A Feature Extraction Algorithm for Corner Cracks in Slabs Based on Multi-Scale Adaptive Gradient Descent

Abstract

1. Introduction

2. Related Work

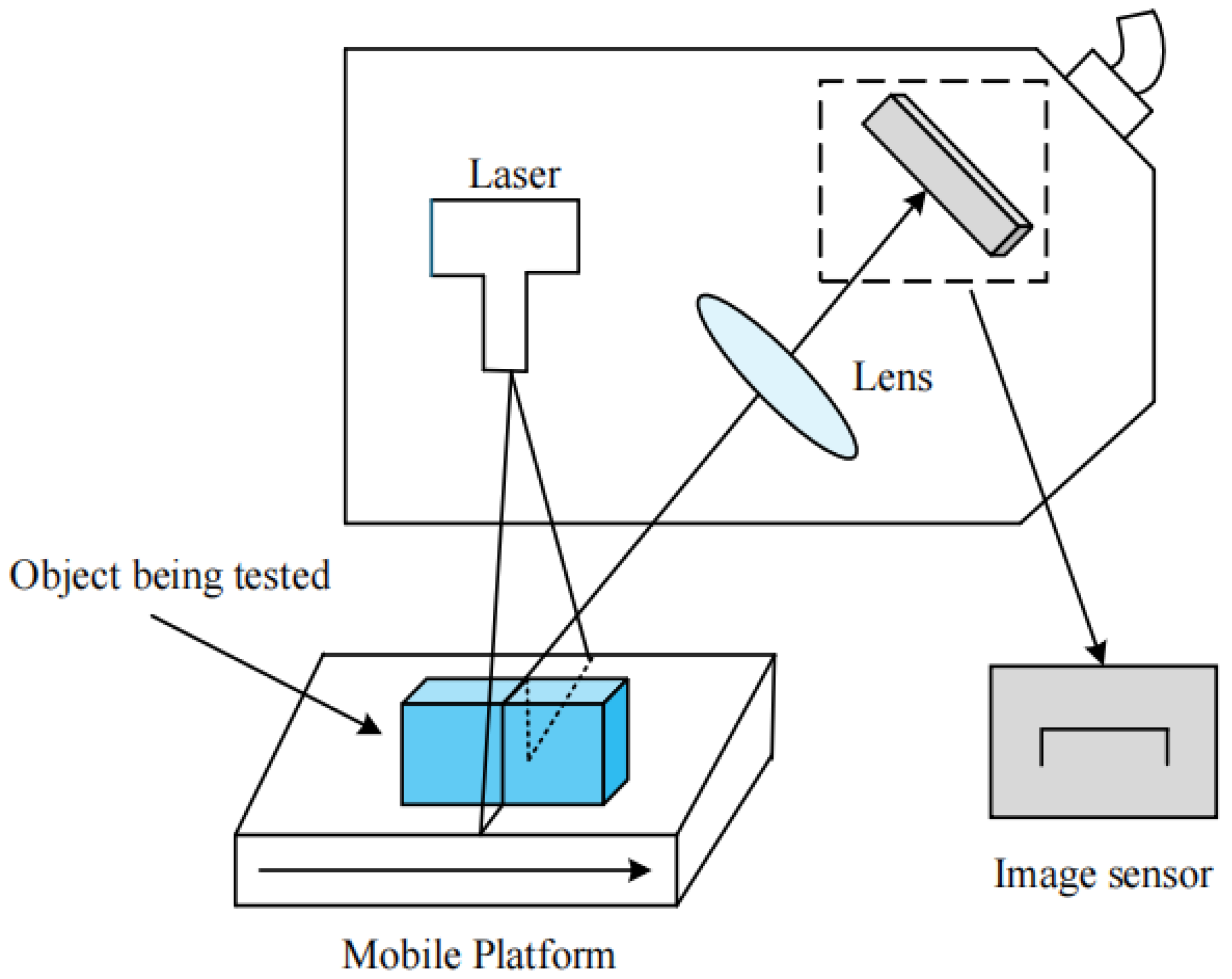

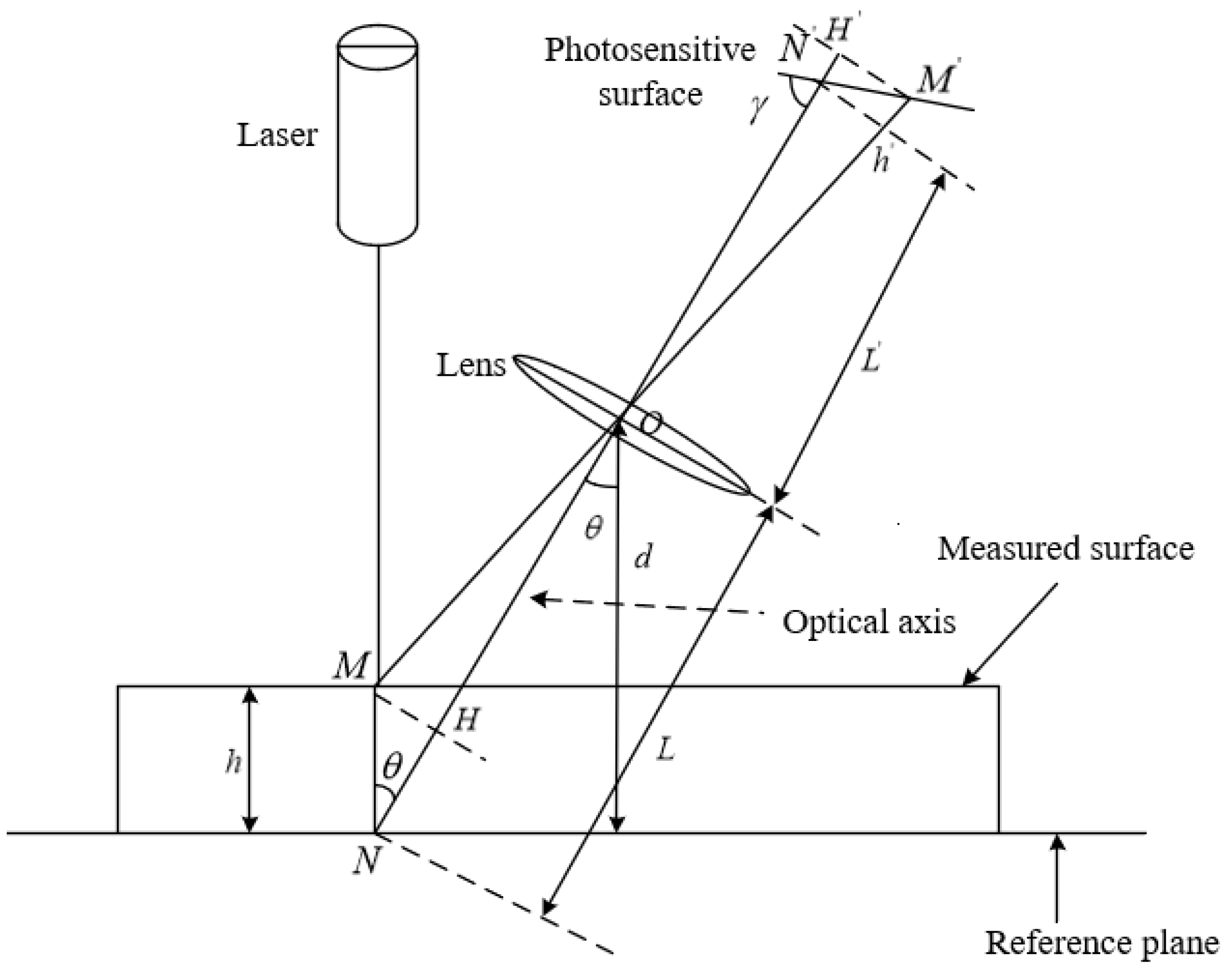

2.1. Detection Principle

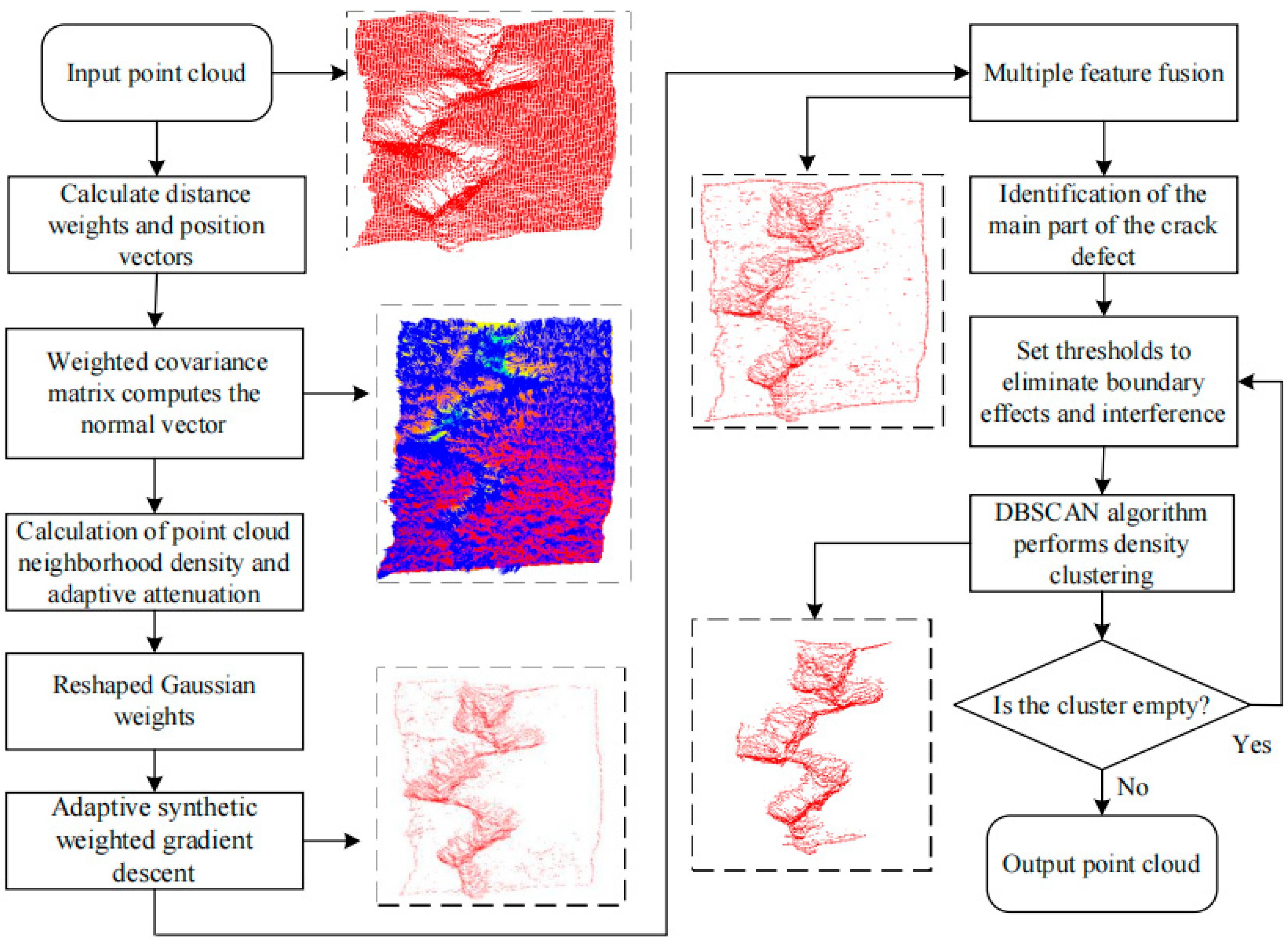

2.2. Algorithm Flow

2.3. Normal Weighted Covariance Calculation

- (1)

- The weight and local position vector are calculated:

- (2)

- The weighted covariance matrix is calculated:

- (3)

- Normal calculation and normalization:

2.4. Adaptive Weighted Gradient Descent

2.4.1. Gradient Descent

2.4.2. Improved Gradient Descent Method

- (1)

- Density calculation in regard to the point cloud neighborhood:

- (2)

- Normal change rate calculation:

- (3)

- Adaptive attenuation rate calculation:

- (4)

- Comprehensive weight construction:

- (5)

- Adaptive Comprehensive Weighted Gradient Descent:

- (6)

- Multi-scale Feature Extraction and Detection:

