The Influence of Interface Morphology on the Mechanical Properties of Binary Laminated Metal Composites Fabricated by Hierarchical Roll-Bonding

Abstract

1. Introduction

2. Materials and Methods

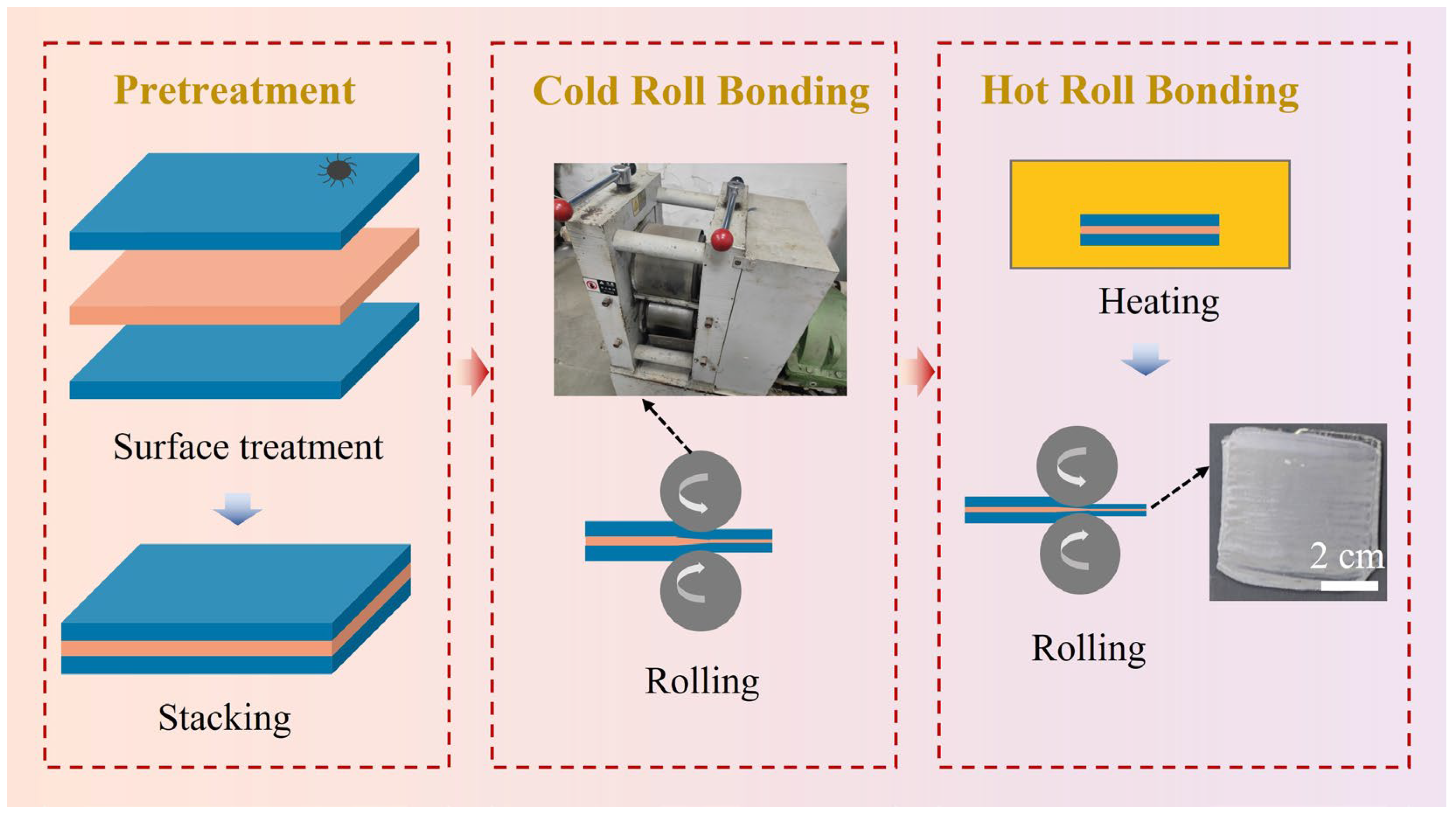

2.1. Fabrication

2.2. Characterization

2.3. Finite Element Simulation

3. Results and Discussion

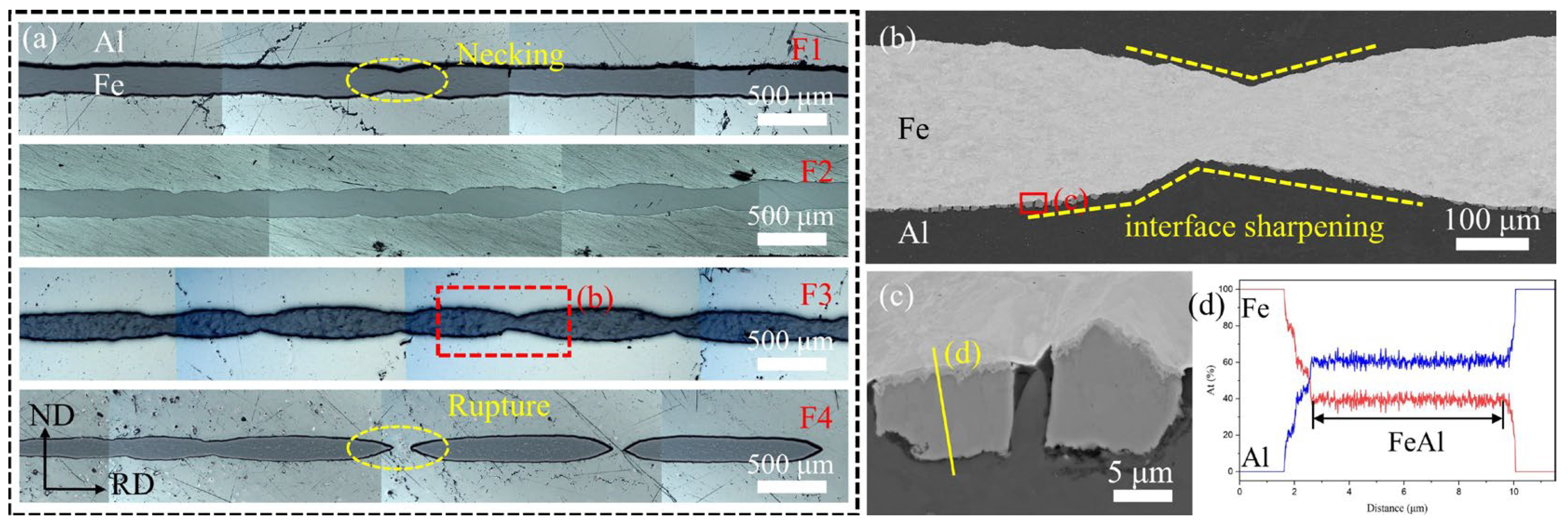

