Research on Arc Characteristics and Microstructure of 6061 Aluminum Alloy Multi-Pulse Composite Arc Welding

Abstract

1. Introduction

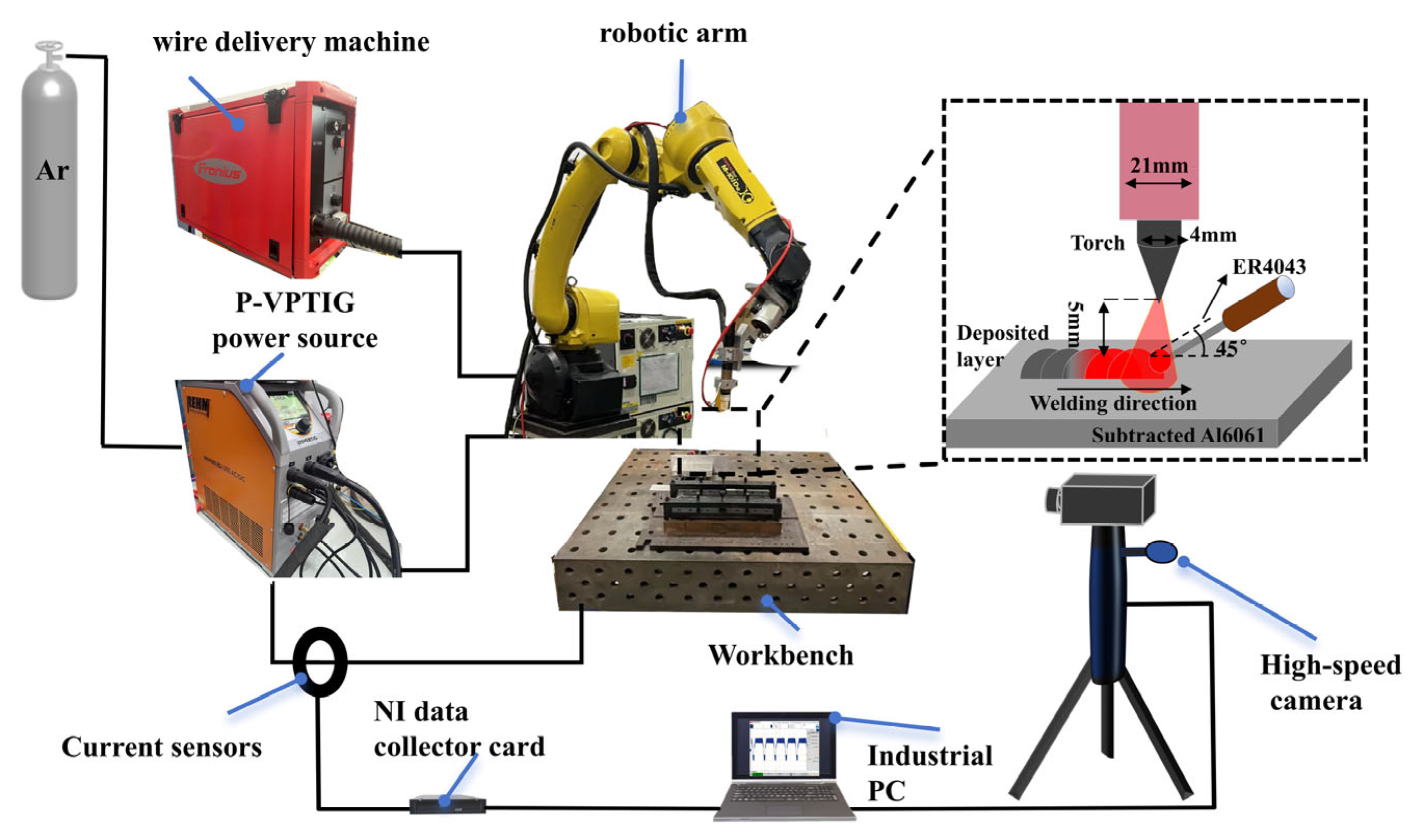

2. Experimental Methods and Materials

2.1. Experimental Materials, Equipment and Processes

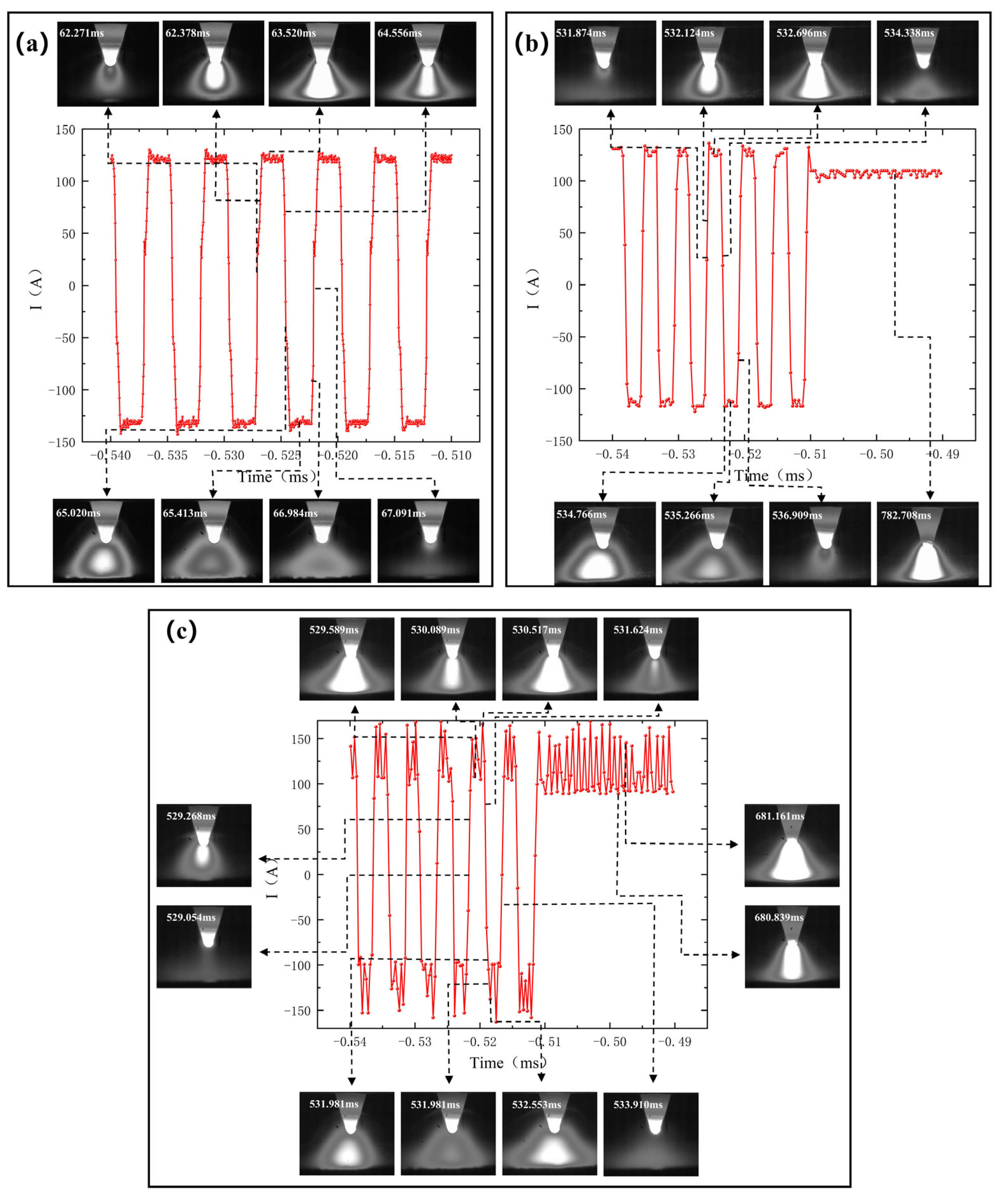

2.2. Signals and Experimental Parameters

3. Results and Discussion

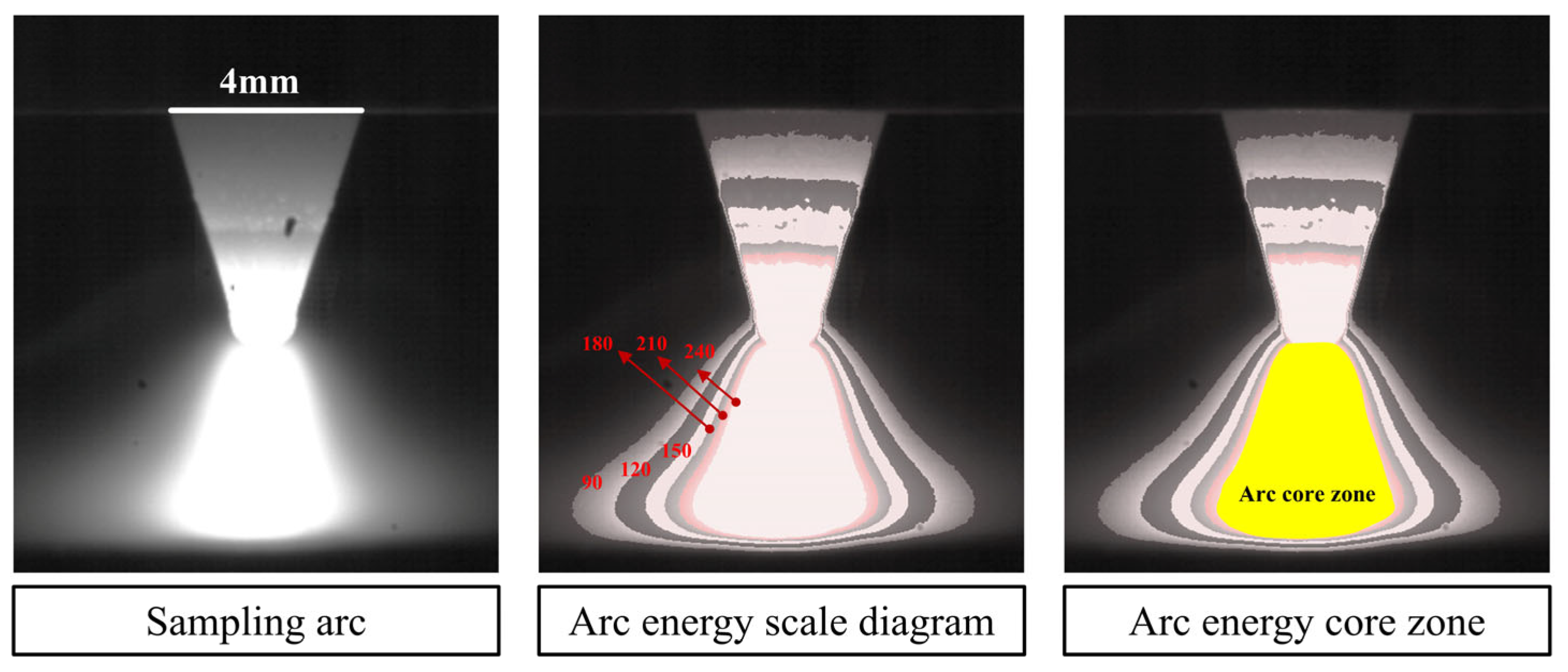

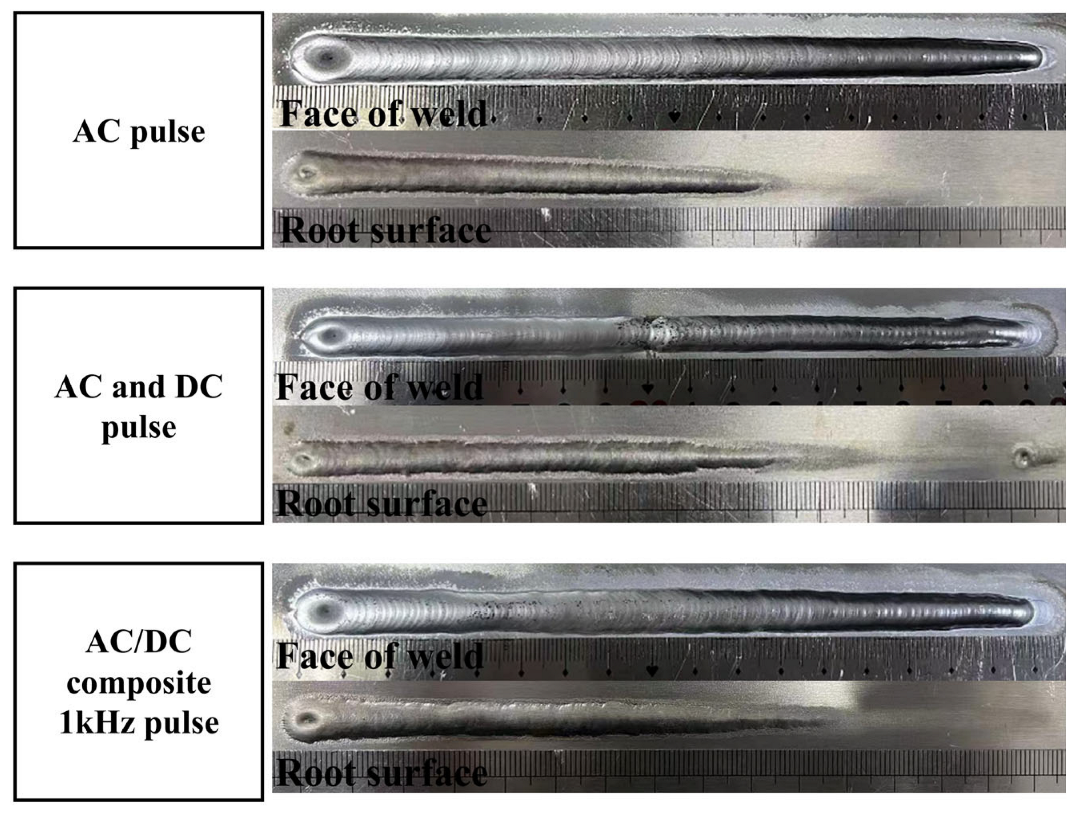

3.1. Welding Process and Forming

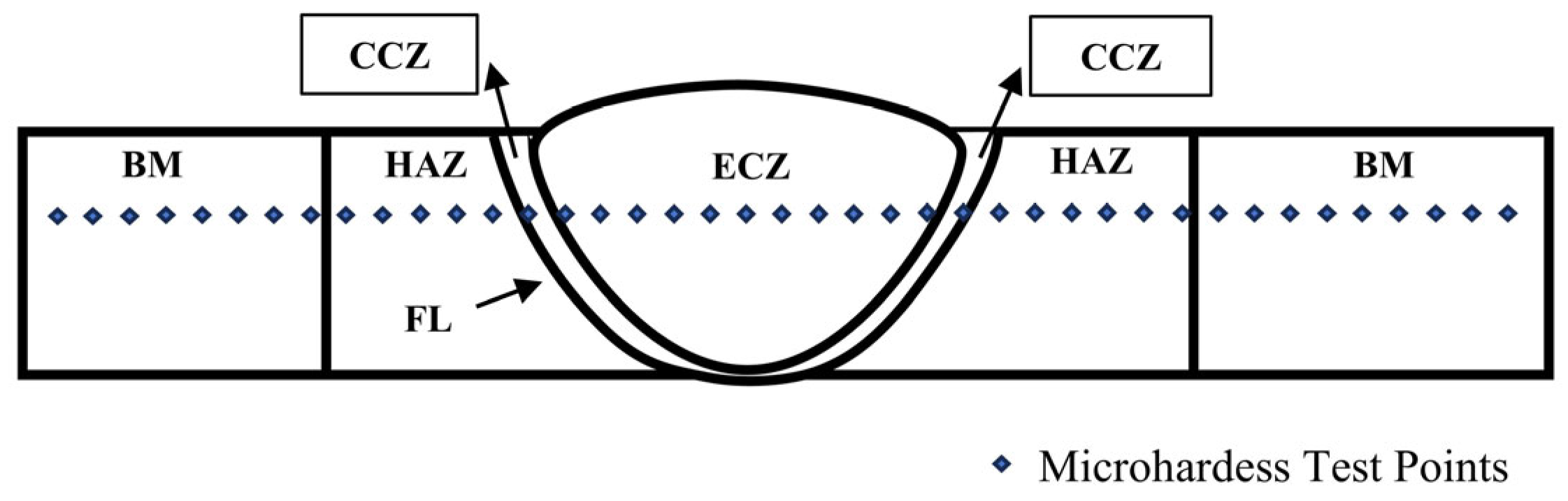

