Direct Energy Deposition of Inconel 718 onto Cu Substrate for Bimetallic Structures with Excellent Comprehensive Properties

Abstract

1. Introduction

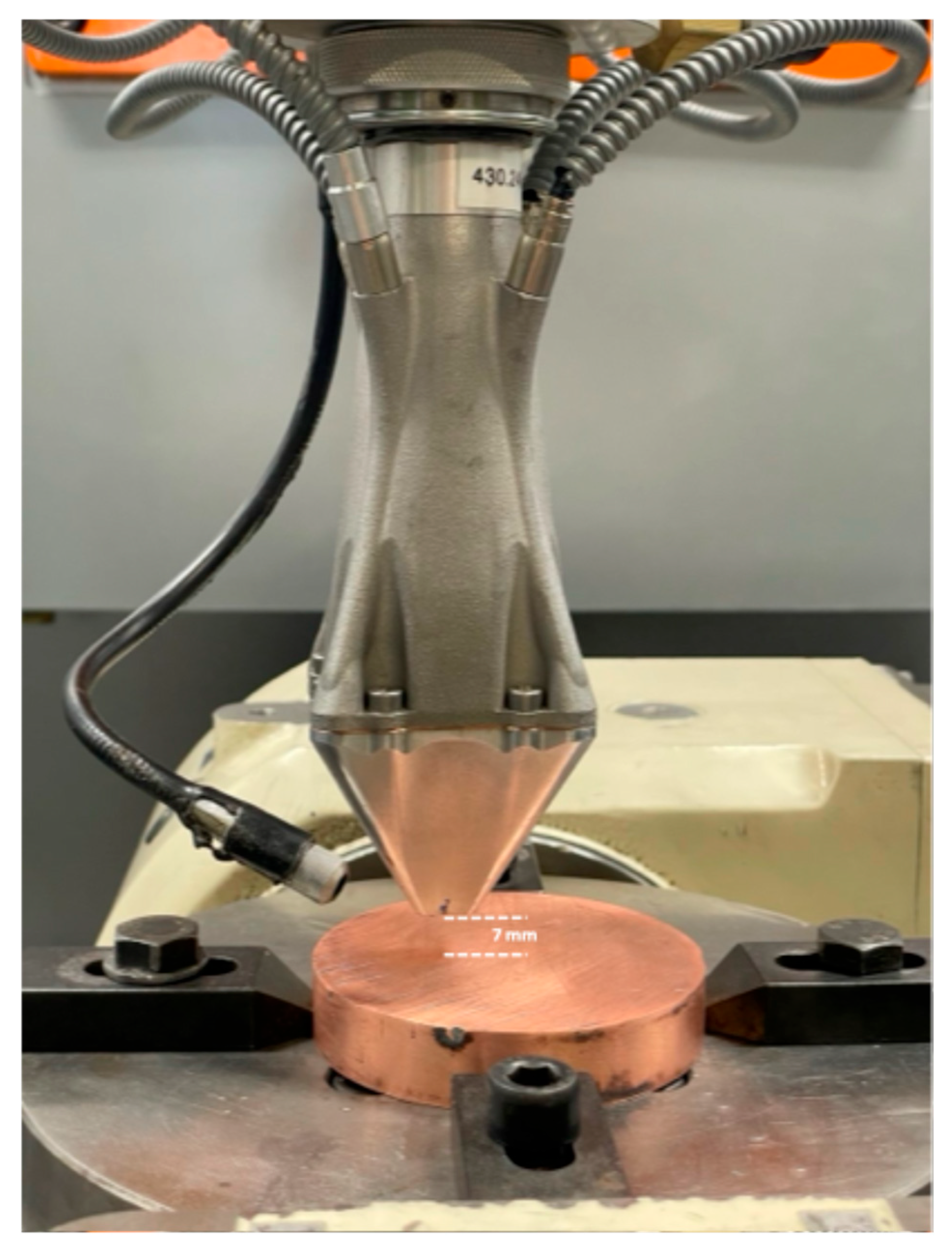

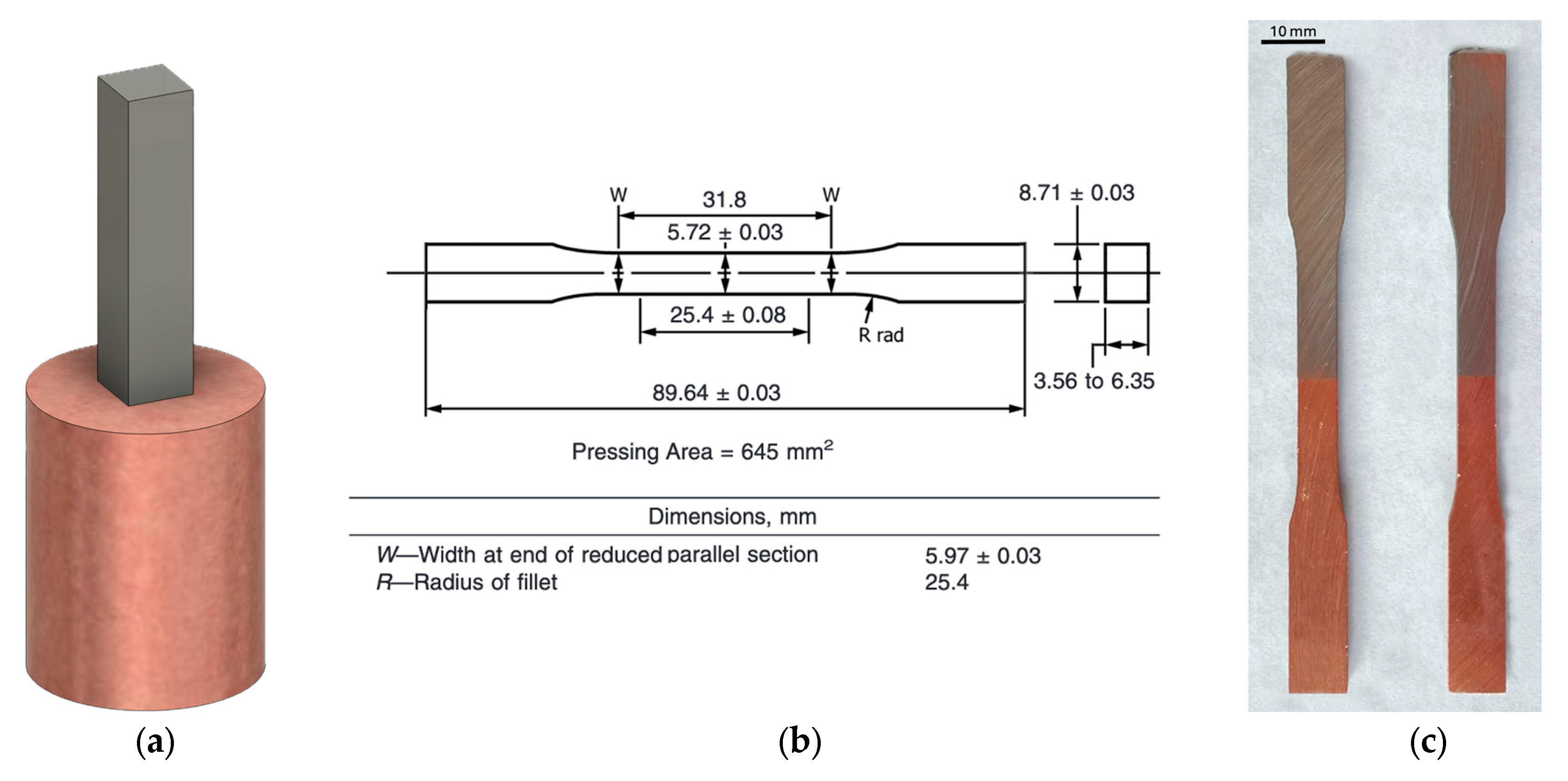

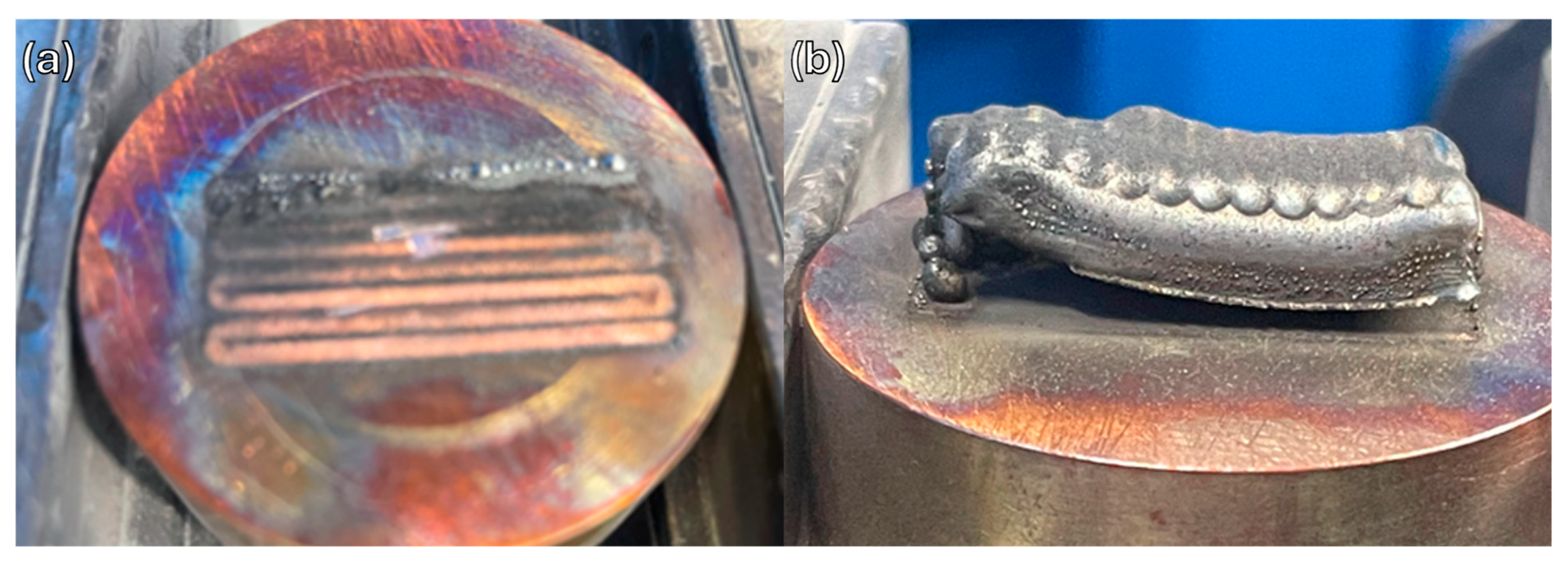

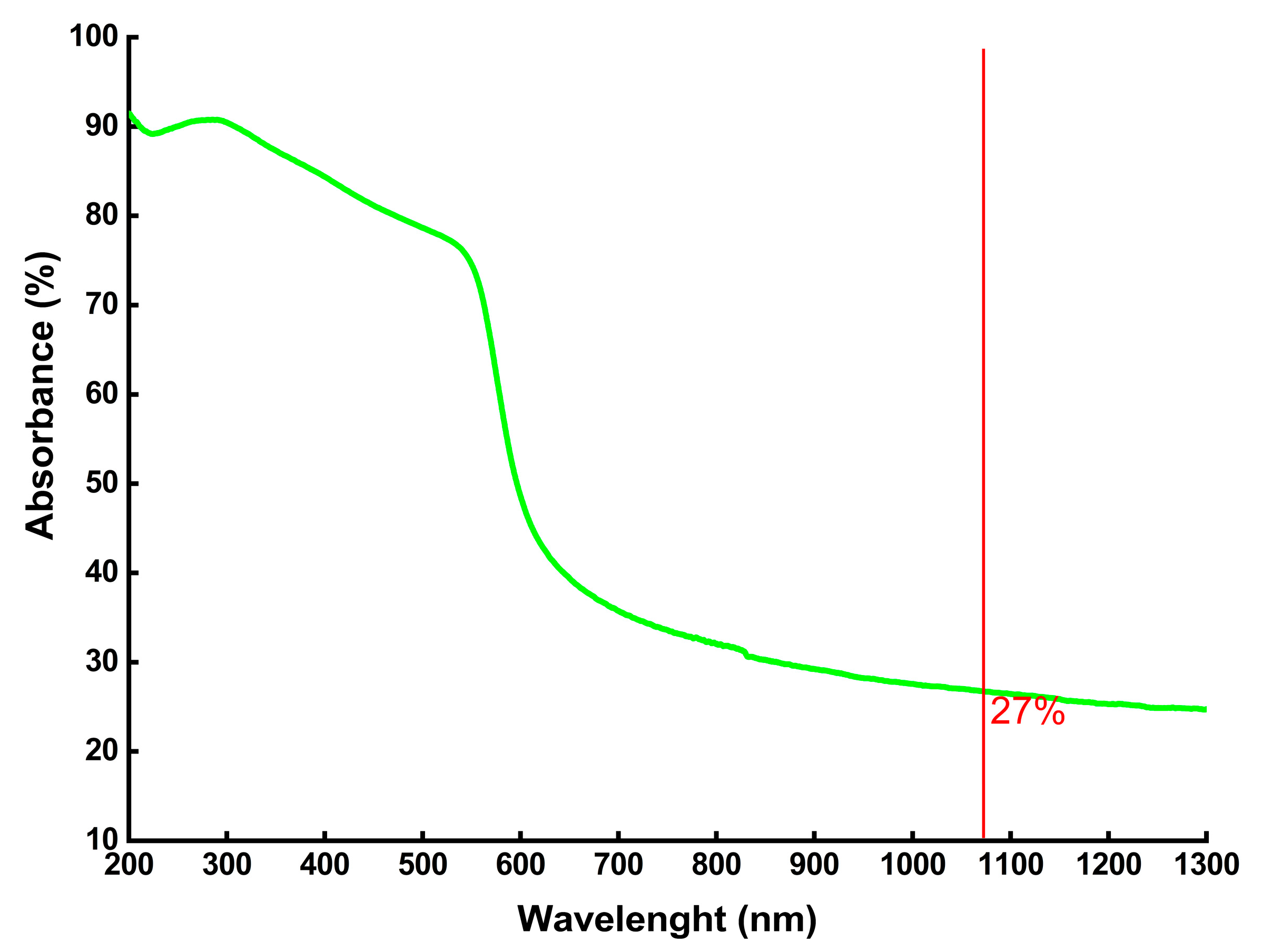

2. Materials and Methods

3. Results and Discussion

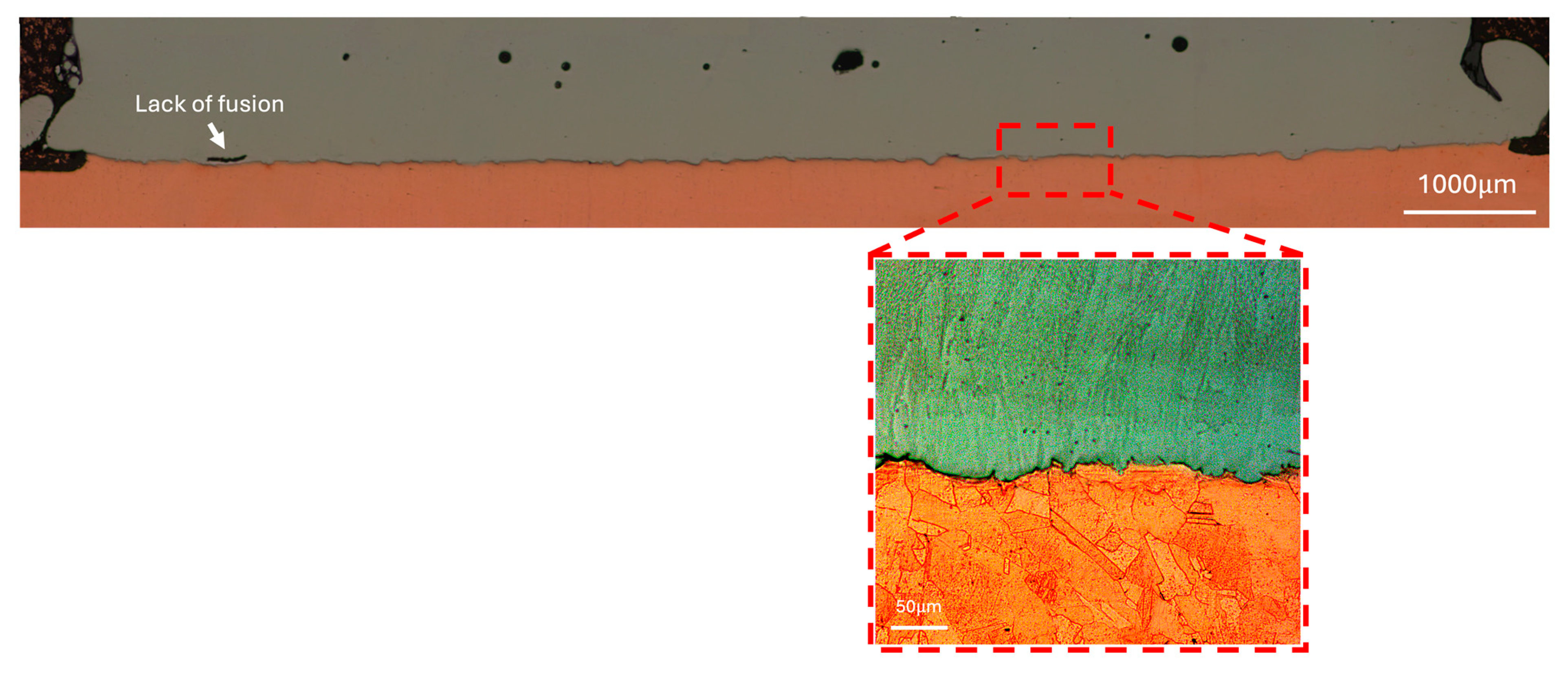

