Microstructures and Deep-Drawing Properties of Copper–Steel Bimetallic Sheets Fabricated Using an Arc Spray-Rolling Short Process

Abstract

1. Introduction

2. Materials and Methods

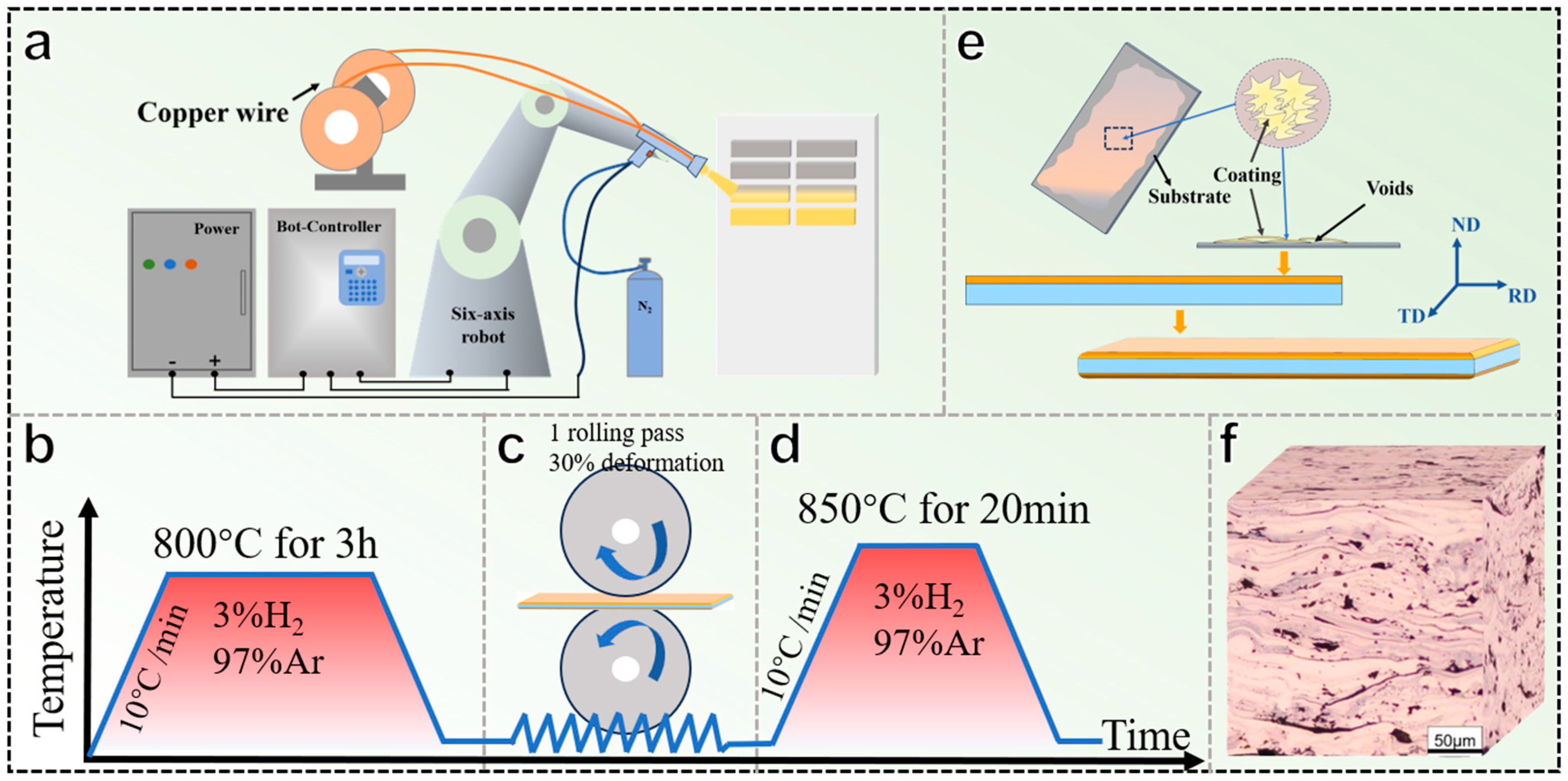

2.1. Materials and CSBS Preparation

2.2. Microstructure and Composition Characterization

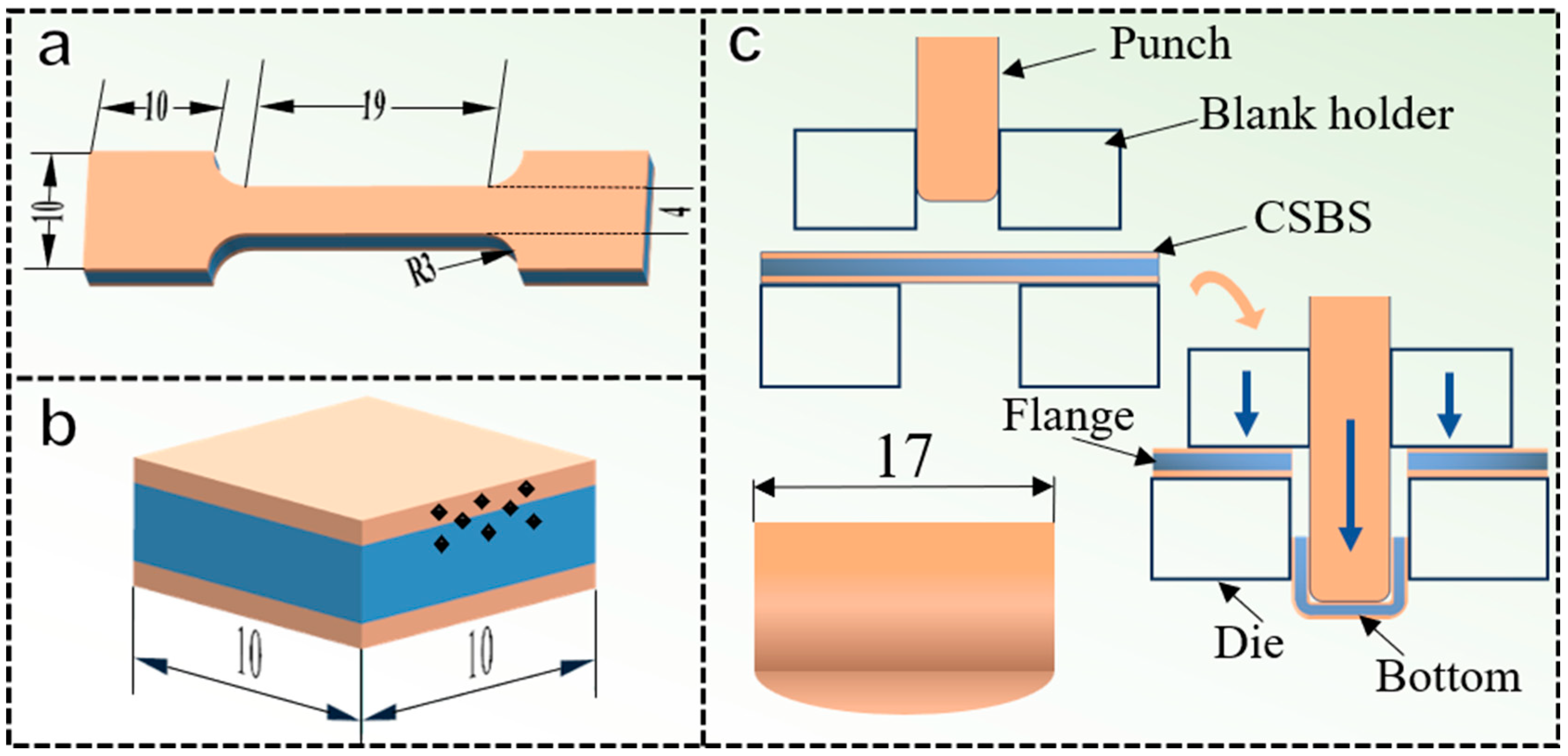

2.3. Mechanical Test

3. Results and Discussion

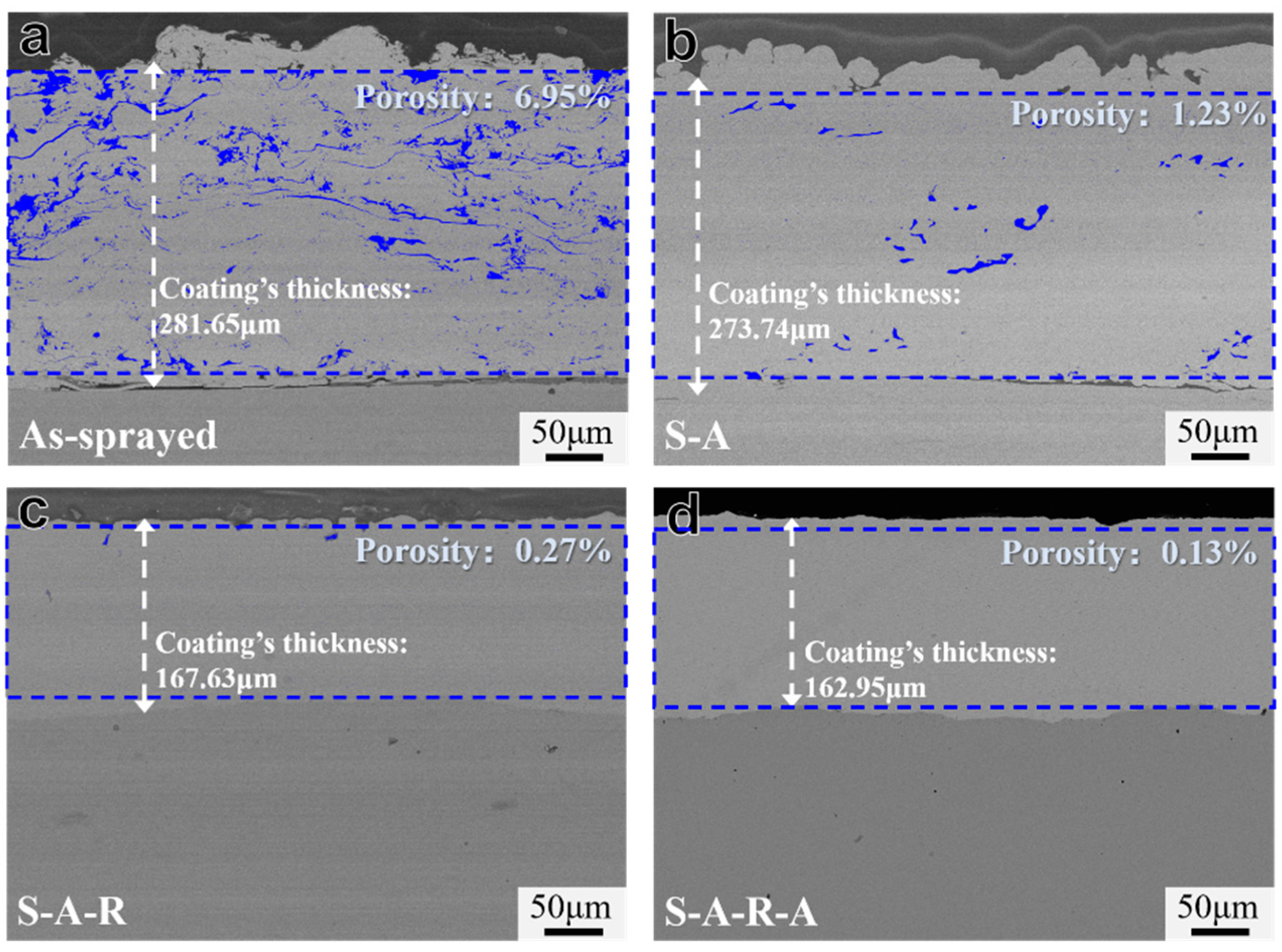

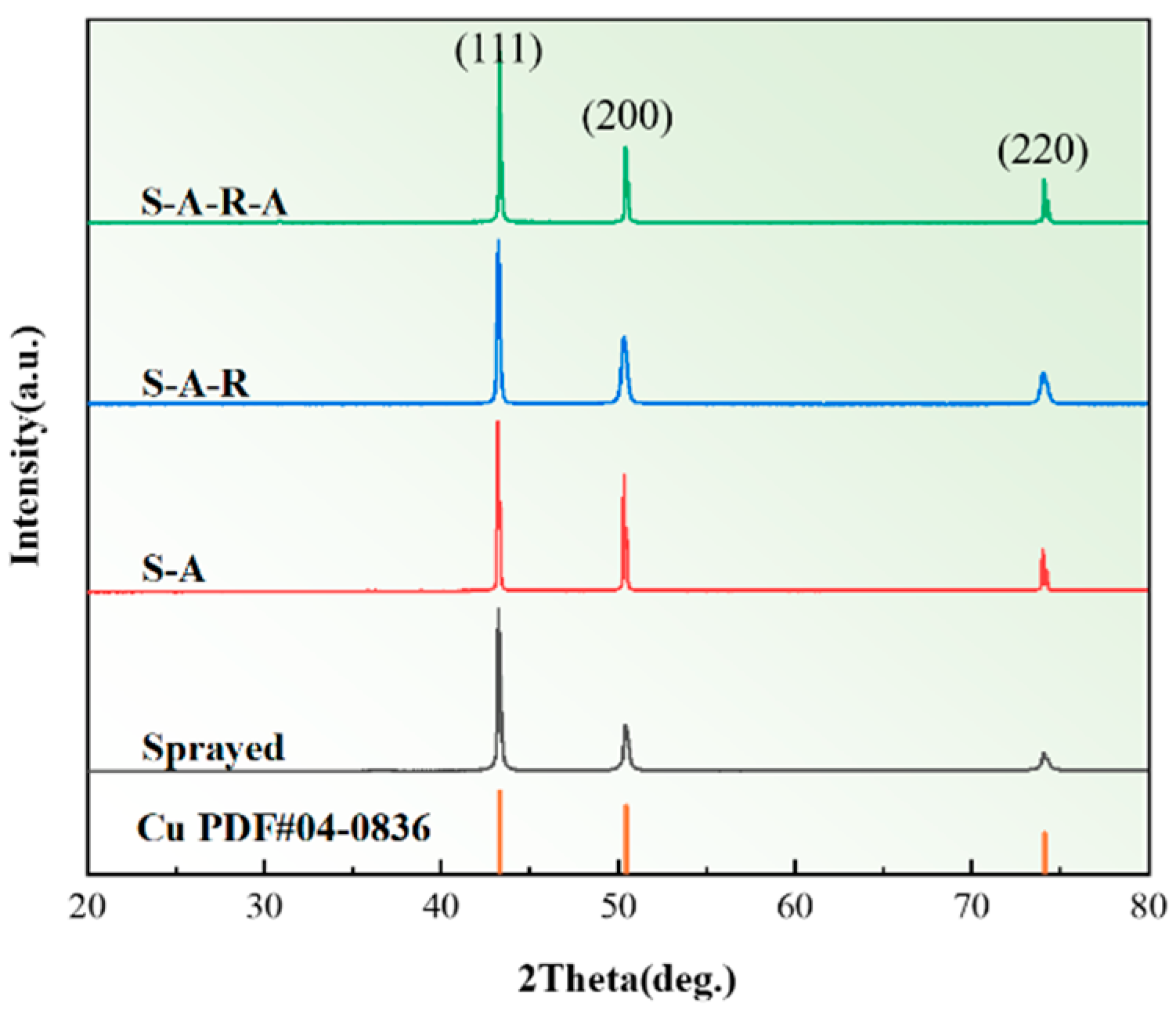

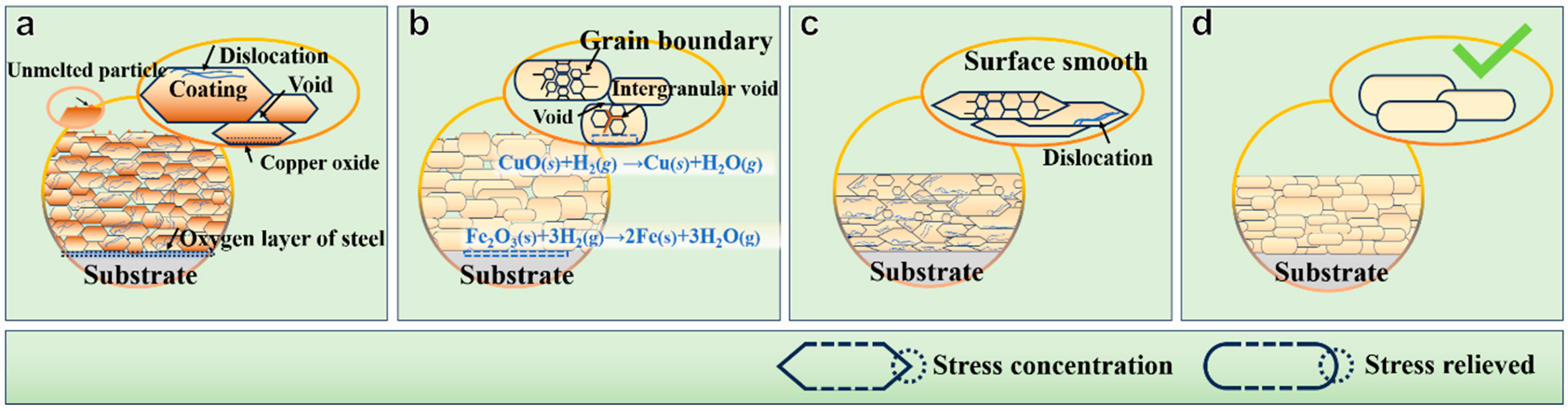

3.1. Morphologies and Phases of Coatings

