Effect of Nano TiO2 Flux on Depth of Penetration and Mechanical Properties of TIG-Welded SA516 Grade 70 Steel Joints—An Experimental Investigation

Abstract

1. Introduction

2. Literature Review

2.1. Fusion Welding of SA516 70 Gd. Alloy

2.2. Activated TIG (A-TIG) Welding of Carbon Steels

2.3. Activated TIG (A-TIG) Welding of Alloy Steels

2.4. A-TIG Welding of Ferrous Alloys Using Nanoparticles

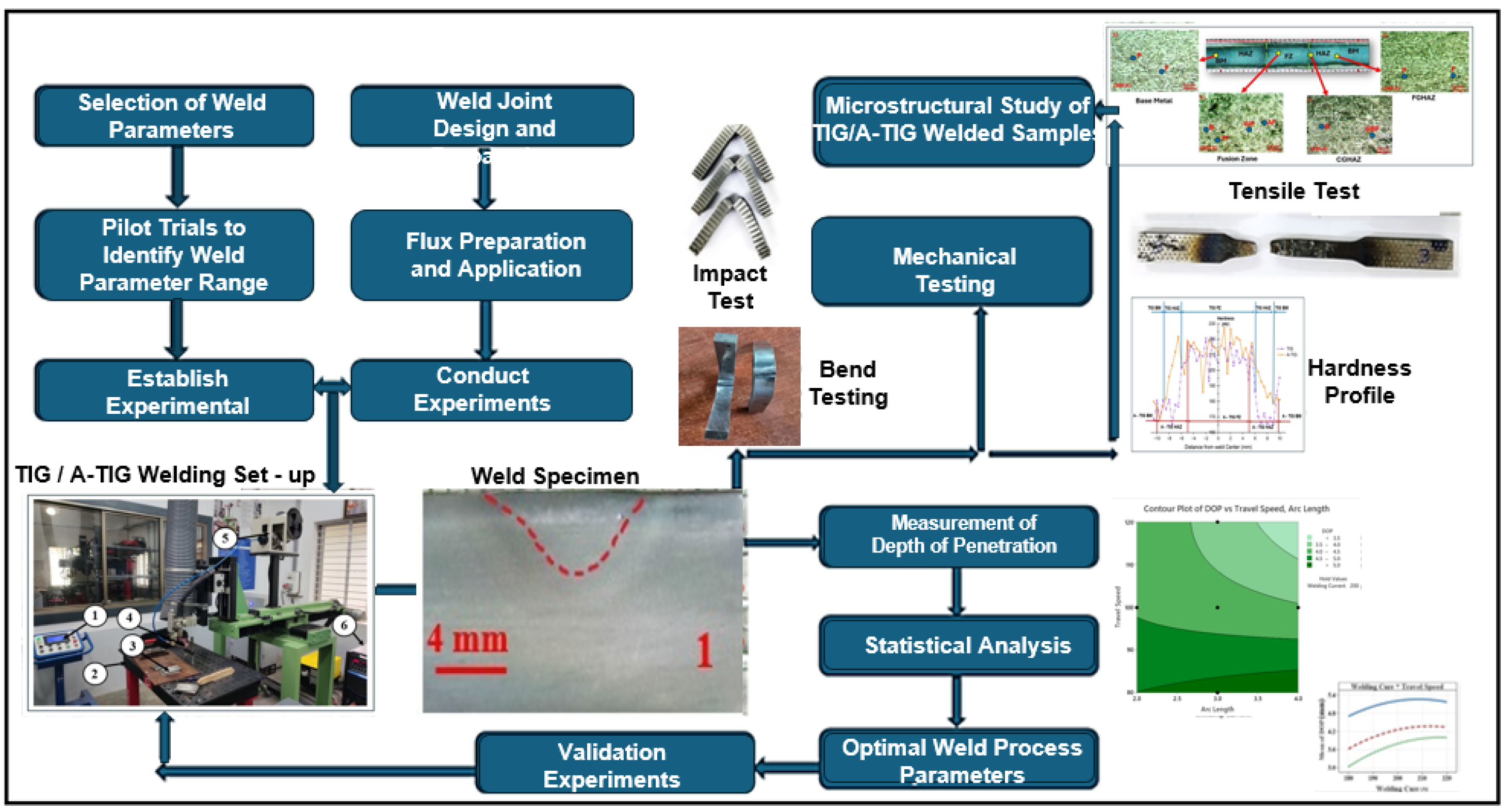

3. Materials and Methods

- Depth of Penetration: evaluating how nano TiO2 flux influences the depth of penetration compared to conventional TIG welding techniques.

- Weld Microstructure: analyzing changes in the weld microstructure resulting from the use of nano TiO2 flux.

- Mechanical Properties: assessing the mechanical properties of the weld, including strength and toughness, with the application of nano TiO2 flux.

- Process Comparison: comparing the novel nano TiO2 flux TIG welding process with traditional TIG welding processes in terms of penetration depth, weld microstructure, mechanical properties, and overall process duration. Through this comprehensive comparison, the research aims to determine the potential benefits and improvements offered by nano TiO2 flux in TIG welding applications.