3.1. DED Processing of In718 on Copper

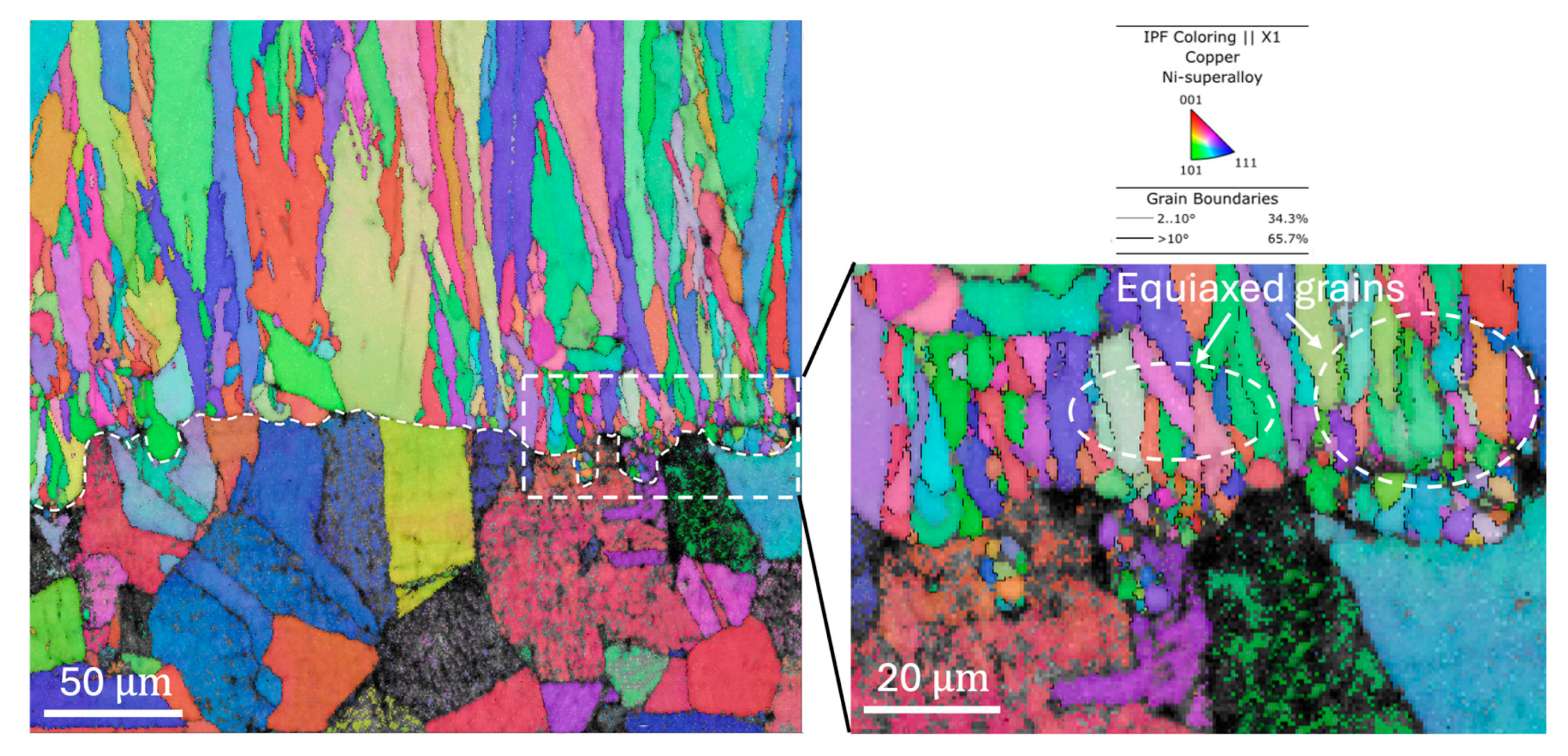

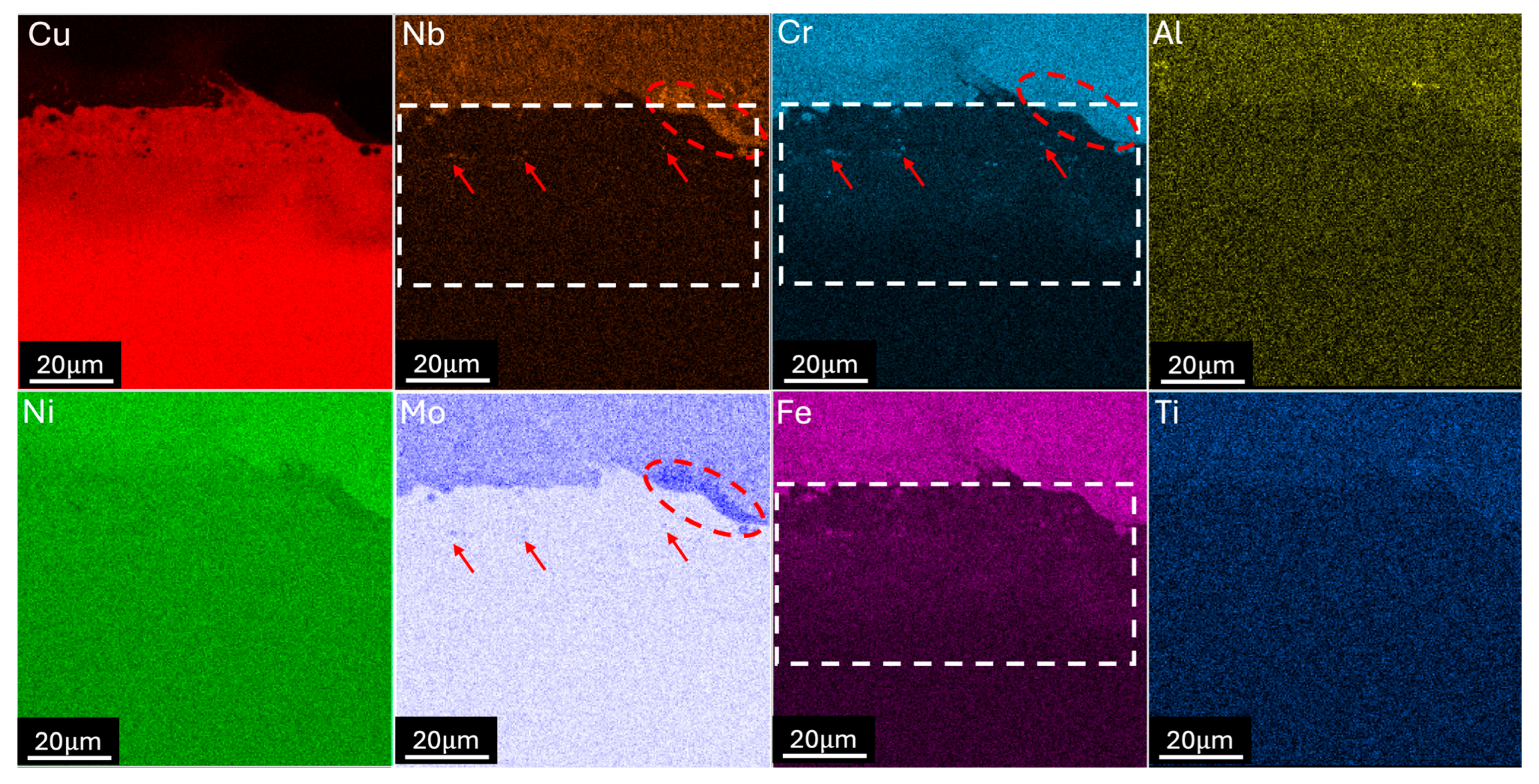

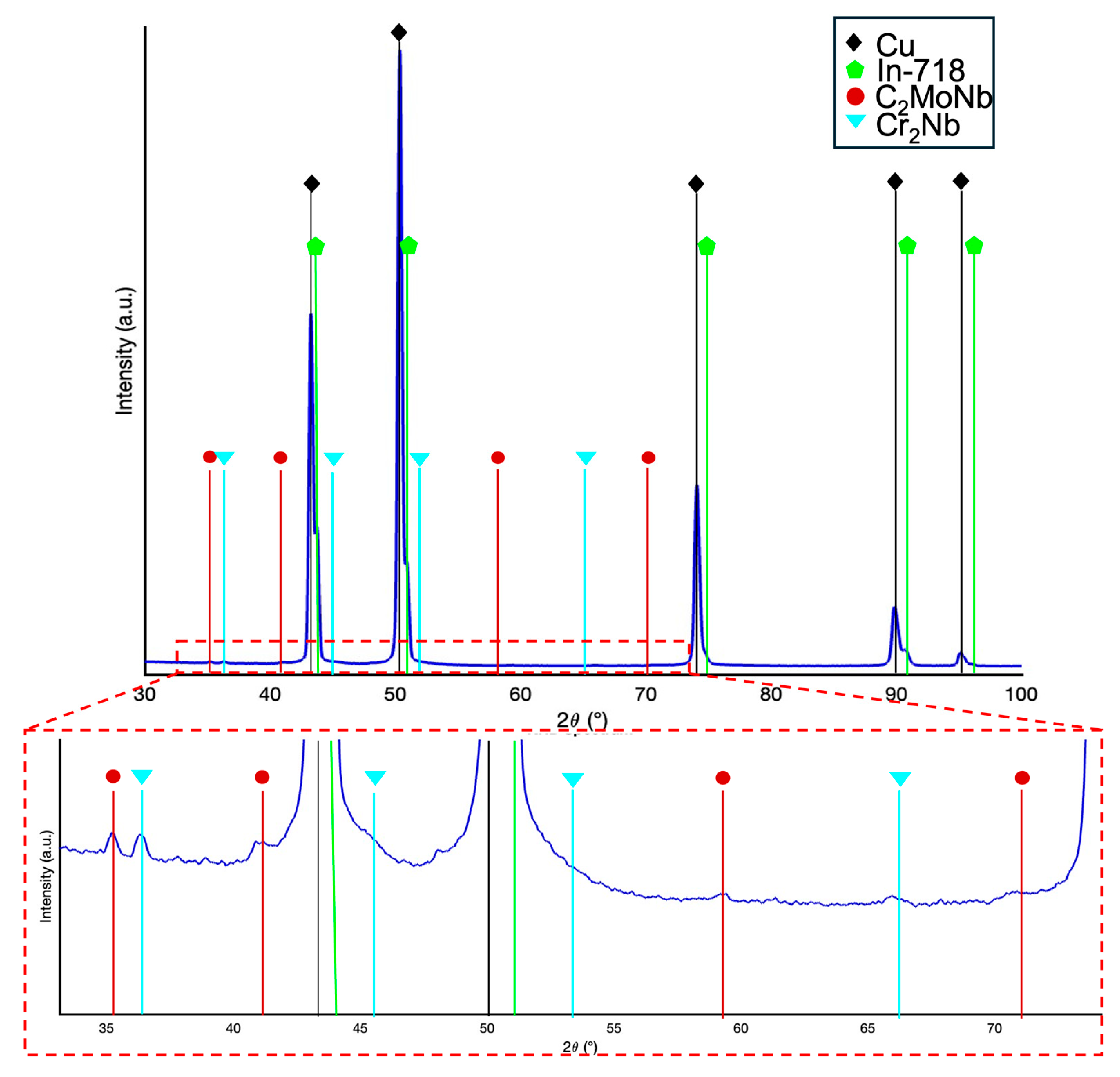

3.2. Microstructural Analysis and Phase Transformation

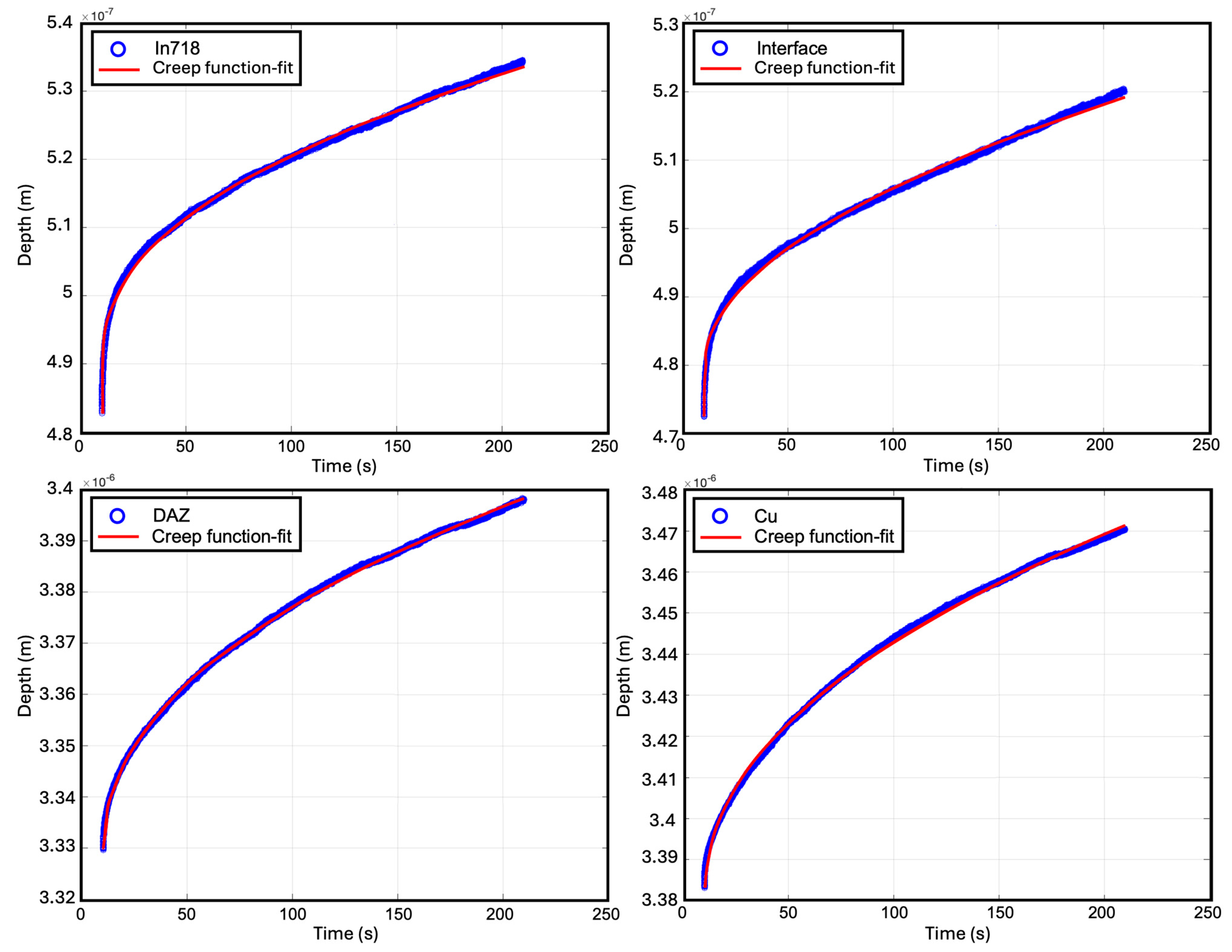

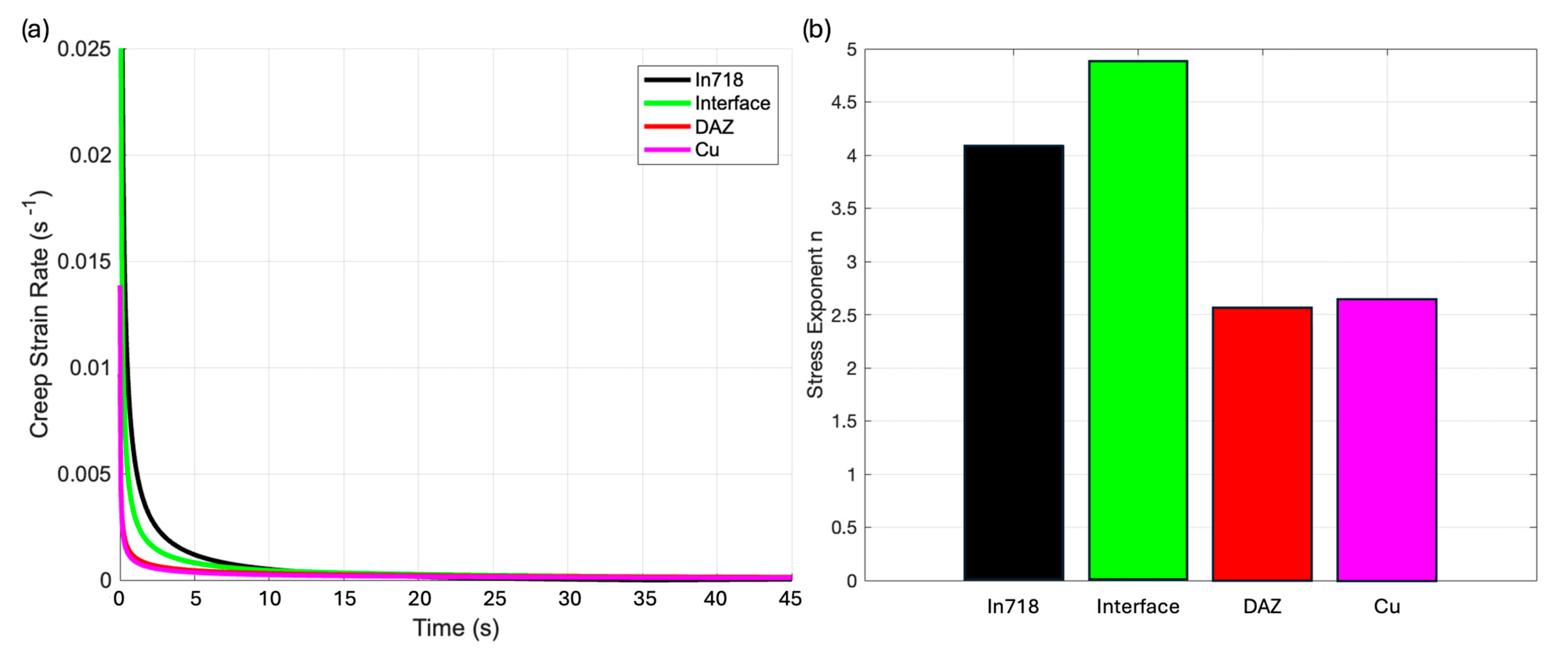

3.3. Hardness Profile and Creep Behavior

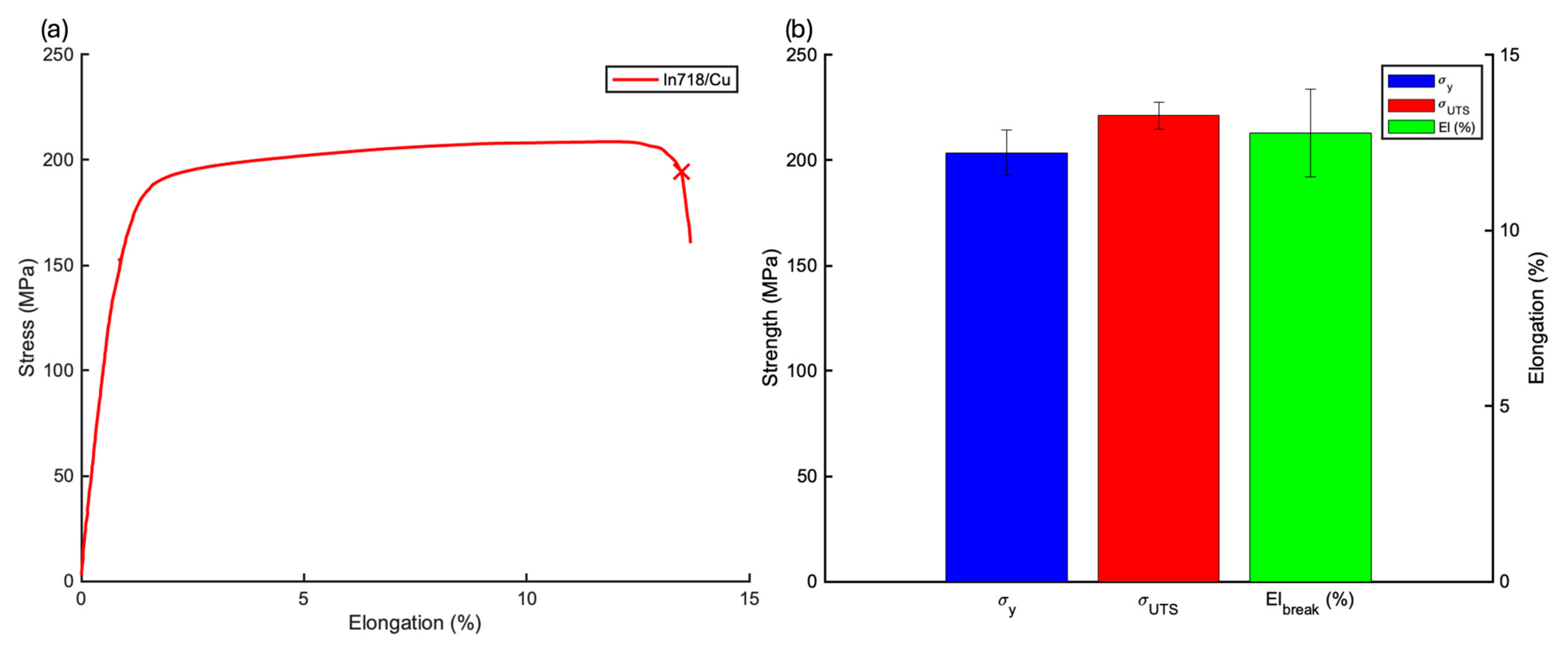

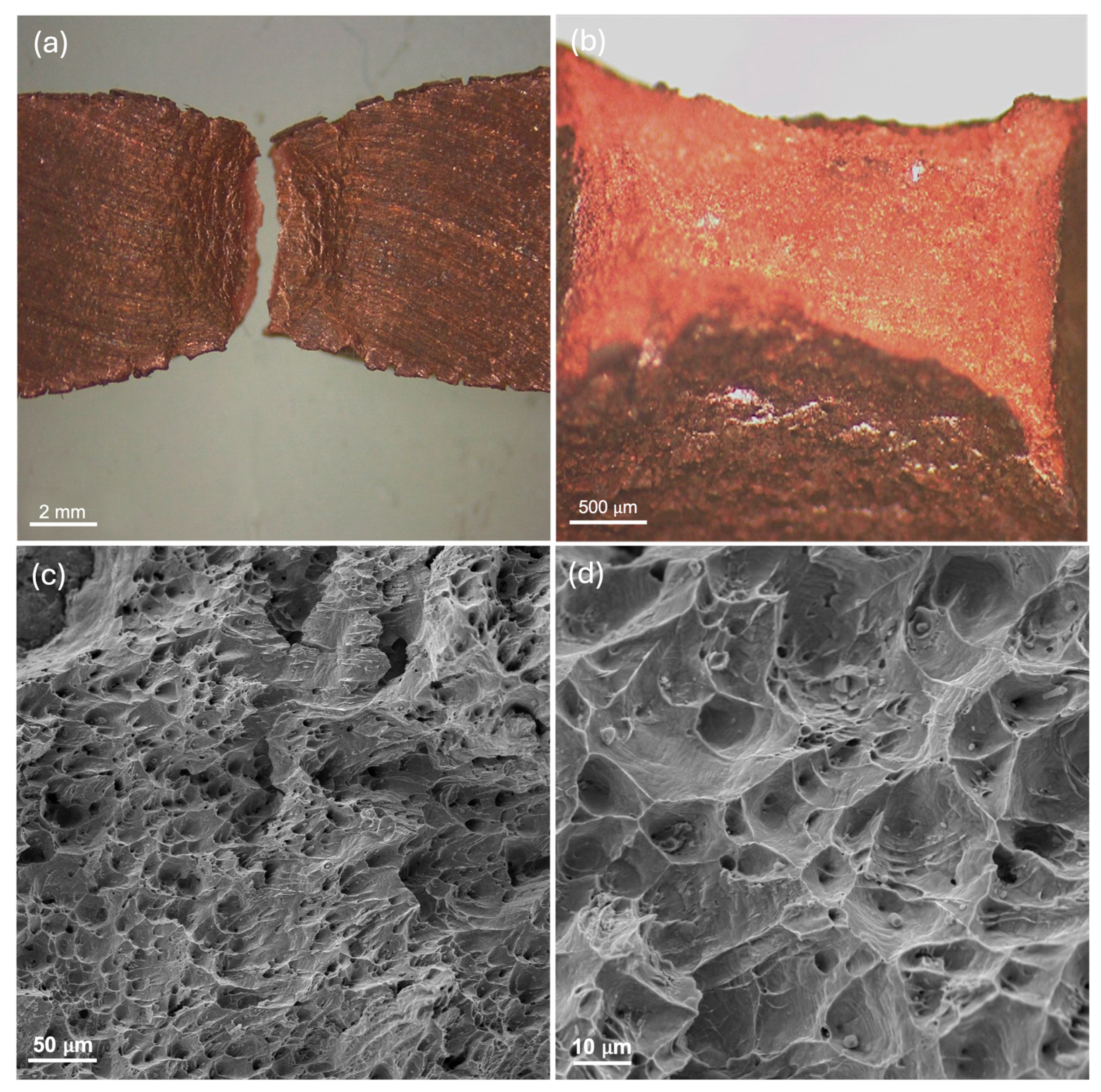

3.4. Tensile Behavior