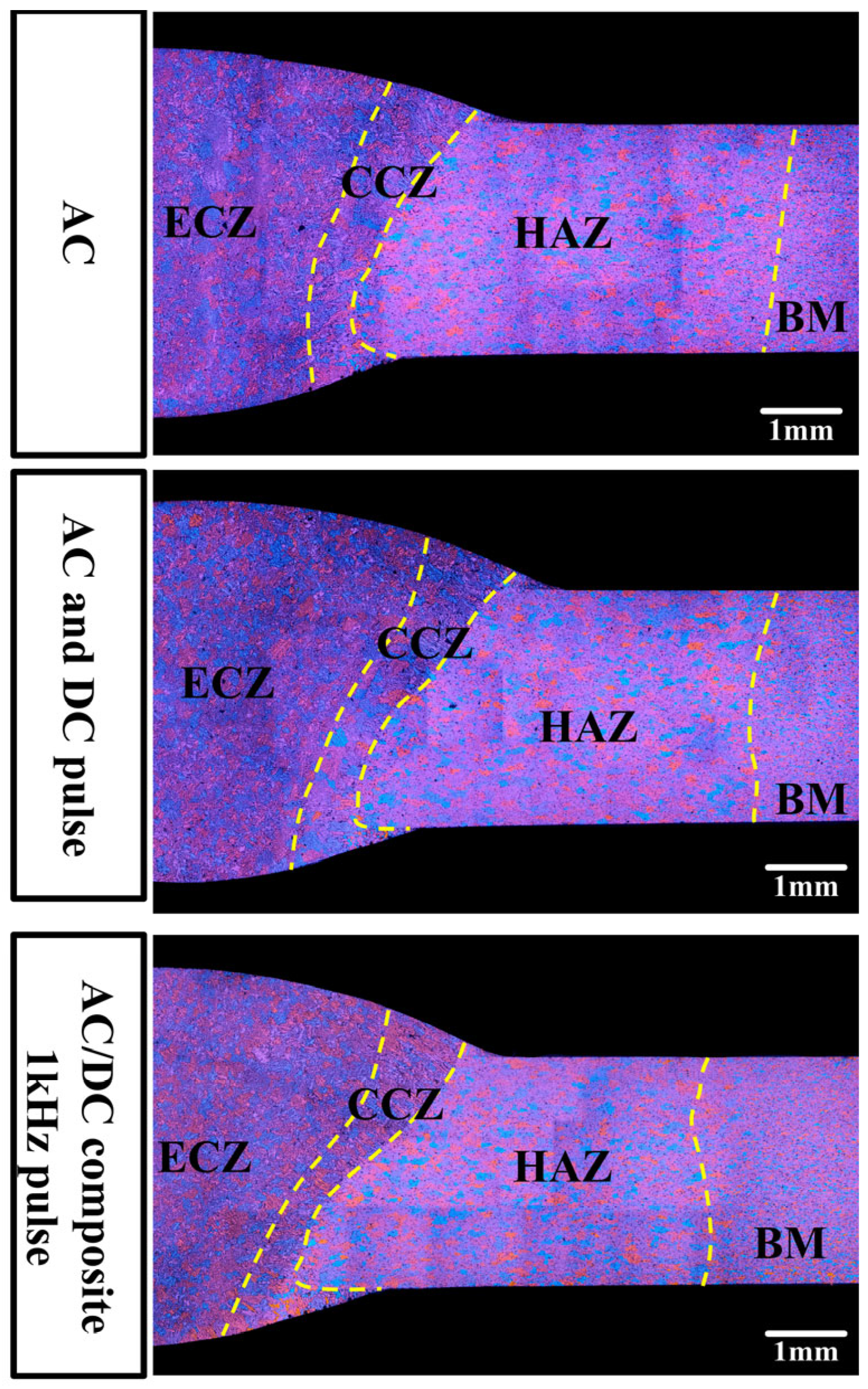

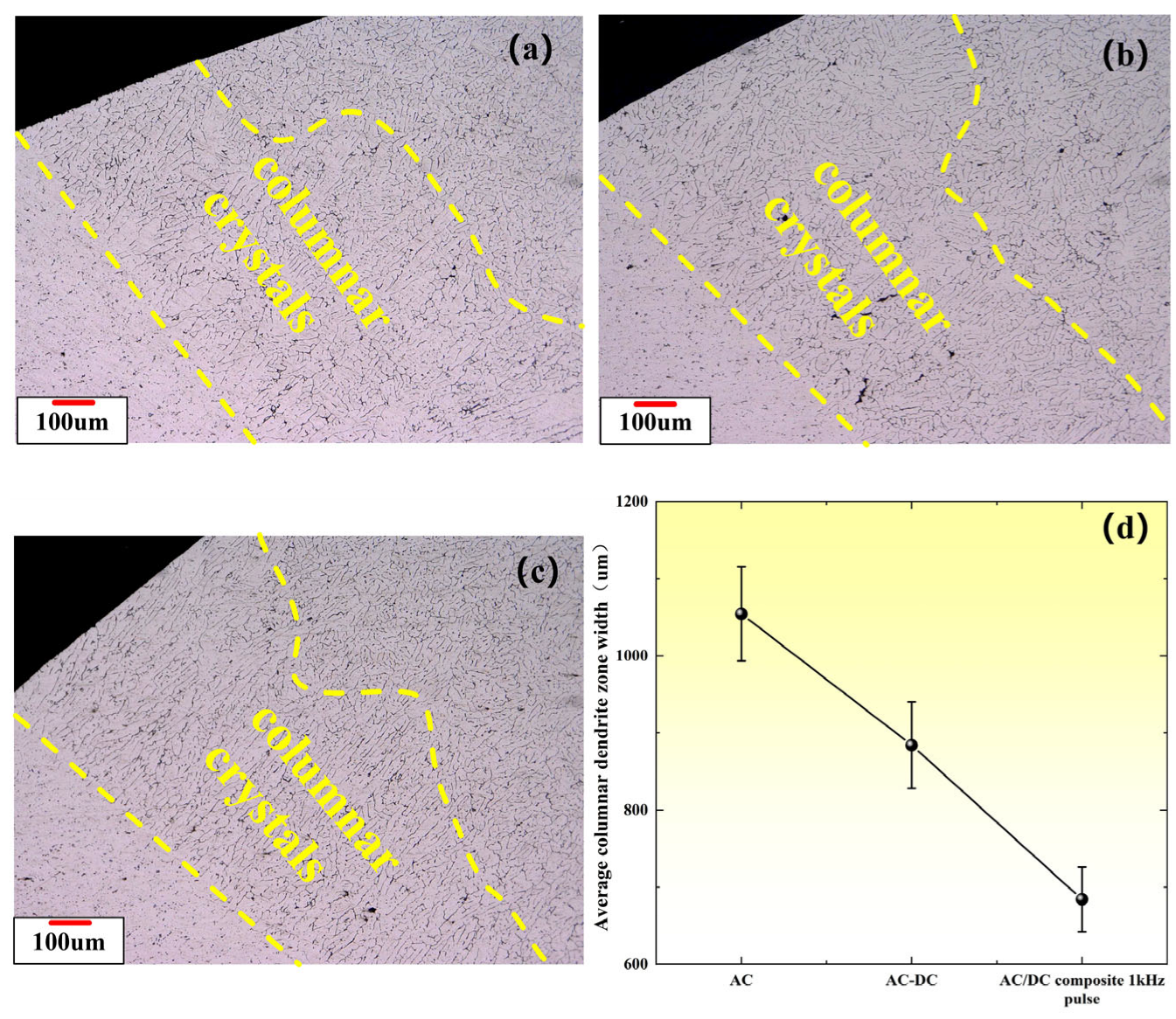

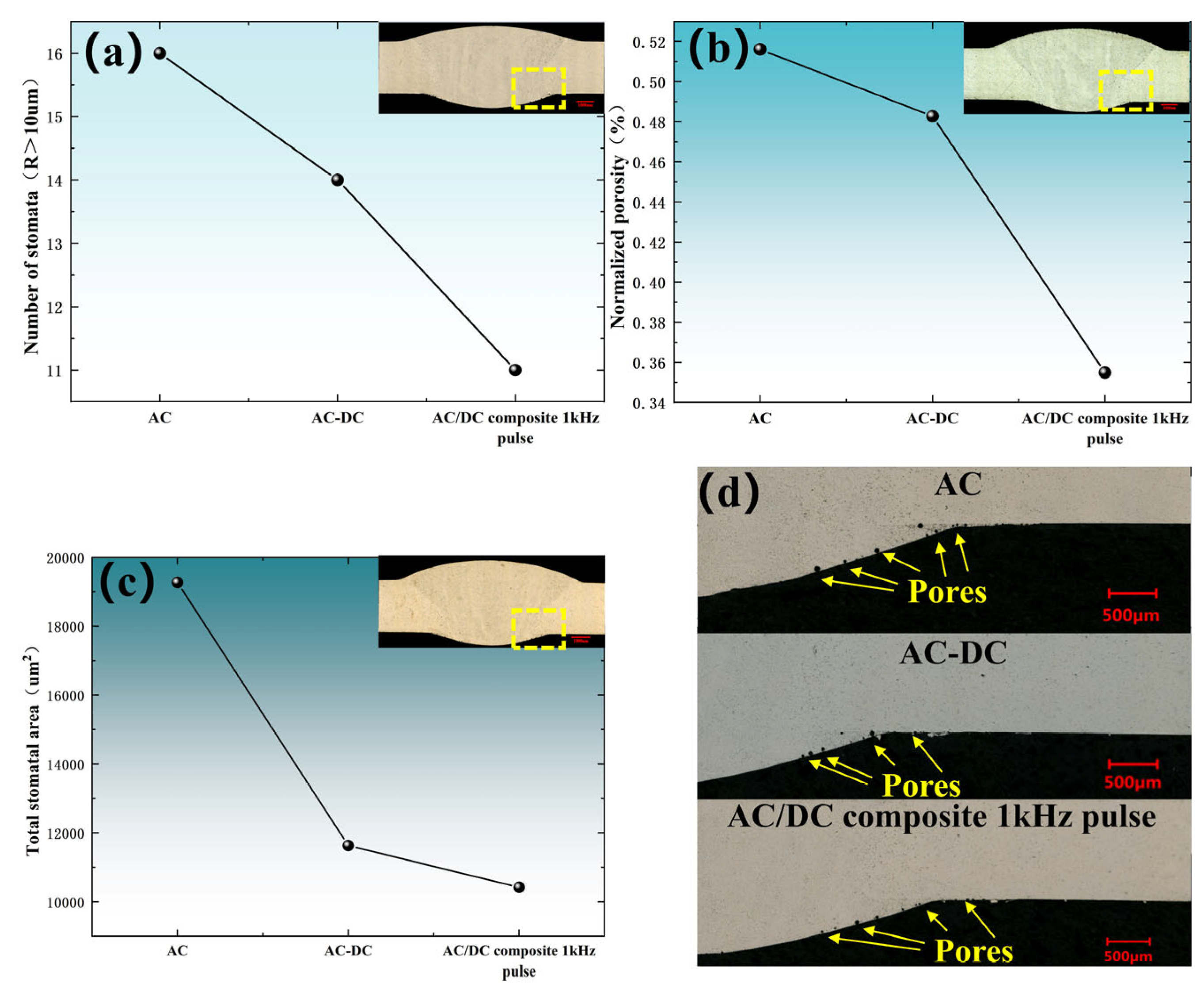

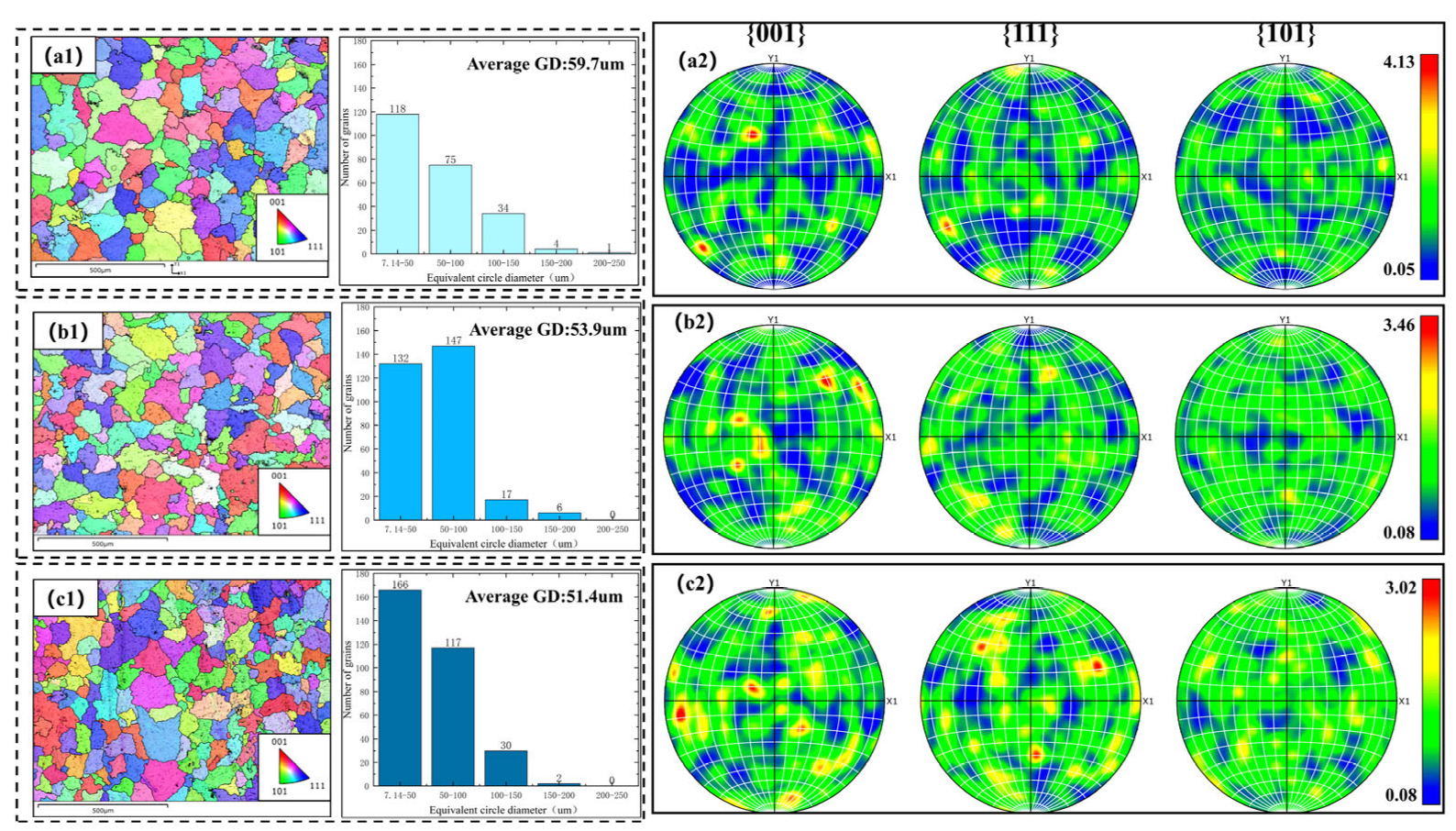

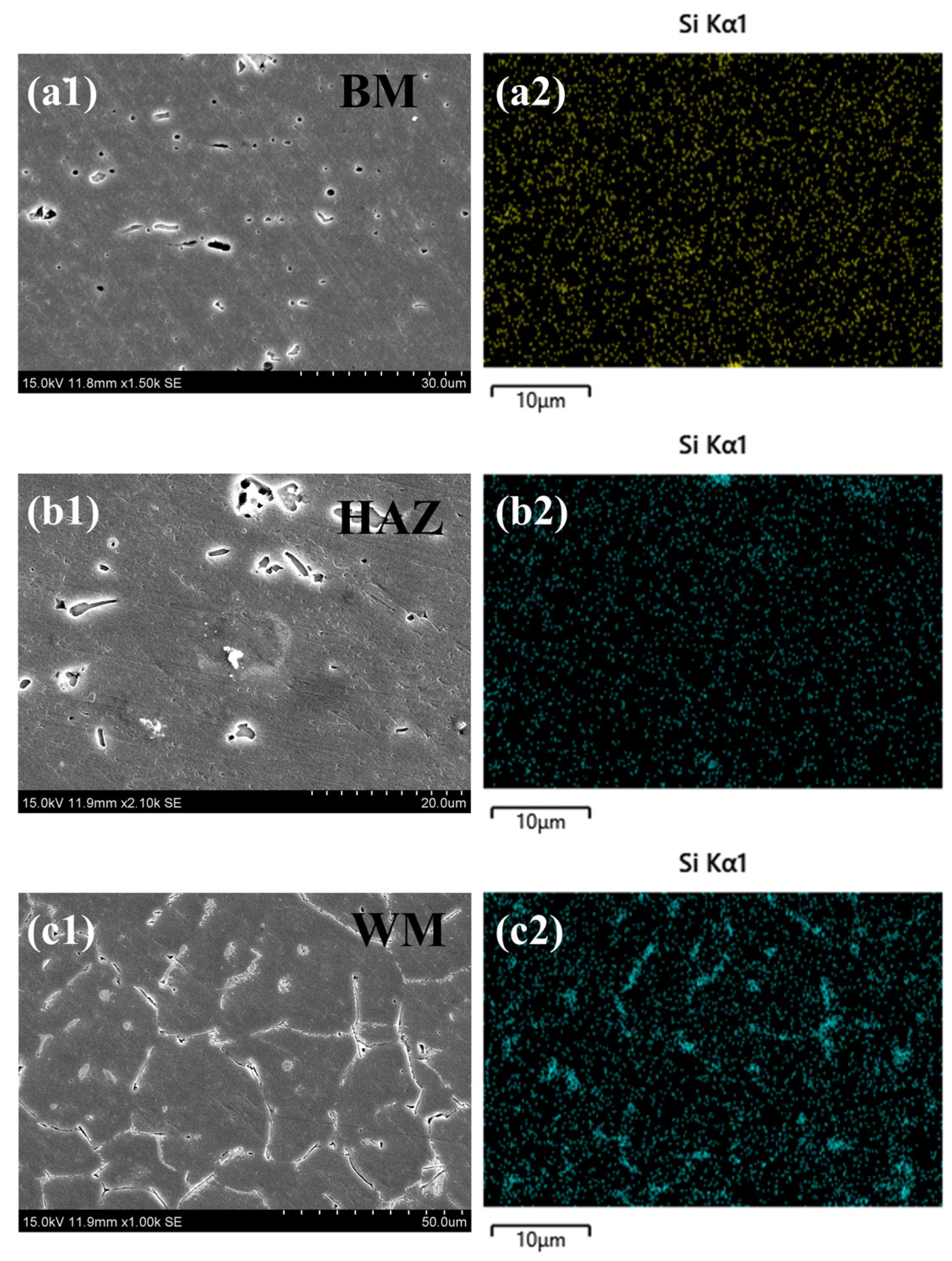

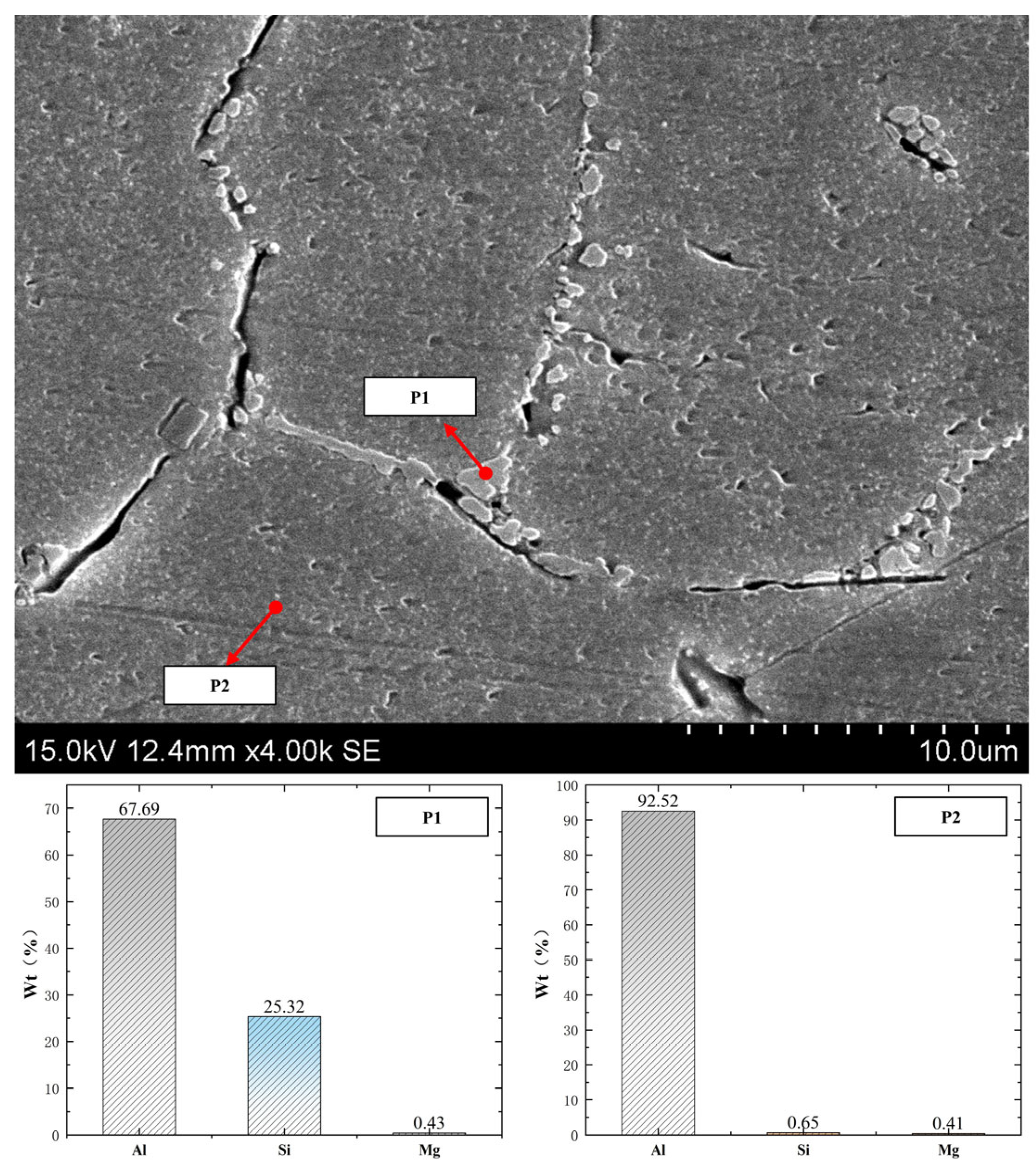

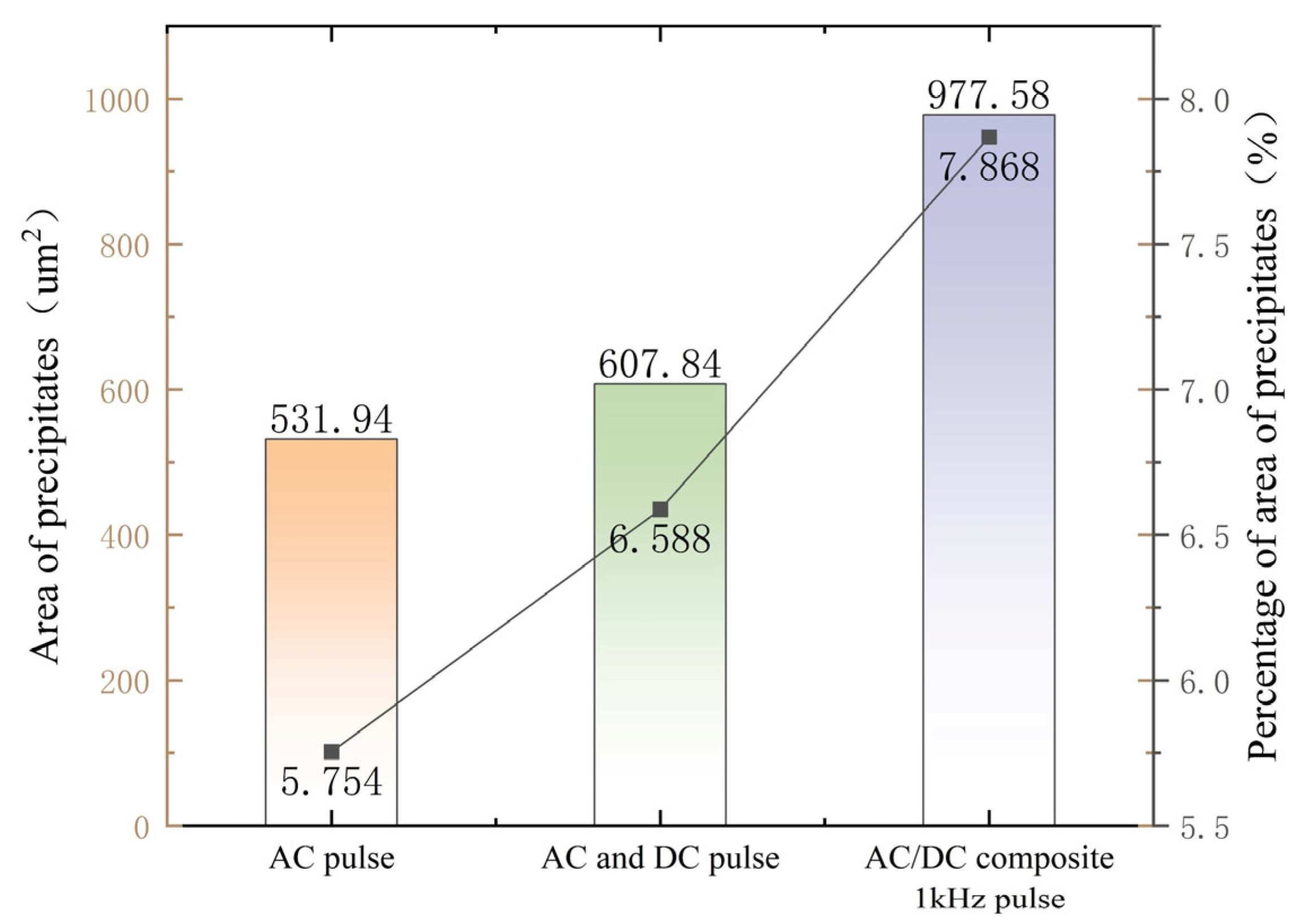

3.2. Microstructure

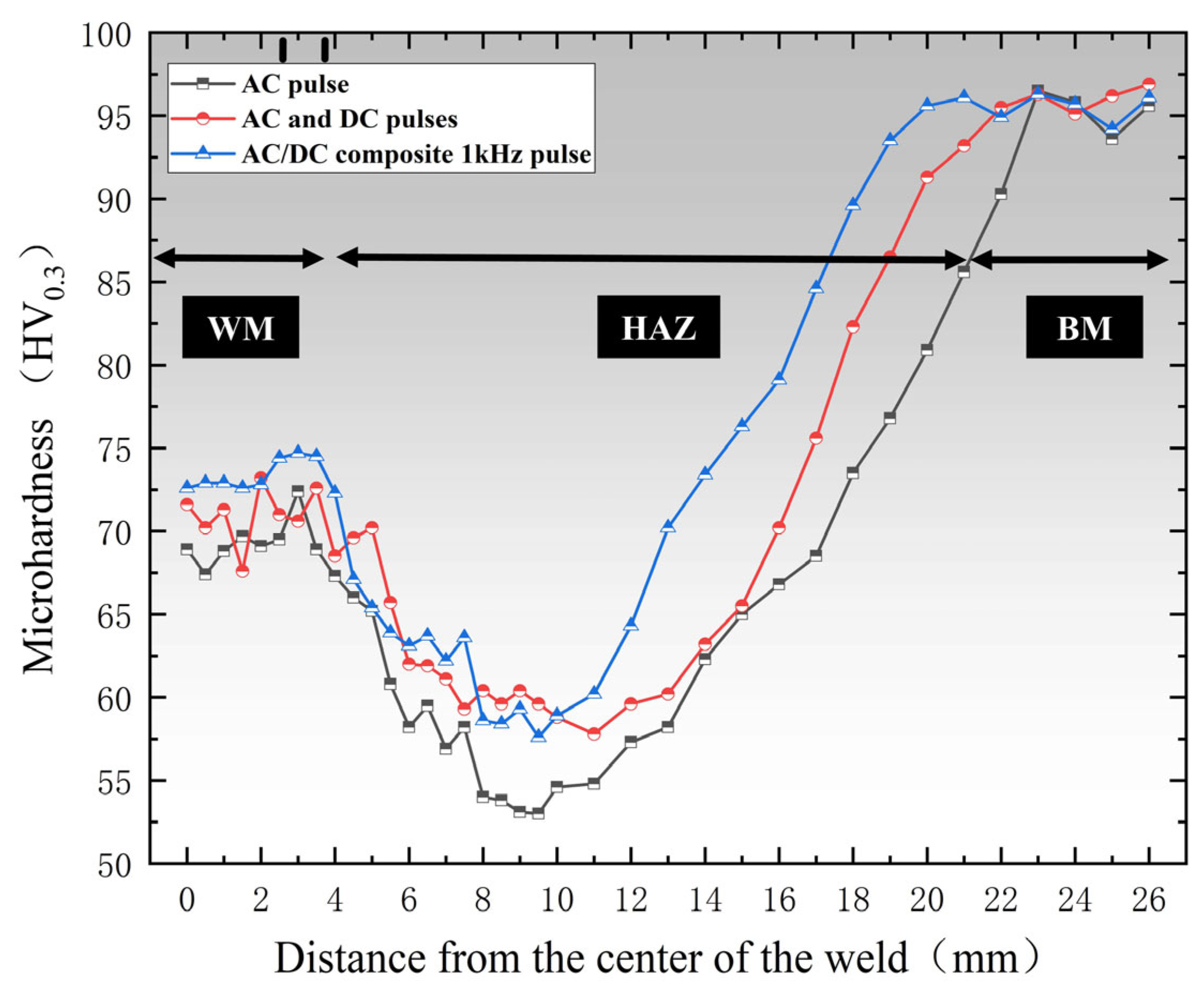

3.3. Hardness Test

4. Conclusions

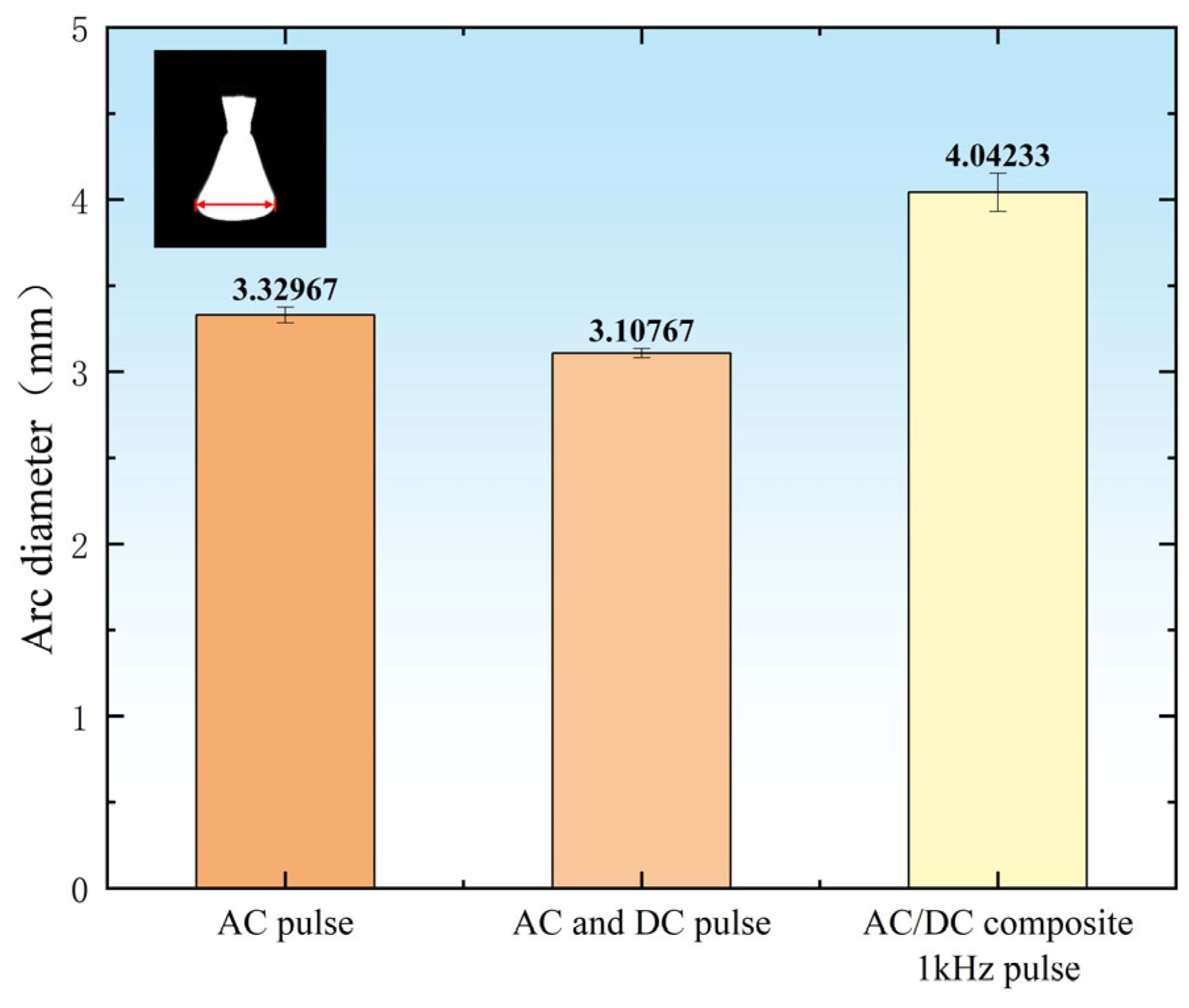

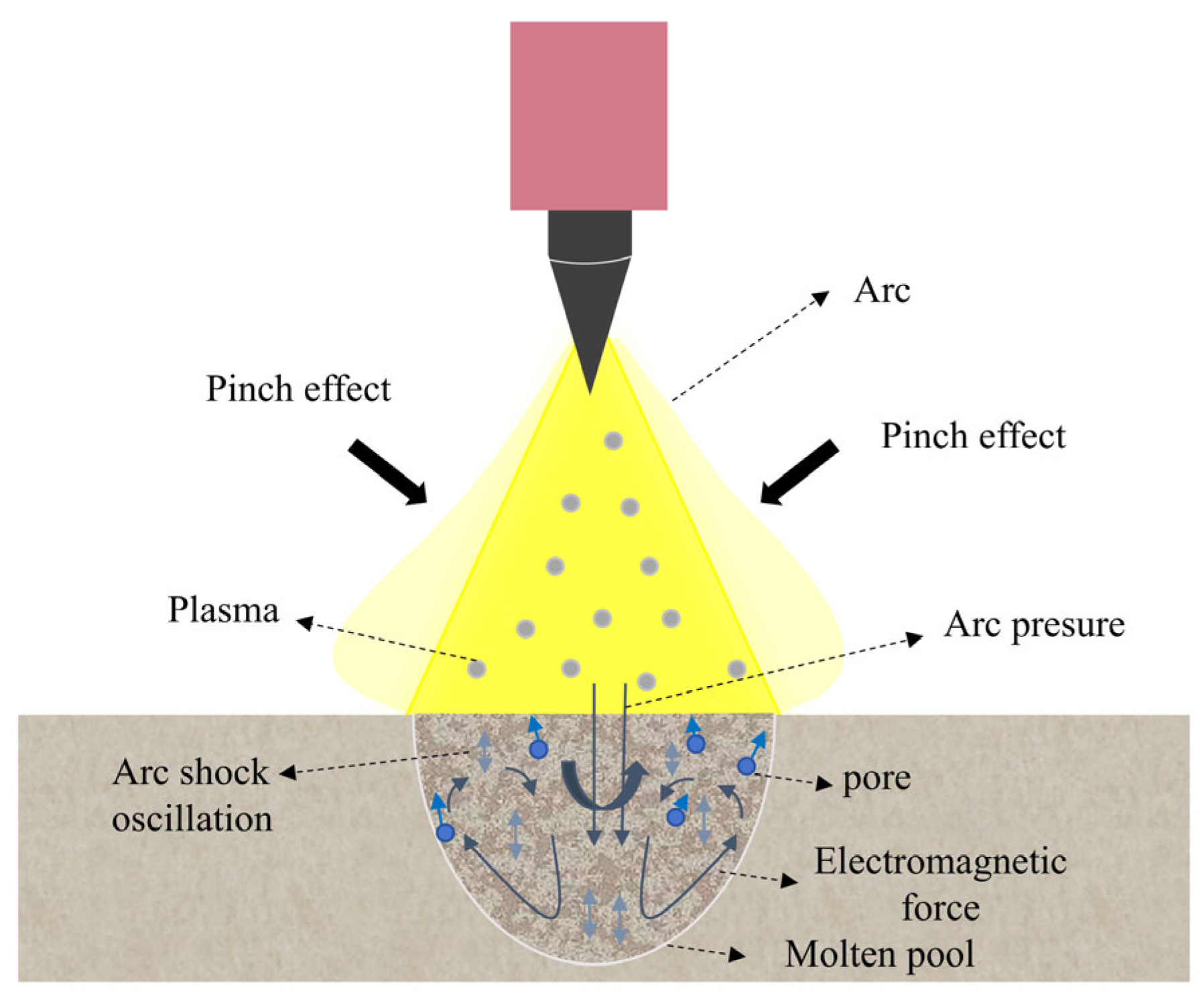

- (1)

