Investigation of Microstructural Evolution of Silicon Steel Weldment After Post-Weld Heat Treatment—Simulation and Experimental Study

Abstract

1. Introduction

2. Materials and Experimental Procedures

3. Results and Discussion

3.1. As-Welded Fusion Zone Structure

3.2. Microstructure Evolution After Post Weld Heat Treatment

3.3. Mechanical Properties of Weld

4. Conclusions

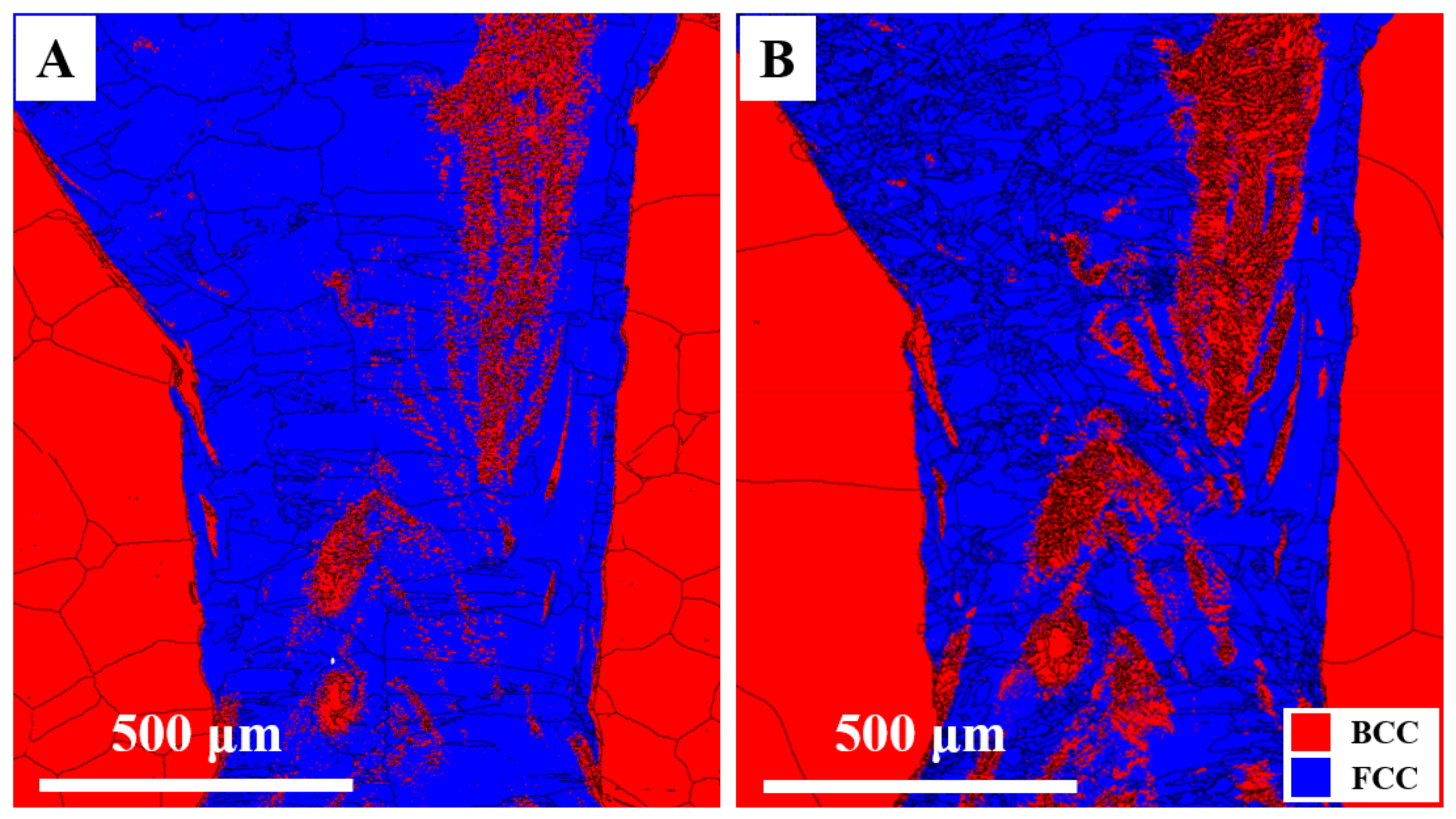

- In the as-weld condition, a complex microstructure was observed due to laser-induced stirring of the weld pool and incomplete mixing of the melted filler wire, leading to phase separation upon cooling. The upper FZ primarily consisted of an FCC structure characterized by interdendritic G-phase precipitates, while the lower FZ exhibited a BCC martensitic matrix interspersed with dispersed interdendritic FCC. These regions were identified as critical sites for microstructural evolution during subsequent heat treatment.

