Dendrite Structure Refinement and Mechanical Property Improvement of a Single-Crystal Superalloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. As-Cast Microstructure

3.2. Heat-Treated Microstructure

3.3. Stress Rupture Property

4. Conclusions

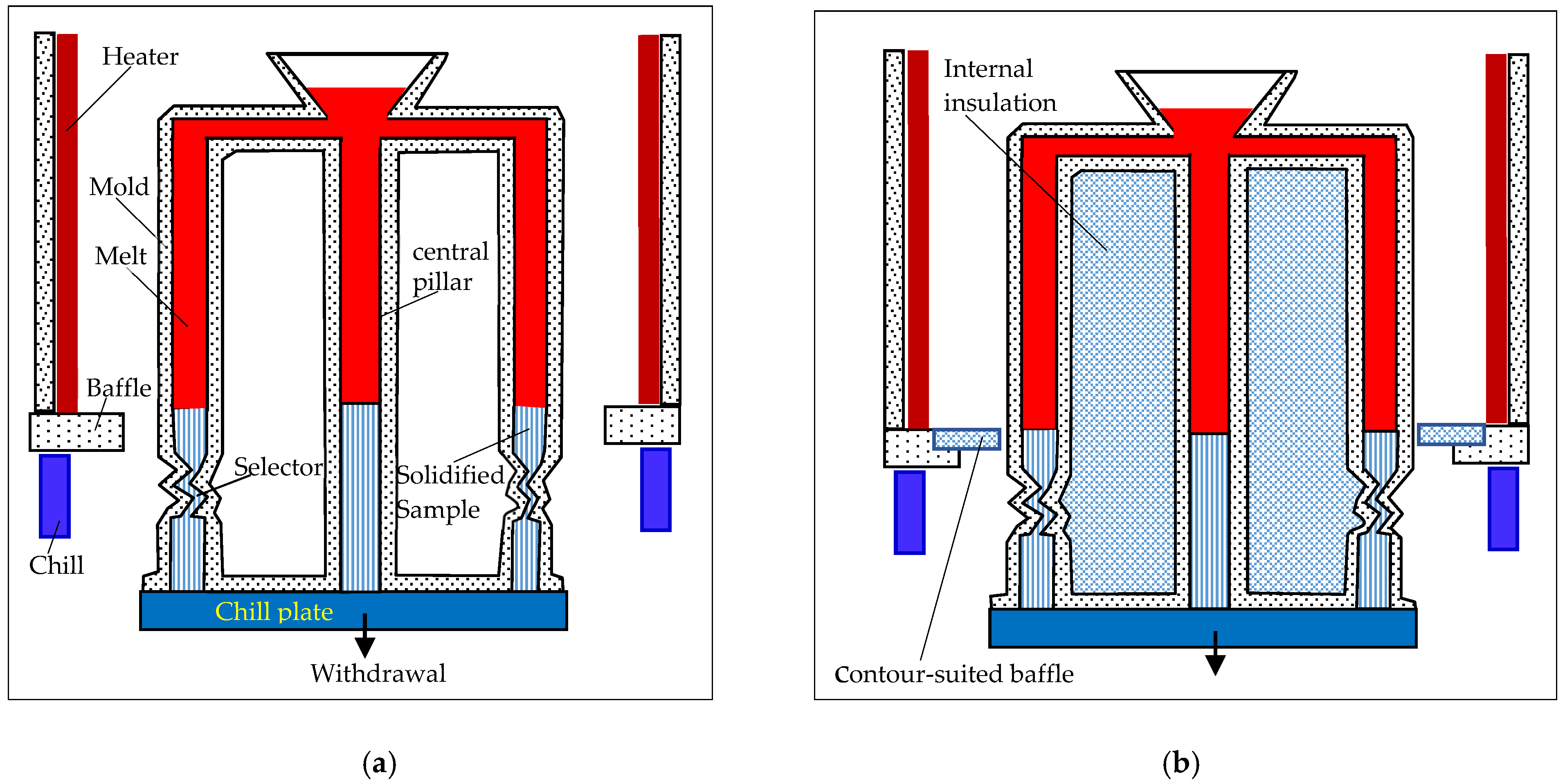

- Single-crystal rods of types A and B were fabricated under conventional production conditions and with contour-suited insulation measures, respectively. The temperature gradients during the solidification process were measured as 1.9 K/mm and 4.9 K/mm for rod types A and B, and the corresponding dendrite spacings were reduced from 391 μm to 266 μm. This demonstrates the effective role of the contour-suited insulation in refining the dendrite structure.

- The average γ/γ′ eutectic fraction in the as-cast structure of rods A and B was 9.97% and 8.20%, respectively, indicating the effect of dendrite structure refinement on the eutectic reduction in the cast structure.