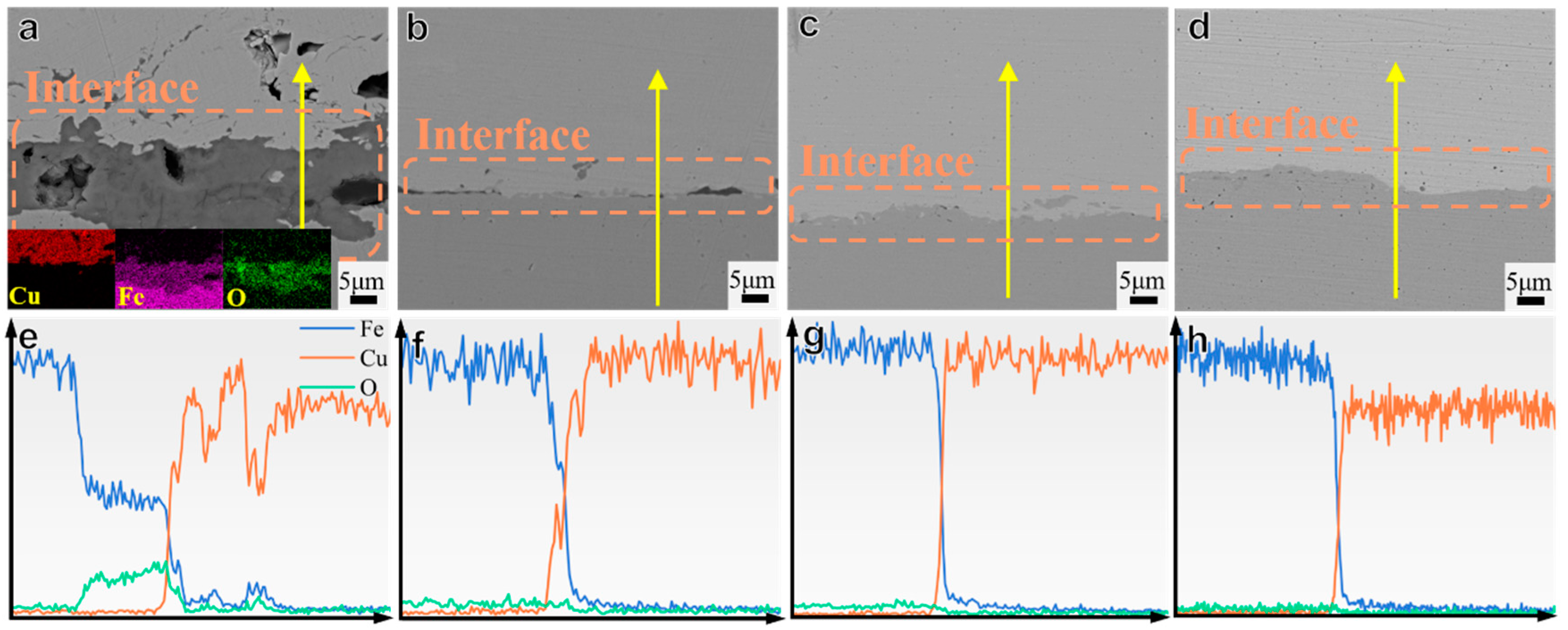

3.2. Interfacial and Coating Microstructures

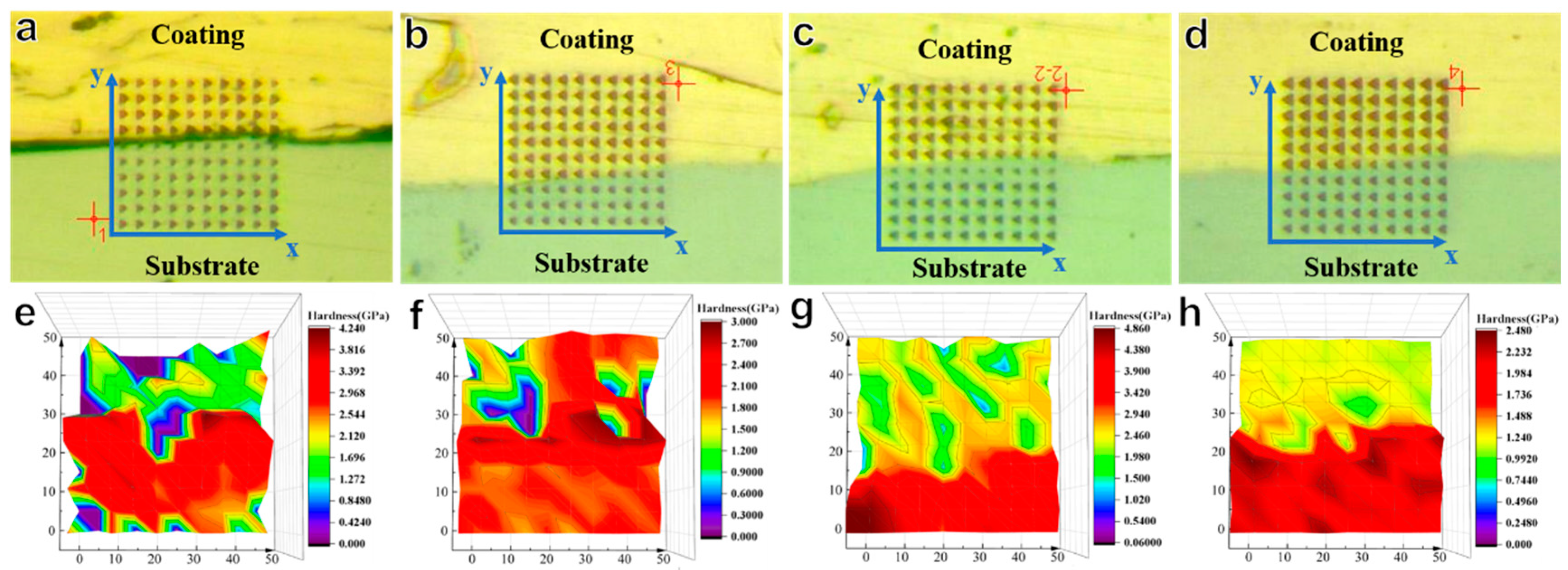

3.3. Micro-Hardness

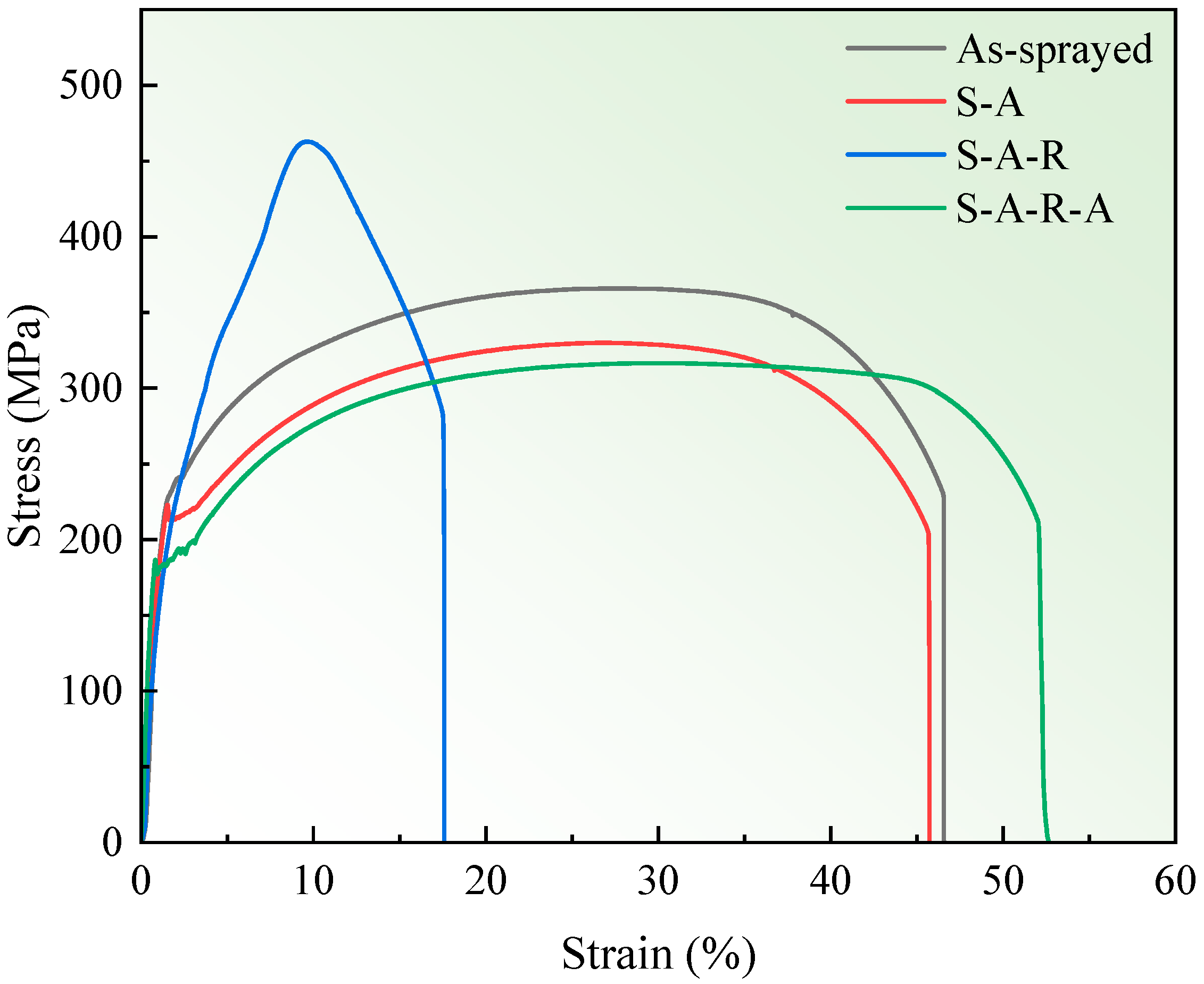

3.4. Fractured Morphologies of Tensile Tests

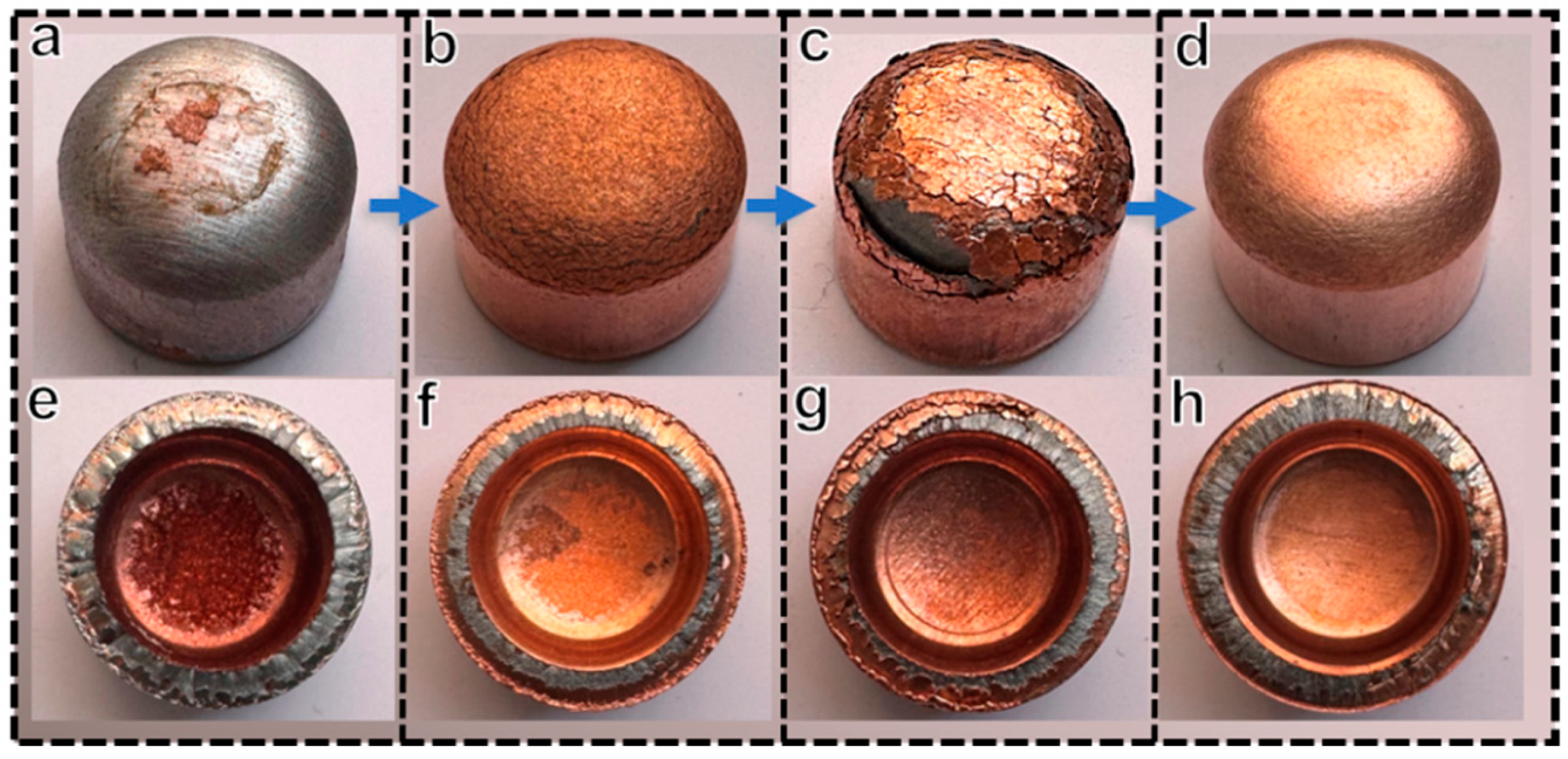

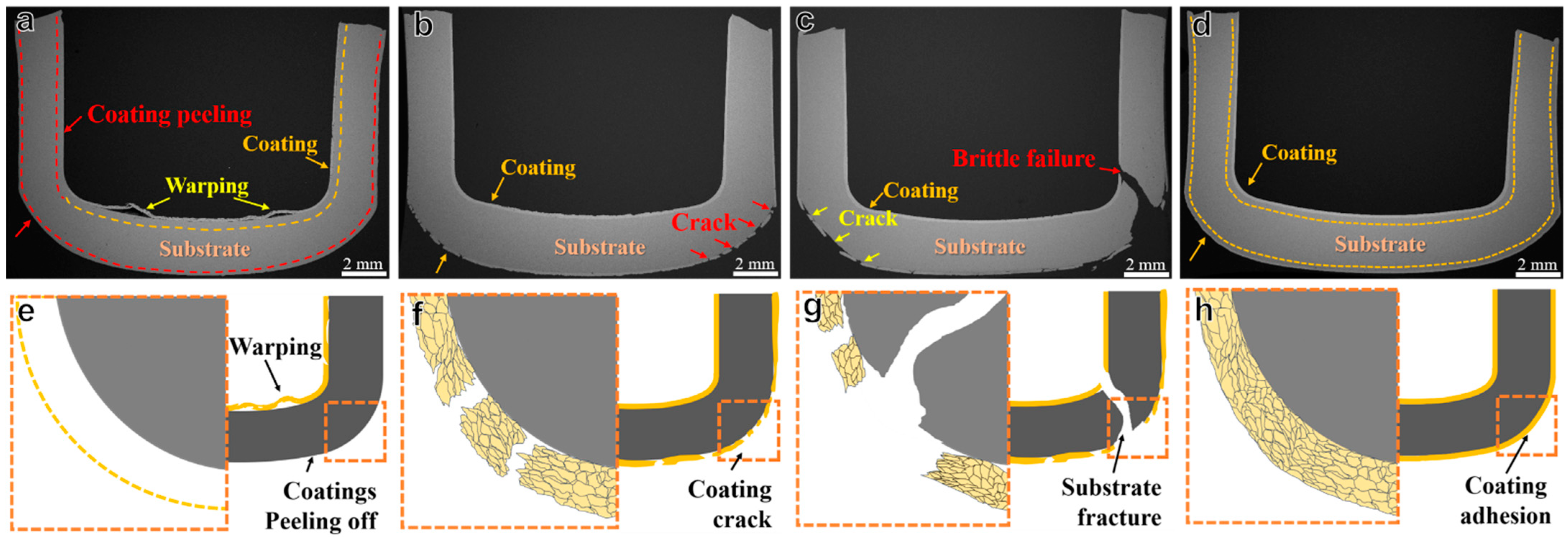

3.5. Deep-Drawing Deformation Behavior

4. Conclusions

- (1)

- Annealing and cold-rolling synergistic treatments effectively reduce the porosity of the As-sprayed coating and improve the density of the copper coating. The voids in the