Electric Arc Furnace Steelmaking

1. Introduction

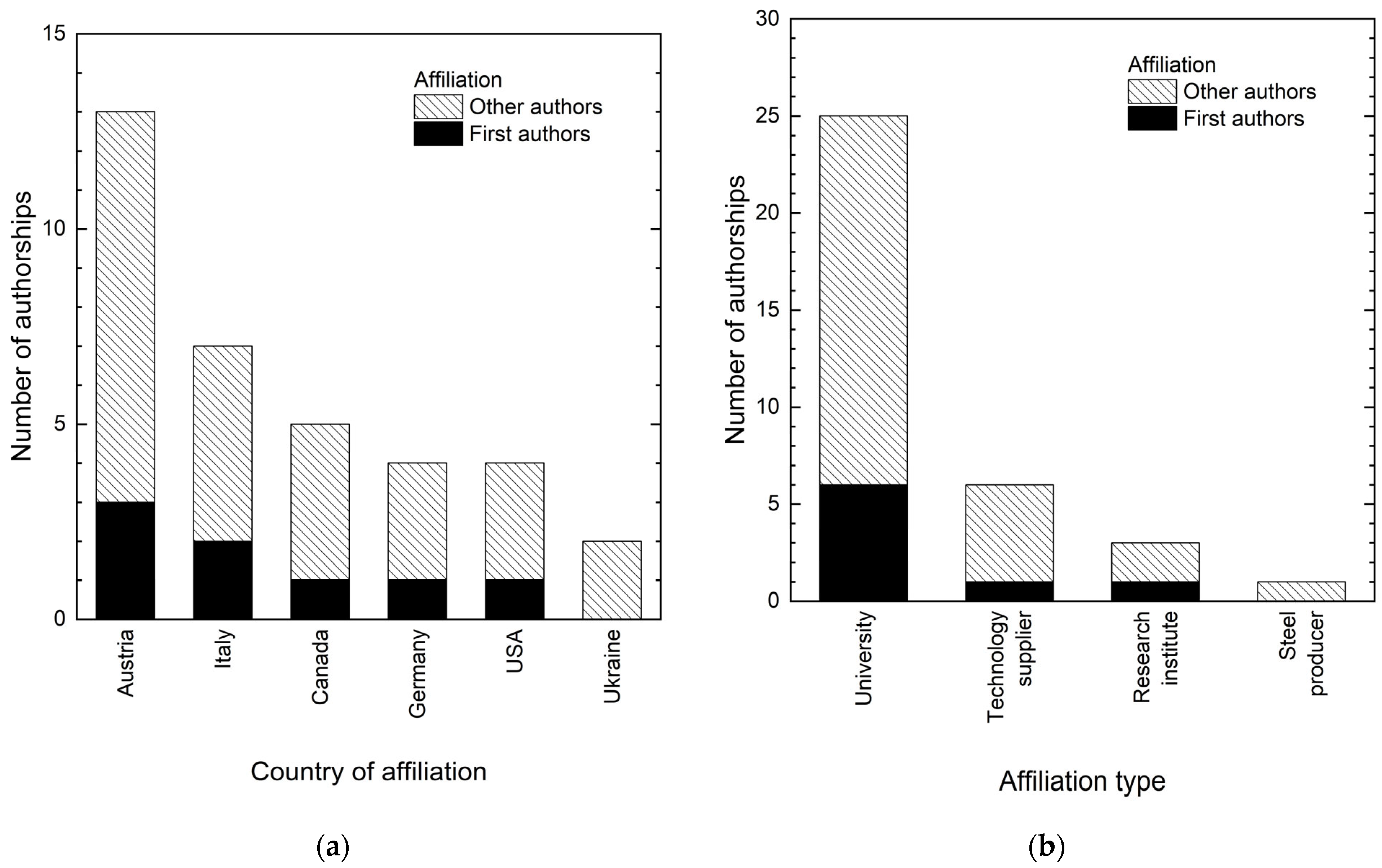

2. Overview of the Contributions

3. Highlights

3.1. DRI-Based EAF Steelmaking

3.2. Substitution of Fossil Carbon

3.3. Modeling and Simulation

3.4. System-Level Investigations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Contributions

- Azzaz, R.; Jahazi, M.; Ebrahimi Kahou, S.; Moosavi-Khoonsari, E. Prediction of Final Phosphorus Content of Steel in a Scrap-Based Electric Arc Furnace Using Artificial Neural Networks. Metals 2025, 15, 62.