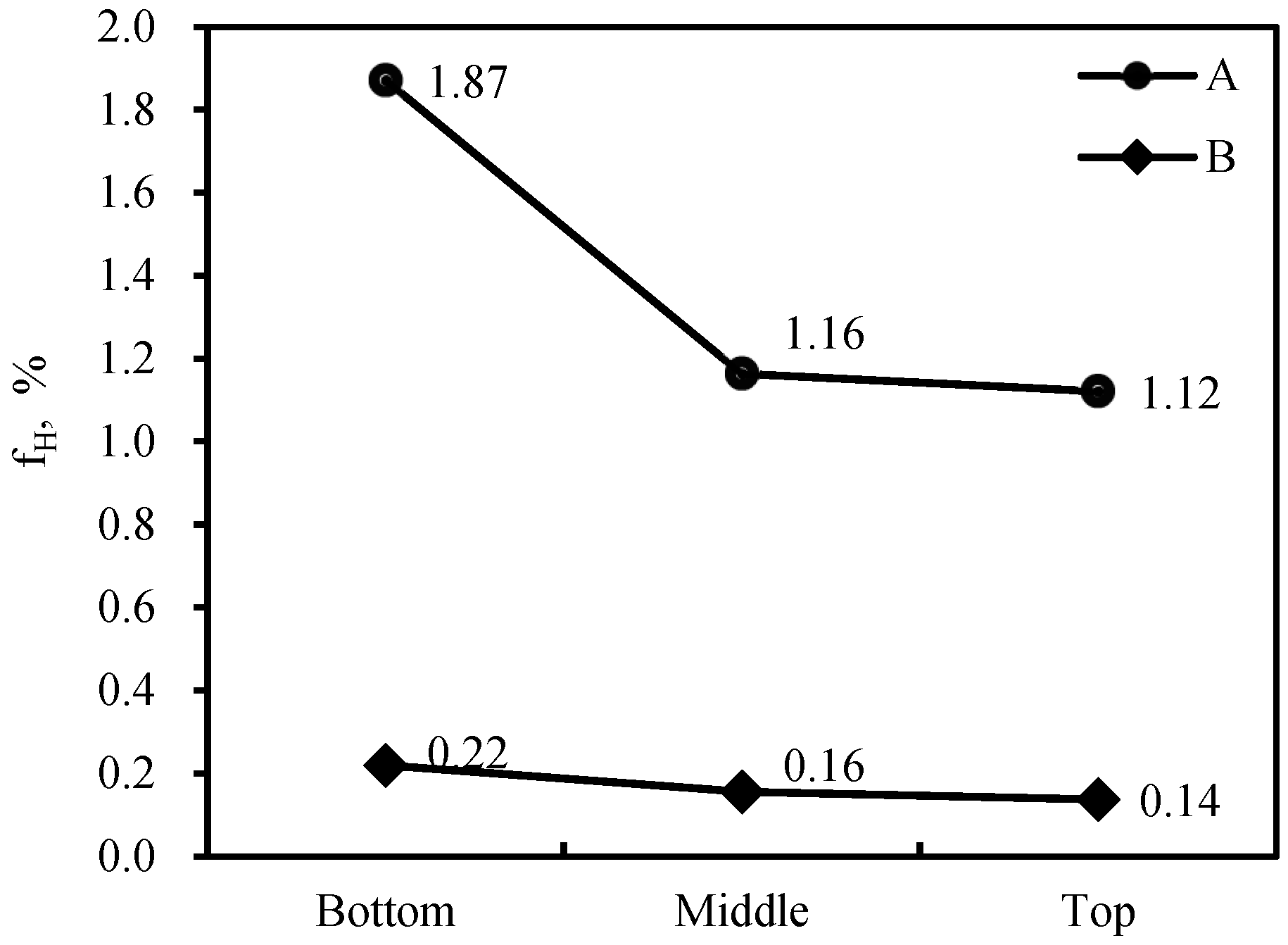

- After heat treatment, the average residual eutectic fraction in rods A and B was 1.39% and 0.17%, with the latter being only 15% of the former.