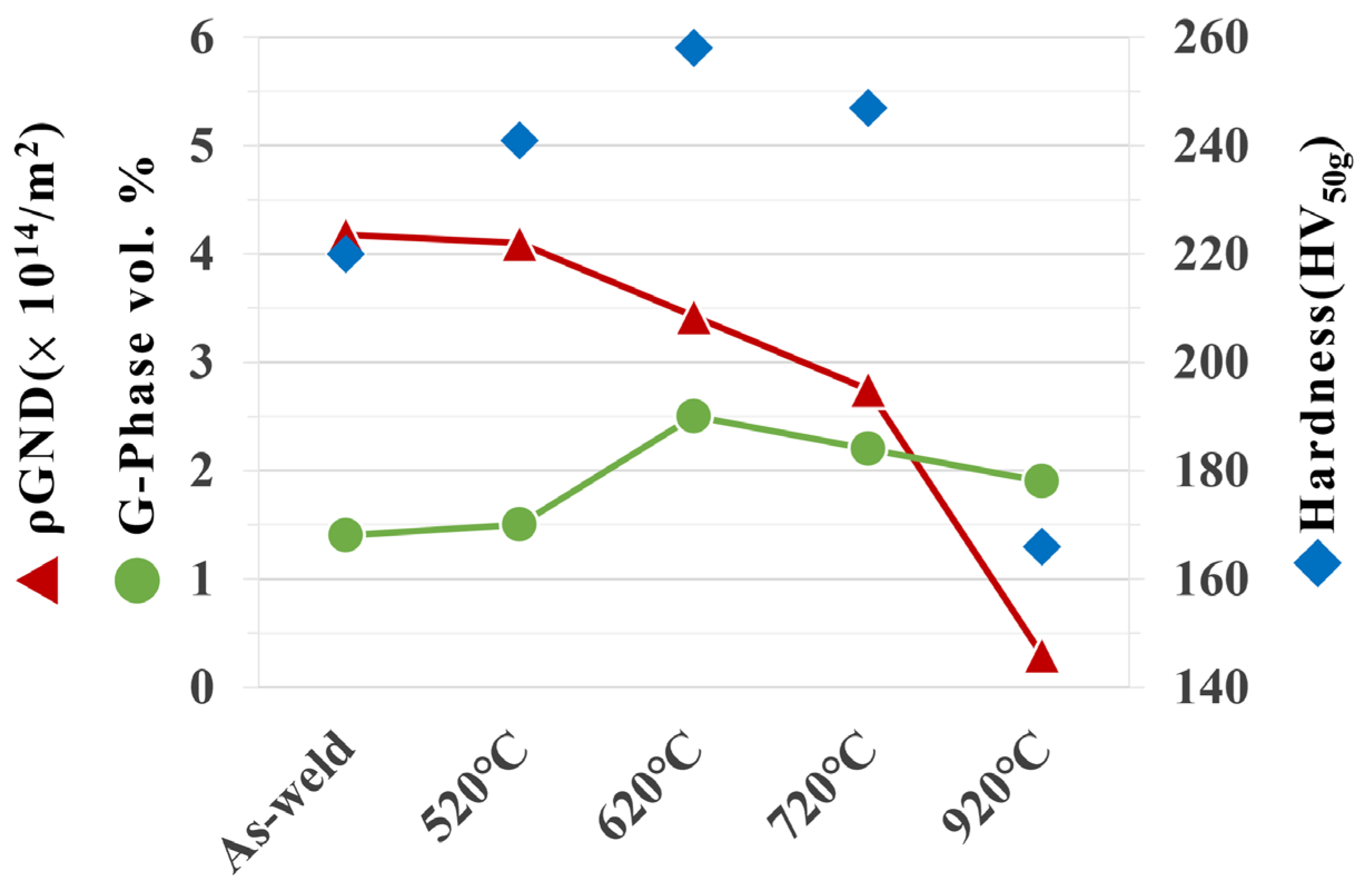

- The peak G-phase fraction occurred at 620 °C; however, deviations were noted when comparing with the predicted equilibrium phases at 720 °C with experimental observation. This discrepancy was likely due to the simulation’s assumption of uniform and equilibrium conditions, which differs from non-equilibrium solidification in practice.

