Effects of Chemical Composition on Welding HAZ Softening of High-Strength Pipeline Steels

Abstract

1. Introduction

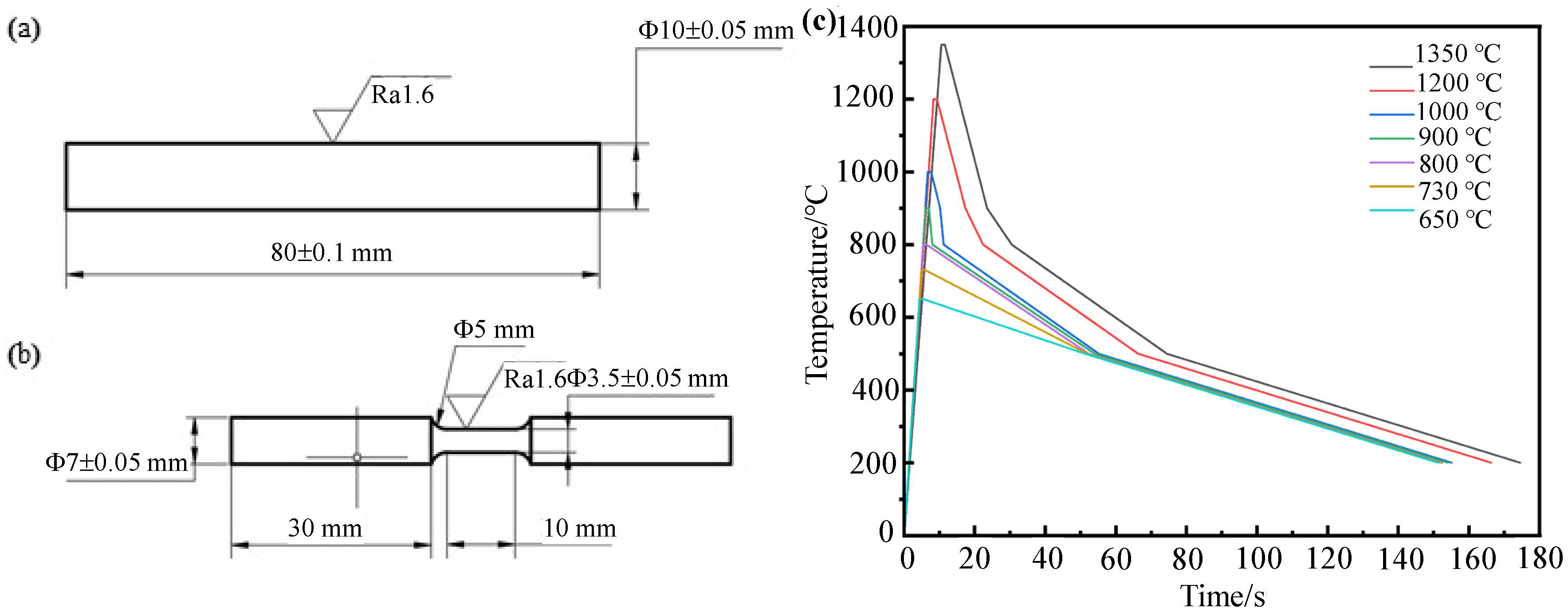

2. Materials and Methods

3. Results