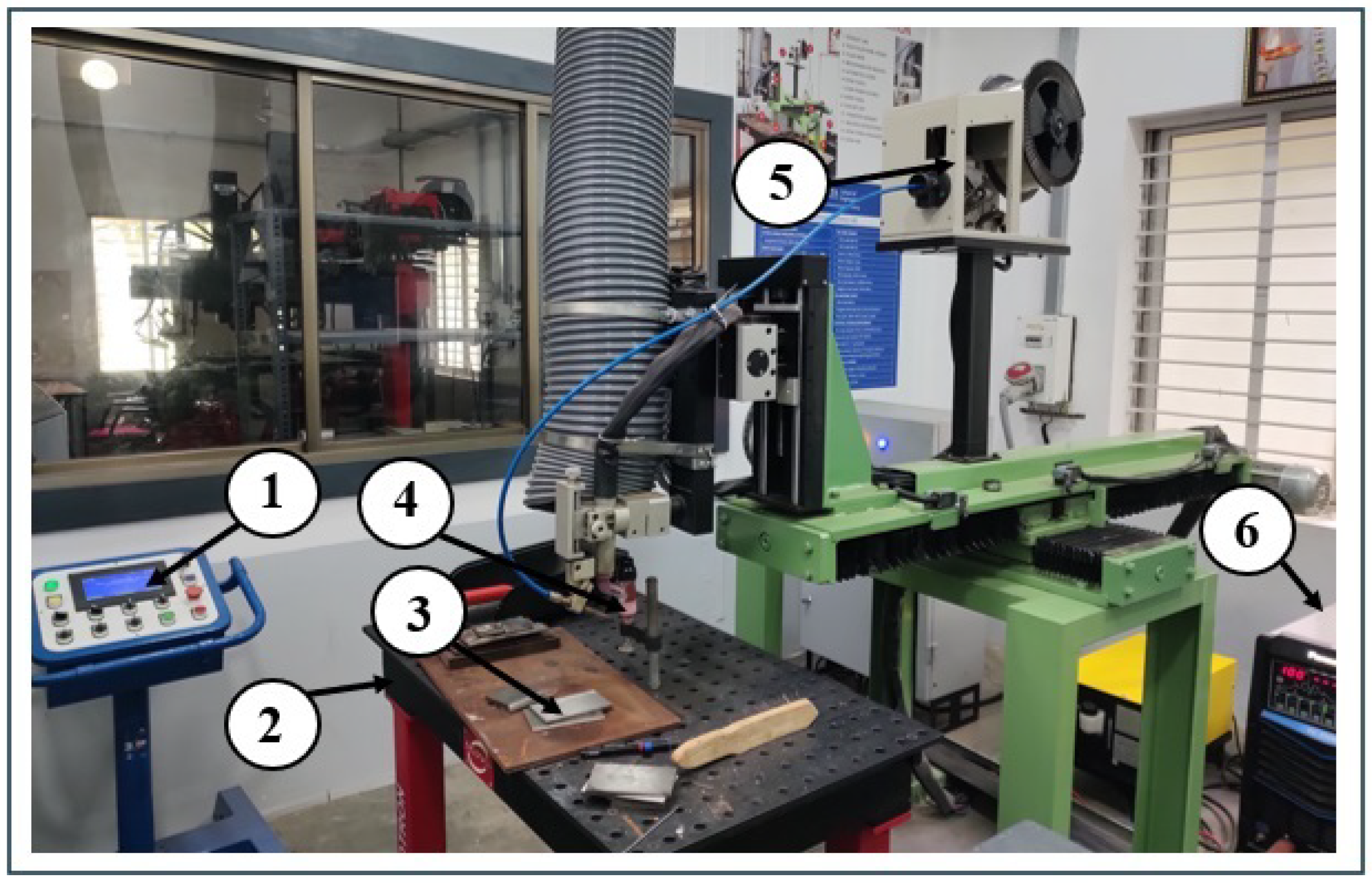

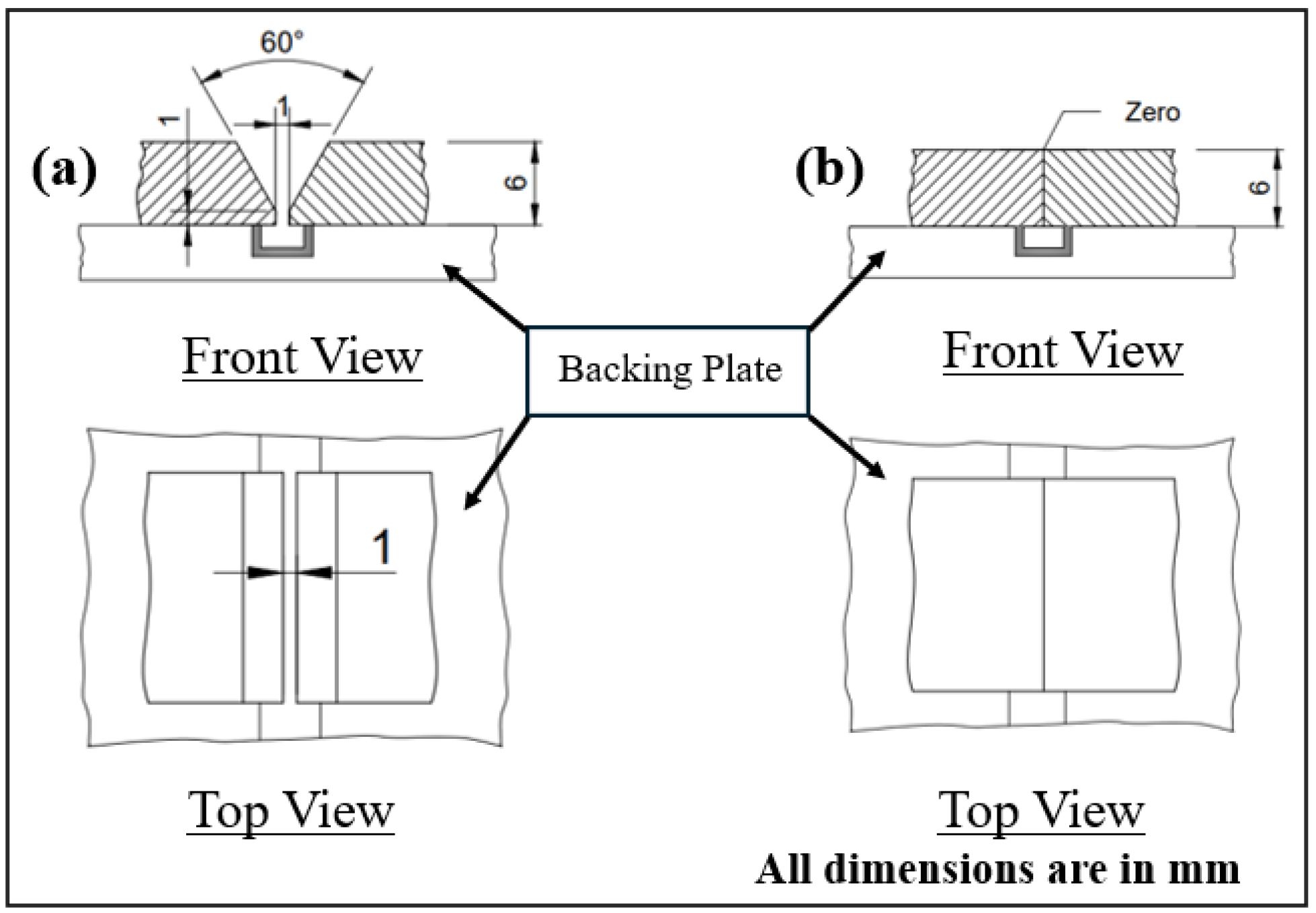

3.1. Experimental Setup

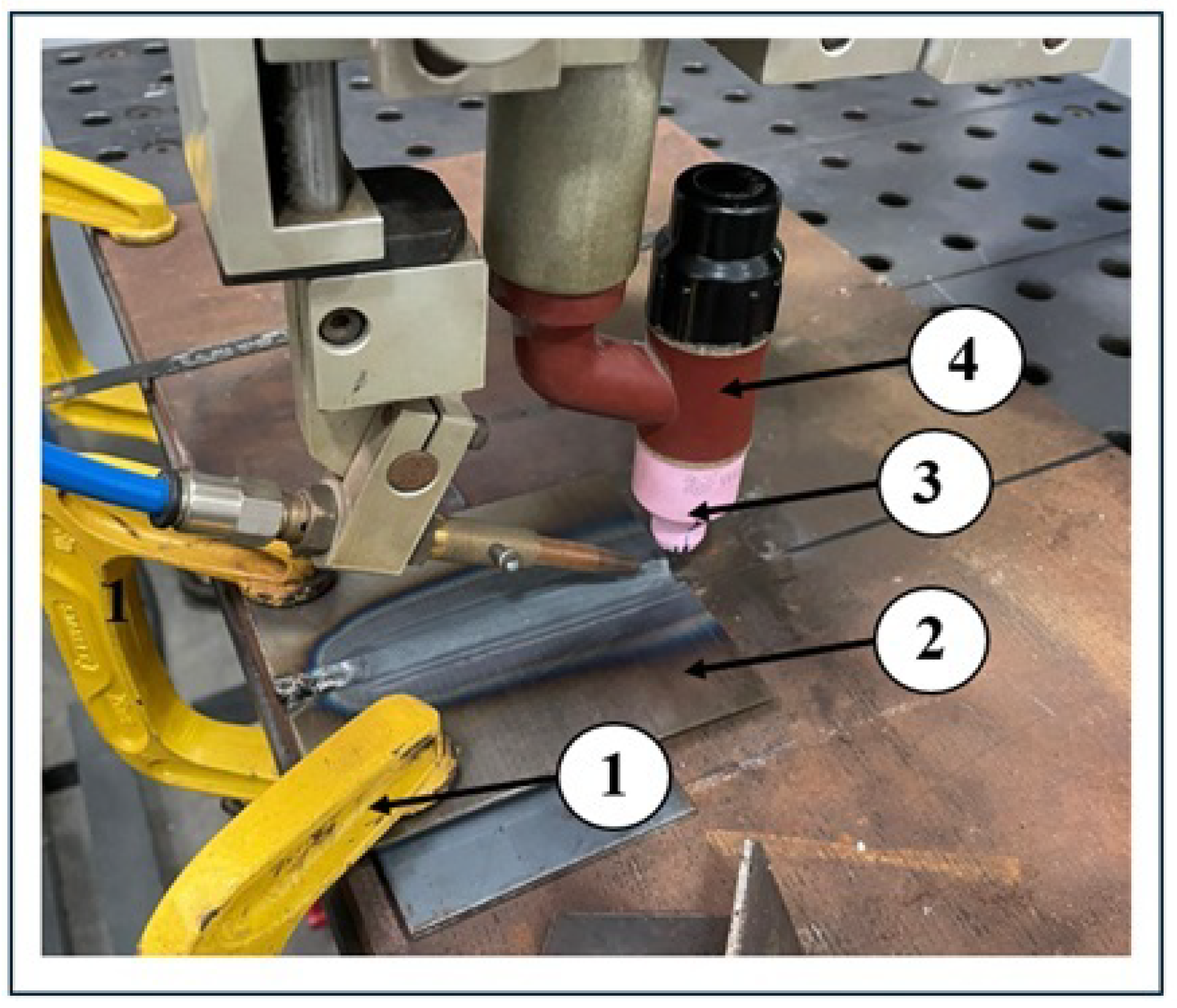

3.2. Application of TiO2 Flux on SA516 70 Gr. Alloy

3.3. Welding Trials

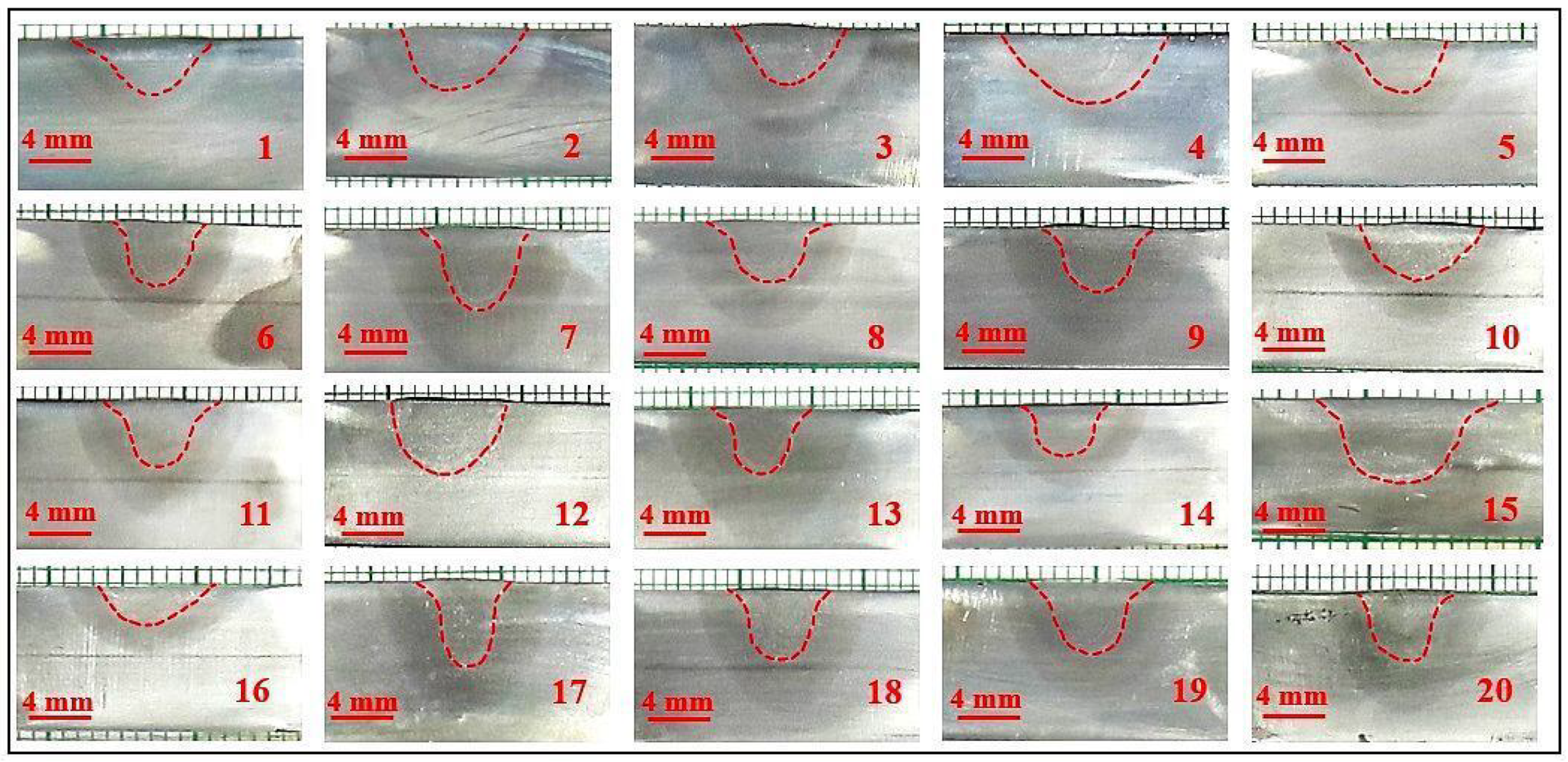

3.4. Design Matrix Based on Central Composite Design

4. Optimization of Weld Parameters Using Response Surface Methodology (RSM)

4.1. TIG Welding of SA516 70 Gd. Carbon Steel

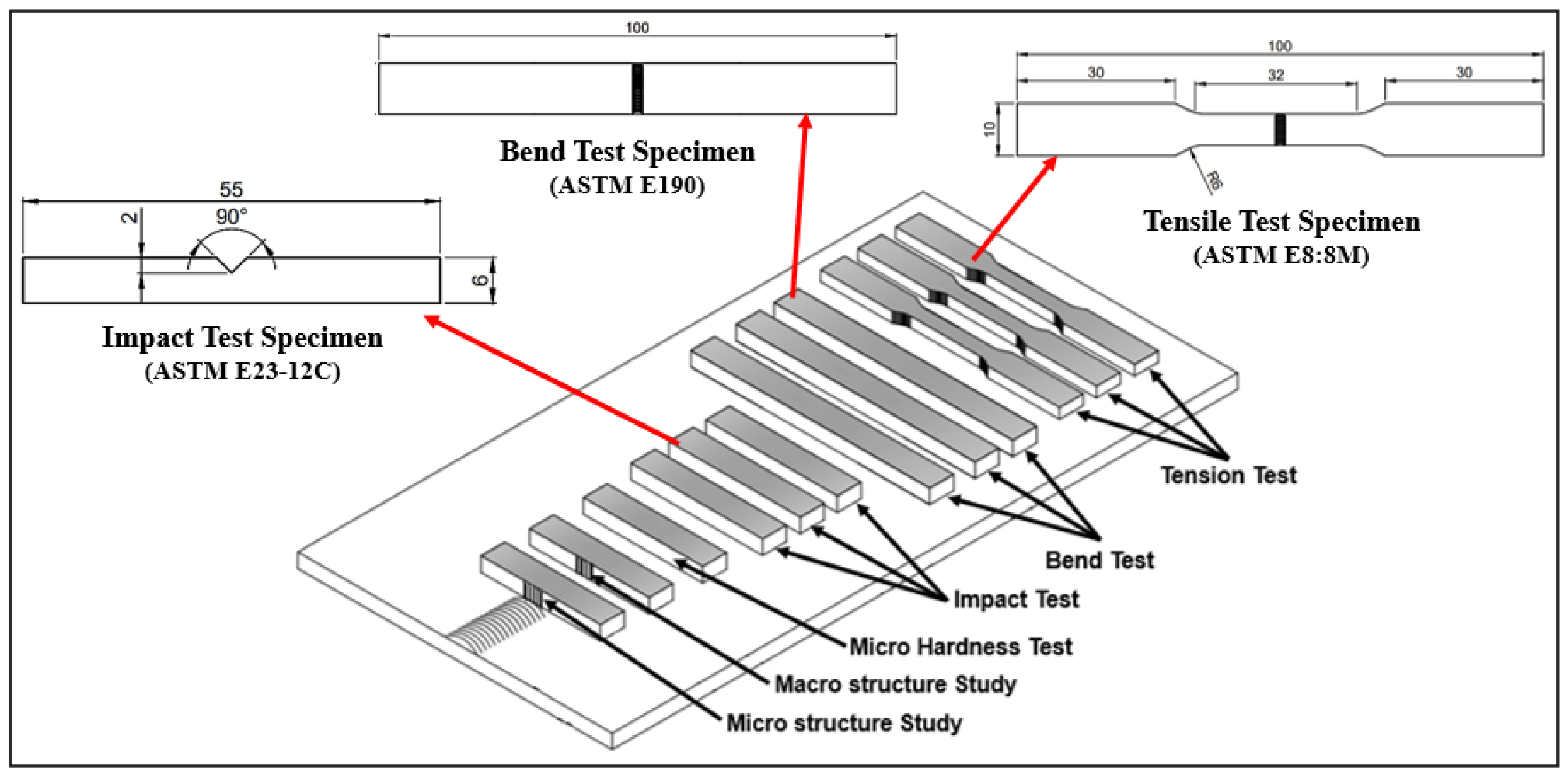

4.2. Mechanical Testing and Microstructural Analysis of Weldment

