Effect of Precipitation Behavior on Mechanical Properties of 6082 Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Heat Treatment Scheme

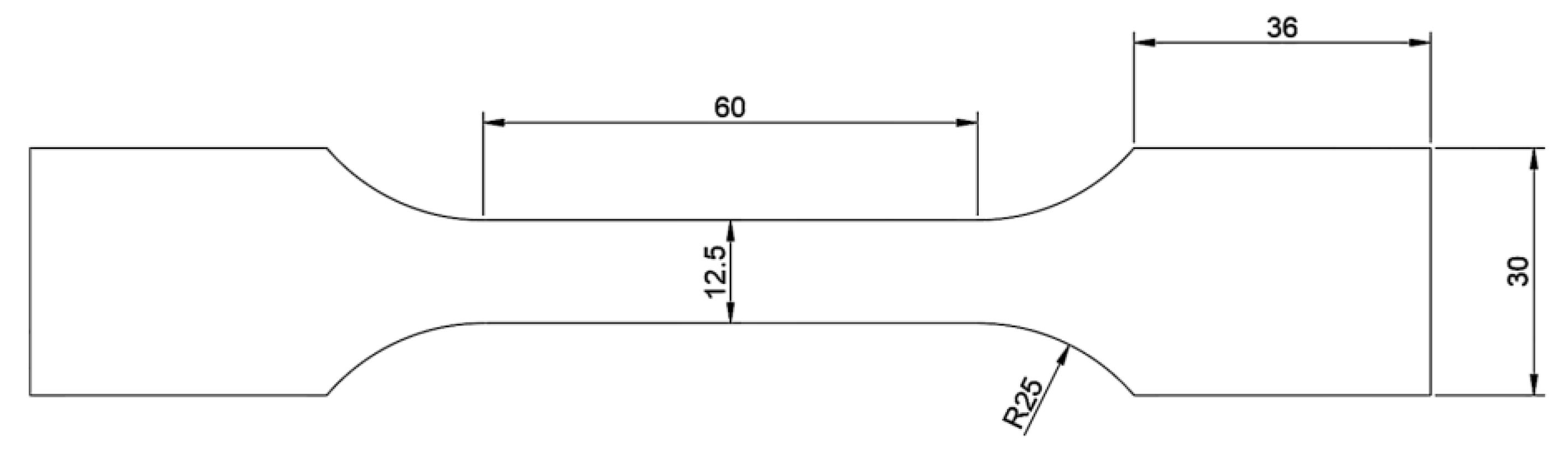

2.2. Determination of Mechanical Properties

2.3. Metallographic Investigations

3. Results

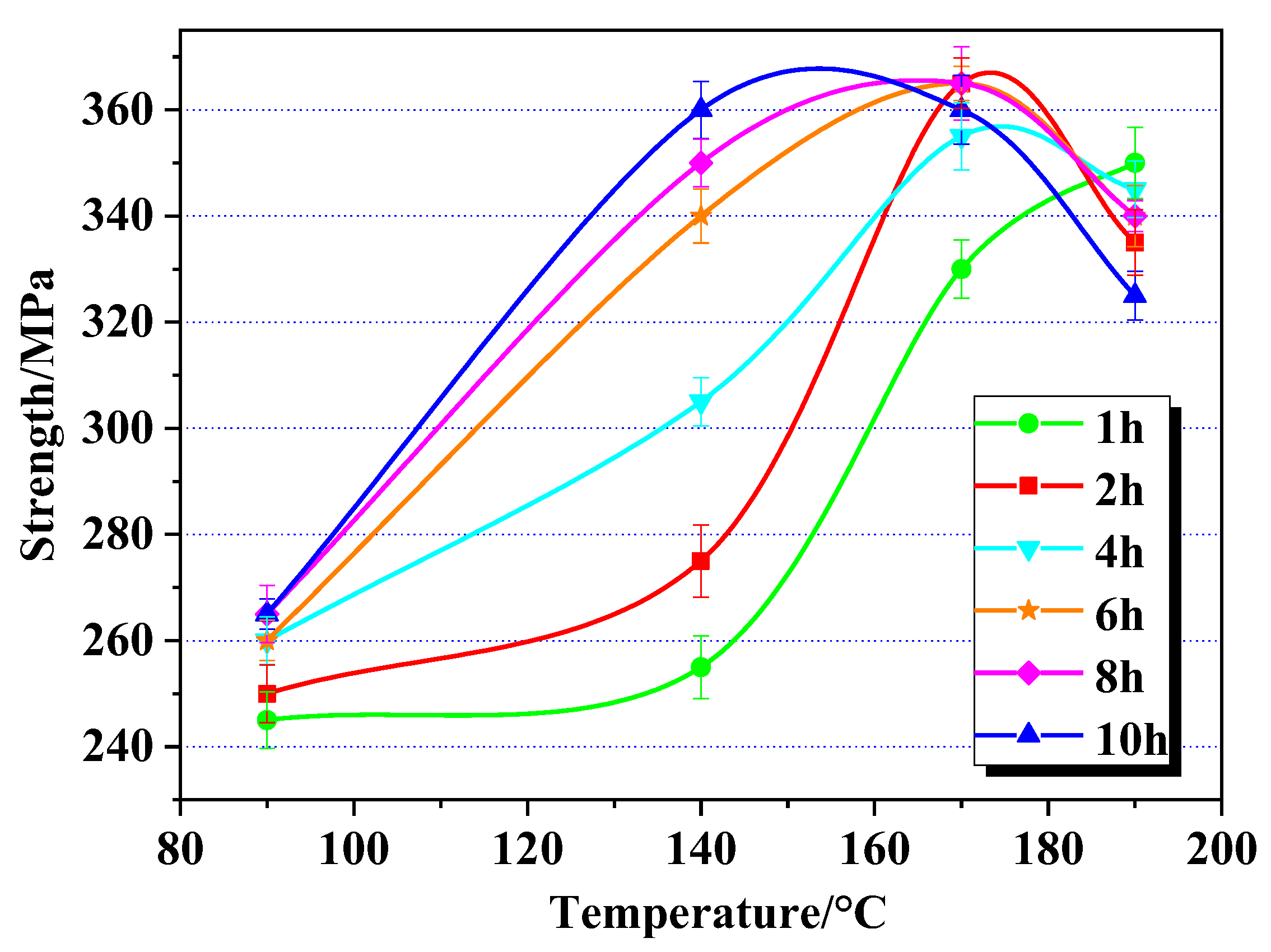

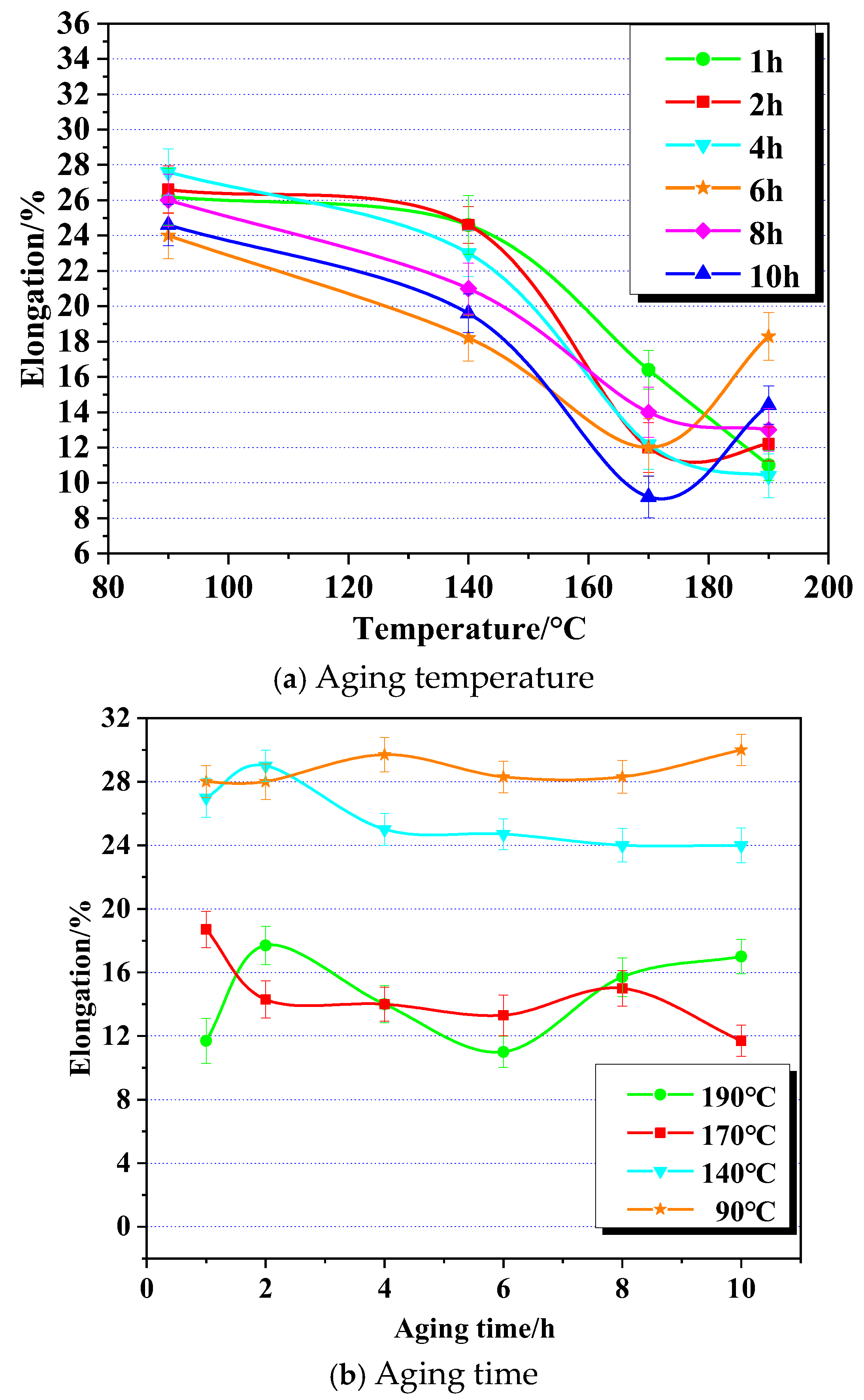

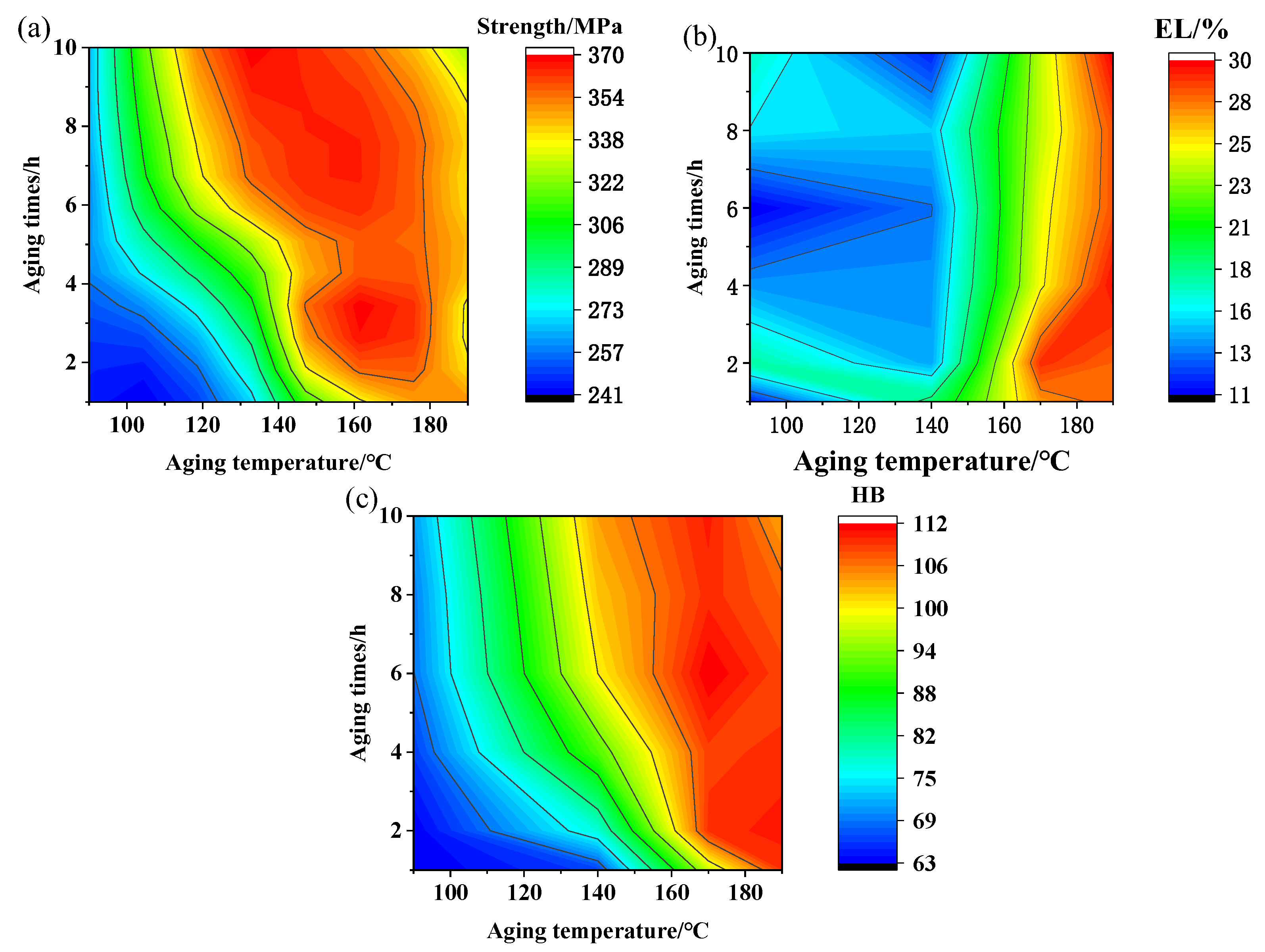

3.1. Mechanical Properties

3.1.1. The Ultimate Tensile Strength (TS) and Total Elongation (TE)

