructural and nanomechanical insights. Surf. Coat. Technol. 2024, 494, 131441. [Google Scholar] [CrossRef]

- Fraley, C.; Raftery, A.E. How many clusters? Which clustering method? Answers via model-based cluster analysis. Comput. J. 1998, 41, 586–588. [Google Scholar] [CrossRef]

- Lord, J.; Cox, D.; Ratzke, A.; Sebastiani, M.; Korsunsky, A.; Salvati, E.; Mughal, M.Z.; Bemporad, E. A Good Practice Guide for Measuring Residual Stresses using FIB-DIC. In Good Practice Guide; The National Physical Laboratory: London, UK, 2018; Volume 143. [Google Scholar]

- Pharr, G.M.; Eberl, C.; Sebastiani, M.; Bemporad, E. Depth-resolved residual stress analysis of thin coatings by a new FIB–DIC method. Mater. Sci. Eng. A 2011, 528, 7901–7908. [Google Scholar] [CrossRef]

- Salvati, E.; Romano-Brandt, L.; Mughal, M.Z.; Sebastiani, M.; Korsunsky, A.M. Generalised residual stress depth profiling at the nanoscale using focused ion beam milling. J. Mech. Phys. Solids 2019, 125, 488–501. [Google Scholar] [CrossRef]

- Olsson, E.; Parareda, S.; Gustafsson, D.; Sieurin, H. Estimating the effect of punching on out-of-plane bending fatigue of steel sheet specimens. Eng. Fail. Anal. 2025, 173, 109415. [Google Scholar] [CrossRef]

- Casellas, D.; Sieurin, H.; Parareda, S.; D’armas, H.; Lara, A. Increasing fatigue performance in AHSS thick sheet by surface treatments. MATEC Web Conf. 2018, 165, 22015. [Google Scholar] [CrossRef][Green Version]

- Picas, I.; Lara, A.; Casellas, D. Effect of the cutting process on the fatigue behaviour of press hardened and high strength dual phase steels. J. Mater. Process. Technol. 2013, 213, 1908–1919. [Google Scholar] [CrossRef]

- Jiménez-Piqué, E.; Mateo, A.; Olsson, E.; Parareda, S.; Ortiz-Membrado, L.; Gustafsson, D. Simulation of metal punching and trimming using minimal experimental characterization. J. Mech. Work. Technol. 2023, 321, 118148. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Bright, G.W.; Gao, Y.; Thomas, D.J. The influence of mechanical and CO2 laser cut-edge characteristics on the fatigue life performance of high strength automotive steels. J. Mech. Work. Technol. 2011, 211, 263–274. [Google Scholar] [CrossRef]

| Material | σYS [MPa] | σUTS [MPa] | A80 [%] | Microstructure |

|---|---|---|---|---|

| HR CP800 SF | 778 | 835 | 17 | F/B matrix—M/A islands |

| HR CP980 SF | 957 | 1034 | 13 | F/TM matrix—UB/A islands |

| HR DP600 | 439 | 622 | 21 | F matrix—M islands |

| Material | Fe | C | Si | Mn | P | S | Al | Cu | B | Ti + Nb | Cr + Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HR CP800 SF | Bal. | ≤0.18 | ≤1.0 | ≤2.2 | ≤0.05 | ≤0.01 | ≤1.2 | ≤0.2 | ≤0.01 | ≤0.25 | ≤1.0 |

| HR CP980 SF | Bal. | ≤0.20 | ≤1.0 | ≤2.2 | ≤0.05 | ≤0.01 | ≤1.2 | ≤0.2 | ≤0.01 | ≤0.25 | ≤1.0 |

| HR DP600 | Bal. | ≤0.10 | ≤0.3 | ≤1.5 | ≤0.08 | ≤0.01 | ≤0.06 | - | - | - | ≤0.9 |