5. Results and Discussion

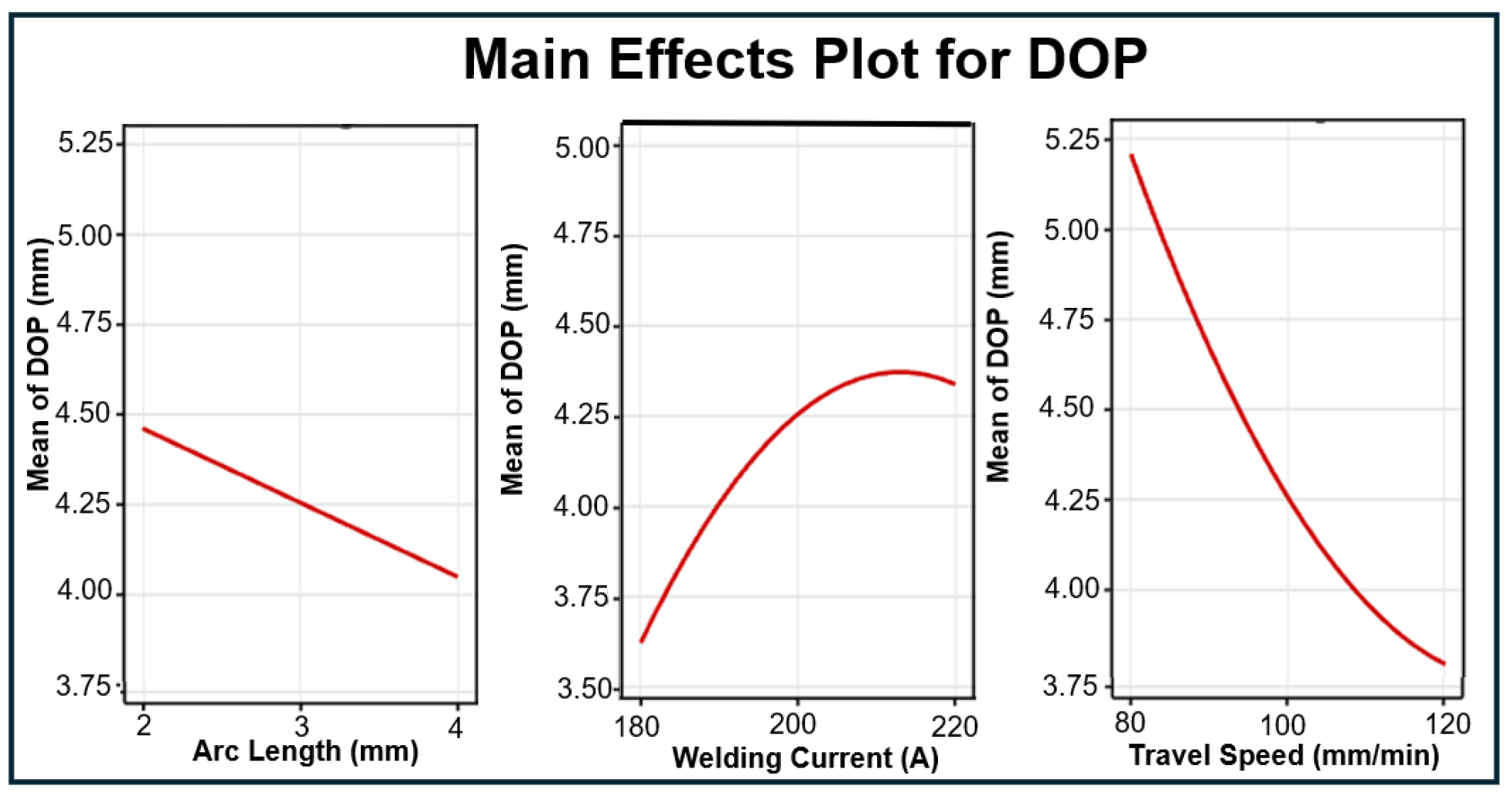

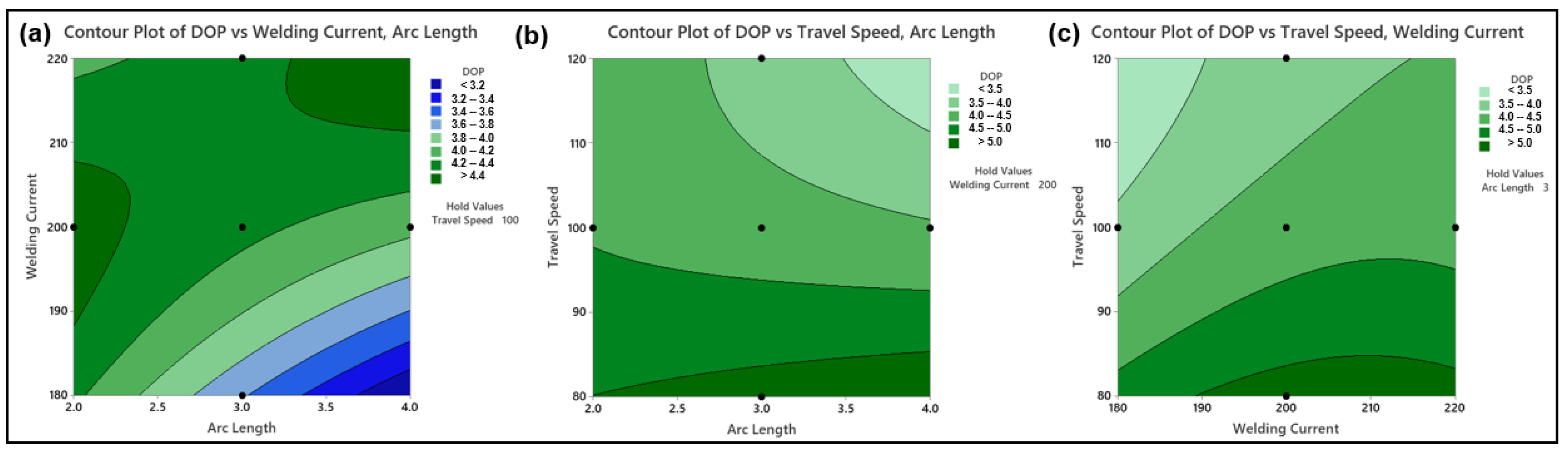

5.1. Effect of Weld Parameters and Flux on the Penetration Depth

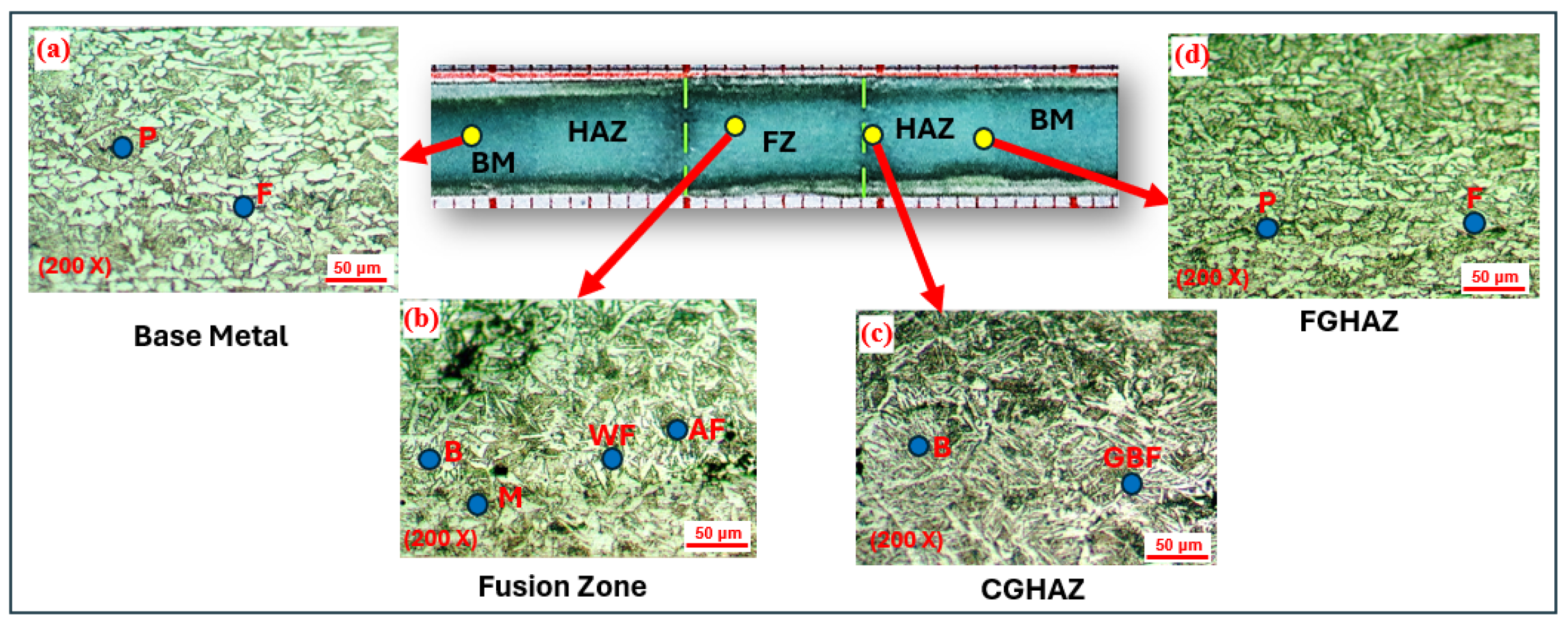

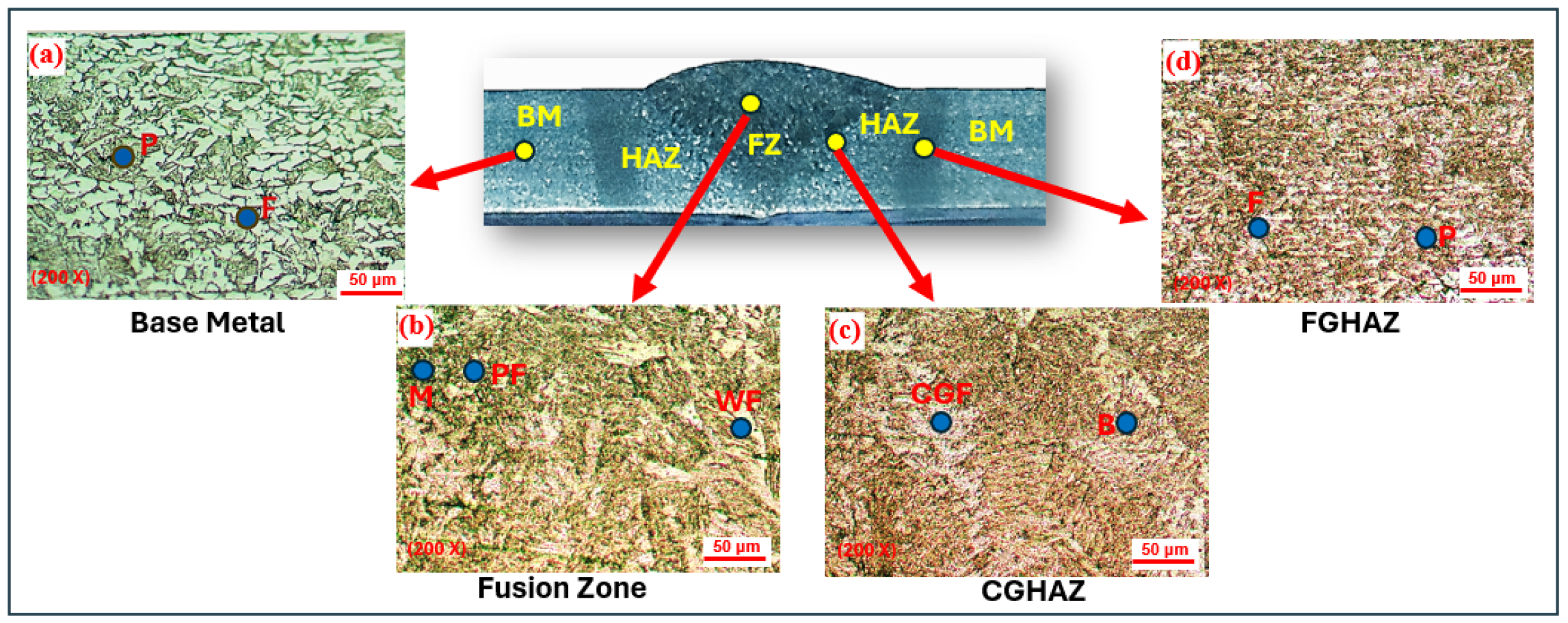

5.2. Metallurgical Analysis of A-TIG and TIG Weldments

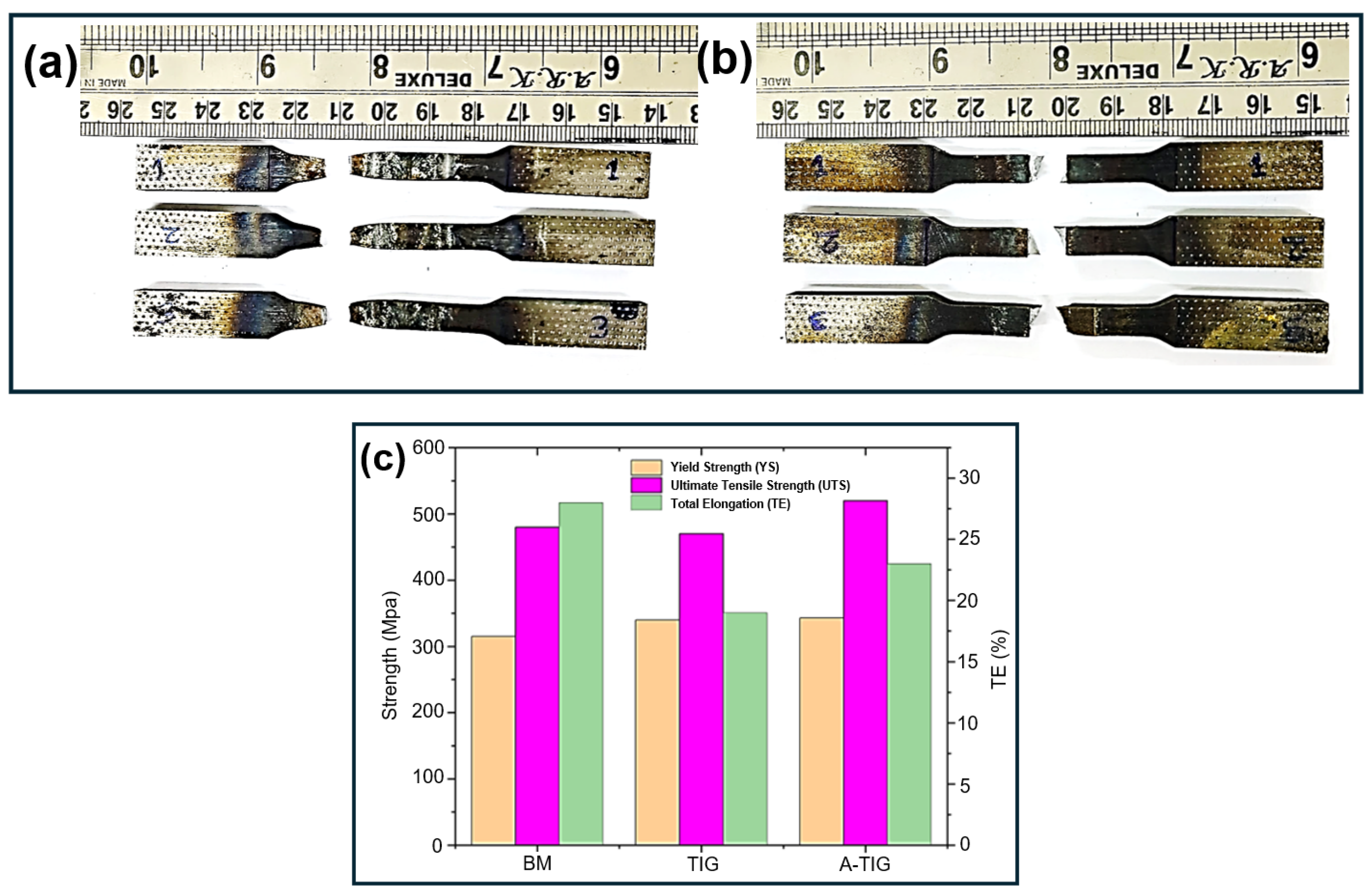

5.3. Tensile Test Results of A-TIG and TIG Weldments

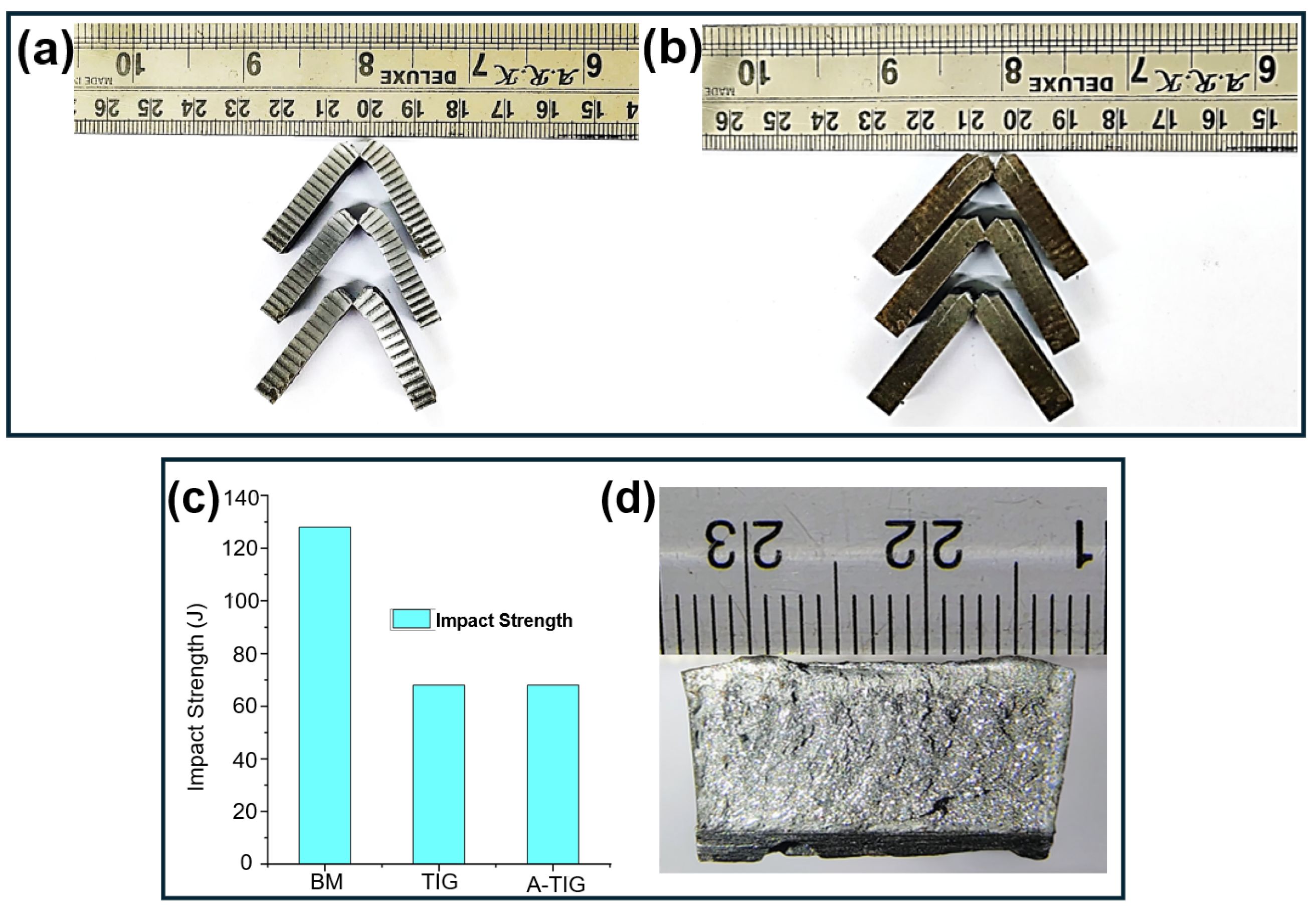

5.4. Impact Test Results of A-TIG and TIG Weldments

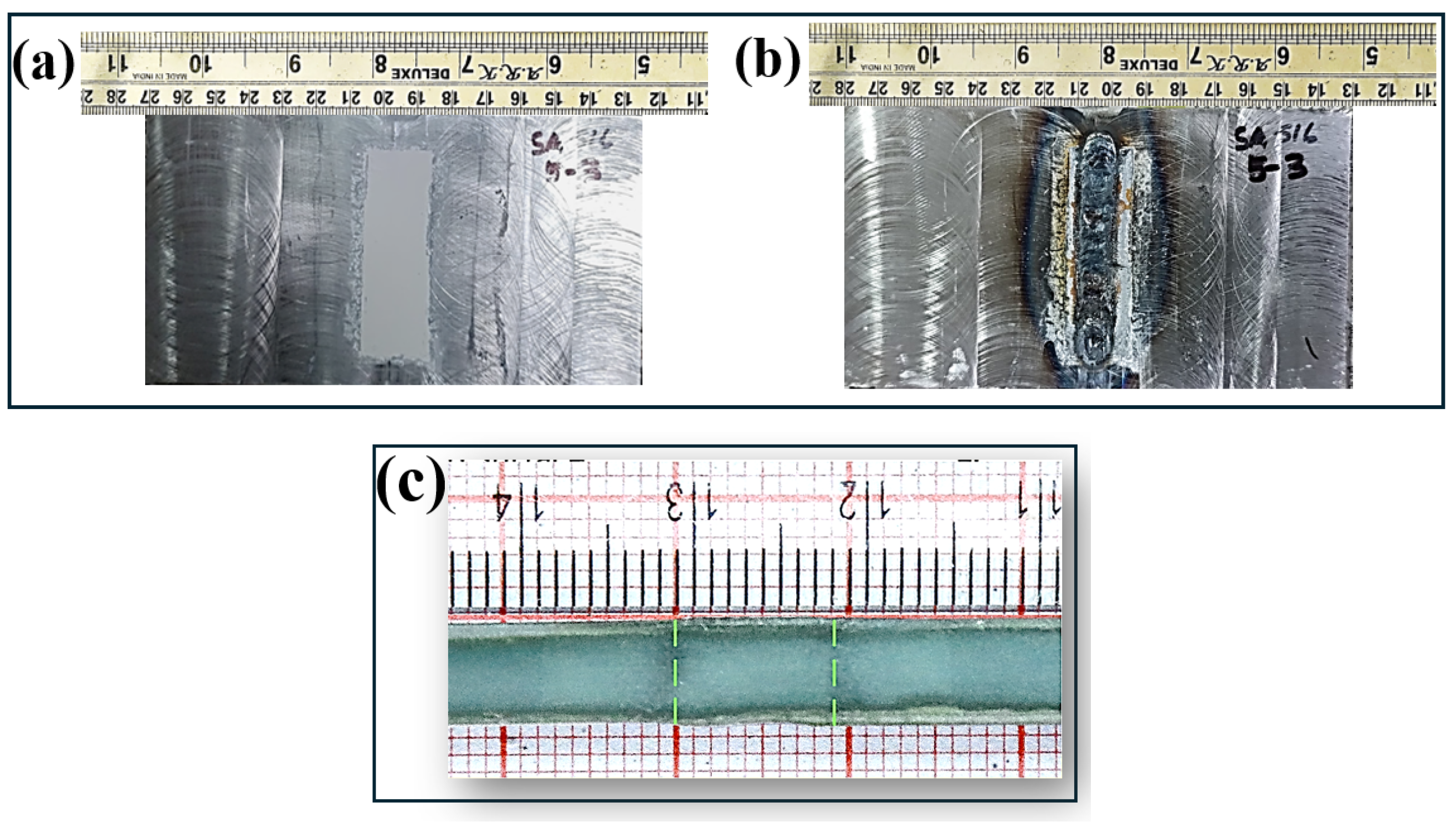

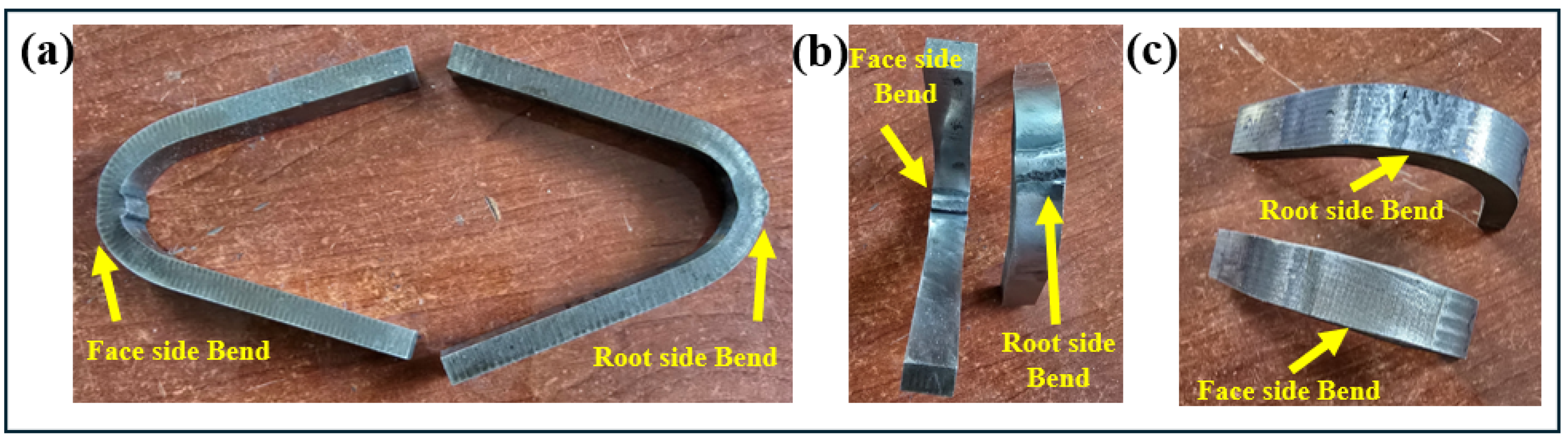