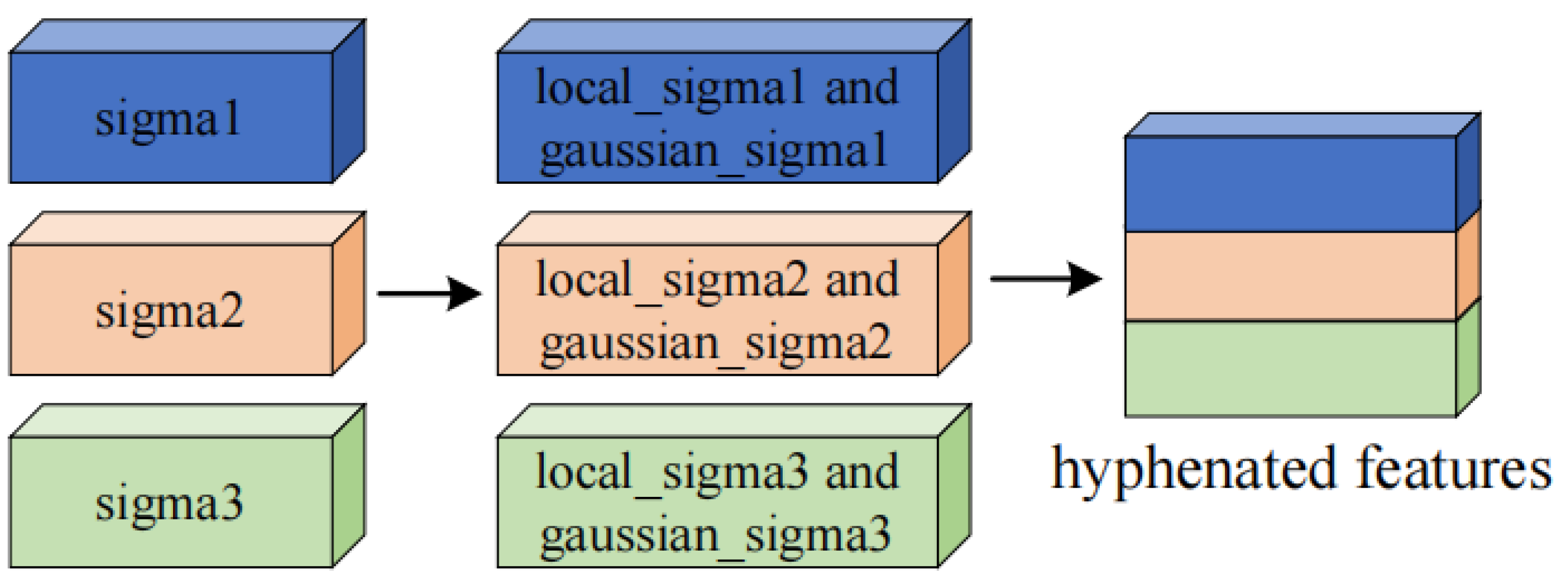

2.5. Multi-Scale Feature Fusion

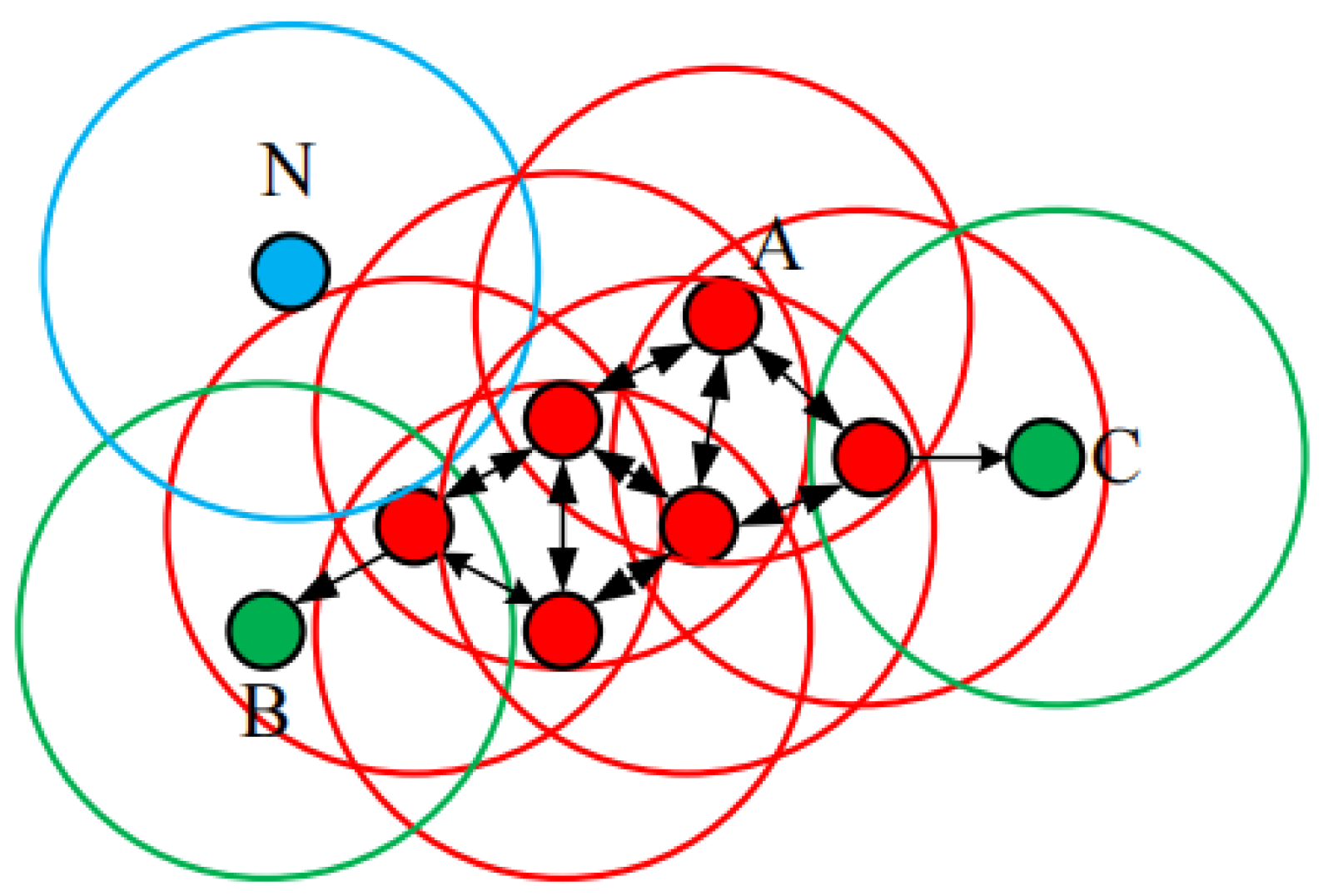

2.6. DBSCAN Clustering

3. Analysis and Discussion

3.1. Experimental Platform

3.2. Evaluation Indicators

3.3. Normal Calculation Comparison Experiment

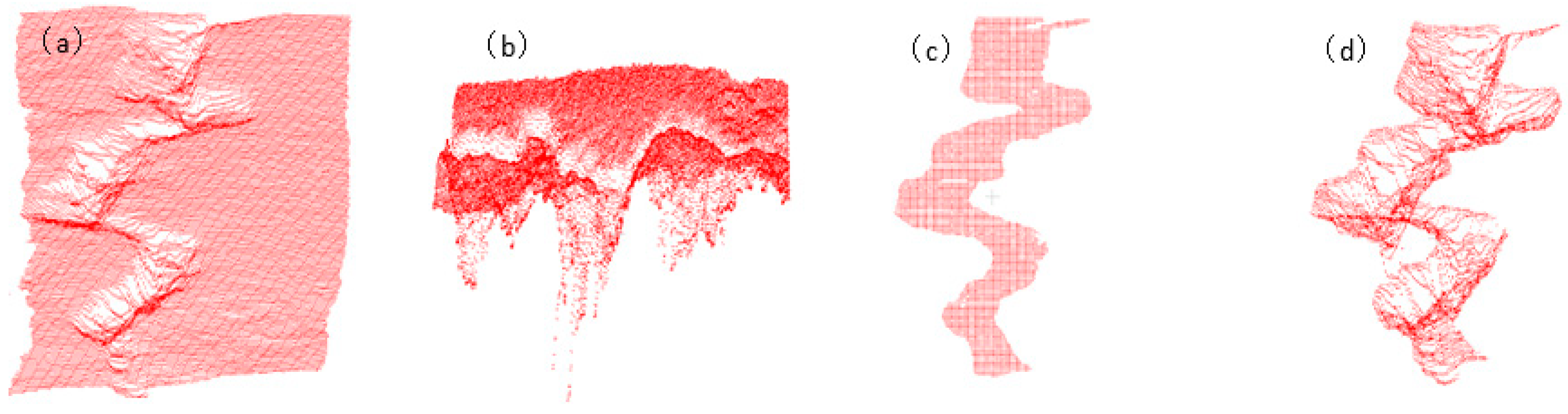

3.4. Multi-Scale Comparative Experiment

3.5. Gradient Descent Comparison Experiment

3.6. Algorithm Comparison Experiment

4. Conclusions

- (1)

- The covariance matrix is optimized to increase the accuracy and stability of the normal calculation. The traditional PCA covariance matrix has limitations when dealing with the uneven distribution of point clouds. The improved algorithm optimizes the covariance matrix by calculating the position distance weight and position vector. It can better adapt to the non-uniformity of point cloud data, which significantly increases the accuracy and stability of the normal calculation. In the case of complex surfaces and noise interference, this optimization ensures the robustness of the normal calculation and provides a more reliable basis for subsequent crack detection;

- (2)

- Multi-scale feature extraction is used to enhance the accuracy of crack point cloud feature extraction. By changing the sigma values, the features are obtained at different scales, and the detailed features are fused. The method can capture the subtle changes in cracks at different scales and avoid the limitations of the single-scale method. Rough surfaces and cracks exhibit different characteristics at different scales. By integrating the characteristics of different scales, the algorithm can describe the geometric characteristics of cracks more comprehensively, thereby significantly increasing the accuracy of feature extraction of crack point clouds;