- The AC/DC composite 1 kHz pulse process features flexibility, arc contraction (The arc diameter has increased to 4.042 mm), and enhanced input efficiency of the molten pool. The “stirring” of the molten pool accelerates its cooling and reduces the heat-affected zone.

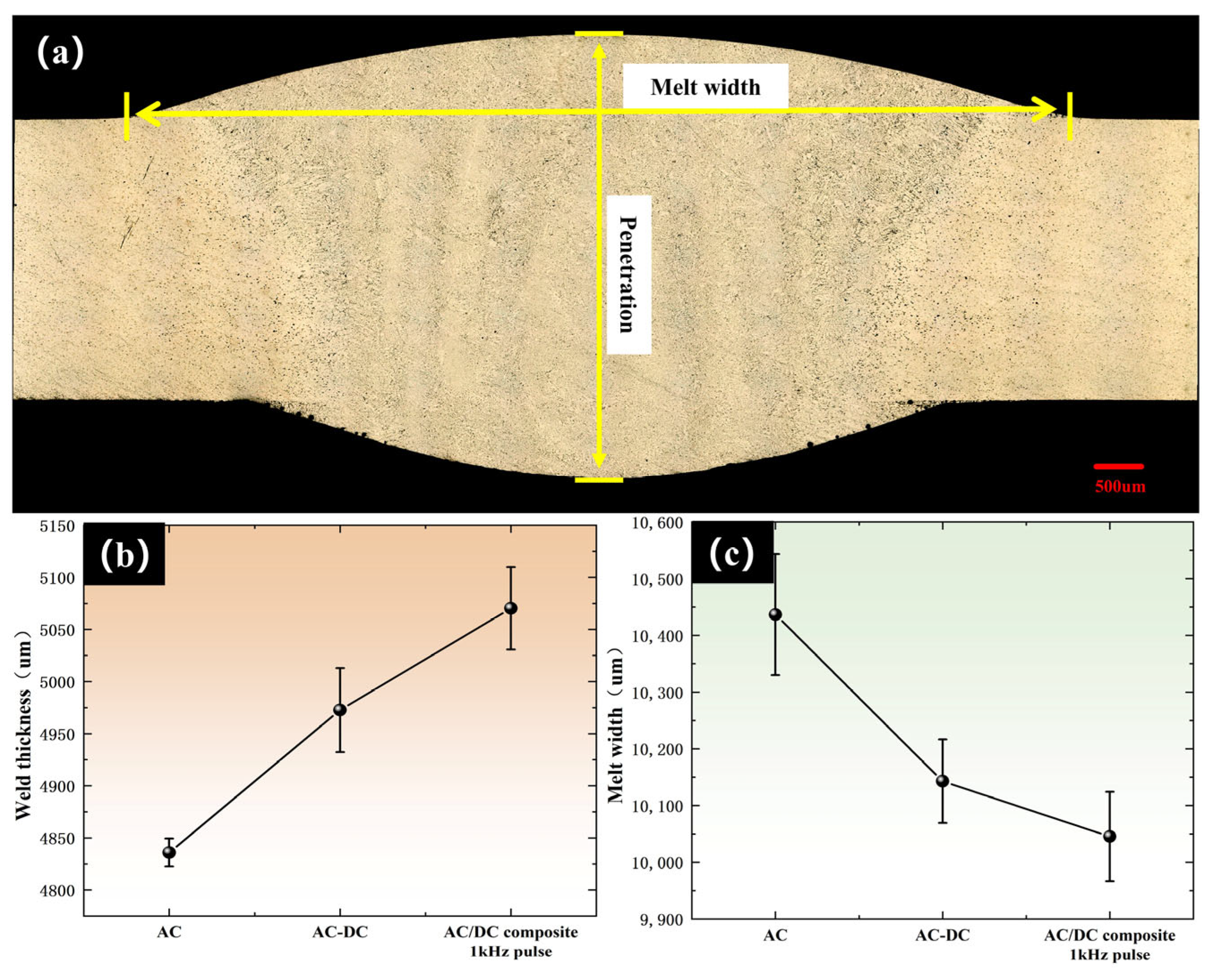

- (2)

- AC/DC compound 1 KHZ pulse process can effectively improve the weld joint of depth-to-width ratio, inhibit columnar dendrite area expansion, and inhibit the growth of weld porosity.

- (3)

- AC/DC compound 1 KHZ pulse process refining the WM zone of weld grain (the average grain size has decreased to 