5.5. Bend Test Results of A-TIG and TIG Weldments

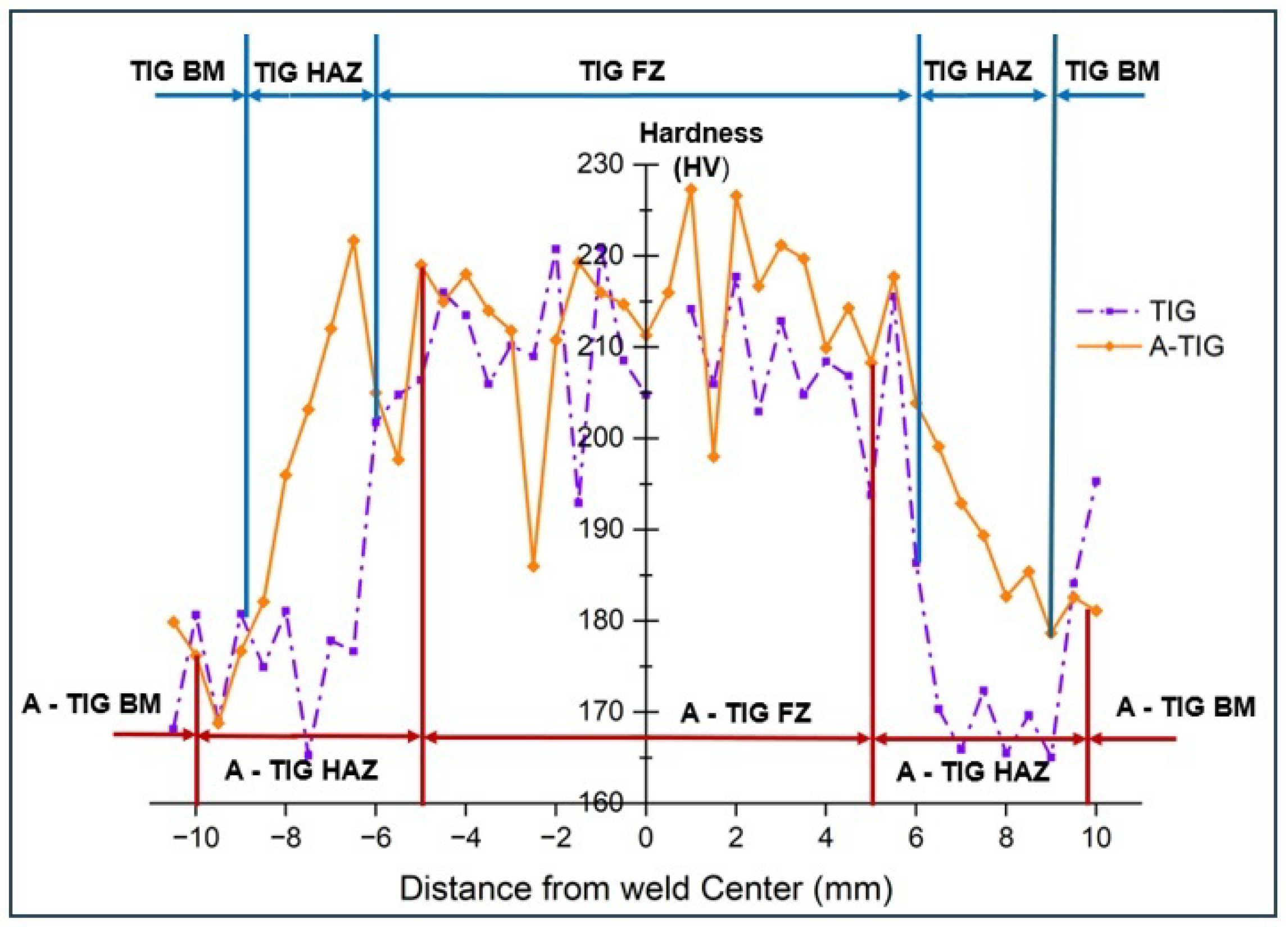

5.6. Hardness Test Results of A-TIG and TIG Weldments

5.7. A-TIG Welding: A Sustainable Solution for Improved Productivity in Welding

5.8. Theoretical and Practical Implications

- Advancing the Knowledge of Nano Flux in Welding: The integration of nano TiO2 flux gives substantial insight into its influence on welding characteristics, including penetration depth, microstructure, and mechanical properties. The new application technique of nano flux opens up new avenues for theoretical exploration in this direction to ensure better weld quality and industrial efficiency.

- Refinement of Welding Parameter Optimization Models: This study will contribute to the development of more robust theoretical models that use RSM to optimize the critical welding parameters, such as arc length, welding current, and travel speed. These refined models offer enhanced understanding of how welding parameters affect the penetration depth and mechanical qualities, advancing the theoretical frameworks for welding optimization.

