Tribological Property of AlCoCrFeNi Coating Electrospark-Deposited on H13 Steel

Abstract

1. Introduction

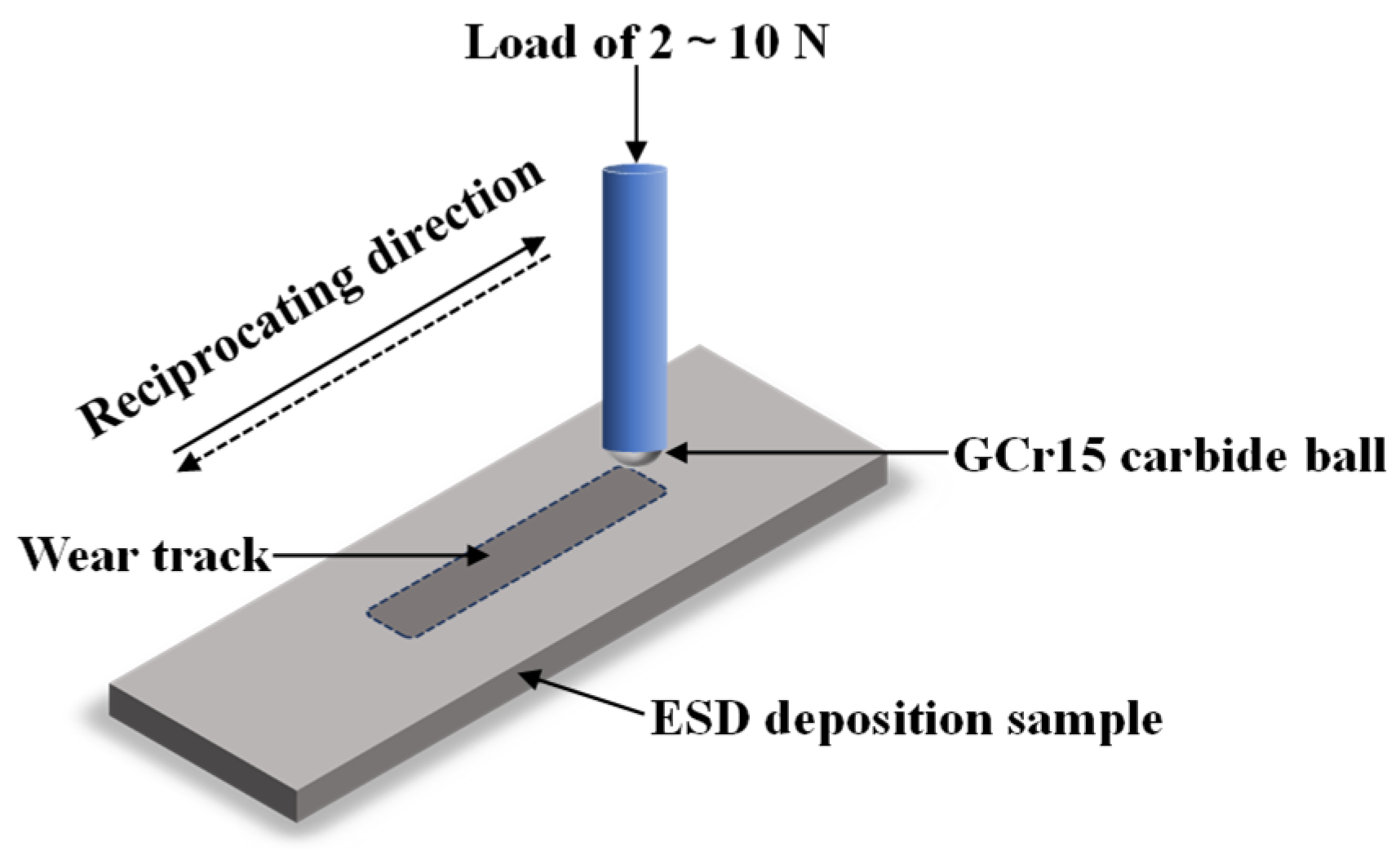

2. Materials and Experimental Methods

2.1. Materials

2.2. Characterization of AlCoCrFeNi Coatings

3. Results

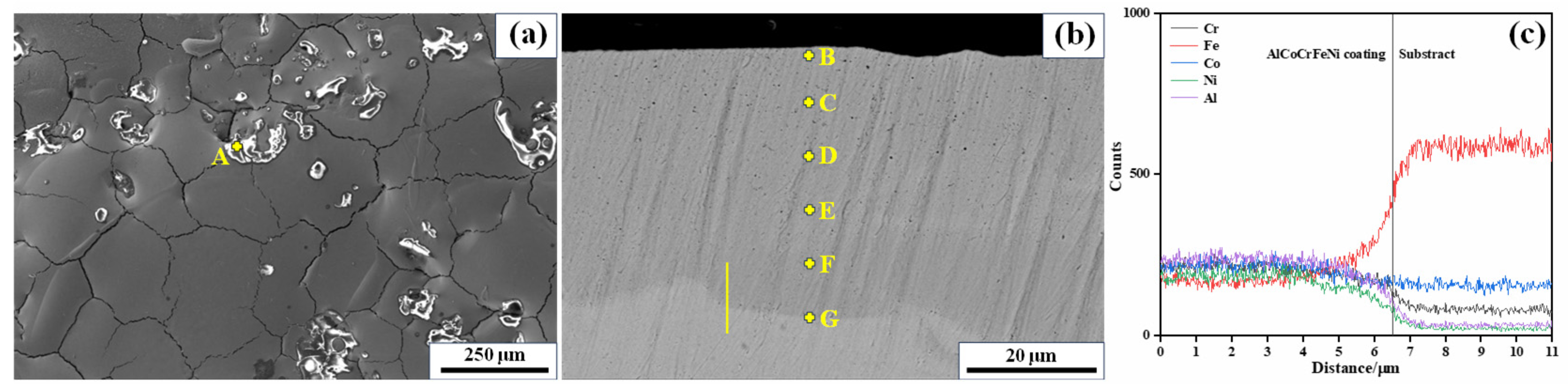

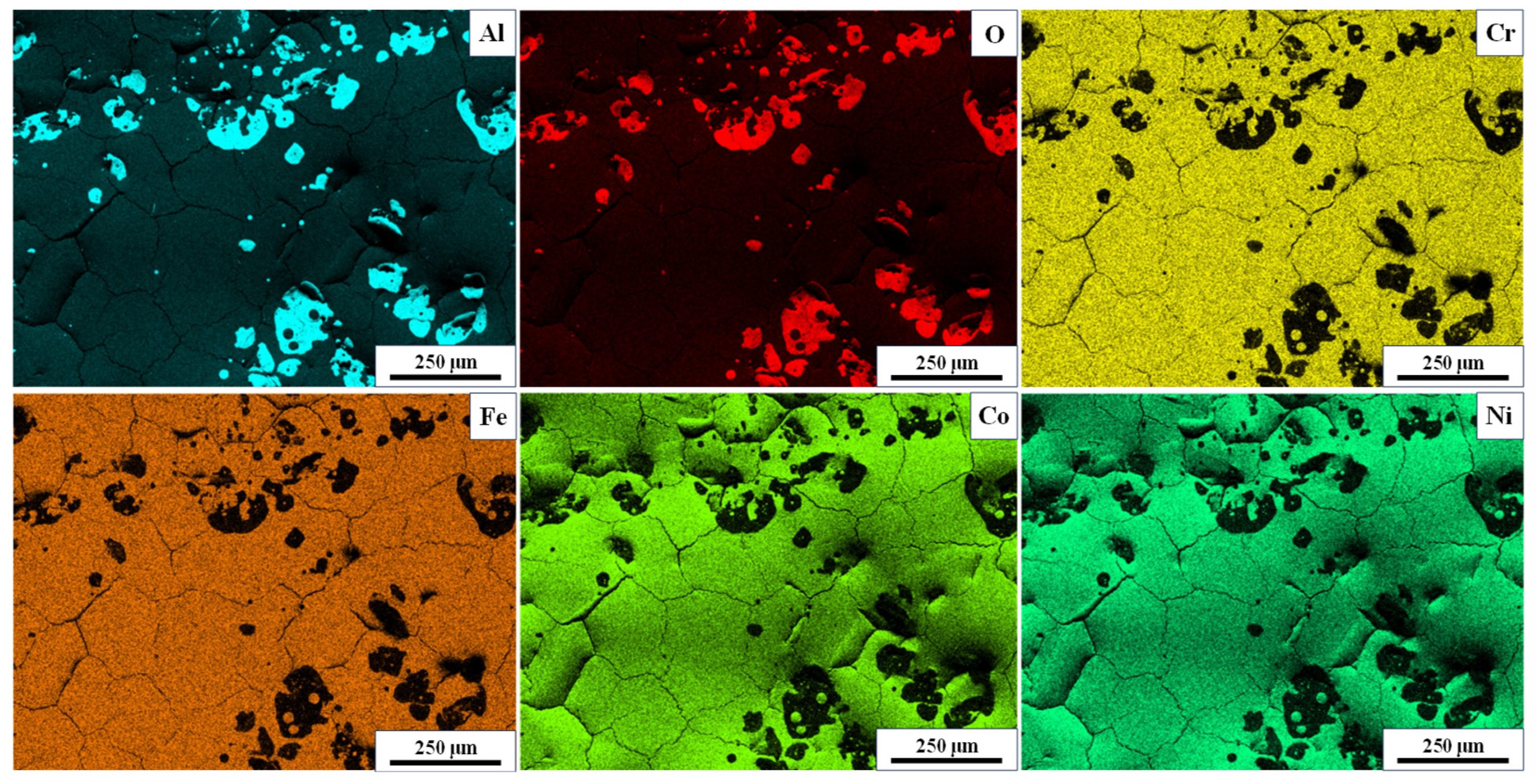