- (3)

- The adaptive comprehensive weighted gradient descent method is utilized to dynamically adjust the gradient descent of point clouds in different neighborhoods, while smoothing noise and strengthening local features. It not only boosts the accuracy of feature extraction, but also enhances the robustness of the algorithm as well. Through adaptive gradient descent, the algorithm can better handle noise and complex surfaces. It has a stable crack detection capability, which can effectively reduce false detections and missed detections;

- (4)

- The experimental results indicate that the precision of the improved algorithm is 0.72% higher than that of the region-growing algorithm. Compared to the RANSAC algorithm, the improved algorithm has an enhancement of 18.18% in regard to the recall rate and 11.16% in regard to the F-value, which has great crack feature extraction performance in order to extract fine cracks with rough surfaces.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, S.; Rai, R.K. Minimization of cracks on the narrow face of cast slab for HCMA grade steel. Trans. Indian Inst. Met. 2024, 77, 4033–4039. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, H.; Liu, H.; Xu, L. Effect of temperature and solidification structure evolution of S355 slabs with different corner shapes on transverse corner cracks. Metals 2022, 12, 1383. [Google Scholar] [CrossRef]

- Liu, G.; Liu, Q.; Ji, C.; Chen, B.; Li, H.; Liu, K. Application of a novel chamfered mold to suppress corner transverse cracking of micro-alloyed steel slabs. Metals 2020, 10, 1289. [Google Scholar] [CrossRef]