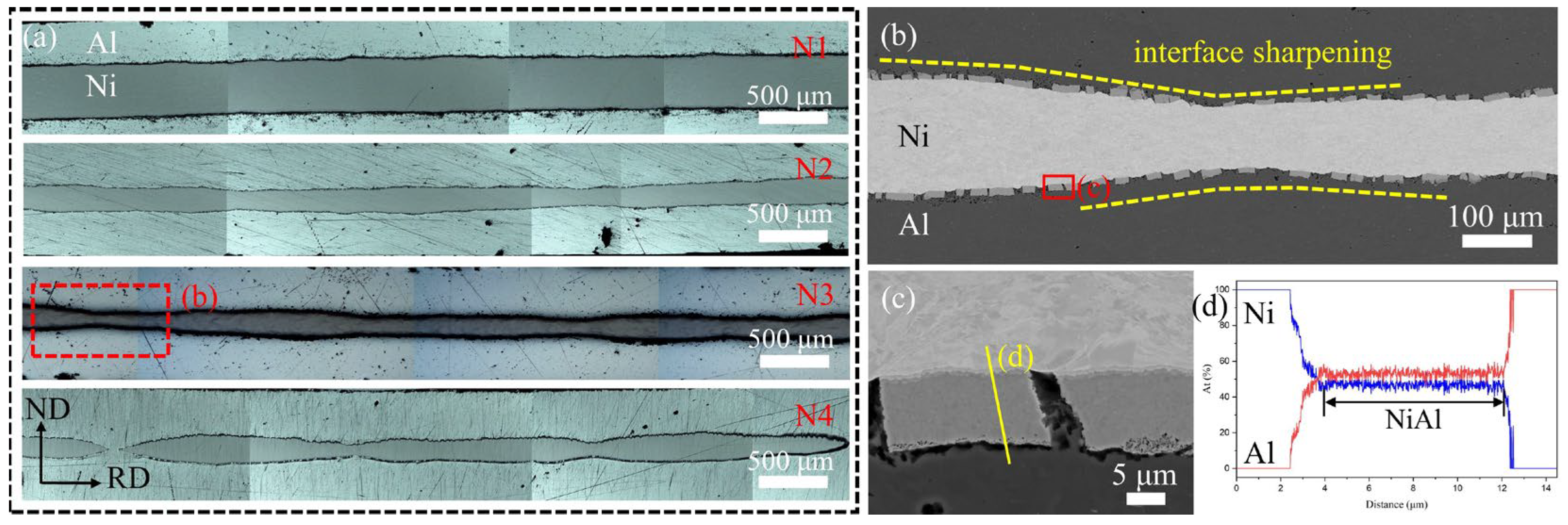

3.1. Interface Morphology of LMC Samples

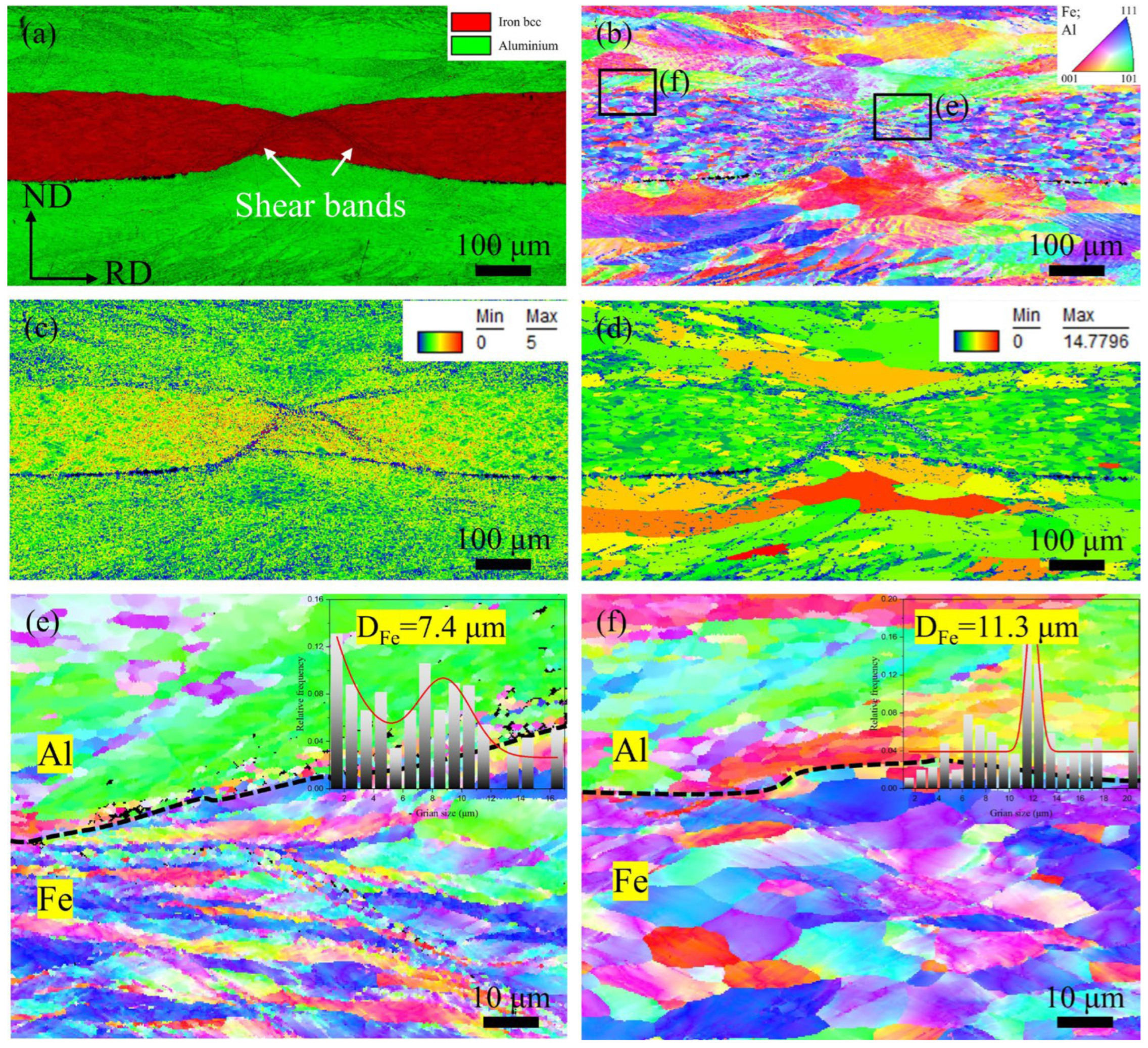

3.2. Microstructure

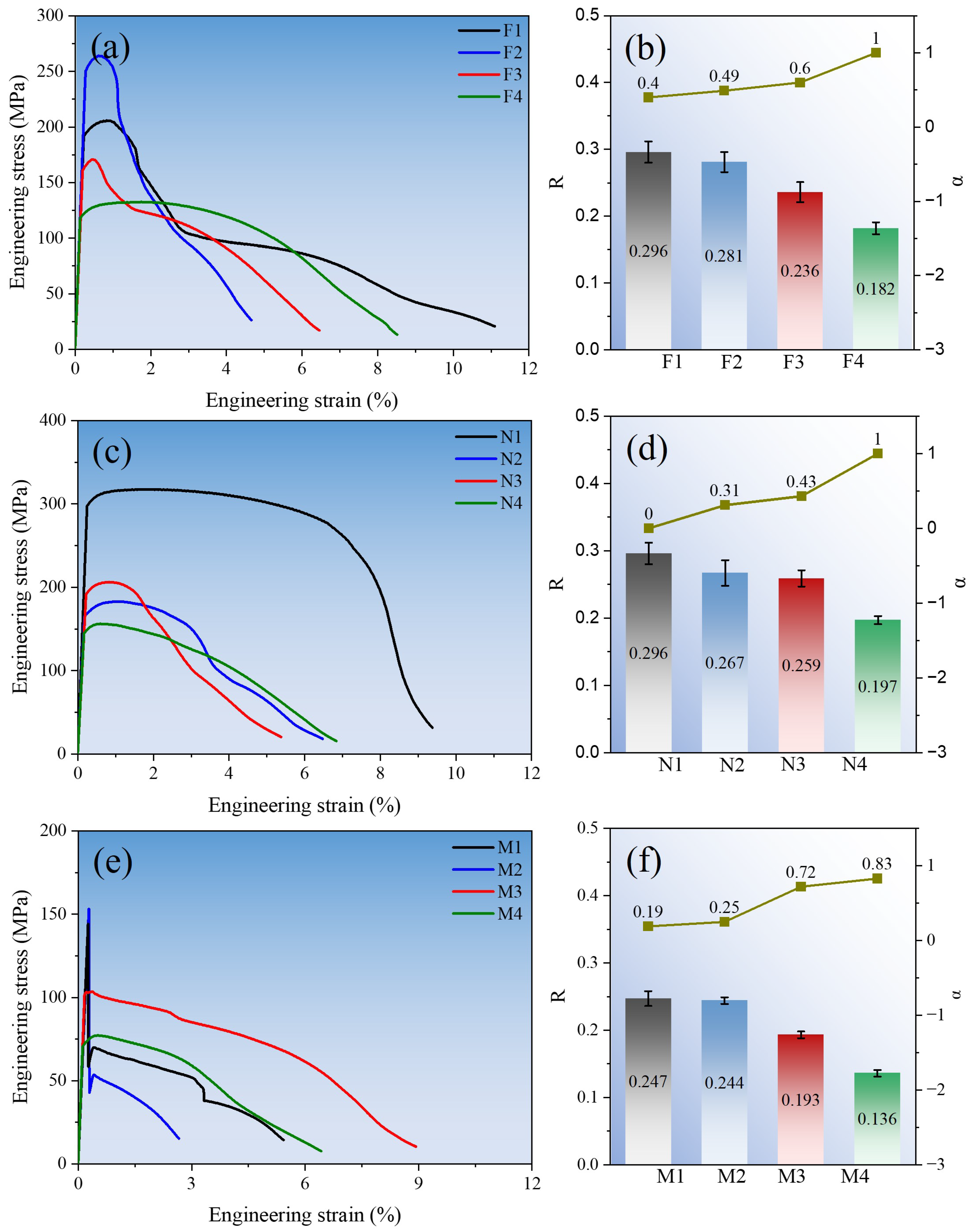

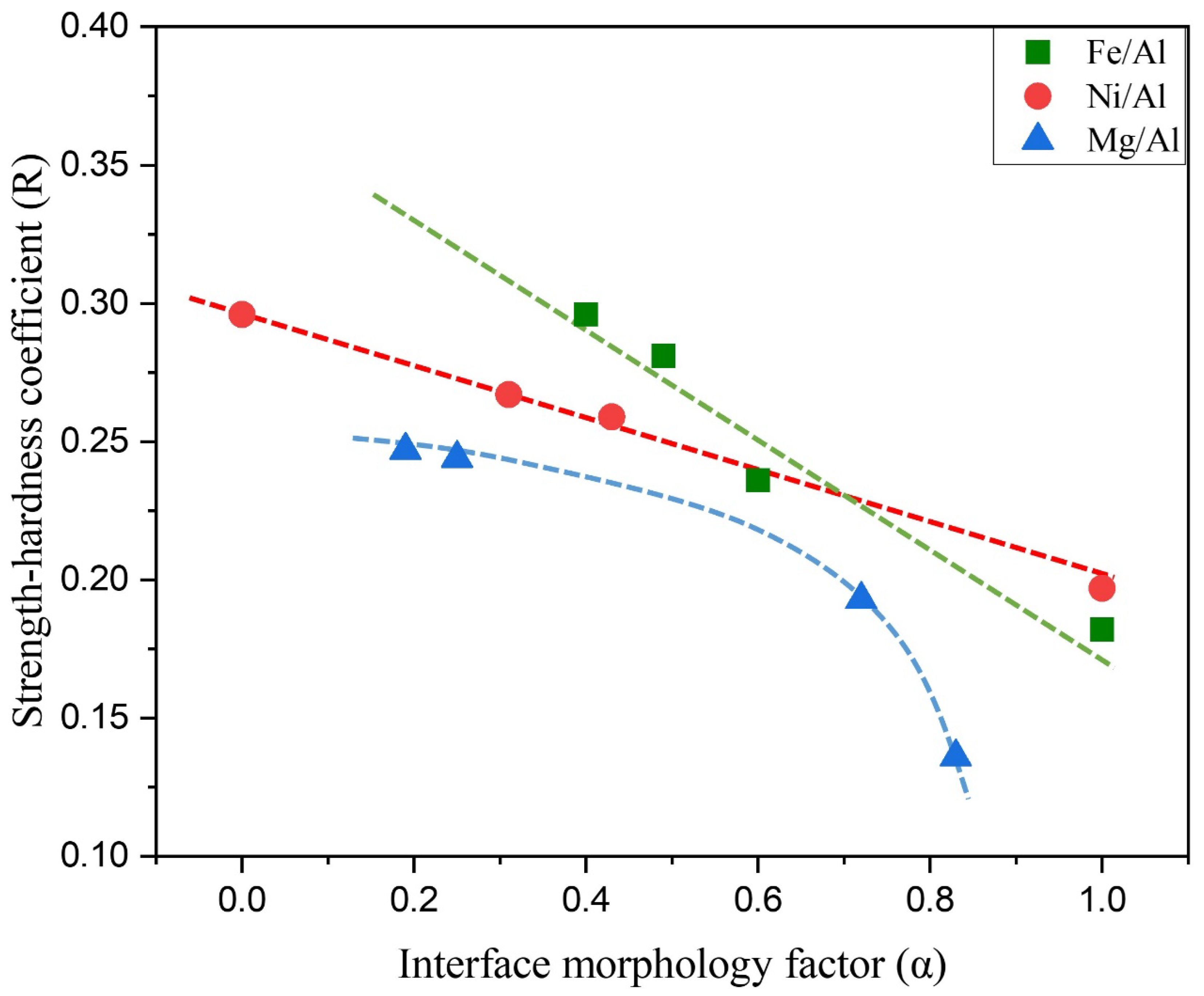

3.3. Relationship Between Interface Morphology and Mechanical Properties

3.4. Finite Element Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konieczny, M. Microstructural characterisation and mechanical response of laminated Ni-intermetallic composites synthesized using Ni sheets and Al foils. Mater. Charact. 2012, 70, 117–124. [Google Scholar] [CrossRef]

- Li, T.; Shao, B.; Gao, C.; Tang, W.; Liu, J.; Zong, Y.; Shan, D.; Guo, B. Study on unsteady rolling cooperative deformation and interface behavior of Ti2AlNb/7075Al laminated metal composites. Compos. Part B 2025, 300, 112458. [Google Scholar] [CrossRef]

- Tang, X.; Peng, Q.; Long, J.; Wang, X.; Lin, Y.; Deng, L.; Jin, J.; Gong, P.; Zhang, M.; Lee, M.-G. Recent progress on plastic forming of laminated metal composites: Processes, heterogeneous deformation, and interfacial regulation. J. Mater. Sci. Technol. 2025, 229, 67–91. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, X.; Liu, B.; He, J.; Feng, J.; Ji, P.; Fang, W.; Yin, F. The Deformation Characteristics, Fracture Behavior and Strengthening-Toughening Mechanisms of Laminated Metal Composites: A Review. Metals 2019, 10, 1–19. [Google Scholar] [CrossRef]