3.1. Microstructure of the AlCoCrFeNi Coating

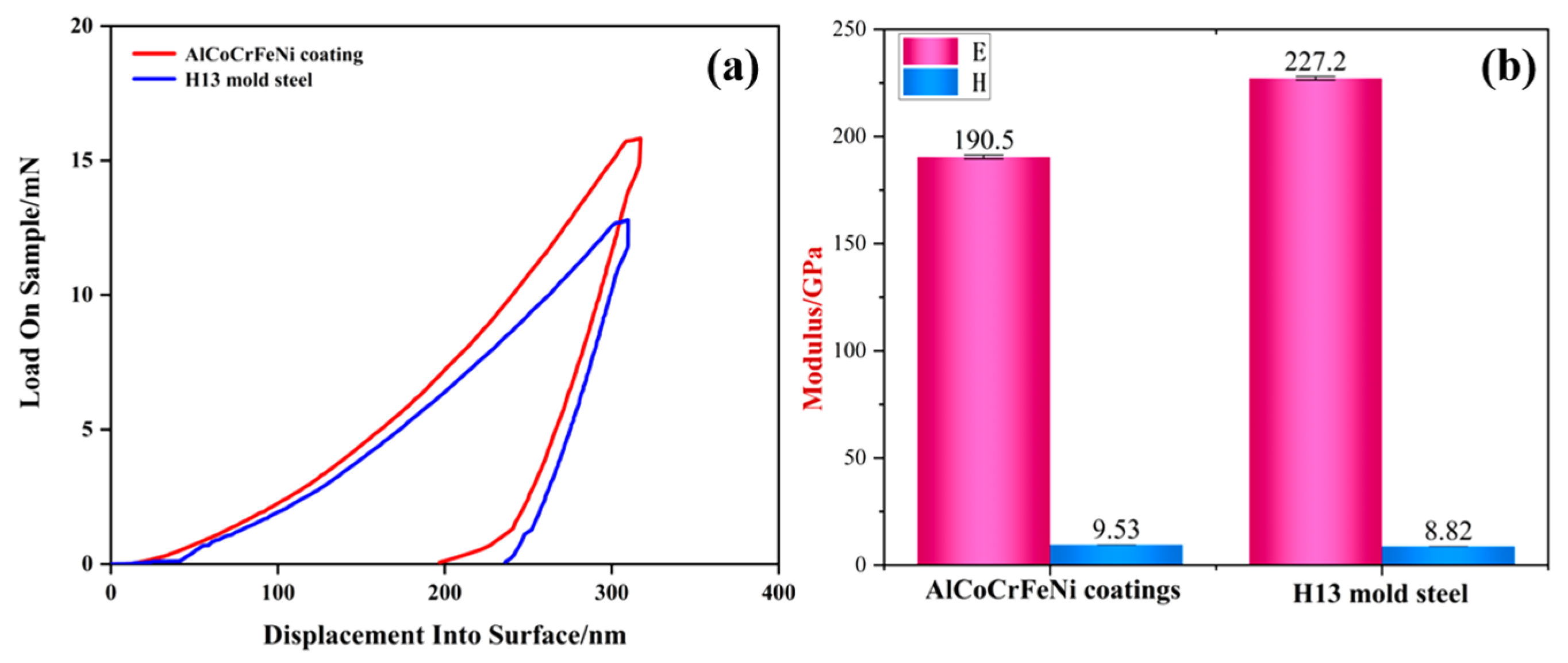

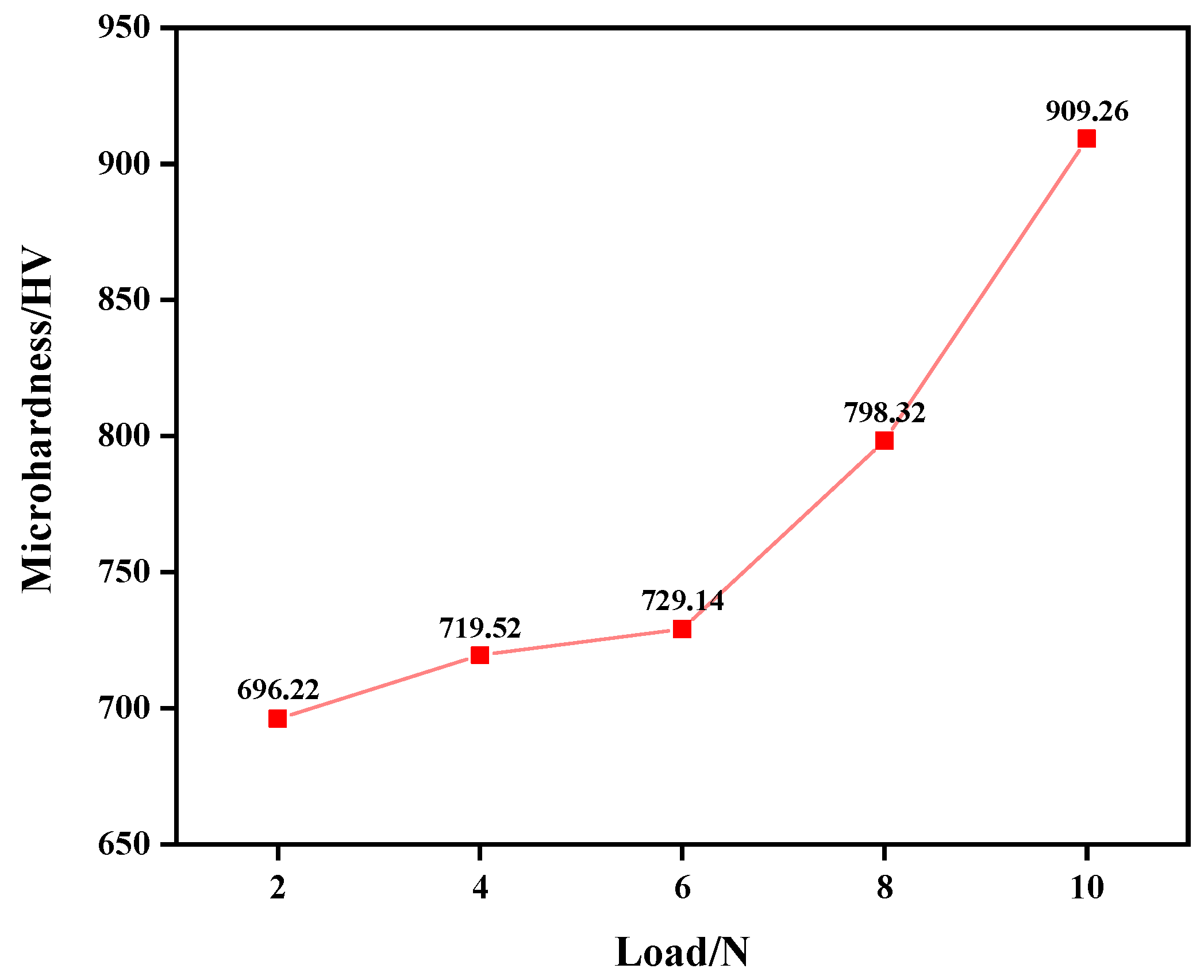

3.2. Nano-Mechanical Properties

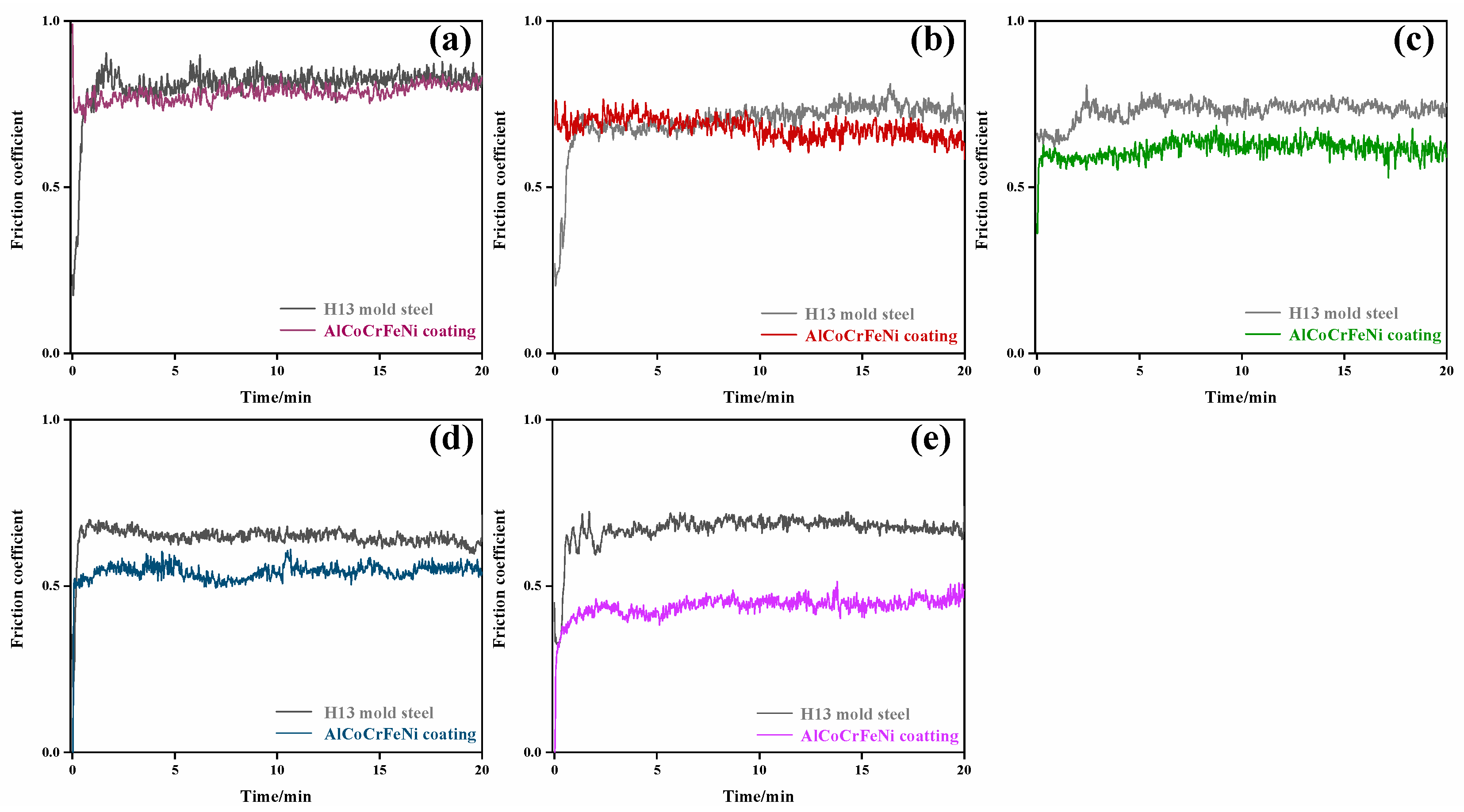

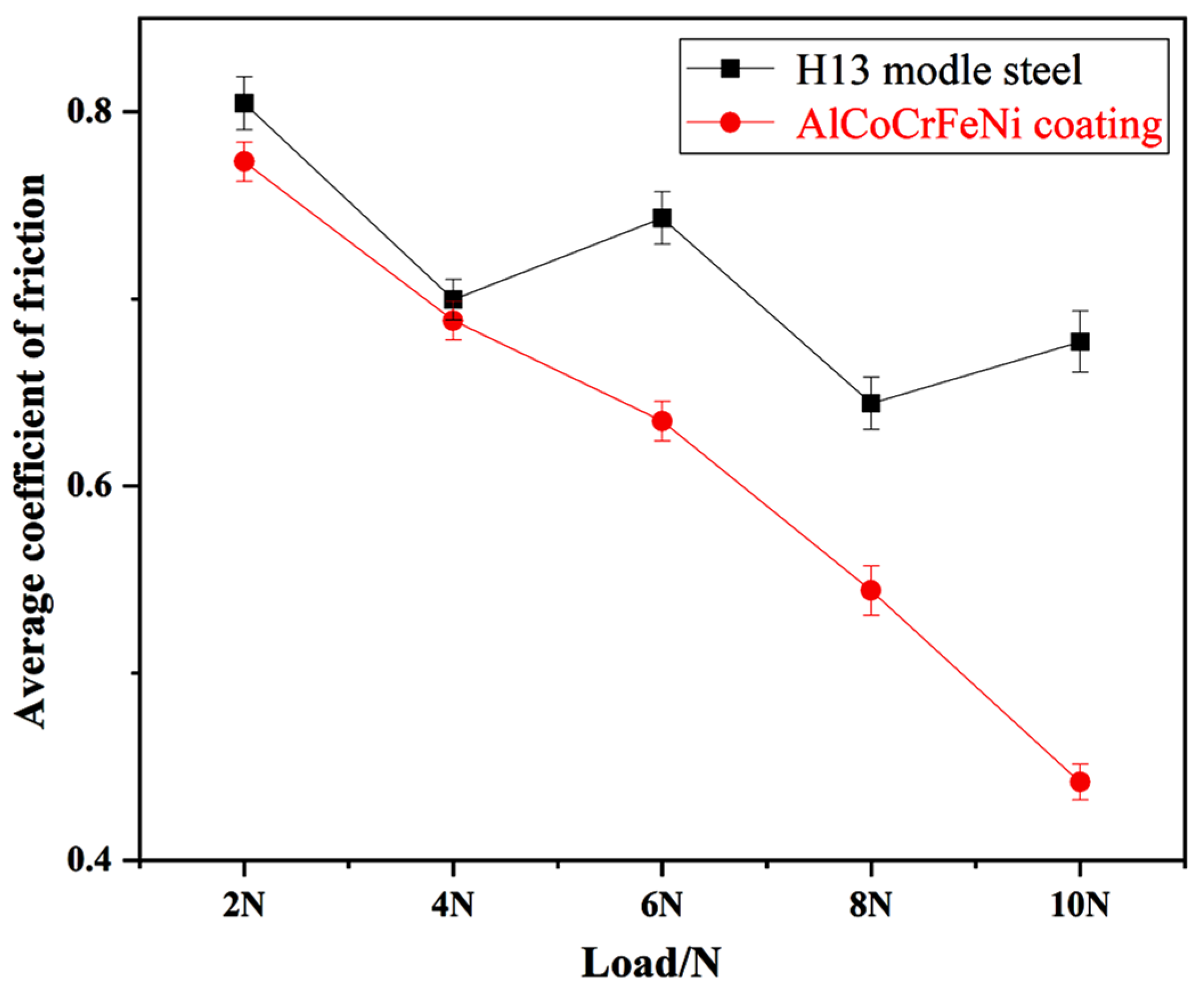

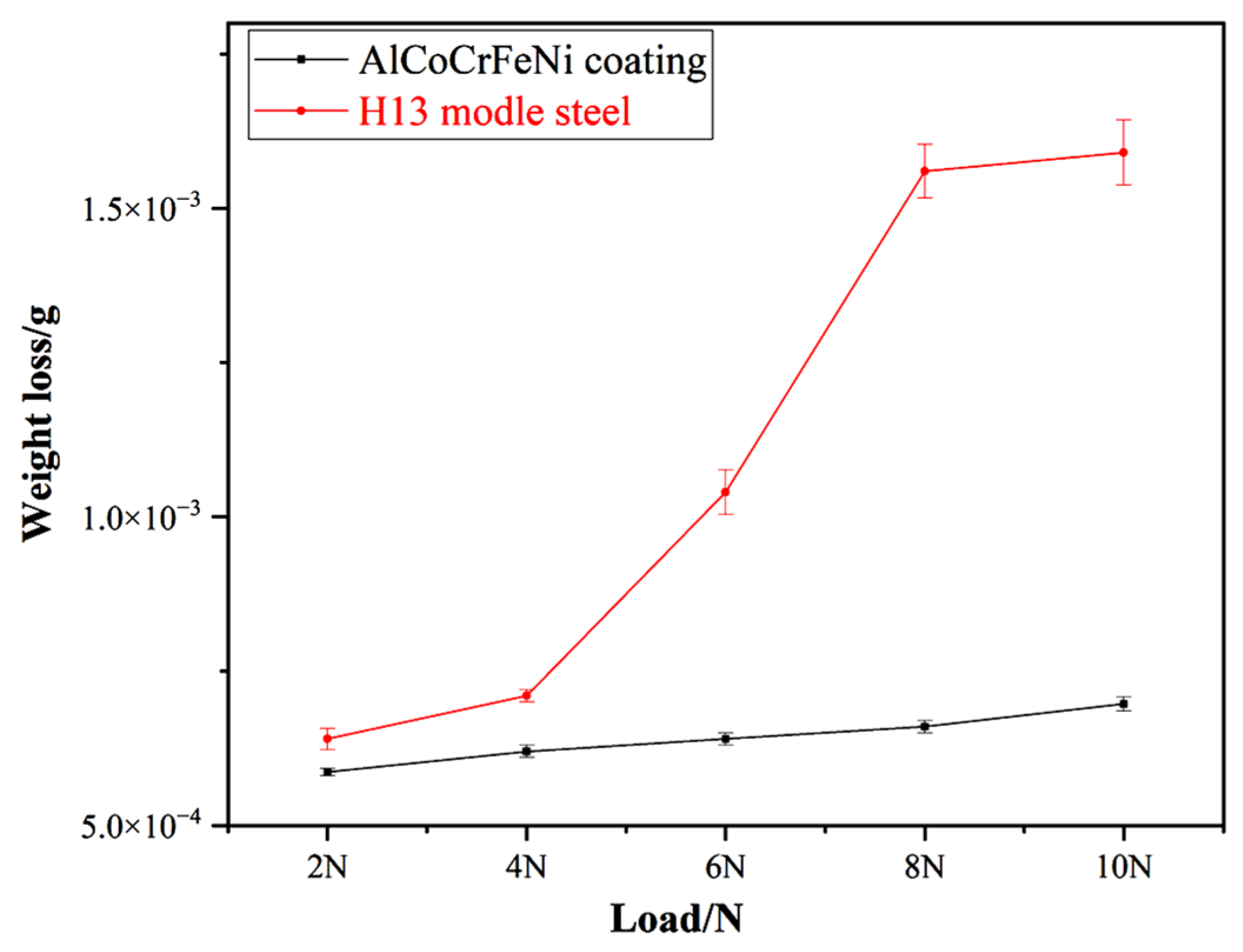

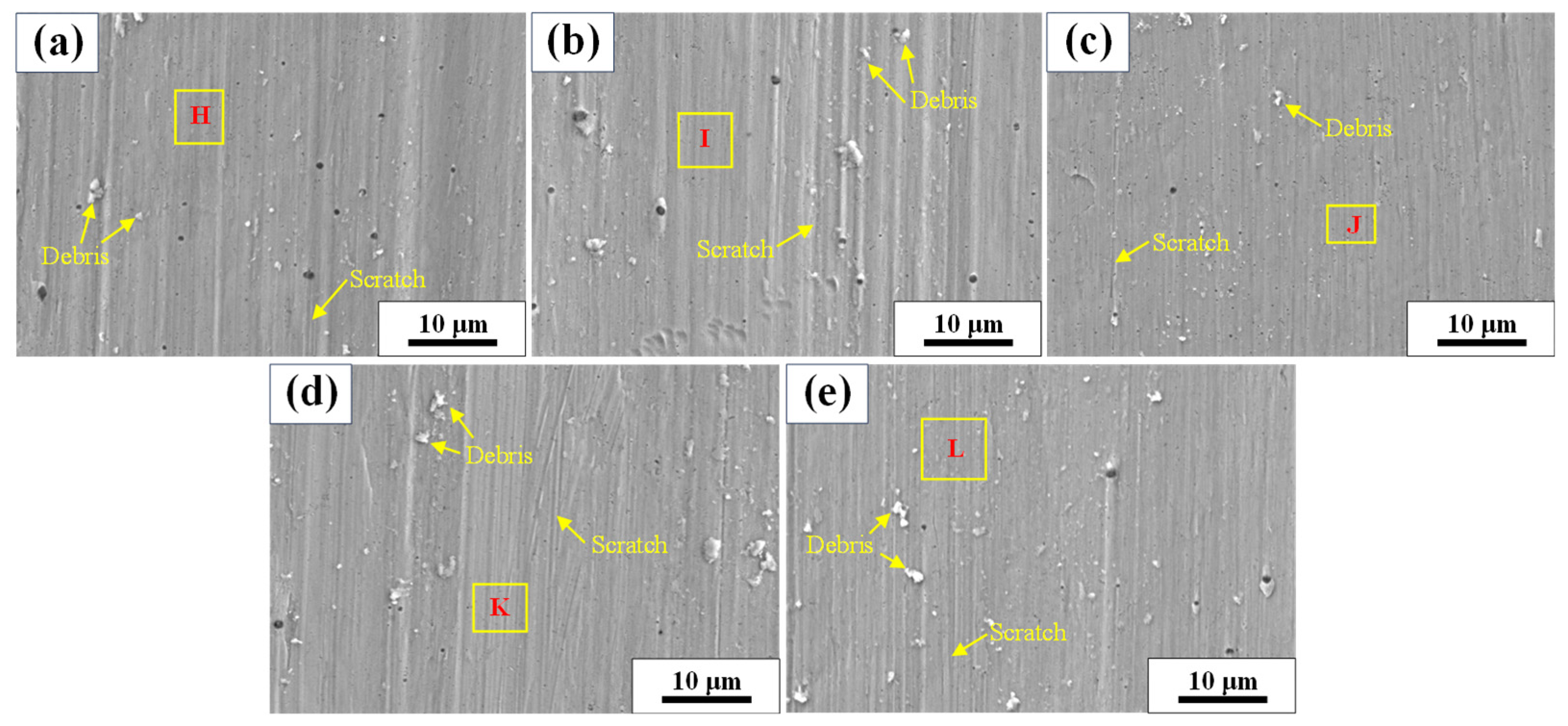

3.3. Tribological Properties

4. Discussion

