Microstructure, Porosity, and Bending Fatigue Behaviour of PBF-LB/M SS316L for Biomedical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and PBF-LB/M Printing

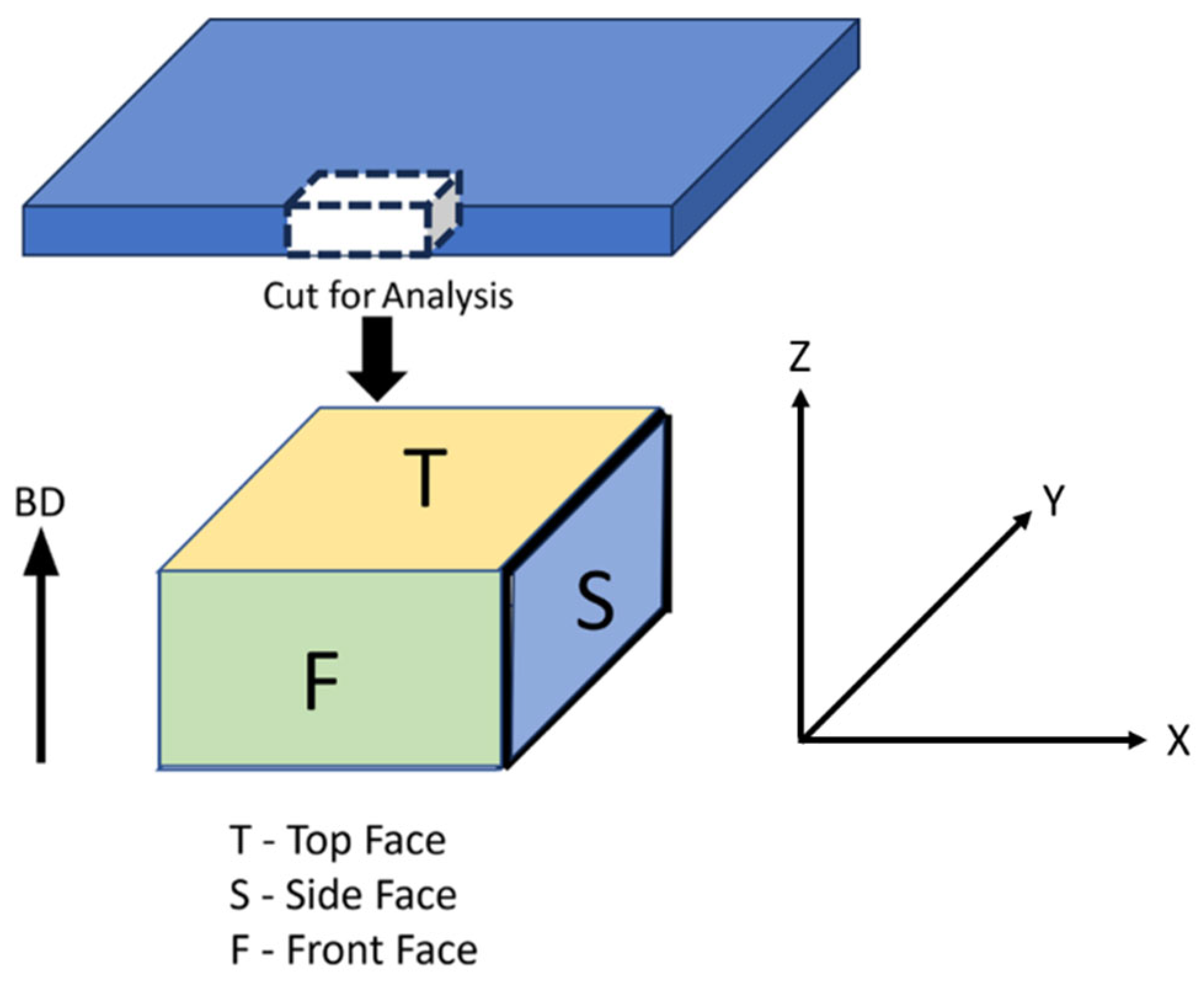

2.2. Sample Preparation

2.3. Microstructural and Elemental Characterisation (OM, SEM, and EDX)

2.3.1. Optical Microscopy (OM)

2.3.2. SEM and EDX

2.4. Crystallographic Structure and Phase Analysis (XRD and EBSD)