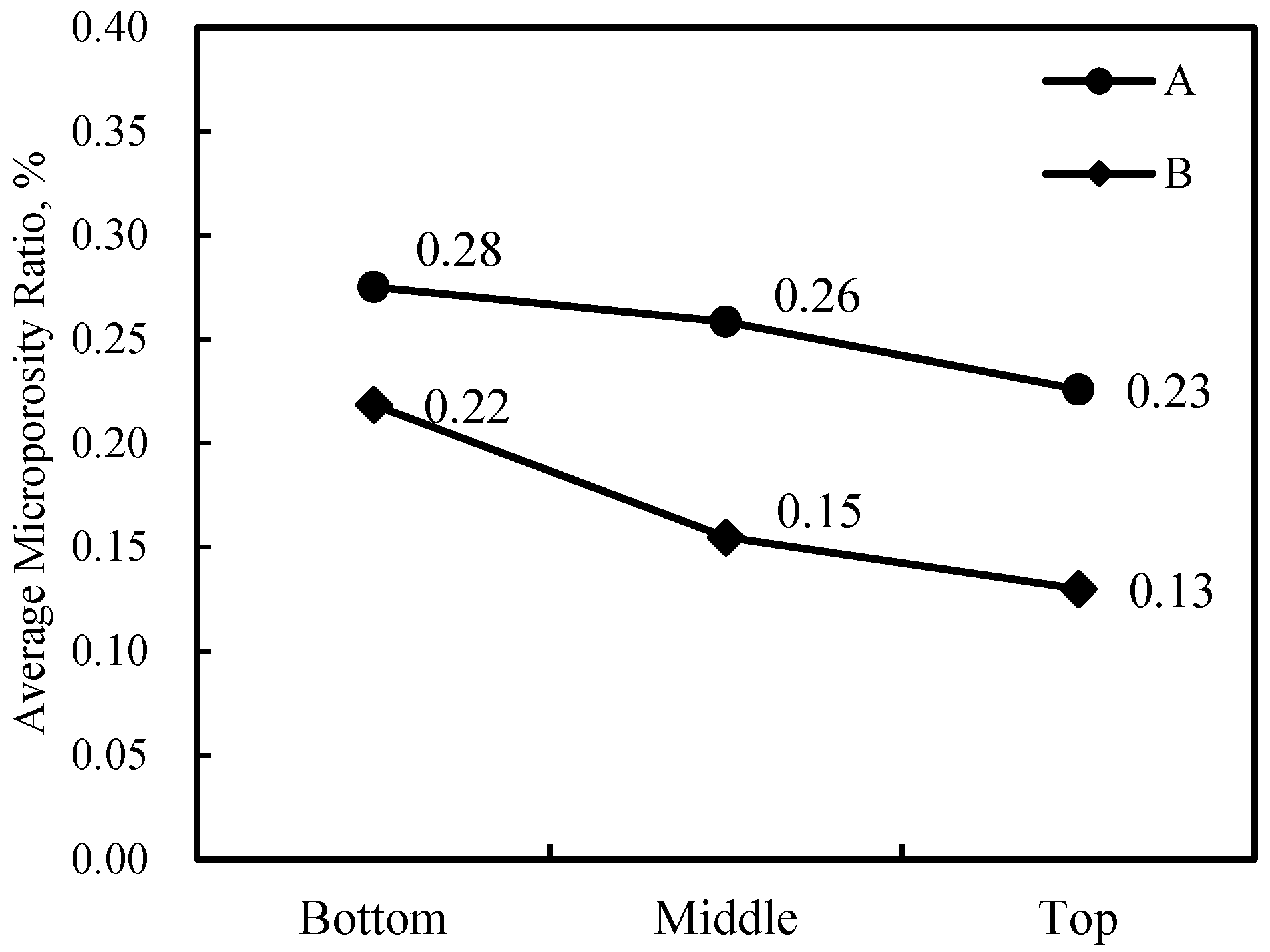

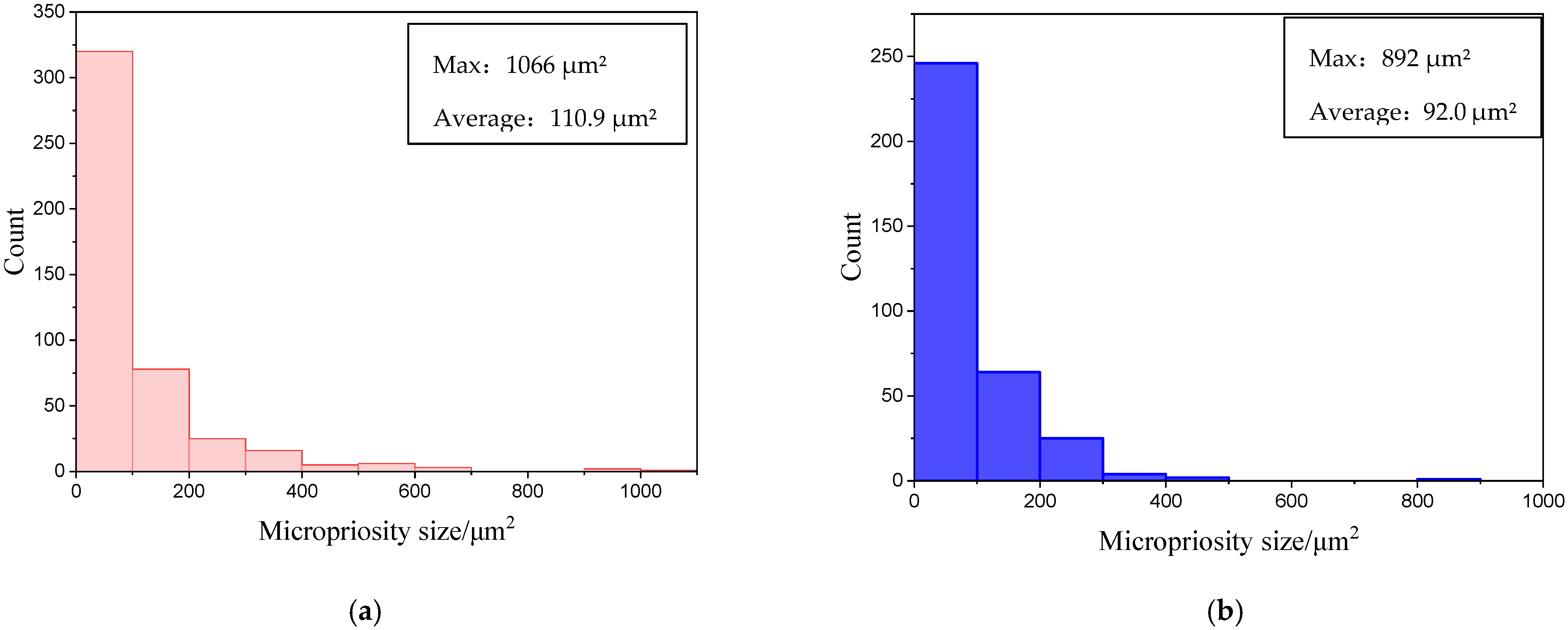

- After heat treatment, the average porosity in rods A and B was 0.26% and 0.17%, respectively. Moreover, the number of large porosity holes in rod A was much greater than that in rod B, causing more significant damage to the material’s performance.

- Under the test conditions of 850 °C/650 MPa and 1050 °C/190 MPa, the mean stress rupture lives of rod B were improved by 25% and 5.2%, respectively, compared to rod A. This suggests that the stress rupture life of the superalloy was evidently improved by dendrite structure refinement, especially at medium temperatures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meetham, G.W. The Development of Gas Turbine Materials; Applied Science Publishers: London, UK, 1981; pp. 89–119. [Google Scholar] [CrossRef]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide; ASM International: Materials Park, OH, USA, 2002; pp. 11–25. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008; pp. 1–216. [Google Scholar] [CrossRef]

- Versnyder, F.I.; Shank, M.E. The development of columnar grain and single crystal high temperature materials through directional solidification. Mater. Sci. Eng. 1970, 6, 213–247. [Google Scholar] [CrossRef]

- Pratt, D.C. Industrial Casting of Superalloys. Mater. Sci. Technol. 1986, 2, 426–435. [Google Scholar] [CrossRef]