- Dall’Osto, G.; Mombelli, D.; Scolari, S.; Mapelli, C. Role of the Biogenic Carbon Physicochemical Properties in the Manufacturing and Industrial Transferability of Mill Scale-Based Self-Reducing Briquettes. Metals 2024, 14, 882.

- Reinicke, A.; Engbrecht, T.-N.; Schüttensack, L.; Echterhof, T. Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model. Metals 2024, 14, 736.

- Dall’Osto, G.; Mombelli, D.; Mapelli, C. Consequences of the Direct Reduction and Electric Steelmaking Grid Creation on the Italian Steel Sector. Metals 2024, 14, 311.

- Ugarte, O.; Busa, N.; Konar, B.; Okosun, T.; Zhou, C.Q. Impact of Injection Rate on Flow Mixing during the Refining Stage in an Electric Arc Furnace. Metals 2024, 14, 134.

- Kieush, L.; Schenk, J.; Koveria, A.; Hrubiak, A. Biocoke Thermochemical Properties for Foamy Slag Formations in Electric Arc Furnace Steelmaking. Metals 2023, 14, 13.

- Pfeiffer, A.; Ernst, D.; Zheng, H.; Wimmer, G.; Schenk, J. The Behavior of Direct Reduced Iron in the Electric Arc Furnace Hotspot. Metals 2023, 13, 978.

- Kieush, L.; Lesiak, S.; Rieger, J.; Leitner, M.; Schmidt, L.; Daghagheleh, O. Reoxidation Behavior of the Direct Reduced Iron and Hot Briquetted Iron during Handling and Their Integration into Electric Arc Furnace Steelmaking: A Review. Metals 2024, 14, 873.

References

- Karbowniczek, M. Electric Arc Furnace Steelmaking; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Cappel, J.; Ahrenhold, F.; Egger, M.W.; Hiebler, H.; Schenk, J. 70 Years of LD-Steelmaking—Quo Vadis? Metals 2022, 12, 912. [Google Scholar] [CrossRef]

- Madias, J. Electric Furnace Steelmaking. In Treatise on Process Metallurgy, 2nd ed.; Volume 3: Industrial Processes; Seetharaman, S., Guthrie, R., McLean, A., Seetharaman, S., Sohn, H.Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 243–265. [Google Scholar]

- Klein, K.-H.; Schindler, J.E. Metallurgie bei Schrotteinsatz. In Elektrostahl-Erzeugung; Heinen, K.-H., Ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1997; pp. 473–502. [Google Scholar]

- Walden, K. Metallurgie bei Eisenschwammeinsatz. In Elektrostahl-Erzeugung; Heinen, K.-H., Ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1997; pp. 503–511. [Google Scholar]

- World Steel Association. World Steel in Figures 2025; World Steel Association: Beijing, China, 2025. [Google Scholar]

- Ariyama, T. Perspectives on the Promising Pathways to Zero Carbon Emissions in the Steel Industry toward 2050. ISIJ Int. 2025, 65, 165–184. [Google Scholar] [CrossRef]

- Pei, M.; Petäjäniemi, M.; Regnell, A.; Wijk, O. Toward a Fossil Free Future with HYBRIT: Development of Iron and Steelmaking Technology in Sweden and Finland. Metals 2020, 10, 972. [Google Scholar] [CrossRef]

- Blastr Green Steel. Blastr Green Steel Chooses Primetals Technologies as Its Technological Partner for the Ultra-Low CO2 Emissions Steel Plant in Inkoo, Finland. Blastr Green Steel, 9 July 2024. [Google Scholar]

- SMS Group. The World’s First Carbon-Neutral Steel Plant. Available online: https://www.sms-group.com/plants/projects/stegra (accessed on 11 November 2025).

- SSAB. The Deputy Prime Minister and SSAB’s CEO Broke Ground on a New Steel Mill in Luleå. SSAB, 17 September 2025. [Google Scholar]

- Hassan, A.; Kotelnikov, G.; Abdelwahed, H. Melting Characteristics of Alternative Charging Materials in an Electric Arc Furnace Steelmaking. Ironmak. Steelmak. 2021, 48, 1136–1141. [Google Scholar] [CrossRef]

- Kallio, R.; Cantaluppi, M.; Louhisalmi, J.; Visuri, V.-V. Mineralogical Characteristics of Fossil-Free Steel Slags. Miner. Eng. 2025, 230, 109396. [Google Scholar] [CrossRef]