4. Conclusions

- A tailored process enables the formation of a defect-free joint between the two materials. In particular, the preheating and interlayer cooling stages are critical for preserving the mechanical properties of the Cu substrate and overcoming challenges associated with the intrinsic characteristics of the material.

- Elemental distribution and microdiffraction analyses indicate that liquid-state reactions and solid-state diffusion can penetrate to depths exceeding 30 µm, promoting the formation of metastable C15-Cr2Nb and Mo-Cr-Nb intermetallic phases, as well as complex carbides.

- The influence of the reaction zone on joint brittleness was assessed by nanoindentation, revealing a positive gradient of mechanical properties from the substrate to the In718 deposition. The peak hardness was recorded precisely at the interface, where intermetallic compounds reached their largest size (tens of microns). In contrast, the DAZ exhibited a more controlled and uniform hardening response, with secondary phases more homogeneously distributed. This highlights the strong correlation between precipitate size and hardening behavior.

- The creep behavior was investigated by nanoindentation creep, focusing on the holding stage, revealing the highest creep resistance at the bonding interface and the greatest creep susceptibility within DAZ. Two distinct creep mechanisms were identified on opposite sides of the joint: dislocation climb on the In718 side and grain boundary creep on the copper side. To further validate these interpretations, future work should include high-temperature nanoindentation and complementary uniaxial creep tests to more directly probe the operative deformation mechanisms.