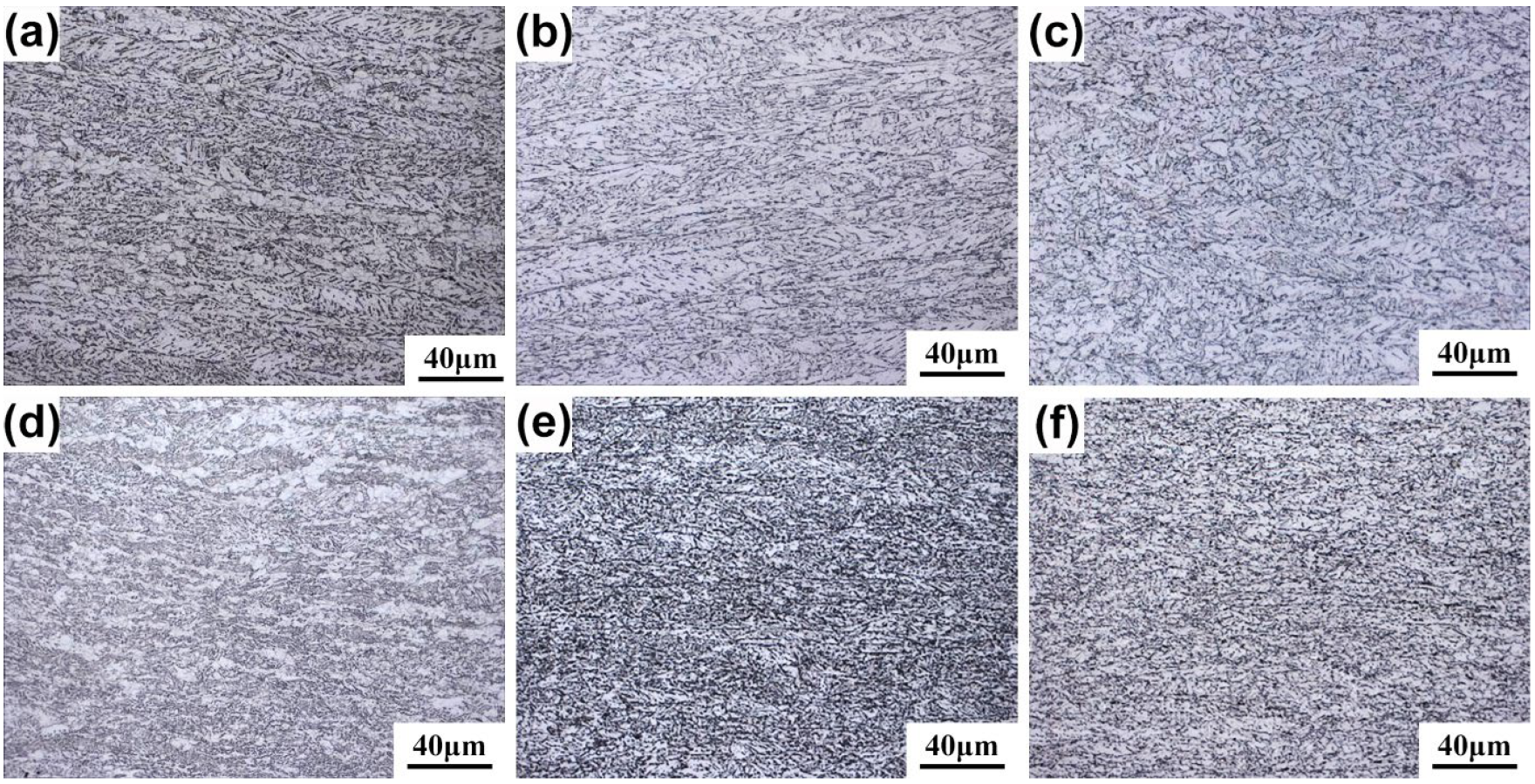

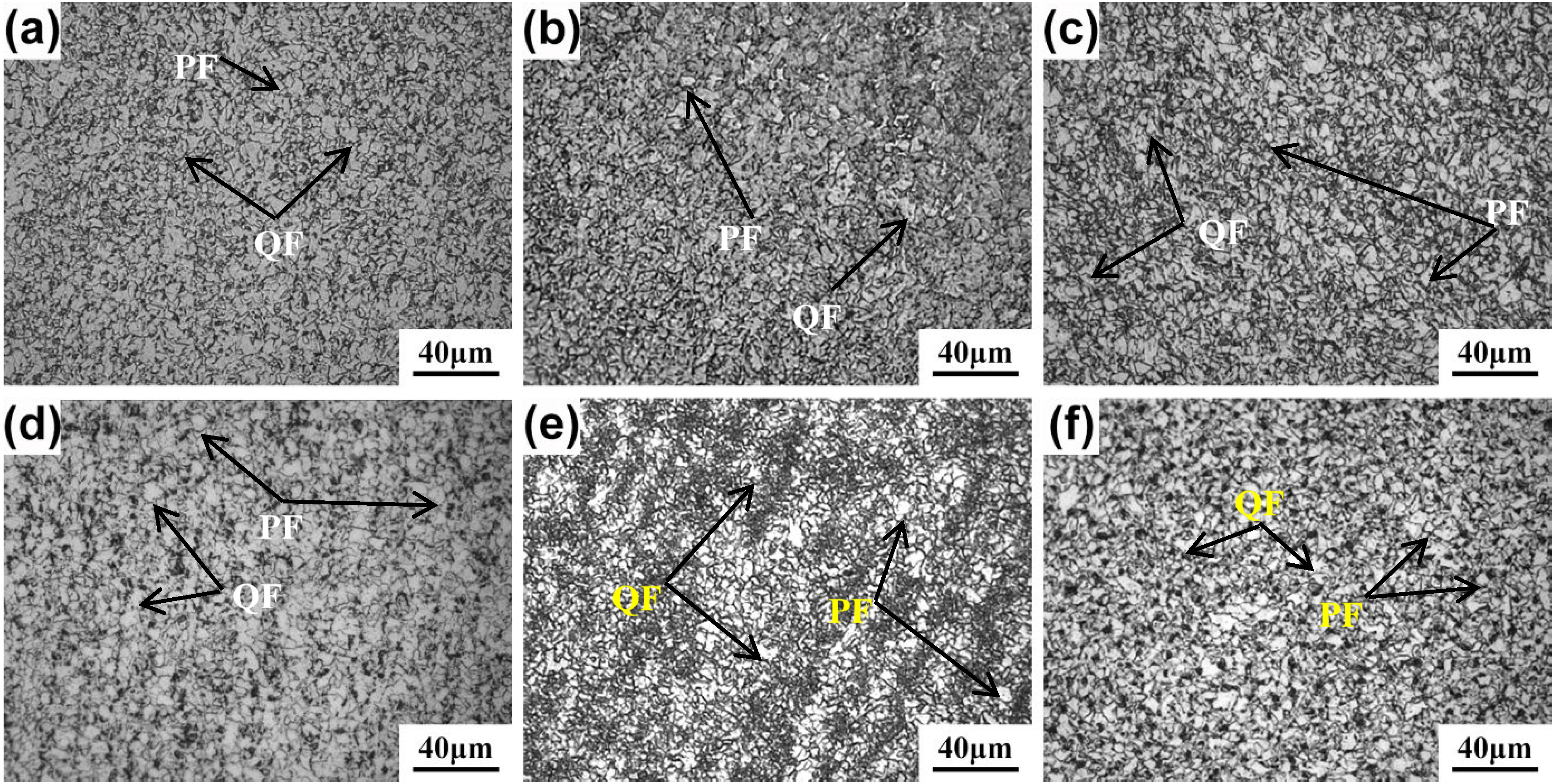

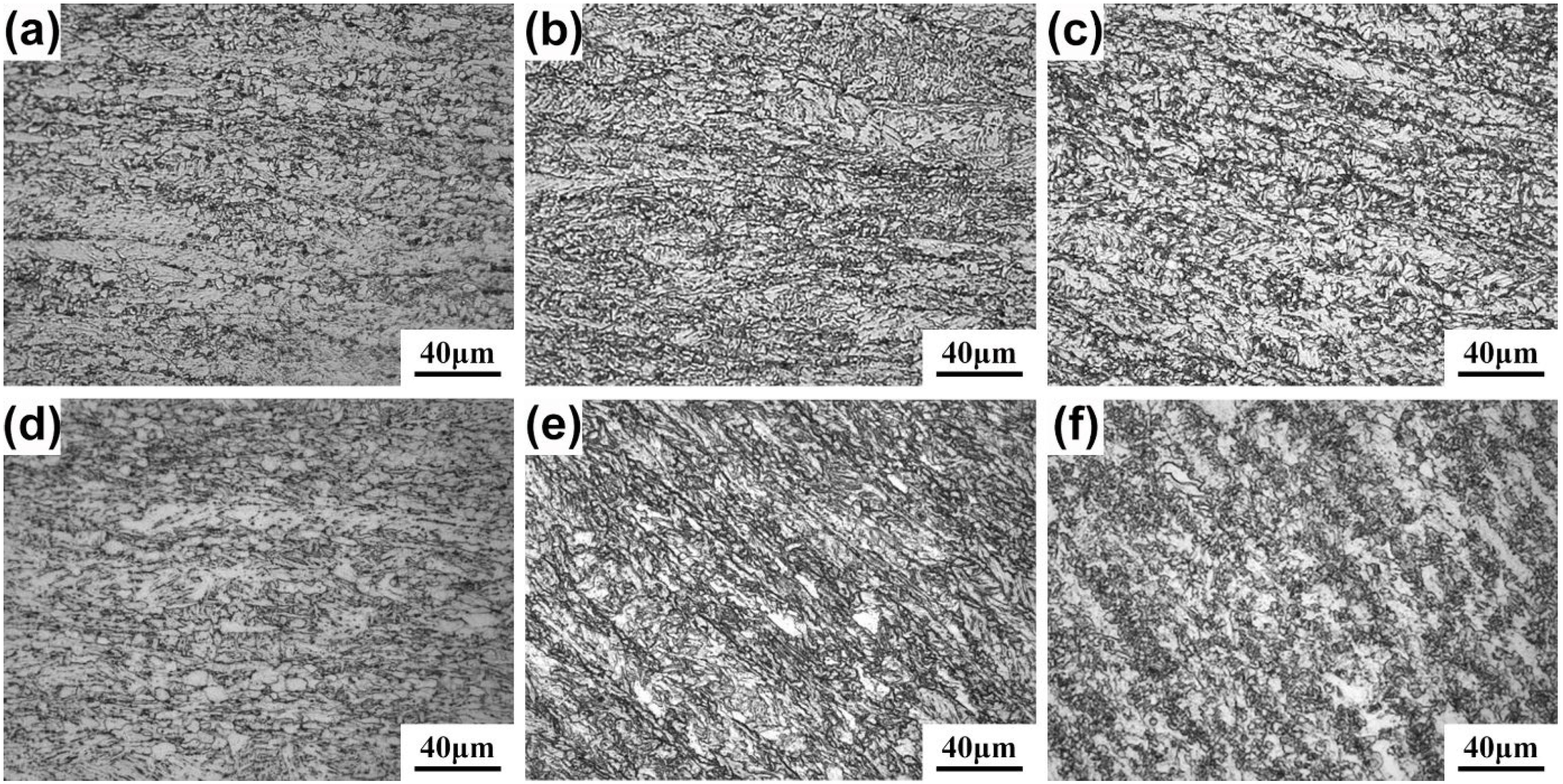

3.1. As-Rolled Microstructure and Tensile Properties of the Pipeline Steels