coating and interface disappear after cold-rolling and two-stage annealing treatment, as well as the oxide at the interface. Tight bonds form between the copper coating and steel substrate.

- (2)

- The grain sizes of the As-sprayed coating are smaller due to the rapid cooling rate during the spraying process. The grains experience the processes of growing, elongating, and growing after annealing–rolling–annealing treatment. The results of micro-hardness testing show that a uniform stress distribution appeared in the 3D microhardness cloud map of the A-R-A sample, indicating a more homogeneous hardness distribution in the coating.

- (3)

- The ARA processing significantly improves the toughness and interface bonding strength of the coating. After tensile testing, the fractured surface of the CSBS sample displays an elongated dimple morphology with the majority oriented along the TD direction. Meanwhile, the copper coating remains firmly bonded to the steel substrate and deforms cooperatively with the substrate.

- (4)

- The copper coating of the As-sprayed CSBS sample falls off directly after deep drawing due to the low interface bonding strength, as well as the poor coating properties. In contrast, the copper coating of the CSBS sample after ARA treatment does not crack and fall off, indicating that this process results in proper hardness and toughness and a better interface bonding strength, leading to a more synergistic deformation under the deep-drawing process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bazhina, A.; Konstantinov, A.; Chizhikov, A.; Bazhin, P.; Stolin, A.; Avdeeva, V. Structure and mechanical characteristics of a layered composite material based on TiB/TiAl/Ti. Ceram. Int. 2022, 48, 14295–14300. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, X.; Ren, G.; Liu, Z.; Yuan, R.; Yang, X.; Dong, P. Microstructure and properties of copper-steel bimetallic sheets prepared by friction stir additive manufacturing. J. Manuf. Process. 2022, 82, 689–699. [Google Scholar] [CrossRef]

- Liang, D.; Zhou, Y.; Liu, X.; Zhou, Q.; Huang, B.; Zhang, E.; Chen, Q.; Shen, J. Wettability and corrosion performance of arc-sprayed Fe-based amorphous coatings. Surf. Coat. Technol. 2022, 433, 128129. [Google Scholar] [CrossRef]