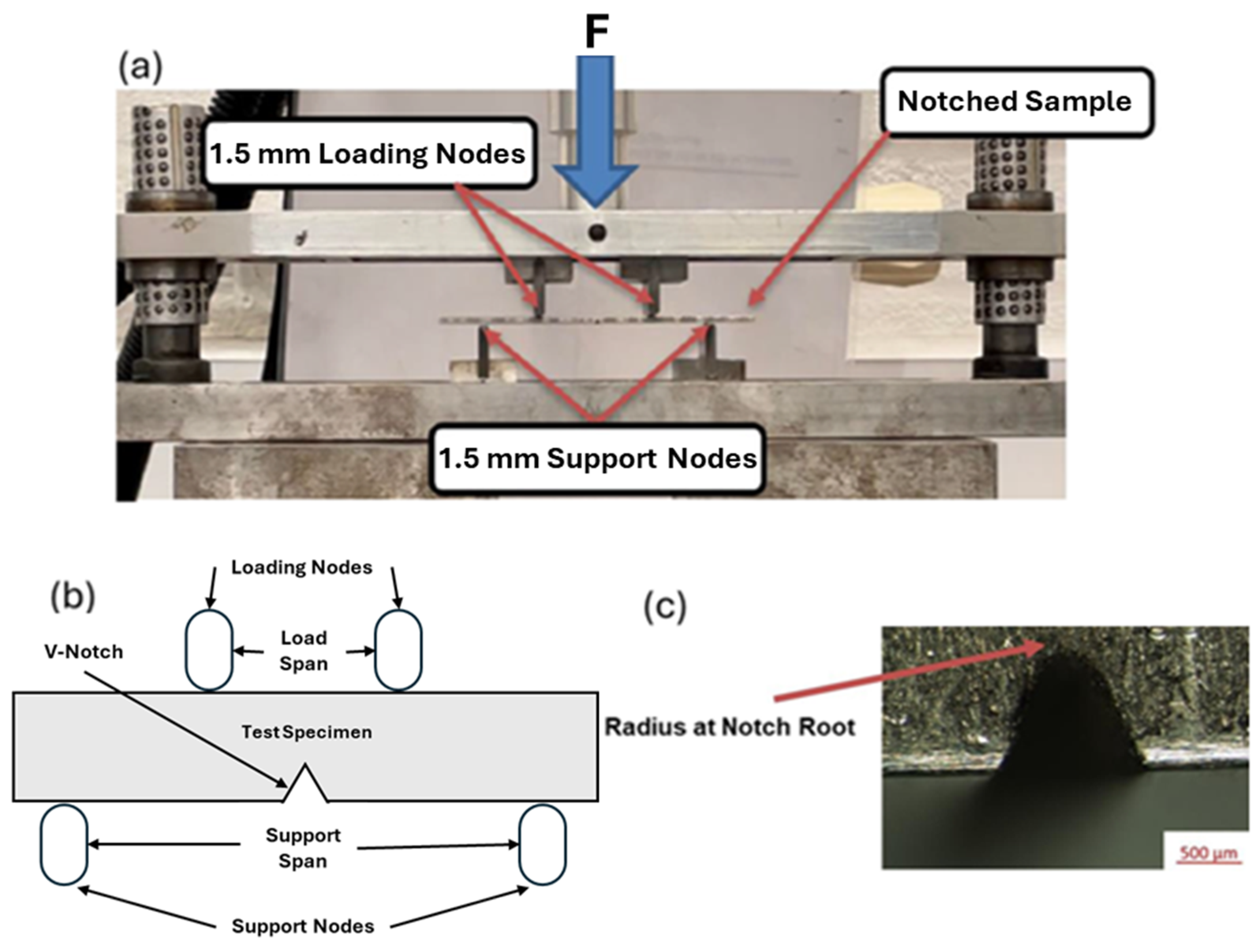

2.5. Four-Point Bending Tests and Fatigue Testing

2.5.1. Sample Preparation and Geometry

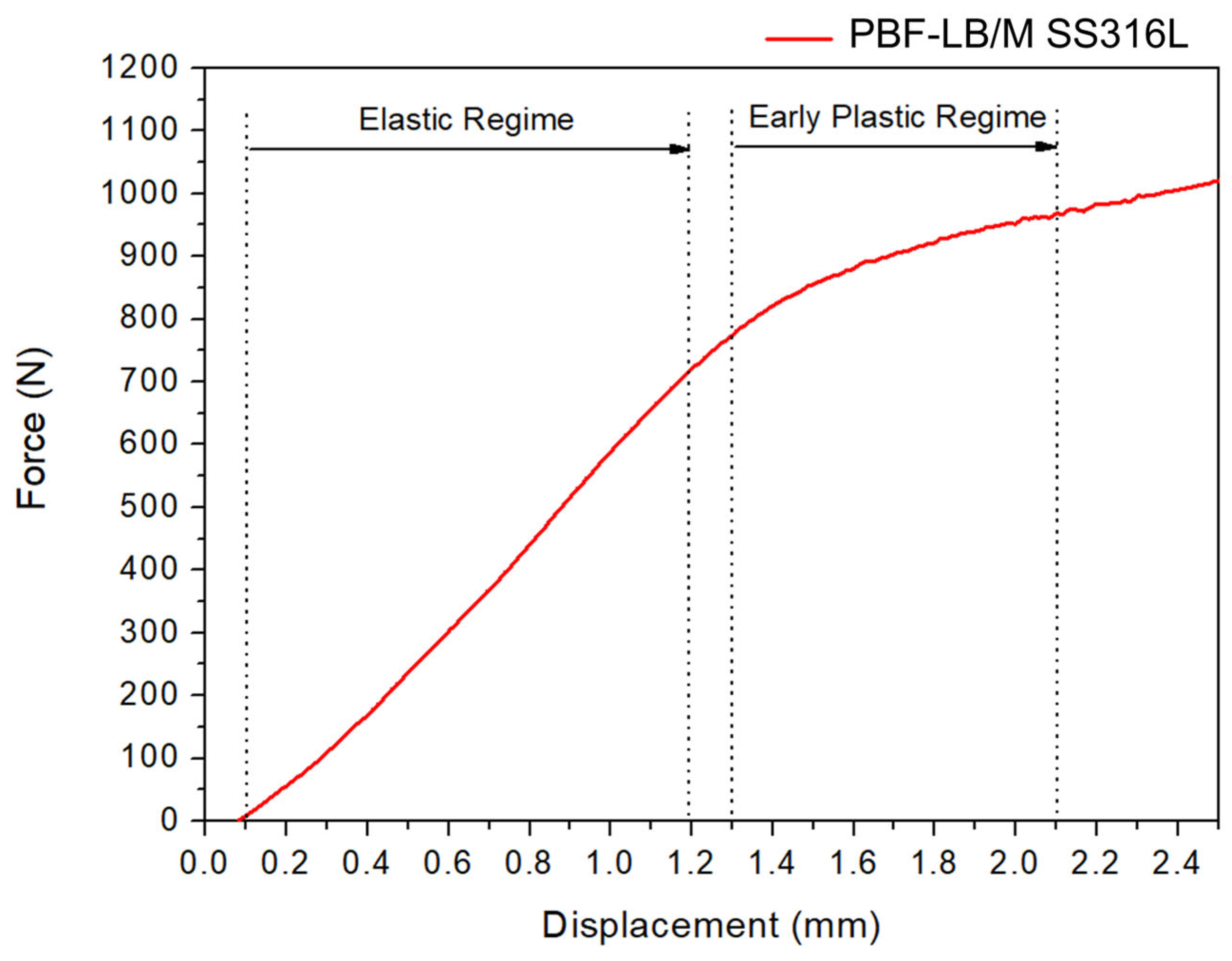

2.5.2. Quasi-Static Four-Point Bending Tests

2.5.3. Fatigue Testing Parameters

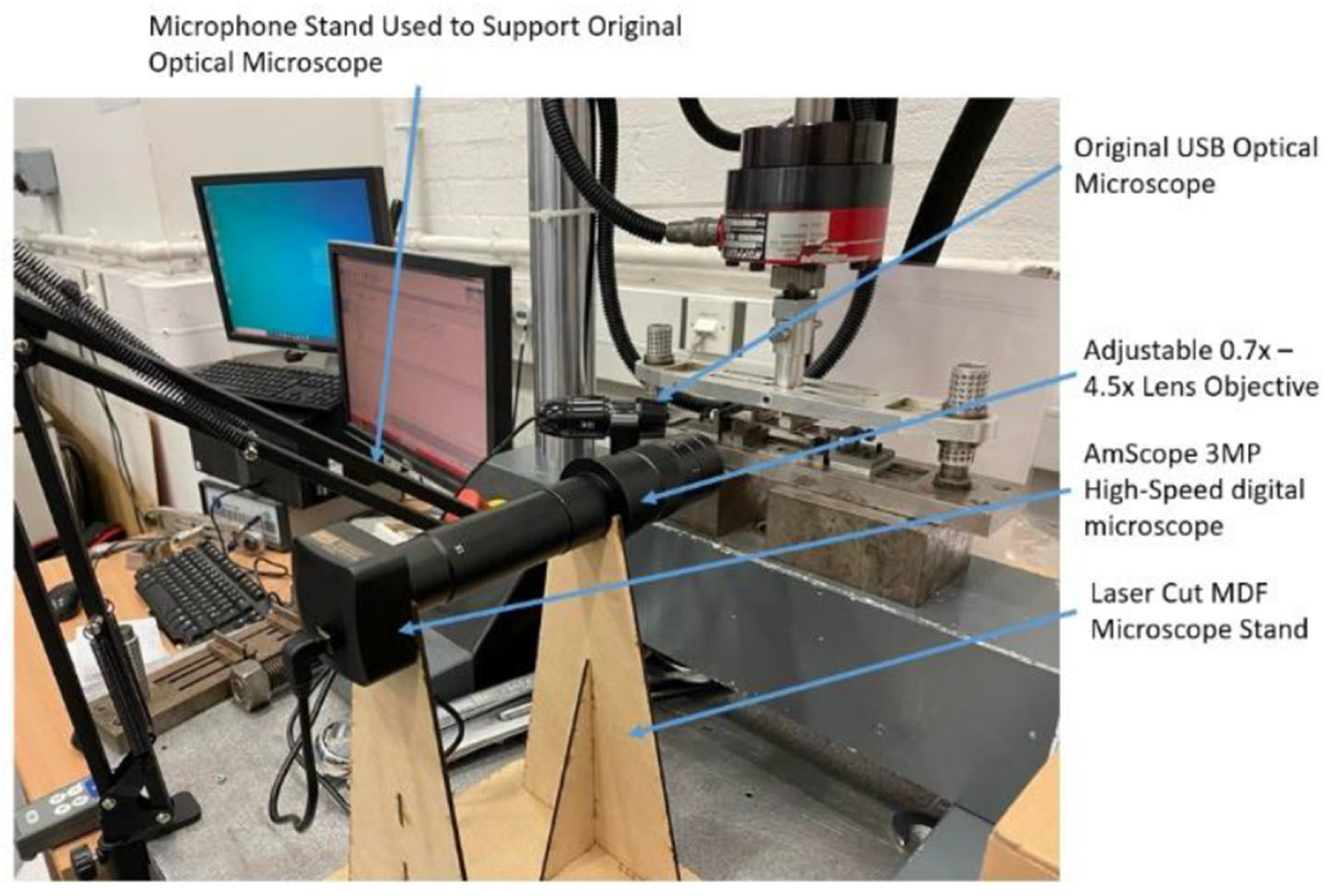

2.5.4. Real Time Crack Monitoring

2.5.5. SEM Fractography Analysis

3. Results

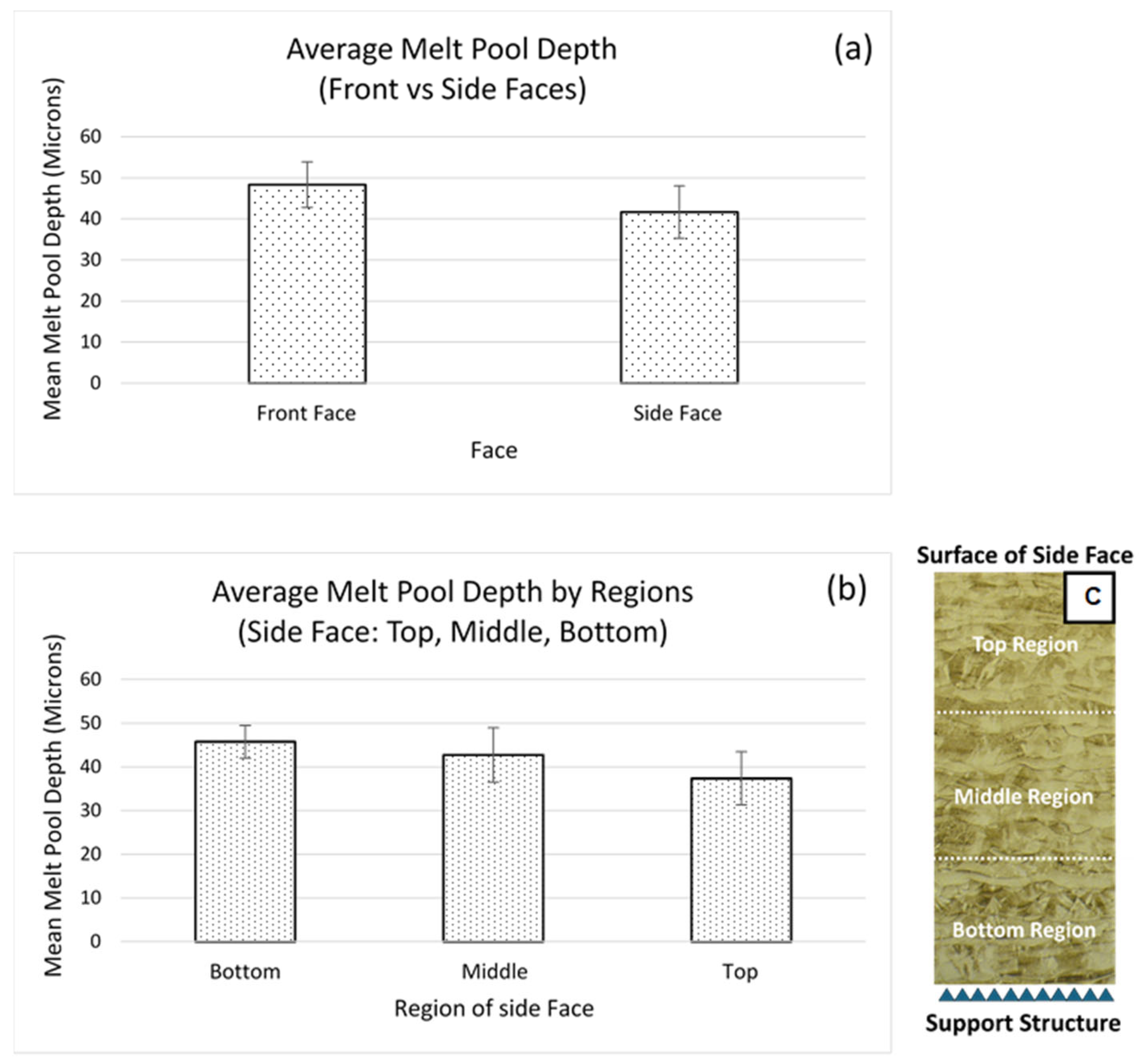

3.1. OM Melt Pool Morphology and Measurements