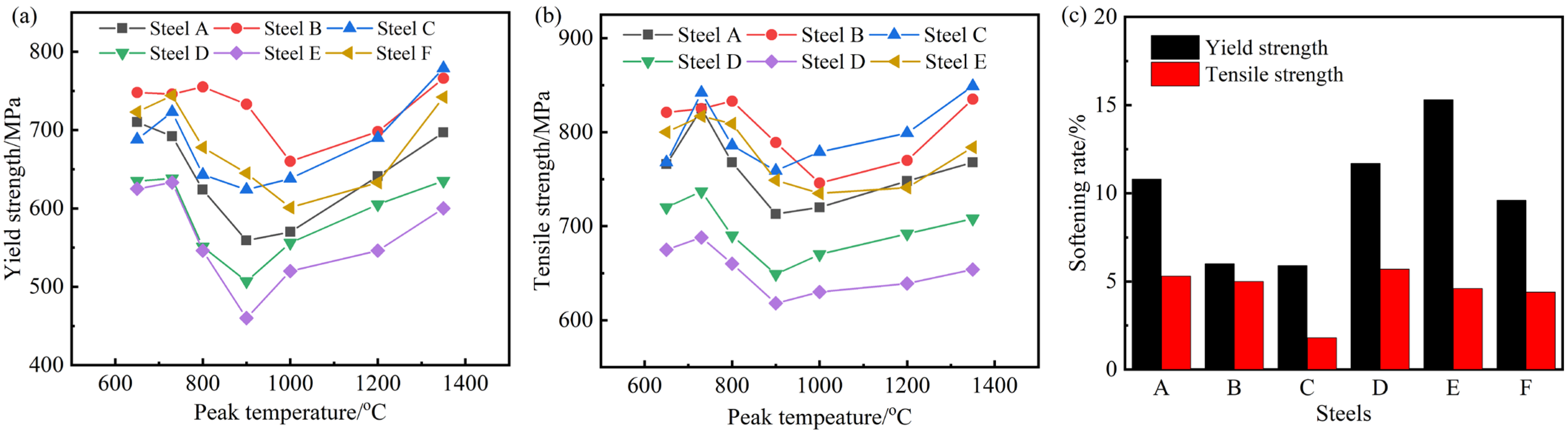

3.2. Strength of HAZ of High-Nb Pipeline Steels

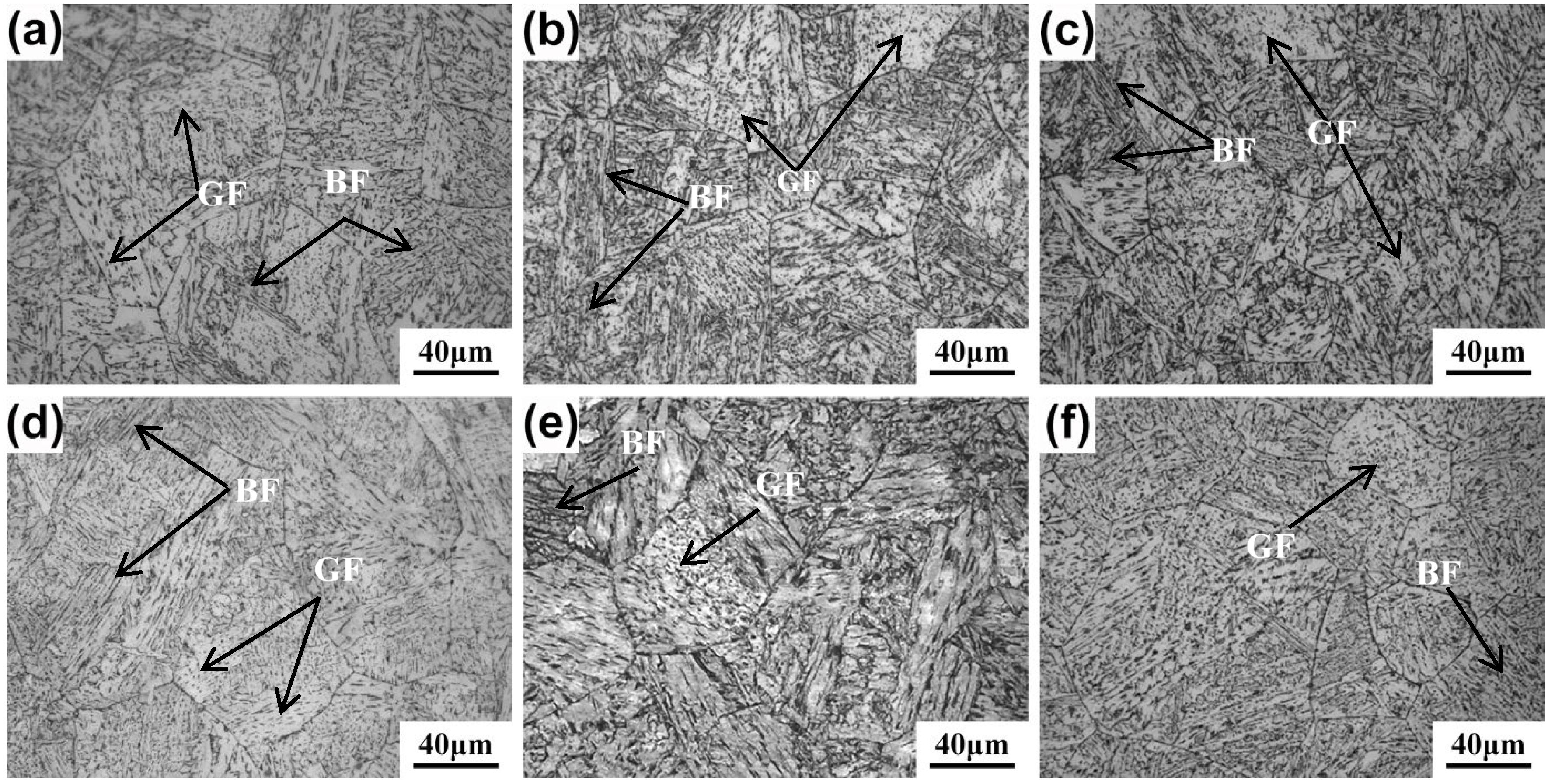

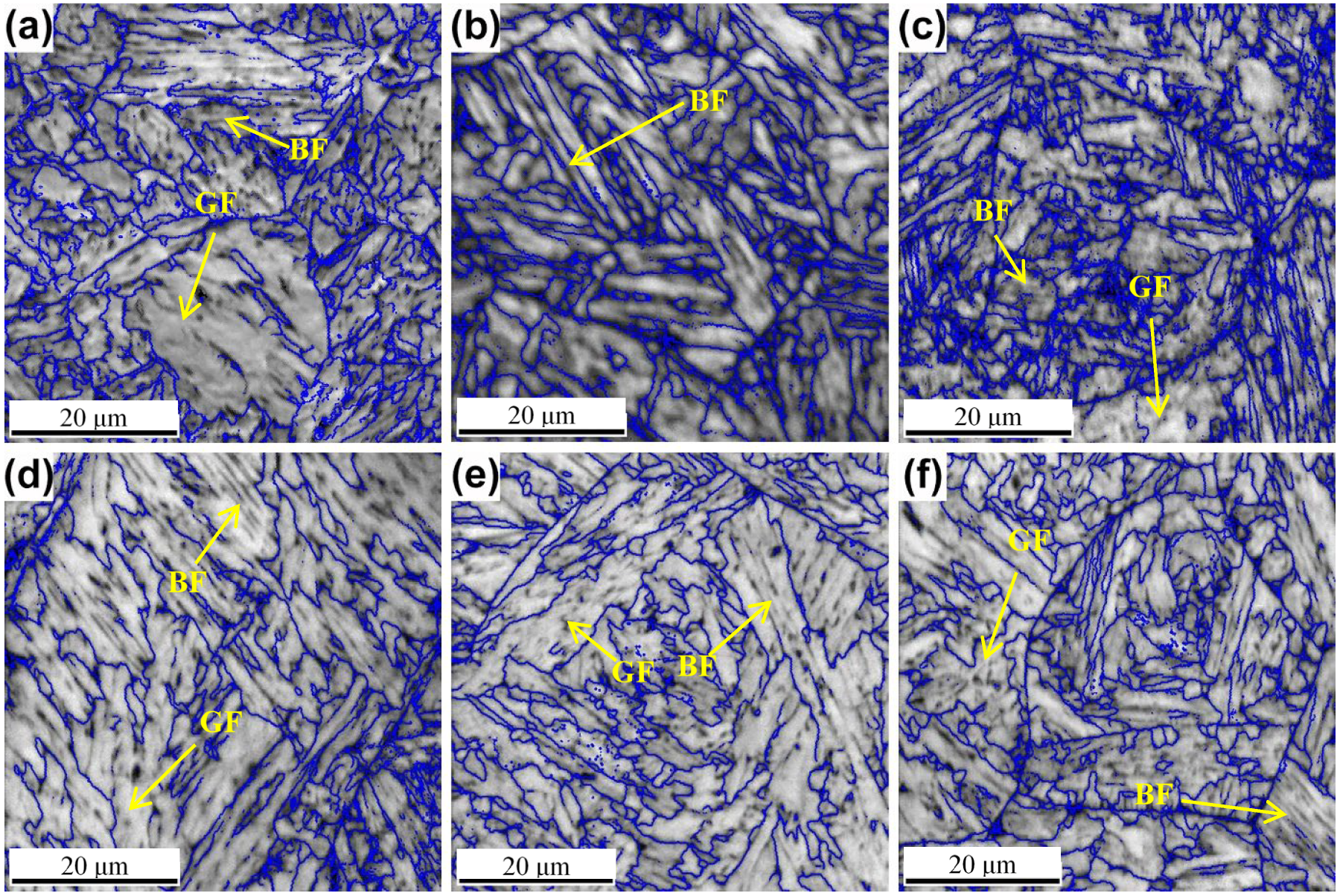