- Daram, P.; Munroe, P.R.; Banjongprasert, C. Microstructural evolution and nanoindentation of NiCrMoAl alloy coating deposited by arc spraying. Surf. Coat. Technol. 2020, 391, 125565. [Google Scholar] [CrossRef]

- Cheng, J.B.; Liang, X.B.; Xu, B.S. Devitrification of arc-sprayed FeBSiNb amorphous coatings: Effects on wear resistance and mechanical behavior. Surf. Coat. Technol. 2013, 235, 720–726. [Google Scholar] [CrossRef]

- Tillmann, W.; Abdulgader, M.; Wirtz, A.; Milz, M.P.; Biermann, D.; Walther, F. The Effect of Argon as Atomization Gas on the Microstructure, Machine Hammer Peening Post-Treatment, and Corrosion Behavior of Twin Wire Arc Sprayed (TWAS) ZnAl4 Coatings. Coatings 2022, 12, 32. [Google Scholar] [CrossRef]

- Yuan, M.; Liu, L.; Wang, J.; Hu, Q.; Zhang, H.; Zhang, S.; Zhou, X. Crack-healing behaviour of MoSi2 dispersed Yb2Si2O7 environmental barrier coatings. Ceram. Int. 2022, 48, 29919–29928. [Google Scholar] [CrossRef]

- Ren, Y.; Tariq, N.U.H.; Liu, H.; Cui, X.; Shen, Y.; Wang, J.; Xiong, T. An innovative and flexible approach to fabricate Mg/Al composite plates: Cold spraying and hot rolling post-treatment. Mater. Sci. Eng. A 2022, 849, 143515. [Google Scholar] [CrossRef]

- Singh, R.; Schruefer, S.; Wilson, S.; Gibmeier, J.; Vassen, R. Influence of coating thickness on residual stress and adhesion-strength of cold-sprayed Inconel 718 coatings. Surf. Coat. Technol. 2018, 350, 64–73. [Google Scholar] [CrossRef]

- Zhang, X. Microstructure and Properties of Particle Reinforced Magnesium Sheet; Taiyuan University of Science and Technology: Taiyuan, China, 2020. [Google Scholar]

- Al-Ghamdi, K.A.; Hussain, G. On the comparison of formability of roll-bonded steel-Cu composite sheet metal in incremental forming and stamping processes. Int. J. Adv. Manuf. Technol. 2016, 87, 267–278. [Google Scholar] [CrossRef]

- Li, S.; Beyerlein, I.J.; Alexander, D.J.; Vogel, S.C. Texture evolution during multi-pass equal channel angular extrusion of copper: Neutron diffraction characterization and polycrystal modeling. Acta. Mater. 2005, 53, 2111–2125. [Google Scholar]

- Xu, J.; Fu, J.; Li, S.; Xu, G.; Li, Y.; Wang, Z. Effect of annealing and cold rolling on interface microstructure and properties of Ti/Al/Cu clad sheet fabricated by horizontal twin-roll casting. J. Mater. Res. Technol. 2022, 16, 530–543. [Google Scholar]

- Sun, L.; Chen, M.-H.; Zhang, L. Microstructure evolution and grain orientation of IMC in Cu-Sn TLP bonding solder joints. J. Alloys. Compd. 2019, 786, 677–687. [Google Scholar]

- Zhang, G.; Yu, J.; Su, C.; Di, C.; Ci, S.; Mou, Y.; Fu, Y.; Qiao, K. The effect of annealing on the properties of copper-coated carbon fiber. Surf. Interfaces 2023, 37, 102630. [Google Scholar]

- Kheiri, S.; Mirzadeh, H.; Naghizadeh, M. Tailoring the microstructure and mechanical properties of AISI 316L austenitic stainless steel via cold rolling and reversion annealing. Mater. Sci. Eng. A 2019, 759, 90–96. [Google Scholar]

- Li, J.; Lin, X.; Wang, J.; Zheng, M.; Guo, P.; Zhang, Y.; Ren, Y.; Liu, J.; Huang, W. Effect of stress-relief annealing on anodic dissolution behaviour of additive manufactured Ti-6Al-4V via laser solid forming. Corros. Sci. 2019, 153, 314–326. [Google Scholar]

- Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Nyambura, S.M. A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials 2021, 11, 2527. [Google Scholar] [CrossRef]

- Tang, Z.; Guo, L.; Li, Z.; Huang, K.; Zheng, T.; Sun, R. A comparative study of void characteristics on the mechanical response of unidirectional composites. Mech. Mater. 2022, 174, 104456. [Google Scholar]

- Seng, D.H.L.; Zhang, Z.; Zhang, Z.-Q.; Meng, T.L.; Teo, S.L.; Tan, B.H.; Loi, Q.; Pan, J.; Ba, T. Impact of spray angle and particle velocity in cold sprayed IN718 coatings. Surf. Coat. Technol. 2023, 466, 129623. [Google Scholar]

- Joshi, R.; Boesl, B.; Agarwal, A.; Thomas, T. Desktop Manufacturing of Plasma-Sprayed Coating and Computational Estimation of its Mechanical Properties. J. Therm. Spray. Technol. 2024, 33, 2686–2697. [Google Scholar] [CrossRef]

- Pan, X.-L.; Hu, X.-G.; Zhao, J.; Qiu, L. Research Progress on Evaluation Methods of Interfacial Bonding Strength of Film/Coating. Surf. Technol. 2022, 51, 50–65. [Google Scholar]

- Feng, Z.; Wang, X.; Tan, H.; Zhang, F.; Fan, W.; Wang, Y.; Fang, Y.; Wang, J.; Wu, F.; Lin, X.; et al. Effect of heat treatment patterns on porosity, microstructure, and mechanical properties of selective laser melted TiB2/Al–Si–Mg composite. Mater. Sci. Eng. A 2022, 855, 143932. [Google Scholar] [CrossRef]