51.4 μm). The texture strength is reduced, the proportion of HAGBs is high, and the Al-Si eutectic structure is uniformly distributed, resulting in strong dislocation obstruction.

- (4)

- AC/DC compound 1 KHZ pulse technology improves the hardness of the weld joint; WM can be up to 77.6% of the average hardness of the parent metal hardness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, C.; Liu, J.; Jia, X. Effect of thermal deformation parameters on the microstructure, texture, and microhardness of 5754 aluminum alloy. Int. J. Miner. Metall. Mater. 2019, 26, 1140–1150. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Li, K.R. Comparison and analysis of main effect elements of machining distortion for aluminum alloy and titanium alloy aircraft monolithic component. Int. J. Adv. Manuf. Technol. 2014, 70, 1803–1811. [Google Scholar] [CrossRef]

- Hakem, M.; Lebaili, S.; Mathieu, S.; Miroud, D.; Lebaili, A.; Cheniti, B. Effect of microstructure and precipitation phenomena on the mechanical behavior of AA6061-T6 aluminum alloy weld. Int. J. Adv. Manuf. Technol. 2019, 102, 2907–2918. [Google Scholar] [CrossRef]

- Li, Y.; Zou, W.; Lee, B.; Babkin, A.; Chang, Y. Research progress of aluminum alloy welding technology. Int. J. Adv. Manuf. Technol. 2020, 109, 1207–1218. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, G.; Hu, C.; Lin, S.; Ren, X.; Wu, J.; Tian, J. A review on fast-frequency pulse TIG welding technology. Weld. Int. 2022, 36, 510–521. [Google Scholar] [CrossRef]

- Nikseresht, Z.; Karimzadeh, F.; Golozar, M.A.; Heidarbeigy, M. Effect of heat treatment on microstructure and corrosion behavior of Al6061 alloy weldment. Mater. Des. 2010, 31, 2643–2648. [Google Scholar] [CrossRef]

- Samiuddin, M.; Li, J.; Taimoor, M.; Siddiqui, M.N.; Siddiqui, S.U.; Xiong, J.-T. Investigation on the process parameters of TIG-welded aluminum alloy through mechanical and microstructural characterization. Def. Technol. 2021, 17, 1234–1248. [Google Scholar] [CrossRef]

- Chen, X.; Tang, S.; Xie, W.; Zhang, D. Numerical Simulation Study of Laser-arc Hybrid Welding of 6063/5083 Aluminum Alloy. J. Mater. Eng. Perform. 2025, 34, 9342–9351. [Google Scholar] [CrossRef]