- Tripathi, P.K.; Kumar, D.S.; Rajendra, T.; Vishwanath, S.C. Mitigation of corner cracking in continuously cast steel slabs through strain induced crack opening test. J. Fail. Anal. Preven 2023, 23, 1918–1931. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, S.; Li, J.; Liu, W.; Wang, T.; Yang, J. Formation mechanism and control of transverse corner cracks in fine blanking steel. J. Mater. Res. Technol. 2022, 18, 1137–1146. [Google Scholar] [CrossRef]

- Du, C.; Wang, C.; Li, B.; Ma, B.; Zhang, J. Effect of the temperature field and cooling rate along casting direction surface transverse crack of microalloyed steel. J. Iron Steel Res. 2018, 30, 523–528. [Google Scholar]

- Gontijo, M.; Hoflehner, C.; Ilie, S.; Six, J.; Sommitsch, C. Analysis of transverse corner cracks from continuous casting process and comparison to laboratory experiments. Eur. J. Mater. 2022, 2, 222–233. [Google Scholar] [CrossRef]

- Deng, L.; Sun, T.; Yang, L.; Cao, R. Binocular video-based 3D reconstruction and length quantification of cracks in concrete structures. Autom. Constr. 2023, 148, 104743. [Google Scholar] [CrossRef]

- Hu, K.; Chen, Z.; Kang, H.; Tang, Y. 3D vision technologies for a self-developed structural external crack damage recognition robot. Autom. Constr. 2024, 159, 105262. [Google Scholar] [CrossRef]

- Qi, C.R.; Su, H.; Mo, K.; Guibas, L.J. Pointnet: Deep learning on point sets for 3d classification and segmentation. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017. [Google Scholar] [CrossRef]

- Qi, C.R.; Yi, L.; Su, H.; Guibas, L.J. Pointnet++: Deep hierarchical feature learning on point sets in a metric space. Adv. Neural Inf. Process. Syst. 2017, 30, 5105–5114. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, J.; Zhou, Z.; Xu, M.; Qi, X.; Qiao, Y. Learning geometry-disentangled representation for complementary understanding of 3d object point cloud. Proc. AAAI Conf. Artif. Intell. 2021, 35, 3056. [Google Scholar] [CrossRef]

- Ma, X.; Qin, C.; You, H.; Ran, H.; Fu, Y. Rethinking network design and local geometry in point cloud: A Simple Residual MLP Framework. arXiv 2022, arXiv:2202.07123. [Google Scholar]

- Zhou, Y.; Ji, A.; Zhang, L. Sewer defect detection from 3D point clouds using a transformer-based deep learning model. Autom. Constr. 2022, 136, 104163. [Google Scholar] [CrossRef]

- Hu, Q.; Hao, K.; Wei, B.; Li, H. An efficient solder joint defects method for 3D point clouds with double-flow region attention network. Adv. Eng. Inform. 2022, 52, 101608. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, W.; Yin, T.; Peng, J.; Liu, Y.; Zhang, J. A measurement method for rail wear based on point cloud registration and nearest neighbor search. J. Yanshan Univ. 2025, 49, 55–65. Available online: https://kns.cnki.net/kcms2/article/abstract?v=HUa8WMVVXl036yC2aoLA72tBDUrrVAJdOIXMP4UeQ1skGzUR1NvumyJnDNf6tcRfCAXuMrgpQY8jKCq2_msp8tnIYFXkabVfe36zFvuqhsf-QPeO-zIjWGIFCNRMdtYf0jC3v4IUmLIr1w2o5GPLbguojl002PBz0yA8oxPVMZ0hToRWbonP-tVLnFynyfzv&uniplatform=NZKPT&language=CHS (accessed on 14 March 2025).

- Cai, S.; Hao, F.; Shi, T. Partition based on features of neighborhood point and the corresponding cloud registration of aero-engine damaged blade point. J. Beijing Univ. Aeronaut. Astronaut. 2024. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J.; Song, T.; Ding, H. A point cloud registration algorithm considering multi-allowance constraints for robotic milling of complex parts. Robot. Comput.-Integr. Manuf. 2025, 92, 102885. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, Z.; Qin, X.; Huang, B.; Dong, K.; Shi, A. Surface defects 3D localization for fluorescent magnetic particle inspection via regional reconstruction and partial-in-complete point clouds registration. Expert Syst. Appl. 2024, 238, 122225. [Google Scholar] [CrossRef]

- Zhang, T.; Xia, R.; Zhao, J.; Fu, S.; Xu, Z. Weld surface quality inspection based on structured light. Modul. Mach. Tool Autom. Manuf. Tech. 2022, 1, 81–84. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Peng, J.; Liang, Z. A novel system for off-line 3D seam extraction and path planning based on point cloud segmentation for arc welding robot. Robot. Comput.-Integr. Manuf. 2020, 64, 101929. [Google Scholar] [CrossRef]