4.1. Enhancement of the Tribological Property of the H13 Steel via the ESD AlCoCrFeNi Coating

4.2. Load Influence on the Tribological Property of the AlCoCrFeNi Coating

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Narvan, M.; Al-Rubaie, K.S.; Elbestawi, M. Process-Structure-Property Relationships of AISI H13 Tool Steel Processed with Selective Laser Melting. Materials 2019, 12, 2284. [Google Scholar] [CrossRef] [PubMed]

- Mazur, M.; Brincat, P.; Leary, M.; Brandt, M. Numerical and experimental evaluation of a conformally cooled H13 steel injection mould manufactured with selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 93, 881–900. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Wei, Q.; Shi, Y. Thermal Fatigue Properties of H13 Hot-Work Tool Steels Processed by Selective Laser Melting. Metals 2020, 10, 116. [Google Scholar] [CrossRef]

- Bae, K.; Moon, H.S.; Park, Y.; Jo, I.; Lee, J. Influence of Tempering Temperature and Time on Microstructure and Mechanical Properties of Additively Manufactured H13 Tool Steel. Materials 2022, 15, 8329. [Google Scholar] [CrossRef]

- Du, K.; Lv, Z.; Fan, W.; Zhang, R.; Li, X.; Xu, L. Effect of Heat Treatment Process on Microstructure and Mechanical Properties of High-Carbon H13 Steel. Processes 2023, 11, 3239. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, G.; Fu, L.; Tian, J. Recent Progress in High-Entropy Alloys. Adv. Mater. Res. 2013, 227, 631–632. [Google Scholar] [CrossRef]