- Insights into Microstructure and Mechanical Behavior: The study gives in-depth theoretical insight into the development of specific microstructures, including acicular ferrite, Widmanstätten ferrite, and bainite in A-TIG weldments. This understanding clearly explains how the changes in microstructure give rise to changes in the most important mechanical properties, such as strength, ductility, and toughness, thus strengthening the metallurgical base of welding science.

- Sustainability and Efficiency in Welding: The theoretical frameworks emanating from this study depict the potential of nano TiO2 flux to enhance sustainability in welding. Showing that fewer welding passes are required for full penetration and, consequently, less processing time, this study provides support for adopting more energy-efficient and resource-conscious welding practices that are in line with global sustainability goals.

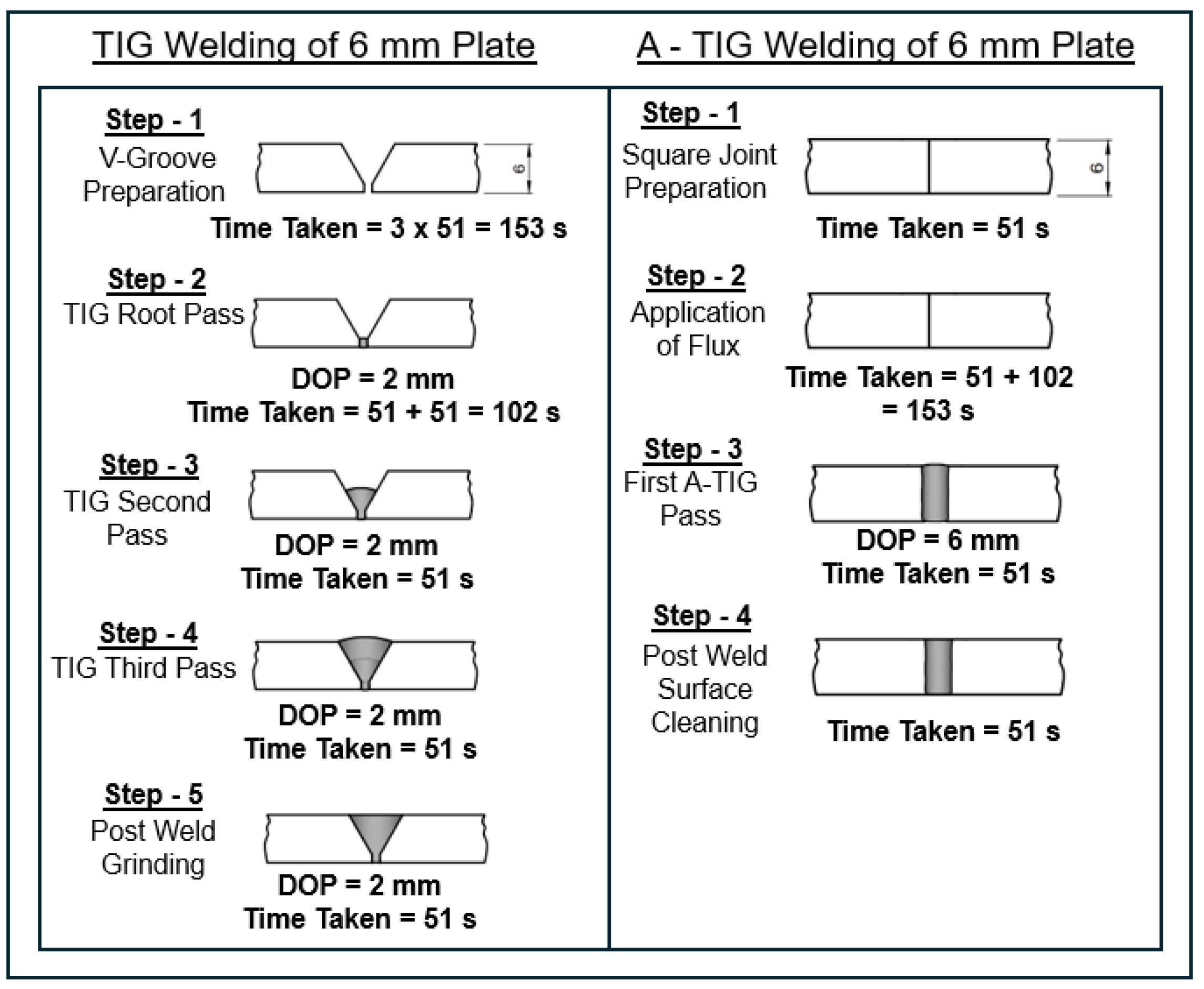

- Increased Welding Productivity: From a practical standpoint, the use of nano TiO2 flux increases productivity because it reduces the number of welding passes required to complete the task, thus reducing the overall process time by 29%. This clearly gives an edge to those industries that involve high-volume manufacturing since it tends to bring down the overall time and production cost.

- Improved Weld Penetration and Quality: By attaining full penetration in a single weld pass, the research work in this paper takes into account the main difficulties in welding thick materials. The results show an improvement in joint quality and a reduction in supplementary passes, while at the same time, defects in the HAZ are decreased.

- Improved Mechanical Properties: A-TIG welding with nano TiO2 flux gives mechanical benefits of increased tensile strength, ductility, and hardness. A-TIG welds have a tensile strength of 520 MPa, while only 470 MPa was obtained using the traditional TIG method. All the enhanced properties make the A-TIG welding process very attractive in applications requiring supreme mechanical performances.

- Cost Efficiency and Resource Utilization: The reduced welding time achieved with A-TIG translates into large cost savings and improved resource efficiency. Industries can achieve better productivity without compromising weld quality by lowering operational expenses through an increase in manufacturing throughput.

- Sustainable Industrial Applications: The adoption of nano TiO2 flux as a cost-effective alternative to conventional TIG welding offers huge practical benefits to industries relying on SA516 Grade 70 steel, including power generation, pressure vessel fabrication, and structural engineering. Furthermore, the reduction in energy consumption and resource efficiency obtained with fewer welding passes contributes to sustainable manufacturing practices and helps promote environmentally responsible industrial operations.

6. Conclusions

- From the ANOVA, out of the three input parameters, the travel speed has the most influence on depth of penetration, followed by welding current and arc length.

- A full penetration of 6 mm was attained in a single weld pass during TIG welding of SA516 70 Gd. alloy with nano TiO2 flux for a travel speed of 80 mm/min, welding current of 220 A, and arc length of 4 mm, whereas three weld passes were necessary to obtain the same penetration without the flux under the identical process parameters.

- The base metal SA516 70 Gd. alloy comprises a combination of pearlite and ferrite. In A-TIG weldments, the fusion zone predominantly comprises acicular ferrite, Widmanstätten ferrite, and minor quantities of Bainite and Martensite, whereas the CGHAZ consists of bainite and grain boundary ferrite, and the FGHAZ comprises fine-grained pearlite and ferrite.

- The TIG weldment’s fusion zone comprises Martensite and Widmanstätten ferrite, whereas the CGHAZ is distinguished by coarse-grained ferrite, Bainite, and Martensite, and the FGHAZ exhibits a refined blend of fine Pearlite and Ferrite.

- In comparison to the base metal (480 MPa) and TIG-welded (470 MPa) specimens, the A-TIG-welded specimen demonstrated enhanced ductility and better tensile strength (520 MPa). The TIG weld’s martensitic fusion zone causes decreased ductility and toughness, whereas the acicular ferrite microstructure of the A-TIG weld enhances toughness and tensile characteristics.

- The base metal demonstrated an impact toughness of 128 J, but the TIG and A-TIG weldments showed a lower toughness of 68 J. While the coarse microstructures and martensite in the welds led to poorer toughness and increased brittleness, the base metal’s ferrite-pearlite microstructure provided a better balance of strength and ductility.

- The hardness profiles of the A-TIG and TIG weldments for SA516 Grade 70 carbon steel indicated that the A-TIG weld exhibited marginally greater hardness in the fusion zone (214 HV) than the TIG weld (209 HV). Hardness reduced towards the base metal due to the presence of acicular ferrite in the fusion zone, coarse Bainite in the heat-affected zone, and softer ferrite and Pearlite in the base metal and fine-grained heat-affected zone, which enhanced ductility.

- The three-point bend test, conducted as per the ASTM E190 standard, evaluated the ductility and integrity of A-TIG and TIG weldments. All four A-TIG specimens passed the bend test showing no discontinuity after a 180° face bend. Both TIG-welded specimens also passed the test without defects. The results, meeting ASME Section IX:2023 criteria, confirm A-TIG welding as a qualified process for fabricating SA516 Grade 70 pressure vessel material.

- The A-TIG welding process requires 29% less time than TIG welding to join a 6 mm plate from one side.

Future Scope of the Study

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Patel, S.; Patel, P.; Mehta, V. Experimental Study of the Effect of Heat Input on Mechanical Properties of TIG Welded Joints of SA516 Grade 70 Material. Int. J. Res. Sci. Innov. 2017, IV, 29–35. [Google Scholar]

- Niagaj, J. Influence of activated fluxes on the bead shape of A-TIG welds on carbon and low-alloy steels in comparison with stainless steel AISI 304L. Metals 2021, 11, 530. [Google Scholar] [CrossRef]

- Paul, B.C.; Saha, S.; Das, S. Productivity Benefits in Employing SiO2 Flux-Based Activated TIG Welding for Joining Thicker Components. In Advances in Additive Manufacturing and Metal Joining: Proceedings of AIMTDR 2021; Springer: Singapore, 2023; pp. 423–434. [Google Scholar]

- ISO 9692-1:2013; Welding and Allied Processes—Recommendations for Joint Preparation—Part 1: Manual Metal Arc Welding, Gas-Shielded Metal Arc Welding, Gas Welding, TIG Welding and Beam Welding of Steels. International Organization for Standardization: Geneva, Switzerland, 2013. Available online: https://cdn.standards.iteh.ai/samples/62520/3c8a9a9f80e740aaa5f8f0a8979bb96d/ISO-9692-1-2013.pdf (accessed on 24 March 2025).

- Thilipkumar, K.; Sellamuthu, R.; Saravanan, R. An investigation on the microstructure, wear rate and hardness of Surface alloying Ni-Hard 4 cast iron with Tungsten Using GTA. Mater. Today Proc. 2020, 24, 548–556. [Google Scholar]

- Rakesh, N.; Rameshkumar, K. Activated flux induced Tungsten inert gas welding of Ferrous alloys—A Review. J. Phys. Conf. Ser. 2022, 2272, 012020. [Google Scholar]

- Shakya, P.; Singh, K.; Arya, H.K. Influence of External Magnetic Field on Mechanical and Metallurgical Properties of Pressure Vessel Steel (SA 516 Grade 70) Welds Using Gas Tungsten Arc Welding. J. Press. Vessel. Technol. 2023, 145, 061504. [Google Scholar]

- de Barros, R.d.M.C.; das Neves, M.D.M. Residual Stress and Fracture Toughness Study in A516 Gr70 Steel Joints Welded and Repaired by Arc Processes. Engineering 2023, 15, 749–758. [Google Scholar]

- ASTM A516/A516M-17; Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service. ASTM International: West Conshohocken, PA, USA, 2017.