- Huang, M.; Xu, C.; Fan, G.; Maawad, E.; Gan, W.; Geng, L.; Lin, F.; Tang, G.; Wu, H.; Du, Y.; et al. Role of layered structure in ductility improvement of layered Ti-Al metal composite. Acta Mater. 2018, 153, 235–249. [Google Scholar] [CrossRef]

- Luo, Z.A.; Mao, L.Y.; Huang, C.; Zhou, H.Y.; Wang, M.K. A strategy for simultaneously enhancing mechanical strength and hydrogen embrittlement resistance: Exceptional performance of laminated metal composite in hydrogen environments. Mater. Des. 2024, 237, 112549. [Google Scholar] [CrossRef]

- Wang, Z.; Bian, Y.; Yang, M.; Ma, R.; Fan, Y.; Du, A.; Zhao, X.; Cao, X. Investigation of coordinated behavior of deformation at the interface of Cu–Al laminated composite. J. Mater. Res. Technol. 2023, 24, 6545–6557. [Google Scholar] [CrossRef]

- Wadsworth, J.; Lesuer, D.R. Ancient and modern laminated composites—From the Great Pyramid of Gizeh to Y2K. Mater. Charact. 2000, 45, 289–313. [Google Scholar] [CrossRef]

- Mozaffari, A.; Danesh Manesh, H.; Janghorban, K. Evaluation of mechanical properties and structure of multilayered Al/Ni composites produced by accumulative roll bonding (ARB) process. J. Alloys Compd. 2010, 489, 103–109. [Google Scholar] [CrossRef]

- Perepezko, J.H.; Hebert, R.J.; Hamann, J. Deformation-induced alloying and reactions in nanostructured multilayers. J. Alloys Compd. 2007, 434–435, 459–462. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, X.; Wang, W.; Yang, Y.; Zhang, W. Diffusion mechanism of immiscible Fe-Mg system induced by high-density defects at the steel/Mg composite interface. J. Mater. Sci. Technol. 2023, 144, 150–160. [Google Scholar] [CrossRef]

- Wang, W.; Wang, H.; Liu, X.; Liu, Z. Interface evolution and strengthening of two-step roll bonded copper/aluminum clad composites. Mater. Charact. 2023, 199, 112778. [Google Scholar] [CrossRef]

- Bay, N. Cold Welding: Part 1. Characteristics, Bonding Mechanisms. Bond. Strength 1986, 18, 369–372. [Google Scholar]

- Yu, Z.; Wang, T.; Liu, C.; Ma, Y.; Liu, W. Investigation on microstructure, mechanical properties and fracture mechanism of Mg/Al laminated composites. Mater. Sci. Eng. A. 2022, 848, 143410. [Google Scholar] [CrossRef]

- Gao, H.; Kong, C.; Yu, H. Lightweight metal laminated plates produced via (hot, cold and cryogenic) roll bonding: A review. Trans. Nonferrous Met. Soc. China 2023, 33, 337–356. [Google Scholar] [CrossRef]

- Wright, P.K.; Snow, D.A.; Tay, C.K. Interfacial conditions and bond strength in cold pressure welding by rolling. Met. Sci. J. 1978, 5, 24–31. [Google Scholar] [CrossRef]

- Gao, B.X.; Hao, Y.C.; Yu, C.; Wu, Y.H.; Xiao, H. Study on temperature control and bonding properties of Ti/Al composite plates rolled by differential temperature rolling with mobile induction heating. J. Manuf. Process. 2025, 134, 348–359. [Google Scholar] [CrossRef]

- Guo, S.; Wang, F.; Wang, Y.; Xie, G. Microstructural evolution and properties of Ti/Al clad plate fabricated by vacuum rolling and heat treatment. Mater. Sci. Eng. A. 2023, 882, 145445. [Google Scholar] [CrossRef]

- Li, S.; Luo, C.; Liu, Z.; Zhao, J.; Han, J.; Wang, T. Interface characteristics and mechanical behavior of Cu/Al clad plate produced by the corrugated rolling technique. J. Manuf. Process. 2020, 60, 75–85. [Google Scholar] [CrossRef]

- Cai, H.S.; Wang, Q.D.; Zhang, N.N.; Ebrahimi, M.; Zhao, Y.C.; Liu, L.; Guo, F. Shear behavior of Cu/Al/Cu trilayered composites prepared by high-temperature oxygen-free rolling. J. Alloys Compd. 2024, 1004, 175857. [Google Scholar] [CrossRef]