3.1.2. Hardening Behavior

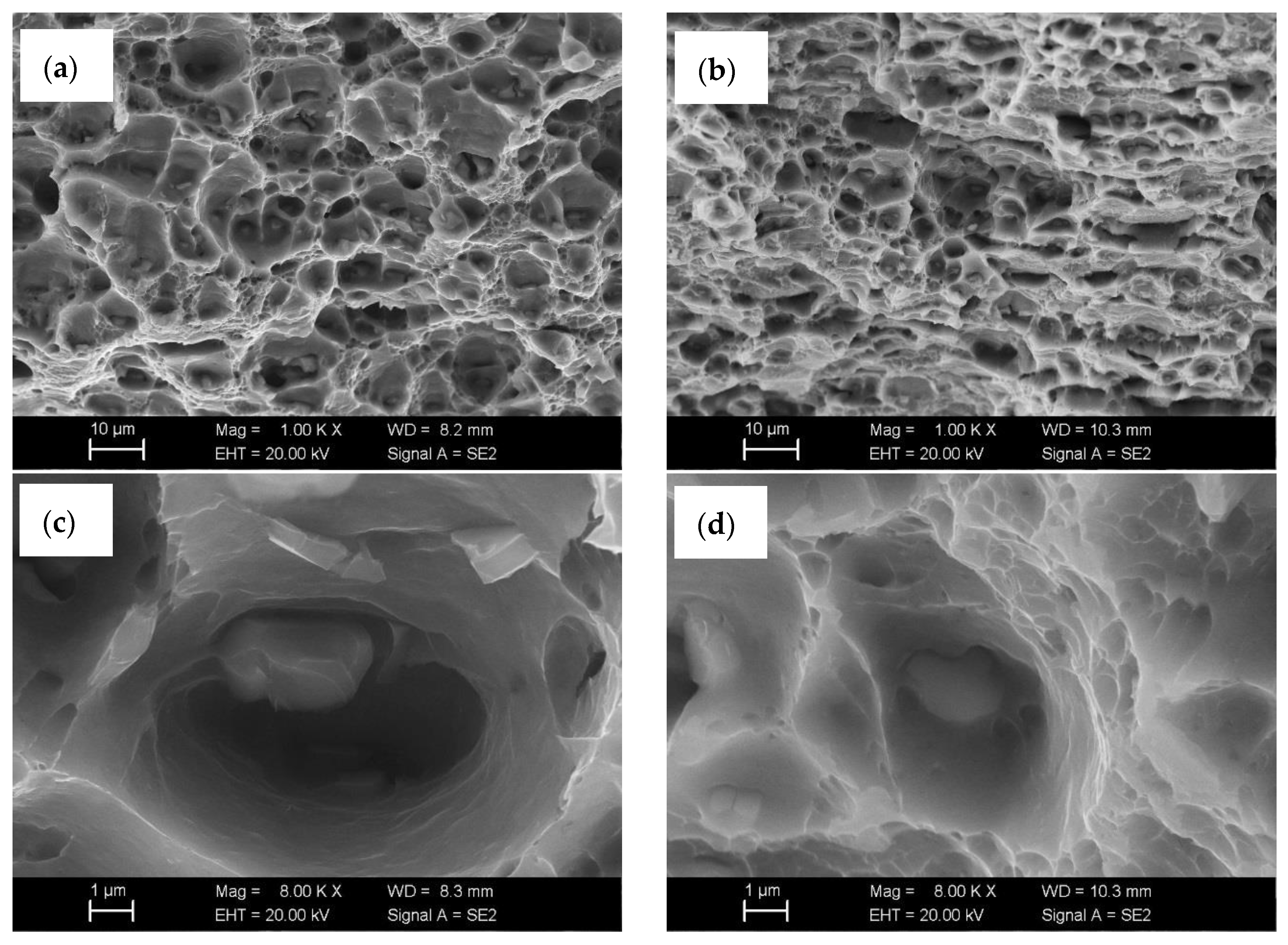

3.2. The Fracture Morphology

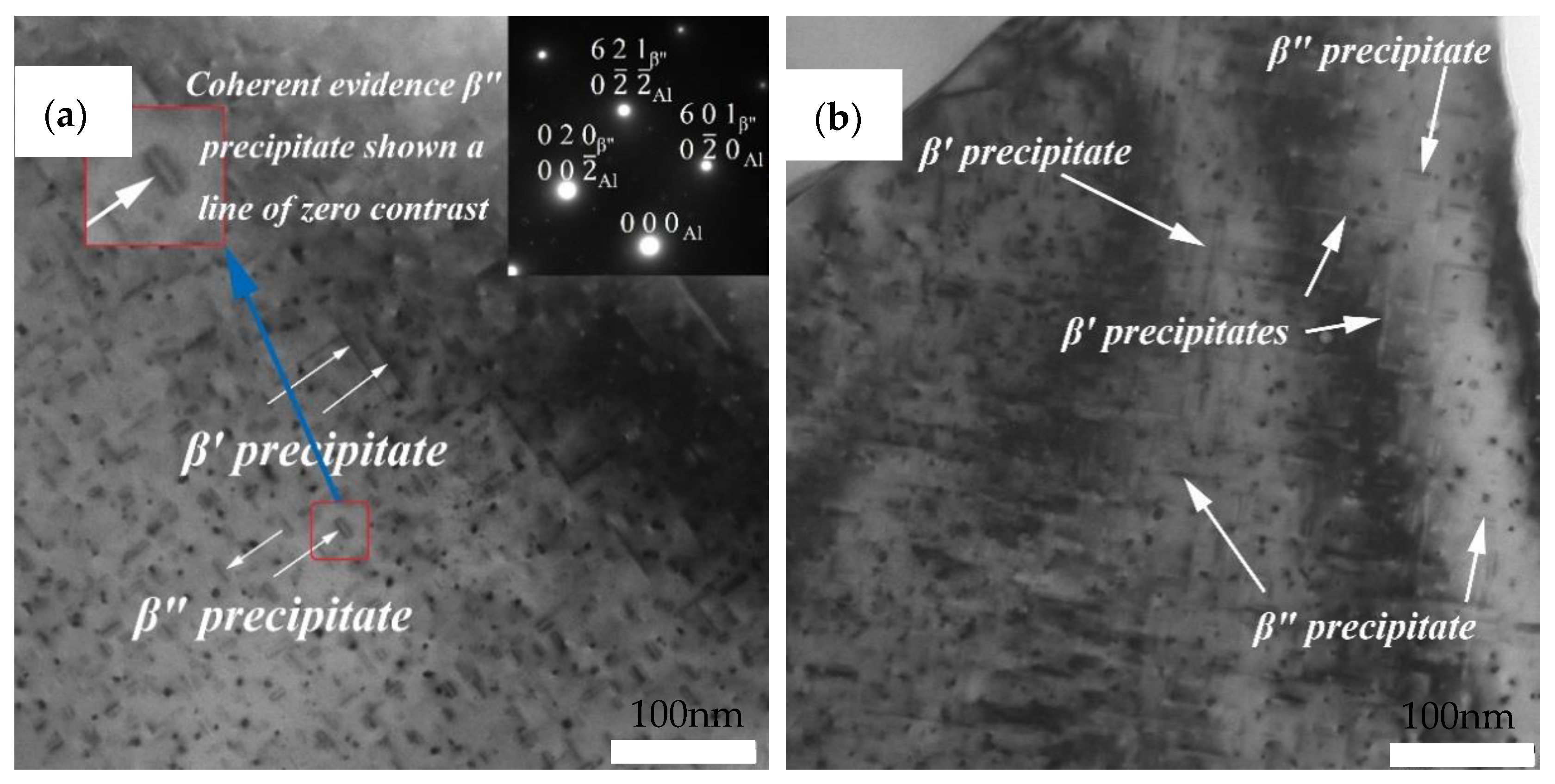

3.3. Precipitates’ Morphology Observed Under TEM

4. Discussion

5. Conclusions

- The alloy under the economical aging treatment procedure (aged at 160~180 °C for 2~4 h) obtain potential mechanical properties, with a combination of a tensile strength of about 360 MPa, hardness of 105 HB, and total elongation over 10%.