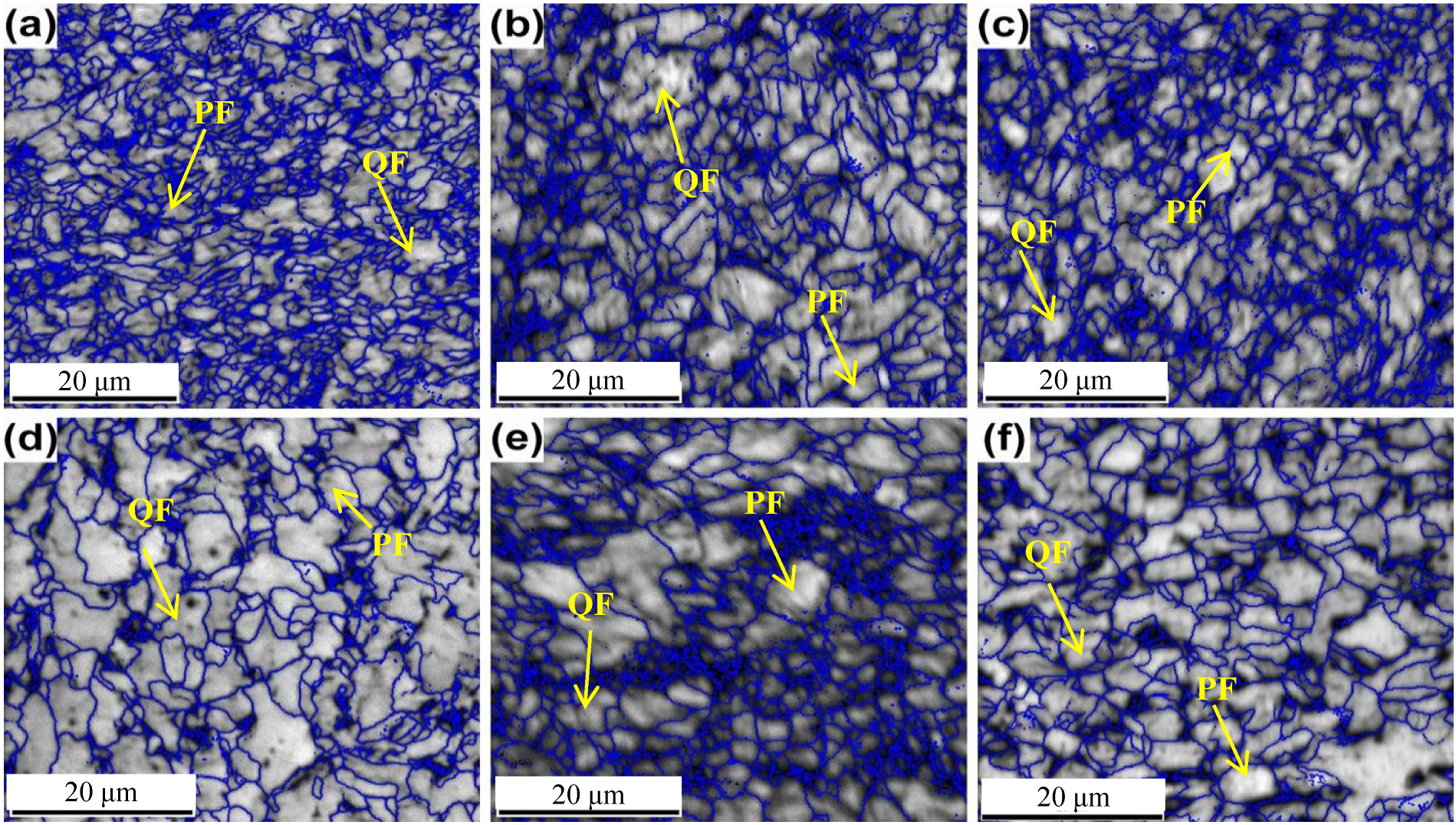

3.3. Effect of Peak Temperature on Microstructure of HAZ

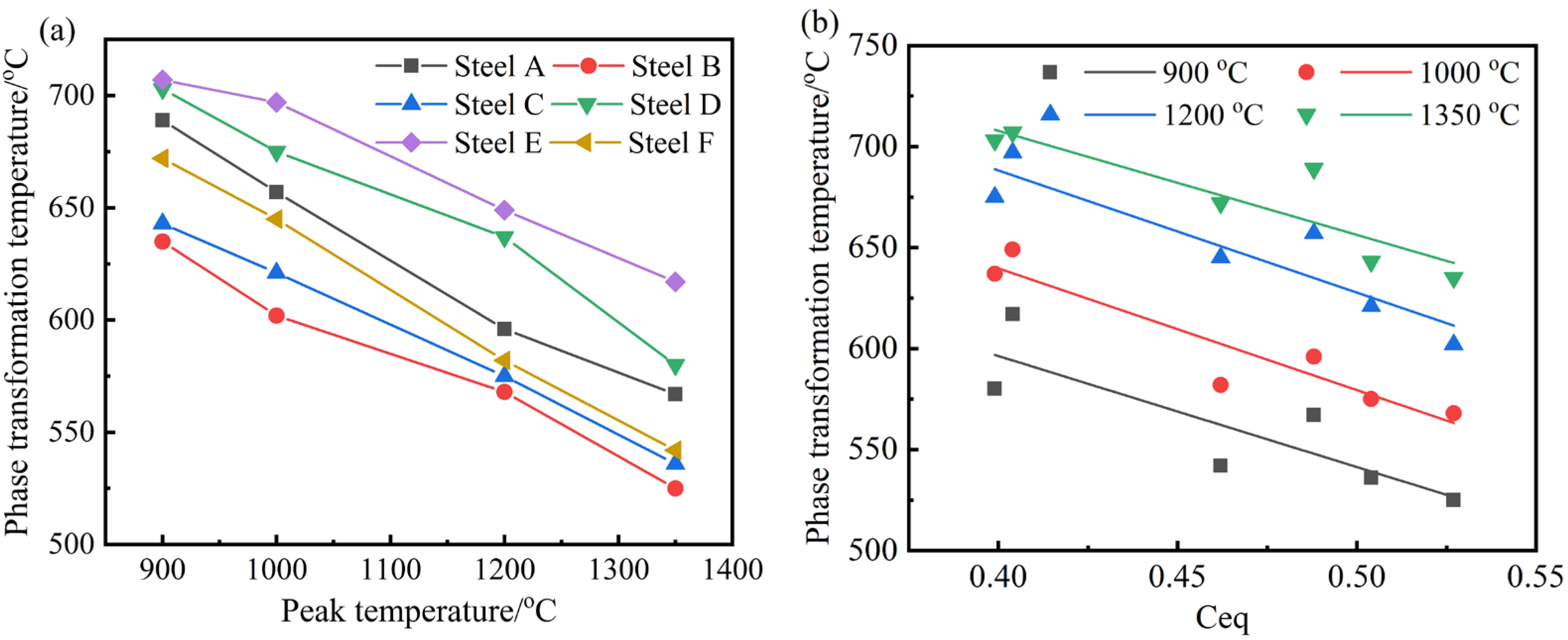

3.4. Effect of Peak Temperature on Phase Transformation Temperature

4. Discussion

5. Conclusions

- (1)

- The strength of HAZs is significantly influenced by the peak temperature, and the softening zone mainly occurs in FGHAZ when the peak temperature is 900~1000 °C.