- Quested, P.N.; Osgerby, S. Mechanical properties of conventionally cast, directionally solidified, and single-crystal superalloys. Mater. Sci. Technol. 1986, 2, 461–475. [Google Scholar] [CrossRef]

- Li, X.W.; Liu, T.; Wang, L.; Liu, X.G.; Lou, L.H.; Zhang, J. Effect of carbon content on the microstructure and creep properties of a 3rd generation single crystal nickel-base superalloy. Mater. Sci. Eng. A 2015, 639, 732–738. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, Y.; Tan, Z.; Liu, L.; Wang, X.; Lv, P.; Liang, Z.; Tao, Y.; Yang, Y.; Liu, J.; et al. Effect of carbon content on the microstructure and stress rupture properties of a 4th-generation nickel-based single crystal superalloy. Mater. Sci. Eng. A 2024, 916, 147383. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Zhang, J.; Luo, Y.S.; Tang, D.Z.; Feng, Q. Effects of Hf on high temperature low stress rupture properties of a second generation Ni-based single crystal superalloy DD11. Acta Metall. Sin. 2015, 51, 1261–1272. [Google Scholar]

- Wang, X.J.; Liu, L.; Huang, T.W. A review on the influence of carbon addition on the solidification defects in nickel-based single crystal superalloys. Mater. Rep. 2020, 34, 3148–3156. [Google Scholar]

- Yu, Z.H.; Liu, L. Effect of C on the rupture properties of single crystal superalloys. Acta Metall. Sin. 2014, 50, 854–862. [Google Scholar]