- The fracture surface of the tensile test specimens of the artificially aged 6082 alloy was ductile. As the aging temperature increased, the size of the fracture surface dimples decreased from 8–10 μm (aging at 90 °C) μm to 4–7 μm (aging at 170 °C).

- Using transmission electron microscopy, β″ precipitates with a coherent strain field were successfully captured and characterized. The coherent distortion effect induced by the β″ precipitates produced a strengthening effect, which is the essence of aging strengthening in 6082 alloy.

- Over-aging causes the transformation of small-sized (20 nm in length) coherent β″ precipitates into large-sized (50~60 nm in length) semi-coherent β′ precipitates, resulting in a slight decrease in the material’s tensile strength and hardness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, W.Y.; Wang, B.Y.; Yang, L.; Tang, X.; Xiao, W.; Zhou, J. Influence of solution heat treatment on mechanical response and fracture behavior of aluminum alloy sheets: An experimental study. Mater. Des. 2015, 88, 1119–1126. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β” phase in a 6082 Al–Mg–Si alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Takeda, M.; Ohkubo, F.; Shirai, T. Stability of metastable phases and microstructures in the ageing process of Al-Mg-Si ternary alloys. J. Mater. Sci. 1998, 33, 2385–2390. [Google Scholar] [CrossRef]

- Bordeasu, I.; Ghiban, B.; Micu, L.M.; Luca, A.N.; Demian, A.M.; Istrate, D. The influence of heat aging treatments on the cavitation erosion behavior of a type 6082 aluminum alloy. Materials 2023, 16, 5875. [Google Scholar] [CrossRef] [PubMed]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Ebner, T.; Uggowitzer, P.J. Mechanisms controlling the artificial aging of Al-Mg-Si Alloys. Acta Mater. 2011, 59, 3352–3363. [Google Scholar] [CrossRef]

- Ravia, C.; Wolvertonb, C. First-principles study of crystal structure and stability of Al–Mg–Si–(Cu) precipitates. Acta Mater. 2004, 52, 4213–4227. [Google Scholar] [CrossRef]