- (2)

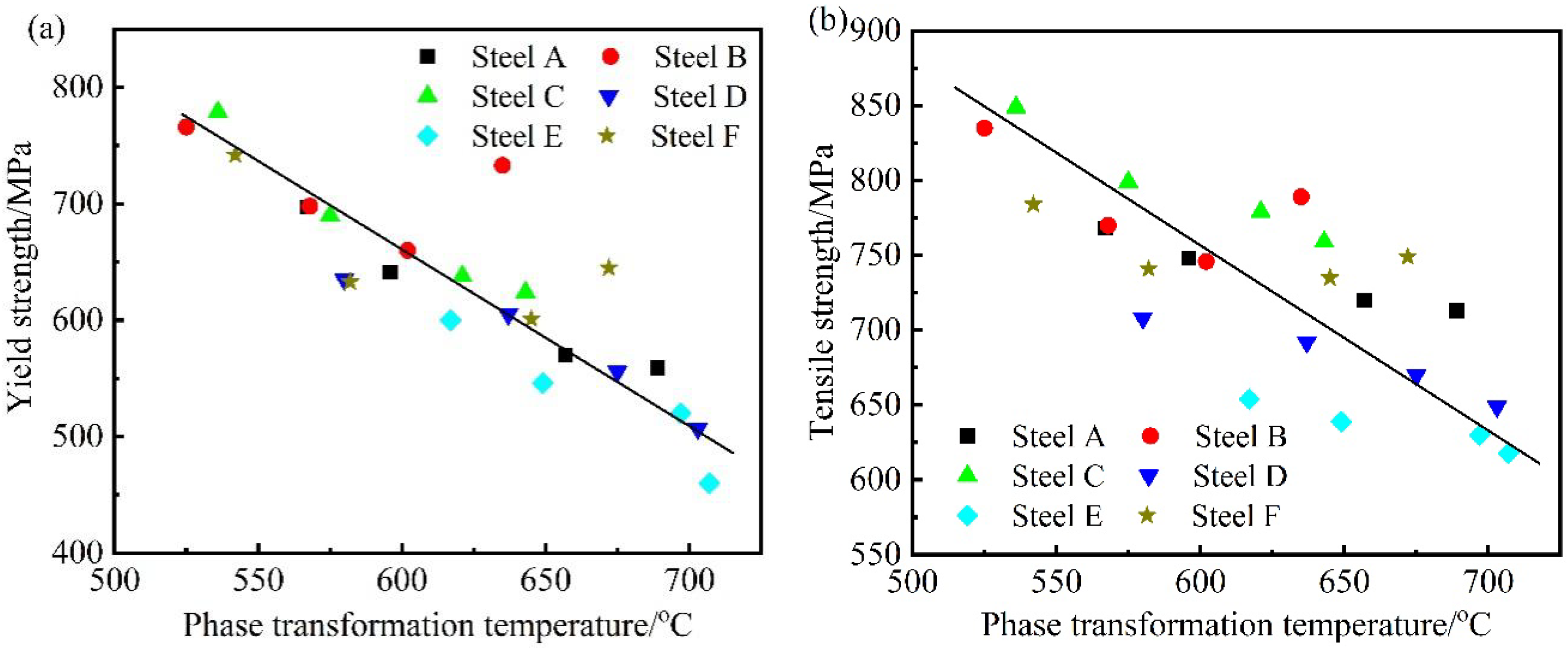

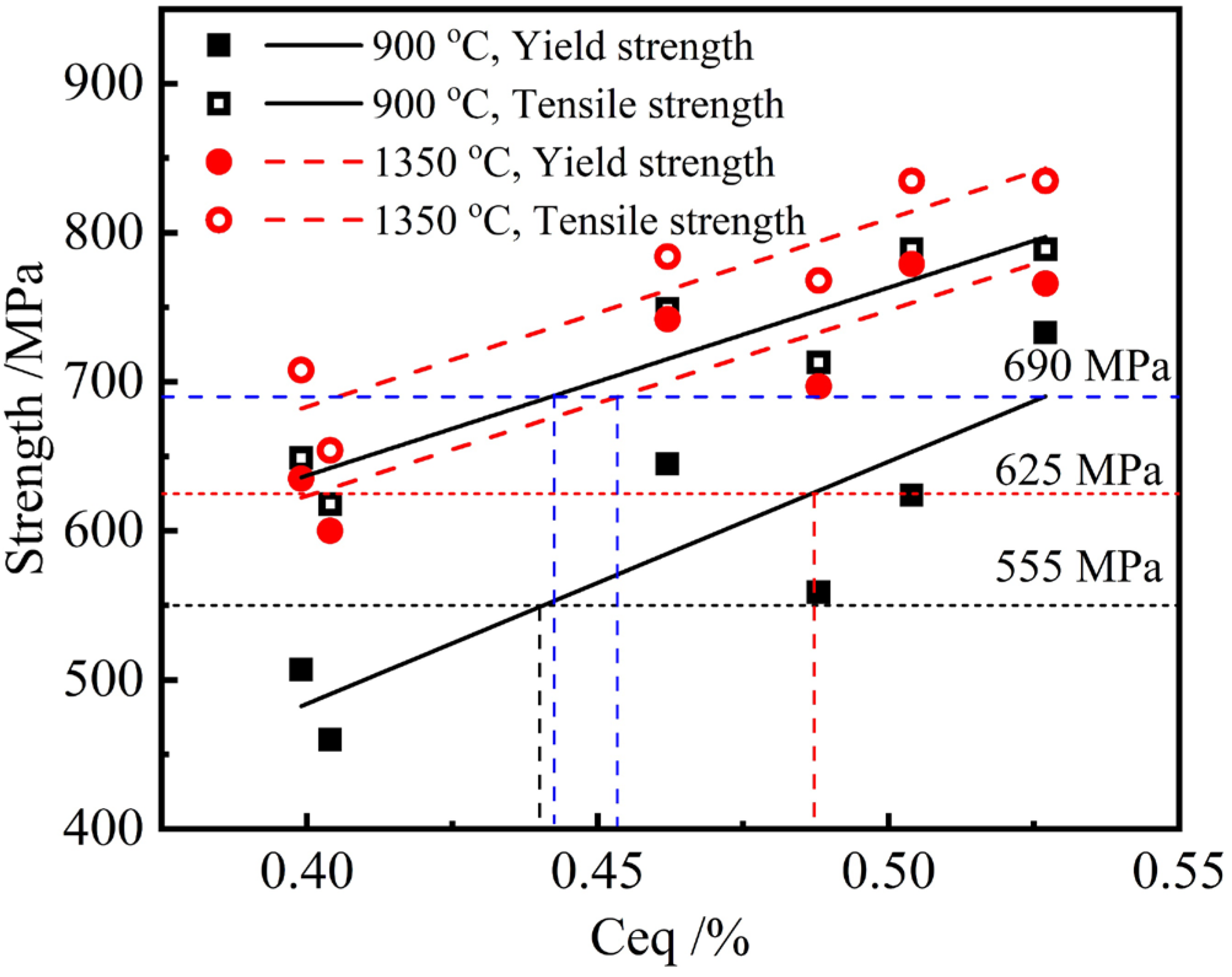

- The peak temperature and chemical composition of the steels affect the phase transformation during the cooling process of the welding thermal cycle, the final microstructure, and the strength of the HAZs. The strength of HAZs is linearly related to the beginning phase temperature.