- The complete elimination of interdendritic FCC was observed only in the 920 °C-annealed specimen. This was attributed to full austenitic transformation at this temperature, which facilitated elemental diffusion and local homogenization. This finding validates the effectiveness of the DICTRA single-phase simulation approach for predicting the homogenization behavior. Additionally, the fully martensitic structure observed after 920 °C annealing further supports the simulation result.

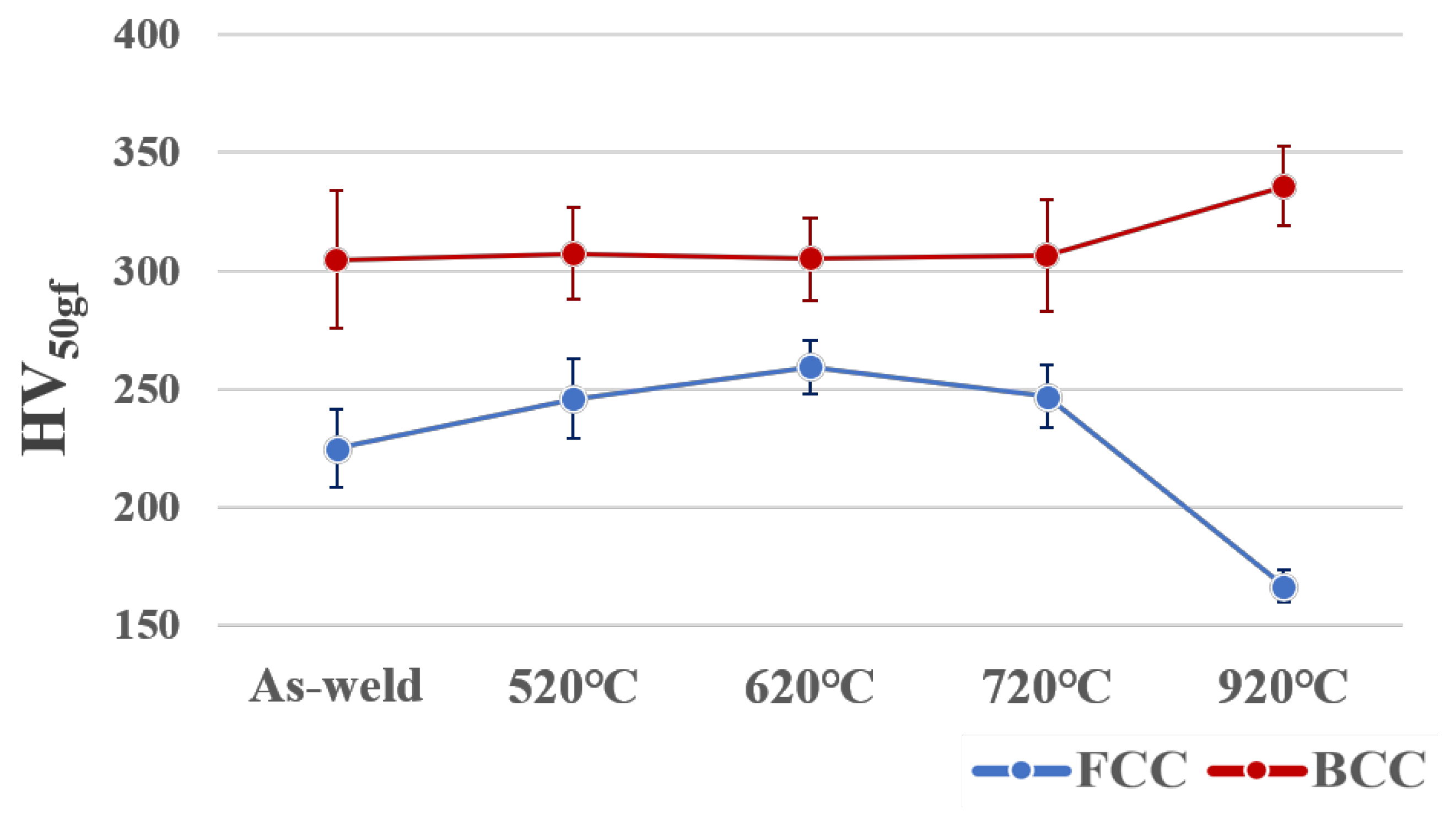

- Annealing at 620 °C resulted in optimal precipitation hardening in the FCC region, demonstrating the effectiveness of G-phase in strengthening the matrix. By contrast, the 920 °C-annealed sample exhibited the highest hardness disparity, which could be attributed to recrystallization-induced softening in the FCC region and the complete martensitic transformation in the BCC region.

- This study successfully used CALPHAD-based simulation tools to elucidate microstructural evolution. The utilization of simulation techniques could provide valuable insights for the design and optimization of heat treatment processes in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inoue, A.; Kong, F. Soft Magnetic Materials. In Encyclopedia of Smart Materials; Olabi, A.-G., Ed.; Elsevier: Oxford, UK, 2022; pp. 10–23. [Google Scholar]

- McHenry, M.E.; Laughlin, D.E. Magnetic properties of metals and alloys. In Physical Metallurgy; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1881–2008. [Google Scholar]

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt% Si high silicon steel—A promising soft magnetic material for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 2016, 64, 2405–2414. [Google Scholar] [CrossRef]

- Chiang, M.-F.; Lo, T.-Y.; Chien, P.-H.; Chi, C.-H.; Chang, K.-C.; Yeh, A.-C.; Shiue, R.-K. The Dilution Effect in High-Power Disk Laser Welding the Steel Plate Using a Nickel-Based Filler Wire. Metals 2021, 11, 874. [Google Scholar] [CrossRef]