- Tensile tests confirmed that the interfacial bonding strength exceeds the intrinsic strength of the Cu substrate, as fractures occurred exclusively on the Cu side and were accompanied by consistent necking phenomena. Fractographic analysis provided insights into the underlying strengthening mechanism, which is consistent with Orowan bowing, as supported by the significant hardness contrast with the matrix.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arnold, R.; Suslov, D.I.; Haidn, O.J. Experimental Investigation of Film Cooling with Tangential Slot Injection in a LOX/CH4 Subscale Rocket Combustion Chamber. Trans. JSASS Space Technol. Jpn. 2009, 7, 81–86. [Google Scholar] [CrossRef]

- Haidn, O. Advanced Rocket Engines. In Advances in Propulsion Technology for High-Speed Aircraft; Research & Technology Organisation (RTO): Neuilly-sur-Seine, France, 2007; pp. 6.1–6.40. [Google Scholar]

- Ellis, D.L. GRCop-84: A High-Temperature Copper Alloy for High-Heat-Flux Applications; Bibliogov: Asheville, NC, USA, 2005. [Google Scholar]

- De Groh, H.C.; Ellis, D.L.; Loewenthal, W.S. Comparison of GRCop-84 to Other Cu Alloys with High Thermal Conductivities. J. Mater. Eng. Perform. 2008, 17, 594–606. [Google Scholar] [CrossRef]

- Poudel, A.; Gradl, P.R.; Shao, S.; Shamsaei, N. Tensile Deformation Behavior of Laser Powder Direct Energy Deposited Inconel 625: Cryogenic to Elevated Temperatures. Mater. Sci. Eng. A 2024, 889, 145826. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Cheng, D.; Sun, Z.; Zhu, M.; Li, L. An Overview of Laser-Based Multiple Metallic Material Additive Manufacturing: From Macro- to Micro-Scales. Int. J. Extrem. Manuf. 2021, 3, 012003. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.-K.; Beese, A.M. Functionally Graded Material of 304L Stainless Steel and Inconel 625 Fabricated by Directed Energy Deposition: Characterization and Thermodynamic Modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Harrison, R.; Carpenter, C.; Bandyopadhyay, A. Stainless Steel to Titanium Bimetallic Structure Using LENSTM. Addit. Manuf. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Gualtieri, T.; Bandyopadhyay, A. Niobium Carbide Compostie Coatings on SS304 Using Laser Engineered Net Shaping (LENSTM). Mater. Lett. 2017, 189, 89–92. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protz, C.; Fikes, J.; Ellis, D.; Evans, L.; Clark, A.; Miller, S.; Hudson, T. Lightweight Thrust Chamber Assemblies Using Multi-Alloy Additive Manufacturing and Composite Overwrap. In Proceedings of the AIAA Propulsion and Energy 2020 Forum; American Institute of Aeronautics and Astronautics, Virtual Event, 24 August 2020. [Google Scholar]

- Gradl, P.R.; Protz, D.C.S.; Ellis, D.D.L.; Greene, S.E. Progress in Additively Manufactured Copper-Alloy GRCop-84, GRCop-42, and Bimetallic Combustion Chambers for Liquid Rocket Engines. In Proceedings of the International Astronautical Congress, Washington, DC, USA, 21–25 October 2019. [Google Scholar]

- Clark, A.; Hudson, T.; Miller, S.; Edrington, S.; Park, C.; Protz, C. Lightweight Thrust Chamber Composite Overwrap Lessons Learned. In Proceedings of the CAMX-The Composites and Advanced Materials Expo, Dallas, TX, USA, 19–21 October 2021. [Google Scholar]

- Gradl, P.R.; Teasley, T.W.; Protz, C.S.; Garcia, M.B.; Ellis, D.; Kantzos, C. Advancing GRCop-Based Bimetallic Additive Manufacturing to Optimize Component Design and Applications for Liquid Rocket Engines. In Proceedings of the AIAA Propulsion and Energy 2021 Forum; American Institute of Aeronautics and Astronautics, Virtual Event, 9 August 2021. [Google Scholar]

- Turchanin, M.A.; Agraval, P.G.; Abdulov, A.R. Phase Equilibria and Thermodynamics of Binary Copper Systems with 3d-Metals. VI. Copper-Nickel System. Powder Met. Met. Ceram. 2007, 46, 467–477. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P. Modelling of Additive Manufacturing Processes: A Review and Classification. Manuf. Rev. 2018, 5, 2. [Google Scholar] [CrossRef]

- Liu, M.; Kumar, A.; Bukkapatnam, S.; Kuttolamadom, M. A Review of the Anomalies in Directed Energy Deposition (DED) Processes & Potential Solutions—Part Quality & Defects. Procedia Manuf. 2021, 53, 507–518. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; John Wiley & Sons, Incorporated: Hoboken, NJ, USA, 2002; ISBN 0-471-43491-4. [Google Scholar]

- Preis, J.; Wang, Z.; Howard, J.; Lu, Y.; Wannenmacher, N.; Shen, S.; Paul, B.K.; Pasebani, S. Effect of Laser Power and Deposition Sequence on Microstructure of GRCop42—Inconel 625 Joints Fabricated Using Laser Directed Energy Deposition. Mater. Des. 2024, 241, 112944. [Google Scholar] [CrossRef]

- Iams, A.D.; Lienert, T.J.; Otazu, D.A.; Ramoni, M. Effects of Deposition Sequence on Microstructural Evolution in Additively Manufactured Cu-Cr-Nb Alloy / Superalloy Bimetallic Structures. Addit. Manuf. Lett. 2023, 6, 100151. [Google Scholar] [CrossRef]

- Anderson, R.; Terrell, J.; Schneider, J.; Thompson, S.; Gradl, P. Characteristics of Bi-Metallic Interfaces Formed During Direct Energy Deposition Additive Manufacturing Processing. Met. Mater. Trans. B 2019, 50, 1921–1930. [Google Scholar] [CrossRef]

- Hales, S.J.; Domack, C.S.; Taminger, K.M. Electron Beam Freeform Fabrication of Dissimilar Materials: Cracking in Inconel® 625 Deposited on GRCop-84; Bibliogov: Asheville, NC, USA, 2020. [Google Scholar]

- Kassner, M.E.; Son, K.T.; Lee, K.A.; Kang, T.-H.; Ermagan, R. The Creep and Fracture Behavior of Additively Manufactured Inconel 625 and 718. Mater. High. Temp. 2022, 39, 499–506. [Google Scholar] [CrossRef]

- Onuike, B.; Heer, B.; Bandyopadhyay, A. Additive Manufacturing of Inconel 718—Copper Alloy Bimetallic Structure Using Laser Engineered Net Shaping (LENSTM). Addit. Manuf. 2018, 21, 133–140. [Google Scholar] [CrossRef]

- B09 Committee ASTM International. Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity; ASM International: Materials Park, OH, USA, 2008. [Google Scholar] [CrossRef]

- E04 Committee. Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar]

- BSI Standards Limited. Metallic Materials. Instrumented Indentation Test for Hardness and Materials Parameters Test Method; Under Review; BSI Standards Limited: London, UK, 2015; ISBN 978-0-580-75794-5. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Gale, J.D.; Achuthan, A. The Effect of Work-Hardening and Pile-up on Nanoindentation Measurements. J. Mater. Sci. 2014, 49, 5066–5075. [Google Scholar] [CrossRef]

- Feng, G.; Ngan, A.H.W. Effects of Creep and Thermal Drift on Modulus Measurement Using Depth-sensing Indentation. J. Mater. Res. 2002, 17, 660–668. [Google Scholar] [CrossRef]

- Mayo, M.J.; Siegel, R.W.; Liao, Y.X.; Nix, W.D. Nanoindentation of Nanocrystalline ZnO. J. Mater. Res. 1992, 7, 973–979. [Google Scholar] [CrossRef]

- E28 Committee. Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Cavalcante, T.R.F.; Bon, D.G.; Pascoal, C.V.P.; Mariani, F.E.; Faria, G.; Coelho, R.T.; Muñoz, J.A.; Muñoz, J.C.; Cabrera, J.M.; Avila, J.A. As-Built Microstructure and Mechanical Behavior of Inconel 718 Processed via Directed Energy Deposition with Laser Beam. Prog. Addit. Manuf. 2025, 10, 7589–7607. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Kim, H.; Zhou, Y.; Cong, W.; Zhang, H. Investigations of Energy Density Effects on Forming Accuracy and Mechanical Properties of Inconel 718 Fabricated by LENS Process. Procedia Manuf. 2018, 26, 731–739. [Google Scholar] [CrossRef]

- Peiponen, K.-E.; Tsuboi, T. Metal Surface Roughness and Optical Reflectance. Opt. Laser Technol. 1990, 22, 127–130. [Google Scholar] [CrossRef]

- Simon, N.J.; Drexler, E.S.; Reed, R.P. Properties of Copper and Copper Alloys at Cryogenic Temperatures, 1st ed.; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1992; p. NIST MONO 177.