- Liu, P.; Wang, X.; Chen, D.; Long, M.; Duan, H. Interface structure characterization and elements doping on interface bonding strength and tensile failure mechanism of NiCo coating/Cu matrix. Results. Phys. 2021, 30, 104883. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, Y.; Sui, H.; Fu, J.; Duan, H. Microstructure-based intergranular fatigue crack nucleation model: Dislocation transmission versus grain boundary cracking. J. Mech. Phys. Solids 2023, 173, 105233. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Recrystallization mechanisms and microstructure development in emerging metallic materials: A review. J. Sci-Adv. Mater. Dev. 2019, 4, 19–33. [Google Scholar] [CrossRef]

- Li, R.; Zhou, J.; Zhang, G. A unified explanation for variation of the grain growth exponent based on grain boundary migration kinetics. J. Alloys. Compd. 2024, 976, 173159. [Google Scholar]

- Deng, Y.; Deng, C. Size and rate dependent grain boundary motion mediated by disconnection nucleation. Acta. Mater. 2017, 131, 400–409. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Wang, R.; Zhang, J.; Hu, R.; Zhang, Y.; Li, G.; Lu, X. Microstructure and properties evolution of Co06/Ni60A duplex coating on copper by plasma cladding, Surf. Coat. Technol. 2022, 429, 127978. [Google Scholar]

- Gallet, J.; Perez, M.; Guillou, R.; Ernould, C.; Le Bourlot, C.; Langlois, C.; Beausir, B.; Bouzy, E.; Chaise, T.; Cazottes, S. Experimental measurement of dislocation density in metallic materials: A quantitative comparison between measurements techniques (XRD, R-ECCI, HR-EBSD, TEM). Mater. Charact. 2023, 199, 112842. [Google Scholar] [CrossRef]

- Vinay, G.; Chavan, N.M.; Kumar, S.; Jyothirmayi, A.; Bodapati, B.R. Improved microstructure and properties of cold sprayed zinc coatings in the as sprayed condition. Surf. Coat. Technol. 2022, 438, 128392. [Google Scholar] [CrossRef]

- Fang, T.; Li, W.; Tao, N.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef]

- Feng, R.; Song, W.; Li, H.; Qi, Y.; Qiao, H.; Li, L. Effects of Annealing on the Residual Stress in γ-TiAl Alloy by Molecular Dynamics Simulation. Materials 2018, 11, 1025. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, D.; Yuan, X.; Song, P.; Feng, J.; Huang, T.; Lu, J. Effect of water vapour on preferential orientation of thermally grown oxide at 1050 °C. Corros. Sci. 2022, 209, 110737. [Google Scholar]

- Huang, J.; Chu, X.; Yang, T.; Fang, H.; Ye, D.; Wang, W.; Zhang, X.; Sun, W.; Huang, R.; Li, C.-J. Achieving high anti-sintering performance of plasma-sprayed YSZ thermal barrier coatings through pore structure design. Surf. Coat. Technol. 2022, 435, 128259. [Google Scholar]

- Wang, J.; Fu, M.; Shi, S. Influences of size effect and stress condition on ductile fracture behavior in micro-scaled plastic deformation. Mater. Des. 2017, 131, 69–80. [Google Scholar] [CrossRef]

- Jiang, S.; Peng, R.L.; Zhao, X.; Zuo, L.; Jia, N. Deformation incompatibility enables hetero-deformation induced strengthening in Ti/Nb laminates. Mater. Res. Lett. 2023, 11, 126–133. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar]

- Qiu, X.; Qi, L.; Zan, Y.-N.; Wang, Y.-J.; Wang, J.-Q.; Du, H.; Xiong, T.-Y. In-situ Sip/A380 alloy nano/micro composite formation through cold spray additive manufacturing and subsequent hot rolling treatment: Microstructure and mechanical properties. J. Alloys. Compd. 2019, 780, 597–606. [Google Scholar]

- Lakkannavar, V.; Yogesha, K.; Prasad, C.D.; Phanden, R.K.; Srinivasa, G.; Prasad, S.C. Interfaces, Thermal spray coatings on high-temperature oxidation and corrosion applications–a comprehensive review. Res. Surf. Interfaces 2024, 16, 100250. [Google Scholar]

- Zhao, Y.; Aoyagi, K.; Yamanaka, K.; Chiba, A. A survey on basic influencing factors of solidified grain morphology during electron beam melting. Mater. Des. 2022, 221, 110927. [Google Scholar]

| Parameters | Values |

|---|---|

| Arc current (A) | 44~47 |

| Power (kW) | 11~13 |

| Spraying distance (mm) | 150 |

| Gun movement speed (mm/s) | 400 |

| Spraying pressure (MPa) | 0.8 |

| Parameters | Values |

|---|---|

| Punch force (kN) | 50 |

| Shear force (kN) | 75 |

| Stretch punch radius (mm) | 1.25 |

| Concave entrance radius (mm) | 9 |

| Taper (°) | 12 |

| Gap (mm) | 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, T.; Bai, J.; Kong, D.; Zhai, R.; Liang, Y.; Huang, T.; Li, Q.; Song, P. Microstructures and Deep-Drawing Properties of Copper–Steel Bimetallic Sheets Fabricated Using an Arc Spray-Rolling Short Process. Metals 2025, 15, 400. https://doi.org/10.3390/met15040400

Yao T, Bai J, Kong D, Zhai R, Liang Y, Huang T, Li Q, Song P. Microstructures and Deep-Drawing Properties of Copper–Steel Bimetallic Sheets Fabricated Using an Arc Spray-Rolling Short Process. Metals. 2025; 15(4):400. https://doi.org/10.3390/met15040400

Chicago/Turabian StyleYao, Tairan, Jinbiao Bai, Dehao Kong, Ruixiong Zhai, Yuwei Liang, Taihong Huang, Qing Li, and Peng Song. 2025. "Microstructures and Deep-Drawing Properties of Copper–Steel Bimetallic Sheets Fabricated Using an Arc Spray-Rolling Short Process" Metals 15, no. 4: 400. https://doi.org/10.3390/met15040400

APA StyleYao, T., Bai, J., Kong, D., Zhai, R., Liang, Y., Huang, T., Li, Q., & Song, P. (2025). Microstructures and Deep-Drawing Properties of Copper–Steel Bimetallic Sheets Fabricated Using an Arc Spray-Rolling Short Process. Metals, 15(4), 400. https://doi.org/10.3390/met15040400