- Bonikila, P.R.; Indimath, S.S.; Shajan, N. Failure assessment of Mash Seam Weld breakage and development of online weld inspection system for early detection of weld failure. Eng. Fail. Anal. 2022, 133, 105967. [Google Scholar] [CrossRef]

- Pawar, S.; Sahoo, S.; Mukhopadhyay, G. Failure analysis of weld joint of high strength quality steel sheets in cold rolling mill. Eng. Fail. Anal. 2019, 103, 392–399. [Google Scholar] [CrossRef]

- Park, J.S.; Lim, K.M. Effect of laser welding variables on the formability of 3 wt% Si-added steel welds. Mater. Manuf. Process. 2009, 24, 431–437. [Google Scholar] [CrossRef]

- Das, C.; Bhaduri, A.; Srinivasan, G.; Shankar, V.; Mathew, S. Selection of filler wire for and effect of auto tempering on the mechanical properties of dissimilar metal joint between 403 and 304L (N) stainless steels. J. Mater. Process. Technol. 2009, 209, 1428–1435. [Google Scholar] [CrossRef]

- Hajiannia, I.; Shamanian, M.; Kasiri, M. Microstructure and mechanical properties of AISI 347 stainless steel/A335 low alloy steel dissimilar joint produced by gas tungsten arc welding. Mater. Des. 2013, 50, 566–573. [Google Scholar] [CrossRef]

- Mortezaie, A.; Shamanian, M. An assessment of microstructure, mechanical properties and corrosion resistance of dissimilar welds between Inconel 718 and 310S austenitic stainless steel. Int. J. Press. Vessel. Pip. 2014, 116, 37–46. [Google Scholar] [CrossRef]

- Chiang, M.-F.; Chien, P.-H.; Lo, T.-Y.; Shiue, R.-K. Microstructure of Butt Joint of High-Silicon Steel Made Using CO2 Laser Welding and Inconel 82 Filler. Metals 2023, 13, 234. [Google Scholar] [CrossRef]

- Ahmad, R.; Bakar, M. Effect of a post-weld heat treatment on the mechanical and microstructure properties of AA6061 joints welded by the gas metal arc welding cold metal transfer method. Mater. Des. 2011, 32, 5120–5126. [Google Scholar] [CrossRef]

- Nam, H.; Park, C.; Kim, C.; Kim, H.; Kang, N. Effect of post weld heat treatment on weldability of high entropy alloy welds. Sci. Technol. Weld. Join. 2018, 23, 420–427. [Google Scholar] [CrossRef]