- Taraphdar, P.K.; Mahapatra, M.M.; Pradhan, A.K.; Singh, P.K.; Sharma, K.; Kumar, S. Evaluation of through-thickness residual stresses and microstructure in SA516 Gr. 70 steel welds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 958–973. [Google Scholar]

- Salah, A.N.; Kaddami, M. Effect of Filler Metal Diameter on Weld Joint of Carbon Steel SA516 Gr 70 and Filler Metal SFA 5.17 in Submerged Arc Welding SAW. Int. J. Mater. Metall. Eng. 2019, 13, 114–117. [Google Scholar]

- Hall, A.M. The Effect of Welding Speed on the Properties of ASME SA516 Grade 70 Steel. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2010. [Google Scholar]

- Amanie, J.; Oguocha, I.; Yannacopoulos, S. Effect of submerged arc welding parameters on microstructure of SA516 steel weld metal. Can. Metall. Q. 2012, 51, 48–57. [Google Scholar]

- Tathgir, S.; Bhattacharya, A.; Bera, T.K. Influence of current and shielding gas in TiO2 flux activated TIG welding on different graded steels. Mater. Manuf. Processes 2015, 30, 1115–1123. [Google Scholar]

- Tathgir, S.; Bhattacharya, A. Activated-TIG welding of different steels: Influence of various flux and shielding gas. Mater. Manuf. Processes 2016, 31, 335–342. [Google Scholar]

- Kurtulmus, M. Effects of welding parameters on penetration depth in mild steel A-TIG welding. Sci. Iran. 2019, 26, 1400–1404. [Google Scholar]

- Rakesh, N.; Mohan, A.; Navaf, P.; Harisankar, M.; Nambiar, S.J.; Harikrishnan, M.; Devadathan, J.; Rameshkumar, K. Effect of fluxes on weld penetration during TIG welding—A review. Mater. Today Proc. 2023, 72, 3040–3048. [Google Scholar]

- Savytsky, O.; Savytsky, M.; Bajić, D.; Shkrabalyur, Y. Influence of the impurities on the depth of penetration with carbon steel weldings. Metalurgija 2014, 53, 167–170. [Google Scholar]

- Vora, J.; Patel, V.K.; Srinivasan, S.; Chaudhari, R.; Pimenov, D.Y.; Giasin, K.; Sharma, S. Optimization of activated tungsten inert gas welding process parameters using heat transfer search algorithm: With experimental validation using case studies. Metals 2021, 11, 981. [Google Scholar] [CrossRef]

- Vora, J.J.; Abhishek, K.; Srinivasan, S. Attaining optimized A-TIG welding parameters for carbon steels by advanced parameter-less optimization techniques: With experimental validation. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 261. [Google Scholar]

- Arivazhagan, B.; Vasudevan, M. Studies on A-TIG welding of 2.25 Cr-1Mo (P22) steel. J. Manuf. Processes 2015, 18, 55–59. [Google Scholar]

- Dhandha, K.H.; Badheka, V.J. Comparison of mechanical and metallurgical properties of modified 9Cr–1Mo steel for conventional TIG and A-TIG welds. Trans. Indian Inst. Met. 2019, 72, 1809–1821. [Google Scholar]

- Saha, S.; Paul, B.C.; Das, S. Productivity improvement in butt joining of thick stainless steel plates through the usage of activated TIG welding. SN Appl. Sci. 2021, 3, 416. [Google Scholar]

- Acharya, S.; Gonda, D.; Das, S.; Bose, D.; Islam, R. Augmentation of Depth of Penetration and Productivity Benefits of ATIG Welds Using the AHP. Int. J. Anal. Hierarchy Process 2023, 15. [Google Scholar] [CrossRef]

- Sunny, K.T.; Korra, N.N.; Vasudevan, M.; Arivazhagan, B. Parameter optimization and experimental validation of A-TIG welding of super austenitic stainless steel AISI 904L using response surface methodology. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 2608–2617. [Google Scholar]

- Bodkhe, S.C.; Dolas, D.R. Optimization of activated tungsten inert gas welding of 304L austenitic stainless steel. Procedia Manuf. 2018, 20, 277–282. [Google Scholar]

- Arunmani, A.; Senthilkumar, T. Enhancing fatigue resistance of activated tungsten inert gas welded UNS S32750 super duplex stainless steel by optimizing its technological properties. Trans. Can. Soc. Mech. Eng. 2020, 45, 81–91. [Google Scholar]

- Korra, N.N.; Balasubramanian, K.; Vasudevan, M. Optimization of activated tungsten inert gas welding of super duplex alloy 2507 based on experimental results. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1407–1417. [Google Scholar]

- Korra, N.N.; Vasudevan, M.; Balasubramanian, K. Multi-objective optimization of activated tungsten inert gas welding of duplex stainless steel using response surface methodology. Int. J. Adv. Manuf. Technol. 2015, 77, 67–81. [Google Scholar]

- Pandya, D.; Badgujar, A.; Ghetiya, N.; Oza, A.D. Characterization and optimization of duplex stainless steel welded by activated tungsten inert gas welding process. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 1–13. [Google Scholar] [CrossRef]

- Vidyarthy, R.S.; Dwivedi, D.K.; Muthukumaran, V. Optimization of A-TIG process parameters using response surface methodology. Mater. Manuf. Processes 2018, 33, 709–717. [Google Scholar]

- Joseph, J.; Muthukumaran, S. Optimization of activated TIG welding parameters for improving weld joint strength of AISI 4135 PM steel by genetic algorithm and simulated annealing. Int. J. Adv. Manuf. Technol. 2017, 93, 23–34. [Google Scholar]

- Balos, S.; Dramicanin, M.; Janjatovic, P.; Zabunov, I.; Pilic, B.; Goel, S.; Szutkowska, M. Suppressing the use of critical raw materials in joining of AISI 304 stainless steel using activated tungsten inert gas welding. Metals 2019, 9, 1187. [Google Scholar] [CrossRef]

- Balos, S.; Dramicanin, M.; Janjatovic, P.; Zabunov, I.; Klobcar, D.; Busic, M.; Grilli, M.L. Metal oxide nanoparticle-based coating as a catalyzer for A-TIG welding: Critical raw material perspective. Metals 2019, 9, 567. [Google Scholar] [CrossRef]

- Balos, S.; Dramicanin, M.; Janjatovic, P.; Kulundzic, N.; Zabunov, I.; Pilic, B.; Klobčar, D. Influence of metallic oxide nanoparticles on the mechanical properties of an A-TIG welded 304l austenitic stainless steel. Materials 2020, 13, 4513. [Google Scholar] [CrossRef] [PubMed]

- Baloš, S.; Dramićanin, M.; Janjatović, P.; Rajnovic, D.; Kulundžić, N.; Zabunov, I.; Šiđanin, L. Activated flux based on TiO2 nano and micro particles for A-TIG welding. Zavar. Zavarene Konstr. 2024, 69, 17–23. [Google Scholar] [CrossRef]

- Baloš, S.; Dramićanin, M.; Janjatović, P.; Zabunov, I.; Kulundžić, N.; Tabaković, S.; Grabulov, V. Influence of oxide content in activated tungsten inert gas welding. Zavar. Zavarene Konstr. 2022, 67, 181–186. [Google Scholar]

- Zhang, L.; Hu, A. Fe2O3 nanowire flux enabling tungsten inert gas welding of high-manganese steel thick plates with improved mechanical properties. Appl. Sci. 2021, 11, 5052. [Google Scholar] [CrossRef]

- Tseng, K.H.; Lin, P.Y. UNS S31603 stainless steel tungsten inert gas welds made with microparticle and nanoparticle oxides. Materials 2014, 7, 4755–4772. [Google Scholar] [CrossRef]

- Afolalu, S.; Ikumapayi, O.; Emetere, M.; Ongbali, S. Investigation of mechanical properties and characterization of a joint using nano flux powder for a-tig welding. Mater. Today Proc. 2021, 44, 2879–2883. [Google Scholar] [CrossRef]

- Mendez, P.F.; Eagar, T.W. Penetration and defect formation in high-current arc welding. Weld. J. 2003, 82, 296. [Google Scholar]

- ASTM E8/E8M-13a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E23-12c; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM E190-14; Standard Test Method for Guided Bend Test for Ductility of Welds. ASTM International: West Conshohocken, PA, USA, 2014.

- Tsai, N.; Eagar, T. Distribution of the heat and current fluxes in gas tungsten arcs. Metall. Trans. B 1985, 16, 841–846. [Google Scholar]

- Mills, K.; Keene, B.; Brooks, R.; Shirali, A. Marangoni effects in welding. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1998, 356, 911–925. [Google Scholar]

- Yang, Y. The Effect of Submerged arc Welding Parameters on the Properties of Pressure Vessel and Wind Turbine Tower Steels. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2008. [Google Scholar]

- Huang, H.H.; Tsai, W.T.; Lee, J.T. The influences of microstructure and composition on the electrochemical behavior of a516 steel weldment. Corros. Sci. 1994, 36, 1027–1038. [Google Scholar]

- Bhadeshia, H.K.D.H.; Honeycombe, R.W.K. Steels: Microstructure and Properties; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Wang, X.; Miao, Z.; Gong, W.; Lu, G.; Sun, J.; Wang, Y.; Xie, G. Enhanced Toughness and Ductility of Friction Stir Welded SA516 Gr. 70 Steel Joint via Post-Welding Annealing. Materials 2023, 17, 116. [Google Scholar] [CrossRef] [PubMed]

- Manivelmuralidaran, V.; Senthilkumar, K.; Ebby, J.; Prabhu, T.R. Optimisation of parameters influencing cold crack resistance of SAE 950A steel. Sādhanā 2021, 46, 157. [Google Scholar] [CrossRef]

- ASME International. Welding, Brazing, and Fusing Qualifications. In ASME Boiler and Pressure Vessel Code, Section IX, ASME International; ASME International: New York, NY, USA, 2023. [Google Scholar]

- Aravind, A.; Saravanan, R. Improvement in hardness, wear rate and corrosion resistance of silicon bronze using gas tungsten arc. Mater. Today Proc. 2020, 24, 406–414. [Google Scholar] [CrossRef]

| Theme | Source | Relevance to Research Questions | Methodology | Contribution and Insight | Identified Gaps |

|---|---|---|---|---|---|

| Enhancement of Weld Penetration and Microstructural Properties Using Nano TiO2 Flux in A-TIG Welding | Patel et al. [1], Niagaj [2], Paul et al. [3], Balos et al. [33], Balos et al. [36], Tseng et al. [39]. | Addresses RQ 01 through nanoparticle flux impacts on weld penetration. | Experimental study | TiO2-enhanced A-TIG welding improves weld penetration, microstructure, and mechanical properties compared to conventional TIG welding. Marangoni convection enhances penetration depth. | Does not explore long-term performance in pressure vessel applications. Limited large-scale industrial applications. |

| Optimization of A-TIG Welding Parameters (Arc Length, Current, Travel Speed) for Industrial Applications | Vora et al. [19], Hall [12], Tathgir et al. [14,15], Kurtulmus [16], Taraphdar et al. [10] | Supports RQ 02 by analyzing critical factors related to weld penetration and optimization of parameters. | Response Surface Methodology (RSM), Experimental study | Identifies optimal welding parameters for maximizing penetration and efficiency. Confirms that welding speed significantly impacts | Limited real-world industrial validation. Does not account for TiO2 activation effects. |

| Mechanical Performance and Structural Integrity of A-TIG Welds for Pressure Vessel Applications | Arivazhagan et al. [21], Dhandha et al. [22], Saha et al. [23], Amanie et al. [13], Shakya et al. [7], Barros et al. [8]. | RQ 03 by linking improvements to pressure vessel properties. | Metallurgical and mechanical property study. | Demonstrates improved hardness, toughness, and integrity of A-TIG welds, making them suitable for pressure vessel applications. Examines welding speed and current influence on SA516 Grade 70 steel. | Lacks direct comparison between A-TIG and conventional TIG for pressure vessel applications. Sustainability impact not thoroughly assessed. |

| Defects, Penetration Behavior, and Sustainability Aspects of A-TIG Welding | Mendez et al. [41], Saha et al. [23], Acharya et al. [24] | Examines flux effects on weld penetration and microstructure for RQ 01, RQ 03 by examining mechanical durability and sustainability. | Experimental and numerical study. | Examines penetration defects in high-current welding. Demonstrates that A-TIG reduces welding time and energy consumption while maintaining high strength. | Does not specifically cover TiO2 flux effects. Sustainability impact not thoroughly assessed. |