3.2. OM Porosity Morphology and Quantification

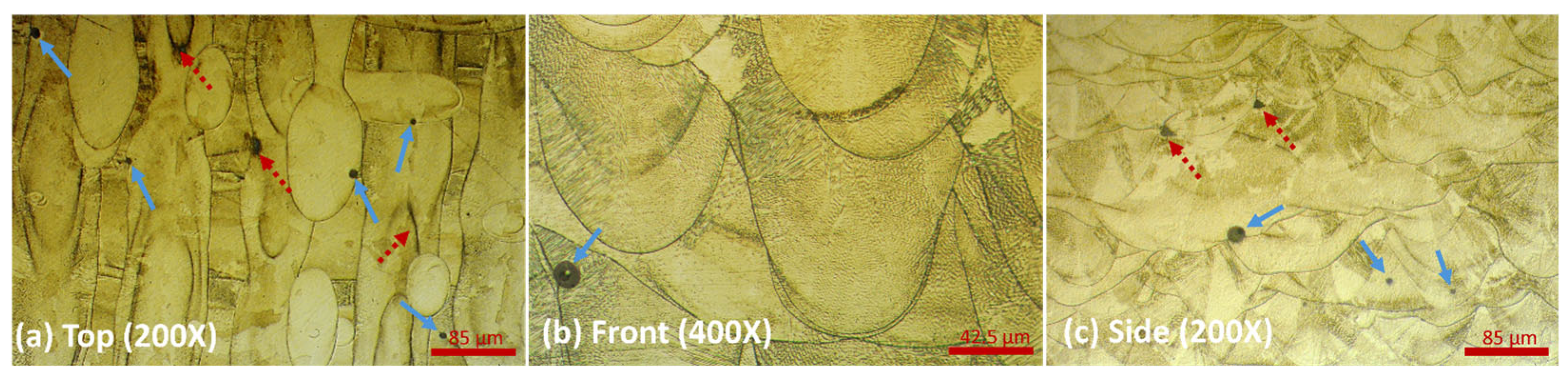

3.2.1. Porosity Morphology and Distribution

3.2.2. Quantitative Analysis of Pore Shape Descriptors

3.3. SEM Microstructure and Microporosity

3.4. EDX Elemental Composition Analysis

3.5. XRD Phase Structure Analysis

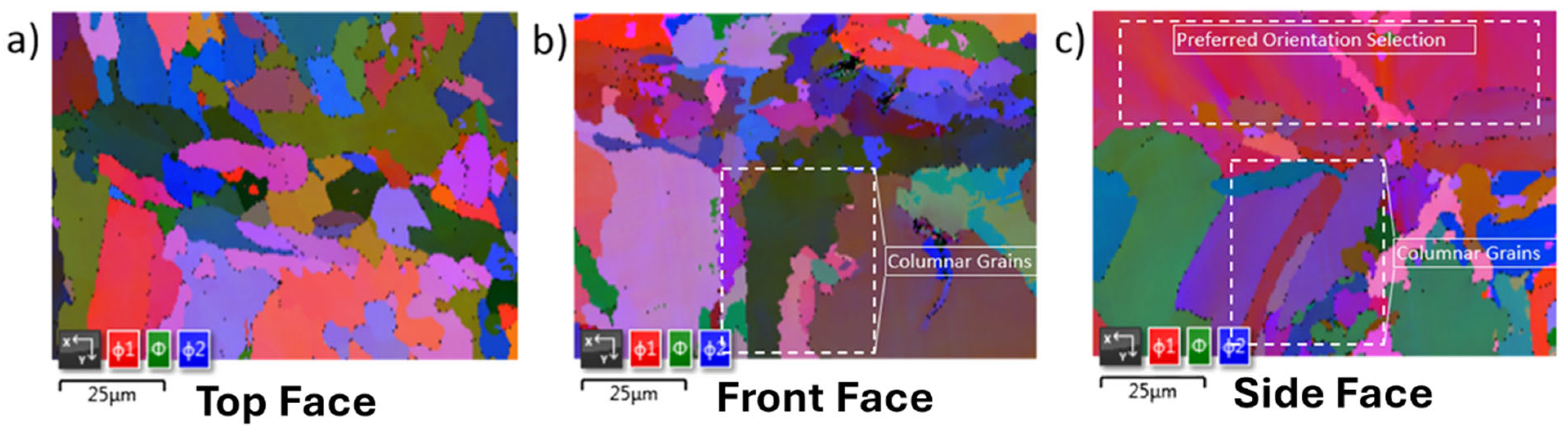

3.6. EBSD Grain Orientation and Morphology Analysis