- Cao, X.; Rivaux, B.; Jahazi, M.; Cuddy, J.; Birur, A. Effect of pre-and post-weld heat treatment on metallurgical and tensile properties of Inconel 718 alloy butt joints welded using 4 kW Nd: YAG laser. J. Mater. Sci. 2009, 44, 4557–4571. [Google Scholar] [CrossRef]

- Jansson, B.; Jönsson, B.; Sundman, B.; Ågren, J. The thermo calc project. Thermochim. Acta 1993, 214, 93–96. [Google Scholar] [CrossRef]

- Thermo-Calc. The CALPHAD Methodology. Available online: https://thermocalc.com/about-us/methodology/the-calphad-methodology/ (accessed on 14 March 2025).

- Borgenstam, A.; Höglund, L.; Ågren, J.; Engström, A. DICTRA, a tool for simulation of diffusional transformations in alloys. J. Phase Equilibria 2000, 21, 269–280. [Google Scholar] [CrossRef]

- Ben, F.; Olubambi, P. Phase and properties prediction of Al–Ag binary system using thermo-calc. MRS Adv. 2023, 8, 577–582. [Google Scholar] [CrossRef]

- Ben, F.; Olubambi, P. Thermo-Calc determination of phase diagram and thermodynamic properties of Ni-Al binary system. Mater. Today Proc. 2024, 105, 259–267. [Google Scholar] [CrossRef]

- Sridar, S.; Zhao, Y.; Xiong, W. Phase transformations during homogenization of inconel 718 alloy fabricated by suction casting and laser powder bed fusion: A CALPHAD case study evaluating different homogenization models. J. Phase Equilibria Diffus. 2021, 42, 28–41. [Google Scholar] [CrossRef]

- Mao, Y.; Li, C.; Ji, X.; Zhang, C.; Ma, J.; Ren, Y.; Zhang, W.; Wang, P.; Liu, Z. Experimental studies on Si mobilities in the Fe3Si/Fe–3% Si alloy diffusion couples and the mathematical simulation by DICTRA. Mater. Chem. Phys. 2025, 337, 130595. [Google Scholar] [CrossRef]

- Saucedo-Muñoz, M.L.; Lopez-Hirata, V.M.; Avila-Davila, E.O.; Hernandez-Santiago, F.; Villegas-Cardenas, J.D. Precipitation Process During Isothermal Aging of an Austenitic Stainless Fe-12Cr-10Mn-12Ni-5Mo-0.24 N-0.03 C Steel and Its Effect on the Mechanical Properties. In Proceedings of the TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1451–1460. [Google Scholar]

- Sanhueza, J.; Rojas, D.; Prat, O.; Garcia, J.; Espinoza, R.; Montalba, C.; Melendrez, M. Precipitation kinetics in a 10.5% Cr heat resistant steel: Experimental results and simulation by TC-PRISMA/DICTRA. Mater. Chem. Phys. 2017, 200, 342–353. [Google Scholar] [CrossRef]

- Chung, D.H.; Lee, H.S.; Yun, D.W.; Jeong, H.W.; Yoo, Y.S.; Jang, J.H.; Kwon, H.J.; Seo, S.M.; Na, Y.S. Microsegregation and homogenization behavior of CoCrFeMnNi high-entropy alloy. Mater. Charact. 2024, 209, 113737. [Google Scholar] [CrossRef]

- Chen, C.; Dong, Y.; Hu, C.; Du, Y.; Wei, S.; Long, J.; Wang, C.; Xiao, L.; Mao, F. Fabrication of gradient cemented carbide with Ni3Al binder: Simulations and experiments. Ceram. Int. 2022, 48, 12756–12763. [Google Scholar] [CrossRef]

- Thorhauer, M.; Heinze, S.; Larsson, H.; Enghardt, S.; Leyens, C. High-temperature-driven degradation analysis and modelling of an industrial gas turbine applicable γ/β NiCoCrAlYRe coating–Part II: Diffusion modelling and experimental validation under isothermal conditions. Surf. Coat. Technol. 2025, 496, 131595. [Google Scholar] [CrossRef]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef]

- Muransky, O.; Balogh, L.; Tran, M.; Hamelin, C.; Park, J.-S.; Daymond, M.R. On the measurement of dislocations and dislocation substructures using EBSD and HRSD techniques. Acta Mater. 2019, 175, 297–313. [Google Scholar] [CrossRef]