- (3)

- The strength of sub-HAZs at the same peak temperature is linearly related to the value of Ceq of steels. From the perspective of controlling the strength of the heat-affected zone, in order to ensure that the yield and tensile strengths of X80 and X90 pipeline steel are higher than the minimum values specified by API 5L, the values of Ceq of the steels should be over 0.438% and 0.487% for yield strength, and 0.399% and 0.453% for tensile strength, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, M.P.; Shukla, D.K.; Kumar, R.; Arora, K.S. The structural integrity of high-strength welded pipeline steels: A review. Int. J. Struct. Integr. 2021, 12, 470–496. [Google Scholar] [CrossRef]

- Sharma, S.K.; Maheshwari, S. A review on welding of high strength oil and gas pipeline steels. J. Nat. Gas Sci. Eng. 2017, 38, 203–217. [Google Scholar] [CrossRef]

- Shin, S.Y.; Hwang, B.; Lee, S.; Kim, N.J.; Ahn, S.S. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels. Mater. Sci. Eng. A 2017, 458, 281–289. [Google Scholar] [CrossRef]

- Chen, Y.F.; Yang, Y.B.; He, X.D.; Han, J.; Qi, L.H. Study on microstructure and mechanical properties of X80 pipeline steel pipe. In Proceedings of the 6th International Conference on ThermoMechanical Processing, TMP 2022, Shengyang, China, 6–8 September 2022; pp. 176–180. [Google Scholar]

- Shome, M.; Mohanty, O.N. Continuous cooling transformation diagrams applicable to the heat-affected zone of HSLA-80 and HSLA-100 steels. Metall. Mater. Trans. A 2006, 37, 2159–2169. [Google Scholar] [CrossRef]

- American Petroleum Institute. API Specification 5L, 46th ed.; API Publishing Services: Washington, DC, USA, 2018. [Google Scholar]

- Bott, I.D.S.; De Souza, L.F.G.; Teixeira, J.C.G.; Rios, P.R. High-strength steel development for pipelines: A Brazilian perspective. Metall. Mater. Trans. A 2025, 36, 443–454. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Guo, A.M.; Shang, C.J.; Liu, Q.Y.; Malcolm, G.; Barbaro, F. Latest development and application of high strength and heavy gauge pipeline steel in China. In Proceedings of the 7th International Conference on High Strength Low Alloy Steels, International Conference on Microalloying and International Conference on Offshore Engineering Steels, Hangzhou, China, 11–13 November 2015; pp. 721–726. [Google Scholar]

- Stepanov, P.P.; Golovin, S.V.; Samohvalov, M.V.; Chervonniy, A.V.; Grishin, S.A.; Shlokov, Y.S.; Uskov, A.V.; Nedzvetskiy, M.Y.; Egorov, V.A.; Arabey, A.B. Production of rolled steel and large-diameter pipes of K70 and K80 strength classes. Metallurgist 2025, 68, 1609–1624. [Google Scholar] [CrossRef]

- Zhao, W.G.; Wang, W.; Chen, S.H.; Qu, J.B. Effect of simulated welding thermal cycle on microstructure and mechanical properties of X90 pipeline steel. Mater. Sci. Eng. A 2011, 528, 7417–7422. [Google Scholar] [CrossRef]

- Guillal, A.; Abdelbaki, N. The optimum use of high-strength steel in the construction of gas transmission pipeline. Int. J. Struct. Integr. 2023, 14, 681–699. [Google Scholar] [CrossRef]

- Lan, L.Y.; Chang, Z.Y.; Kong, X.W.; Qiu, C.L.; Zhao, D.W. Phase transformation, microstructure, and mechanical properties of X100 pipeline steels based on TMCP and HTP concepts. J. Mater. Sci. 2017, 52, 1661–1678. [Google Scholar] [CrossRef]

- Schwinn, V.; Bauer, J.; Flüss, P.; Kirsch, H.J.; Amoris, E. Recent developments and applications of TMCP steel plates. Rev. De Métallurgie 2011, 108, 283–294. [Google Scholar] [CrossRef]

- Gervasyev, A.; Carretero Olalla, V.; Sidor, J.; Sanchez Mouriño, N.; Kestens, L.A.I.; Petrov, R.H. An approach to microstructure quantification in terms of impact properties of HSLA pipeline steels. Mater. Sci. Eng. A 2016, 677, 163–170. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, Y.; Qiu, C.L.; Du, L.X.; Wu, D. Effects of rolling processes on bainite and mechanical properties of ultra-high strength pipeline steel. J. Iron Steel Res. Int. 2011, 18, 629–632. [Google Scholar]

- Urtsev, N.V.; Platov, S.I.; Shmakov, A.V.; Ryzhkov, M.A.; Lobanov, M.L. Thermophysical properties of high-strength low-alloyed pipe steel. Phys. Met. Metallogr. 2024, 125, 1284–1290. [Google Scholar] [CrossRef]

- Zhang, J.M.; Huo, C.Y.; Ma, Q.R.; Feng, Y.R. NbC-TiN co-precipitation behavior and mechanical properties of X90 pipeline steels by critical-temperature rolling process. Int. J. Press. Vessel. Pip. 2018, 165, 29–33. [Google Scholar] [CrossRef]

- Tang, H.P.; Ding, Y.P.; Qiu, G.Y.; Yi, P.; Liu, Z.G. Numerical Study on the in-service welding stress of X80 steel natural gas pipeline. Materials 2025, 18, 719. [Google Scholar] [CrossRef]

- Arora, K.S.; Ranga Pandu, S.; Shajan, N.; Pathak, P.; Shome, M. Microstructure and impact toughness of reheated coarse grain heat affected zones of API X65 and API X80 linepip steels. Int. J. Press. Vessel. Pip. 2018, 163, 36–44. [Google Scholar] [CrossRef]

- Davis, C.L.; King, J.E. Cleavage initiation in the intercritically reheated coarse grained heat-affected zone: Part I. Fractographic evidence. Metall. Mater. Trans. A 1994, 25, 563–573. [Google Scholar] [CrossRef]

- Pratap, M.S.; Arora, K.S.; Shajan, N.; Pandu, S.R.; Shome, M.; Kumar, R.; Shukla, D. Comparative analysis of continuous cooling transformation behaviour in CGHAZ of API X80 and X65 line pipe steels. J. Therm. Anal. Calorim. 2019, 137, 1155–1167. [Google Scholar]

- Zhou, P.S.; Wang, B.; Wang, L.; Hu, Y.W.; Zhou, L. Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel. Mater. Sci. Eng. A 2018, 722, 112–121. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, L.; Xu, Z.; Lu, H.; Chen, X.; Wang, X. Fracture toughness of the materials in welded joint of X80 pipeline steel. Eng. Fract. Mech. 2015, 148, 337–349. [Google Scholar] [CrossRef]