- Liu, J.L.; Sun, J.X.; Meng, J.; Li, J.G. Microstructural stability and stress rupture properties of a third-generation Ni base single crystal superalloy. Acta Metall. Sin. 2024, 60, 770–776. [Google Scholar]

- Liu, Y.; Wu, J.M.; Wang, Z.C.; Lu, X.G.; Avdeev, M.; Shi, S.Q.; Wang, C.Y.; Yu, T. Predicting creep rupture life of Ni-based single crystal superalloys using divide-and-conquer approach based machine learning. Acta Mater. 2020, 195, 454–467. [Google Scholar] [CrossRef]

- Cao, L.M.; Li, X.H.; Chen, J.Y.; Xue, M.; Zhang, Y. Influence of solution heat treatment temperature on the microstructure of the third generation Ni-based single crystal superalloy DD10. J. Mater. Eng. 2011, 1, 23–27. [Google Scholar]

- Yu, J.; Sun, X.; Zhao, N.; Jin, T.; Guan, H.; Hu, Z. Effect of heat treatment on microstructure and stress rupture life of DD32 single crystal Ni-base superalloy. Mater. Sci. Eng. A 2007, 460, 420–427. [Google Scholar] [CrossRef]

- Fuchs, G.E. Solution heat treatment response of a third generation single crystal Ni-base superalloy. Mater. Sci. Eng. A 2001, 300, 52–60. [Google Scholar] [CrossRef]

- Zhang, S.H.; Lu, Y.Z.; Zheng, W.; Peng, J.; Xie, G.; Zhang, G.; Shen, J. Effect of primary dendrite arm spacing on the anisotropic stress rupture properties in a nickel-base single crystal superalloy DD26. Mater. Rev. 2016, 30, 4. [Google Scholar]

- Li, H.T.; Wang, X.M.; Li, Z.X.; Liu, H.; Qiao, S.Z.; Yv, Z.Y.; Zhang, K.; Li, L. A statistical microstructures-based method for the prediction of mechanical properties in nickel-based single crystal alloys. Mater. High Temp. 2023, 40, 412–423. [Google Scholar] [CrossRef]

- Sun, J.X.; Liu, J.L.; Chen, C.; Li, J.G.; Sun, X.F. Effect of γ′ size on intermediate temperature stress rupture property of the third generation single crystal nickel-base superalloy containing Re. Rare Met. Mater. Eng. 2022, 51, 369–373. [Google Scholar]

- Wang, J.; Liang, J.; Zhang, D.; Peng, Y.; Wen, Z. The effect of small orientation deviation from [001] to [011] on high-temperature creep properties of nickel-based single crystal. Int. J. Plast. 2023, 166, 103648. [Google Scholar] [CrossRef]

- MacKay, R.A.; Maier, R.D. The influence of orientation on the stress rupture properties of nickel-base superalloy single crystals. Metall. Trans. A 1982, 13, 1747–1754. [Google Scholar] [CrossRef]

- Heep, L.; Bürger, D.; Bonnekoh, C.; Wollgramm, P.; Dlouhy, A.; Eggeler, G. The effect of deviations from precise [001] tensile direction on creep of Ni-base single crystal superalloys. Scr. Mater. 2022, 207, 114274. [Google Scholar] [CrossRef]

- Qu, P.; Yang, W.; Wang, Q.; Liu, C.; Qin, J.; Zhang, J.; Liu, L. Unveiling the orientation sensitivity of creep life in near [001] oriented Ni-based single crystal superalloys at intermediate temperatures. Int. J. Plast. 2024, 179, 104035. [Google Scholar] [CrossRef]

- Yue, Z.F.; Lv, Z.Z.; Yang, Z.G.; Cheng, X.M.; Yin, Z.Y. Influence of deviation and randomness of crystallographic orientations on the strength and life of nickel-base single crystal superalloy turbine blades. J. Aerosp. Power 2003, 18, 477–480. [Google Scholar]

- Rae, C.M.F.; Reed, R.C. Primary creep in single crystal superalloys: Origins, mechanisms, and effects. Acta Mater. 2007, 55, 1067–1081. [Google Scholar] [CrossRef]

- Zhao, J.Q.; Li, J.R.; Liu, S.Z.; Yuan, H.L.; Han, M. Effects of low angle grain boundaries on stress rupture properties of single crystal superalloy DD6. J. Aeronaut. Mater. 2007, 27, 6–10. [Google Scholar]

- Shi, Z.; Li, J.; Liu, S.; Zhao, J. Effect of LAB on the Stress Rupture Properties and Fracture Characteristic of DD6 Single Crystal Superalloy. Rare Met. Mater. Eng. 2012, 41, 962–966. [Google Scholar] [CrossRef]