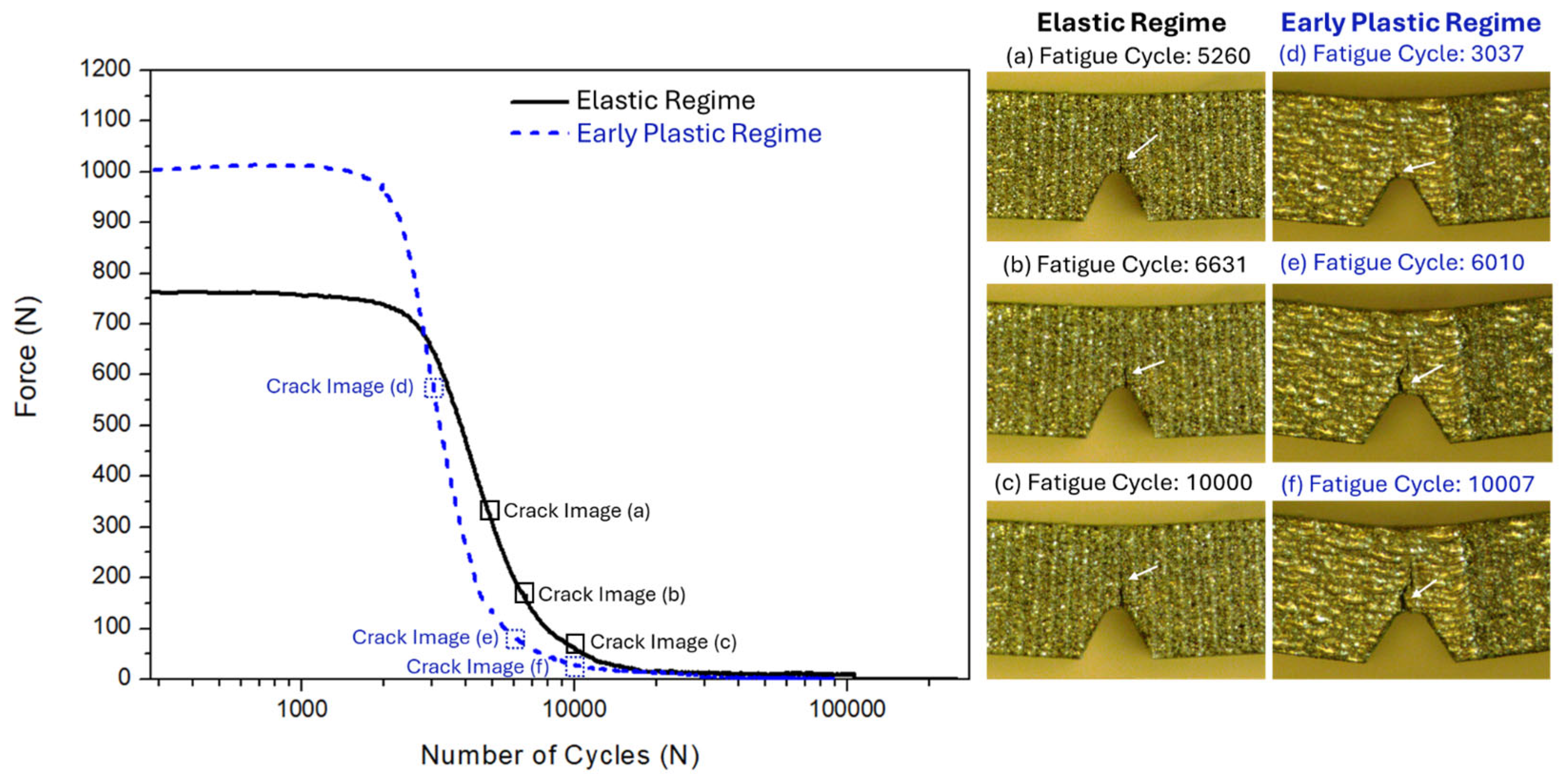

3.7. Bending Fatigue Behaviour and Crack Propagation

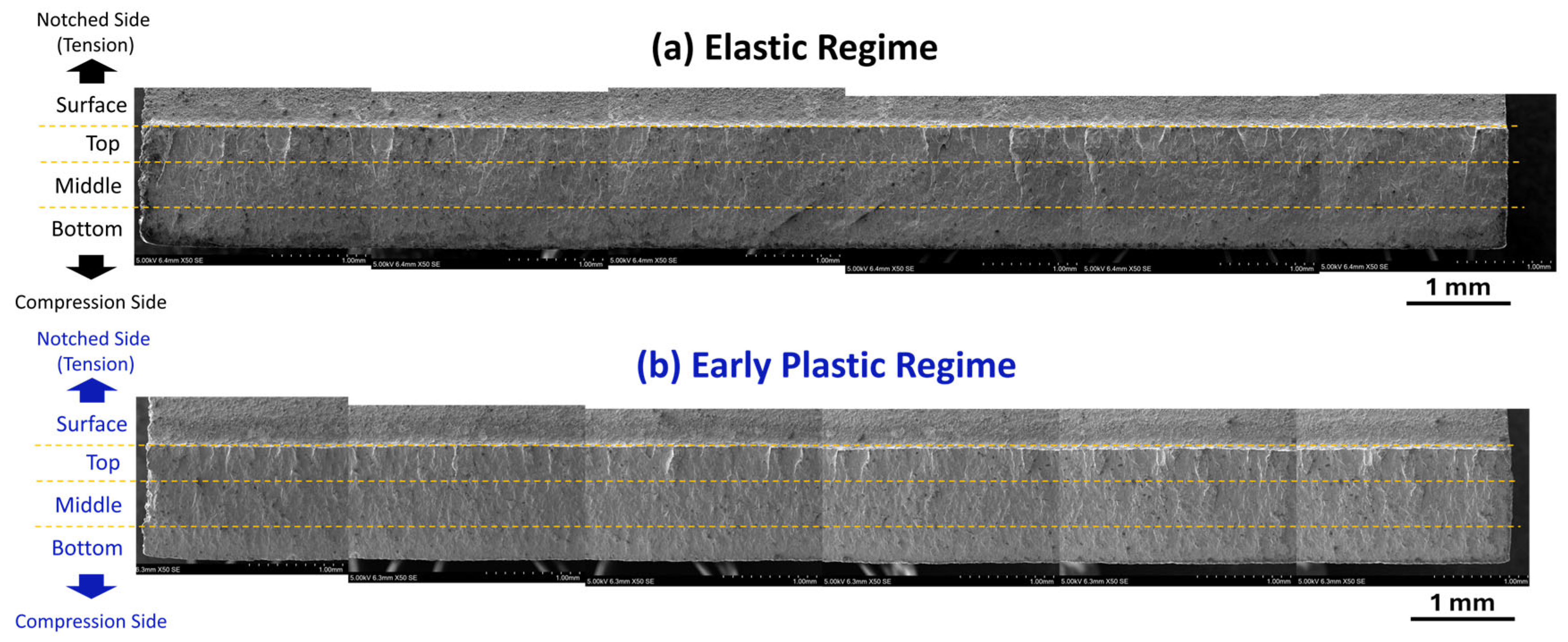

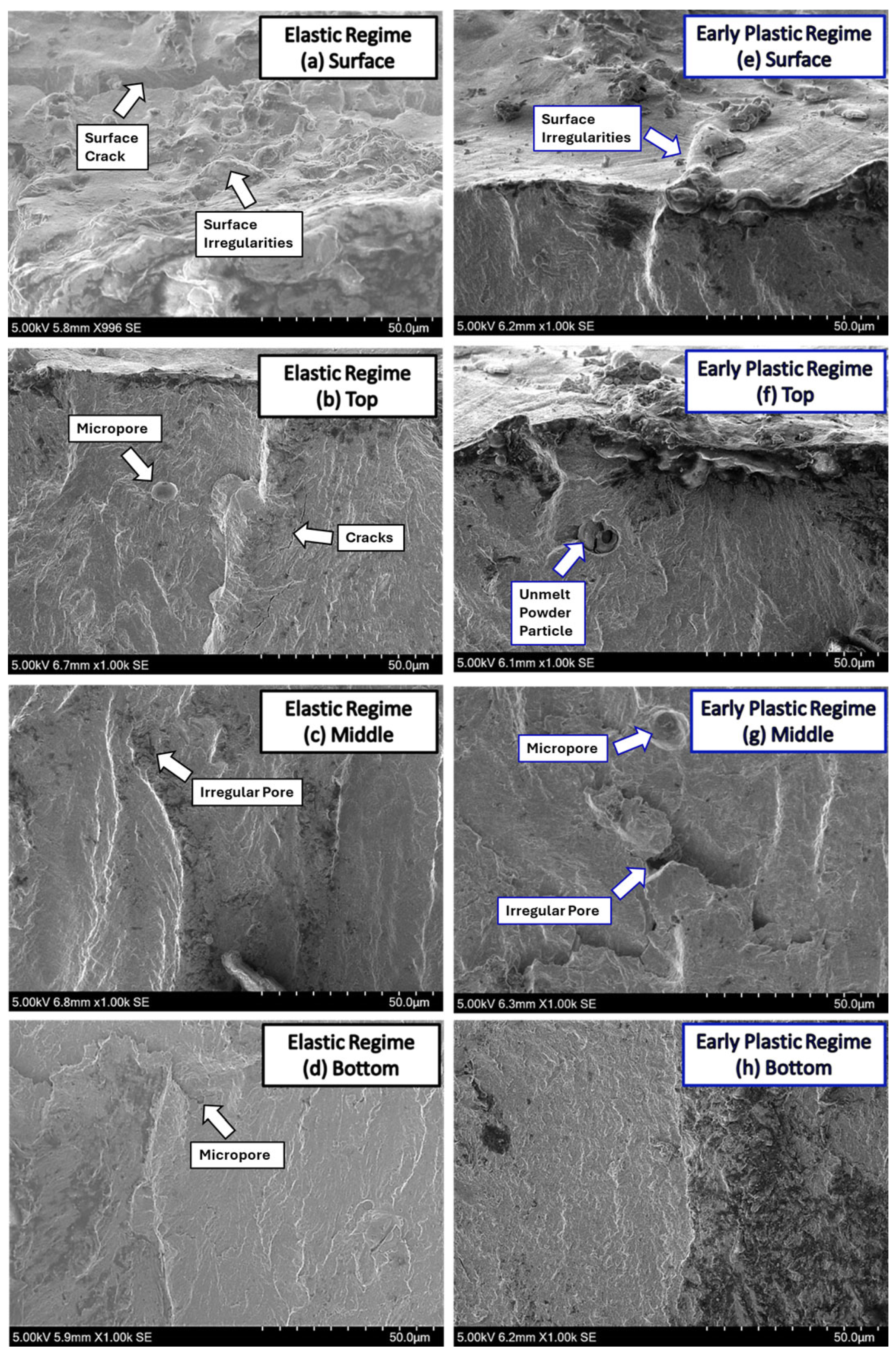

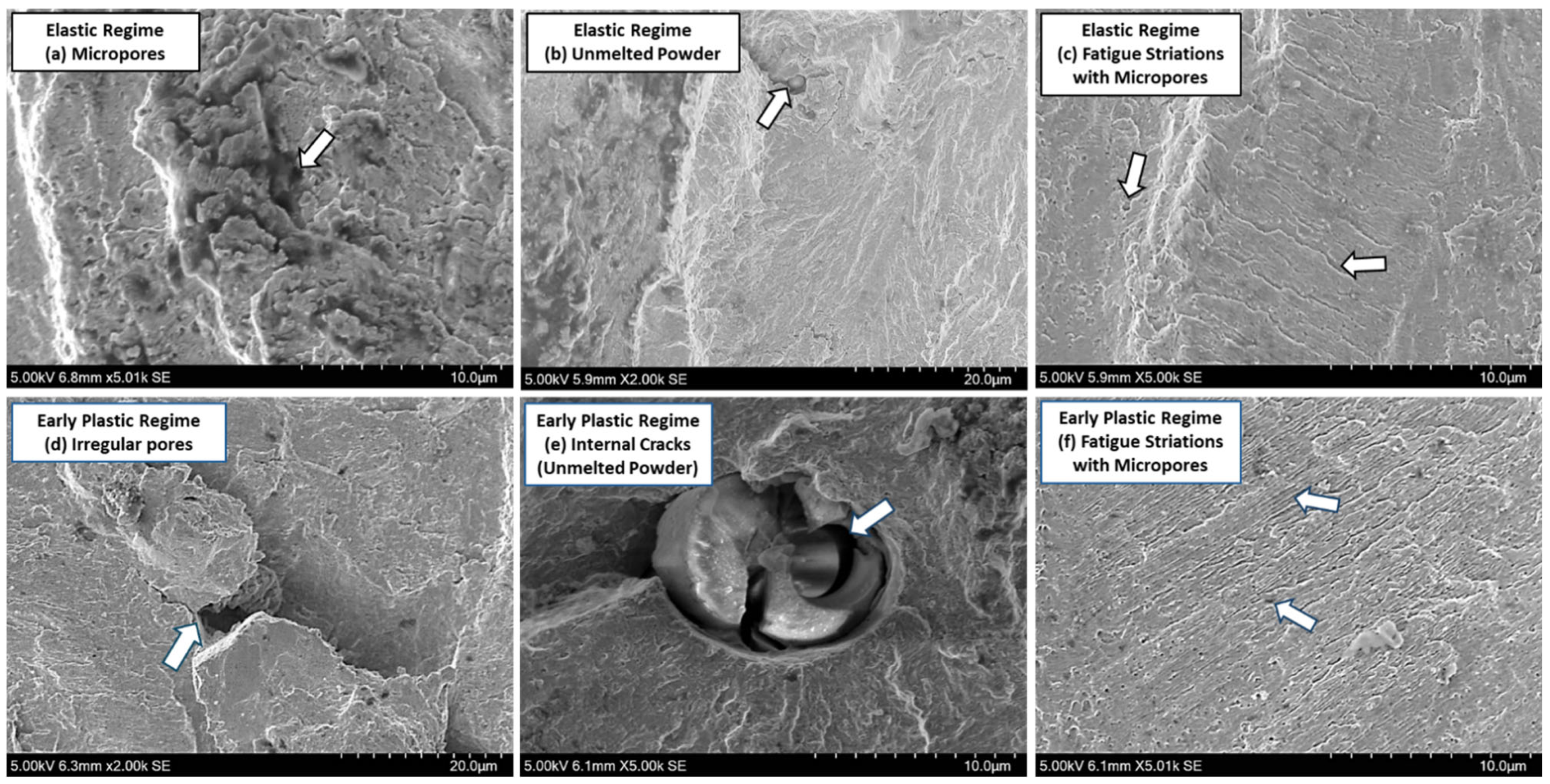

3.8. SEM Fracture Surfaces After Bending Fatigue Tests

3.9. Comprehensive Microstructure and Chemical Analyses

3.9.1. Microstructural and Porosity Findings

3.9.2. Influence of Microstructure on Bending Fatigue Behaviour

3.9.3. Relative Influence of Microstructural Factors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, J.-A.; Koh, Y.-G.; Kang, K.-T. Biomechanical and Clinical Effect of Patient-Specific or Customized Knee Implants: A Review. J. Clin. Med. 2020, 9, 1559. [Google Scholar] [CrossRef] [PubMed]

- Moret, C.S.; Schelker, B.L.; Hirschmann, M.T. Clinical and Radiological Outcomes after Knee Arthroplasty with Patient-Specific versus Off-the-Shelf Knee Implants: A Systematic Review. J. Pers. Med. 2021, 11, 590. [Google Scholar] [CrossRef] [PubMed]

- O’Connor, M.I.; Kransdorf, M.J. Customized Knee Arthroplasty and the Role of Preoperative Imaging. Am. J. Roentgenol. 2013, 201, W443–W450. [Google Scholar] [CrossRef] [PubMed]

- Nagpure, D.; Asutkar, S. 3D Printing in Surgery: Transforming Patient-Specific Solutions. Multidiscip. Rev. 2024, 8, 2025154. [Google Scholar] [CrossRef]