- Jiang, J.; Britton, T.; Wilkinson, A. Measurement of geometrically necessary dislocation density with high resolution electron backscatter diffraction: Effects of detector binning and step size. Ultramicroscopy 2013, 125, 1–9. [Google Scholar] [CrossRef]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Katayama, S. Handbook of Laser Welding Technologies; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Morito, S.; Nishikawa, J.; Maki, T. Dislocation density within lath martensite in Fe-C and Fe-Ni alloys. ISIJ Int. 2003, 43, 1475–1477. [Google Scholar] [CrossRef]

- Berecz, T.; Jenei, P.; Csóré, A.; Lábár, J.; Gubicza, J.; Szabó, P.J. Determination of dislocation density by electron backscatter diffraction and X-ray line profile analysis in ferrous lath martensite. Mater. Charact. 2016, 113, 117–124. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H.; Rinker, T.; Tan, W. Investigation of metal mixing in laser keyhole welding of dissimilar metals. Mater. Des. 2020, 195, 109056. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Wang, X.; Xue, F. G-phase precipitation in duplex stainless steels after long-term thermal aging: A high-resolution transmission electron microscopy study. J. Nucl. Mater. 2014, 452, 382–388. [Google Scholar] [CrossRef]

- Hamaoka, T.; Nomoto, A.; Nishida, K.; Dohi, K.; Soneda, N. Effects of aging temperature on G-phase precipitation and ferrite-phase decomposition in duplex stainless steel. Philos. Mag. 2012, 92, 4354–4375. [Google Scholar] [CrossRef]

- Matsukawa, Y.; Takeuchi, T.; Kakubo, Y.; Suzudo, T.; Watanabe, H.; Abe, H.; Toyama, T.; Nagai, Y. The two-step nucleation of G-phase in ferrite. Acta Mater. 2016, 116, 104–113. [Google Scholar] [CrossRef]

- Yang, M.; King, D.J.; Povstugar, I.; Wen, Y.; Luan, J.; Kuhn, B.; Jiao, Z.; Wang, C.; Wenman, M.; Liu, X. Precipitation behavior in G-phase strengthened ferritic stainless steels. Acta Mater. 2021, 205, 116542. [Google Scholar] [CrossRef]

- Yang, M.; Zhu, J.; Yang, T.; Luan, J.; Jiao, Z.; Fan, X.; Kuhn, B.; Xiong, X.; Wang, C.; Liu, C.T. A novel ferritic steel family hardened by intermetallic compound G-phase. Mater. Sci. Eng. A 2019, 745, 390–399. [Google Scholar] [CrossRef]

- Sun, S.; Pugh, M. Manganese partitioning in dual-phase steel during annealing. Mater. Sci. Eng. A 2000, 276, 167–174. [Google Scholar] [CrossRef]

- Kurokawa, S.; Ruzzante, J.; Hey, A.; Dyment, F. Diffusion of Nb in Fe and Fe alloys. Met. Sci. 1983, 17, 433–438. [Google Scholar] [CrossRef]

- Bukovská, Š.; Moravec, J.; Švec, M. Kinetics of nickel diffusion into austenitic stainless steels AISI 304 and 316L and calculation of diffusion coefficients. Materials 2023, 16, 6783. [Google Scholar] [CrossRef]

- Uemura, K. Diffusion of elements in solid iron and steel. Tetsu-to-Hagane 1943, 29, 329–335. [Google Scholar] [CrossRef]

- Deng, D. FEM prediction of welding residual stress and distortion in carbon steel considering phase transformation effects. Mater. Des. 2009, 30, 359–366. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, D.; He, L.; Ye, X.; Zhang, W. Laser beam welding of AlCoCrFeNi2. 1 eutectic high-entropy alloy. Mater. Lett. 2022, 308, 131137. [Google Scholar] [CrossRef]

- Ram, G.J.; Reddy, A.V.; Rao, K.P.; Reddy, G.M.; Sundar, J.S. Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds. J. Mater. Process. Technol. 2005, 167, 73–82. [Google Scholar]

- Li, S.; Zhu, G.; Kang, Y. Effect of substructure on mechanical properties and fracture behavior of lath martensite in 0.1 C–1.1 Si–1.7 Mn steel. J. Alloys Compd. 2016, 675, 104–115. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Klueh, R.; Maziasz, P.; Lee, E.H. Manganese as an austenite stabilizer in Fe-Cr-Mn-C steels. Mater. Sci. Eng. A 1988, 102, 115–124. [Google Scholar] [CrossRef]