- Xu, X.; Guo, S.; Nieh, T.; Liu, C.; Hirata, A.; Chen, M. Effects of mixing enthalpy and cooling rate on phase formation of AlxCoCrCuFeNi high-entropy alloys. Materialia 2019, 6, 100292. [Google Scholar] [CrossRef]

- Nartita, R.; Ionita, D.; Demetrescu, I. A Modern Approach to HEAs: From Structure to Properties and Potential Applications. Crystals 2024, 14, 451. [Google Scholar] [CrossRef]

- Jeong, H.T.; Kim, W.J. Deformation Mechanisms and Processing Maps for High Entropy Alloys (Presentation of Processing Maps in Terms of Zener–Hollomon Parameter): Review. Materials 2023, 16, 919. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, M.; Wang, Q.; Qi, F.; Kong, M.; Han, B. Investigation of the Microstructure and Properties of CoCrFeNiMo High-Entropy Alloy Coating Prepared through High-Speed Laser Cladding. Coatings 2023, 13, 1211. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, C.; Li, L.; Yang, Y. Microstructure and Properties of CoCrFeNiMnTix High-Entropy Alloy Coated by Laser Cladding. Coatings 2024, 14, 620. [Google Scholar] [CrossRef]

- Wu, T.; Chen, Y.; Shi, S.; Wu, M.; Gui, W.; Tan, Y.; Li, J.; Wu, Y. Effects of W Alloying on the Lattice Distortion and Wear Behavior of Laser Cladding AlCoCrFeNiWx High-Entropy Alloy Coatings. Materials 2021, 14, 5450. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Ge, W.; Hui, X. Progress on New Preparation Methods, Microstructures, and Protective Properties of High-Entropy Alloy Coatings. Coatings 2022, 12, 1472. [Google Scholar] [CrossRef]

- Wang, H.; Kang, J.; Yue, W.; Jin, G.; Li, R.; Zhou, Y.; Liang, J.; Yang, Y. Microstructure and Corrosive Wear Properties of CoCrFeNiMn High-Entropy Alloy Coatings. Materials 2023, 16, 55. [Google Scholar] [CrossRef]

- Li, T.; Liu, Y.; Liu, B.; Guo, W.; Xu, L. Microstructure and Wear Behavior of FeCoCrNiMo0.2 High Entropy Coatings Prepared by Air Plasma Spray and the High Velocity Oxy-Fuel Spray Processes. Coatings 2017, 7, 151. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, Y.; Ye, Q.; Yang, B. Enhanced Corrosion-Resistance of AlTiCrFeMoSi High−Entropy Alloy Coating by Magnetron Sputtering. Coatings 2023, 13, 332. [Google Scholar] [CrossRef]

- Li, Z.; Jing, C.; Feng, Y.; Wu, Z.; Lin, T.; Zhao, J. Phase evolution and properties of AlxCoCrFeNi high-entropy alloys coatings by laser cladding. Mater. Today Commun. 2023, 35, 105800. [Google Scholar] [CrossRef]

- Wang, Y.; Nie, C.; Wang, S.; Gong, P.; Zhang, M.; Hu, Z.; Li, B. Study on the Properties of TiC Coating Deposited by Spark Discharge on the Surface of AlFeCoCrNiCu High-Entropy Alloy. Materials 2024, 17, 4110. [Google Scholar] [CrossRef]

- Geambazu, L.E.; Cotrut, C.M.; Miculescu, F.; Csaki, I. Mechanically Alloyed CoCrFeNiMo0.85 High-Entropy Alloy for Corrosion Resistance Coatings. Materials 2021, 14, 3802. [Google Scholar] [CrossRef]

- Yang, H.; Chen, X.; Chen, L.; Wang, Z.; Hou, G.; Guo, C.; Zhang, J. Influence of temperature on tribological behavior of AlCoCrFeNi coatings prepared by electrospark deposition. Dig. J. Nanomater. Biostruct. 2023, 18, 145–156. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, G.; Lu, F.; Zhang, L.; Wang, Y.; Zhao, S.; Zhang, J. Friction and Wear Performance of an Electrospark-Deposited Ta Coating on CrNi3MoVA ST. Mater. Technol. 2024, 58, 17–23. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Renna, G. Advancements in Electrospark Deposition (ESD) Technique: A Short Review. Coatings 2022, 12, 1536. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G. Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes. Appl. Sci. 2017, 7, 945. [Google Scholar] [CrossRef]

- Guo, C.; Liang, T.; Lu, F.; Liang, Z.; Zhao, S.; Zhang, J. Isothermal Oxidation Behavior of Electrosparkdeposited NiCrAlY Coatings on a NI-Based Single-Crystal Superalloy. Mater. Technol. 2019, 53, 389–394. [Google Scholar]

- Zhang, W.; Zhang, J.; Wang, H.; Lou, W.; Liu, X. Influences of Cr and Co on the Growth of Thermally Grown Oxide in Thermal Barrier Coating during High-Temperature Exposure. Coatings 2018, 8, 195. [Google Scholar] [CrossRef]

- Wang, W.; Du, M.; Zhang, X.; Luan, C.; Tian, Y. Preparation and Properties of Mo Coating on H13 Steel by Electro Spark Deposition Process. Materials 2021, 14, 3700. [Google Scholar] [CrossRef]

- Deutsch, S. High Pressure Phase Transformations in Polycrystalline Yttrium Oxide. Ph.D. Thesis, Rutgers, The State University of New Jersey, New Brunswick, NJ, USA, 2012. [Google Scholar]