- Stendal, J.; Fergani, O.; Yamaguchi, H.; Espallargas, N. A Comparative Tribocorrosion Study of Additive Manufactured and Wrought 316L Stainless Steel in Simulated Body Fluids. J. Bio Tribo Corros. 2018, 4, s40735-s017. [Google Scholar] [CrossRef]

- Liang, X.; Hor, A.; Robert, C.; Salem, M.; Lin, F.; Morel, F. High. Cycle Fatigue Behavior of 316L Steel Fabricated by Laser Powder Bed Fusion: Effects of Surface Defect and Loading Mode. Int. J. Fatigue 2022, 160, 106843. [Google Scholar] [CrossRef]

- Kotrych, D.; Angelini, A.; Bohatyrewicz, A.; Ruggieri, P. 3D Printing for Patient-Specific Implants in Musculoskeletal Oncology. EFORT Open Rev. 2023, 8, 331–339. [Google Scholar] [CrossRef]

- Pilliar, R.M.; Cameron, H.U.; Binnington, A.G.; Szivek, J.; Macnab, I. Bone Ingrowth and Stress Shielding with a Porous Surface Coated Fracture Fixation Plate. J. Biomed. Mater. Res. 1979, 13, 799–810. [Google Scholar] [CrossRef]

- Chua, M.; Chui, C.-K. Optimization of Patient-Specific Design of Medical Implants for Manufacturing. Procedia CIRP 2016, 40, 402–406. [Google Scholar] [CrossRef][Green Version]

- Yadav, D.; Garg, R.; Ahlawat, A.; Chhabra, D. 3D Printable Biomaterials for Orthopedic Implants: Solution for Sustainable and Circular Economy. Resour. Policy 2020, 68, 101767. [Google Scholar] [CrossRef]

- Fantin, L. de B.; Moreira, M.F.; de Souza, J.M.P. Failure Analysis of a Fractured Stainless Steel Femoral Bone Plate. Eng. Fail. Anal. 2025, 173, 109466. [Google Scholar] [CrossRef]

- Guerra-Fuentes, L.; Garcia-Sanchez, E.; Juarez-Hernandez, A.; Hernandez-Rodriguez, M.A.L. Failure Analysis in 316L Stainless Steel Supracondylar Blade Plate. Eng. Fail. Anal. 2015, 57, 243–247. [Google Scholar] [CrossRef]

- Sudhakar, K.V. Metallurgical Investigation of a Failure in 316L Stainless Steel Orthopaedic Implant. Eng. Fail. Anal. 2005, 12, 249–256. [Google Scholar] [CrossRef]

- Polak, S.; Beever, L.; Wade, A.; Fukuoka, M.; Worth, A.J. Biomechanical Comparison of Titanium Alloy Additively Manufactured and Conventionally Manufactured Plate-Screw Constructs. N. Zealand Vet. J. 2024, 72, 17–27. [Google Scholar] [CrossRef]

- Wu, K.; Li, B.; Guo, J. Fatigue Crack Growth and Fracture of Internal Fixation Materials in In Vivo Environments—A Review. Materials 2021, 14, 176. [Google Scholar] [CrossRef]

- Zhang, H.; Chiang, R.; Qin, H.; Ren, Z.; Hou, X.; Doll, G.; Vasudevan, V.; Dong, Y.; Ye, C. The Effects of Ultrasonic Nanocrystal Surface Modification on the Fatigue Performance of 3D-Printed Ti64. Int. J. Fatigue 2017, 103. [Google Scholar] [CrossRef]

- Rivolta, B.; Gerosa, R.; Panzeri, D. Selective Laser Melted 316L Stainless Steel: Influence of Surface and Inner Defects on Fatigue Behavior. Int. J. Fatigue 2023, 172, 107664. [Google Scholar] [CrossRef]

- Concli, F.; Gerosa, R.; Panzeri, D.; Fraccaroli, L. High and Low Cycle Fatigue Properties of Selective Laser Melted AISI 316L and AlSi10Mg. Int. J. Fatigue 2023, 177, 107931. [Google Scholar] [CrossRef]

- Blinn, B.; Krebs, F.; Ley, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Teutsch, R.; Beck, T. Influence of the Chemical Composition of the Used Powder on the Fatigue Behavior of Additively Manufactured Materials. Metals 2019, 9, 1285. [Google Scholar] [CrossRef]

- Kong, D.; Ni, X.; Dong, C.; Zhang, L.; Man, C.; Cheng, X.; Li, X. Anisotropy in the Microstructure and Mechanical Property for the Bulk and Porous 316L Stainless Steel Fabricated via Selective Laser Melting. Mater. Lett. 2019, 235, 1–5. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjörvarsson, B.; Sahlberg, M. The Effect of Laser Scanning Strategies on Texture, Mechanical Properties, and Site-Specific Grain Orientation in Selective Laser Melted 316L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Dixit, S.; Liu, S.; Murdoch, H.A.; Smith, P.M. Investigating Build Orientation-Induced Mechanical Anisotropy in Additive Manufacturing 316L Stainless Steel. Mater. Sci. Eng. A 2023, 880, 145308. [Google Scholar] [CrossRef]

- Ganesh, P.; Kaul, R.; Sasikala, G.; Kumar, H.; Venugopal, S.; Tiwari, P.; Rai, S.; Prasad, R.C.; Kukreja, L.M. Fatigue Crack Propagation and Fracture Toughness of Laser Rapid Manufactured Structures of AISI 316L Stainless Steel. Metallogr. Microstruct. Anal. 2014, 3, 36–45. [Google Scholar] [CrossRef]

- Jaskari, M.; Mäkikangas, J.; Järvenpää, A.; Mäntyjärvi, K.; Karjalainen, P. Effect of High Porosity on Bending Fatigue Properties of 3D Printed AISI 316L Steel. Procedia Manuf. 2019, 36, 33–41. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Shen, J.; Peng, Y.; Jiang, Y.; Yang, X.; Leen, S.B.; Gong, J. Deformation Mechanisms of Selective Laser Melted 316L Austenitic Stainless Steel in High Temperature Low Cycle Fatigue. Mater. Sci. Eng. A 2022, 843, 143123. [Google Scholar] [CrossRef]

- Winwood, K.; Zioupos, P.; Currey, J.D.; Cotton, J.R.; Taylor, M. The Importance of the Elastic and Plastic Components of Strain in Tensile and Compressive Fatigue of Human Cortical Bone in Relation to Orthopaedic Biomechanics. J. Musculoskelet. Neuronal Interact. 2006, 6, 134–141. [Google Scholar]

- Xie, W.; Hussain, I.; Man, H.-C.; Chan, C.-W. Adoption of Appropriate Scanning Strategy on Selective Laser Melting of Stainless Steel 316L to Enable Healthy Mesenchymal Stem Cells Response. J. Laser Appl. 2023, 35, 022019. [Google Scholar] [CrossRef]

- ASTM E112-13(2021); Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://compass.astm.org/document/?contentCode=ASTM%7CE0112-13R21%7Cen-US&proxycl=https%3A%2F%2Fsecure.astm.org&fromLogin=true (accessed on 18 October 2023).