- Andersen, S.J.; Zandbergen, H.W.; Jansen, J.; TrÆholt, C.; Tundal, U.; Reiso, O. The crystal structure of the β” phase in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3283–3298. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. Atomic model for G.P.-zones in a 6082 Al–Mg–Si System. Acta Mater. 2001, 49, 321–328. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G.; Hono, K. Secondary precipitation in an Al–Mg–Si–Cu alloy. Acta Mater. 2007, 55, 3015–3024. [Google Scholar] [CrossRef]

- Zandbergen, H.W.; Andersen, S.J.; Jansen, J. Structure determination of Mg5Si6 particles in Al by dynamic electron diffraction studies. Science 1997, 277, 1221–1225. [Google Scholar] [CrossRef]

- Yang, L.; Bai, D.; Wang, D.; Liu, C.; Yang, S.; Huang, G. Effect of aging temperature on microstructure and corrosion behavior of 6082 aluminum alloy. Mater. Today Commun. 2023, 36, 106583. [Google Scholar] [CrossRef]

- Bartawi, E.H.; Shaban, G.; Ambat, R. Role of aging time and Cu/Zn additions on the microstructure and intergranular corrosion resistance of 6082 Al-Mg-Si alloy. Corros. Sci. 2025, 254, 113027. [Google Scholar] [CrossRef]

- Hu, Z.; Zheng, J.; Pang, Q.; Sun, Q.; Zhao, N. Influence of strain rates and aging time on microstructure and hardness of integrally compressed 6082 aluminum alloy. J. Mater. Res. Technol. 2023, 27, 826–838. [Google Scholar] [CrossRef]

- Jiang, J.; Cui, J.; Wang, Y.; Huang, M.; Dong, J.; Yan, J. Effect of T6 heat treatment on microstructure and mechanical properties of 6082 aluminum alloy automotive flange components formed by squeeze casting. Mater. Sci. Eng. A 2024, 912, 146974. [Google Scholar] [CrossRef]

- GB/T228.1-2010; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2010.

- Rong, Y.H. Introduction to Analytical Electron Microscopy; Higher Education Press: Beijing, China, 2015; pp. 286–287. [Google Scholar]

- Gaber, A.; Afify, N.; Mostafa, M.S.; Abbady, G. Effect of heat treatment on the precipitation in Al-1 at.% Mg-x at.% Si (x = 0.6, 1.0 and 1.6) alloys. J. Alloys Compd. 2009, 477, 295–300. [Google Scholar] [CrossRef]

- Afify, N.; Gaber, A.; Mostafa, M.S.; Abbady, G. Influence of Si concentration on the precipitation in Al-1 at.% Mg alloy. J. Alloys Compd. 2008, 462, 80–87. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al-Mg-Si Alloys. Acta Mater 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

| Alloy | Si | Mg | Fe | Cu | Mn | Cr | Al |

|---|---|---|---|---|---|---|---|

| 6082 | 0.85 | 0.80 | 0.21 | 0.05 | 0.50 | 0.06 | Bal. |

| Solution Treatment | Aging Temperature/°C | Aging Time/h |

|---|---|---|

| 530 °C + 2 h | 90/140/170/190 | 1/2/4/6/8/10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Piao, E.; Li, W.; Wang, W.; Feng, C.; Zhang, M. Effect of Precipitation Behavior on Mechanical Properties of 6082 Aluminum Alloy. Metals 2025, 15, 1287. https://doi.org/10.3390/met15121287

Yang Z, Piao E, Li W, Wang W, Feng C, Zhang M. Effect of Precipitation Behavior on Mechanical Properties of 6082 Aluminum Alloy. Metals. 2025; 15(12):1287. https://doi.org/10.3390/met15121287

Chicago/Turabian StyleYang, Zhi, Enjun Piao, Wenhao Li, Weikun Wang, Chengxiang Feng, and Mei Zhang. 2025. "Effect of Precipitation Behavior on Mechanical Properties of 6082 Aluminum Alloy" Metals 15, no. 12: 1287. https://doi.org/10.3390/met15121287

APA StyleYang, Z., Piao, E., Li, W., Wang, W., Feng, C., & Zhang, M. (2025). Effect of Precipitation Behavior on Mechanical Properties of 6082 Aluminum Alloy. Metals, 15(12), 1287. https://doi.org/10.3390/met15121287