- Liu, T.; Song, B.; Huang, G.; Jiang, X.; Guo, S.; Zheng, K.; Pan, F. Preparation, structure and properties of Mg/Al laminated metal composites fabricated by roll-bonding, a review. J. Magnes. Alloys. 2022, 10, 2062–2093. [Google Scholar] [CrossRef]

- Sun, Y.F.; Chen, Y.; Tsuji, N.; Guan, S. Microstructural evolution and mechanical properties of nanostructured Cu/Ni multilayer fabricated by accumulative roll bonding. J. Alloys. Compd. 2020, 819, 152956. [Google Scholar] [CrossRef]

- Goli, E.; Eghbali, B.; Sahu, S. Texture Evolution and Mechanical Properties of Copper/Niobium Laminated Composite Processed Through Accumulative Roll Bonding and Intermediate Annealing. Metall. Microstruct. Anal. 2024, 13, 657–666. [Google Scholar] [CrossRef]

- Hosseini, M.; Pardis, N.; Danesh Manesh, H.; Abbasi, M.; Kim, D.-I. Structural characteristics of Cu/Ti bimetal composite produced by accumulative roll-bonding (ARB). Mater. Des. 2017, 113, 128–136. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Liu, M.; Liu, Y.; Liu, J.; Ignatov, A.V.; Wang, T. Microstructure and mechanical behavior of Ti/Cu/Ti laminated composites produced by corrugated and flat rolling. Trans. Nonferrous Met. Soc. China 2022, 32, 2598–2608. [Google Scholar] [CrossRef]

- Lee, J.M.; Lee, B.R.; Kang, S.B. Control of layer continuity in metallic multilayers produced by deformation synthesis method. Mater. Sci. Eng. A. 2005, 406, 95–101. [Google Scholar] [CrossRef]

- Mahdavian, M.M.; Ghalandari, L.; Reihanian, M. Accumulative roll bonding of multilayered Cu/Zn/Al: An evaluation of microstructure and mechanical properties. Mater. Sci. Eng. A. 2013, 579, 99–107. [Google Scholar] [CrossRef]

- Rahdari, M.; Reihanian, M.; Baghal, S.M.L. Microstructural control and layer continuity in deformation bonding of metallic laminated composites. Mater. Sci. Eng. A. 2018, 738, 98–110. [Google Scholar] [CrossRef]

- Zheng, S.J.; Wang, J.; Carpenter, J.S.; Mook, W.M.; Dickerson, P.O.; Mara, N.A.; Beyerlein, I. Plastic instability mechanisms in bimetallic nanolayered composites. Acta Mater. 2014, 79, 282–291. [Google Scholar] [CrossRef]

- Liu, H.S.; Zhang, B.; Zhang, G.P. Delaying premature local necking of high-strength Cu: A potential way to enhance plasticity. Scr. Mater. 2011, 64, 13–16. [Google Scholar] [CrossRef]

- Miyajima, Y.; Yamada, T.; Fujii, T. Plastic instability criterion based on new necking parameters for Cu-Al, Cu-A5052, and Cu-A5083 roll-bonded laminated metal composites fabricated without post-annealing. J. Mater. Process Technol. 2022, 306, 117634. [Google Scholar] [CrossRef]

- Luo, C.; Liang, W.; Chen, Z.; Zhang, J.; Chi, C.; Yang, F. Effect of high temperature annealing and subsequent hot rolling on microstructural evolution at the bond-interface of Al/Mg/Al alloy laminated composites. Mater. Charact. 2013, 84, 34–40. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Y.; Bian, L.; Huang, Q. Microstructural evolution and mechanical behavior of Mg/Al laminated composite sheet by novel corrugated rolling and flat rolling. Mater. Sci. Eng. A. 2019, 765, 138318. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, J.; Bai, Y.; Meyers, M.A. Shear Localization in Dynamic Deformation: Microstructural Evolution. Met. Mater. Trans. A. 2008, 39, 811–843. [Google Scholar] [CrossRef]

- Li, D.H.; Liu, Y.; Zhang, X. An extended Layerwise method for composite laminated beams with multiple delaminations and matrix cracks. Int. J. Numer. Methods Eng. 2015, 101, 407–434. [Google Scholar] [CrossRef]

- Dai, L.H.; Liu, L.F.; Bai, Y.L. Effect of particle size on the formation of adiabatic shear band in particle reinforced metal matrix composites. Mater. Lett. 2004, 58, 1773–1776. [Google Scholar] [CrossRef]