- Wimmer, G.; Voraberger, B.; Kradel, B.; Fleischanderl, A. Breakthrough Pathways to Decarbonize the Steel Sector. Mitsubishi Heavy Ind. Tech. Rev. 2022, 59, 1–7. [Google Scholar]

- Wimmer, G.; Voraberger, B.; Rosner, J.; Pfeiffer, A. Smelter—Green Steelmaking Using Low-Grade DRI. In Proceedings of the Iron & Steel Technology Conference, Columbus, OH, USA, 6–9 May 2024; pp. 180–187. [Google Scholar]

- Metso. Metso Opens DRI Smelting Furnace Pilot Facility in Pori, Finland. Metso, 25 October 2024. [Google Scholar]

- Weinberg, M. Transformation of Steel Production. In Proceedings of the Plenary presentation—13th European Electric Steelmaking Conference, Essen, Germany, 3–7 June 2024; Steel Institute VDEh: Essen, Germany, 2024. [Google Scholar]

- Worldstainless. Stainless Steel Melt Shop Production Increases by 7% in 2024. Worldstainless, 14 April 2025. [Google Scholar]

- Visuri, V.-V.; Holappa, L. Converter Steelmaking. In Treatise on Process Metallurgy—Volume 3: Industrial Processes; Seetharaman, S., Guthrie, R., McLean, A., Seetharaman, S., Sohn, H.Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 183–241. [Google Scholar]

- Satritama, B.; Cooper, C.; Fellicia, D.; Pownceby, M.I.; Palanisamy, S.; Ang, A.; Mukhlis, R.Z.; Pye, J.; Rahbari, A.; Brooks, G.A.; et al. Hydrogen Plasma for Low-Carbon Extractive Metallurgy: Oxides Reduction, Metals Refining, and Wastes Processing. J. Sustain. Metall. 2024, 10, 1845–1894. [Google Scholar] [CrossRef]

- Adami, B.; Hoffelner, F.; Zarl, M.A.; Schenk, J. Strategic Selection of a Pre-Reduction Reactor for Increased Hydrogen Utilization in Hydrogen Plasma Smelting Reduction. Processes 2025, 13, 420. [Google Scholar] [CrossRef]

- Zarl, M.A.; Farkas, M.A.; Schenk, J. A Study on the Stability Fields of Arc Plasma in the HPSR Process. Metals 2020, 10, 1394. [Google Scholar] [CrossRef]

- Büyükuslu, Ö.K.; Aota, L.S.; Raabe, D.; Springer, H.; Souza Filho, I.R. Mechanisms and Elemental Partitioning during Simultaneous Dephosphorization and Reduction of Fe-O-P Melts by Hydrogen Plasma. Acta Mater. 2024, 277, 120221. [Google Scholar] [CrossRef]

- Sassi, E.-M. Slag and Refractory Interactions in Hydrogen Plasma Smelting Reduction. Master’s Thesis, University of Oulu, Oulu, Finland, 2025. [Google Scholar]

- Huss, J.; Vickerfält, A.; Kojola, N. Some Aspects of the Melting and Dephosphorization Mechanism of Hydrogen-DRI. Steel Res. Int. 2023, 94, 2300064. [Google Scholar] [CrossRef]

- Vickerfält, A.; Huss, J.; Martinsson, J.; Sichen, D. Reaction Mechanisms During Melting of H-DRI Focusing on Slag Formation and the Behavior of Vanadium. Metall. Mater. Trans. B 2023, 54, 2206–2215. [Google Scholar] [CrossRef]

- Govro, J.; Meena, A.; Chakraborty, S.; Meshram, A.; Korobeinikov, Y.; Phillips, K.; Athavale, V.; Bartlett, L.; Smith, J.; Emdadi, A.; et al. Melting Behavior of Hydrogen-Reduced DRI in a Simulated EAF Steel Bath. Iron Steel Technol. 2023, 20, 58–63. [Google Scholar]

- Huss, J.; Vickerfält, A.; Kojola, N. The Melting Mechanism of Hydrogen Direct Reduced Iron in Liquid Slag. Steel Res. Int. 2024, 95, 2300325. [Google Scholar] [CrossRef]

- Svantesson, J.; Kojola, N.; Ersson, M. Numerical Study on the Effect of Material Parameters and Process Conditions on the Melting Time of Hydrogen-Direct Reduced Iron. Metall. Mater. Trans. B 2025, 56, 2846–2872. [Google Scholar] [CrossRef]