- Crosby, R.L.; Desy, D.H. Dispersion-Strengthening in Copper-Alumina and Copper-Yttria Alloys; Report of Investigations/Bureau of Mines; U.S. Department of the Interior, Bureau of Mines: Washington, DC, USA, 1969; Volume 7266.

- Schneider, J.; Farris, L.; Nolze, G.; Reinsch, S.; Cios, G.; Tokarski, T.; Thompson, S. Microstructure Evolution in Inconel 718 Produced by Powder Bed Fusion Additive Manufacturing. J. Manuf. Mater. Process. 2022, 6, 20. [Google Scholar] [CrossRef]

- Saumitra, V. Microstructural Evolution and Precipitation Kinetics of Carbides in L-PBF Processed Inconel 718 during Long-Term Homogenization. Mater. Today Commun. 2025, 42, 111192. [Google Scholar] [CrossRef]

- Preis, J.; Xu, D.; Paul, B.K.; Eschbach, P.A.; Pasebani, S. Effect of Liquid Miscibility Gap on Defects in Inconel 625–GRCop42 Joints through Analysis of Gradient Composition Microstructure. J. Manuf. Mater. Process. 2024, 8, 42. [Google Scholar] [CrossRef]

- Bazaz, B.; Zarei-Hanzaki, A.; Fatemi-Varzaneh, S.M. Hardness and Microstructure Homogeneity of Pure Copper Processed by Accumulative Back Extrusion. Mater. Sci. Eng. A 2013, 559, 595–600. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, J. Microstructure and Properties of Inconel 718 Fabricated by Directed Energy Deposition with In-Situ Ultrasonic Impact Peening. Met. Mater. Trans. B 2019, 50, 2815–2827. [Google Scholar] [CrossRef]

- Yeoh, Y.C.; Macchi, G.; Jain, E.; Gaskey, B.; Raman, S.; Tay, G.; Verdi, D.; Patran, A.; Grande, A.M.; Seita, M. Multiscale Microstructural Heterogeneity and Mechanical Property Scatter in Inconel 718 Produced by Directed Energy Deposition. J. Alloys Compd. 2021, 887, 161426. [Google Scholar] [CrossRef]

- Müller, C.J.; Büßenschütt, K.; Schwedt, A.; Schleifenbaum, J.H.; Sudmanns, M. Enabling Tailored Microstructures by Hybrid Directed Energy Deposition Processing of a Nickel-Based Superalloy. Addit. Manuf. Lett. 2024, 11, 100248. [Google Scholar] [CrossRef]

- Elmustafa, A.A.; Stone, D.S. Nanoindentation and the Indentation Size e’ect: Kinetics of Deformation and Strain Gradient Plasticity. J. Mech. Phys. Solids 2003, 51, 357–381. [Google Scholar] [CrossRef]

- Profitiliotis, T.; Kladovasilakis, N.; Giarmas, E.; Pechlivani, E.M.; Tzetzis, D. Mechanical Performance and Microstructural Characterization of Additive Manufactured Selective Laser Melted Bimetallic IN718/17-4 PH Stainless Steel. Mater. Sci. Eng. A 2025, 930, 148158. [Google Scholar] [CrossRef]

- Khan, S.; Junaid, M.; Khan, F.N. Nanoindentation and Indentation Creep Analysis of Diffusion Bonded of Inconel 718 and AISI 304L Stainless Steel Joint Interface. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2025, 239, 1620–1632. [Google Scholar] [CrossRef]

- Jiang, R.; Mostafaei, A.; Pauza, J.; Kantzos, C.; Rollett, A.D. Varied Heat Treatments and Properties of Laser Powder Bed Printed Inconel 718. Mater. Sci. Eng. A 2019, 755, 170–180. [Google Scholar] [CrossRef]

- Wu, X.; Liu, R.; Khelfaoui, F. Creep Phenomena, Mechanisms, and Modeling of Complex Engineering Alloys. Modelling 2024, 5, 819–840. [Google Scholar] [CrossRef]

- Nix, W.D.; Ilschner, B. Mechanisms Controlling Creep of Single Phase Metals and Alloys. Strength. Met. Alloys 1979, 3, 1503–1530. [Google Scholar] [CrossRef]

- Chen, Y.; Schuh, C.A. Coble Creep in Heterogeneous Materials: The Role of Grain Boundary Engineering. Phys. Rev. B 2007, 76, 064111. [Google Scholar] [CrossRef]

- Atefi, S.; Parsa, M.H.; Ahmadkhaniha, D.; Zanella, C.; Jafarian, H.R. A Study on Microstructure Development and Mechanical Properties of Pure Copper Subjected to Severe Plastic Deformation by the ECAP-Conform Process. J. Mater. Res. Technol. 2022, 21, 1614–1629. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Z.; Wang, Y.; Chen, Z. Experimental Study on the Mechanical Properties of Oxygen-Free Copper Used in High Energy Physics Detectors and Accelerators. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 935, 8–16. [Google Scholar] [CrossRef]

| Element wt.% | C | Cr | Ni | Fe | Mo | Nb + Ta | Co | Al | Si | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Result | 0.07 | 19.2 | 53.72 | Bal. | 3.22 | 4.98 | 0.1 | 0.49 | 0.06 | 0.87 |

| P [W] | v [mm/min] | Δz [mm] | f [g/min] | Ov. [%] | Rel. Density |

|---|---|---|---|---|---|

| 850 | 660 | 0.5 | 7.7 | 50% | 99.78% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Felicioni, S.; Vincic, J.; Zacco, A.; Aversa, A.; Fino, P.; Bondioli, F. Direct Energy Deposition of Inconel 718 onto Cu Substrate for Bimetallic Structures with Excellent Comprehensive Properties. Metals 2025, 15, 1292. https://doi.org/10.3390/met15121292

Felicioni S, Vincic J, Zacco A, Aversa A, Fino P, Bondioli F. Direct Energy Deposition of Inconel 718 onto Cu Substrate for Bimetallic Structures with Excellent Comprehensive Properties. Metals. 2025; 15(12):1292. https://doi.org/10.3390/met15121292

Chicago/Turabian StyleFelicioni, Stefano, Josip Vincic, Annalisa Zacco, Alberta Aversa, Paolo Fino, and Federica Bondioli. 2025. "Direct Energy Deposition of Inconel 718 onto Cu Substrate for Bimetallic Structures with Excellent Comprehensive Properties" Metals 15, no. 12: 1292. https://doi.org/10.3390/met15121292

APA StyleFelicioni, S., Vincic, J., Zacco, A., Aversa, A., Fino, P., & Bondioli, F. (2025). Direct Energy Deposition of Inconel 718 onto Cu Substrate for Bimetallic Structures with Excellent Comprehensive Properties. Metals, 15(12), 1292. https://doi.org/10.3390/met15121292