- Yang, L.; Yang, L. Revisit initiation of localized plastic deformation: Shear band & necking. Extreme Mech. Lett. 2020, 40, 100914. [Google Scholar]

- Bai, Y.; Dodd, B. Adiabatic Shear Localization: Occurrence, Theories and Applications; Pergamon Press: Oxford, UK, 1992. [Google Scholar]

- Yan, N.; Li, Z.; Xu, Y.; Meyers, M.A. Shear localization in metallic materials at high strain rates. Prog. Mater. Sci. 2021, 119, 100755. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Recrystallization mechanisms and microstructure development in emerging metallic materials: A review. J. Sci. Adv. Mater. Devices 2019, 4, 19–33. [Google Scholar] [CrossRef]

- Onodera, R.; Hokamoto, K. Plastic instability of sandwich sheet materials in rolling. Bull. Jpn. Inst. Met. 1987, 26, 1028–1035. [Google Scholar] [CrossRef]

- Bauccio. ASM Metals Reference Book, 3rd ed.; Asm Intl: Geauga County, OH, USA, 1993. [Google Scholar]

| Sample | Layer Sequence | Volume Fraction (%) | Thickness Reduction (%) | |

|---|---|---|---|---|

| Fe/Al (BCC/FCC) | F1 | Al-Fe-Al | 14.7 | 60 |

| F2 | Al-Fe-Al | 22.3 | 64 | |

| F3 | Al-Fe-Al | 16.4 | 63 | |

| F4 | Al-Fe-Al | 14.9 | 71 | |

| Ni/Al (FCC/FCC) | N1 | Al-Ni-Al | 39.0 | 66 |

| N2 | Al-Ni-Al | 20.9 | 77 | |

| N3 | Al-Ni-Al | 17.6 | 74 | |

| N4 | Al-Ni-Al | 18.0 | 77 | |

| Mg/Al (HCP/FCC) | M1 | Al-Mg-Al | 57.3 | 40 |

| M2 | Al-Mg-Al | 65.0 | 34 | |

| M3 | Al-Mg-Al | 35.7 | 52 | |

| M4 | Al-Mg-Al | 38.4 | 52 |

| Material | Yield Strength (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio | Density (g/cm3) |

|---|---|---|---|---|

| Al | 35 | 70 | 0.30 | 2.70 |

| Fe | 242 | 208 | 0.30 | 7.87 |

| Samples | Yield Strength (σYS, MPa) | Ultimate Tensile Strength (σUTS, MPa) | Uniform Elongation (δ, %) |

|---|---|---|---|

| F1 | 191.9 | 205.7 | 0.92 |

| F2 | 250.4 | 264.0 | 0.63 |

| F3 | 160.9 | 170.7 | 0.46 |

| F4 | 117.9 | 132.6 | 1.74 |

| N1 | 297.7 | 317.6 | 1.89 |

| N2 | 163.9 | 182.8 | 1.03 |

| N3 | 191.8 | 206.0 | 0.80 |

| N4 | 144.6 | 156.1 | 0.59 |

| M1 | / | 144.1 | 0.26 |

| M2 | / | 153.2 | 0.28 |

| M3 | 101.7 | 103.5 | 0.39 |

| M4 | 70.4 | 77.2 | 0.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Mei, Q.; Luo, X. The Influence of Interface Morphology on the Mechanical Properties of Binary Laminated Metal Composites Fabricated by Hierarchical Roll-Bonding. Metals 2025, 15, 580. https://doi.org/10.3390/met15060580

Tan Y, Mei Q, Luo X. The Influence of Interface Morphology on the Mechanical Properties of Binary Laminated Metal Composites Fabricated by Hierarchical Roll-Bonding. Metals. 2025; 15(6):580. https://doi.org/10.3390/met15060580

Chicago/Turabian StyleTan, Yuanyuan, Qingsong Mei, and Xu Luo. 2025. "The Influence of Interface Morphology on the Mechanical Properties of Binary Laminated Metal Composites Fabricated by Hierarchical Roll-Bonding" Metals 15, no. 6: 580. https://doi.org/10.3390/met15060580

APA StyleTan, Y., Mei, Q., & Luo, X. (2025). The Influence of Interface Morphology on the Mechanical Properties of Binary Laminated Metal Composites Fabricated by Hierarchical Roll-Bonding. Metals, 15(6), 580. https://doi.org/10.3390/met15060580