- Ma, W.; Wang, J.; Zhang, J.; Ma, Y.; Zhang, Z. Feature extraction from point cloud based on improved normal vector. Sci. Surv. Mapp. 2021, 46, 84–90+146. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, H.; Guo, J.; Ye, H.; Yang, X.; Yao, Q. Method for extracting point clouds of inspection pits based on normal vector region clustering segmentation. Yangtze River 2023, 54, 113–118. [Google Scholar] [CrossRef]

- Yu, M.; Cui, X.; Wu, L.; Wu, S. 3D recognition algorithm based on curvature point pair features. Laser Optoelectron. Prog. 2023, 60, 222–229. [Google Scholar] [CrossRef]

- Luo, Q.; Zhang, C.; Luo, J. Indoor 3D point cloud plane segmentation based on boundary feature constraints. Laser J. 2024, 45, 106–112. [Google Scholar] [CrossRef]

- Li, Z.; Wang, T.; Hu, K.; Li, X.; Wang, X. Lidar object real-time detection method under complex environment. Laser J. 2018, 39, 41–46. [Google Scholar] [CrossRef]

- Deng, B.; Wang, Z.; Jin, Y.; Chen, Y.; Wu, Q.; Li, H. Feature extraction method of laser scanning point cloud based on morphological gradient. Laser Optoelectron. Prog. 2018, 55, 239–245. [Google Scholar] [CrossRef]

- Chen, H.; Ding, Q.; Pan, L. Edge optimized extraction from the organized point-cloud data base on gradient clustering. Chin. J. Instrum. 2022, 43, 165–174. [Google Scholar] [CrossRef]

- Zhang, B.; Cai, L.; Wang, X.; Wu, J. Automatic extraction algorithm of step lines from point cloud in open-pit mine based on gradient of scalar field. Bull. Surv. Mapp. 2023, 7, 63–68. [Google Scholar] [CrossRef]

- Huang, Z.; He, H.; Zhang, X. Linear feature extraction of LiDAR point cloud based on PCA. Bull. Surv. Mapp. 2024, 2, 146–150. [Google Scholar] [CrossRef]

- Peng, K.; Tan, J.; Zhang, G. A Method of Curve Reconstruction Based on Point Cloud Clustering and PCA. Symmetry 2022, 14, 726. [Google Scholar] [CrossRef]

- Marghani, K.; Dlay, S.S.; Sharif, B.S.; Sims, A.J. Automated morphological analysis approach for classifying colorectal microscopic images. Proc. SPIE-Int. Soc. Opt. Eng. 2003, 52, 240–249. [Google Scholar] [CrossRef]

- Lu, J.; Qian, J.; Han, W. Discrete gradient method in solid mechanics. Int. J. Numer. Methods Eng. 2008, 74, 619–641. [Google Scholar] [CrossRef]

- Qian, J.; Lu, J. A stabilized formulation for discrete gradient method. Int. J. Numer. Methods Biomed. Eng. 2011, 27, 860–873. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, D.; Chen, Y.; Xu, Z.; He, B. Research on Three-Dimensional Reconstruction of Ribs Based on Point Cloud Adaptive Smoothing Denoising. Sensors 2024, 24, 4076. [Google Scholar] [CrossRef]

- Cabo, C.; Ordóñez, C.; Sáchez-Lasheras, F.; Roca-Pardiñas, J.; de Cos-Juez, J. Multiscale Supervised Classification of Point Clouds with Urban and Forest Applications. Sensors 2019, 19, 4523. [Google Scholar] [CrossRef]

- Zhou, N.; Jiang, P.; Jiang, S.; Shu, L.; Ni, X.; Zhong, L. An Identification and Localization Method for 3D Workpiece Welds Based on the DBSCAN Point Cloud Clustering Algorithm. J. Manuf. Mater. Process 2024, 8, 287. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, R.; Gao, C.; Chen, Z. Centerline Extraction Method of Structured Light Stripe Based on GWGCGM and DBSCAN. Appl. Laser. 2024, 44, 164–171. [Google Scholar] [CrossRef]

- Ester, M.; Hans-Peter, K.; Jorg, S.; Xu, X. A Density-Based Algorithm for Discovering Clusters in Large Spatial Databases with Noise; AAAI Press: Washington, DC, USA, 1996; pp. 226–231. [Google Scholar]

- Flach, P.A.; Meelis, K. Precision-recall-gain curves: PR analysis done right. Adv. Neural Inf. Process. Syst. 2015, 28, 838–846. [Google Scholar]

- Fouhey, D.F.; Gupta, A.; Hebert, M. Data-Driven 3D Primitives for Single Image Understanding. In Proceedings of the 2013 IEEE International Conference on Computer Vision, Sydney, Australia, 1–8 December 2013; pp. 3392–3399. [Google Scholar] [CrossRef]