- Yue, Y.; Wang, G.; Yang, K.; Wu, B.; Yan, D. Friction stir butt welding thin aluminum alloy sheets. Int. J. Adv. Manuf. Technol. 2018, 96, 3139–3147. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S. Investigation of Laser-MIG Hybrid Welding of Al-Mg-Si Aluminum Alloy. Metals 2024, 14, 729. [Google Scholar] [CrossRef]

- Bardel, D.; Nelias, D.; Robin, V.; Pirling, T.; Boulnat, X.; Perez, M. Residual stresses induced by electron beam welding in a 6061 aluminium alloy. J. Mater. Process. Technol. 2016, 235, 1–12. [Google Scholar] [CrossRef]

- Norrish, J. 1—An introduction to welding processes. In Advanced Welding Processes; Norrish, J., Ed.; Woodhead Publishing: Sawston, UK, 2006; pp. 1–15. [Google Scholar]

- Ye, Y.; Yang, B.; Yang, Y.; Pan, Z.; Chen, C.; Zhang, X. Research on the Formation, Microstructure, and Properties of 304 Stainless Steel AC-DC Hybrid TIG Welding. Metals 2023, 13, 1127. [Google Scholar] [CrossRef]

- Guo, B.; Cong, X.; Du, W.; Zhang, H.; Chen, C. Effect of AC signal ratio on the formation, microstructure and mechanical properties of welded joint of AZ31B Mg alloy during the AC/DC mix GTAW. J. Manuf. Process. 2023, 85, 306–313. [Google Scholar] [CrossRef]

- Han, Y.; Chen, S.; Yin, S. Principle of produced heat by arc properties in VPPA of aluminum alloy. Trans. China Weld. Inst. 2007, 12, 35–37,42. [Google Scholar]

- Wang, Y.; Chen, M.; Wu, C. High-frequency pulse-modulated square wave AC TIG welding of AA6061-T6 aluminum alloy. Weld. World 2020, 64, 1749–1762. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Inagaki, F.; Kamai, M. Development of high frequency tungsten inert gas welding method. Mater. Des. 1980–2015 2013, 44, 12–16. [Google Scholar] [CrossRef]

- Meng, Y.; Yu, Q.; Gao, M.; Chen, H.; Jiang, Y.; Yang, Z. High-frequency oscillating laser-arc hybrid welding of 8-mm-thick high-strength aluminum alloy through synchronous wire-powder feeding. Int. J. Heat Mass Transf. 2024, 222, 125180. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, H.; Li, L. Arc Shape Characteristics with Ultra-High-Frequency pulsed Arc Welding. Appl. Sci. 2017, 7, 45. [Google Scholar] [CrossRef]

- ASTM RR-B07-1001; B0647—Test Method for Indentation Hardness of Aluminum Alloys by Means of a Webster Hardness Gage. ASTM: West Conshohocken, PA, USA, 2023.

- Han, Y.; Hong, H.; Guo, L.; Yao, Q. Vertical welding of aluminum alloy during variable polarity plasma arc welding process with AC-DC mixing output current. Trans. China Weld. Inst. 2013, 9, 59–62. [Google Scholar]

- Peng, Z.; Liang, Y.; Liu, H.; Wang, F.; Yang, J.; Song, Y. Research on Process Characteristics and Properties in Deep-Penetration Variable-Polarity Tungsten Inert Gas Welding of AA7075 Aluminum Alloy. Metals 2024, 14, 1068. [Google Scholar] [CrossRef]

- Wu, K.; Liu, Z.; Chen, Q.; Wu, Y.; Chen, Z.; Hong, X. Effect of high-frequency pulse frequency on arc characteristics and weld formation of aluminum alloy in variable polarity 1 kHz pulse GMAW. Weld. World 2025, 69, 2691–2709. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, D.; Wu, J.; Xu, M. A review on high-frequency pulsed arc welding. J. Manuf. Process. 2020, 60, 503–519. [Google Scholar] [CrossRef]

- Mesbah, M.; Fadaeifard, F.; Nasiri-Tabrizi, B.; Matori, K.; Basirun, W. The impacts of grain boundary on the scattering of intermetallics in friction-stir-welded AA6061-T6. Mater. Lett. 2021, 300, 130206. [Google Scholar] [CrossRef]

- Liu, X.; Jia, R.; Zhang, H.; Cheng, W.; Zhai, X. EBSD Characterization of the Microstructure of 7A52 Aluminum Alloy Joints Welded by Friction Stir Welding. Materials 2021, 14, 6362. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Xu, Y. A quasi-in-situ EBSD study on abnormal grain growth in 2219 aluminum alloy friction stir welded joints during post-weld heat treatment. Mater. Des. 2024, 247, 113386. [Google Scholar] [CrossRef]

- Liang, Y.; Hu, S.; Shen, J.; Zhang, H.; Wang, P. Geometrical and microstructural characteristics of the TIG-CMT hybrid welding in 6061 aluminum alloy cladding. J. Mater. Process. Technol. 2017, 239, 18–30. [Google Scholar] [CrossRef]

- Liang, Y.; Shen, J.; Hu, S.; Wang, H.; Pang, J. Effect of TIG current on microstructural and mechanical properties of 6061-T6 aluminium alloy joints by TIG–CMT hybrid welding. J. Mater. Process. Technol. 2018, 255, 161–174. [Google Scholar] [CrossRef]

- Selvamani, S.T. Microstructure and stress corrosion behaviour of CMT welded AA6061 T-6 aluminium alloy joints. J. Mater. Res. Technol. 2021, 15, 315–326. [Google Scholar] [CrossRef]

- Li, R.; Yuan, X.; Zhang, H.; Yang, J.; Wu, K.; Li, T.; Wang, G.; Tao, S. Effect of axial magnetic field on TIG welding–brazing of AA6061 aluminum alloy to HSLA350 steel. J. Mater. Res. Technol. 2021, 12, 882–893. [Google Scholar] [CrossRef]

- Han, J.; Shi, Y.; Zhang, G.; Volodymyr, K.; Le, W.-Y. Minimizing defects and controlling the morphology of laser welded aluminum alloys using power modulation-based laser beam oscillation. J. Manuf. Process. 2022, 83, 49–59. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, B.; Cai, X.; Chen, Q.; Fan, Y.; Lin, S. Ultrasonic-driven grain refinement in high-frequency pulsed welding of Inconel 690 alloy: Interplay between ultrasonic and molten pool dynamic. J. Manuf. Process. 2025, 146, 172–190. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Al6061 | 0.4–0.8 | <0.7 | 0.15–0.4 | <0.15 | 0.8–1.2 | 0.04–0.35 | 0.25 | <0.15 | Bal. |

| Alloy | Si | Fe | Cu | Mn | Mg | Other | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| ER4043 | 4.5 | 0.8 | 0.3 | 0.05 | 0.05 | 0.15 | 0.1 | 0.2 | Bal. |

| Parameters | Value |

|---|---|

| Rated current (A) | 130 |

| Welding speed Vw (cm, min) | 20 |

| Wire feed rate Vf (m, min) | 1.8 |

| The proportion of AC and DC pulse time (AC-0.3 s, DC-0.2 s) | 3:2 |

| The protective gas is 99.99% industrial pure argon (L, min) | 15 |

| Signal | Current Value | DC | Low-Frequency Pulses | High-Frequency Pulses | ||||

|---|---|---|---|---|---|---|---|---|

| Process Sequence Number | Waveform | Peak Current Ip, A | Background Current Ib, A | Yes, No | Frequency f1, Hz | Duty Cycle | Frequency f2, kHz | Duty Cycle |

| 1 | square | 0 | 0 | No | 200 | 50 | 0 | 0 |

| 2 | square | 0 | 0 | Yes | 200 | 50 | 0 | 0 |

| 3 | square | 170 | 90 | Yes | 200 | 50 | 1 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Ye, X.; Li, F.; Du, Y.; Chang, G.; Xia, P. Research on Arc Characteristics and Microstructure of 6061 Aluminum Alloy Multi-Pulse Composite Arc Welding. Metals 2025, 15, 1294. https://doi.org/10.3390/met15121294

Zhang G, Ye X, Li F, Du Y, Chang G, Xia P. Research on Arc Characteristics and Microstructure of 6061 Aluminum Alloy Multi-Pulse Composite Arc Welding. Metals. 2025; 15(12):1294. https://doi.org/10.3390/met15121294

Chicago/Turabian StyleZhang, Guangshun, Xin Ye, Fang Li, Yonggang Du, Guangcai Chang, and Peng Xia. 2025. "Research on Arc Characteristics and Microstructure of 6061 Aluminum Alloy Multi-Pulse Composite Arc Welding" Metals 15, no. 12: 1294. https://doi.org/10.3390/met15121294

APA StyleZhang, G., Ye, X., Li, F., Du, Y., Chang, G., & Xia, P. (2025). Research on Arc Characteristics and Microstructure of 6061 Aluminum Alloy Multi-Pulse Composite Arc Welding. Metals, 15(12), 1294. https://doi.org/10.3390/met15121294