- Garcia, M.P.; Gervasyev, A.; Lu, C.; Barbaro, F.J. Chemical composition and weld cooling time effects on heat-affected zone hardness of line pipe steels. Int. J. Press. Vessel. Pip. 2022, 200, 104837. [Google Scholar] [CrossRef]

- Stroetmann, R.M.; Kästner, T.; Rust, B. Design and execution of welded connections on high-strength steels. Adv. Struct. Eng. 2023, 26, 2282–2291. [Google Scholar] [CrossRef]

- Liu, L.G.; Zhang, C.F.; Liu, Y.; Sun, S.M.; Yu, H. Notice of removal: Evaluation of softening zone in X80 pipeline steels under tension-bending load. In Proceedings of the 5th International Conference on Mechanical, Automotive and Materials Engineering (CMAME), Guangzhou, China, 1–3 August 2017; pp. 92–97. [Google Scholar]

- Hochhauser, F.; Ernst, W.; Rauch, R.; Vallant, R.; Enzinger, N. Influence of the soft zone on the strength of welded modern HSLA steels. Weld. World 2012, 56, 77–85. [Google Scholar] [CrossRef]

- Hamada, M.; Hirata, H.; Okaguchi, S.; Shitamoto, H.; Yamamoto, A.; Takahashi, N.; Miura, M.; Takeuch, I. Material design for line pipe steel to minimize HAZ softening and obtain good HAZ toughness. Int. J. Offshore Polar Eng. 2008, 18, 204–210. [Google Scholar]

- Amraei, M.; Afkhami, S.; Javaheri, V.; Larkiola, J.; Skriko, T.; Björk, T.; Zhao, X.-L. Mechanical properties and microstructural evaluation of the heat-affected zone in ultra-high strength steels. Thin-Walled Struct. 2020, 157, 107072. [Google Scholar] [CrossRef]

- Chen, X.-W.; Qiao, G.-Y.; Han, X.-L.; Wang, X.; Xiao, F.-R.; Liao, B. Effects of Mo, Cr and Nb on microstructure and mechanical properties of heat affected zone for Nb-bearing X80 pipeline steels. Mater. Des. 2014, 53, 888–901. [Google Scholar] [CrossRef]

- Stepanov, P.P.; Zikeev, V.N.; Efron, L.I.; Frantov, I.I.; Morozov, Y.D. Improvement in steel weldability for large diameter thick-walled gas pipelines by optimizing chemical composition. Metallurgist 2011, 54, 767–774. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Standards Press: Beijing, China, 2022. (In Chinese)

- Qiao, G.-Y.; Chen, X.-W.; Zhang, Z.-E.; Han, X.-L.; Wang, X.; Liao, B.; Xiao, F.-R. Mechanical properties of high-Nb X80 steel weld pipes for the second west-to-east gas transmission pipeline project. Adv. Mater. Sci. Eng. 2017, 2017, 7409873. [Google Scholar] [CrossRef]

- Gu, Y.; Tian, P.; Wang, X.; Han, X.-L.; Liao, B.; Xiao, F.-R. Non-isothermal prior austenite grain growth of a high-Nb X100 pipeline steel during a simulated welding heat cycle process. Mater. Des. 2016, 89, 589–596. [Google Scholar] [CrossRef]

- Frantov, I.I.; Velichko, A.A.; Bortsov, A.N.; Utkin, I.Y. Weldability of niobium-containing high-strength steel for pipelines Welding. Weld. J. 2014, 93, 23–29. [Google Scholar]

- Li, B.; Liu, Q.Y.; Jia, S.J.; Ren, Y.; Yang, P. Effect of V content and heat input on HAZ softening of deep-sea pipeline steel. Materials 2022, 15, 794. [Google Scholar] [CrossRef]

| Steels | Grade | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | Nb | Ti | N | Fe | Ceq |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | X90 | 0.06 | 0.24 | 1.80 | 0.009 | 0.002 | 0.21 | 0.28 | 0.234 | 0.213 | 0.095 | 0.014 | 0.004 | Bal. | 0.488 |

| B | X90 | 0.05 | 0.24 | 1.95 | 0.008 | 0.002 | 0.31 | 0.30 | 0.425 | 0.021 | 0.062 | 0.014 | 0.004 | Bal. | 0.527 |

| C | X90 | 0.06 | 0.18 | 1.84 | 0.008 | 0.002 | 0.30 | 0.19 | 0.384 | 0.203 | 0.080 | 0.011 | 0.004 | Bal. | 0.504 |

| D | X80 | 0.06 | 0.22 | 1.65 | 0.010 | 0.003 | 0.23 | 0.01 | 0.215 | 0.019 | 0.079 | 0.016 | 0.006 | Bal. | 0.399 |

| E | X80 | 0.06 | 0.22 | 1.64 | 0.007 | 0.003 | 0.22 | 0.01 | 0.224 | 0.139 | 0.079 | 0.017 | 0.006 | Bal. | 0.404 |

| F | X80 | 0.06 | 0.20 | 1.79 | 0.011 | 0.001 | 0.26 | 0.24 | 0.037 | 0.016 | 0.062 | 0.014 | 0.004 | Bal. | 0.462 |

| Steels | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Yield strength/MPa | 669 | 702 | 663 | 574 | 543 | 665 |

| Tensile strength/MPa | 753 | 785 | 773 | 688 | 648 | 769 |

| Yield ratio | 0.89 | 0.89 | 0.86 | 0.83 | 0.84 | 0.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Y.; Chen, X.-W.; Kang, H.-H.; Zhang, C.-G.; Wang, Z.-X.; Xiao, F.-R. Effects of Chemical Composition on Welding HAZ Softening of High-Strength Pipeline Steels. Metals 2025, 15, 1314. https://doi.org/10.3390/met15121314

Gu Y, Chen X-W, Kang H-H, Zhang C-G, Wang Z-X, Xiao F-R. Effects of Chemical Composition on Welding HAZ Softening of High-Strength Pipeline Steels. Metals. 2025; 15(12):1314. https://doi.org/10.3390/met15121314

Chicago/Turabian StyleGu, Yu, Xiao-Wei Chen, He-He Kang, Cheng-Guang Zhang, Zong-Xuan Wang, and Fu-Ren Xiao. 2025. "Effects of Chemical Composition on Welding HAZ Softening of High-Strength Pipeline Steels" Metals 15, no. 12: 1314. https://doi.org/10.3390/met15121314

APA StyleGu, Y., Chen, X.-W., Kang, H.-H., Zhang, C.-G., Wang, Z.-X., & Xiao, F.-R. (2025). Effects of Chemical Composition on Welding HAZ Softening of High-Strength Pipeline Steels. Metals, 15(12), 1314. https://doi.org/10.3390/met15121314