| Steel | Thickness (mm) | Trimming Clearance (%) | Post-Cutting Treatment |

|---|---|---|---|

| HR CP800 SF | 3.4 | 8.8 | Untreated Sandblasted |

| HR CP980 SF | 3.5 | 8.5 17.0 | Untreated |

| HR DP600 | 4.3 | 7.0 | Untreated |

| Specimen | Zone | Phase | Mean Hardness (GPa) | Std. Dev. (GPa) |

|---|---|---|---|---|

| CP800 8.8% clearance | Burnish | Base (cyan) | 4.6 | 0.3 |

| Hardened (red) | 4.9 | 0.8 | ||

| Fracture | Base (cyan) | 4.5 | 9.4 | |

| Hardened (red) | 5.99 | 1.6 | ||

| Burr | Base (cyan) | 4.2 | 0.3 | |

| Hardened (red) | 5.16 | 0.7 | ||

| CP980 8.5% clearance | Burnish | Base (cyan) | 4.6 | 0.4 |

| Hardened (red) | 5.8 | 0.5 | ||

| Fracture | Base (cyan) | 4.6 | 0.3 | |

| Hardened (red) | 5.2 | 0.4 | ||

| Burr | Base (cyan) | 4.6 | 0.3 | |

| Hardened (red) | 5.3 | 0.4 | ||

| DP600 7% clearance | Burnish | Base (cyan) | 3.6 | 0.3 |

| Hardened (red) | 5.9 | 1.6 | ||

| Fracture | Base (cyan) | 3.6 | 0.3 | |

| Hardened (red) | 5.8 | 1.5 | ||

| Burr | Base (cyan) | 3.9 | 0.4 | |

| Hardened (red) | 6.9 | 1.9 |

| Specimen | Zone | Phase | Mean Hardness (GPa) | Std. Dev. (GPa) |

|---|---|---|---|---|

| CP800 8.8% clearance untreated | Burnish–transition | Base (cyan) | 4.6 | 0.3 |

| Hardened (red) | 5.0 | 0.8 | ||

| Fracture | Base (cyan) | 4.5 | 0.4 | |

| Hardened (red) | 5.9 | 1.6 | ||

| Burr | Base (cyan) | 4.2 | 0.3 | |

| Hardened (red) | 5.2 | 0.7 | ||

| CP800 8.8% clearance sandblasted | Burnish–transition | Base (cyan) | 4.8 | 0.4 |

| Hardened (red) | 5.8 | 0.9 | ||

| Fracture | Base (cyan) | 4.8 | 0.5 | |

| Hardened (red) | 6.2 | 1.6 | ||

| Burr | Base (cyan) | 4.3 | 0.4 | |

| Hardened (red) | 5.5 | 0.7 |

| Specimen | Zone | Phase | Mean Hardness (GPa) | Std. Dev. (GPa) |

|---|---|---|---|---|

| CP980 8.5% clearance | Burnish–transition | Base (cyan) | 4.7 | 0.4 |

| Hardened (red) | 5.8 | 0.5 | ||

| Fracture | Base (cyan) | 4.6 | 0.3 | |

| Hardened (red) | 5.2 | 0.4 | ||

| Burr | Base (cyan) | 4.6 | 0.3 | |

| Hardened (red) | 5.3 | 0.4 | ||

| CP980 17.14% clearance | Burnish–transition | Base (cyan) | 4.8 | 0.3 |

| Hardened (red) | 5.6 | 1.0 | ||

| Fracture | Base (cyan) | 4.7 | 0.3 | |

| Hardened (red) | 5.4 | 0.8 | ||

| Burr | Base (cyan) | 4.6 | 0.3 | |

| Hardened (red) | 5.0 | 0.8 |

| Specimen | Zone | Stresses (MPa) | Std. Dev. (MPa) |

|---|---|---|---|

| CP980 8.5% clearance | Burnish | −613 | 296 |

| Transition | 688 | 560 | |

| Fracture | 561 | 695 | |

| Burr | 347 | 100 | |

| CP980 17.14% clearance | Burnish | −237 | 307 |

| Transition | −198 | 548 | |

| Fracture | 75 | 893 | |

| Burr | 908 | 435 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz-Membrado, L.; Parareda, S.; Casellas, D.; Jiménez-Piqué, E.; Mateo, A. High-Speed Nanoindentation and Local Residual Stress Analysis for Cut Edge Damage in Complex Phase Steels for Automotive Applications. Metals 2025, 15, 651. https://doi.org/10.3390/met15060651

Ortiz-Membrado L, Parareda S, Casellas D, Jiménez-Piqué E, Mateo A. High-Speed Nanoindentation and Local Residual Stress Analysis for Cut Edge Damage in Complex Phase Steels for Automotive Applications. Metals. 2025; 15(6):651. https://doi.org/10.3390/met15060651

Chicago/Turabian StyleOrtiz-Membrado, Laia, Sergi Parareda, Daniel Casellas, Emilio Jiménez-Piqué, and Antonio Mateo. 2025. "High-Speed Nanoindentation and Local Residual Stress Analysis for Cut Edge Damage in Complex Phase Steels for Automotive Applications" Metals 15, no. 6: 651. https://doi.org/10.3390/met15060651

APA StyleOrtiz-Membrado, L., Parareda, S., Casellas, D., Jiménez-Piqué, E., & Mateo, A. (2025). High-Speed Nanoindentation and Local Residual Stress Analysis for Cut Edge Damage in Complex Phase Steels for Automotive Applications. Metals, 15(6), 651. https://doi.org/10.3390/met15060651