- Wang, W.; Lu, X.; Shao, D.; Liu, X.; Dazeley, R.; Robles-Kelly, A.; Pan, W. Weighted point cloud normal estimation. In Proceedings of the 2023 IEEE International Conference on Multimedia and Expo (ICME), Brisbane, Australia, 10–14 July 2023; pp. 2015–2020. [Google Scholar] [CrossRef]

- Zhou, L.; Sun, G.; Li, Y.; Li, W.; Su, Z. Point cloud denoising review: From classical to deep learning-based approaches. Graph. Models 2022, 121, 101140. [Google Scholar] [CrossRef]

- Li, Q.; Feng, H.; Shi, K.; Gao, Y.; Fang, Y.; Liu, Y.; Han, Z. Learning signed hyper surfaces for oriented point cloud normal estimation. IEEE Trans. Pattern Anal. Mach. Intell. 2024, 46, 9957–9974. [Google Scholar] [CrossRef]

- Pan, X.; Ling, T.; Zhang, L.; Lou, Y. Forward simulation and waveform feature analysis of cracks in lining structures. J. Transp. Sci. Eng. 2024, 41, 1605–1609. [Google Scholar]

- Zhou, Y.; Du, J.; Tao, Y. Method for precipitation forecast based on improved k-nearest neighbor algorithm. Comput. Eng. Des. 2020, 41, 1605–1609. [Google Scholar] [CrossRef]

- Zhang, J.; Quan, T. A local Gaussian distribution model for image registration. Chin. J. Eng. Math. 2024, 41, 421–431. [Google Scholar] [CrossRef]

| Sigma Value | Number of Feature Points Extracted |

|---|---|

| sigma = 0.0001 | 27,789 |

| sigma = 0.0002 | 15,087 |

| sigma = 0.0003 | 10,257 |

| sigma = 0.0004 | 7719 |

| Algorithm | Noise Ratio/% | MSE/% | MAE/% |

|---|---|---|---|

| ① | 15 | 51.69 | 39.50 |

| ② | 51.37 | 38.57 | |

| ① | 20 | 52.53 | 41.41 |

| ② | 52.22 | 40.37 | |

| ① | 25 | 54.13 | 43.71 |

| ② | 53.01 | 41.93 | |

| ① | 30 | 55.05 | 45.47 |

| ② | 54.07 | 43.85 |

| Algorithm | Number of Feature Points Extracted |

|---|---|

| Finite Difference Method | 7889 |

| Nearest Neighbor Method | 12,365 |

| Gaussian Weight Method | 8756 |

| Improved Method | 11,927 |

| Algorithm | Number of Feature Points | Number of Overlapping Point Clouds (TP) | Number of False Negative Point Clouds (FN) | Number of False Positive Point Clouds (FP) |

|---|---|---|---|---|

| Curvature Algorithm | 8254 | 5728 | 5673 | 2526 |

| RANSAC Algorithm | 8784 | 8337 | 3064 | 447 |

| Region-Growing Algorithm | 7923 | 7603 | 3798 | 320 |

| Improved Algorithm | 10,767 | 10,410 | 991 | 357 |

| Algorithm | Precision/% | Recall/% | F/% |

|---|---|---|---|

| Curvature Algorithm | 69.39 | 50.24 | 58.47 |

| RANSAC Algorithm | 94.90 | 73.13 | 82.76 |

| Region-Growing Algorithm | 95.96 | 66.69 | 79.57 |

| Improved Algorithm | 96.68 | 91.31 | 93.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, K.; Xia, Z.; Qian, J.; Du, X.; Xiao, P.; Zhu, L. A Feature Extraction Algorithm for Corner Cracks in Slabs Based on Multi-Scale Adaptive Gradient Descent. Metals 2025, 15, 324. https://doi.org/10.3390/met15030324

Zeng K, Xia Z, Qian J, Du X, Xiao P, Zhu L. A Feature Extraction Algorithm for Corner Cracks in Slabs Based on Multi-Scale Adaptive Gradient Descent. Metals. 2025; 15(3):324. https://doi.org/10.3390/met15030324

Chicago/Turabian StyleZeng, Kai, Zibo Xia, Junlei Qian, Xueqiang Du, Pengcheng Xiao, and Liguang Zhu. 2025. "A Feature Extraction Algorithm for Corner Cracks in Slabs Based on Multi-Scale Adaptive Gradient Descent" Metals 15, no. 3: 324. https://doi.org/10.3390/met15030324

APA StyleZeng, K., Xia, Z., Qian, J., Du, X., Xiao, P., & Zhu, L. (2025). A Feature Extraction Algorithm for Corner Cracks in Slabs Based on Multi-Scale Adaptive Gradient Descent. Metals, 15(3), 324. https://doi.org/10.3390/met15030324