- Gwalani, B.; Torgerson, T.; Dasari, S.; Jagetia, A.; Nartu, M.-Y.; Gangireddy, S.; Pole, M.; Wang, T.; Scharf, T.W.; Banerjee, R. Influence of fine-scale B2 precipitation on dynamic compression and wear properties in hypo-eutectic Al0.5CoCrFeNi high-entropy alloy. J. Alloys Compd. 2021, 853, 157126. [Google Scholar] [CrossRef]

- Lozynskyi, V.; Trembach, B.; Hossain, M.M.; Kabir, M.H.; Silchenko, Y.; Krbata, M.; Sadovyi, K.; Kolomiitse, O.; Ropyak, L. Prediction of phase composition and mechanical properties Fe-Cr-C-B-Ti-Cu hardfacing alloys: Modeling and experimental Validations. Heliyon 2024, 10, e25199. [Google Scholar] [CrossRef]

- Jin, G.; Cai, Z.; Guan, Y.; Cui, X.; Liu, Z.; Li, Y.; Dong, M.; Zhang, D. High temperature wear performance of laser-cladded FeNiCoAlCu high-entropy alloy coating. Appl. Surf. Sci. 2018, 445, 113. [Google Scholar] [CrossRef]

- Guo, C.A.; Zhao, Z.K.; Lu, F.S. Performance of high-speed friction and wear of electrospark deposited AlCoCrFeNi high-entropy. Dig. J. Nanomater. Biostructures 2018, 13, 931–939. [Google Scholar]

- Stott, F.H.; Jordan, M.P. The effects of load and substrate hardness on the development and maintenance of wear-protective layers during sliding at elevated temperatures. Wear 2001, 250, 391–400. [Google Scholar] [CrossRef]

- Betancourt-Dougherty, L.C.; Smith, R.W. Effects of load and sliding speed on the wear behaviour of plasma sprayed TiC-NiCrBSi coatings. Wear 1998, 217, 147–154. [Google Scholar] [CrossRef]

- Zurcher, T.; Bouvard, G.; Abry, J.-C.; Charkaluk, E.; Fridrici, V. Effect of the scanning strategy and tribological conditions on the wear resistance of IN718 obtained by Laser Metal Deposition. Wear 2023, 534, 205152. [Google Scholar] [CrossRef]

- Kato, K. Wear in relation to friction—A review. Wear 2000, 241, 151–157. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, I. Wear and corrosion behavior of laser surface engineered AISI H13 hot working tool steel. Surf. Coat. Technol. 2015, 261, 69–78. [Google Scholar] [CrossRef]

| Element | Cr | Mo | Si | V | C | Mn | S | P | Fe |

| Content | 5.0 | 1.30 | 0.95 | 0.92 | 0.4 | 0.35 | 0.05 | 0.03 | Bal. |

| Power | Electrode Rotation Speed | Argon Flow Rate | Specific Deposition Time |

|---|---|---|---|

| 800 W | 2000 r/min | 15 L/min | 2.5 min/cm2 |

| O (at.%) | Al (at.%) | Cr (at.%) | Fe (at.%) | Co (at.%) | Ni (at.%) | |

|---|---|---|---|---|---|---|

| Area Figure 2a | 8.79 | 19.74 | 18.87 | 18.17 | 17.49 | 17.03 |

| Point A | 66.45 | 33.02 | 0.35 | 0.08 | 0.07 | 0.04 |

| Point B | - | 18.39 | 19.60 | 21.79 | 19.76 | 20.46 |

| Point C | - | 17.83 | 19.33 | 22.37 | 19.74 | 20.73 |

| Point D | - | 15.91 | 20.58 | 22.22 | 20.27 | 21.02 |

| Point E | - | 14.26 | 18.41 | 32.80 | 17.52 | 17.01 |

| Point F | - | 13.09 | 18.21 | 34.22 | 17.23 | 17.25 |

| Point G | - | 12.51 | 13.80 | 48.74 | 12.77 | 12.18 |

| O (at.%) | Al (at.%) | Cr (at.%) | Fe (at.%) | Co (at.%) | Ni (at.%) | |

|---|---|---|---|---|---|---|

| Point H | 2.57 | 18.66 | 19.54 | 20.08 | 19.40 | 19.74 |

| Point I | 2.72 | 15.69 | 20.28 | 20.45 | 20.42 | 20.44 |

| Point J | 3.16 | 20.30 | 19.07 | 19.37 | 19.09 | 19.02 |

| Point K | 3.57 | 17.63 | 19.41 | 21.03 | 18.95 | 19.41 |

| Point L | 3.75 | 17.93 | 19.24 | 20.66 | 19.23 | 19.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, K.; Zhu, G.; Li, J.; Cao, X.; Song, H.; Guo, C. Tribological Property of AlCoCrFeNi Coating Electrospark-Deposited on H13 Steel. Metals 2025, 15, 649. https://doi.org/10.3390/met15060649

Lv K, Zhu G, Li J, Cao X, Song H, Guo C. Tribological Property of AlCoCrFeNi Coating Electrospark-Deposited on H13 Steel. Metals. 2025; 15(6):649. https://doi.org/10.3390/met15060649

Chicago/Turabian StyleLv, Ke, Guanglin Zhu, Jie Li, Xiong Cao, Haonan Song, and Cean Guo. 2025. "Tribological Property of AlCoCrFeNi Coating Electrospark-Deposited on H13 Steel" Metals 15, no. 6: 649. https://doi.org/10.3390/met15060649

APA StyleLv, K., Zhu, G., Li, J., Cao, X., Song, H., & Guo, C. (2025). Tribological Property of AlCoCrFeNi Coating Electrospark-Deposited on H13 Steel. Metals, 15(6), 649. https://doi.org/10.3390/met15060649