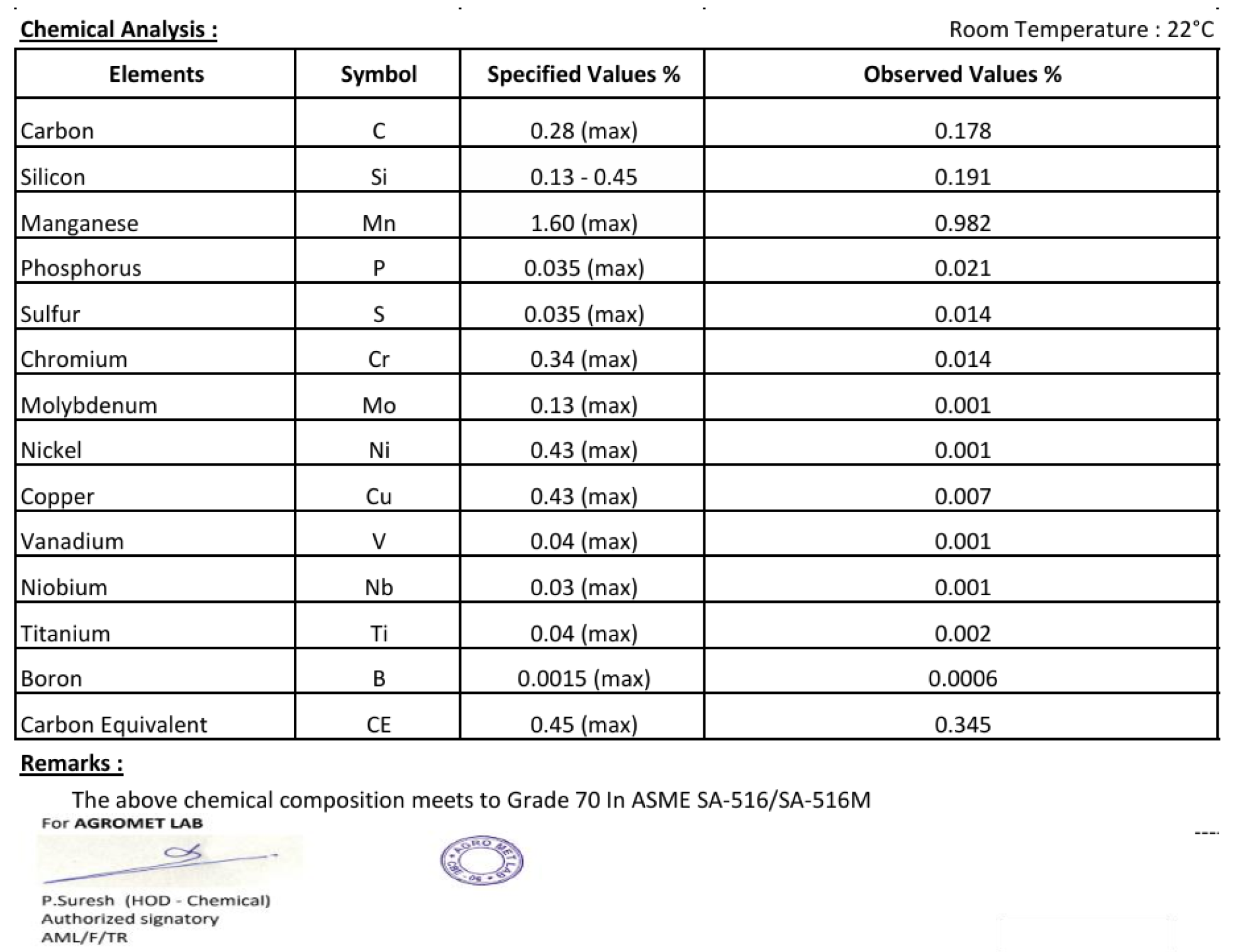

| C | Mn | S | P | Si | Cr | Ni | Cu | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.178 | 0.982 | 0.014 | 0.021 | 0.191 | 0.014 | 0.001 | 0.007 | 0.001 | 0.001 | Balance |

| Levels | ||||

|---|---|---|---|---|

| Notation | Min | Mid | Max | |

| Arc Length (mm) | A | 2 | 3 | 4 |

| Weld Current (A) | C | 180 | 200 | 220 |

| Travel Speed (mm/min) | T | 80 | 100 | 120 |

| Standard Order | RunOrder | Arc Length (mm) | Welding Current (A) | Travel Speed (mm/min) | Bead Depth (mm) |

|---|---|---|---|---|---|

| 15 | 1 | 3 | 180 | 100 | 3.56 |

| 16 | 2 | 3 | 220 | 100 | 4.00 |

| 14 | 3 | 4 | 200 | 100 | 3.52 |

| 18 | 4 | 3 | 200 | 120 | 3.32 |

| 19 | 5 | 3 | 200 | 100 | 4.30 |

| 13 | 6 | 2 | 200 | 100 | 4.56 |

| 17 | 7 | 3 | 200 | 80 | 5.28 |

| 20 | 8 | 3 | 200 | 100 | 4.30 |

| 11 | 9 | 3 | 200 | 100 | 4.30 |

| 10 | 10 | 4 | 220 | 120 | 3.88 |

| 12 | 11 | 3 | 200 | 100 | 4.30 |

| 8 | 12 | 2 | 220 | 80 | 4.34 |

| 7 | 13 | 4 | 180 | 80 | 4.36 |

| 9 | 14 | 2 | 180 | 120 | 3.92 |

| 2 | 15 | 4 | 220 | 80 | 6.10 |

| 3 | 16 | 4 | 180 | 120 | 2.40 |

| 1 | 17 | 2 | 180 | 80 | 5.00 |

| 5 | 18 | 3 | 200 | 100 | 4.30 |

| 4 | 19 | 2 | 220 | 120 | 4.50 |

| 6 | 20 | 3 | 200 | 100 | 4.30 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 10 | 10.1594 | 1.01594 | 13.56 | 0.000 |

| Blocks | 2 | 0.3649 | 0.18244 | 2.43 | 0.143 |

| Linear | 3 | 6.6904 | 2.23012 | 29.76 | 0.000 |

| Arc Length | 1 | 0.4244 | 0.42436 | 5.66 | 0.041 |

| Welding Current | 1 | 1.2816 | 1.28164 | 17.10 | 0.003 |

| Travel Speed | 1 | 4.9844 | 4.98436 | 66.52 | 0.000 |

| Square | 2 | 0.2734 | 0.13668 | 1.82 | 0.216 |

| Two-Way Interaction | 3 | 2.8097 | 0.93658 | 12.50 | 0.001 |

| Arc Length × Welding Current | 1 | 1.3612 | 1.36125 | 18.17 | 0.002 |

| Arc Length × Travel Speed | 1 | 1.3285 | 1.32845 | 17.73 | 0.002 |

| Welding Current × Travel Speed | 1 | 0.1200 | 0.12005 | 1.60 | 0.237 |

| Error | 9 | 0.6744 | 0.07493 | ||

| Lack-of-Fit | 6 | 0.6744 | 0.11240 | * | * |

| Pure Error | 3 | 0.0000 | 0.00000 | ||

| Total | 19 | 10.8338 | |||

| 0.9370 | |||||

| Adjusted | 0.8686 |

| Parameter | Value/Specification |

|---|---|

| Welding Current (I) | 220 A |

| Arc Length | 4 mm |

| Travel Speed (TS) | 80 mm/min (1.33 mm/s) |

| Shielding Gas | Argon (10 L/min) |

| Electrode Type | 2% Thoriated Tungsten (3 mm) |

| Electrode Polarity | DCEN (Direct Current Electrode Negative) |

| Filler Material | ER70S-6 (1.2 mm diameter) (for GTAW) |

| Flux Composition | TiO2 nano-flux |

| Flux Thickness | 0.15 mm (applied using blade-coating method) |

| Joint Configuration | SinglePatel-pass square butt weld (zero root gap) |

| Sl. No. | Sample | Position | Thickness (mm) | Discontinuity | Result | Image |

|---|---|---|---|---|---|---|

| 1 | A-TIG | Face | 5 | No | Acceptable |  |

| 2 | A-TIG | Face | 6 | No | Acceptable |  |

| 3 | TIG | Face | 6 | No | Acceptable |  |

| 4 | A-TIG | Root | 5 | No | Acceptable |  |

| 5 | TIG | Root | 6 | No | Acceptable |  |

| 6 | A-TIG | Root | 6 | No | Acceptable |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narayanan, R.; Rameshkumar, K.; Sumesh, A.; Shankar, B.; Thekkuden, D.T. Effect of Nano TiO2 Flux on Depth of Penetration and Mechanical Properties of TIG-Welded SA516 Grade 70 Steel Joints—An Experimental Investigation. Metals 2025, 15, 399. https://doi.org/10.3390/met15040399

Narayanan R, Rameshkumar K, Sumesh A, Shankar B, Thekkuden DT. Effect of Nano TiO2 Flux on Depth of Penetration and Mechanical Properties of TIG-Welded SA516 Grade 70 Steel Joints—An Experimental Investigation. Metals. 2025; 15(4):399. https://doi.org/10.3390/met15040399

Chicago/Turabian StyleNarayanan, Rakesh, Krishnaswamy Rameshkumar, Arangot Sumesh, Balakrishnan Shankar, and Dinu Thomas Thekkuden. 2025. "Effect of Nano TiO2 Flux on Depth of Penetration and Mechanical Properties of TIG-Welded SA516 Grade 70 Steel Joints—An Experimental Investigation" Metals 15, no. 4: 399. https://doi.org/10.3390/met15040399

APA StyleNarayanan, R., Rameshkumar, K., Sumesh, A., Shankar, B., & Thekkuden, D. T. (2025). Effect of Nano TiO2 Flux on Depth of Penetration and Mechanical Properties of TIG-Welded SA516 Grade 70 Steel Joints—An Experimental Investigation. Metals, 15(4), 399. https://doi.org/10.3390/met15040399