- Rezaei, M.; Kermanpur, A.; Sadeghi, F. Effects of withdrawal rate and starter block size on crystal orientation of a single crystal Ni-based single crystal alloy. J. Cryst. Growth 2018, 485, 19–27. [Google Scholar] [CrossRef]

- Huo, M.; Liu, L.; Yang, W.; Hu, S.; Sun, D.; Su, H.; Zhang, J.; Fu, H. Dendrite growth and defects formation with increasing withdrawal rates in the rejoined platforms of Ni-based single crystal single crystal alloys. Vacuum 2019, 161, 29–36. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Sun, D.; Yue, Q.; Huang, T.; Gan, B.; Zhang, J.; Fu, H. Quantitative analysis of withdrawal rate on stray grain formation in the platforms of a Ni-Based single crystal dummy blade. J. Alloys Compd. 2019, 773, 432–442. [Google Scholar] [CrossRef]

- Lian, Y.; Gao, L.; Hu, P.; Yin, Q.; Wang, X.; Wen, Z.; Wang, J. Effect of withdrawal rate on the microstructure and mechanical properties of a novel monocrystalline CoNibased superalloy. Mater. Today Commun. 2022, 30, 103053. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, X.; Zhao, J.; Shi, Z.; Liu, S.; Li, J. Effect of Withdrawal Rate on Solidification Microstructures of DD9 Single Crystal Turbine Blade. Materials 2023, 16, 3409. [Google Scholar] [CrossRef]

- Gancarczyk, K.; Albrecht, R.; Sułkowicz, P.; Szala, M.; Walczak, M. Evaluation of the Influence of Primary and Secondary Crystal Orientations and Selected Structural Characteristics on Creep Resistance in Single-Crystal Nickel-Based Turbine Blades. Materials 2025, 18, 919. [Google Scholar] [CrossRef]

- Hu, B.; Xie, W.; Zhong, W.; Zhang, D.; Wang, X.; Hu, J.; Wu, Y.; Liu, Y. The Effect of Pulling Speed on the Structure and Properties of DZ22B Superalloy Blades. Coatings 2023, 13, 1225. [Google Scholar] [CrossRef]

- Zhang, Y.; Qin, L.; Zhu, B.; Jiang, H.; Tan, L.; Huang, T.; Gan, B.; Jie, Z.; Liu, L. Optimizing a Solution Heat Treatment by Increasing the Cooling Rate of Directional Solidification for Ni-Based Superalloys. Materials 2023, 16, 3433. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, Q.; You, X.; Qiang, J. Effect of Melt Superheating Treatment on the Microstructures and Purity of a Directionally Solidified Superalloy. Crystals 2023, 13, 1632. [Google Scholar] [CrossRef]

- Karunaratne, M.S.A.; Cox, D.C.; Carter, P.; Reed, R.C. Modelling of the Microsegregation in CMSX-4 Superalloy and its Homogenisation During Heat Treatment. Superalloys 2000, 263–272. [Google Scholar] [CrossRef]

| Cr | Co | Mo | W | Re | Al | Ti | Ta | Hf | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 6.44 | 9.57 | 0.61 | 6.38 | 2.94 | 5.60 | 1.02 | 6.47 | 0.11 | Bal. |

| Stress rupture properties (h) | Samples | A | Ave. | B | Ave. | ||||

|---|---|---|---|---|---|---|---|---|---|

| 850 °C/650 MPa | 117.3 | 108.5 | 120.0 | 115.3 | 153.1 | 137.0 | 141.8 | 144.0 | |

| 1050 °C/190 MPa | 86.0 | 88.2 | 93.1 | 89.1 | 99.2 | 94.3 | 87.7 | 93.7 | |

| Description | Rod A | Rod B | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bottom | Middle | Top | Ave. | Bottom | Middle | Top | Ave. | |||

| Temperature gradient: G (K/mm) | 1.9 | 4.9 | ||||||||

| Dendrite spacing: λ (μm) (Figure 2) | 348 | 374 | 452 | 391 | 287 | 269 | 243 | 266 | ||