- Svantesson, J.L.; Ersson, M.; Kojola, N. Capillary Infiltration of Slag in Hydrogen-Direct Reduced Iron and Influence on Melting. ISIJ Int. 2025, 65, 1607–1619. [Google Scholar] [CrossRef]

- Pauna, H.; Kokkonen, T.; Cavaliere, P.; Bayat, M.; Mirowska, A.; Alatarvas, T.; Huttula, M.; Fabritius, T. Hydrogen Direct Reduced Iron Melting in an Electric Arc Furnace: Benefits of In Situ Monitoring. J. Sustain. Metall. 2025, 11, 1–13. [Google Scholar] [CrossRef]

- Demus, T.; Echterhof, T.; Pfeifer, H.; Schulten, M.; Noel, Y.; Quicker, P. Investigations on the Use of Biogenic Residues as a Substitute for Fossil Coal in the EAF Steelmaking Process. In Proceedings of the 10th European Electric Steelmaking Conference, Graz, Austria, 25–28 September 2012; ASMET: Graz, Austria, 2012. [Google Scholar]

- Liu, X.; Yan, W. Current Advances in Slag Foaming Processes toward Reduced CO2 Emission for Electric Arc Furnace Steelmaking. J. CO2 Util. 2024, 90, 102979. [Google Scholar] [CrossRef]

- Odenthal, H.-J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on Modeling and Simulation of the Electric Arc Furnace (EAF). Steel Res. Int. 2018, 89, 1700098. [Google Scholar] [CrossRef]

- Carlsson, L.S.; Samuelsson, P.B.; Jönsson, P.G. Predicting the Electrical Energy Consumption of Electric Arc Furnaces Using Statistical Modeling. Metals 2019, 9, 959. [Google Scholar] [CrossRef]

- Hay, T.; Visuri, V.-V.; Aula, M.; Echterhof, T. A Review of Mathematical Process Models for the Electric Arc Furnace Process. Steel Res. Int. 2021, 92, 2000395. [Google Scholar] [CrossRef]

- Niyayesh, M.; Yilmaz, U. Predicting Endpoint Parameters of Electric Arc Furnace–Based Steelmaking Using Artificial Neural Network. Int. J. Adv. Manuf. Tech. 2025, 138, 155–167. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and Validation of an Electric Arc Furnace: Part 1, Heat and Mass Transfer. ISIJ Int. 2012, 52, 402–412. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and Validation of an Electric Arc Furnace: Part 2, Thermo-Chemistry. ISIJ Int. 2012, 52, 413–423. [Google Scholar] [CrossRef]

- Meier, T. Modellierung und Simulation des Elektrolichtbogenofens. Doctoral Thesis, RWTH Aachen University, Aachen, Germany, 2016. [Google Scholar]

- Hay, T.A. Mathematische Modellierung des Elektrostahlverfahrens. Doctoral Thesis, RWTH Aachen University, Aachen, Germany, 2021. [Google Scholar]

| Focus | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | Article | Article Type 1 | Raw Materials | Melting | Slag Foaming | Impurity Removal | Modelling and Simulation | System Level |

| 1 | Azzaz et al. (Contribution 1) | O | X | X | ||||

| 2 | Dall’Osto et al. (Contribution 2) | O | X | X | ||||

| 3 | Reinicke et al. (Contribution 3) | O | X | |||||

| 4 | Dall’Osto et al. (Contribution 4) | O | X | |||||

| 5 | Ugarte et al. (Contribution 5) | O | X | X | ||||

| 6 | Kieush et al. (Contribution 6) | O | X | X | ||||

| 7 | Pfeiffer et al. (Contribution 7) | O | X | X | ||||

| 8 | Kieush et al. (Contribution 8) | R | X | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Visuri, V.-V.; Echterhof, T. Electric Arc Furnace Steelmaking. Metals 2025, 15, 1285. https://doi.org/10.3390/met15121285

Visuri V-V, Echterhof T. Electric Arc Furnace Steelmaking. Metals. 2025; 15(12):1285. https://doi.org/10.3390/met15121285

Chicago/Turabian StyleVisuri, Ville-Valtteri, and Thomas Echterhof. 2025. "Electric Arc Furnace Steelmaking" Metals 15, no. 12: 1285. https://doi.org/10.3390/met15121285

APA StyleVisuri, V.-V., & Echterhof, T. (2025). Electric Arc Furnace Steelmaking. Metals, 15(12), 1285. https://doi.org/10.3390/met15121285