- Wang, S.; Ning, J.; Zhu, L.; Yang, Z.; Yan, W.; Dun, Y.; Xue, P.; Xu, P.; Bose, S.; Bandyopadhyay, A. Role of Porosity Defects in Metal 3D Printing: Formation Mechanisms, Impacts on Properties and Mitigation Strategies. Mater. Today 2022, 59, 133–160. [Google Scholar] [CrossRef]

- Liu, J.; Song, Y.; Chen, C.; Wang, X.; Li, H.; Zhou, C.; Wang, J.; Guo, K.; Sun, J. Effect of Scanning Speed on the Microstructure and Mechanical Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting. Mater. Des. 2020, 186, 108355. [Google Scholar] [CrossRef]

- Minns, R.J.; Bremble, G.R.; Campbell, J. A Biomechanical Study of Internal Fixation of the Tibial Shaft. J. Biomech. 1977, 10, 569–579. [Google Scholar] [CrossRef]

- ISO 12108:2018; Metallic Materials—Fatigue Testing—Fatigue Crack Growth Method. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/73809.html (accessed on 24 March 2025).

- Leary, M.; Maconachie, T.; Sarker, A.; Faruque, O.; Brandt, M. Mechanical and Thermal Characterisation of AlSi10Mg SLM Block Support Structures. Mater. Des. 2019, 183, 108138. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in Additive Manufactured Metals and Their Effect on Fatigue Performance: A State-of-the-Art Review. Prog. Mater. Sci. 2021, 117, 100724. [Google Scholar] [CrossRef]

- Qu, H.; Li, J.; Zhang, F.; Bai, J. Anisotropic Cellular Structure and Texture Microstructure of 316L Stainless Steel Fabricated by Selective Laser Melting via Rotation Scanning Strategy. Mater. Des. 2022, 215, 110454. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.-D.; Saintier, N.; Pessard, E.; De Terris, T.; Dupuy, C.; Baudin, T. Texture Control of 316L Parts by Modulation of the Melt Pool Morphology in Selective Laser Melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef]

- Avanzini, A. Fatigue Behavior of Additively Manufactured Stainless Steel 316L. Materials 2022, 16, 65. [Google Scholar] [CrossRef]

- Chepkoech, M.; Omoniyi, P.; Owolabi, G. Fatigue Response of Additive-Manufactured 316L Stainless Steel. Metals 2024, 14, 988. [Google Scholar] [CrossRef]

- Zhang, W.; Pommier, S.; Curtit, F.; Léopold, G.; Courtin, S. Mode I Crack Propagation under High Cyclic Loading in 316L Stainless Steel. Procedia Mater. Sci. 2014, 3, 1197–1203. [Google Scholar] [CrossRef][Green Version]

- Deev, A.A.; Kuznetcov, P.A.; Petrov, S.N. Anisotropy of Mechanical Properties and Its Correlation with the Structure of the Stainless Steel 316L Produced by the SLM Method. Phys. Procedia 2016, 83, 789–796. [Google Scholar] [CrossRef]

- Carassus, H.; Guérin, J.D.; Morvan, H.; Haugou, G.; Sadat, T.; Guérard, S.; Markiewicz, E. An Experimental Investigation into Influences of Build Orientation and Specimen Thickness on Quasi-Static and Dynamic Mechanical Responses of Selective Laser Melting 316L Stainless Steel. Mater. Sci. Eng. A 2022, 835, 142683. [Google Scholar] [CrossRef]

- Aiza, I.; Baldi, C.; de la Vega, F.M.; Sebastiani, S.; Veronese, N.E.; Yousefi, M.; Mosallanejad, M.H.; Maleki, E.; Guagliano, M.; Iuliano, L.; et al. Effects of Build Orientation and Inclined Features on Physical, Microstructural and Mechanical Properties of Powder Bed Fusion Additively Manufactured Metallic Parts. Prog. Mater. Sci. 2025, 147, 101357. [Google Scholar] [CrossRef]

| Face | Fe (wt%) | Cr (wt%) | Ni (wt%) | Mn (wt%) | C (wt%) | O (wt%) | Others: Mo, Si, S (wt%) |

|---|---|---|---|---|---|---|---|

| Top | 66.0 ± 0.17 | 16.0 ± 0.04 | 10.1 ± 0.07 | 1.2 ± 0.02 | 1.2 ± 0.02 | 0.8 ± 0.11 | 4.7 ± 0.18 |

| Front | 65.0 ± 0.28 | 16.1 ± 0.04 | 10.0 ± 0.07 | 1.3 ± 0.07 | 5.1 ± 0.08 | 0.9 ± 0.15 | 1.6 ± 0.13 |

| Side | 66.2 ± 0.22 | 16.3 ± 0.06 | 10.0 ± 0.06 | 1.2 ± 0.05 | 3.8 ± 0.17 | 0.8 ± 0.08 | 1.7 ± 0.20 |

| Phase Name | Top | Front | Side |

|---|---|---|---|

| Fe-BCC | 0.04 | 0.03 | 0.03 |

| Fe-FCC | 98.35 | 98.71 | 99.07 |

| Cr23C6 | 0.07 | 0.07 | 0.05 |

| Cr7C3 | 0.03 | 0.02 | 0.02 |

| Zero Solutions | 1.51 | 1.17 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirk, C.; Xie, W.; Das, S.; Ferguson, B.; Wu, C.; Man, H.-C.; Chan, C.-W. Microstructure, Porosity, and Bending Fatigue Behaviour of PBF-LB/M SS316L for Biomedical Applications. Metals 2025, 15, 650. https://doi.org/10.3390/met15060650

Kirk C, Xie W, Das S, Ferguson B, Wu C, Man H-C, Chan C-W. Microstructure, Porosity, and Bending Fatigue Behaviour of PBF-LB/M SS316L for Biomedical Applications. Metals. 2025; 15(6):650. https://doi.org/10.3390/met15060650

Chicago/Turabian StyleKirk, Conall, Weijie Xie, Shubhangi Das, Ben Ferguson, Chenliang Wu, Hau-Chung Man, and Chi-Wai Chan. 2025. "Microstructure, Porosity, and Bending Fatigue Behaviour of PBF-LB/M SS316L for Biomedical Applications" Metals 15, no. 6: 650. https://doi.org/10.3390/met15060650

APA StyleKirk, C., Xie, W., Das, S., Ferguson, B., Wu, C., Man, H.-C., & Chan, C.-W. (2025). Microstructure, Porosity, and Bending Fatigue Behaviour of PBF-LB/M SS316L for Biomedical Applications. Metals, 15(6), 650. https://doi.org/10.3390/met15060650