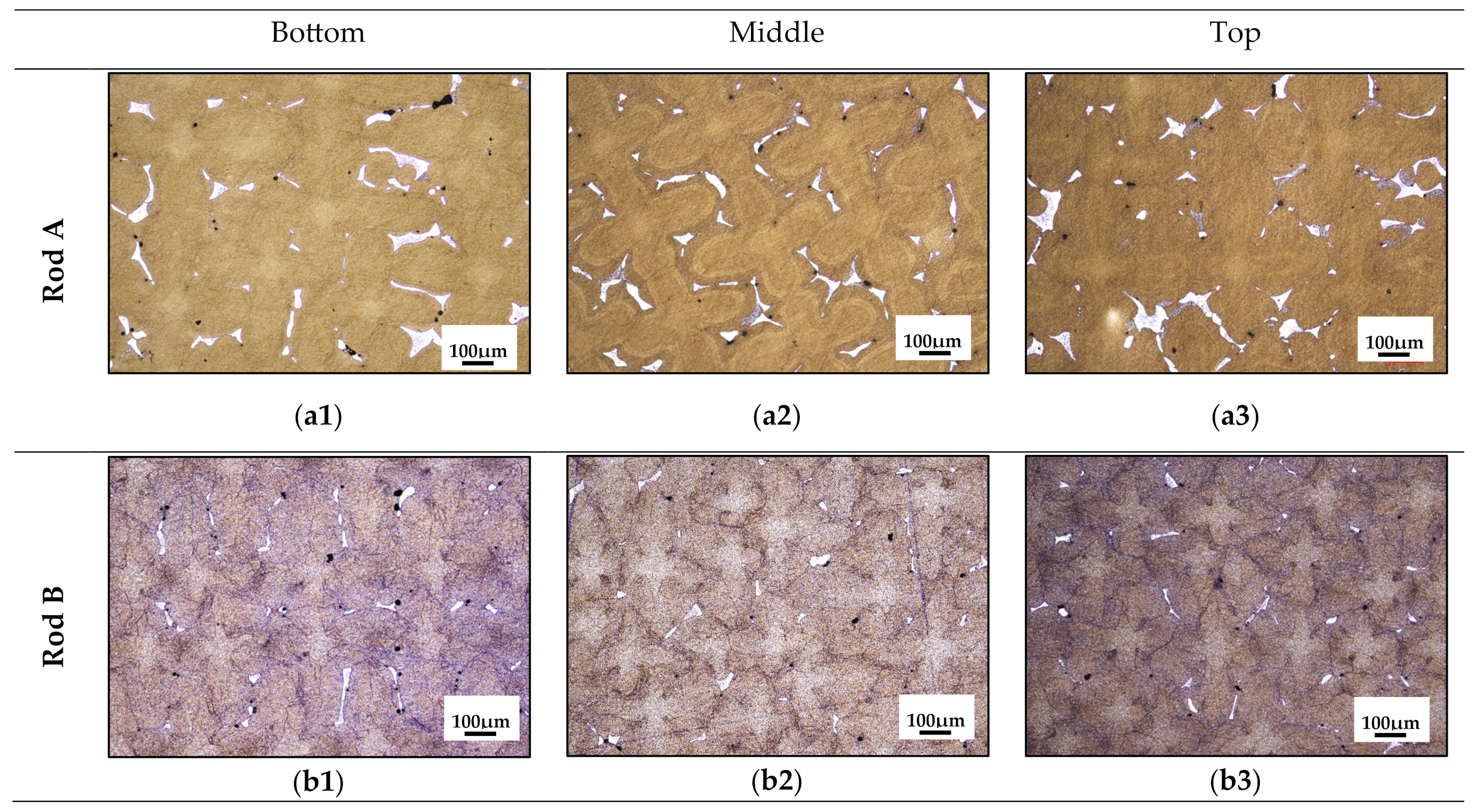

| As-cast eutectic fraction: fE (%) (Figure 3) | 9.50 | 9.80 | 10.61 | 9.97 | 9.10 | 7.67 | 7.43 | 8.20 | ||

| After heat treatment | Residual eutectic fraction | Average: fH (%) (Figure 6) | 1.87 | 1.16 | 1.12 | 1.39 | 0.22 | 0.16 | 0.14 | 0.17 |