- Ayad, A.; Ramoul, M.; Rollett, A.; Wagner, F. Quantifying primary recrystallization from EBSD maps of partially recrystallized states of an IF steel. Mater. Charact. 2021, 171, 110773. [Google Scholar] [CrossRef]

- Peranio, N.; Li, Y.; Roters, F.; Raabe, D. Microstructure and texture evolution in dual-phase steels: Competition between recovery, recrystallization, and phase transformation. Mater. Sci. Eng. A 2010, 527, 4161–4168. [Google Scholar] [CrossRef]

- Mattucci, M.; Cherubin, I.; Changizian, P.; Skippon, T.; Daymond, M. Indentation size effect, geometrically necessary dislocations and pile-up effects in hardness testing of irradiated nickel. Acta Mater. 2021, 207, 116702. [Google Scholar] [CrossRef]

| Location | Chemical Composition (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| Fe | Si | Ni | Cr | Mn | Nb | Al | |

| A | 53 | 1.6 | 32.6 | 9.7 | 1.5 | 1.2 | 0.4 |

| B | 53.8 | 1.7 | 32 | 9.3 | 1.5 | 1.3 | 0.4 |

| C | 70.8 | 1.7 | 20.5 | 5.2 | 0.8 | 0.6 | 0.4 |

| D | 88.1 | 2.4 | 6.4 | 2 | 0.4 | 0.2 | 0.5 |

| E | 88.9 | 2.5 | 5.8 | 1.8 | 0.3 | 0.1 | 0.5 |

| F | 87.8 | 2.5 | 6.6 | 2 | 0.4 | 0.2 | 0.5 |

| FCC | 56.5 | 1.7 | 30.3 | 8.7 | 1.4 | 1.0 | 0.4 |

| BCC | 88.4 | 2.6 | 6.1 | 1.7 | 0.4 | 0.2 | 0.6 |

| Location | Chemical Composition (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| Fe | Si | Ni | Cr | Mn | Nb | Al | |

| BCC Matrix | 75.0 | 2.0 | 16.3 | 5.0 | 0.8 | 0.5 | 0.4 |

| Interdendritic Site | 71.6 | 1.9 | 19.0 | 5.4 | 1.0 | 0.6 | 0.5 |

| Location/Hardness (HV50gf) | Annealing Conditions | ||||

|---|---|---|---|---|---|

| As-Weld | 520 °C for 8 h | 620 °C for 8 h | 720 °C for 8 h | 920 °C for 8 h | |

| FCC | 224.94 | 245.82 | 259.33 | 246.89 | 166.39 |

| BCC | 304.78 | 307.38 | 305.00 | 306.53 | 335.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, J.-T.; Chi, C.-H.; Chiang, M.-F.; Tsao, T.-K.; Hsu, W.-L.; Yeh, A.-C. Investigation of Microstructural Evolution of Silicon Steel Weldment After Post-Weld Heat Treatment—Simulation and Experimental Study. Metals 2025, 15, 549. https://doi.org/10.3390/met15050549

Kuo J-T, Chi C-H, Chiang M-F, Tsao T-K, Hsu W-L, Yeh A-C. Investigation of Microstructural Evolution of Silicon Steel Weldment After Post-Weld Heat Treatment—Simulation and Experimental Study. Metals. 2025; 15(5):549. https://doi.org/10.3390/met15050549

Chicago/Turabian StyleKuo, Jyun-Ting, Chih-Hsien Chi, Ming-Feng Chiang, Te-Kang Tsao, Wei-Lin Hsu, and An-Chou Yeh. 2025. "Investigation of Microstructural Evolution of Silicon Steel Weldment After Post-Weld Heat Treatment—Simulation and Experimental Study" Metals 15, no. 5: 549. https://doi.org/10.3390/met15050549

APA StyleKuo, J.-T., Chi, C.-H., Chiang, M.-F., Tsao, T.-K., Hsu, W.-L., & Yeh, A.-C. (2025). Investigation of Microstructural Evolution of Silicon Steel Weldment After Post-Weld Heat Treatment—Simulation and Experimental Study. Metals, 15(5), 549. https://doi.org/10.3390/met15050549