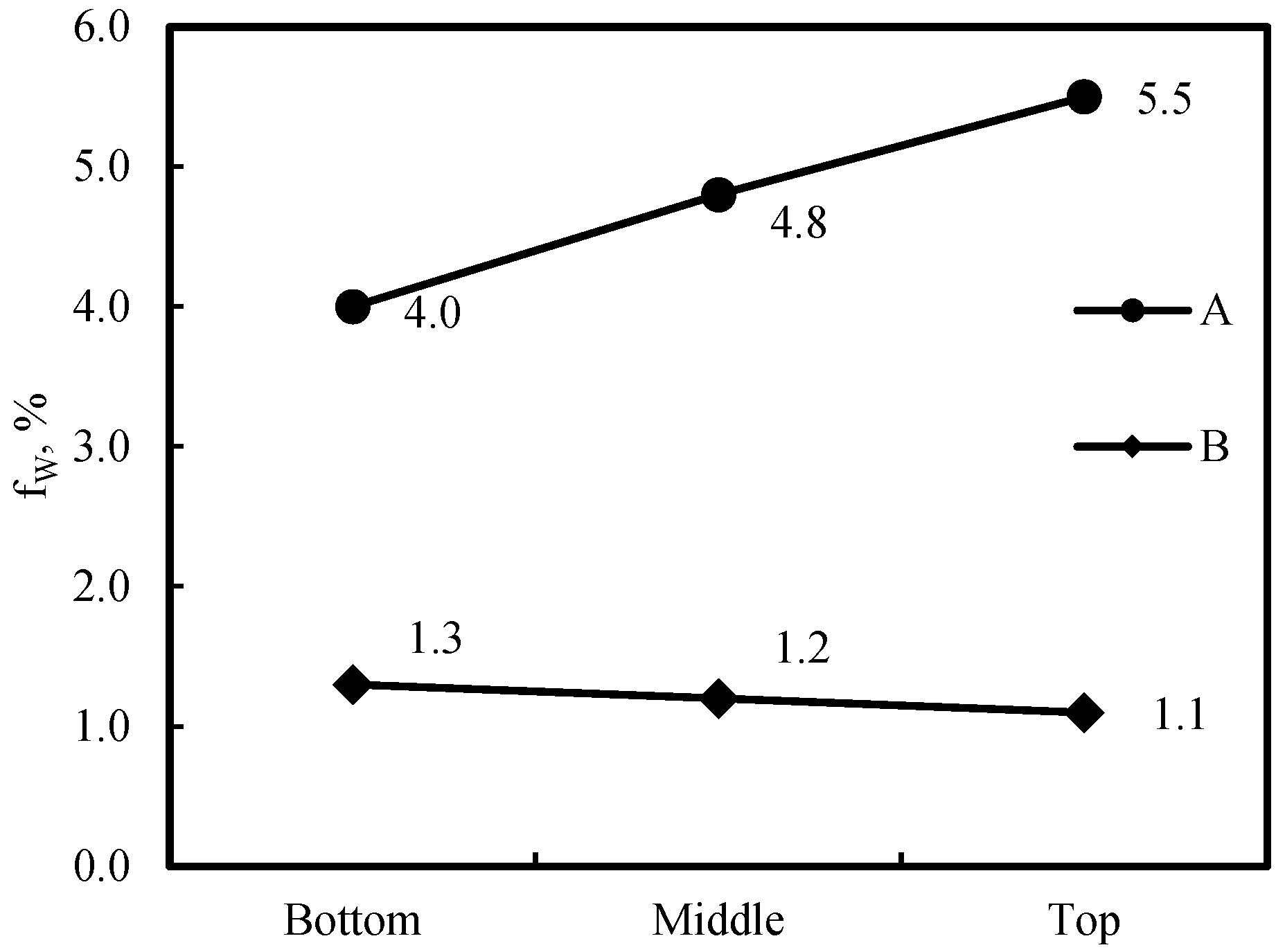

| Worst: fW (%) (Figure 7) | 4.0 | 4.8 | 5.5 | 4.8 | 1.3 | 1.2 | 1.1 | 1.2 | ||

| Micro-porosity ratio ρ(%) | Average: (Figure 10) | 0.28 | 0.26 | 0.23 | 0.27 | 0.22 | 0.15 | 0.13 | 0.17 | |

| Worst: (Figure 11) | 0.43 | 0.30 | 0.26 | 0.33 | 0.30 | 0.25 | 0.24 | 0.26 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Ma, D.; Zhao, Y.; Wei, J.; Gong, X.; Sun, Z. Dendrite Structure Refinement and Mechanical Property Improvement of a Single-Crystal Superalloy. Metals 2025, 15, 295. https://doi.org/10.3390/met15030295

Sun H, Ma D, Zhao Y, Wei J, Gong X, Sun Z. Dendrite Structure Refinement and Mechanical Property Improvement of a Single-Crystal Superalloy. Metals. 2025; 15(3):295. https://doi.org/10.3390/met15030295

Chicago/Turabian StyleSun, Hongyuan, Dexin Ma, Yunxing Zhao, Jianhui Wei, Xiaoyi Gong, and Zhongyuan Sun. 2025. "Dendrite Structure Refinement and Mechanical Property Improvement of a Single-Crystal Superalloy" Metals 15, no. 3: 295. https://doi.org/10.3390/met15030295

APA StyleSun, H., Ma, D., Zhao, Y., Wei, J., Gong, X., & Sun, Z. (2025). Dendrite Structure Refinement and Mechanical Property Improvement of a Single-Crystal Superalloy. Metals, 15(3), 295. https://doi.org/10.3390/met15030295